Synthesis of Hybrid Carbon Materials Consisting of N-Doped Microporous Carbon and Amorphous Carbon Nanotubes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of ACNT/N-Doped AC without or with FeCl3

2.2. Characterization Methods

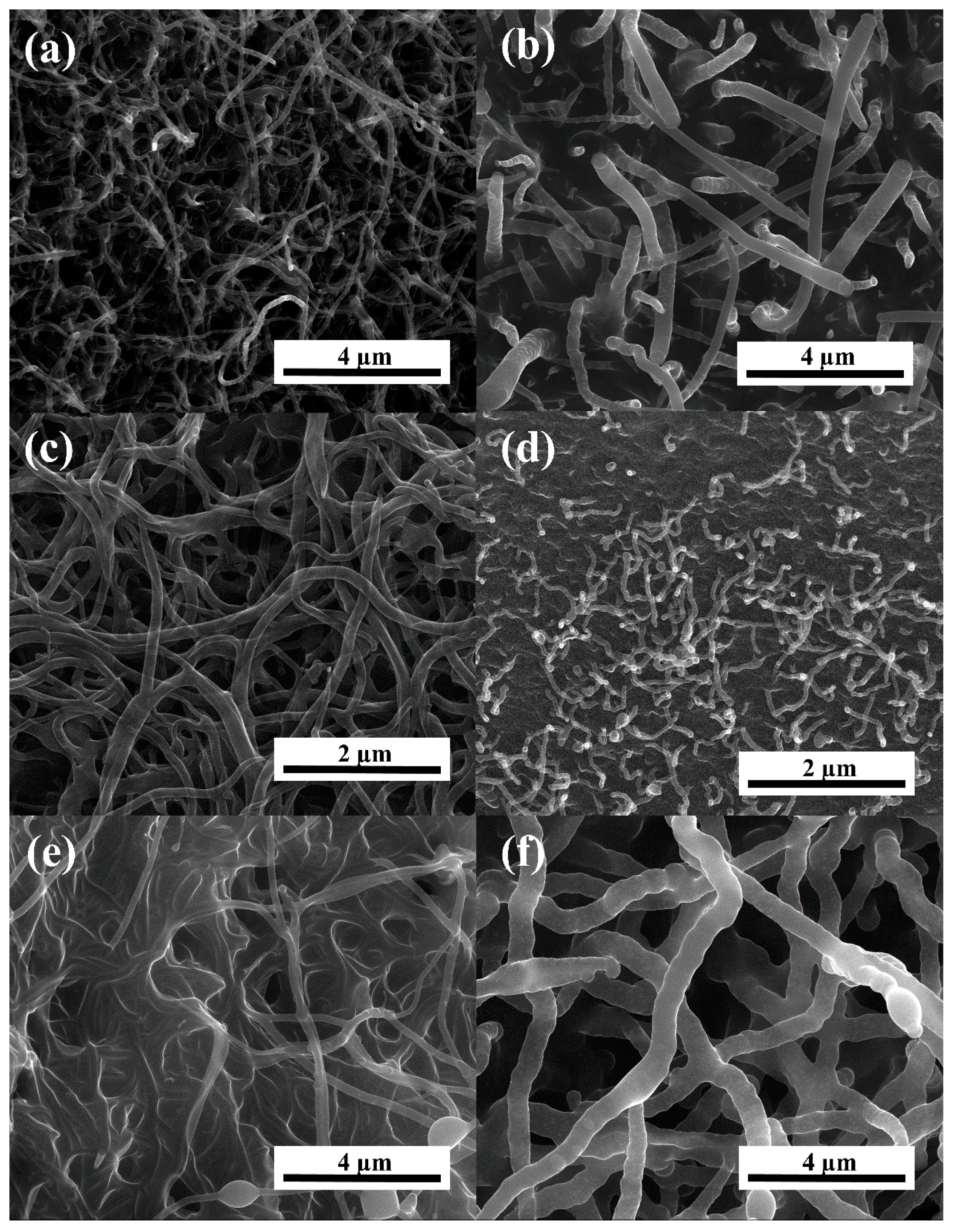

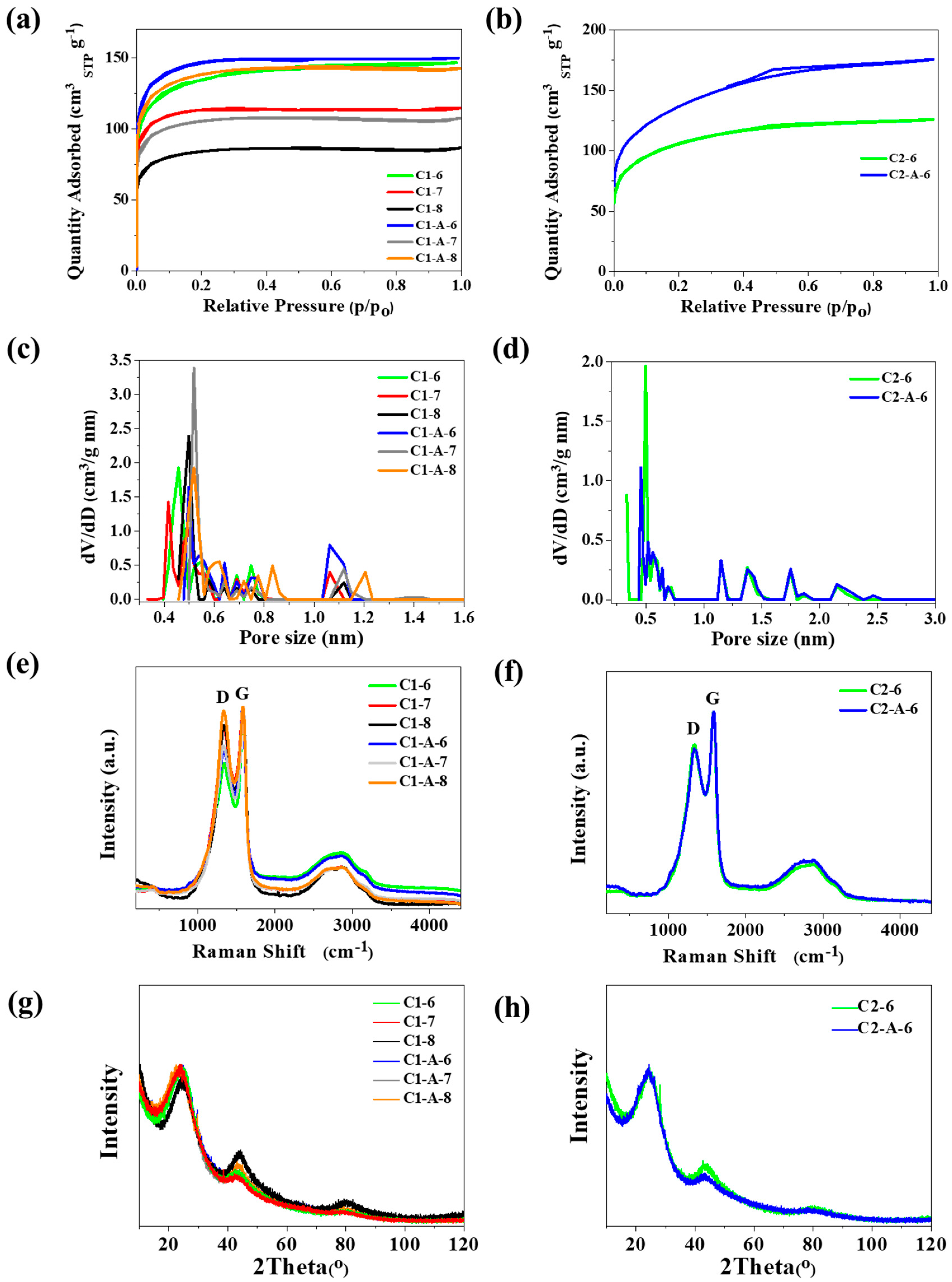

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- José-Yacamán, M.; Miki-Yoshida, M.; Rendon, L.; Santiesteban, J. Catalytic growth of carbon microtubules with fullerene structure. Appl. Phys. Lett. 1993, 62, 657–659. [Google Scholar] [CrossRef]

- Guo, T.; Nikolaev, P.; Thess, A.; Colbert, D.T.; Smalley, R.E. Catalytic growth of single-walled manotubes by laser vaporization. Chem. Phys. Lett. 1995, 243, 49–54. [Google Scholar] [CrossRef]

- Ebbesen, T.; Ajayan, P. Large-scale synthesis of carbon nanotubes. Nature 1992, 358, 220–222. [Google Scholar] [CrossRef]

- Ci, L.; Wei, B.; Xu, C.; Liang, J.; Wu, D.; Xie, S.; Zhou, W.; Li, Y.; Liu, Z.; Tang, D. Crystallization behavior of the amorphous carbon nanotubes prepared by the CVD method. J. Cryst. Growth 2001, 233, 823–828. [Google Scholar] [CrossRef]

- Sun, L.; Yan, C.; Chen, Y.; Wang, H.; Wang, Q. Preparation of amorphous carbon nanotubes using attapulgite as template and furfuryl alcohol as carbon source. J. Non Cryst. Solids 2012, 358, 2723–2726. [Google Scholar] [CrossRef]

- Liu, B.; Jia, D.; Zhou, Y.; Feng, H.; Meng, Q. Low temperature synthesis of amorphous carbon nanotubes in air. Carbon 2007, 45, 1710–1713. [Google Scholar] [CrossRef]

- Jha, A.; Ghorai, U.; Banerjee, D.; Mukherjee, S.; Chattopadhyay, K. Surface modification of amorphous carbon nanotubes with copper phthalocyanine leading to enhanced field emission. RSC Adv. 2013, 3, 1227–1234. [Google Scholar] [CrossRef]

- Maity, S.; Das, N.S.; Chattopadhyay, K.K. Controlled surface damage of amorphous and crystalline carbon nanotubes for enhanced field emission. Phys. Status Solidi 2013, 250, 1919–1925. [Google Scholar] [CrossRef]

- Schwan, J.; Batori, V.; Ulrich, S.; Ehrhardt, H.; Silva, S. Nitrogen doping of amorphous carbon thin films. J. Appl. Phys. 1998, 84, 2071–2081. [Google Scholar] [CrossRef] [Green Version]

- Cuomo, J.J.; Pappas, D.L.; Bruley, J.; Doyle, J.P.; Saenger, K.L. Vapor deposition processes for amorphous carbon films with sp 3 fractions approaching diamond. J. Appl. Phys. 1991, 70, 1706–1711. [Google Scholar] [CrossRef]

- Nishino, H.; Yamaguchi, C.; Nakaoka, H.; Nishida, R. Carbon nanotube with amorphous carbon wall: α-CNT. Carbon 2003, 41, 2165–2167. [Google Scholar] [CrossRef]

- Ci, L.; Zhu, H.; Wei, B.; Xu, C.; Wu, D. Annealing amorphous carbon nanotubes for their application in hydrogen storage. Appl. Surf. Sci. 2003, 205, 39–43. [Google Scholar] [CrossRef]

- Wang, W.; Lu, W.; Yang, S.; Li, X. Amorphous-carbon nanotube: The growth intermediates of graphitic carbon nanotube? In Proceedings of the Symposium on Recent Advances in the Chemistry and Physics of Fullerenes and Related Materials; The Electrochemical Society: Pennington, NJ, USA, 1997; Volume 97, pp. 814–824. [Google Scholar]

- Tang, Y.; Wang, N.; Zhang, Y.; Lee, C.; Bello, I.; Lee, S. Synthesis and characterization of amorphous carbon nanowires. Appl. Phys. Lett. 1999, 75, 2921–2923. [Google Scholar] [CrossRef]

- Huang, J.; Chen, S.; Ren, Z.; Chen, G.; Dresselhaus, M. Real-time observation of tubule formation from amorphous carbon nanowires under high-bias Joule heating. Nano Lett. 2006, 6, 1699–1705. [Google Scholar] [CrossRef]

- Chen, J.T.; Shin, K.; Leiston-Belanger, J.M.; Zhang, M.; Russell, T.P. Amorphous carbon nanotubes with tunable properties via template wetting. Adv. Funct. Mater. 2006, 16, 1476–1480. [Google Scholar] [CrossRef]

- Hu, B.; Qin, X.; Asiri, A.M.; Alamry, K.A.; Al-Youbi, A.O.; Sun, X. WS2 nanoparticles-encapsulated amorphous carbon tubes: A novel electrode material for supercapacitors with a high rate capability. Electrochem. Commun. 2013, 28, 75–78. [Google Scholar] [CrossRef]

- Nishino, H.; Nishida, R.; Matsui, T.; Kawase, N.; Mochida, I. Growth of amorphous carbon nanotube from poly (tetrafluoroethylene) and ferrous chloride. Carbon 2003, 41, 2819–2823. [Google Scholar] [CrossRef]

- Zhao, T.; Ji, X.; Jin, W.; Yang, W.; Li, T. Coral-like amorphous carbon nanotubes synthesized by a modified arc discharge. Fuller. Nanotub. Carbon Nanostructures 2017, 25, 359–362. [Google Scholar] [CrossRef]

- Suzuki, H.; Fukuzawa, N.; Tanigaki, T.; Sato, T.; Kido, O.; Kimura, Y.; Kaito, C. Fabrication of an amorphous carbon tube from copper oxide whisker. J. Cryst. Growth 2002, 244, 168–172. [Google Scholar] [CrossRef]

- Zhao, N.; Wang, G.; Huang, Y.; Wang, B.; Yao, B.; Wu, Y. Preparation of nanowire arrays of amorphous carbon nanotube-coated single crystal SnO2. Chem. Mater. 2008, 20, 2612–2614. [Google Scholar] [CrossRef]

- Hu, Z.; Hu, Y.; Chen, Q.; Duan, X.; Peng, L.-M. Synthesis and characterizations of amorphous carbon nanotubes by pyrolysis of ferrocene confined within AAM templates. J. Phys. Chem. B 2006, 110, 8263–8267. [Google Scholar] [CrossRef] [PubMed]

- Im, C.; Yun, Y.S.; Kim, B.; Park, H.H.; Jin, H.-J. Amorphous carbon nanotube/MnO2/graphene oxide ternary composite electrodes for electrochemical capacitors. J. NanoSci. Nanotechnol. 2013, 13, 1765–1768. [Google Scholar] [CrossRef]

- Sarkar, S.; Banerjee, D.; Das, N.S.; Chattopadhyay, K.K. A simple chemical synthesis of amorphous carbon nanotubes–MnO2 flake hybrids for cold cathode application. Appl. Surf. Sci. 2015, 347, 824–831. [Google Scholar] [CrossRef]

- Zhu, S.J.; Zhang, J.; Ma, J.J.; Zhang, Y.X.; Yao, K.X. Rational design of coaxial mesoporous birnessite manganese dioxide/amorphous-carbon nanotubes arrays for advanced asymmetric supercapacitors. J. Power Sources 2015, 278, 555–561. [Google Scholar] [CrossRef]

- Nawn, D.; Banerjee, D.; Chattopadhyay, K. Zinc oxide nanostructure decorated amorphous carbon nanotubes: An improved field emitter. Diam. Relat. Mater. 2013, 34, 50–59. [Google Scholar] [CrossRef]

- Xu, X.; Tan, H.; Xi, K.; Ding, S.; Yu, D.; Cheng, S.; Yang, G.; Peng, X.; Fakeeh, A.; Kumar, R.V. Bamboo-like amorphous carbon nanotubes clad in ultrathin nickel oxide nanosheets for lithium-ion battery electrodes with long cycle life. Carbon 2015, 84, 491–499. [Google Scholar] [CrossRef]

- Jiang, J.; Fang, H.; Zhang, X.; He, K.; Wei, Z.; Pang, X.; Dai, J. Electrochemical synthesis of aligned amorphous carbon nanotubes/TiO2 nanotubes heterostructured arrays and its field emission properties. Diam. Relat. Mater. 2017, 74, 205–211. [Google Scholar] [CrossRef]

- Li, S.; Liu, Y.; Guo, P.; Wang, C. Self-Climbed Amorphous Carbon Nanotubes Filled with Transition Metal Oxide Nanoparticles for Large Rate and Long Lifespan Anode Materials in Lithium Ion Batteries. ACS Appl. Mater. Interface 2017, 9, 26818–26825. [Google Scholar] [CrossRef]

- Maity, S.; Das, S.; Sen, D.; Chattopadhyay, K.K. Tailored CuO nanostructures decorated amorphous carbon nanotubes hybrid for efficient field emitter with theoretical validation. Carbon 2018, 127, 510–518. [Google Scholar] [CrossRef]

- Liang, W.; Tang, Y.; Liu, L.; Gao, Y.; Zeng, X. Physical forces inducing thin amorphous carbon nanotubes derived from polymer nanotubes/SiO2 hybrids with superior rate capability for lithium-ion batteries. ACS Appl. Mater. Interface 2019. [Google Scholar] [CrossRef]

- Zhao, T.; Hou, C.; Zhang, H.; Zhu, R.; She, S.; Wang, J.; Li, T.; Liu, Z.; Wei, B. Electromagnetic wave absorbing properties of amorphous carbon nanotubes. Sci. Rep. 2014, 4, 5619. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Laurila, T.; Sainio, S.; Caro, M.A. Hybrid carbon based nanomaterials for electrochemical detection of biomolecules. Prog. Mater. Sci. 2017, 88, 499–594. [Google Scholar] [CrossRef]

- Pahari, D.; Das, B.; Das, N.; Howli, P.; Chattopadhyay, K.; Sarkar, S.; Banerjee, D. Enhanced Electrochemical Performance of Copper Oxide Nanoparticle Decorated Amorphous Carbon Nanotubes. Adv. Sci. Eng. Med. 2017, 9, 263–270. [Google Scholar] [CrossRef]

- Xu, X.; Chen, S.; Xiao, C.; Xi, K.; Guo, C.; Guo, S.; Ding, S.; Yu, D.; Kumar, R.V. Rational design of NiCoO2@ SnO2 heterostructure attached on amorphous carbon nanotubes with improved lithium storage properties. ACS Appl. Mater. Interface 2016, 8, 6004–6010. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Yu, L.; Yu, X.Y.; Lou, X.W. Encapsulating Sn nanoparticles in amorphous carbon nanotubes for enhanced lithium storage properties. Adv. Energy Mater. 2016, 6, 1601177. [Google Scholar] [CrossRef]

- Zhao, T.; Liu, Y.; Li, T.; Zhao, X. Electrochemical performance of amorphous carbon nanotube as anode materials for lithium ion battery. J. NanoSci. Nanotechnol. 2010, 10, 3873–3877. [Google Scholar] [CrossRef]

- Guo, W.; Li, X.; Xu, J.; Liu, H.K.; Ma, J.; Dou, S.X. Growth of highly nitrogen-doped amorphous carbon for lithium-ion battery anode. Electrochim. Acta 2016, 188, 414–420. [Google Scholar] [CrossRef]

- Yu, Z.-L.; Xin, S.; You, Y.; Yu, L.; Lin, Y.; Xu, D.-W.; Qiao, C.; Huang, Z.-H.; Yang, N.; Yu, S.-H. Ion-catalyzed synthesis of microporous hard carbon embedded with expanded nanographite for enhanced lithium/sodium storage. J. Am. Chem. Soc. 2016, 138, 14915–14922. [Google Scholar] [CrossRef]

- Wang, Y.; Tian, W.; Wang, L.; Zhang, H.; Liu, J.; Peng, T.; Pan, L.; Wang, X.; Wu, M. A tunable molten-salt route for scalable synthesis of ultrathin amorphous carbon nanosheets as high-performance anode materials for lithium-ion batteries. ACS Appl. Mater. Interface 2018, 10, 5577–5585. [Google Scholar] [CrossRef]

- Xu, X.; Yu, D.; Zhou, H.; Zhang, L.; Xiao, C.; Guo, C.; Guo, S.; Ding, S. MoS 2 nanosheets grown on amorphous carbon nanotubes for enhanced sodium storage. J. Mater. Chem. A 2016, 4, 4375–4379. [Google Scholar] [CrossRef]

- Bhowmick, P.; Banerjee, D.; Santra, S.; Sen, D.; Das, B.; Chattopadhyay, K.K. Amorphous carbon nanotubes as potent sorbents for removal of a phenolic derivative compound and arsenic: Theoretical support of experimental findings. RSC Adv. 2016, 6, 8913–8922. [Google Scholar] [CrossRef]

- Banerjee, D.; Bhowmick, P.; Pahari, D.; Santra, S.; Sarkar, S.; Das, B.; Chattopadhyay, K.K. Pseudo first ordered adsorption of noxious textile dyes by low-temperature synthesized amorphous carbon nanotubes. Phys. E Low Dimens. Syst. Nanostructures 2017, 87, 68–76. [Google Scholar] [CrossRef]

- Zhong, L.; Tang, A.; Yan, P.; Wang, J.; Wang, Q.; Wen, X.; Cui, Y. Palygorskite-template amorphous carbon nanotubes as a superior adsorbent for removal of dyes from aqueous solutions. J. Collid Interface Sci. 2019, 537, 450–457. [Google Scholar] [CrossRef] [PubMed]

- Maity, S.; Jha, A.; Das, N.; Chattopadhyay, K. Fabrication of barium/strontium carbonate coated amorphous carbon nanotubes as an improved field emitter. Appl. Phys. 2013, 110, 493–499. [Google Scholar] [CrossRef]

- Park, G.S.; Lee, J.-S.; Kim, S.T.; Park, S.; Cho, J. Porous nitrogen doped carbon fiber with churros morphology derived from electrospun bicomponent polymer as highly efficient electrocatalyst for Zn-air batteries. J. Power Sources 2013, 243, 267–273. [Google Scholar] [CrossRef]

- Chen, L.-F.; Zhang, X.-D.; Liang, H.-W.; Kong, M.; Guan, Q.-F.; Chen, P.; Wu, Z.-Y.; Yu, S.-H. Synthesis of nitrogen-doped porous carbon nanofibers as an efficient electrode material for supercapacitors. ACS Nano 2012, 6, 7092–7102. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, J.; Zhang, B.; Dong, S.; Guo, X.; Mu, X.; Fei, B. A novel hierarchical porous nitrogen-doped carbon derived from bamboo shoot for high performance supercapacitor. Sci. Rep. 2017, 7, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Ilnicka, A.; Gauden, P.A.; Terzyk, A.P.; Lukaszewicz, J.P. Nano-structured carbon matrixes obtained from chitin and chitosan by a novel method. J. NanoSci. Nanotechnol. 2016, 16, 2623–2631. [Google Scholar] [CrossRef]

- Beamson, G.; Briggs, D. High Resolution XPS of Organic Polymers: The Scienta ESCA300 Database. J. Chem. Educ. 1993, 70, A25. [Google Scholar]

- Rouxhet, P.; Genet, M. XPS analysis of bio-organic systems. Surf. Interface Anal. 2011, 43, 1453–1470. [Google Scholar] [CrossRef]

- Genet, M.J.; Dupont-Gillain, C.C.; Rouxhet, P.G. XPS Analysis of Biosystems and Biomaterials. In Medical Applictions of Colloids; Matijevic, E., Ed.; Springer Science and Business Media: Berlin, Germany, 2008. [Google Scholar]

- Briggs, D. Surface Analysis of Polymers by XPS and Static SIMS; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Bagai, R.; Christopher, J.; Kapur, G.S. Evaluating industrial grade functionalized multiwalled carbon nanotubes by X-ray photoelectron spectroscopy. Fuller. Nanotub. Carbon Nanostructures 2019, 27, 240–246. [Google Scholar] [CrossRef]

- Puziy, A.; Poddubnaya, O.; Socha, R.; Gurgul, J.; Wisniewski, M. XPS and NMR studies of phosphoric acid activated carbons. Carbon 2008, 46, 2113–2123. [Google Scholar] [CrossRef]

- Razmjooei, F.; Singh, K.; Kang, T.H.; Chaudhari, N.; Yuan, J.; Yu, J.-S. Urine to highly porous heteroatom-doped carbons for supercapacitor: A value added journey for human waste. Sci. Rep. 2017, 7, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Panja, T.; Bhattacharjya, D.; Yu, J.-S. Nitrogen and phosphorus co-doped cubic ordered mesoporous carbon as a supercapacitor electrode material with extraordinary cyclic stability. J. Mater. Chem. A 2015, 3, 18001–18009. [Google Scholar] [CrossRef]

- Zou, B.-X.; Wang, Y.; Huang, X.; Lu, Y. Hierarchical N-and O-doped porous carbon composites for high-performance supercapacitors. J. Nanomater. 2018, 2018. [Google Scholar] [CrossRef]

- Yan, L.; Yu, J.; Houston, J.; Flores, N.; Luo, H. Biomass derived porous nitrogen doped carbon for electrochemical devices. Green Energy Environ. 2017, 2, 84–99. [Google Scholar] [CrossRef]

- Deng, Y.; Xie, Y.; Zou, K.; Ji, X. Review on recent advances in nitrogen-doped carbons: Preparations and applications in supercapacitors. J. Mater. Chem. A 2016, 4, 1144–1173. [Google Scholar] [CrossRef]

| Carbon Background | Short Name of Carbon Background | Addition of FeCl3 | Carbonization Temperature (°C) | ||

|---|---|---|---|---|---|

| 600 | 700 | 800 | |||

| Sample Name | |||||

| CH_2.46 * | C1 | - | C1-6 | C1-7 | C1-8 |

| CH_5.53 * | C2 | - | C2-6 | - | - |

| CH_2.46 * | C1 | 0.01 g | C1-A-6 | C1-A-7 | C1-A-8 |

| CH_5.53 * | C2 | 0.01 g | C2-A-6 | - | - |

| Sample | Content (wt.%) | SBET (m2 g−1) | ||

|---|---|---|---|---|

| N | C | H | ||

| C1-6 | 2.6 | 78.8 | 1.9 | 500 |

| C1-7 | 2.3 | 68.6 | 1.7 | 437 |

| C1-8 | 2.2 | 69.8 | 1.2 | 320 |

| C1-A-6 | 3.3 | 71.2 | 1.7 | 557 |

| C1-A-7 | 2.3 | 66 | 1.8 | 403 |

| C1-A-8 | 2.2 | 64.8 | 1.6 | 524 |

| C2-6 | 1.8 | 78 | 2 | 392 |

| C2-A-6 | 2.1 | 73.9 | 2.1 | 356 |

| Sample | Binding Energy (eV) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 284.6 | 285.0 | 286.4 | 287.7 | 288.6 | 531.6 | 533.2 | 536.0 | 399.1 | 400.5 | 132.9 | |

| Elemental Content (at.%) | |||||||||||

| C | O | N | P | ||||||||

| C1-6 | 27.1 | 38.4 | 12.3 | 4.4 | 2.3 | 3.9 | 7.2 | 0.5 | 2.0 | 0.5 | 1.4 |

| C1-7 | 30.2 | 37.0 | 11.1 | 3.7 | 2.0 | 4.7 | 6.4 | 0.5 | 1.3 | 0.4 | 2.6 |

| C1-8 | 29.5 | 38.5 | 8.9 | 4.0 | 1.1 | 5.6 | 7.0 | 0.6 | 1.5 | 0.5 | 3.0 |

| C1-A-6 | 31.1 | 35.7 | 9.9 | 3.9 | 1.9 | 6.0 | 6.8 | 0.6 | 1.7 | 0.6 | 2.0 |

| C1-A-7 | 31.9 | 36.2 | 9.6 | 4.0 | 1.1 | 5.5 | 6.4 | 0.6 | 1.7 | 0.5 | 2.5 |

| C1-A-8 | 32.7 | 34.4 | 9.7 | 4.2 | 1.6 | 5.9 | 6.7 | 0.7 | 1.4 | 0.5 | 2.1 |

| C2-6 | 30.7 | 39.8 | 9.2 | 3.9 | 1.2 | 4,8 | 5.9 | 0.4 | 1.6 | 0.5 | 2.1 |

| C2-A-6 | 31.5 | 33.1 | 9.3 | 4.4 | 2.2 | 7.6 | 6.5 | 0.4 | 2.2 | 1.3 | 1.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zielinski, W.; Kamedulski, P.; Smolarkiewicz-Wyczachowski, A.; Skorupska, M.; Lukaszewicz, J.P.; Ilnicka, A. Synthesis of Hybrid Carbon Materials Consisting of N-Doped Microporous Carbon and Amorphous Carbon Nanotubes. Materials 2020, 13, 2997. https://doi.org/10.3390/ma13132997

Zielinski W, Kamedulski P, Smolarkiewicz-Wyczachowski A, Skorupska M, Lukaszewicz JP, Ilnicka A. Synthesis of Hybrid Carbon Materials Consisting of N-Doped Microporous Carbon and Amorphous Carbon Nanotubes. Materials. 2020; 13(13):2997. https://doi.org/10.3390/ma13132997

Chicago/Turabian StyleZielinski, Wojciech, Piotr Kamedulski, Aleksander Smolarkiewicz-Wyczachowski, Malgorzata Skorupska, Jerzy P. Lukaszewicz, and Anna Ilnicka. 2020. "Synthesis of Hybrid Carbon Materials Consisting of N-Doped Microporous Carbon and Amorphous Carbon Nanotubes" Materials 13, no. 13: 2997. https://doi.org/10.3390/ma13132997

APA StyleZielinski, W., Kamedulski, P., Smolarkiewicz-Wyczachowski, A., Skorupska, M., Lukaszewicz, J. P., & Ilnicka, A. (2020). Synthesis of Hybrid Carbon Materials Consisting of N-Doped Microporous Carbon and Amorphous Carbon Nanotubes. Materials, 13(13), 2997. https://doi.org/10.3390/ma13132997