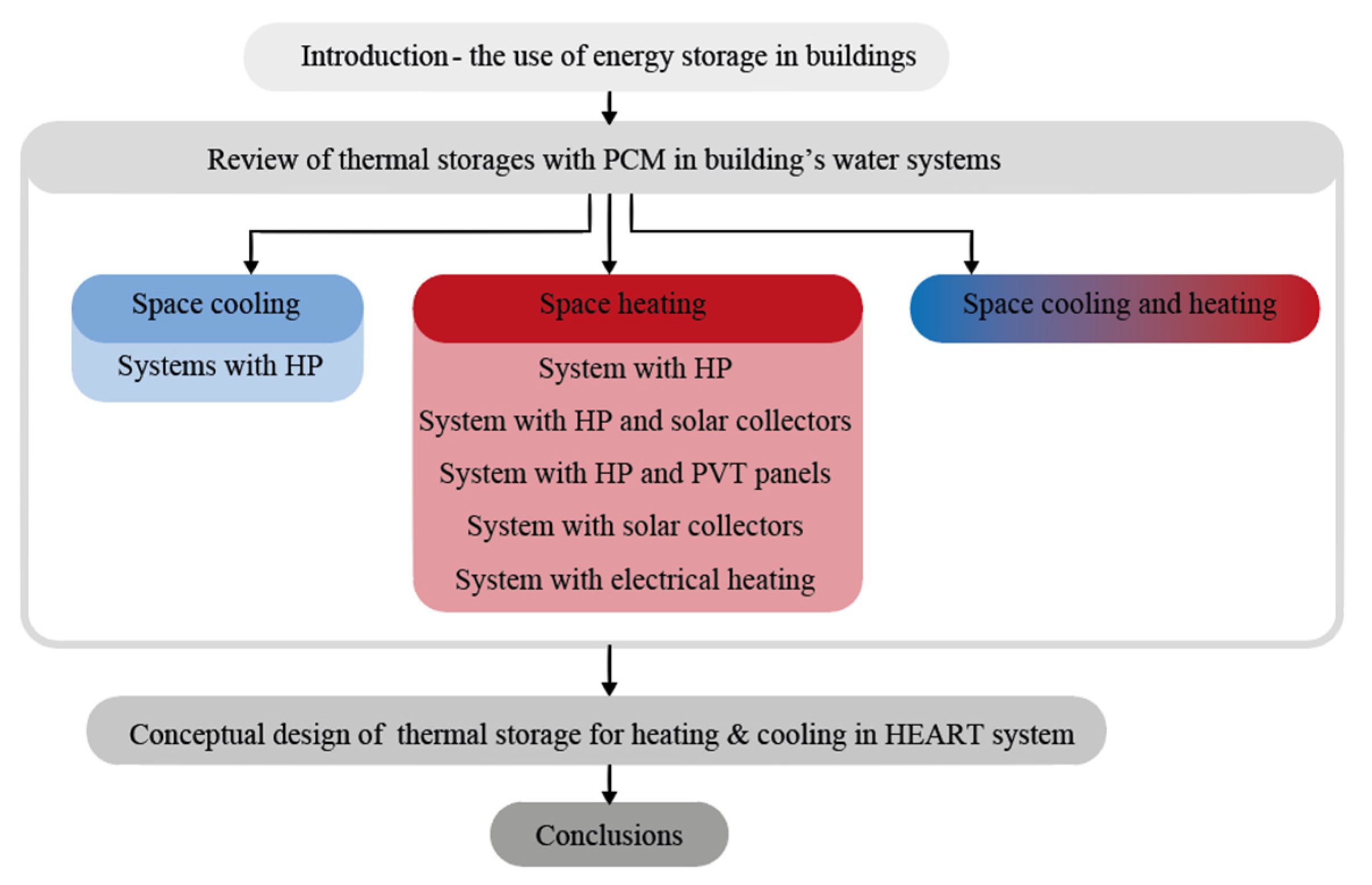

Phase-Change Materials in Hydronic Heating and Cooling Systems: A Literature Review

Abstract

:1. Introduction—The Use of Energy Storage in Buildings

2. Review of Thermal Storages with PCM in Building’s Hydronic Systems

2.1. Space Cooling

Systems with HP

2.2. Space Heating

2.2.1. System with HP

2.2.2. System with HP and Solar Collectors

2.2.3. System with HP and PVT Panels

2.2.4. System with Solar Collectors

2.2.5. System with Electrical Heating

2.3. Space Cooling and Heating

2.4. Indirect Electrical Storage for Space Cooling and Heating

3. Maturity of PCM for Thermal Storage

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Temperature (K) | |

| Temperature difference (K) | |

| Specific heat (J/kgK) | |

| Latent heat of fusion (J/kg) | |

| Thermal conductivity (W/mK) | |

| Density (kg/m3) | |

| Acronyms | |

| COP | Coefficient of performance |

| DHW | Domestic hot water |

| DC | Direct current |

| EASE | European association for storage of energy |

| EER | Energy efficiency ratio |

| EES | Electrical energy storage |

| GSHP | Ground-source heat pump |

| HEART | Holistic energy and architectural retrofit toolkit |

| HP | Heat pump |

| HPWH | Heat pump water heater |

| HTF | Heat transfer fluid |

| IDX-SAHP | Indirect solar assisted heat pump |

| KPI | Key performance indicators |

| LTS | Latent thermal storage |

| PCM | Phase-change material |

| PV | Photovoltaics |

| PVT | Photovoltaic/thermal |

| RES | Renewable energy sources |

| SAT | Sodium Acetate Trihydrate |

| SF | Solar fraction |

| SPF | Seasonal performance factor |

| STS | Sensible thermal storage |

| TRL | Technology readiness level |

| TS | Thermal storage |

References

- IEA. Global Status Report Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector; Global Alliance for Buildings and Construction: Paris, France, 2018. [Google Scholar]

- IEA. Transition to Sustainable Buildings Strategies and Opportunities to 2050; International Energy Agency: Paris, France, 2013. [Google Scholar]

- European Commission. Directive (EU) 2018/844 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2010/31/EU on the Energy Performance of Buildings and Directive 2012/27/EU on Energy, Efficiency (Text with EEA Relevance); European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Smith, J.C.; Beuning, S.; Durrwachter, H.; Ela, E.; Hawkins, D.; Kirby, B.; Lasher, W.; Lowell, J.; Porter, K.; Schuyler, K.; et al. The Impact of Variable Renewable Energy on U.S. Electricity Markets. IEEE Power Energy Mag. 2010. [Google Scholar] [CrossRef]

- Chel, A.; Kaushik, G. Renewable energy technologies for sustainable development of energy efficient building. Alex. Eng. J. 2018, 57, 655–669. [Google Scholar] [CrossRef]

- Thygesen, R.; Karlsson, B. Simulation and analysis of a solar assisted heat pump system with two different storage types for high levels of PV electricity self-consumption. Sol. Energy 2014, 103, 19–27. [Google Scholar] [CrossRef]

- Mahapatra, C.; Moharana, A.K.; Leung, V.C.M. Energy management in smart cities based on internet of things: Peak demand reduction and energy savings. Sensors 2017, 17, 2812. [Google Scholar] [CrossRef] [Green Version]

- Balijepalli, V.S.K.M.; Pradhan, V.; Khaparde, S.A.; Shereef, R.M. Review of demand response under smart grid paradigm. In Proceedings of the 2011 IEEE PES International Conference on Innovative Smart Grid Technologies-India, ISGT India, Kollam, Kerala, India, 1–3 December 2011; pp. 236–243. [Google Scholar]

- Oldewurtel, F.; Ulbig, A.; Parisio, A.; Andersson, G.; Morari, M. Reducing peak electricity demand in building climate control using real-time pricing and model predictive control. In Proceedings of the 49th IEEE Conference on Decision and Control, Atlanta, GA, USA, 15–17 December 2010; IEEE: Piscataway, NJ, USA; pp. 1927–1932.

- Amin, Z.M.; Hawlader, M.N.A. A review on solar assisted heat pump systems in Singapore. Renew. Sustain. Energy Rev. 2013, 26, 286–293. [Google Scholar] [CrossRef]

- Costanzo, G.T.; Zhu, G.; Anjos, M.F.; Savard, G. A System Architecture for Autonomous Demand Side Load Management in Smart Buildings. IEEE Trans. Smart Grid 2012, 3, 2157–2165. [Google Scholar] [CrossRef]

- Østergaard, S.; Grønborg, R.; Byskov, K.; Joanna, A.; Ø, S. Annex 67: Energy Flexible Buildings-Energy Flexibility as a Key Asset in a Smart Building Future Annex 67: Energy Flexible Buildings; IEA Energy in Buildings and Communities: Paris, France, 2017. [Google Scholar]

- Lizana, J.; Chacartegui, R.; Barrios-Padura, A.; Ortiz, C. Advanced low-carbon energy measures based on thermal energy storage in buildings: A review. Renew. Sustain. Energy Rev. 2018, 82, 3705–3749. [Google Scholar] [CrossRef]

- Holistic Energy and Architectural Retrofit Toolkit—HEART, H2020-EEB. Grant Agreement No. 768921; European Commision, Directorate-General Research & Innovation: Brussels, Belgium, 2017. [Google Scholar]

- STORY H2020 LC-BAT-8-2020 (ENERGY)—Next-Generation Batteries for Stationary Energy Storage. Available online: http://horizon2020-story.eu/ (accessed on 24 April 2020).

- TESSe2b H2020 LC-BAT-9-2020 (ENERGY)—Hybridisation of Battery Systems for Stationary Energy Storage. Available online: http://www.tesse2b.eu/ (accessed on 24 April 2020).

- IEA SHC Task 58/ECES Annex 33 Material and Component Development for Thermal Energy Storage. Available online: http://task58.iea-shc.org/ (accessed on 21 July 2019).

- IEA Tracking Clean Energy Progress. Available online: https://www.iea.org/tcep/ (accessed on 21 July 2019).

- IEA Sustainable Development Scenario. Available online: https://www.iea.org/weo/weomodel/sds/ (accessed on 21 July 2019).

- Environmental Defense Fund. Demand: Clean Energy Sustaibnability and the New American Workforce; EDF Climate Corps: New York, NY, USA, 2018. [Google Scholar]

- Lazard. Lazard’s Levelized Cost of Storage Analysis—Version 4.0; Lazard: Hamilton, Bermuda, 2018. [Google Scholar]

- Widén, J.; Wäckelgård, E.; Lund, P.D. Options for improving the load matching capability of distributed photovoltaics: Methodology and application to high-latitude data. Sol. Energy 2009, 83, 1953–1966. [Google Scholar] [CrossRef]

- Evans, A.; Strezov, V.; Evans, T.J. Assessment of utility energy storage options for increased renewable energy penetration. Renew. Sustain. Energy Rev. 2012, 16, 4141–4147. [Google Scholar] [CrossRef]

- Del Pero, C.; Aste, N.; Paksoy, H.; Haghighat, F.; Grillo, S.; Leonforte, F. Energy storage key performance indicators for building application. Sustain. Cities Soc. 2018, 40, 54–65. [Google Scholar] [CrossRef]

- Miglioli, A.; Del Pero, C.; Leonforte, F.; Aste, N. Load matching in residential buildings through the use of thermal energy storages. In Proceedings of the 2019 IEEE International Conference on Clean Electrical Power (ICCEP), Otranto, Italy, 2–4 July 2019; pp. 272–279. [Google Scholar]

- Hesaraki, A.; Holmberg, S.; Haghighat, F. Seasonal thermal energy storage with heat pumps and low temperatures in building projects—A comparative review. Renew. Sustain. Energy Rev. 2015, 43, 1199–1213. [Google Scholar] [CrossRef] [Green Version]

- Mehling, H.; Cabeza, L.F. Heat and Cold Storage with PCM; Heat and Mass Transfer; Springer: Berlin/Heidelberg, Germany, 2008; ISBN 978-3-540-68556-2. [Google Scholar]

- Kutlu, C.; Zhang, Y.; Elmer, T.; Su, Y.; Riffat, S. A simulation study on performance improvement of solar assisted heat pump hot water system by novel controllable crystallization of supercooled PCMs. Renew. Energy 2020, 152, 601–612. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, N.; Ding, Z. Investigation on the energy performance of using air-source heat pump to charge PCM storage tank. J. Energy Storage 2020, 28, 101270. [Google Scholar] [CrossRef]

- Arteconi, A.; Hewitt, N.J.; Polonara, F. State of the art of thermal storage for demand-side management. Appl. Energy 2012, 93, 371–389. [Google Scholar] [CrossRef]

- Li, Y.; Huang, G.; Wu, H.; Xu, T. Feasibility study of a PCM storage tank integrated heating system for outdoor swimming pools during the winter season. Appl. Therm. Eng. 2018, 134, 490–500. [Google Scholar] [CrossRef]

- Li, G.; Hwang, Y.; Radermacher, R. Review of cold storage materials for air conditioning application. Int. J. Refrig. 2012, 35, 2053–2077. [Google Scholar] [CrossRef]

- Oró, E.; De Gracia, A.; Castell, A.; Farid, M.M.; Cabeza, L.F. Review on phase change materials (PCMs) for cold thermal energy storage applications. Appl. Energy 2012, 99, 513–533. [Google Scholar] [CrossRef]

- Fang, G.; Wu, S.; Liu, X. Experimental study on cool storage air-conditioning system with spherical capsules packed bed. Energy Build. 2010, 42, 1056–1062. [Google Scholar] [CrossRef]

- Liu, M.; Bruno, F.; Saman, W. Thermal performance analysis of a flat slab phase change thermal storage unit with liquid-based heat transfer fluid for cooling applications. Sol. Energy 2011, 85, 3017–3027. [Google Scholar] [CrossRef]

- Liu, M.; Saman, W.; Bruno, F. Validation of a mathematical model for encapsulated phase change material flat slabs for cooling applications. Appl. Therm. Eng. 2011, 31, 2340–2347. [Google Scholar] [CrossRef]

- Rismanchi, B.; Saidur, R.; Masjuki, H.H.; Mahlia, T.M.I. Energetic, economic and environmental benefits of utilizing the ice thermal storage systems for office building applications. Energy Build. 2012, 50, 347–354. [Google Scholar] [CrossRef]

- Venegas-Troncoso, T.; Ugarte-Larraguibel, G.; Vasco, D.A.; Rouault, F.; Pérez, R. Feasibility study of the application of a cooling energy storage system in a chiller plant of an office building located in santiago, Chile. Int. J. Refrig. 2019, 102, 142–150. [Google Scholar] [CrossRef]

- Dincer, I. Thermal Energy Storage: Systems and Applications, 2nd ed.; Wiley: Hoboken, NJ, USA, 2010; ISBN 978-0-470-74706-3. [Google Scholar]

- Panchabikesan, K.; Vincent, A.A.R.; Ding, Y.; Ramalingam, V. Enhancement in free cooling potential through PCM based storage system integrated with direct evaporative cooling (DEC) unit. Energy 2018, 144, 443–455. [Google Scholar] [CrossRef] [Green Version]

- Helm, M.; Keil, C.; Hiebler, S.; Mehling, H.; Schweigler, C. Solar heating and cooling system with absorption chiller and low temperature latent heat storage: {Energetic} performance and operational experience. Int. J. Refrig. 2009, 32, 596–606. [Google Scholar] [CrossRef]

- Helm, M.; Hagel, K.; Pfeffer, W.; Hiebler, S.; Schweigler, C. Solar Heating and Cooling System with Absorption Chiller and Latent Heat Storage—A Research Project Summary. Energy Procedia 2014, 48, 837–849. [Google Scholar] [CrossRef] [Green Version]

- Agyenim, F.; Hewitt, N. The development of a finned phase change material (PCM) storage system to take advantage of off-peak electricity tariff for improvement in cost of heat pump operation. Energy Build. 2010, 42, 1552–1560. [Google Scholar] [CrossRef]

- Pardo, N.; Montero, Á.; Martos, J.; Urchueguía, J.F. Optimization of hybrid–ground coupled and air source–heat pump systems in combination with thermal storage. Appl. Therm. Eng. 2010, 30, 1073–1077. [Google Scholar] [CrossRef]

- Long, J.-Y.; Zhu, D.-S. Numerical and experimental study on heat pump water heater with PCM for thermal storage. Energy Build. 2008, 40, 666–672. [Google Scholar] [CrossRef]

- Moreno, P.; Castell, A.; Solé, C.; Zsembinszki, G.; Cabeza, L.F. PCM thermal energy storage tanks in heat pump system for space cooling. Energy Build. 2014, 82, 399–405. [Google Scholar] [CrossRef]

- Real, A.; García, V.; Domenech, L.; Renau, J.; Montés, N.; Sánchez, F. Improvement of a heat pump based HVAC system with PCM thermal storage for cold accumulation and heat dissipation. Energy Build. 2014, 83, 108–116. [Google Scholar] [CrossRef]

- Maccarini, A.; Hultmark, G.; Bergsøe, N.C.; Afshari, A. Free cooling potential of a PCM -based heat exchanger coupled with a novel HVAC system for simultaneous heating and cooling of buildings. Sustain. Cities Soc. 2018, 42, 384–395. [Google Scholar] [CrossRef]

- McKenna, P.; Turner, W.J.N.; Finn, D.P. Geocooling with integrated PCM thermal energy storage in a commercial building. Energy 2018, 144, 865–876. [Google Scholar] [CrossRef]

- Alam, M.; Zou, P.X.W.; Sanjayan, J.; Ramakrishnan, S. Energy saving performance assessment and lessons learned from the operation of an active phase change materials system in a multi-storey building in Melbourne. Appl. Energy 2019, 238, 1582–1595. [Google Scholar] [CrossRef]

- Zou, D.; Ma, X.; Liu, X.; Zheng, P.; Cai, B.; Huang, J.; Guo, J.; Liu, M. Experimental research of an air-source heat pump water heater using water—PCM for heat storage. Appl. Energy 2017, 206, 784–792. [Google Scholar] [CrossRef]

- Youssef, W.; Ge, Y.T.; Tassou, S.A. Effects of latent heat storage and controls on stability and performance of a solar assisted heat pump system for domestic hot water production. Sol. Energy 2017, 150, 394–407. [Google Scholar] [CrossRef]

- Besagni, G.; Croci, L.; Nesa, R.; Molinaroli, L. Field study of a novel solar-assisted dual-source multifunctional heat pump. Renew. Energy 2019, 132, 1185–1215. [Google Scholar] [CrossRef]

- Trp, A. An experimental and numerical investigation of heat transfer during technical grade paraffin melting and solidification in a shell-and-tube latent thermal energy storage unit. Sol. Energy 2005, 79, 648–660. [Google Scholar] [CrossRef]

- Deng, J.; Furbo, S.; Kong, W.; Fan, J. Thermal performance assessment and improvement of a solar domestic hot water tank with PCM in the mantle. Energy Build. 2018, 172, 10–21. [Google Scholar] [CrossRef]

- Lu, S.; Zhang, T.; Chen, Y. Study on the performance of heat storage and heat release of water storage tank with PCMs. Energy Build. 2018, 158, 1770–1780. [Google Scholar] [CrossRef]

- Fazilati, M.A.; Alemrajabi, A.A. Phase change material for enhancing solar water heater, an experimental approach. Energy Convers. Manag. 2013, 71, 138–145. [Google Scholar] [CrossRef]

- Raul, A.; Jain, M.; Gaikwad, S.; Saha, S.K. Modelling and experimental study of latent heat thermal energy storage with encapsulated PCMs for solar thermal applications. Appl. Therm. Eng. 2018, 143, 415–428. [Google Scholar] [CrossRef]

- Englmair, G.; Moser, C.; Schranzhofer, H.; Fan, J.; Furbo, S. A solar combi-system utilizing stable supercooling of sodium acetate trihydrate for heat storage: Numerical performance investigation. Appl. Energy 2019, 242, 1108–1120. [Google Scholar] [CrossRef]

- Zayed, M.E.; Zhao, J.; Elsheikh, A.H.; Hammad, F.A.; Ma, L.; Du, Y.; Kabeel, A.E.; Shalaby, S.M. Applications of cascaded phase change materials in solar water collector storage tanks: A review. Sol. Energy Mater. Sol. Cells 2019, 199, 24–49. [Google Scholar] [CrossRef]

- De Gracia, A.; Oró, E.; Farid, M.M.; Cabeza, L.F. Thermal analysis of including phase change material in a domestic hot water cylinder. App. Therm. Eng 2011, 31, 3938–3945. [Google Scholar] [CrossRef] [Green Version]

- Ge, T.S.; Wang, R.Z.; Xu, Z.Y.; Pan, Q.W.; Du, S.; Chen, X.M.; Ma, T.; Wu, X.N.; Sun, X.L.; Chen, J.F. Solar heating and cooling: Present and future development. Renew. Energy 2018, 126, 1126–1140. [Google Scholar] [CrossRef]

- Lazzarin, R.M.; Noro, M. Past, present, future of solar cooling: Technical and economical considerations. Sol. Energy 2018, 172, 2–13. [Google Scholar] [CrossRef]

- Xu, Z.Y.; Wang, R.Z. Comparison of absorption refrigeration cycles for efficient air-cooled solar cooling. Sol. Energy 2018, 172, 14–23. [Google Scholar] [CrossRef]

- Behi, M.; Mirmohammadi, S.A.; Ghanbarpour, M.; Behi, H.; Palm, B. Evaluation of a novel solar driven sorption cooling/heating system integrated with PCM storage compartment. Energy 2018, 164, 449–464. [Google Scholar] [CrossRef]

- Mendecka, B.; Cozzolino, R.; Leveni, M.; Bella, G. Energetic and exergetic performance evaluation of a solar cooling and heating system assisted with thermal storage. Energy 2019, 176, 816–829. [Google Scholar] [CrossRef]

- Mehling, H.; Cabeza, L.F. Heat and Cold Storage with PCM—An up to Date Introduction into Basic and Applications; Springer: Berlin/Heidelberg, Germany, 2008; ISBN 9783540685562. [Google Scholar]

- Paksoy, H. Thermal Energy Storage for Sustainable Energy Consumption, Fundamentals, Case Studies and Design; Springer & NATO Science Series: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Streicher, W.; Cabeza, L.; Heinz, A. Inventory of Phase Change Materials (PCM) A Report of IEA Solar Heating and Cooling Programme-Task 32 “Advanced Wtorage Doncepts for Wolar and low Energy Buildings” Report C2 of Subtask C; IEA Solar Heating and Cooling Programme: Paris, France, 2005. [Google Scholar]

- Cabeza, L.F.; Castell, A.; Barreneche, C.; de Gracia, A.; Fernández, A.I. Materials used as PCM in thermal energy storage in buildings: A review. Renew. Sustain. Energy Rev. 2011, 15, 1675–1695. [Google Scholar] [CrossRef]

- Koželj, R.; Stropnik, R.; Zavrl, E.; Stritih, U. Improved thermal energy storage with PCM—An important part of EU project concept Holistic Energy and Architectural Retrofit Toolkit (HEART). In Proceedings of the International Conference—Industrial Engineering and Environmental Protection, Zrenjamin, Serbia, 11 October 2018. [Google Scholar]

- Stropnik, R.; Koželj, R.; Zavrl, E.; Stritih, U. Improved thermal energy storage for nearly zero energy buildings with PCM integration. Sol. Energy 2019, 190, 420–426. [Google Scholar] [CrossRef]

- Stolten, D.; Scherer, V. Transition to Renewable Energy Systems; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2013; ISBN 978-3-527-33239-7. [Google Scholar]

- RHC Platform. Strategic Research Priorities for Corss-Cutting Technology; European Technology Platform on Renewable Heating and Cooling: Brussels, Belgium, 2012. [Google Scholar]

- Nguyen, T.-T.; Martin, V.; Malmquist, A.; Silva, C.A.S. A review on technology maturity of small scale energy storage technologies. Renew. Energy Environ. Sustain. 2017, 2, 36. [Google Scholar] [CrossRef] [Green Version]

- EASE/EERA. European Energy Storage Technology Development Roadmap 2017 Update; European Association for Storage of Energy and European Energy Research Alliance: Brussels, Belgium, 2017. [Google Scholar]

| Cooling | Technology | Encapsulation/PCM Type | Material Properties | Accumulation | Size | Energy Density | SPF |

|---|---|---|---|---|---|---|---|

| PCM thermal energy storage tanks in heat pump system for space cooling [46] | Water/water heat pump | Plates encapsulation Salt hydrate (S10) Melting point: 10 °C | h = 155 kJ/kg (228 kJ/L) cp = 1.9 kJ/kgK λ = 0.43 W/mK ρ = 1470 kg/m3 | Stored: 2.79 kWh (water) 3.88 kWh (LTS) Released: 2.32 (water) 2.61 kWh (LTS) | 56 L water + 48 L PCM (46%) | 25 kWh/m3 (PCM) 22 kWh/m3 (water) | / |

| Improvement of a heat pump based HVAC system with PCM thermal storage for cold accumulation and heat dissipation [47] | Water/water heat pump | FlatICE panels Salt hydrate (S10) Melting point: 10 °C (cold) and 27 °C (heat) | h = 183 kJ/kg (280 kJ/L) cp = 2.2 kJ/kgK λ = 0.54 W/mK ρ = 1530 kg/m3 | / | / | / | / |

| Free cooling potential of a PCM-based heat exchanger coupled with a novel HVAC system for simultaneous heating and cooling of buildings [48] | Reversible air-to-water heat pump with dry cooler | PCM-based heat exchanger Plant-based PCM Melting point: 18 °C | h = 192 kJ/kg cp = 1.47–1.74 kJ/kgK λ = 0.15–0.25 W/mK ρ = 860–950 kg/m3 | 1.1 MWh | 21 m3 | 52 kWh/m3 | SPF = 5.6 (HP + LTS) |

| Geocooling with integrated PCM thermal energy storage in a commercial building [49] | Geocooling | Spherical capsules Mix of water & nucleating agents Melting point: 0 °C | h = 333 kJ/kg cp = 1.47–1.74 kJ/kgK λ = 0.56–2.2 W/mK ρ = 1000–917 kg/m3 | Stored: 27 kWh (one unit) | 200 L water + 300 L PCM (60%) -one unit | 54 kWh/m3 | SPF1 = 3.0 (base) SPF2 = 5.0 (no PCM) SPF3 = 5.1 (with PCM) 41% and 2% increase |

| Energy saving performance assessment and lessons learned from the operation of an active PCMs system in a multi-story building in Melbourne [50] | Adiabatic cooler | 5120 FlatICE PCM panels Salt hydrate Melting point: 15 °C | h = 160 kJ/kg cp = 1.9 kJ/kgK λ = 0.43 W/mK ρ = 1510 kg/m3 | Total: 1500 kWh (max. in winter) Latent: 1307 kWh (theoretically) | 20 m3 water + 20 m3 PCM (50%) | 36 kWh/m3 | / |

| Heating | Technology | Encapsulation/PCM Type | Material Properties | Accumulation | Size | Energy Density | COP |

|---|---|---|---|---|---|---|---|

| Experimental research of an air-source heat pump water heater using water-PCM for heat storage [51] | Air-source HPWH | Around condenser coil Paraffin (RT44HC) Melting point: 43 °C | h = 255 kJ/kg λ = 0.2 W/mK ρ = 760–860 kg/m3 | Water: 6.4 kWh LTS: 7.3 kWh (14% increase) | 138 L water + 11 L PCM (7.5%) | 49 kWh/m3 ΔT = 40 K | 3.74 (HP) 5% increase |

| Effects of latent heat storage and controls on stability and performance of a solar assisted heat pump system for domestic hot water production [52] | Water-source HP (DHW) | PCM heat exchanger tank Paraffin Melting point: 17 °C | h = 260 kJ/kg λ = 0.2 W/mK cp = 2 kJ/kgK ρ = 770–880 kg/m3 | 77.90 kWh (test day) | 300 L water + 40 L PCM (12%) | / | System COP: 4.99 (sunny) 4.8 (cloudy) 6%–14% increase |

| Field study of a novel solar-assisted dual-source multifunctional heat pump [53] | Air-source HP (DHW) | Water DHW: 48–58 °C Tank: 22–38 °C | cp = 4.18 kJ/kgK λ = 0.64 W/mK ρ(53 °C) = 987 kg/m3 ρ(30 °C) = 995 kg/m3 | DHW: 4 kWh | 186 L (DHW) + 300 L (tank) | DHW: 21.5 kWh/m3 | Monthly: 3.75 (max) 2.47 (min) 34% increase |

| Thermal performance assessment and improvement of a solar domestic hot water tank with PCM in the mantle [55] | Solar water tank—DHW | PCM in a mantle, Sodium Acetate Trihydrate (SAT) Melting point: 58 °C | h = 262 kJ/kg λ = 0.54 W/mK cp = 3.22 kJ/kgK ρ = 1450 kg/m3 | Total: 12 kWh PCM: 3.8 kWh | 148 L water + 23 L PCM (13.5%) | Water:12 kWh/m3 LTS: 92 kWh/m3 T = 87–40 °C | / |

| Study on the performance of heat storage and heat release of water storage tank with PCMs [56] | Solar water tank—DHW | Embedded containers SAT (58 °C), Lauric acid (44 °C) | h = 262 & 180 kJ/kg λ = 0.54 W/mK cp = 3.22 & 2.5 kJ/kgK ρ = 1450 & 880 kg/m3 | Water: 5.9 kWh LTS: 8.3 kWh 39.2% increase | 110 L water + 30 L PCM (19%) | 57 kWh/m3 T = 70–40 °C | / |

| Phase-change material for enhancing solar water heater, an experimental approach [57] | Solar water tank—DHW | 180 spherical capsules Paraffin Melting point: 55 °C | h = 187 kJ/kg λ = 0.2 W/mK cp = 2–2.15 kJ/kgK ρ = 790–910 kg/m3 | 25% increase | Approx.: 6.7 L water + 2.8 L PCM (30–40%) | / | / |

| Modeling and experimental study of latent heat thermal energy storage with encapsulated PCMs for solar thermal applications [58] | Solar water tank | 209 spherical capsules Organic material A164 Melting point: 169 °C | h = 250 kJ/kg λ = 0.45 W/mK cp = 2.01 kJ/kgK ρ = 1500 kg/m3 | 0.5 kWh | 5.7 L water + 2.5 L PCM (31%) | 61 kWh/m3 T = 185–120 °C | / |

| A solar combi-system utilizing stable supercooling of sodium acetate trihydrate for heat storage: Numerical performance investigation [59] | Solar water tank—DHW | Compact storage tank Sodium Acetate Trihydrate Melting point: 58 °C | h = 180–200 kJ/kg λ = 2–5 W/mK cp = 2.5 kJ/kgK ρ = 1350–1400 kg/m3 | 4 × 2.6 kWh = 10.4 kWh | 735 L water + 4 × 150 L PCM (82%) | 17.3 kWh/m3 T = 58–45 °C | / |

| Thermal analysis of including phase-change material in a domestic hot water cylinder [61] | Electrical hot water cylinder | 57 PVC tubes Salt hydrate TH58 Melting point: 58 °C | h = 185 kJ/kg λ = 0.54–1.09 W/mK cp = 2.88–4.19 kJ/kgK ρ = 1290–1400 kg/m3 | Water-only: 11.9 kWh LTS: 14.3 kWh (20% increase) | 141 L water + 39 L PCM (22%) | 79.6 kWh/m3 T = 70–15 °C | / |

| Heating and Cooling | Technology | Encapsulation/PCM | Material Properties | Accumulation | Size | Energy Density | COP |

|---|---|---|---|---|---|---|---|

| Evaluation of a novel solar driven sorption cooling/heating system integrated with PCM storage compartment [65] | Sorption cooling LiCl-H2O | Paraffin: RT27 (heat), RT11(cold) Melting point:27 °C (heat), 11 °C (cold) | h = 149 (RT27) & 160 (RT11) kJ/kg λ = 0.2 W/mK cp= 2 kJ/kgK ρ = 760–800 kg/m3 (RT27) ρ = 770–880 kg/m3 (RT11) | 331 Wh (cooling) 425 Wh (heating) 756 Wh (overall) | 2 × 0.1 m3 | Cold: 3.3 kWh/m3 (ΔT = 20–9 °C) Heat: 4.3 kWh/m3 (T = 27–20 °C) | Cooling: 0.36 Heating: 0.42 |

| Energetic and exergetic performance evaluation of a solar cooling and heating system assisted with thermal storage [66] | Adsorption chiller + radiation heating | Shell and tube heat exchanger Paraffin Melting point: 62 °C | h = 200 kJ/kg λ = 0.162–0.35 W/mK cp = 2.05–2.26 kJ/kgK ρ = 825–880 kg/m3 | 36 kWh | LTS: 0.5 m3 Water: 1.1 m3 | 72 kWh/m3 (T = 80–55 °C) | Annual system en. efficiency: No TS: 24.2%, Water: 31.9%, LTS: 33.4% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koželj, R.; Osterman, E.; Leonforte, F.; Del Pero, C.; Miglioli, A.; Zavrl, E.; Stropnik, R.; Aste, N.; Stritih, U. Phase-Change Materials in Hydronic Heating and Cooling Systems: A Literature Review. Materials 2020, 13, 2971. https://doi.org/10.3390/ma13132971

Koželj R, Osterman E, Leonforte F, Del Pero C, Miglioli A, Zavrl E, Stropnik R, Aste N, Stritih U. Phase-Change Materials in Hydronic Heating and Cooling Systems: A Literature Review. Materials. 2020; 13(13):2971. https://doi.org/10.3390/ma13132971

Chicago/Turabian StyleKoželj, Rok, Eneja Osterman, Fabrizio Leonforte, Claudio Del Pero, Alessandro Miglioli, Eva Zavrl, Rok Stropnik, Niccolò Aste, and Uroš Stritih. 2020. "Phase-Change Materials in Hydronic Heating and Cooling Systems: A Literature Review" Materials 13, no. 13: 2971. https://doi.org/10.3390/ma13132971

APA StyleKoželj, R., Osterman, E., Leonforte, F., Del Pero, C., Miglioli, A., Zavrl, E., Stropnik, R., Aste, N., & Stritih, U. (2020). Phase-Change Materials in Hydronic Heating and Cooling Systems: A Literature Review. Materials, 13(13), 2971. https://doi.org/10.3390/ma13132971