The Influence of Corn Straw Extrusion Pretreatment Parameters on Methane Fermentation Performance

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

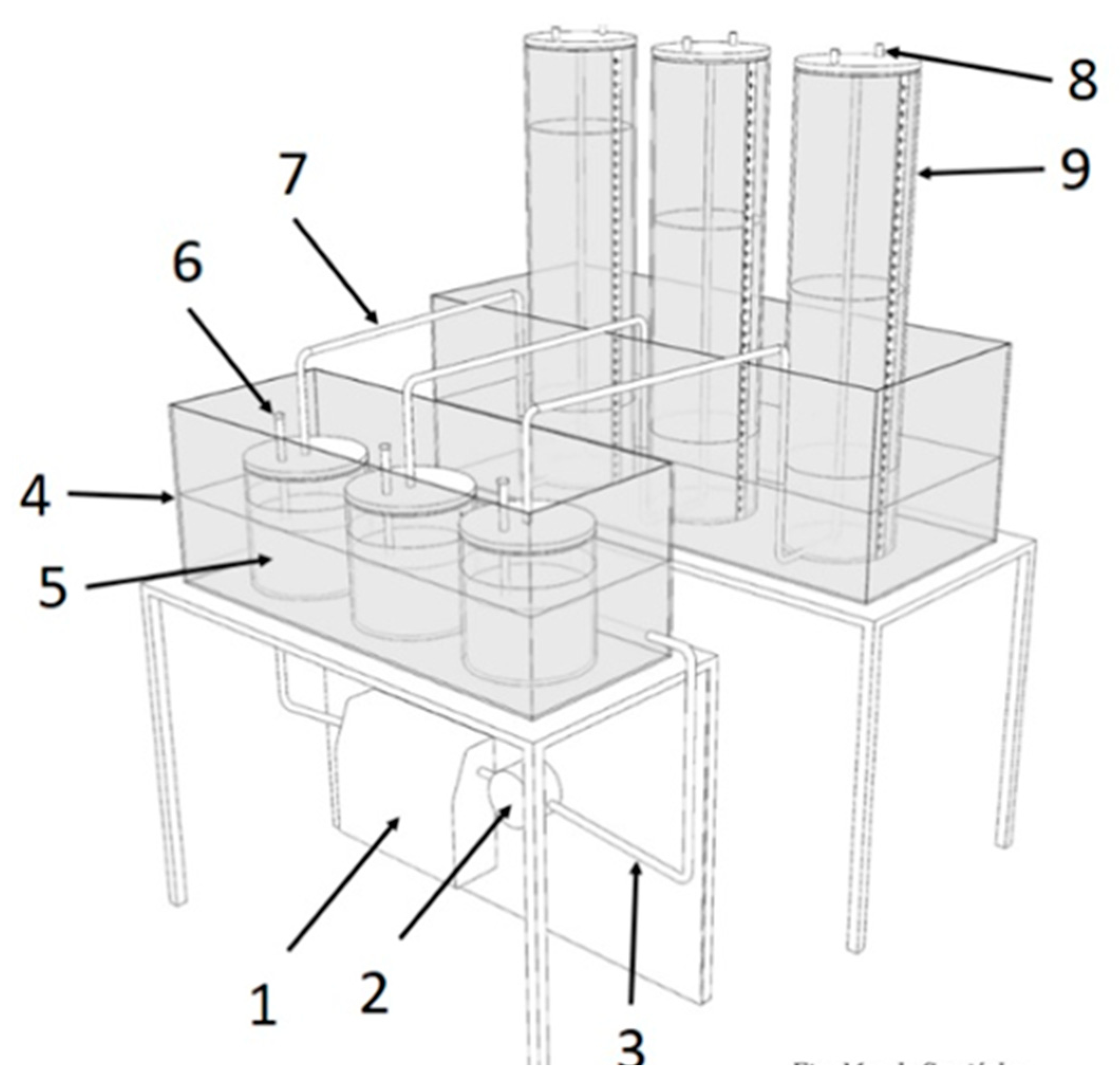

2.2. Processing

2.3. Energy Consumption during Processing

2.4. Water Absorption and Solubility Measurements

2.5. Biogas Efficiency Analysis

2.6. Infrared Spectra Measurements

2.7. Statistical Analysis

3. Results and Discussions

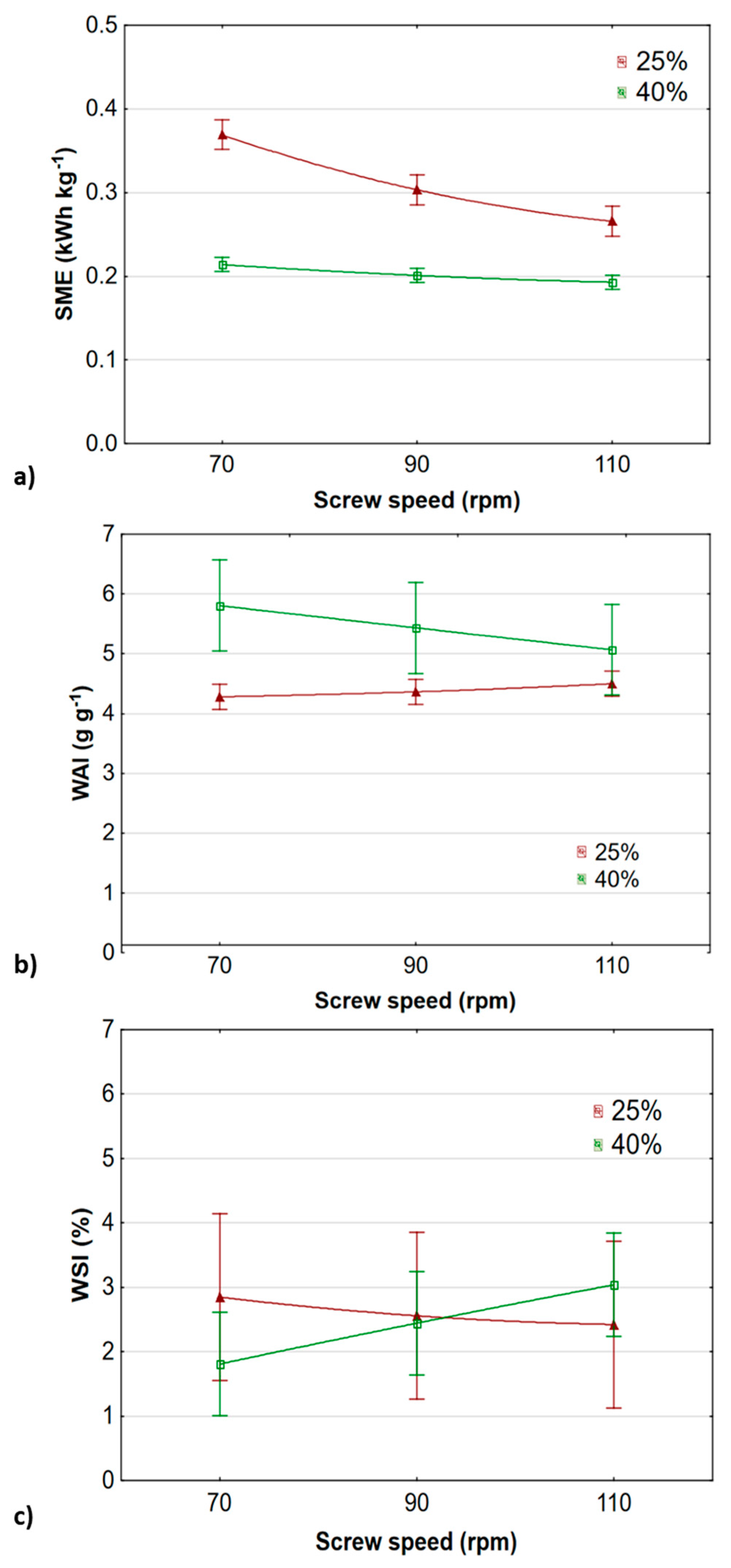

3.1. Effect of Processing Conditions on Extrusion Energy Consumption

3.2. WAI and WSI of Extruded Corn Straw

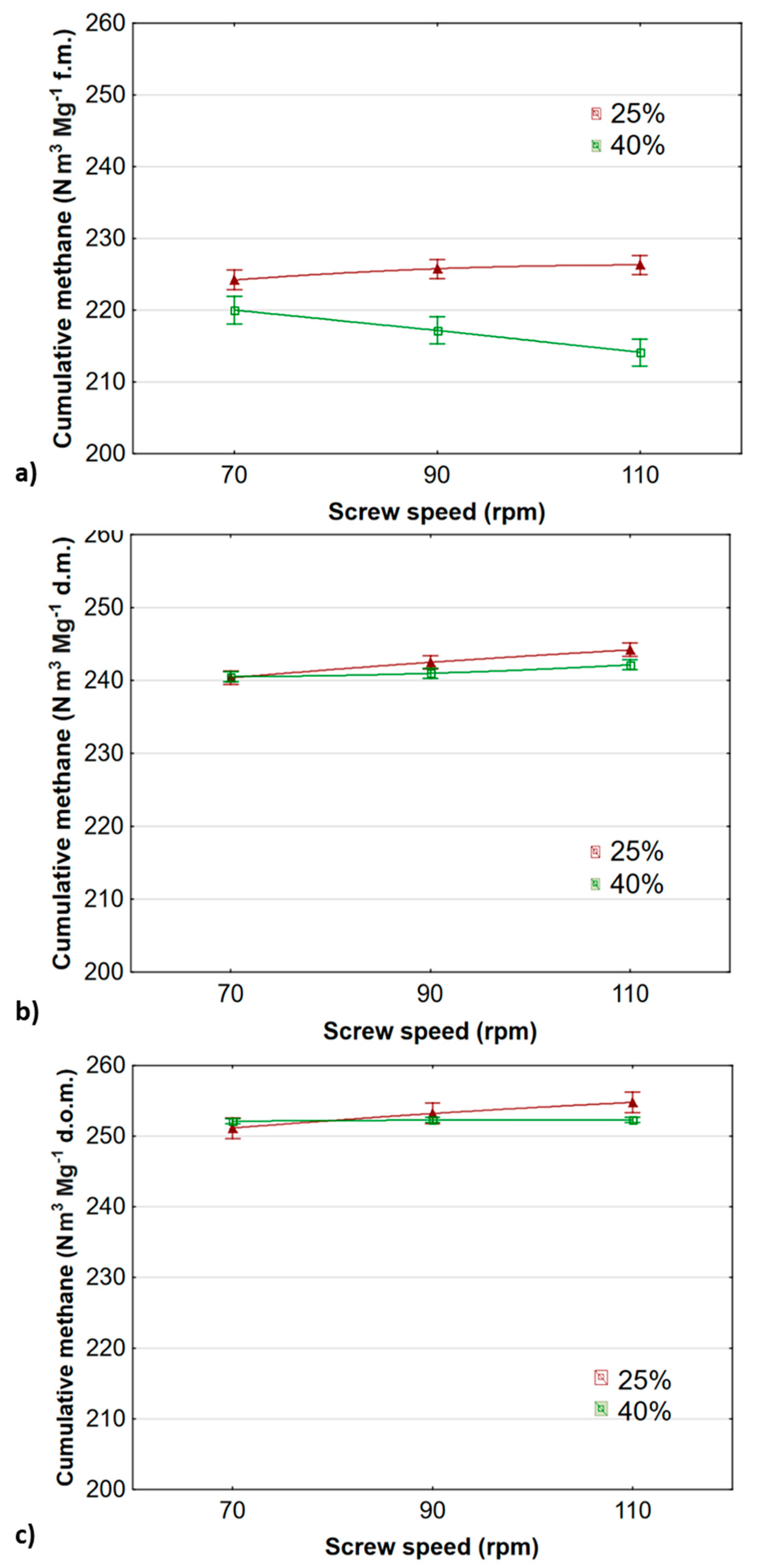

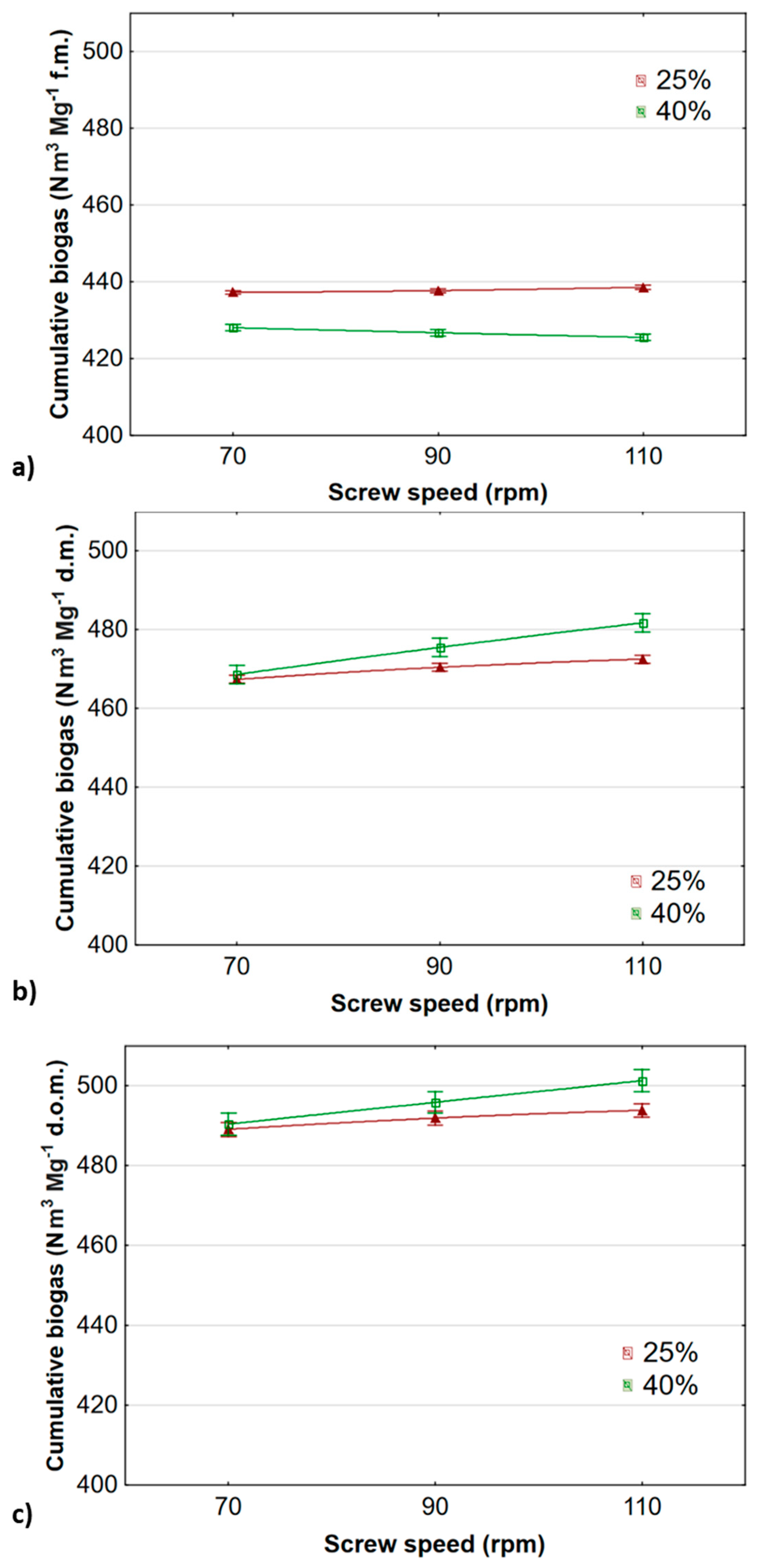

3.3. Biogas Efficiency

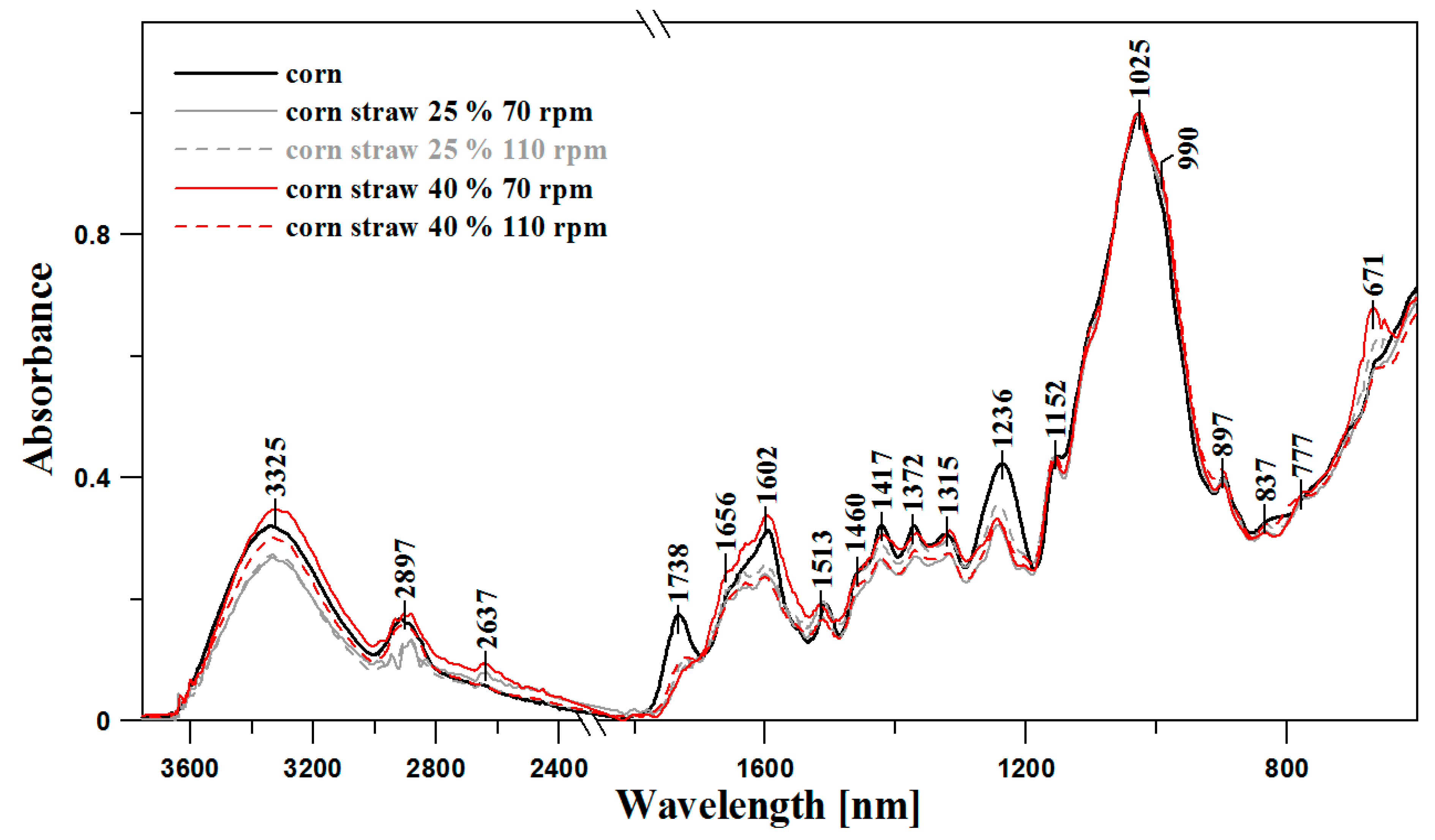

3.4. Analysis of Samples Using FTIR Infrared Spectroscopy

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| rpm | rotations per minute |

| Nm3 Mg−1 | normal cubic meter per megagram |

| FTIR | Fourier transform Infrared spectroscopy |

| NaWaRo | NachWachsendeRohstoffe |

| L/D | length/diameter |

| SME | specific mechanical energy (kWh kg−1) |

| n | screw rotation (rpm) |

| nm | screw rating rotation (rpm) |

| O | engine load compared to maximum (%) |

| P | rated power (kW) |

| Q | process efficiency (kg h−1) |

| WAI | water absorption index (g g−1) |

| WSI | water solubility index (%) |

| ATR | Attenuated Total Reflection |

| SD | standard deviation |

| f.m. | fresh matter |

| d.m. | dry matter |

| d.o.m. | dry organic matter |

| ATR | Attenuated Total Reflection |

References

- Bruni, E.; Jensen, A.P.; Angelidaki, I. Comparative study of mechanical, hydrothermal, chemical and enzymatic treatments of digested biofibers to improve biogas production. Bioresour. Technol. 2010, 101, 8713–8717. [Google Scholar] [CrossRef] [PubMed]

- Waliszewska, H.; Zborowska, M.; Waliszewska, B.; Borysiak, S.; Antczak, A.; Czekała, W. Transformation of Miscanthus and Sorghum cellulose during methane fermentation. Cellulose 2018, 25, 1207–1216. [Google Scholar] [CrossRef]

- Waliszewska, H.; Zborowska, M.; Stachowiak-Wencek, A.; Waliszewska, B.; Czekała, W. Lignin Transformation of One-Year-Old Plants during Anaerobic Digestion (AD). Polymers 2019, 11, 835. [Google Scholar] [CrossRef] [PubMed]

- Obidziński, S.; Joka, M.; Fijoł, O. Two-stage agglomeration of fine-grained herbal nettle waste. Int. Agrophys. 2017, 31, 515–523. [Google Scholar] [CrossRef]

- Oniszczuk, T.; Kupryaniuk, K.; Smurzyńska, A.; Brzoski, M.; Wójtowicz, A.; Mitrus, M.; Oniszczuk, A.; Combrzyński, M.; Do Carmo, I.E.P. Effect of extrusion-cooking parameters on energetic efficiency of corn straw during methane fermentation. In Proceedings of the 3rd International Conference on Energy and Environment, Porto, Portugal, 29–30 June 2017; Available online: https://www.fep.up.pt/conferences/icee2017/images/ICEE2017_0808_VF.pdf (accessed on 30 June 2017).

- Zheng, Y.; Zhao, J.; Xu, F.; Li, Y. Pretreatment of lignocellulosic biomass for enhanced biogas production. Prog. Energy Combust. Sci. 2014, 42, 35–53. [Google Scholar] [CrossRef]

- Eastman, J.A.; Ferguson, J.F. Solubilization of particulate organic carbon during the acid phase of anaerobic digestion. J. Water Pollut. Control Fed. 1981, 53, 352–366. [Google Scholar]

- Di Matteo, U.; Nastasi, B.; Albo, A.; Garcia, D.A. Energy Contribution of OFMSW (Organic Fraction of Municipal Solid Waste) to Energy-Environmental Sustainability in Urban Areas at Small Scale. Energies 2017, 10, 229. [Google Scholar] [CrossRef]

- Tong, X.; Smith, L.H.; Mccarty, P.L. Methane fermentation of selected lignocellulosic materials. Biomass 1990, 21, 239–255. [Google Scholar] [CrossRef]

- Pilarski, K.; Pilarska, A.A.; Witaszek, K.; Dworecki, Z.; Żelaziński, T.; Ekielski, A.; Makowska, A.; Michniewicz, J. The impact of extrusion on the biogas and biomethane yield of plant substrates. J. Ecol. Eng. 2016, 17, 264–272. [Google Scholar] [CrossRef]

- Chandra, R.; Takeuchi, H.; Hasegawa, T. Hydrothermal pretreatment of rice straw biomass: A potential and promising method for enhanced methane production. Appl. Energy 2012, 94, 129–140. [Google Scholar] [CrossRef]

- Song, Z.; Yang, G.; Han, X.; Feng, Y.; Ren, G. Optimization of the Alkaline Pretreatment of Rice Straw for Enhanced Methane Yield. BioMed Res. Int. 2012, 2013, 1–9. [Google Scholar] [CrossRef]

- Zhu, S.; Wu, Y.; Yu, Z.; Liao, J.; Zhang, Y. Pretreatment by microwave/alkali of rice straw and its enzymic hydrolysis. Process. Biochem. 2005, 40, 3082–3086. [Google Scholar] [CrossRef]

- Hjorth, M.; Gränitz, K.; Adamsen, A.P.; Møller, H. Extrusion as a pretreatment to increase biogas production. Bioresour. Technol. 2011, 102, 4989–4994. [Google Scholar] [CrossRef] [PubMed]

- Wójtowicz, A.; Mitrus, M.; Oniszczuk, T.; Moscicki, L.; Kręcisz, M.; Oniszczuk, A. Selected Physical Properties, Texture and Sensory Characteristics of Extruded Breakfast Cereals based on Wholegrain Wheat Flour. Agric. Agric. Sci. Procedia 2015, 7, 301–308. [Google Scholar] [CrossRef]

- Wójtowicz, A.; Oniszczuk, A.; Oniszczuk, T.; Kocira, S.; Wojtunik-Kulesza, K.A.; Mitrus, M.; Kocira, A.; Widelski, J.; Skalicka-Woźniak, K. Application of Moldavian dragonhead (Dracocephalum moldavica L.) leaves addition as a functional component of nutritionally valuable corn snacks. J. Food Sci. Technol. 2017, 54, 3218–3229. [Google Scholar] [CrossRef] [PubMed]

- Pilarska, A.; Pilarski, K.; Dach, J.; Boniecki, P. Wpływ rozwoju biogazowni na dywersyfikację dochodów w rolnictwie. Tech. Rol. Ogrod. Leśna 2014, 1, 10–12. Available online: http://yadda.icm.edu.pl/yadda/element/bwmeta1.element.agro-8f7f2fe7-ff9a-45a5-8491-64e320e5b0eb/c/PPB1_2014.pdf (accessed on 1 January 2014).

- Oniszczuk, T.; Pilawka, R. Effect of cellulose fibers on thermal strength of thermoplastic starch. Przem. Chem. 2013, 92, 265–269. [Google Scholar]

- Oniszczuk, T. Addition of bark in the production of the starch-based composites Dodatek kory w produkcji biokompozytów skrobiowych. Przem. Chem. 2015, 1, 122–125. [Google Scholar] [CrossRef]

- Oniszczuk, T.; Wójtowicz, A.; Mościcki, L.; Mitrus, M.; Kupryaniuk, K.; Kusz, A.; Bartnik, G. Effect of natural fibres on the mechanical properties of thermoplastic starch. Int. Agrophys. 2016, 30, 211–218. [Google Scholar] [CrossRef]

- Czekała, W. Agricultural Biogas Plants as a Chance for the Development of the Agri-Food Sector. J. Ecol. Eng. 2018, 19, 179–183. [Google Scholar] [CrossRef]

- Weiland, P. Biogas production: Current state and perspectives. Appl. Microbiol. Biotechnol. 2009, 85, 849–860. [Google Scholar] [CrossRef] [PubMed]

- Raven, R.; Gregersen, K. Biogas plants in Denmark: Successes and setbacks. Renew. Sustain. Energy Rev. 2007, 11, 116–132. [Google Scholar] [CrossRef]

- Lantz, M.; Svensson, M.; Björnsson, L.; Börjesson, P. The prospects for an expansion of biogas systems in Sweden—Incentives, barriers and potentials. Energy Policy 2007, 35, 1830–1843. [Google Scholar] [CrossRef]

- Rasi, S.; Veijanen, A.; Rintala, J. Trace compounds of biogas from different biogas production plants. Energy 2007, 32, 1375–1380. [Google Scholar] [CrossRef]

- Wojcieszak, D.; Przybył, J.; Ratajczak, I.; Goliński, P.; Janczak, D.; Waśkiewicz, A.; Szentner, K.; Woźniak, M. Chemical composition of maize stover fraction versus methane yield and energy value in fermentation process. Energy 2020, 198, 117258. [Google Scholar] [CrossRef]

- Sousa, G.O.C.; Rodrigues, R.C.; Lima, J.R.L.; Lima, N.M.; Miranda, B.E.C.; Jesus, A.P.R.; Parente, H.N.; Costa, C.D.S. Nutritional value of dehydrated maize straw ammoniated with urea. Rev. Bras. Saúde Prod. Anim. 2019, 20, 0132019. [Google Scholar] [CrossRef]

- Combrzyński, M.; Matwijczuk, A.; Wójtowicz, A.; Oniszczuk, T.; Karcz, D.; Szponar, J.; Niemczynowicz, A.; Bober, D.; Mitrus, M.; Kupryaniuk, K.; et al. Potato Starch Utilization in Ecological Loose-Fill Packaging Materials—Sustainability and Characterization. Materials 2020, 13, 1390. [Google Scholar] [CrossRef]

- Bouasla, A.; Wójtowicz, A.; Zidoune, M.N. Gluten-free precooked rice pasta enriched with legumes flours: Physical properties, texture, sensory attributes and microstructure. LWT 2017, 75, 569–577. [Google Scholar] [CrossRef]

- Dach, J.; Czekała, W.; Boniecki, P.; Lewicki, A.; Piechota, T. Specialised Internet Tool for Biogas Plant Modelling and Marked Analysing. Adv. Mater. Res. 2014, 909, 305–310. [Google Scholar] [CrossRef]

- Czekała, W. Concept of in-oil project based on bioconversion of by-products from food processing industry. J. Ecol. Eng. 2017, 18, 180–185. [Google Scholar] [CrossRef][Green Version]

- Chocyk, D.; Gładyszewska, B.; Ciupak, A.; Oniszczuk, T.; Mościcki, L.; Rejak, A. Influence of water addition on mechanical properties of thermoplastic starch foils. Int. Agrophys. 2015, 29, 267–273. [Google Scholar] [CrossRef]

- Menardo, S.; Cacciatore, V.; Balsari, P. Batch and continuous biogas production arising from feed varying in rice straw volumes following pre-treatment with extrusion. Bioresour. Technol. 2015, 180, 154–161. [Google Scholar] [CrossRef] [PubMed]

- Mitrus, M.; Combrzyński, M.; Kupryaniuk, K.; Oniszczuk, T.; Kręcisz, M.; Matysiak, A.; Smurzyńska, A.; Mościcki, L.; Wójtowicz, A. A study of the solubility of biodegradable foams of thermoplastic starch. J. Ecol. Eng. 2016, 17, 184–189. [Google Scholar] [CrossRef]

- Wolna-Maruwka, A.; Pilarski, K. Microbiological characteristic of compost prepared on the basis of sewage sludge supplemented with refined glycerol. Arch. Environ. Prot. 2011, 37, 43–45. [Google Scholar]

- Czekała, W.; Smurzyńska, A.; Cieślik, M.; Boniecki, P.; Kozłowski, K. Biogas efficiency of selected fresh fruit covered by the Russian embargo. Energy Clean Technol. Conf. Proc. 2016, 3, 227–233. [Google Scholar] [CrossRef]

- Gizińska-Górna, M.; Czekała, W.; Jóźwiakowski, K.; Lewicki, A.; Dach, J.; Marzec, M.; Pytka, A.; Janczak, D.; Kowalczyk-Juśko, A.; Listosz, A. The possibility of using plants from hybrid constructed wetland wastewater treatment plant for energy purposes. Ecol. Eng. 2016, 95, 534–541. [Google Scholar] [CrossRef]

- Kowalczyk-Juśko, A.; Kupryaniuk, K.; Oniszczuk, T.; Wójtowicz, A.; Janczak, D.; Smurzyńska, A.; Jóźwiakowski, K.; Czechlowski, M. Applicability of Jerusalem artichoke in agricultural biogas plants as maize silage alternative. In Proceedings of the 3rd International Conference on Energy and Environment, Porto, Portugal, 29–30 June 2017; Available online: https://www.fep.up.pt/conferences/icee2017/images/ICEE2017_0808_VF.pdf (accessed on 30 June 2017).

- Kozłowski, K.; Lewicki, A.; Czekała, W.; Wójtowicz, A.; Kupryaniuk, K.; Dróżd, D. Extrusion pretreatment of maize straw—Case study for a Polish biogas plants. Int. Agrophys. 2019, 33, 527–535. [Google Scholar] [CrossRef]

- Abraham, A.; Mathew, A.K.; Park, H.; Choi, O.; Sindhu, R.; Parameswaran, B.; Pandey, A.; Park, J.H.; Sang, B.-I. Pretreatment strategies for enhanced biogas production from lignocellulosic biomass. Bioresour. Technol. 2020, 301, 122725. [Google Scholar] [CrossRef]

- Dell’Omo, P.P.; Spena, V.A. Mechanical pretreatment of lignocellulosic biomass to improve biogas production: Comparison of results for giant reed and wheat straw. Energy 2020, 203, 117798. [Google Scholar] [CrossRef]

- Kondo, T. The assignment of IR absorption bands due to free hydroxyl groups in cellulose. Cellulose 1997, 4, 281–292. [Google Scholar] [CrossRef]

- Liang, C.Y.; Marchessault, R.H. Infrared spectra of crystalline polysaccharides. II. Native celluloses in the region from 640 to 1700 cm.1. J. Polym. Sci. 1959, 39, 269–278. [Google Scholar] [CrossRef]

- Hospodarova, V.; Singovszka, E.; Stevulova, N. Characterization of Cellulosic Fibers by FTIR Spectroscopy for Their Further Implementation to Building Materials. Am. J. Anal. Chem. 2018, 9, 303–310. [Google Scholar] [CrossRef]

- Driemeier, C.; Mendes, F.M.; Ling, L.Y. Hydrated fractions of cellulosics probed by infrared spectroscopy coupled with dynamics of deuterium exchange. Carbohydr. Polym. 2015, 127, 152–159. [Google Scholar] [CrossRef] [PubMed]

- Das, A.M.; Ali, A.A.; Hazarika, M.P. Synthesis and characterization of cellulose acetate from rice husk: Eco-friendly condition. Carbohydr. Polym. 2014, 112, 342–349. [Google Scholar] [CrossRef]

- De Dicastillo, C.L.; Rodríguez, F.; Guarda, A.; Galotto, M.J. Antioxidant films based on cross-linked methyl cellulose and native Chilean berry for food packaging applications. Carbohydr. Polym. 2016, 136, 1052–1060. [Google Scholar] [CrossRef]

- Abidi, N.; Cabrales, L.; Haigler, C.H. Changes in the cell wall and cellulose content of developing cotton fibers investigated by FTIR spectroscopy. Carbohydr. Polym. 2014, 100, 9–16. [Google Scholar] [CrossRef]

| Variable | Moisture Content (%) | Equation | Correlation Coefficient | F-Test | p Value | Kruskal-Wallis Test | p Value |

|---|---|---|---|---|---|---|---|

| SME (kWh kg−1) | 25 | 0.463 − 0.108x + 0.014x2 | −0.974 | 105.315 | 0.00002 * | 7.200 | 0.0273 * |

| 40 | 0.232 − 0.021x + 0.003x2 | −0.919 | 18.611 | 0.0027 * | 7.200 | 0.0273 * | |

| WAI (g g−1) | 25 | 4.243 + 0.012x + 0.024x2 | 0.717 | 3.282 | 0.1089 | 3.518 | 0.1722 |

| 40 | 6.181 − 0.379x + 0.003x2 | −0.696 | 2.823 | 0.1367 | 5.535 | 0.0628 | |

| WSI (%) | 25 | 3.295 − 0.524x + 0.078x2 | −0.312 | 0.339 | 0.7253 | 1.412 | 0.4937 |

| 40 | 1.134 + 0.694x − 0.019x2 | 0.838 | 7.055 | 0.0266 * | 6.489 | 0.0390 * | |

| Methane content (%) | 25 | 51.24 + 0.145x − 0.005x2 | 0.982 | 82.765 | 0.00004 * | 7.200 | 0.0273 * |

| 40 | 52.47 − 1.282x + 0.182x2 | −0.715 | 3.381 | 0.1039 | 4.622 | 0.0992 | |

| Cumulative methane (Nm3 Mg−1 f.m.) | 25 | 221.66 + 3.082x − 0.512x2 | 0.816 | 7.687 | 0.0221 * | 6.879 | 0.0321 * |

| 40 | 222.6 − 2.487x − 0.113x2 | −0.952 | 28.984 | 0.0008 * | 7.200 | 0.2730 | |

| Cumulative biogas (Nm3 Mg−1 f.m.) | 25 | 437.21 − 0.138x + 0.202x2 | 0.924 | 21.939 | 0.0017 * | 6.879 | 0.0321 * |

| 40 | 429.54 − 1.52x + 0.067x2 | −0.940 | 22.785 | 0.0016 * | 7.2605 | 0.0265 * | |

| Cumulative methane (Nm3 Mg−1 d.m.) | 25 | 237.81 + 2.755x − 0.208x2 | 0.970 | 51.939 | 0.0002 * | 7.200 | 0.2730 |

| 40 | 240.74 − 0.583x + 0.35x2 | 0.895 | 17.006 | 0.0034 * | 6.252 | 0.0439 * | |

| Cumulative biogas (Nm3 Mg−1 d.m.) | 25 | 448.33 + 27.082 − 8.005x2 | −0.296 | 0.588 | 0.5843 | 2.400 | 0.3012 |

| 40 | 461.07 + 7.892x − 0.332x2 | 0.984 | 91.690 | 0.00003 * | 7.200 | 0.2730 | |

| Cumulative methane (Nm3 Mg−1 d.o.m.) | 25 | 248.59 + 2.77x − 0.237x2 | 0.924 | 18.196 | 0.0028 * | 7.200 | 0.0273 * |

| 40 | 251.84 + 0.352x − 0.068x2 | 0.383 | 0.675 | 0.5439 | 1.367 | 0.5049 | |

| Cumulative biogas (Nm3 Mg−1 d.o.m.) | 25 | 485.31 + 4.258x − 0.468x2 | 0.933 | 22.458 | 0.0016 * | 7.200 | 0.0273 * |

| 40 | 484.95 + 5.53x − 0.023x2 | 0.970 | 47.510 | 0.0002 * | 7.200 | 0.0273 * |

| FTIR | Type and Origin of Vibrations | ||||

|---|---|---|---|---|---|

| Position of Bands [cm−1] | |||||

| Corn | Corn Straw 25% 70 rpm | Corn Straw 25% 110 rpm | Corn Straw 40% 70 rpm | Corn Straw 40% 110 rpm | |

| 3332 | 3332 | 3336 | 3320 | 3324 | ν (O-H) in H2O And intra-molecular hydrogen bonding |

| 2912 | 2936 | 2944 | 2924 | 2912 | ν (C-H) in CH2 and CH3 asymetrical and symmetrical |

| 2876 | 2892 | 2892 | 2888 | 2884 | |

| 1731 | 1727 | 1725 | 1724 | 1731 | ν (C=O) |

| 1656 | 1663 | 1661 | 1660 | 1665 | ν (C=C)and δ (O-H) |

| - | 1635 | 1639 | 1626 | 1633 | δ (O-H) adsorbed H2O |

| 1599 | 1597 | 1599 | 1597 | 1603 | ν (C=C) |

| 1509 | 1511 | 1516 | 1513 | 1513 | |

| 1460 | 1460 | 1462 | 1458 | 1460 | δ (-OH in plane), δ (CH2), δ (C-H) |

| 1424 | 1422 | 1422 | 1426 | 1426 | |

| 1373 | 1375 | 1368 | 1371 | 1371 | |

| 1322 | 1319 | 1320 | 1317 | 1320 | δ (C-H) and δ (O-H) |

| 1236 | 1239 | 1241 | 1249 | 1239 | δ (C-H) and antisymmetrical bridge oxygen stretching –OH in-plane bending |

| 1158 | 1156 | 1156 | 1160 | 1158 | antisymmetrical in phase ring stretching and ν (C-O) |

| 1096 | 1098 | 1100 | 1106 | 1096 | |

| 1028 | 1025 | 1026 | 1028 | 1030 | |

| 987 | 994 | 994 | 989 | 989 | ν (C-O) |

| 896 | 895 | 896 | 895 | 898 | CH2 rocking β-linkage of cellulose ring breathing and antisymmetrical out of phase stretching -OH out-of-plane bending |

| 827 | 832 | 834 | 834 | 836 | |

| 778 | 782 | 774 | 774 | 778 | |

| 702 | - | - | - | - | |

| 663 | 659 | 663 | 669 | 659 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kupryaniuk, K.; Oniszczuk, T.; Combrzyński, M.; Czekała, W.; Matwijczuk, A. The Influence of Corn Straw Extrusion Pretreatment Parameters on Methane Fermentation Performance. Materials 2020, 13, 3003. https://doi.org/10.3390/ma13133003

Kupryaniuk K, Oniszczuk T, Combrzyński M, Czekała W, Matwijczuk A. The Influence of Corn Straw Extrusion Pretreatment Parameters on Methane Fermentation Performance. Materials. 2020; 13(13):3003. https://doi.org/10.3390/ma13133003

Chicago/Turabian StyleKupryaniuk, Karol, Tomasz Oniszczuk, Maciej Combrzyński, Wojciech Czekała, and Arkadiusz Matwijczuk. 2020. "The Influence of Corn Straw Extrusion Pretreatment Parameters on Methane Fermentation Performance" Materials 13, no. 13: 3003. https://doi.org/10.3390/ma13133003

APA StyleKupryaniuk, K., Oniszczuk, T., Combrzyński, M., Czekała, W., & Matwijczuk, A. (2020). The Influence of Corn Straw Extrusion Pretreatment Parameters on Methane Fermentation Performance. Materials, 13(13), 3003. https://doi.org/10.3390/ma13133003