Process-Induced Distortions Characterization of MBWK Fabric Reinforced Composite Helmet Shell

Abstract

1. Introduction

2. Composite Materials and Manufacturing Process

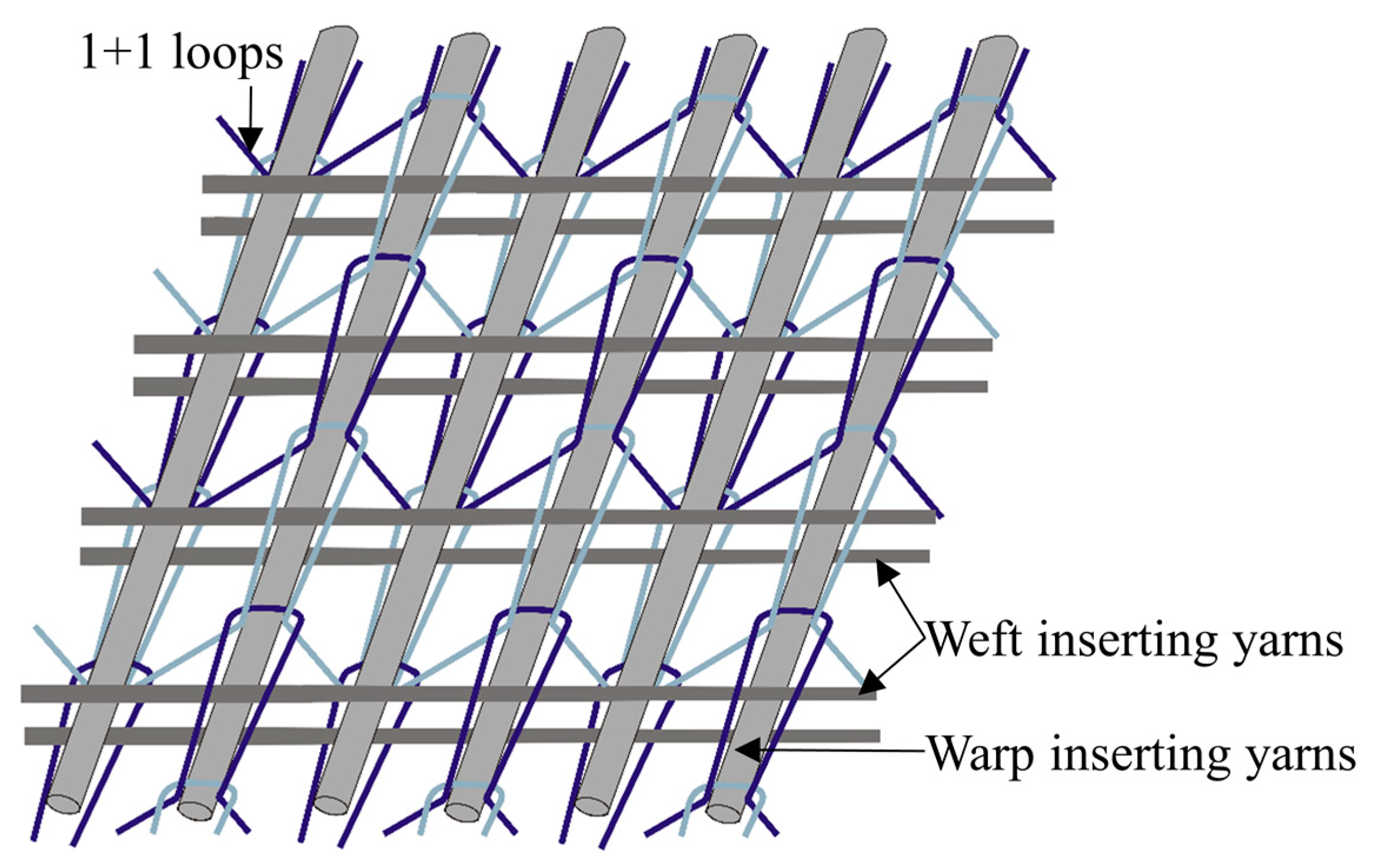

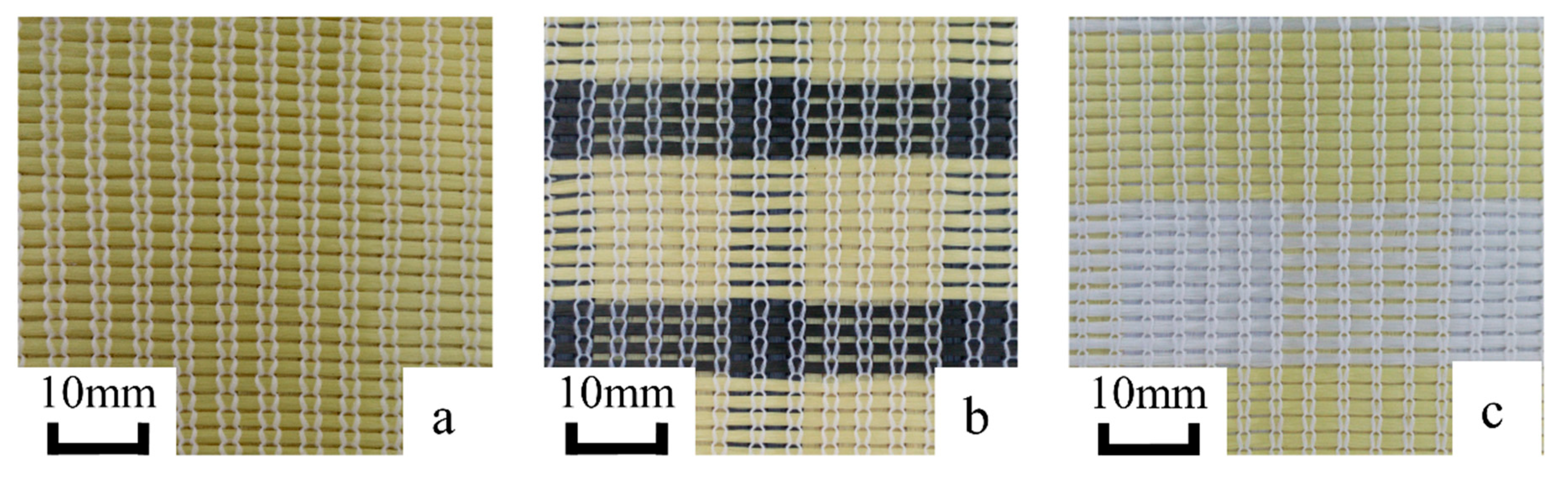

2.1. Preparation of Raw Materials

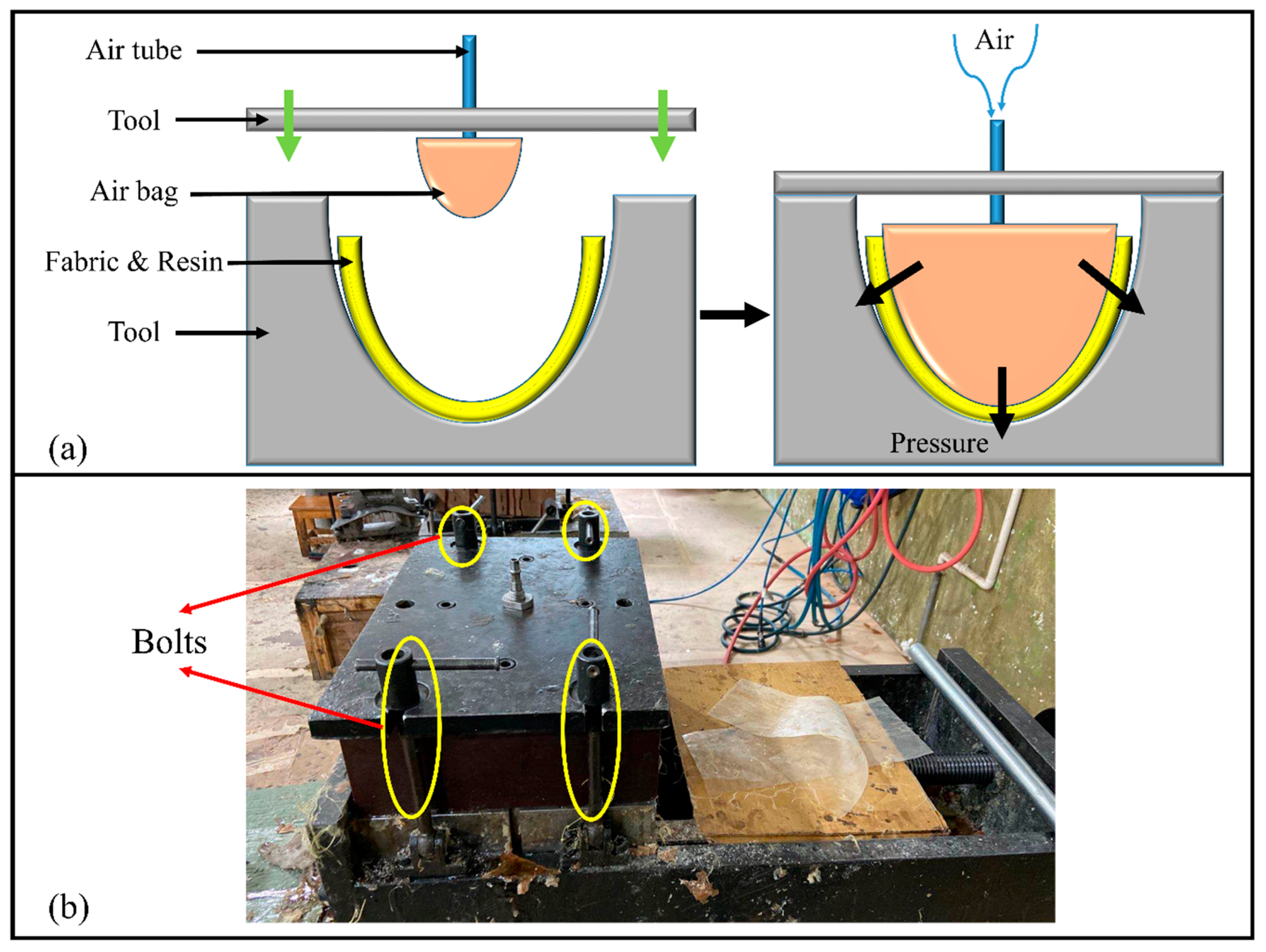

2.2. Sample Preparation

3. Data Extraction and Analysis

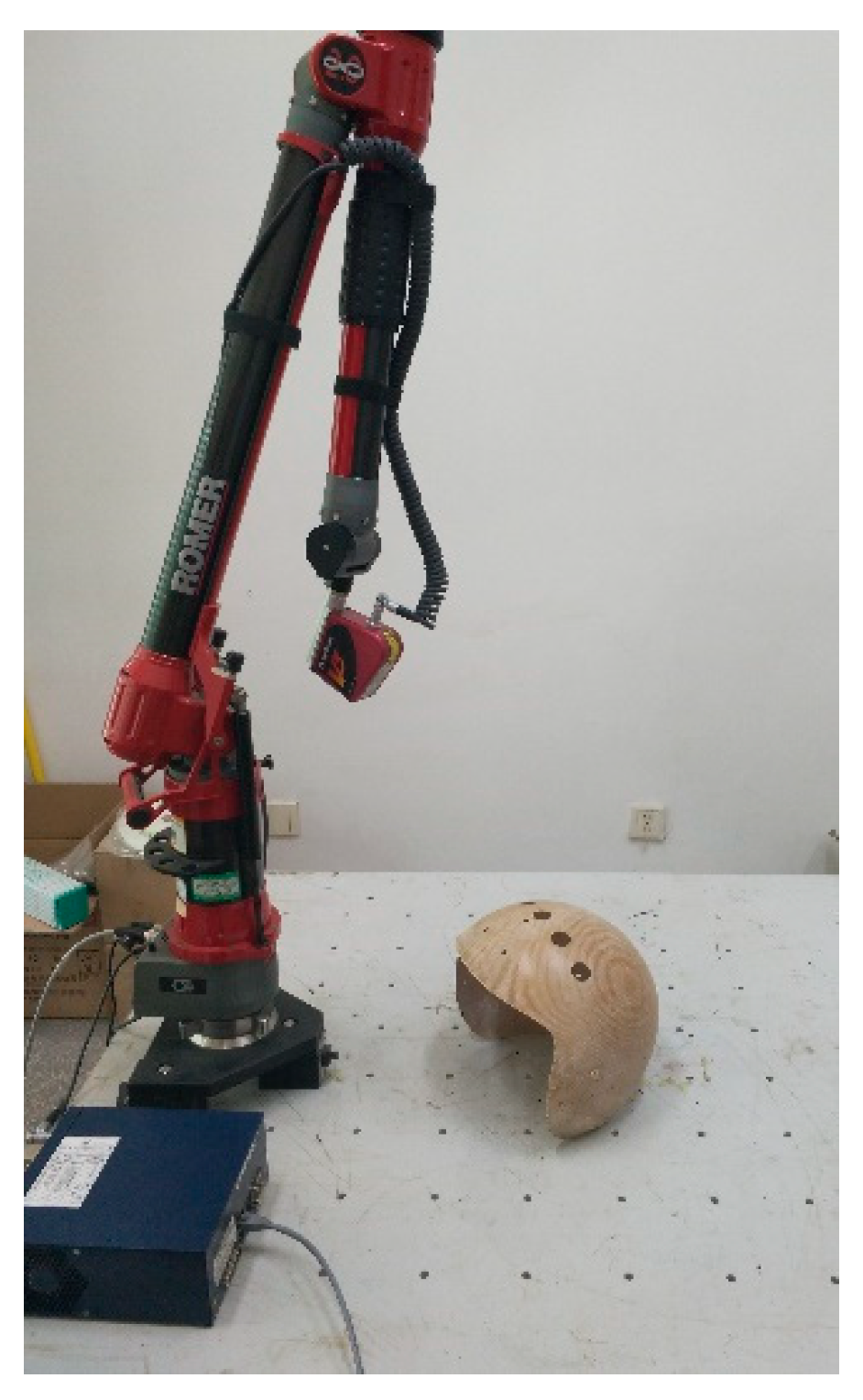

3.1. Helmet Molding and Surface Scanning

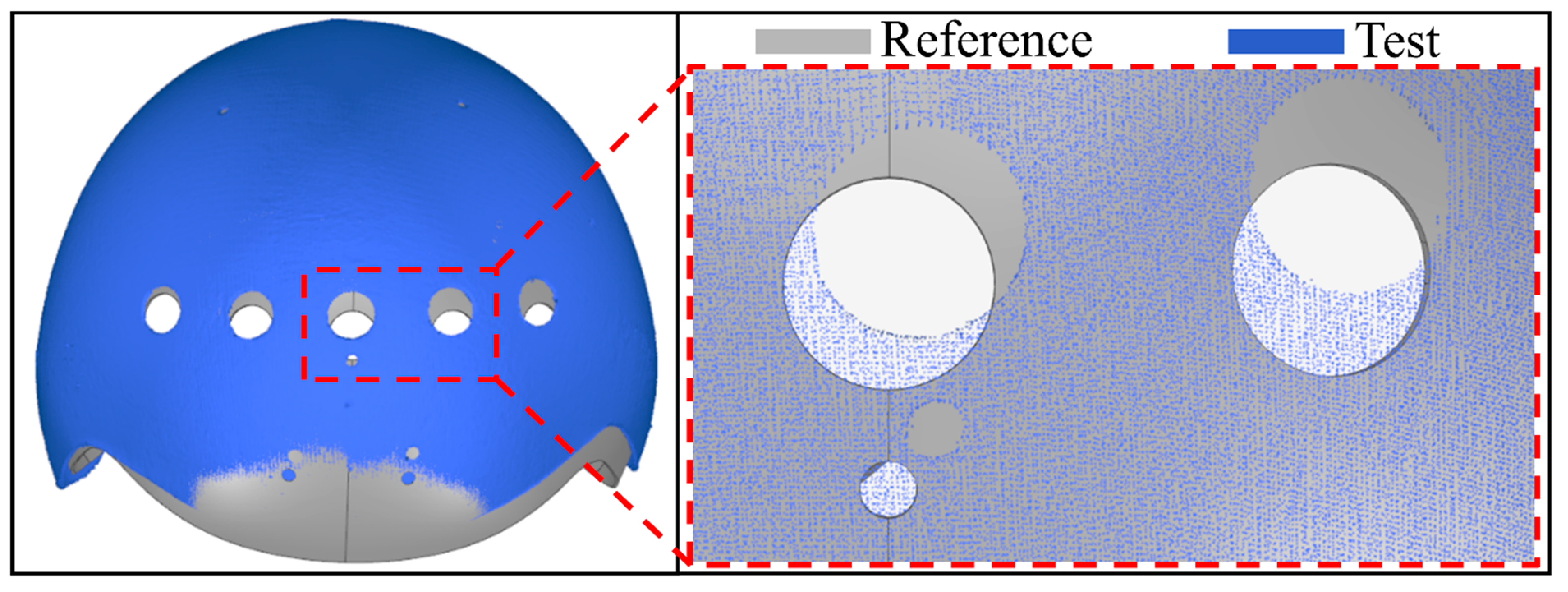

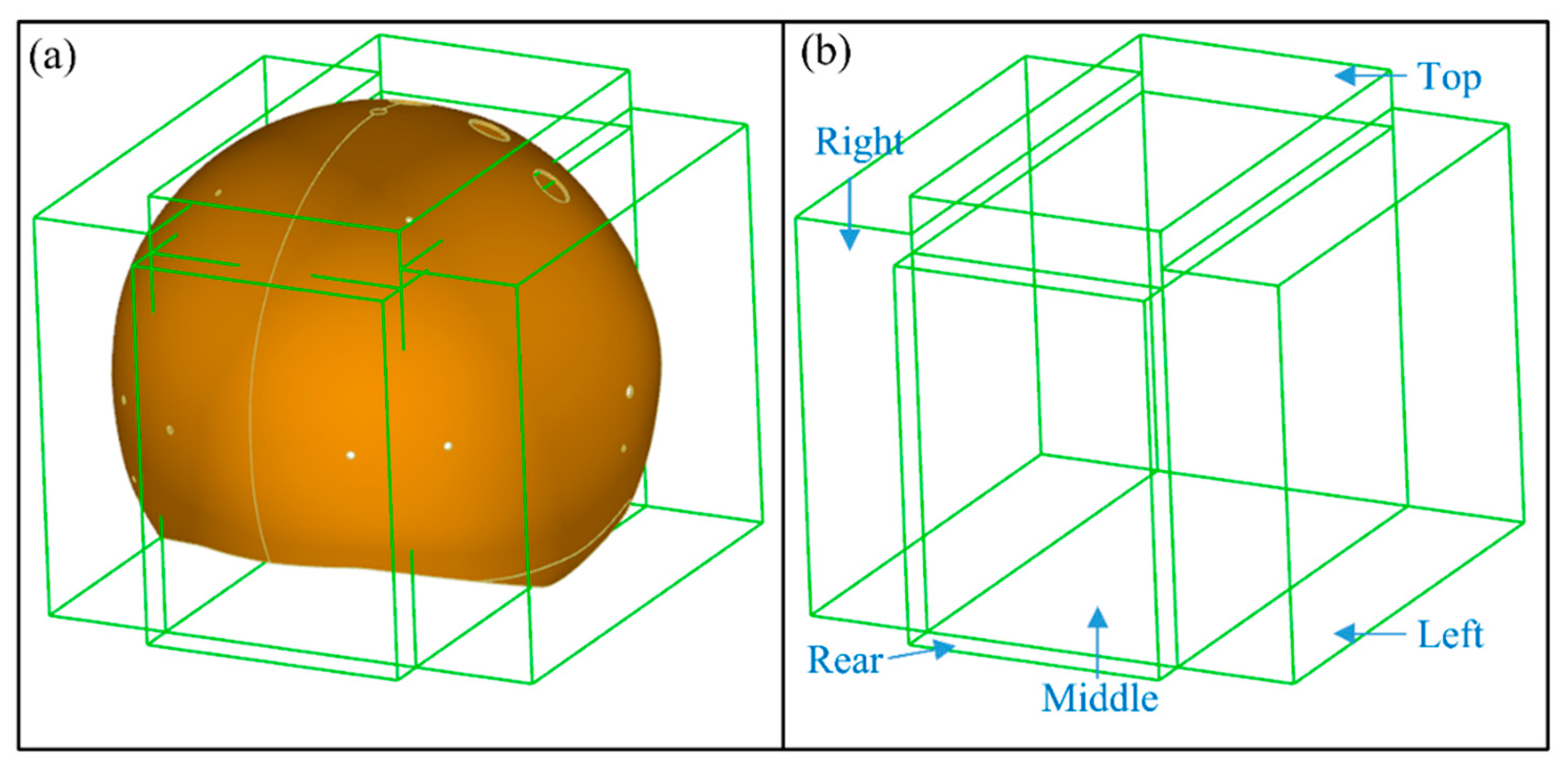

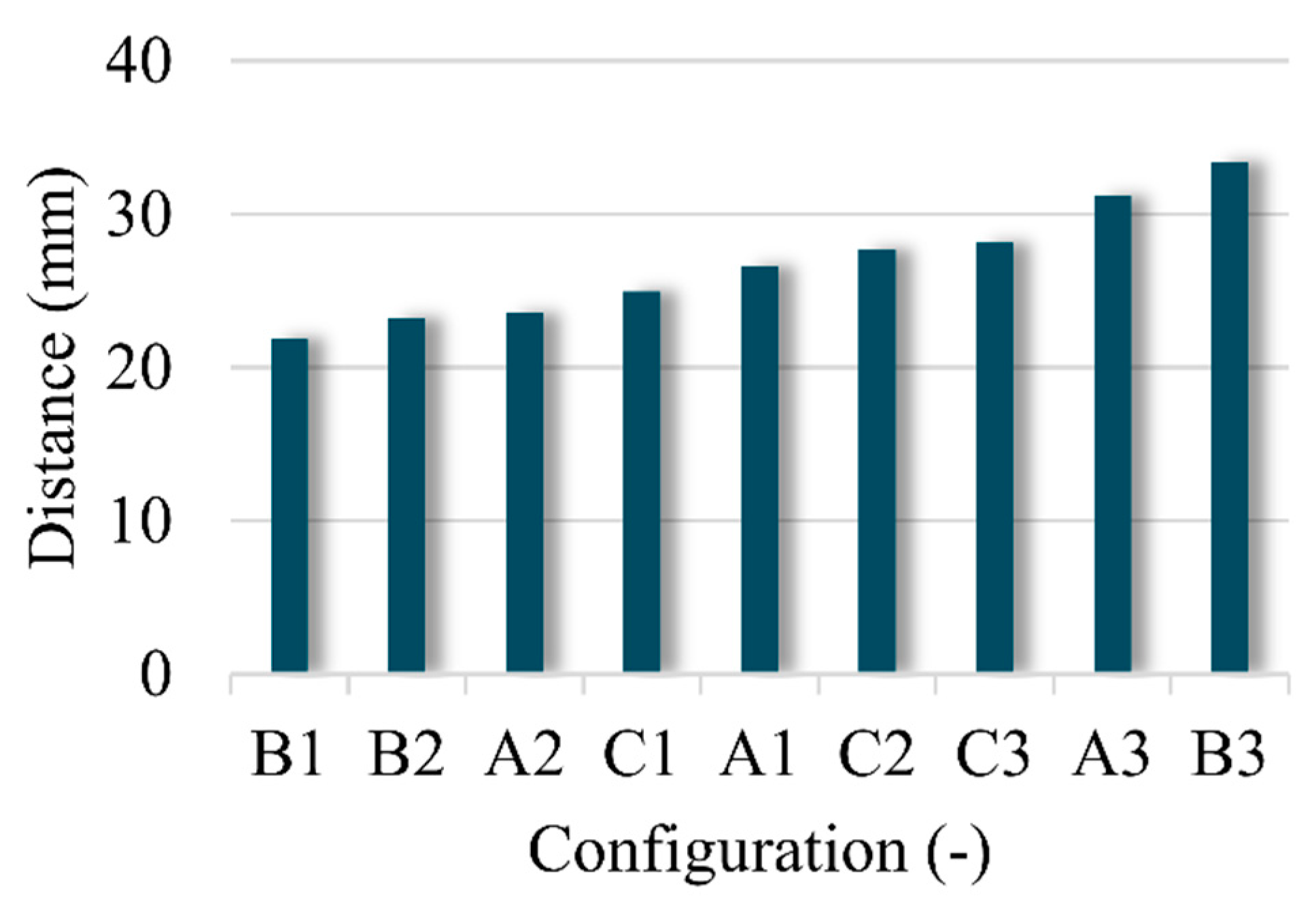

3.2. Conventional Analysis Method based on ICP Algorithm

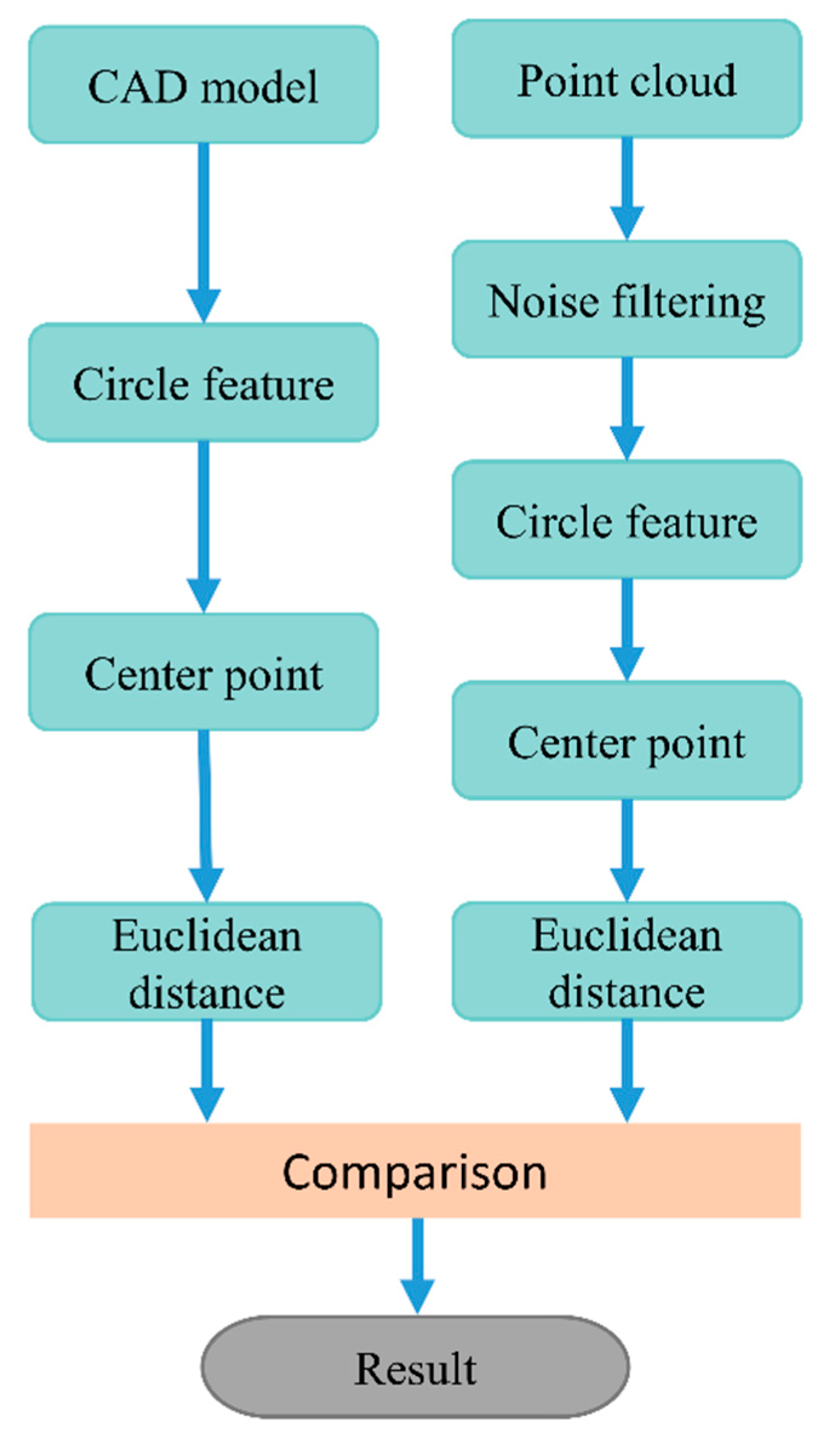

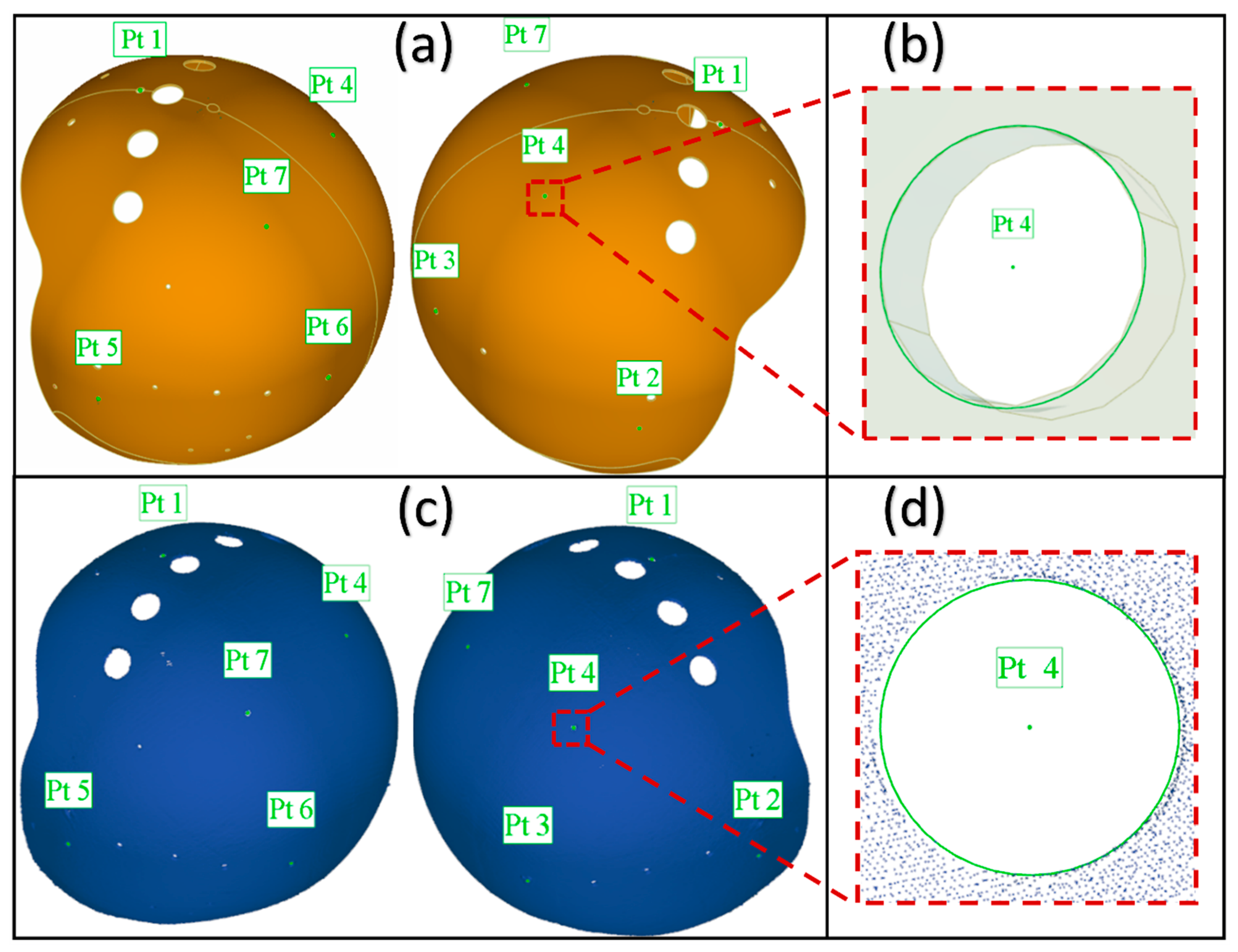

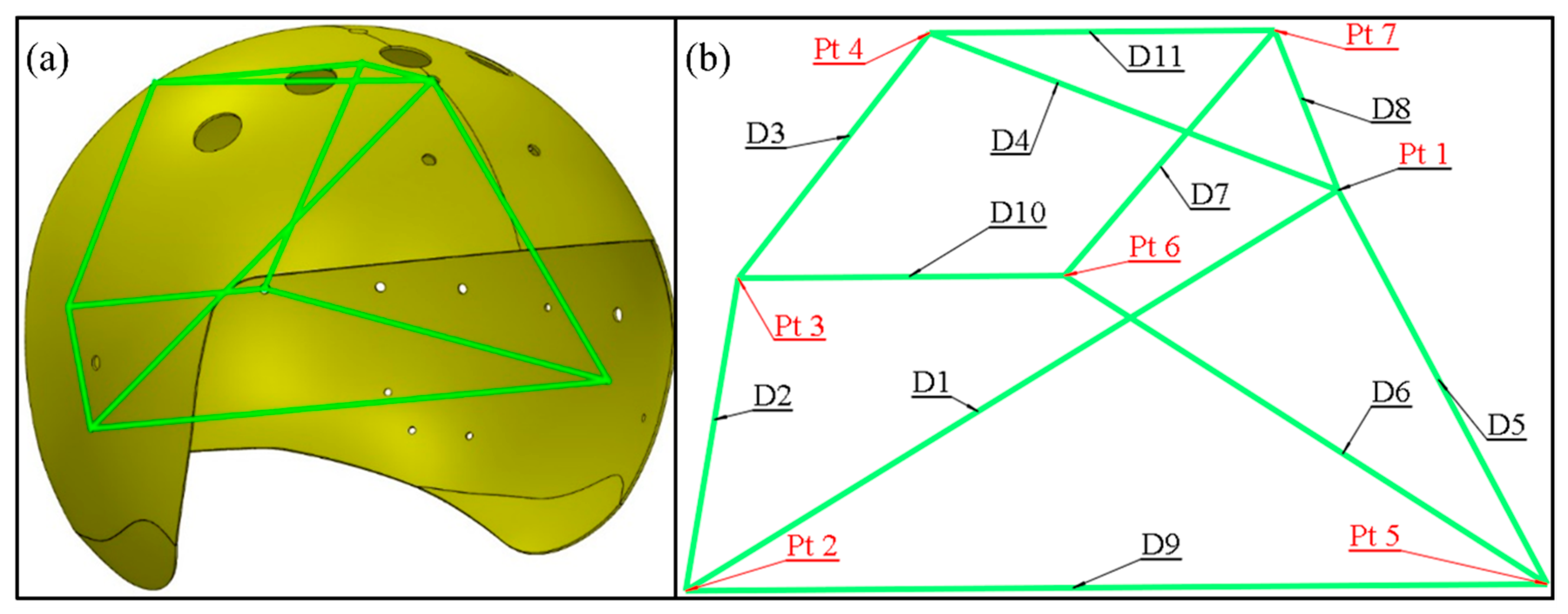

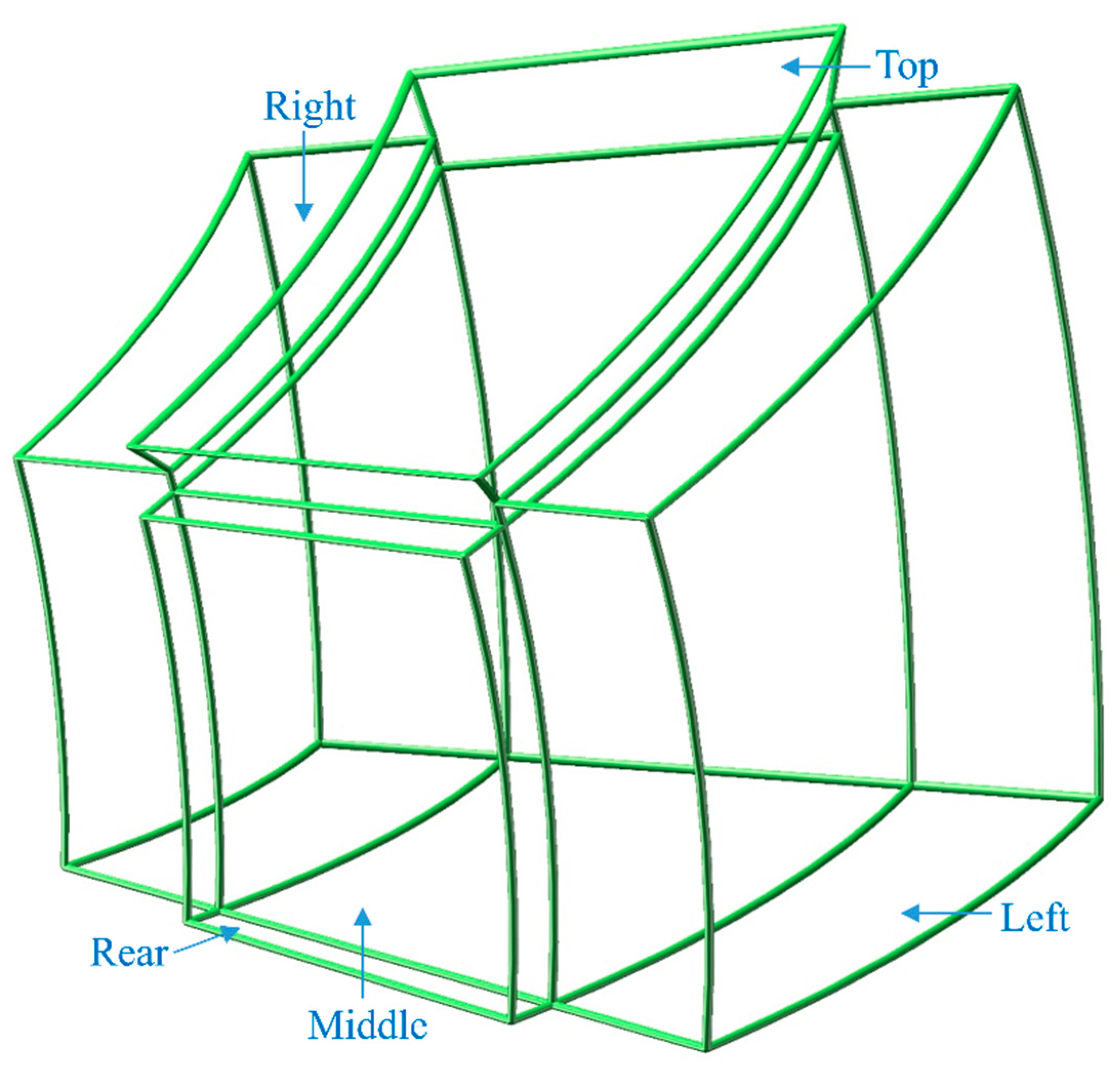

3.3. Analysis Based on Feature Distance

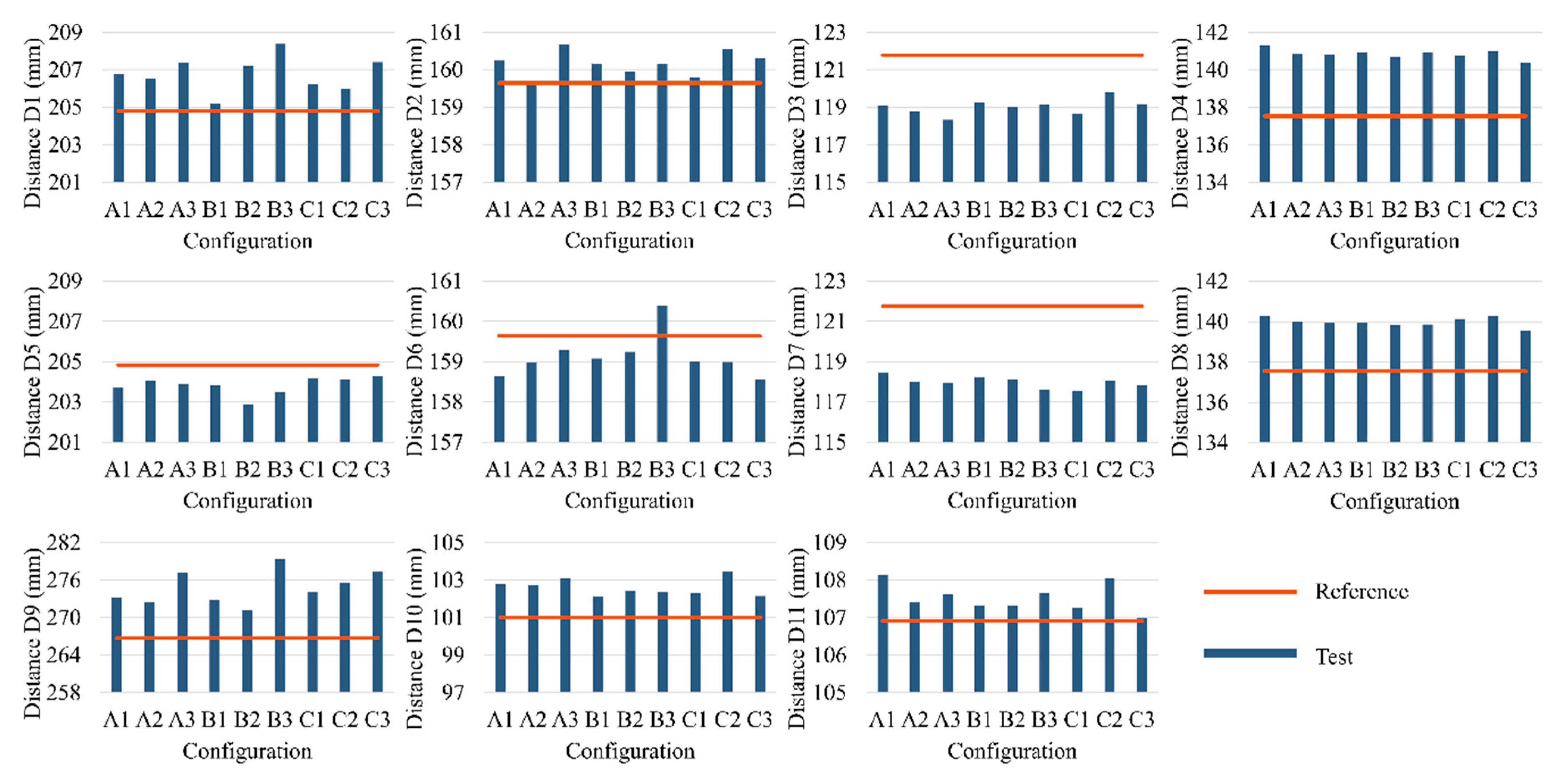

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A. Experimentally Determined Feature Distance of Reference model and Nine Helmets

| cad | A1 | A2 | A3 | B1 | B2 | B3 | C1 | C2 | C3 | |

| D1 | 204.842 | 206.803 | 206.525 | 207.418 | 205.238 | 207.202 | 208.397 | 206.226 | 205.985 | 207.428 |

| D2 | 159.644 | 160.238 | 159.662 | 160.684 | 160.167 | 159.959 | 160.161 | 159.796 | 160.552 | 160.304 |

| D3 | 121.785 | 119.088 | 118.804 | 118.335 | 119.293 | 119.041 | 119.173 | 118.689 | 119.800 | 119.181 |

| D4 | 137.548 | 141.287 | 140.853 | 140.836 | 140.938 | 140.706 | 140.921 | 140.771 | 140.991 | 140.409 |

| D5 | 204.843 | 203.732 | 204.061 | 203.892 | 203.856 | 202.865 | 203.513 | 204.203 | 204.142 | 204.285 |

| D6 | 159.643 | 158.654 | 158.974 | 159.298 | 159.081 | 159.249 | 160.391 | 159.023 | 158.996 | 158.549 |

| D7 | 121.778 | 118.478 | 118.022 | 117.972 | 118.233 | 118.098 | 117.628 | 117.545 | 118.059 | 117.864 |

| D8 | 137.549 | 140.269 | 139.994 | 139.954 | 139.959 | 139.829 | 139.865 | 140.097 | 140.292 | 139.545 |

| D9 | 266.751 | 273.218 | 272.438 | 277.264 | 272.792 | 271.219 | 279.388 | 274.154 | 275.594 | 277.388 |

| D10 | 101.010 | 102.787 | 102.723 | 103.083 | 102.146 | 102.433 | 102.402 | 102.320 | 103.451 | 102.164 |

| D11 | 106.908 | 108.148 | 107.411 | 107.629 | 107.338 | 107.336 | 107.670 | 107.263 | 108.049 | 106.998 |

| Unit: mm | ||||||||||

References

- Hu, Q.; Memon, H.; Qiu, Y.; Wei, Y. The Failure Mechanism of Composite Stiffener Components Reinforced with 3D Woven Fabrics. Materials 2019, 12, 2221. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; Xiao, J.; Tao, L.; Wei, Y.; Wang, S.; Zhang, H.; Zhu, S.; Yu, M. Preparation of High-Performance Carbon Fiber-Reinforced Epoxy Composites by Compression Resin Transfer Molding. Materials 2018, 12, 13. [Google Scholar] [CrossRef] [PubMed]

- Zhu, M.; Chen, D.; Hu, Q. Failure Mechanisms and Reinforcing Modes of Ply Splice Fiber-Reinforced Composite Laminates under Tensile Load. Materials 2019, 12, 2912. [Google Scholar] [CrossRef] [PubMed]

- Antin, K.-N.; Laukkanen, A.; Andersson, T.; Smyl, D.; Vilaça, P. A Multiscale Modelling Approach for Estimating the Effect of Defects in Unidirectional Carbon Fiber Reinforced Polymer Composites. Materials 2019, 12, 1885. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.P.; Zhang, G.L.; Zhu, Y.X.; Zhang, L.Q.; Shi, X.P.; Wang, W.W. Theoretical analysis of braiding strand trajectories and simulation of three-dimensional parametric geometrical models for multilayer interlock three-dimensional tubular braided preforms. Text. Res. J. 2019, 89, 4306–4322. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, J.; Ni, A. Process-Induced Stress and Deformation of Variable-Stiffness Composite Cylinders during Curing. Materials 2019, 12, 259. [Google Scholar] [CrossRef]

- Ding, A.X.; Wang, J.H.; Ni, A.Q.; Li, S.X. A new analytical solution for cure-induced spring-in of L-shaped composite parts. Compos. Sci. Technol. 2019, 171, 1–12. [Google Scholar] [CrossRef]

- Liu, K.; Zhang, B.; Xu, X.; Ye, J.; Liu, C. Simulation and Analysis of Process-Induced Distortions in Hemispherical Thermostamping for Unidirectional Thermoplastic Composites. Polym. Compos. 2018, 40, 1786–1800. [Google Scholar] [CrossRef]

- Kappel, E. Distortions of composite aerospace frames due to processing, thermal loads and trimming operations and an assessment from an assembly perspective. Compos. Struct. 2019, 220, 338–346. [Google Scholar] [CrossRef]

- Yuan, Z.; Wang, Y.; Peng, X.; Wang, J.; Wei, S. An analytical model on through-thickness stresses and warpage of composite laminates due to tool–part interaction. Compos. Sci. Part B Eng. 2016, 91, 408–413. [Google Scholar] [CrossRef]

- Ding, A.X.; Li, S.X.; Wang, J.H.; Ni, A.Q.; Zu, L. A new path-dependent constitutive model predicting cure-induced distortions in composite structures. Compos. Part A Appl Sci. 2017, 95, 183–196. [Google Scholar] [CrossRef]

- Kappel, E. Forced-interaction and spring-in - Relevant initiators of process-induced distortions in composite manufacturing. Compos. Struct. 2016, 140, 217–229. [Google Scholar] [CrossRef]

- Ding, A.X.; Li, S.X.; Wang, J.H.; Ni, A.Q. A new analytical solution for spring-in of curved composite parts. Compos. Sci. Technol. 2017, 142, 30–40. [Google Scholar] [CrossRef]

- Muller, M.T.; Potzsch, H.F.; Gohs, U.; Heinrich, G. Online Structural-Health Monitoring of Glass Fiber-Reinforced Thermoplastics Using Different Carbon Allotropes in the Interphase. Materials 2018, 11, 75. [Google Scholar] [CrossRef] [PubMed]

- Jovančević, I.; Pham, H.-H.; Orteu, J.-J.; Gilblas, R.; Harvent, J.; Maurice, X.; Brèthes, L. 3D Point Cloud Analysis for Detection and Characterization of Defects on Airplane Exterior Surface. J. Nondestruct. Eval 2017, 36, s10921¨Cs017. [Google Scholar]

- Xu, X.Y.; Kargoll, B.; Bureick, J.; Yang, H.; Alkhatib, H.; Neumann, I. TLS-based profile model analysis of major composite structures with robust B-spline method. Compos. Struct. 2018, 184, 814–820. [Google Scholar] [CrossRef]

- Wu, D.W.; Ding, X.F.; Tong, G. Surface Design of Molding Tool for Composite Component Based on Reverse Engineering. Adv. Mater. Res. 2012, 503–504, 215–218. [Google Scholar] [CrossRef]

- Kwiatkowski, J.; Anigacz, W.; Beben, D. Comparison of Non-Destructive Techniques for Technological Bridge Deflection Testing. Materials 2020, 13, 1908. [Google Scholar] [CrossRef]

- Bellini, C.; Sorrentino, L. Analysis of cure induced deformation of CFRP U-shaped laminates. Compos. Struct. 2018, 197, 1–9. [Google Scholar] [CrossRef]

- Che, L.; Zhou, Z.; Fang, G.; Ma, Y.; Dong, W.; Zhang, J. Cured shape prediction of fiber metal laminates considering interfacial interaction. Compos. Struct. 2018, 194, 564–574. [Google Scholar] [CrossRef]

- Baran, I.; Hattel, J.H.; Akkerman, R. Investigation of process induced warpage for pultrusion of a rectangular hollow profile. Compos. Part B Eng. 2015, 68, 365–374. [Google Scholar] [CrossRef]

- Filippatos, A.; Langkamp, A.; Gude, M. Influence of Gradual Damage on the Structural Dynamic Behaviour of Composite Rotors: Simulation Assessment. Materials 2018, 11, 2453. [Google Scholar] [CrossRef]

- Xu, X.Y.; Yang, H.; Zhang, Y.; Neumann, I. Intelligent 3D data extraction method for deformation analysis of composite structures. Compos. Struct. 2018, 203, 254–258. [Google Scholar] [CrossRef]

- Yang, H.; Xu, X.Y.; Neumann, I. Deformation behavior analysis of composite structures under monotonic loads based on terrestrial laser scanning technology. Compos. Struct. 2018, 183, 594–599. [Google Scholar] [CrossRef]

- Yang, H.; Xu, X.Y.; Neumann, I. An automatic finite element modelling for deformation analysis of composite structures. Compos. Struct. 2019, 212, 434–438. [Google Scholar] [CrossRef]

- Cheng, X.; Li, Z.; Zhong, K.; Shi, Y. An automatic and robust point cloud registration framework based on view-invariant local feature descriptors and transformation consistency verification. Opt. Las. Eng. 2017, 98, 37–45. [Google Scholar] [CrossRef]

- Tan, L.B.; Tse, K.M.; Lee, H.P.; Tan, V.B.C.; Lim, S.P. Performance of an advanced combat helmet with different interior cushioning systems in ballistic impact: Experiments and finite element simulations. Int. J. Impact Eng. 2012, 50, 99–112. [Google Scholar] [CrossRef]

- Pei, X.Y.; Shang, B.; Chen, L.; Li, J.L.; Tang, Y.H. Compression properties of multilayer-connected biaxial weft knitted carbon fiber fabric reinforced composites. Compos. Part. B-Eng. 2016, 91, 296–305. [Google Scholar] [CrossRef]

- Qi, Y.X.; Li, J.L.; Liu, L.S. Stiffness prediction of multilayer-connected biaxial weft-knitted fabric-reinforced composites. J. Reinf. Plast. Compos. 2015, 34, 1113–1125. [Google Scholar] [CrossRef]

- Jiang, G.; Gao, Z.; Ma, P.; Miao, X.; Zhu, Y. Comparative study on the mechanical behavior of carbon weft-knitted biaxial fabrics stitched by polyester fibers and preoxidized polyacrylonitrile fibers. J. Ind. Text. 2013, 44, 5–21. [Google Scholar] [CrossRef]

- Li, X.K.; Bai, S.L. Sheet forming of the multi-layered biaxial weft knitted fabric reinforcement. Part I: On hemispherical surfaces. Compos. Part. A-Appl. S 2009, 40, 766–777. [Google Scholar] [CrossRef]

- Qi, Y.; Li, J.; Liu, L. Tensile properties of multilayer-connected biaxial weft knitted fabric reinforced composites for carbon fibers. Mater. Des. (1980–2015) 2014, 54, 678–685. [Google Scholar] [CrossRef]

- Hasani, H.; Hassanzadeh, S.; Abghary, M.J.; Omrani, E. Biaxial weft-knitted fabrics as composite reinforcements: A review. J. Ind. Text. 2016, 46, 1439–1473. [Google Scholar] [CrossRef]

- Demircan, Ö.; Ashibe, S.; Kosui, T.; Nakai, A. Mechanical properties of biaxial weft-knitted and cross-ply thermoplastic composites. J. Thermoplast. Compos. Mater. 2014, 28, 1058–1074. [Google Scholar] [CrossRef]

- Bi, Z.M.; Wang, L. Advances in 3D data acquisition and processing for industrial applications. Robot. Comput. Integr. Manuf. 2010, 26, 403–413. [Google Scholar] [CrossRef]

- Li, T.; Gao, L.; Li, P.; Pan, Q. An ensemble fruit fly optimization algorithm for solving range image registration to improve quality inspection of free-form surface parts. Inf. Sci. 2016, 367–368, 953–974. [Google Scholar] [CrossRef]

- Besl, P.J.; McKay, N.D. A method for registration of 3-D shapes. IEEE Trans. Pattern Anal. Mach. Intell. 1992, 14, 239–256. [Google Scholar] [CrossRef]

- O’Toole, S.; Osnes, C.; Bartlett, D.; Keeling, A. Investigation into the accuracy and measurement methods of sequential 3D dental scan alignment. Dent. Mater. Off. Publ. Acad. Dent. Mater. 2019, 35, 495–500. [Google Scholar] [CrossRef]

- Li, Y.; Gu, P. Free-form surface inspection techniques state of the art review. Comput. Aided Des. 2004, 36, 1395–1417. [Google Scholar] [CrossRef]

- Gruen, A.; Akca, D. Least squares 3D surface and curve matching. ISPRS J. Photogramm. Remote Sens. 2005, 59, 151–174. [Google Scholar] [CrossRef]

- Nikmatin, S.; Hermawan, B.; Irmansyah, I.; Indro, M.N.; Kueh, A.B.H.; Syafiuddin, A. Evaluation of the Performance of Helmet Prototypes Fabricated from Acrylonitrile Butadiene Styrene Composites Filled with Natural Resource. Materials 2018, 12, 34. [Google Scholar] [CrossRef] [PubMed]

- Kaczynski, P.; Ptak, M.; Fernandes, A.O.F.; Chybowski, L.; Wilhelm, J.; Alves de Sousa, R.J. Development and Testing of Advanced Cork Composite Sandwiches for Energy-Absorbing Structures. Materials 2019, 12, 697. [Google Scholar] [CrossRef] [PubMed]

| Type | Density | Tensile Strength | Tensile Modulus | CTE |

|---|---|---|---|---|

| /(g·cm−3) | /GPa | /GPa | /10−6 ℃ | |

| Carbon | 1.76 | 3.53 | 230 | −0.54 |

| Aramid | 1.44 | 3.00 | 112 | −2.7 |

| UHMWPE | 0.97 | 3.20 | 99 | −12 |

| Type | Fineness of Stitch Yarns (Polyester) | Weft Yarns’ Composition | Warp Yarns’ Composition | Thickness |

|---|---|---|---|---|

| Aramid | 75D × 2 | Aramid 100% | Aramid 100% | 1.0 mm |

| Aramid/Carbon | 75D × 2 | Aramid: Carbon 8: 4 | Aramid: Carbon 8: 4 | 0.9 mm |

| Aramid/UHMWPE | 75D × 2 | Aramid: UHMWPE 10: 10 | Aramid: UHMWPE 10: 10 | 0.9 mm |

| Resin | Tensile Modulus | Bending Modulus | CTE |

|---|---|---|---|

| /GPa | /GPa | /10−6·℃ | |

| VE (R806) | 2.9 | 3.2 | 24 |

| UP (191S) | 3.8 | 3.4 | 135 |

| EP (6349) | 2.3 | 2.6 | 68 |

| VE (R806) | UP (191S) | EP(6349) | |

|---|---|---|---|

| Aramid | A1 | B1 | C1 |

| Aramid/Carbon | A2 | B2 | C2 |

| Aramid/UHMWPE | A3 | B3 | C3 |

| Laser System | Parameter |

|---|---|

| Accuracy | 0.034 mm |

| Point acquisition rate | 23,040 points/s |

| Points per line | 768 |

| Line rate | 30 Hz |

| Pt1 | Pt2 | Pt3 | Pt4 | Pt5 | Pt6 | Pt7 | |

|---|---|---|---|---|---|---|---|

| Pt1 | |||||||

| Pt2 | D1 | ||||||

| Pt3 | D2 | Symmetric | |||||

| Pt4 | D4 | D3 | |||||

| Pt5 | D5 | D9 | |||||

| Pt6 | D10 | D6 | |||||

| Pt7 | D8 | D11 | D7 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiang, H.; Jiang, Y.; Qi, Y.; Li, J. Process-Induced Distortions Characterization of MBWK Fabric Reinforced Composite Helmet Shell. Materials 2020, 13, 2983. https://doi.org/10.3390/ma13132983

Xiang H, Jiang Y, Qi Y, Li J. Process-Induced Distortions Characterization of MBWK Fabric Reinforced Composite Helmet Shell. Materials. 2020; 13(13):2983. https://doi.org/10.3390/ma13132983

Chicago/Turabian StyleXiang, He, Yaming Jiang, Yexiong Qi, and Jialu Li. 2020. "Process-Induced Distortions Characterization of MBWK Fabric Reinforced Composite Helmet Shell" Materials 13, no. 13: 2983. https://doi.org/10.3390/ma13132983

APA StyleXiang, H., Jiang, Y., Qi, Y., & Li, J. (2020). Process-Induced Distortions Characterization of MBWK Fabric Reinforced Composite Helmet Shell. Materials, 13(13), 2983. https://doi.org/10.3390/ma13132983