Upgrading the Quality of Recycled Aggregates from Construction and Demolition Waste by Using a Novel Brick Separation and Surface Treatment Method

Abstract

1. Introduction

2. Materials and Methods

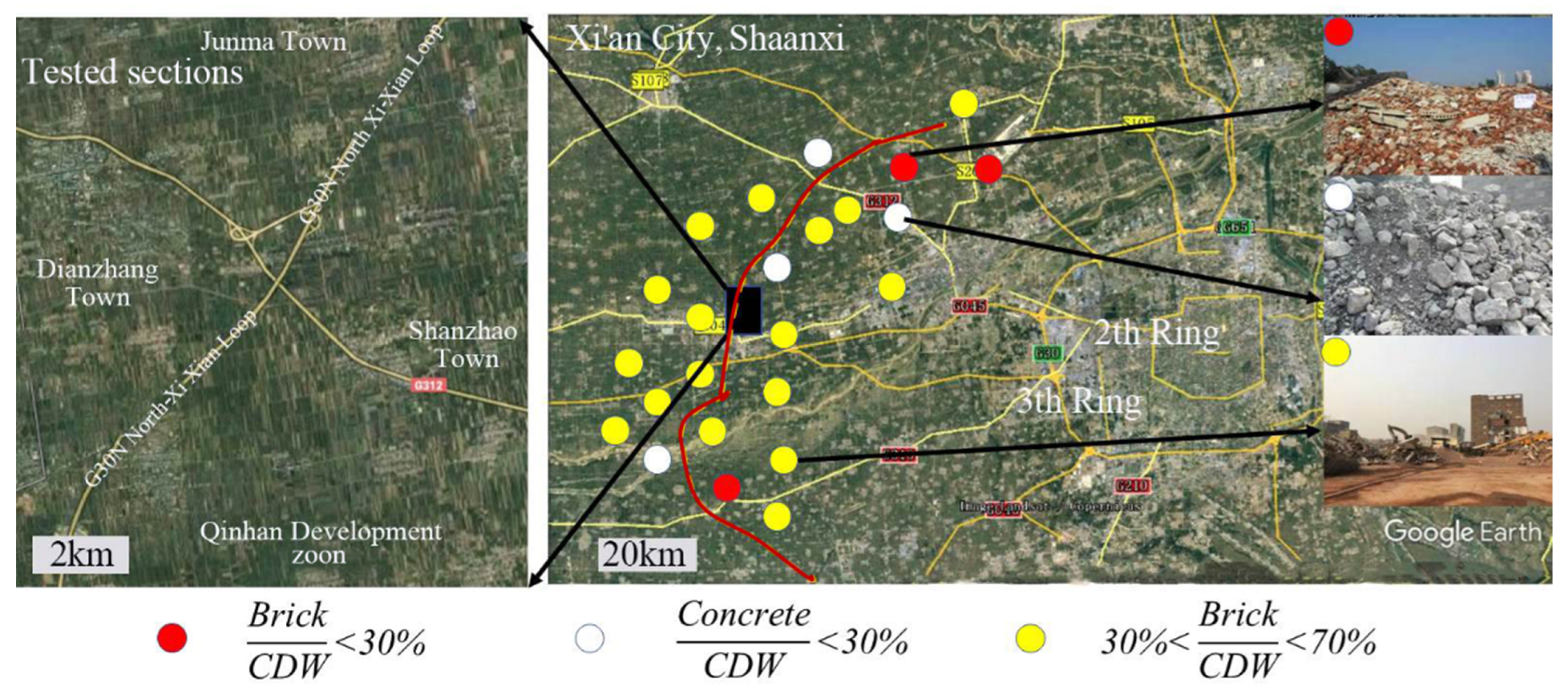

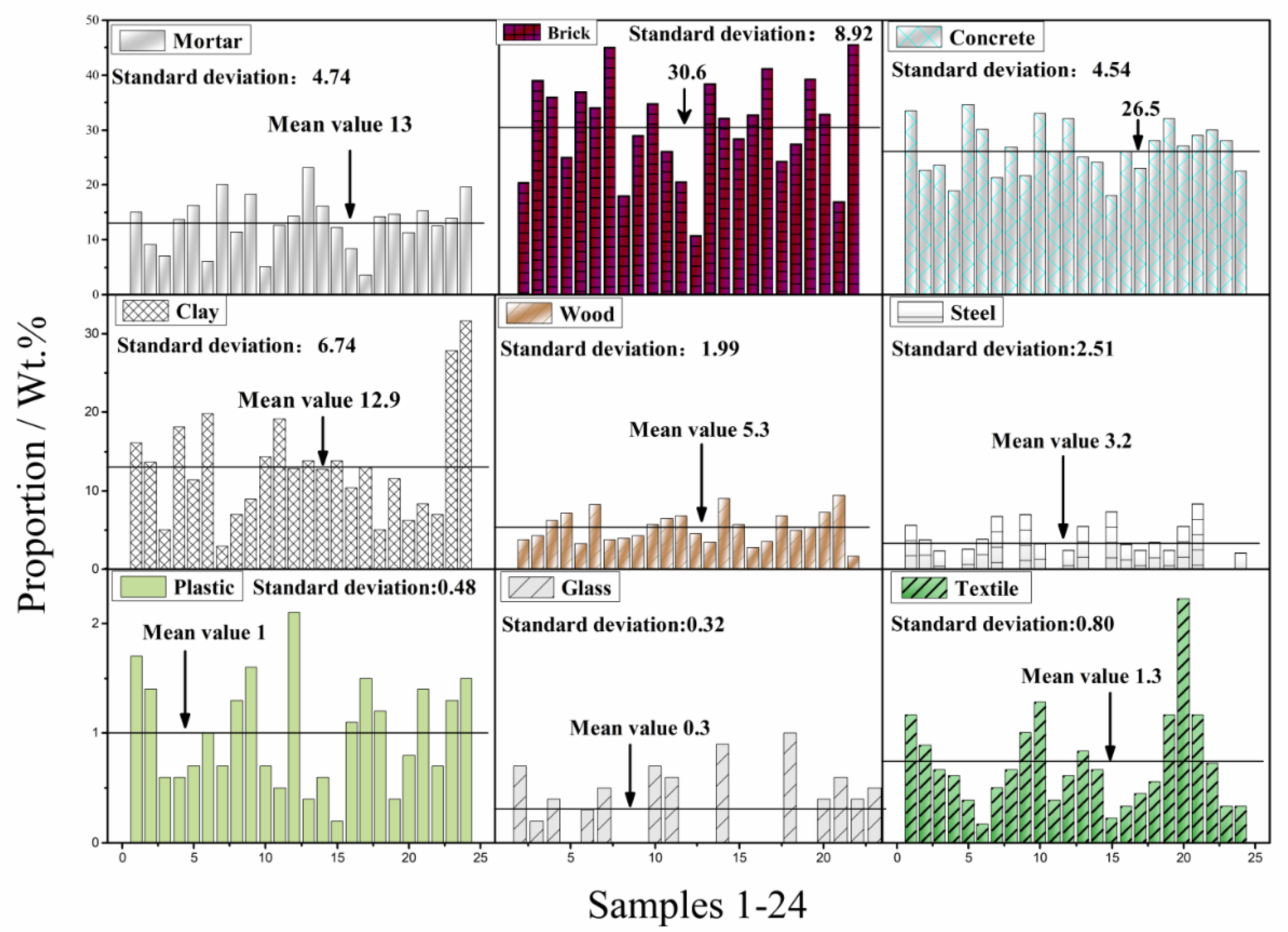

2.1. Description of Test Section Materials

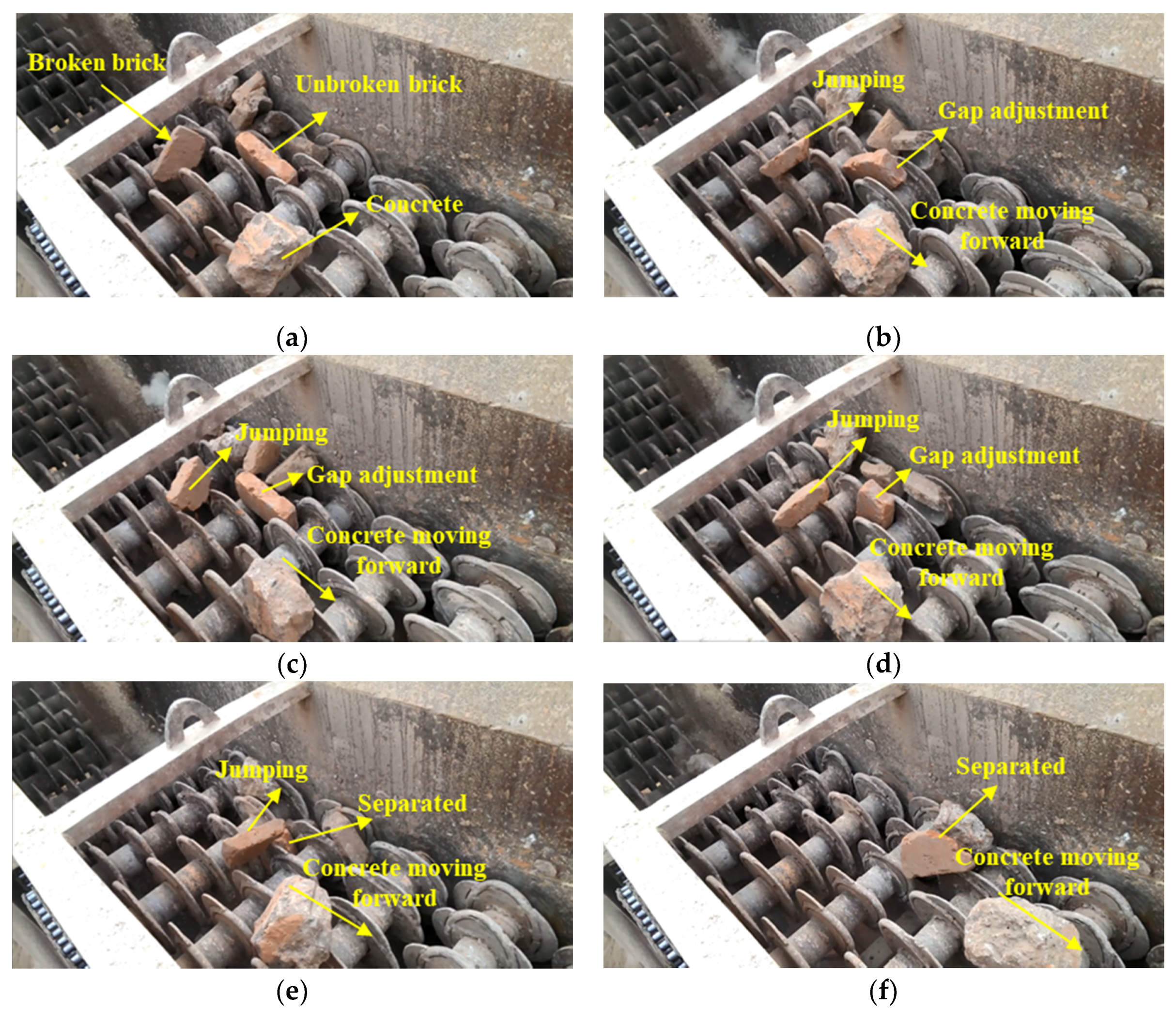

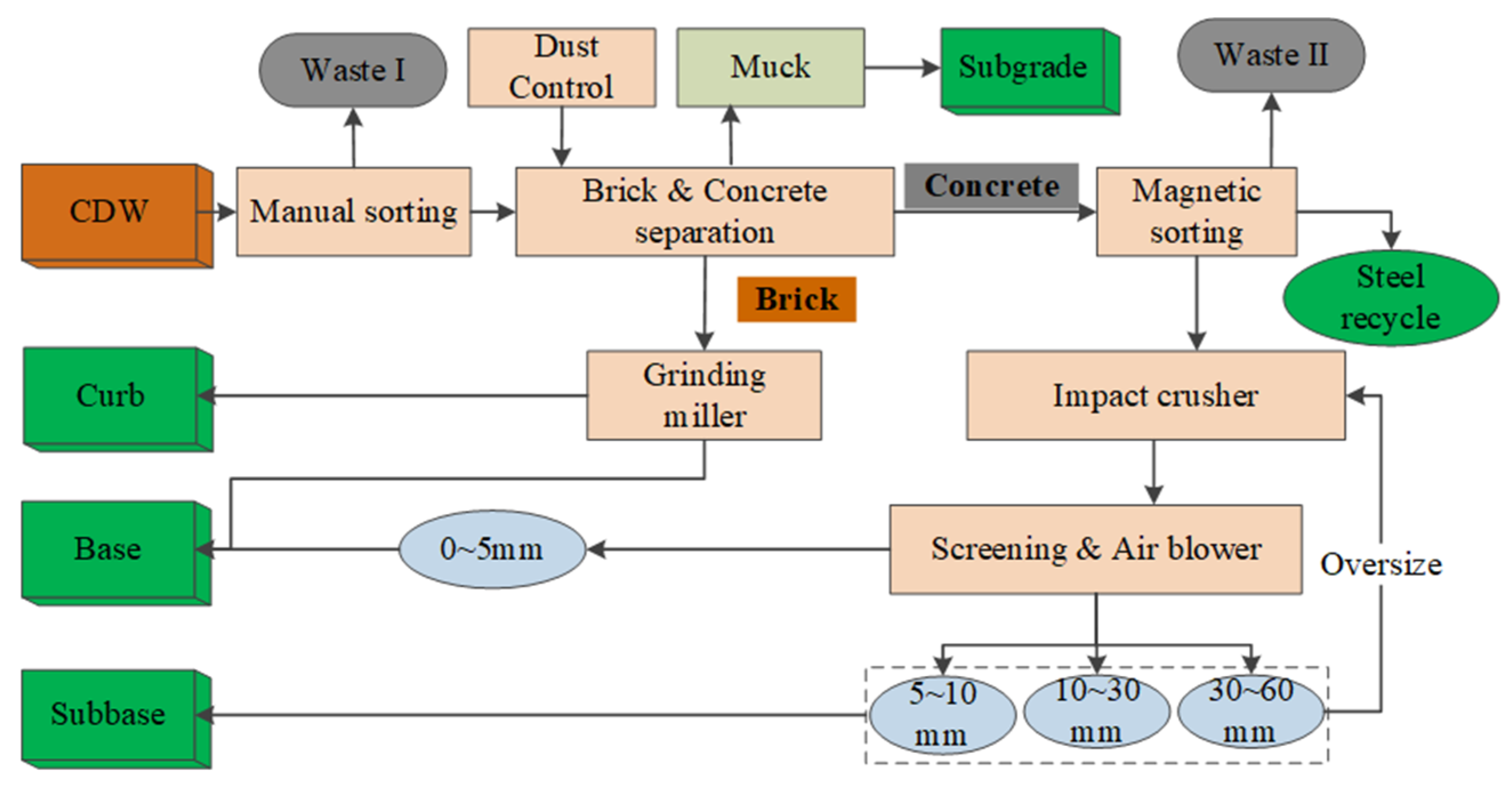

2.2. Brick Separation Technology

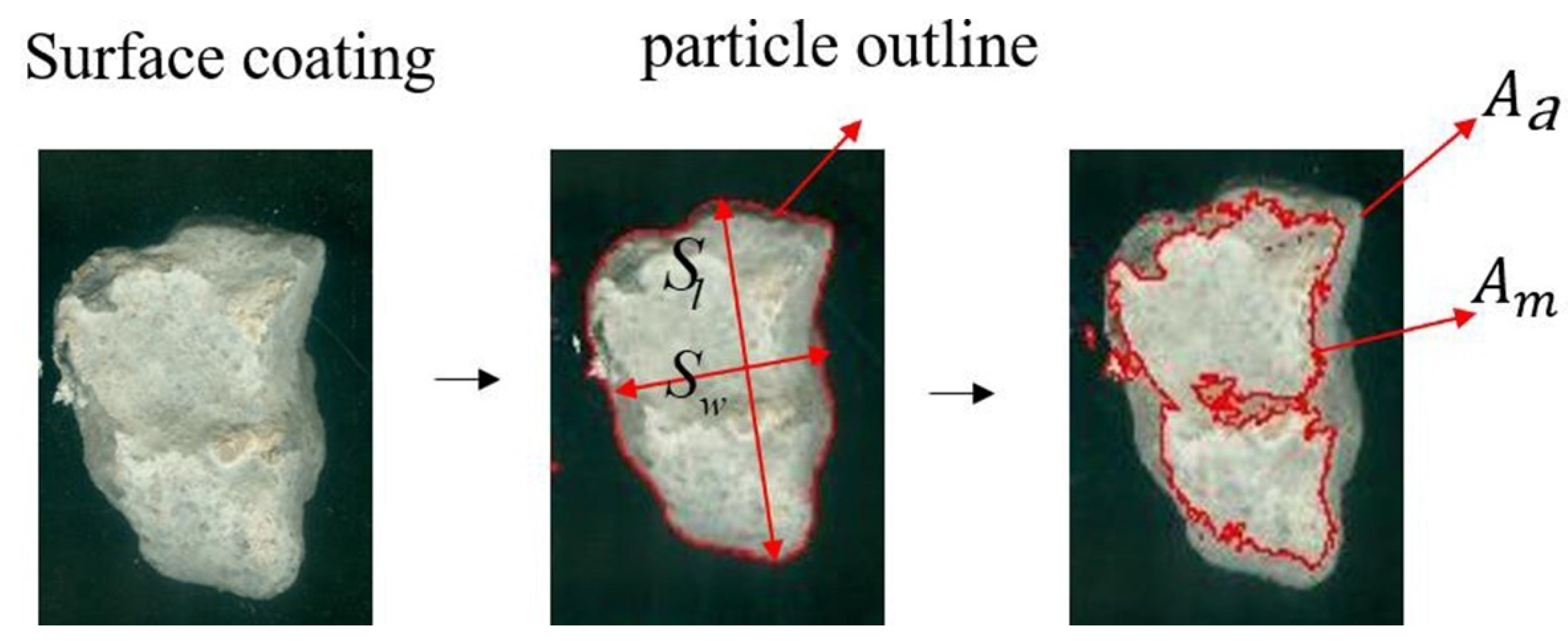

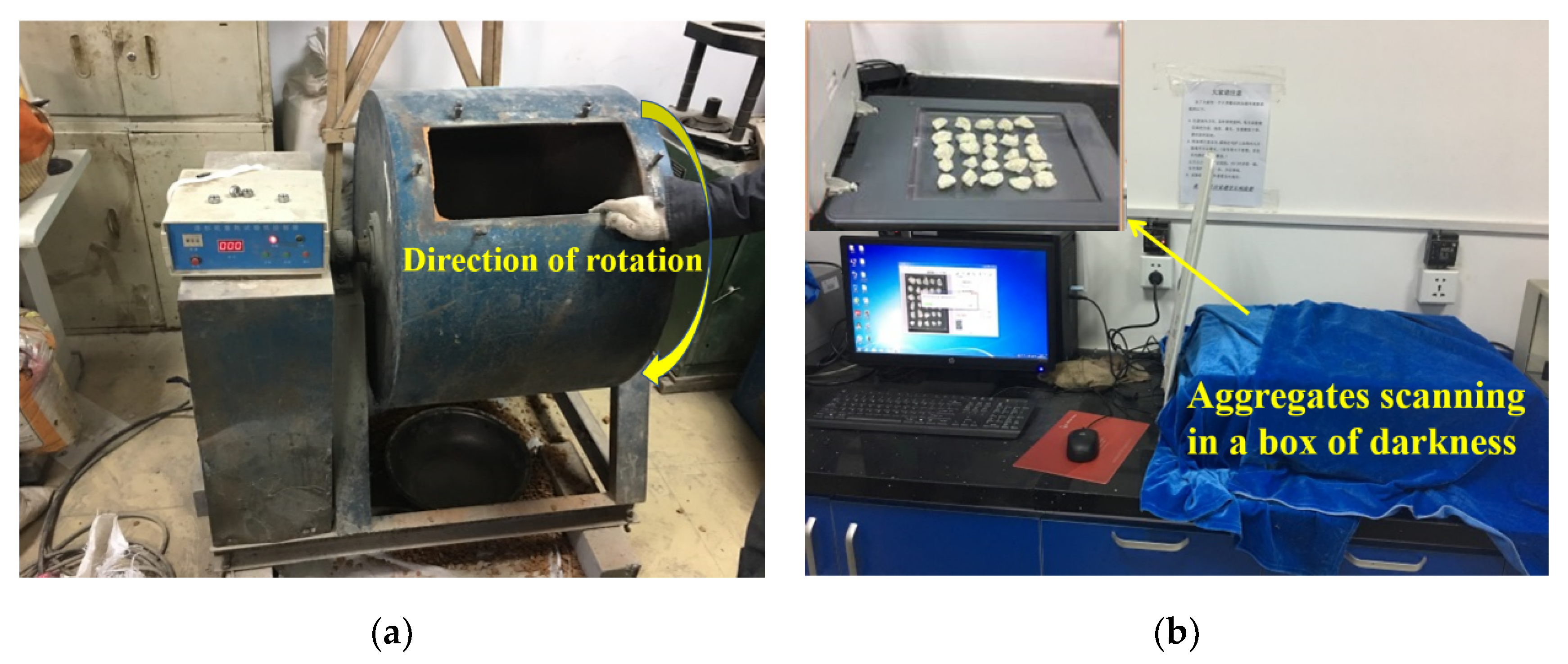

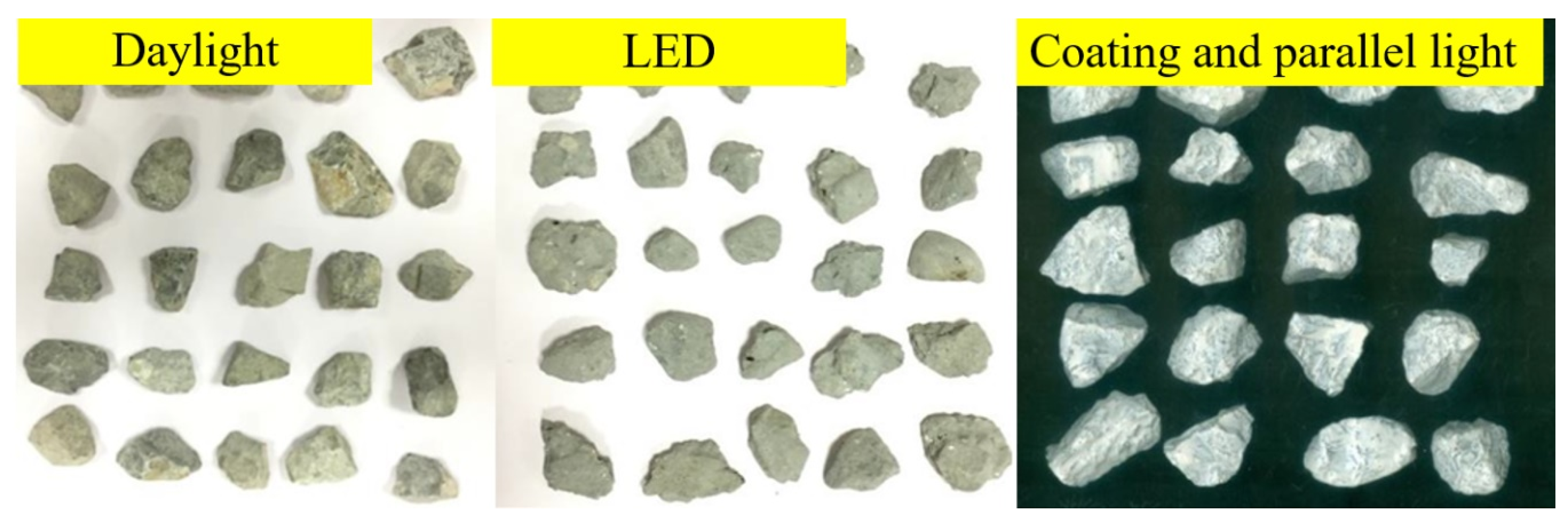

2.3. Surface Treatment

2.4. Preparing Brick Aggregates Mixed Concrete

3. Results

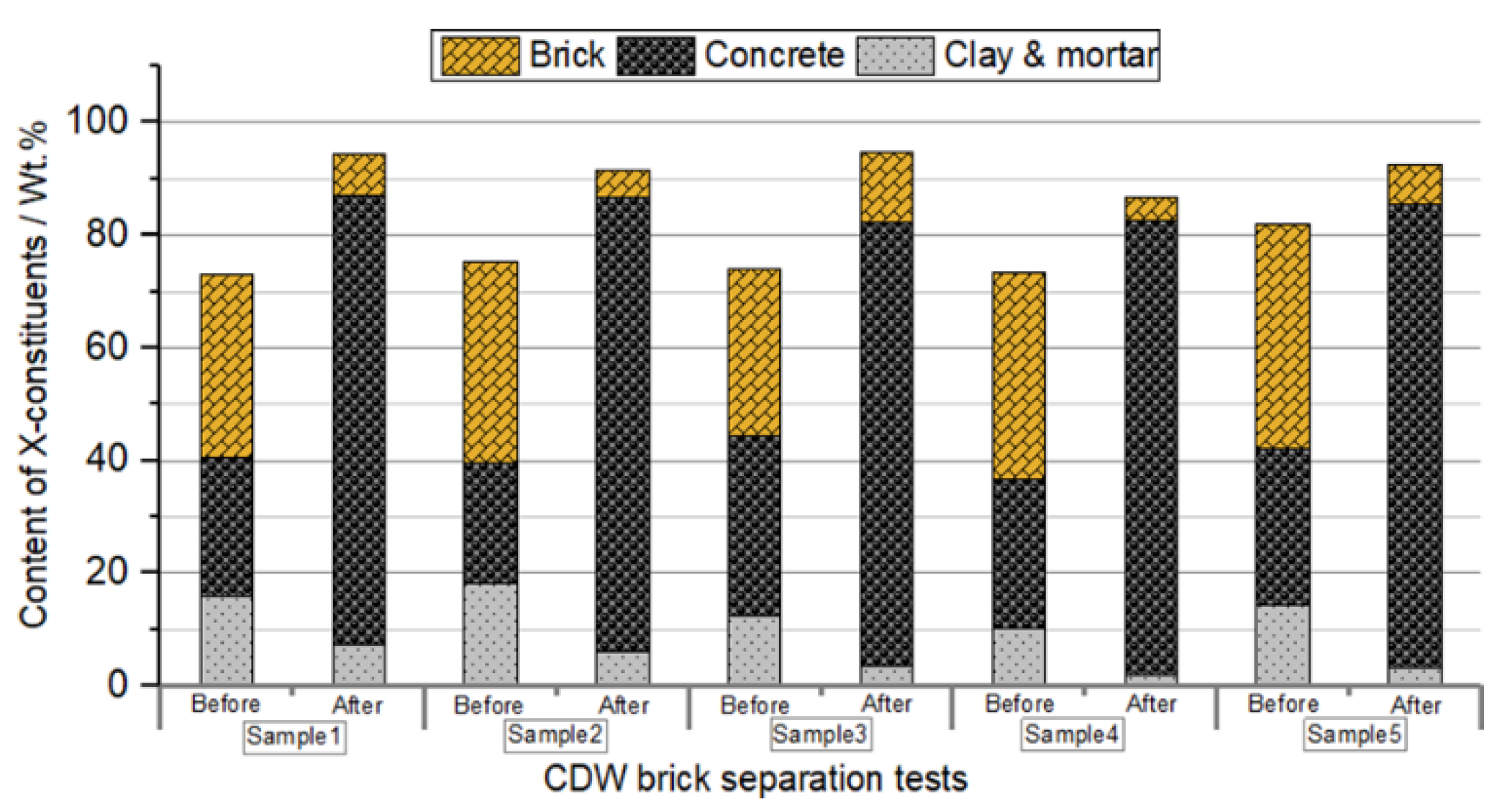

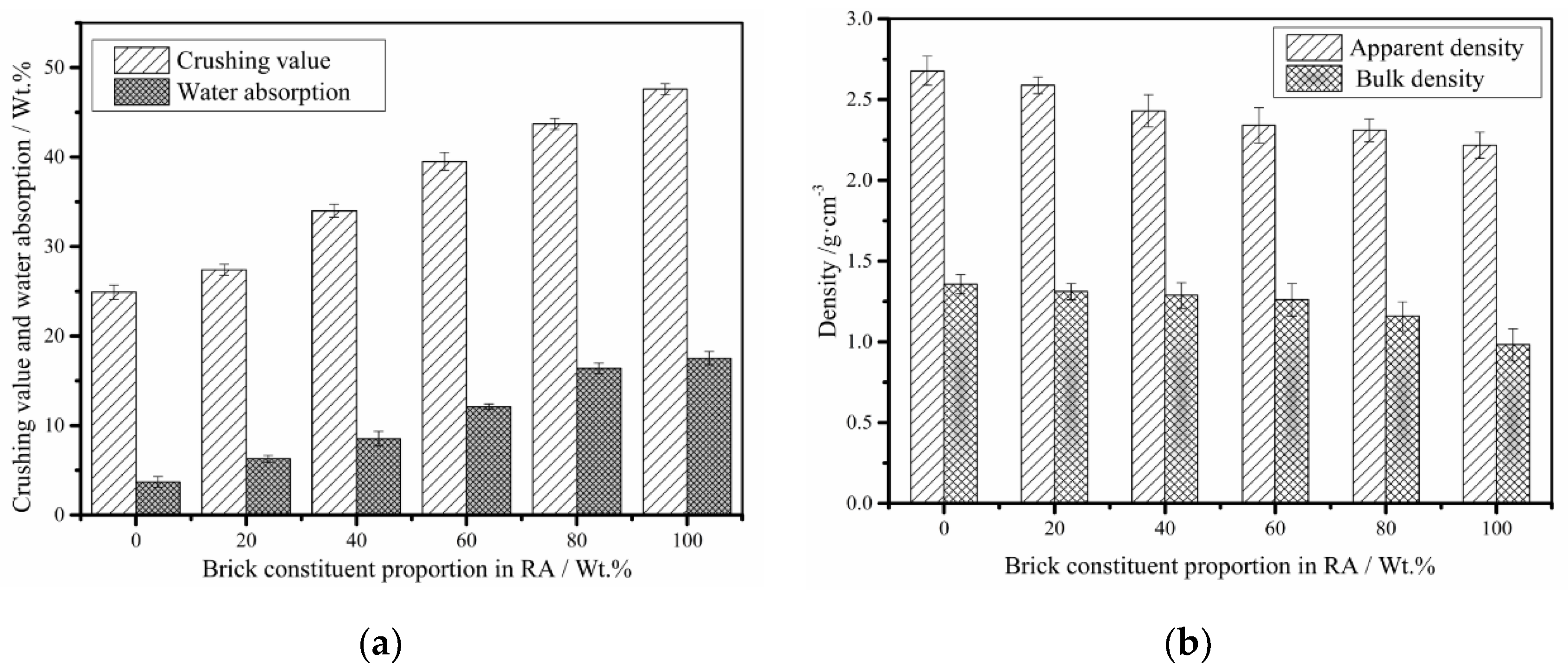

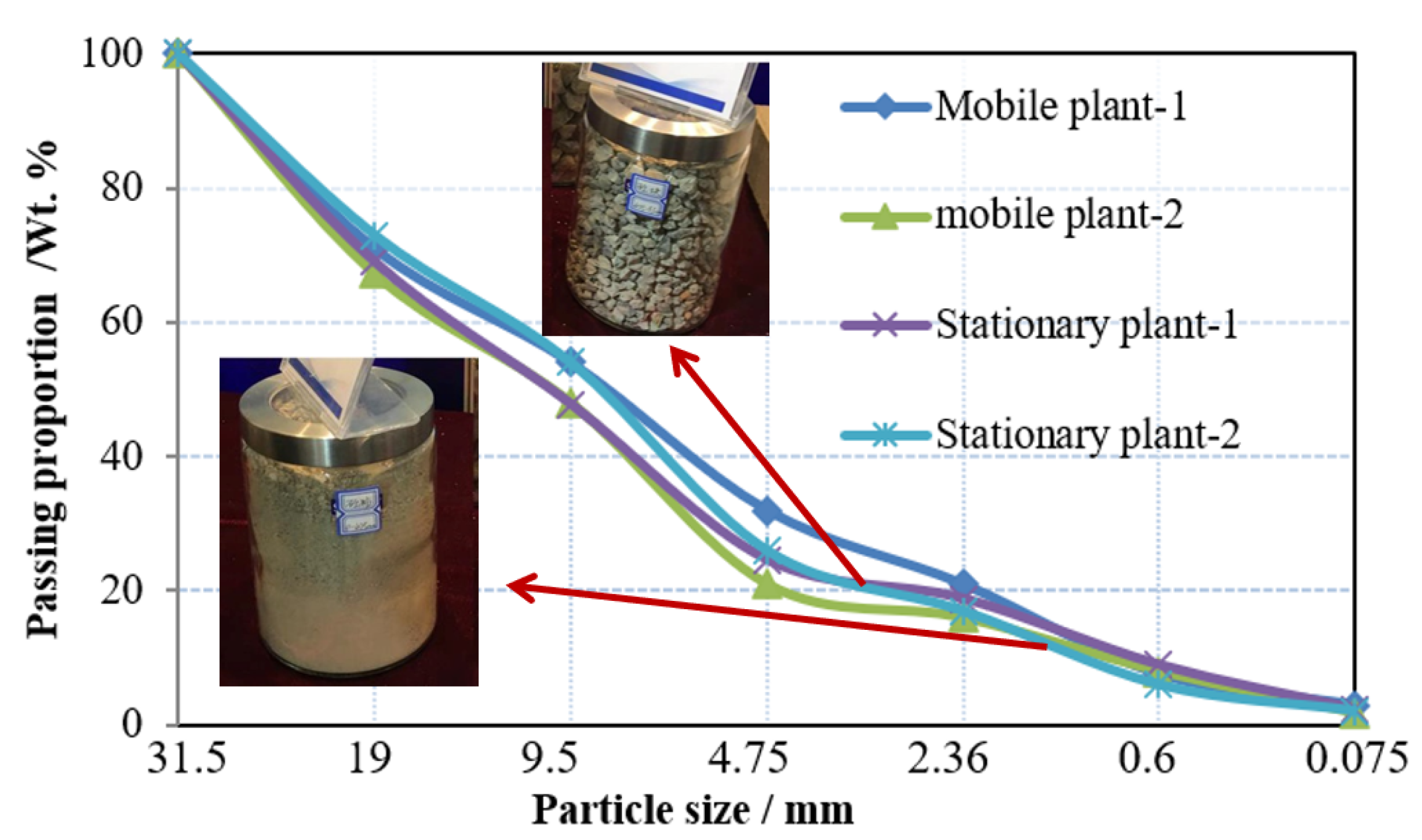

3.1. MRA Quality Evaluation by Brick Separation Treatment

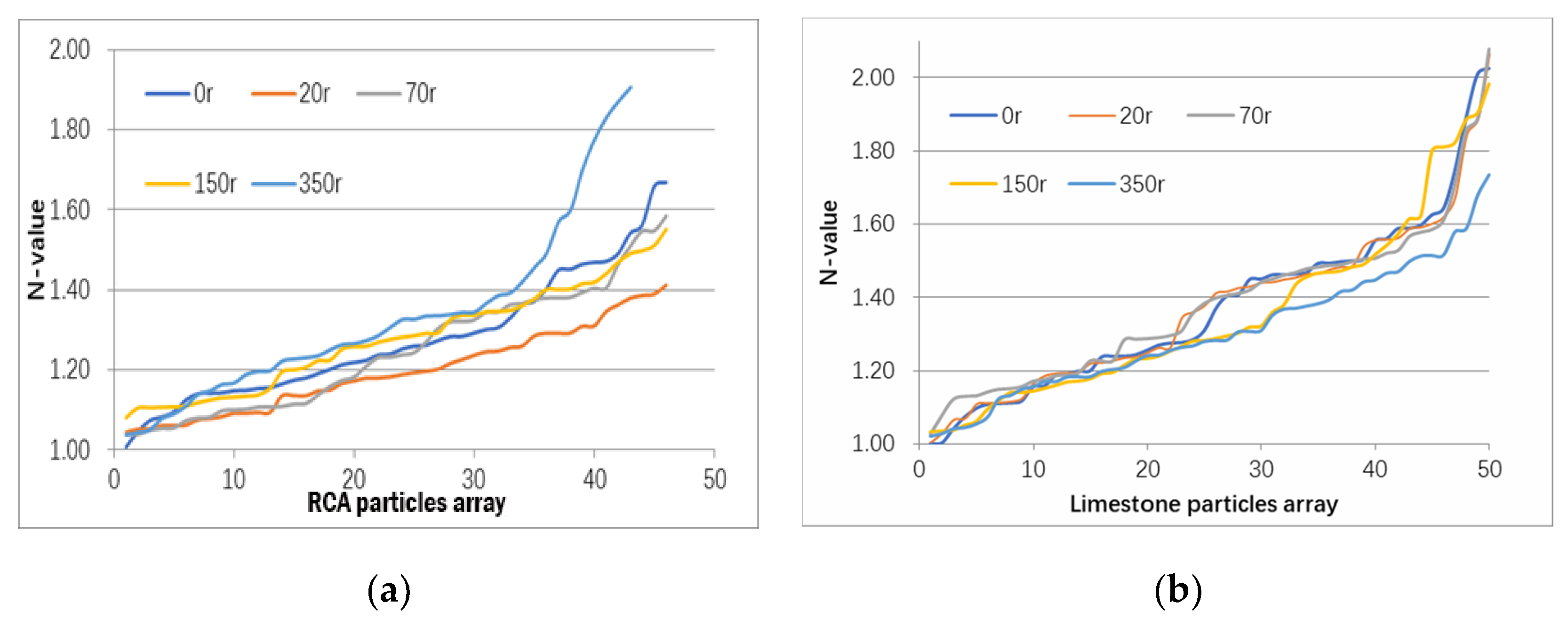

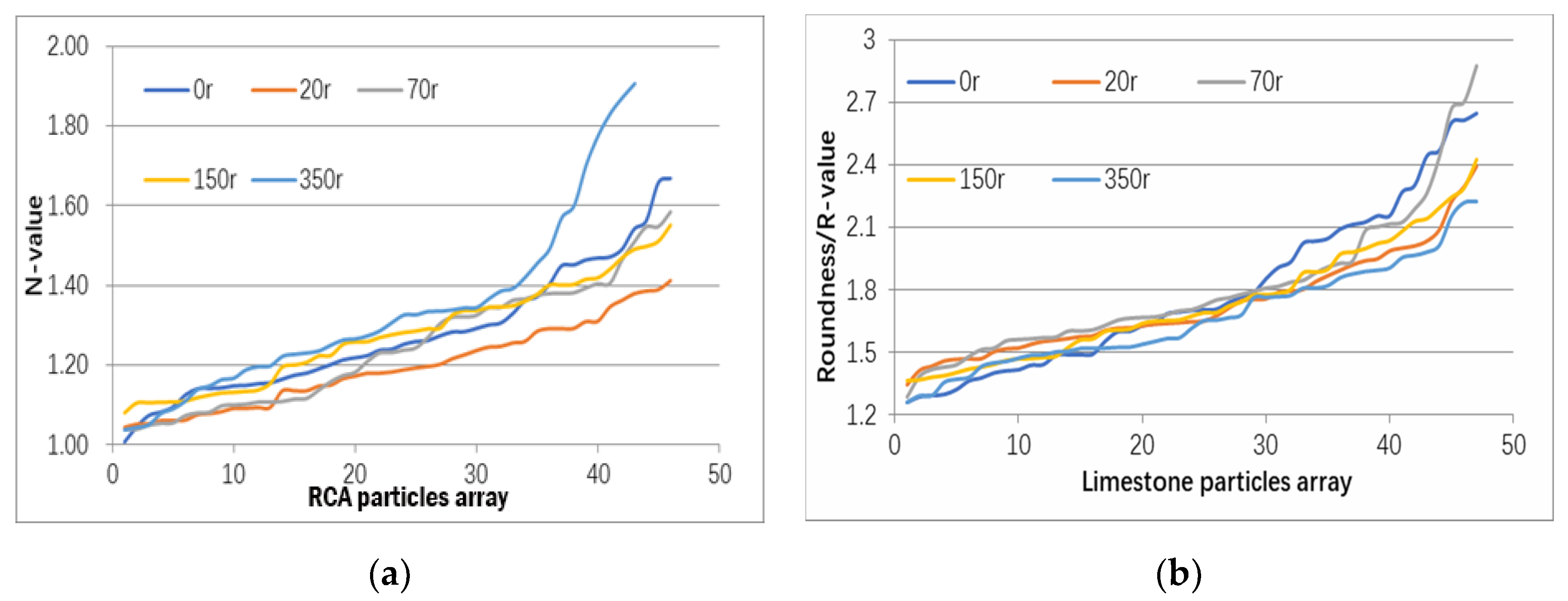

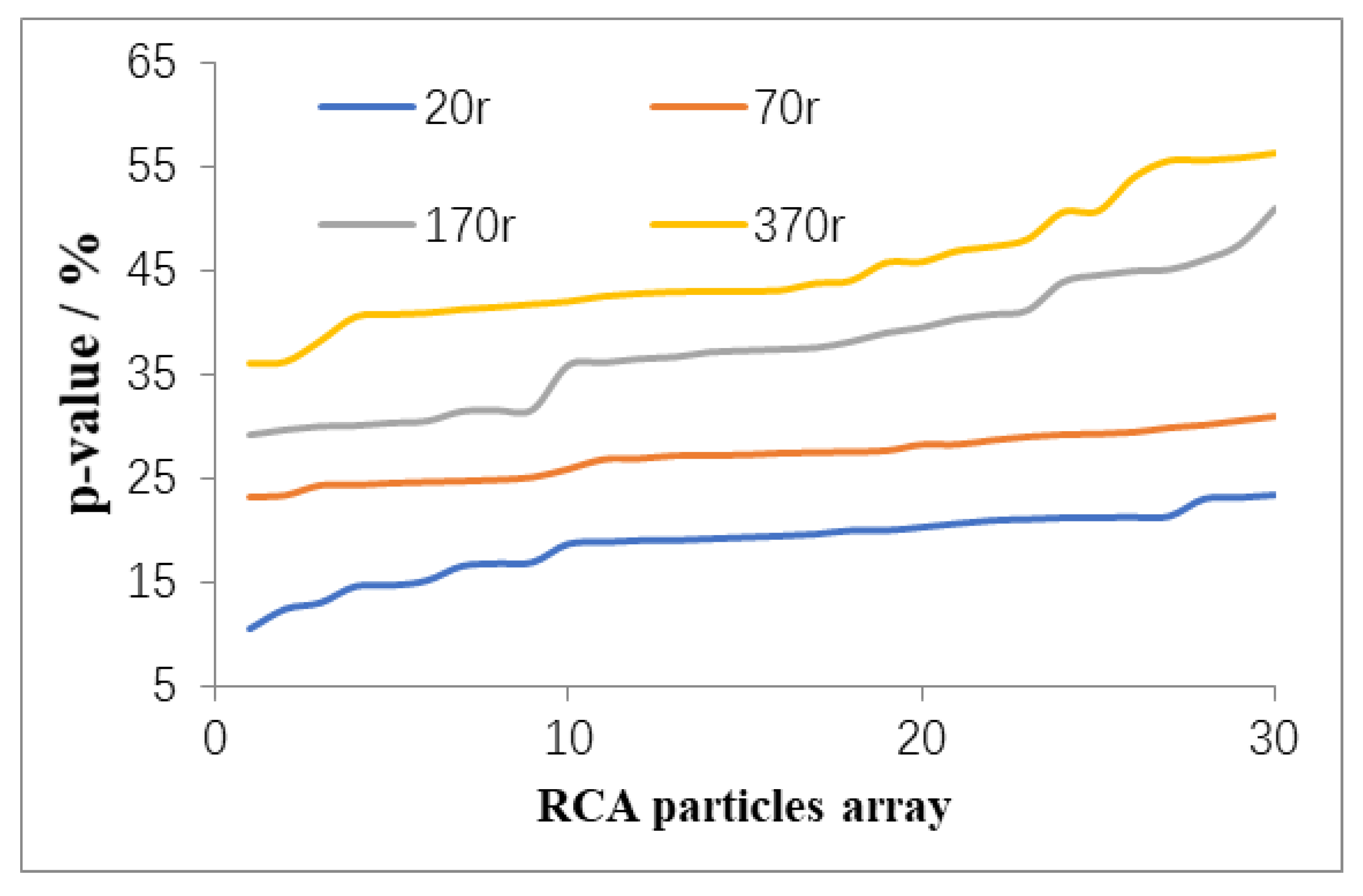

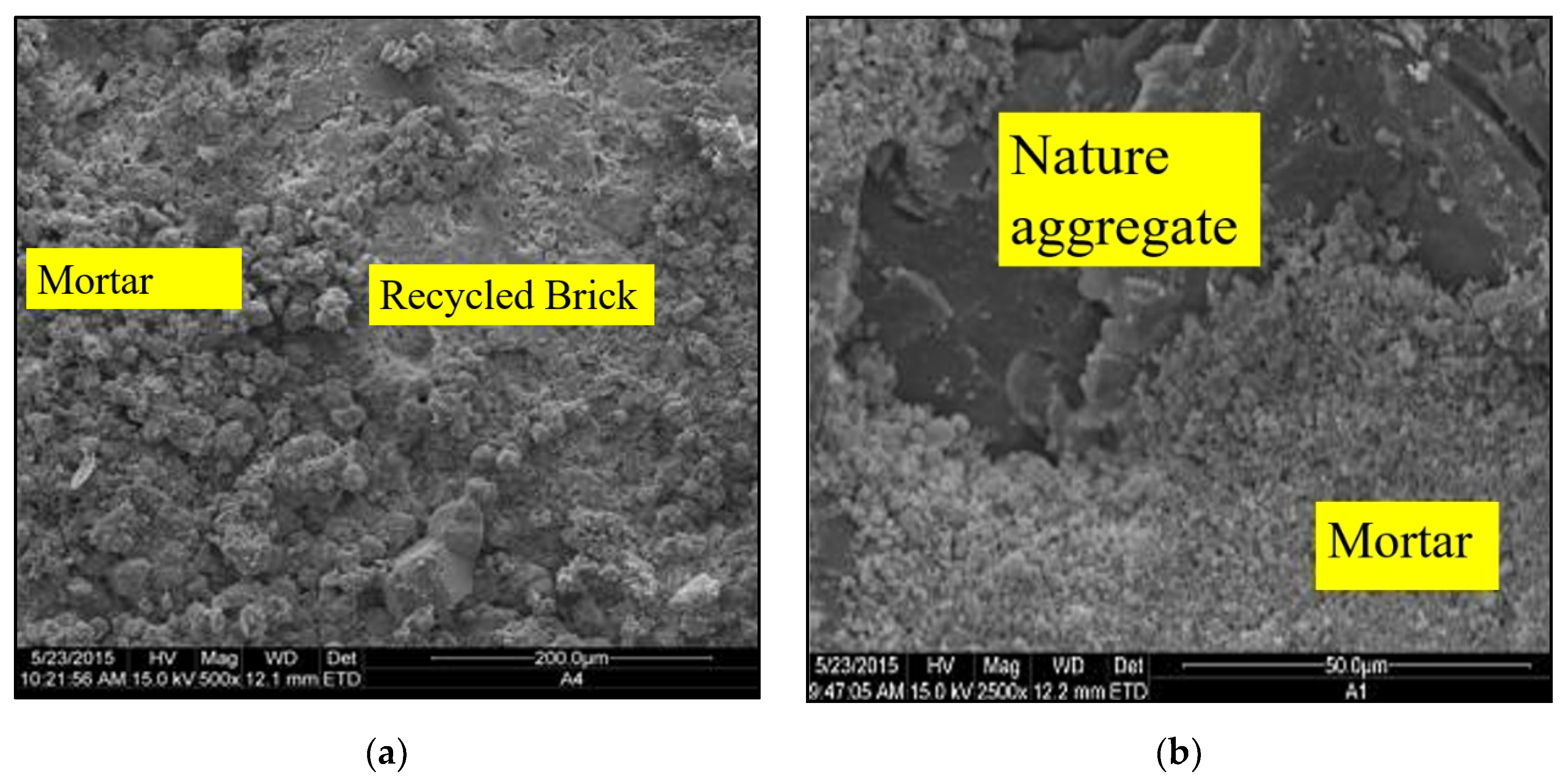

3.2. RCA Quality Evaluation by Surface Treatment

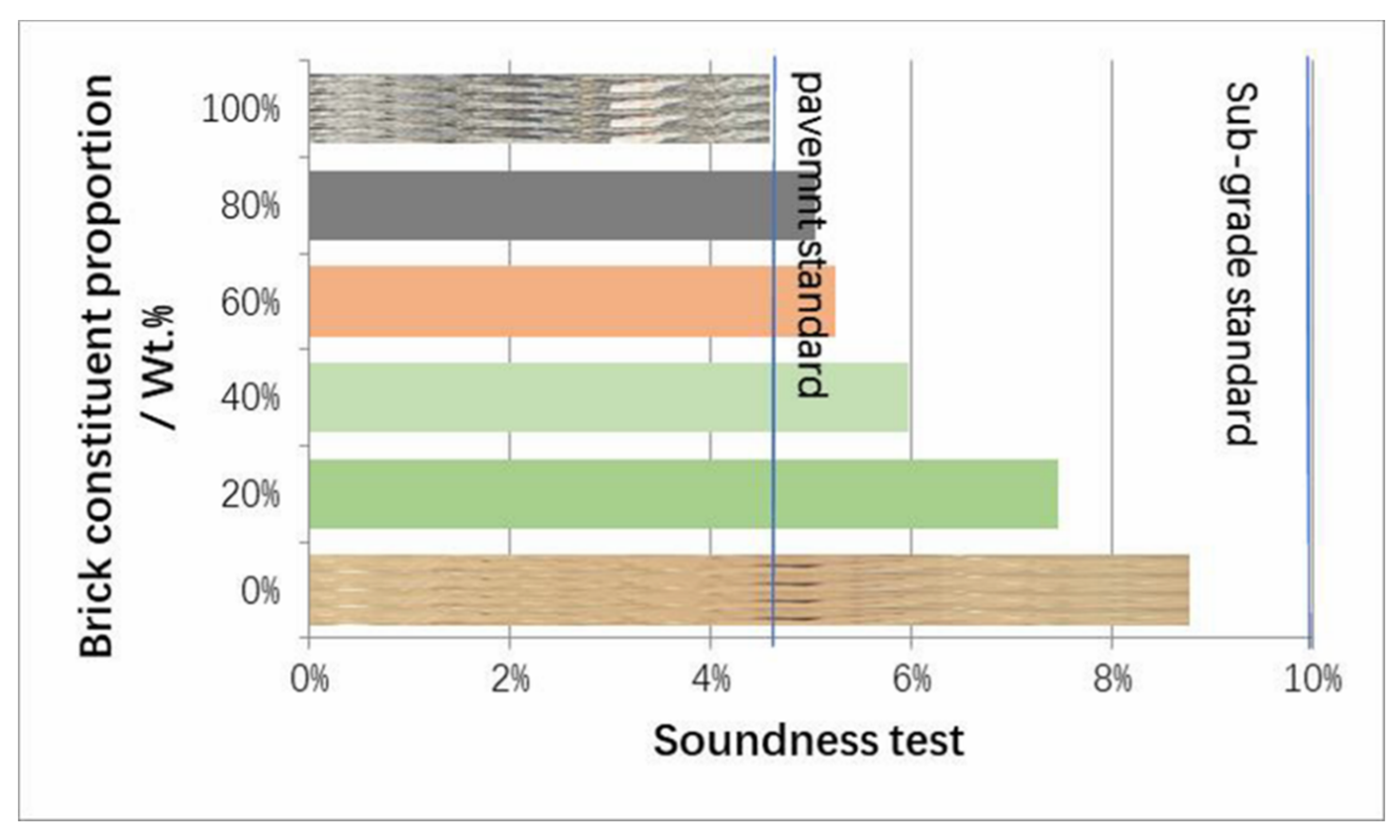

3.3. Field Evaluation of Upgraded MRA Production for Highway Construction

3.4. Small Precast Concrete Curbs

- The brick fraction is problematic for construction and building materials because of its large water absorption ratio, weak strength, high flaky proportion, and low soundness stability.

- In general, it can be concluded that the brick fractions can be reduced from 45 wt.%~55 wt.% to less than 15 wt.% after processed by brick separation technology adopted in this study. Moreover, this technology innovation was proved to be practical in a stationary plant with a production capacity of 50–70 tons/hour.

- Regarding the surface treatment method adopted for MRA, R values of MRA in range of 1.5 to 6.5 were gradually reduced to the range of 1.1 to 2.0. This indicates that the flaky structure content of MRA was notably reduced.

- Twenty-five to thirty percent of the RCA weakness and attached mortar were removed by using the brick separation and surface treatment method in the stationary CDW recycling plant.

- The quality of recycled aggregates was upgraded from level-3 to level-2 based on the standard for recycled concrete materials currently used in China. As the same time, the quality was upgraded from subbase material to base material of highway construction based on standard for pavement materials in China.

- The compressive and splitting tensile properties were enhanced with low proportion of the brick fraction. The upgraded recycled materials were applied in base layer and small precast concrete curbs in a 113 km highway construction. Considerable economic and environment benefits were obtained by the CDW recycling project equipped with brick separation and surface treatment method proposed in this study.

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yang, H.; Xia, J.Q.; Thompson, J.R.; Flower, R.J. Urban construction and demolition waste and landfill failure in Shenzhen, China. Waste Manag. 2017, 63, 393–396. [Google Scholar] [CrossRef]

- Coppola, L.; Coffetti, D.; Crotti, E.; Gazzaniga, G.; Pastore, T. An Empathetic Added Sustainability Index (EASI) for cementitious based construction materials. J. Clean. Prod. 2019, 220, 475–482. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Rodriguez, C.; Parra, C.; Casado, G.; Minano, I.; Albaladejo, F.; Benito, F.; Sanchez, I. The incorporation of construction and demolition wastes as recycled mixed aggregates in non-structural concrete precast pieces. J. Clean. Prod. 2016, 127, 152–161. [Google Scholar] [CrossRef]

- Del Rey, I.; Ayuso, J.; Galvin, A.P.; Jimenez, J.R.; Barbudo, A. Feasibility of Using Unbound Mixed Recycled Aggregates from CDW over Expansive Clay Subgrade in Unpaved Rural Roads. Materials 2016, 9, 931. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhang, Z.; Yu, J.; Xiao, J.; Xu, Q. Using Green Supplementary Materials to Achieve More Ductile ECC. Materials 2019, 12, 858. [Google Scholar] [CrossRef]

- Ma, Z.; Li, W.; Wu, H.; Cao, C. Chloride permeability of concrete mixed with activity recycled powder obtained from C&D waste. Constr. Build. Mater. 2019, 199, 652–663. [Google Scholar] [CrossRef]

- Fraile-Garcia, E.; Ferreiro-Cabello, J.; Lopez-Ochoa, L.M.; Lopez-Gonzalez, L.M. Study of the Technical Feasibility of Increasing the Amount of Recycled Concrete Waste Used in Ready-Mix Concrete Production. Materials 2017, 10, 817. [Google Scholar] [CrossRef]

- Wong, C.L.; Mo, K.H.; Yap, S.P.; Alengaram, U.J.; Ling, T.C. Potential use of brick waste as alternate concrete-making materials: A review. J. Clean. Prod. 2018, 18, 226–239. [Google Scholar] [CrossRef]

- Medina, C.; Zhu, W.; Howind, T.; Frias, M.; de Rojas, M.I.S. Effect of the constituents (asphalt, clay materials, floating particles and fines) of construction and demolition waste on the properties of recycled concretes. Constr. Build. Mater. 2015, 79, 22–33. [Google Scholar] [CrossRef]

- Pawluczuk, E.; Kalinowska-Wichrowska, K.; Boltryk, M.; Ramon Jimenez, J.; Maria Fernandez, J. The Influence of Heat and Mechanical Treatment of Concrete Rubble on the Properties of Recycled Aggregate Concrete. Materials 2019, 12, 367. [Google Scholar] [CrossRef] [PubMed]

- Vegas, I.; Broos, K.; Nielsen, P.; Lambertz, O.; Lisbona, A. Upgrading the quality of mixed recycled aggregates from construction and demolition waste by using near-infrared sorting technology. Constr. Build. Mater. 2015, 75, 121–128. [Google Scholar] [CrossRef]

- Ambros, W.M.; Cazacliu, B.G.; Sampaio, C.H. Wall effects on particle separation in air jigs. Powder Technol. 2016, 301, 369–378. [Google Scholar] [CrossRef]

- Sampaio, C.H.; Cazacliu, B.G.; Miltzarek, G.L.; Huchet, F.; le Guen, L.; Petter, C.O.; Paranhos, R.; Ambros, W.M.; Oliveira, M.L.S. Stratification in air jigs of concrete/brick/gypsum particles. Constr. Build. Mater. 2016, 109, 63–72. [Google Scholar] [CrossRef]

- Hu, K.; Chen, Y.; Naz, F.; Zeng, C.; Cao, S. Separation studies of concrete and brick from construction and demolition waste. Waste Manag. 2019, 85, 396–404. [Google Scholar] [CrossRef]

- Ambros, W.M.; Sampaio, C.H.; Cazacliu, B.G.; Miltzarek, G.L.; Miranda, L.R. Usage of air jigging for multi-component separation of construction and demolition waste. Waste Manag. 2017, 60, 75–83. [Google Scholar] [CrossRef] [PubMed]

- Abdollahnejad, Z.; Mastali, M.; Falah, M.; Luukkonen, T.; Mazari, M.; Illikainen, M. Construction and Demolition Waste as Recycled Aggregates in Alkali-Activated Concretes. Materials 2019, 12, 4016. [Google Scholar] [CrossRef]

- Sen, R. Developments in the durability of FRP-concrete bond. Constr. Build. Mater. 2015, 78, 112–125. [Google Scholar] [CrossRef]

- Qiu, J.; Tng, D.Q.S.; Yang, E.H. Surface treatment of recycled concrete aggregates through microbial carbonate precipitation. Constr. Build. Mater. 2014, 57, 144–150. [Google Scholar] [CrossRef]

- Ondova, M.; Sicakova, A. Evaluation of the Influence of Specific Surface Treatments of RBA on a Set of Properties of Concrete. Materials 2016, 9, 156. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.Z.; Yu, A.T.W.; Shen, L.Y.; Liu, G.W. Quantifying construction and demolition waste: An analytical review. Waste Manag. 2014, 34, 1683–1692. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Seco, A.; Omer, J.; Marcelino, S.; Espuelas, S.; Prieto, E. Sustainable unfired bricks manufacturing from construction and demolition wastes. Constr. Build. Mater. 2018, 167, 154–165. [Google Scholar] [CrossRef]

- Ucer, D.; Ulybin, A.; Zubkov, S.; Elias-Ozkan, S.T. Analysis on the mechanical properties of historical brick masonry after machinery demolition. Constr. Build. Mater. 2018, 161, 186–195. [Google Scholar] [CrossRef]

- Alexandridou, C.; Angelopoulos, G.N.; Coutelieris, F.A. Mechanical and durability performance of concrete produced with recycled aggregates from Greek construction and demolition waste plants. J. Clean. Prod. 2018, 176, 745–757. [Google Scholar] [CrossRef]

- Andrade, J.J.D.; Possan, E.; Squiavon, J.Z.; Ortolan, T.L.P. Evaluation of mechanical properties and carbonation of mortars produced with construction and demolition waste. Constr. Build. Mater. 2018, 161, 70–83. [Google Scholar] [CrossRef]

- Tavira, J.; Jiménez, J.R.; Ayuso, J.; Sierra, M.J.; Ledesma, E.F. Functional and structural parameters of a paved road section constructed with mixed recycled aggregates from non-selected construction and demolition waste with excavation soil. Constr. Build. Mater. 2018, 164, 57–69. [Google Scholar] [CrossRef]

- Ledesma, E.F.; Jimenez, J.R.; Ayuso, J.; Fernandez, J.M.; de Brito, J. Maximum feasible use of recycled sand from construction and demolition waste for eco-mortar production—Part-I: Ceramic masonry waste. J. Clean. Prod. 2015, 87, 692–706. [Google Scholar] [CrossRef]

- Abid, S.R.; Nahhab, A.H.; Al-aayedi, H.K.H.; Nuhair, A.M. Expansion and strength properties of concrete containing contaminated recycled concrete aggregate. Case Stud. Constr. Mater. 2018, 9, e00201. [Google Scholar] [CrossRef]

- Bassani, M.; Tefa, L. Compaction and freeze-thaw degradation assessment of recycled aggregates from unseparated construction and demolition waste. Constr. Build. Mater. 2018, 160, 180–195. [Google Scholar] [CrossRef]

- Zaharaki, D.; Galetakis, M.; Komnitsas, K. Valorization of construction and demolition (C&D) and industrial wastes through alkali activation. Constr. Build. Mater. 2016, 121, 686–693. [Google Scholar] [CrossRef]

- Bazaz, J.B.; Khayati, M.; Akrami, N. Performance of concrete produced with crushed bricks as the coarse and fine aggregate. J. Geol. Soc. 2006, 616, 1–10. [Google Scholar]

| Compound/Element (wt.%) | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | K2O | Others |

|---|---|---|---|---|---|---|---|---|

| Brick | 69.22 | 11.29 | 8.64 | 3.87 | 1.42 | - | - | 2.21 |

| Concrete | 45.07 | 10.43 | 3.02 | 19.81 | 1.01 | 0.52 | 3.04 | 12.90 |

| Mortar | 38.52 | 12.32 | 3.49 | 25.41 | 1.72 | 0.23 | 2.07 | 15.20 |

| Lime stone | 0.82 | 0.31 | 0.94 | 55.72 | 0.34 | 0.02 | 0.13 | 41.31 |

| Clay | 75.15 | 9.56 | 3.18 | 0.96 | 0.71 | - | 3.73 | 4.16 |

| Brick Proportion in MRA | Cement | Flyash | Water | Fine Aggregates 0–4.75 mm | Natural Aggregates | Recycled Brick | Recycled Concrete | Additives | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 4.75–9.5 mm | 9.5–19 mm | 19–31.5 mm | 9.5–19 mm | 19–31.5 mm | ||||||

| 5 wt.% | 275 | 70 | 165 | 700 | 165 | 21 | 21 | 368 | 368 | 6.9 |

| 8 wt.% | 275 | 70 | 165 | 700 | 165 | 29 | 29 | 356 | 356 | 6.9 |

| 12 wt.% | 275 | 70 | 165 | 700 | 165 | 37 | 37 | 344 | 344 | 6.9 |

| 15 wt.% | 275 | 70 | 165 | 700 | 165 | 45 | 45 | 333 | 333 | 6.9 |

| 17 wt.% | 275 | 70 | 165 | 700 | 165 | 62 | 62 | 309 | 309 | 6.9 |

| 23 wt.% | 275 | 70 | 165 | 700 | 165 | 83 | 83 | 274 | 274 | 6.9 |

| 31 wt.% | 275 | 70 | 165 | 700 | 165 | 110 | 110 | 235 | 235 | 6.9 |

| 41 wt.% | 275 | 70 | 165 | 700 | 165 | 138 | 138 | 196 | 196 | 6.9 |

| 51 wt.% | 275 | 70 | 165 | 700 | 165 | 165 | 165 | 156 | 156 | 6.9 |

| 62 wt.% | 275 | 70 | 165 | 700 | 165 | 193 | 193 | 117 | 117 | 6.9 |

| 74 wt.% | 275 | 70 | 165 | 700 | 165 | 220 | 220 | 78 | 78 | 6.9 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, K.; Chen, Y.; Yu, C.; Xu, D.; Cao, S.; Pang, R. Upgrading the Quality of Recycled Aggregates from Construction and Demolition Waste by Using a Novel Brick Separation and Surface Treatment Method. Materials 2020, 13, 2893. https://doi.org/10.3390/ma13132893

Hu K, Chen Y, Yu C, Xu D, Cao S, Pang R. Upgrading the Quality of Recycled Aggregates from Construction and Demolition Waste by Using a Novel Brick Separation and Surface Treatment Method. Materials. 2020; 13(13):2893. https://doi.org/10.3390/ma13132893

Chicago/Turabian StyleHu, Kui, Yujing Chen, Caihua Yu, Dong Xu, Shihao Cao, and Rui Pang. 2020. "Upgrading the Quality of Recycled Aggregates from Construction and Demolition Waste by Using a Novel Brick Separation and Surface Treatment Method" Materials 13, no. 13: 2893. https://doi.org/10.3390/ma13132893

APA StyleHu, K., Chen, Y., Yu, C., Xu, D., Cao, S., & Pang, R. (2020). Upgrading the Quality of Recycled Aggregates from Construction and Demolition Waste by Using a Novel Brick Separation and Surface Treatment Method. Materials, 13(13), 2893. https://doi.org/10.3390/ma13132893