Effect of Strain Rate on Compressive Behavior of a Zr-Based Metallic Glass under a Wide Range of Strain Rates

Abstract

1. Introduction

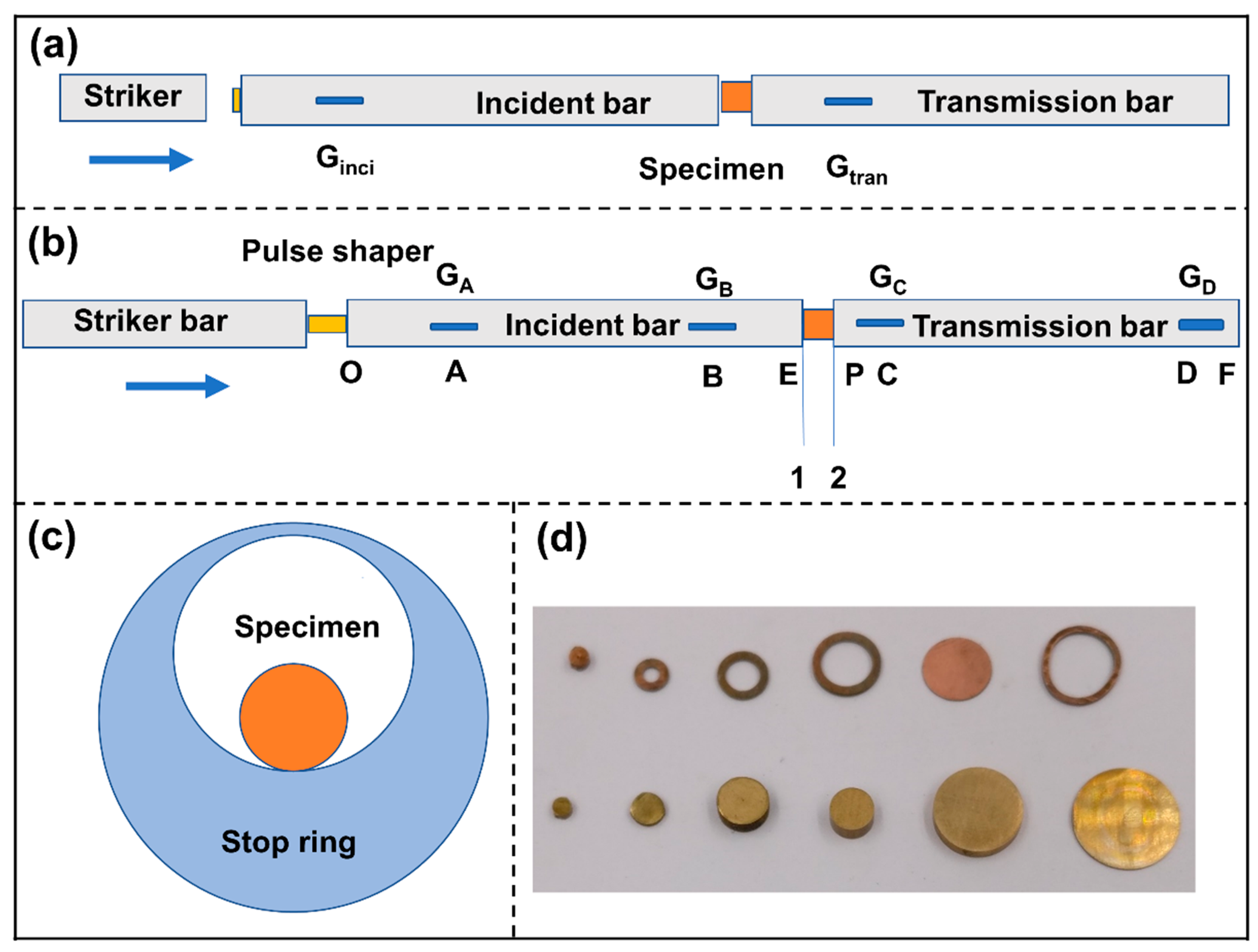

2. Materials and Methods

3. Results and Discussion

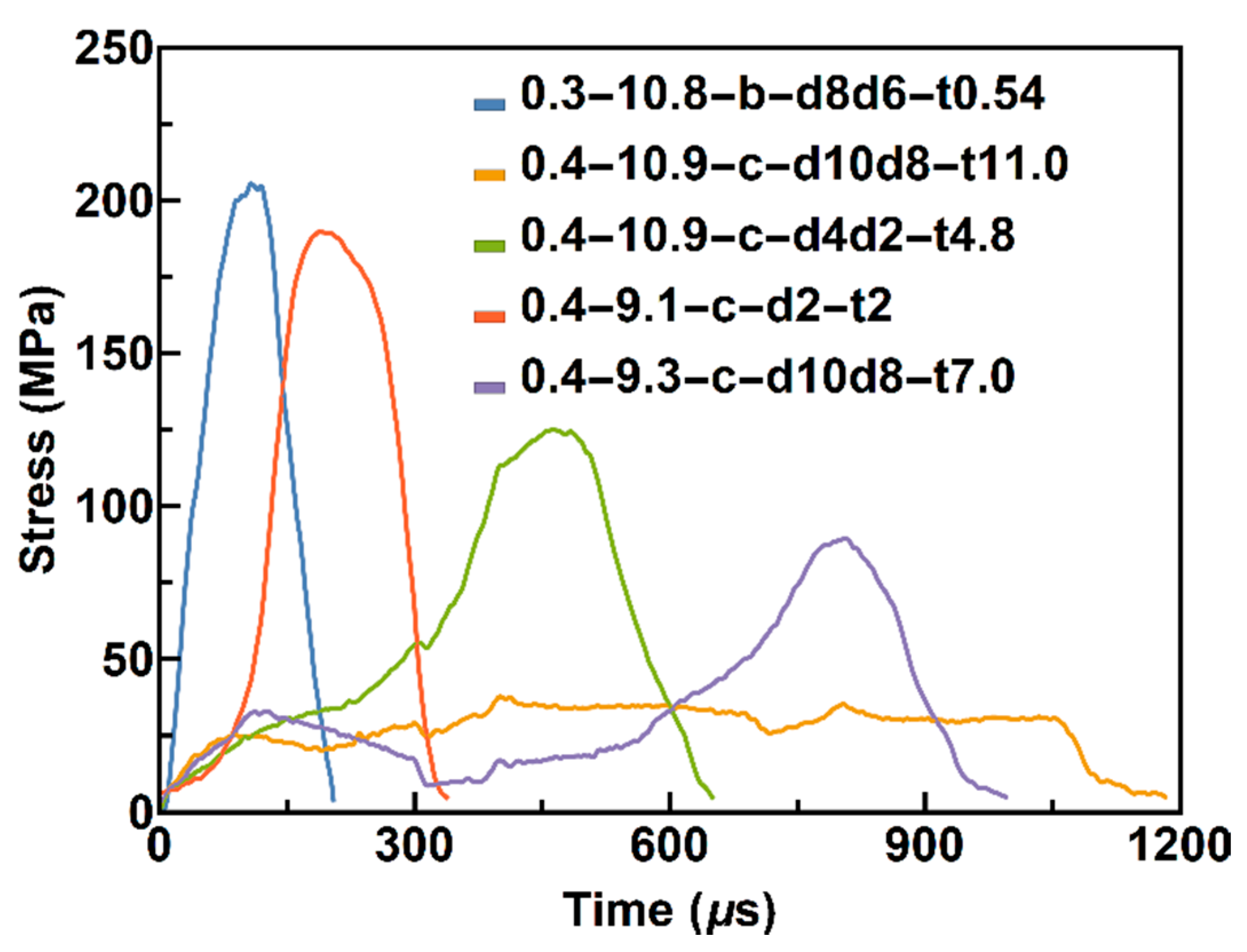

3.1. Medium and High Strain Rate Loading Using SHPB

3.1.1. Incident Waves under Different Pulse Shapers

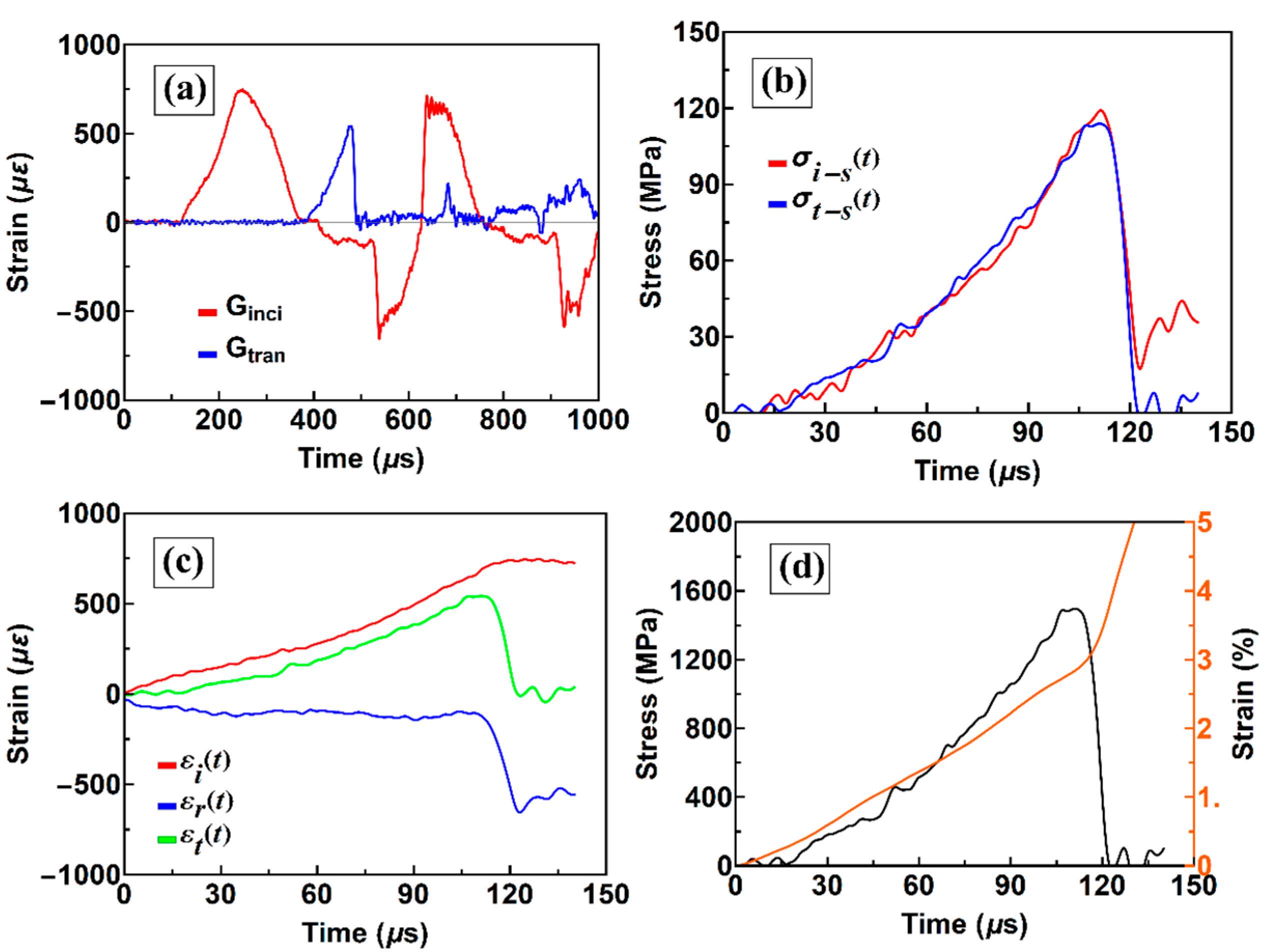

3.1.2. SHPB Curves under a Strain Rate of 300 s−1

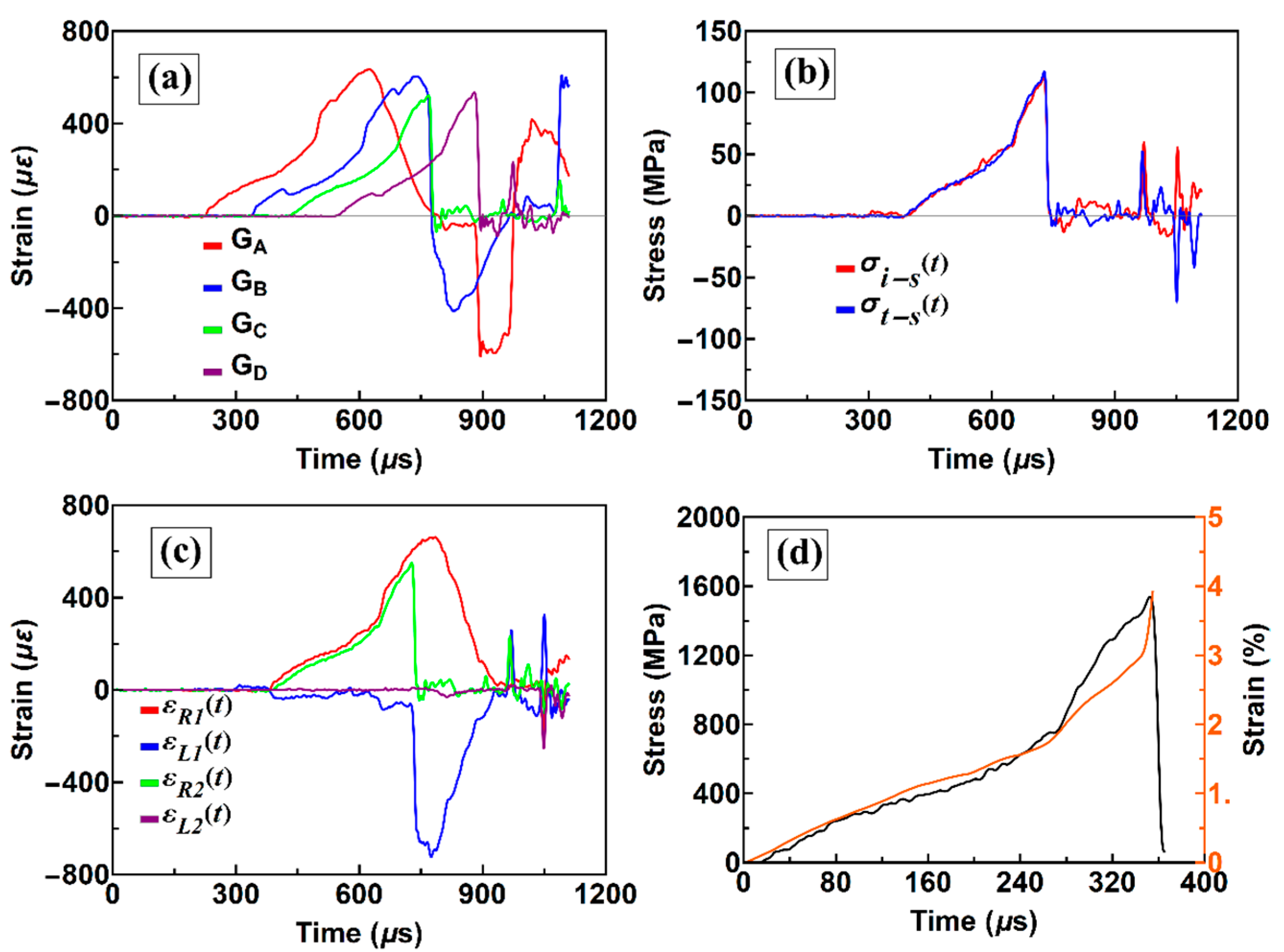

3.1.3. SHPB Curves under a Strain Rate of 100 s−1

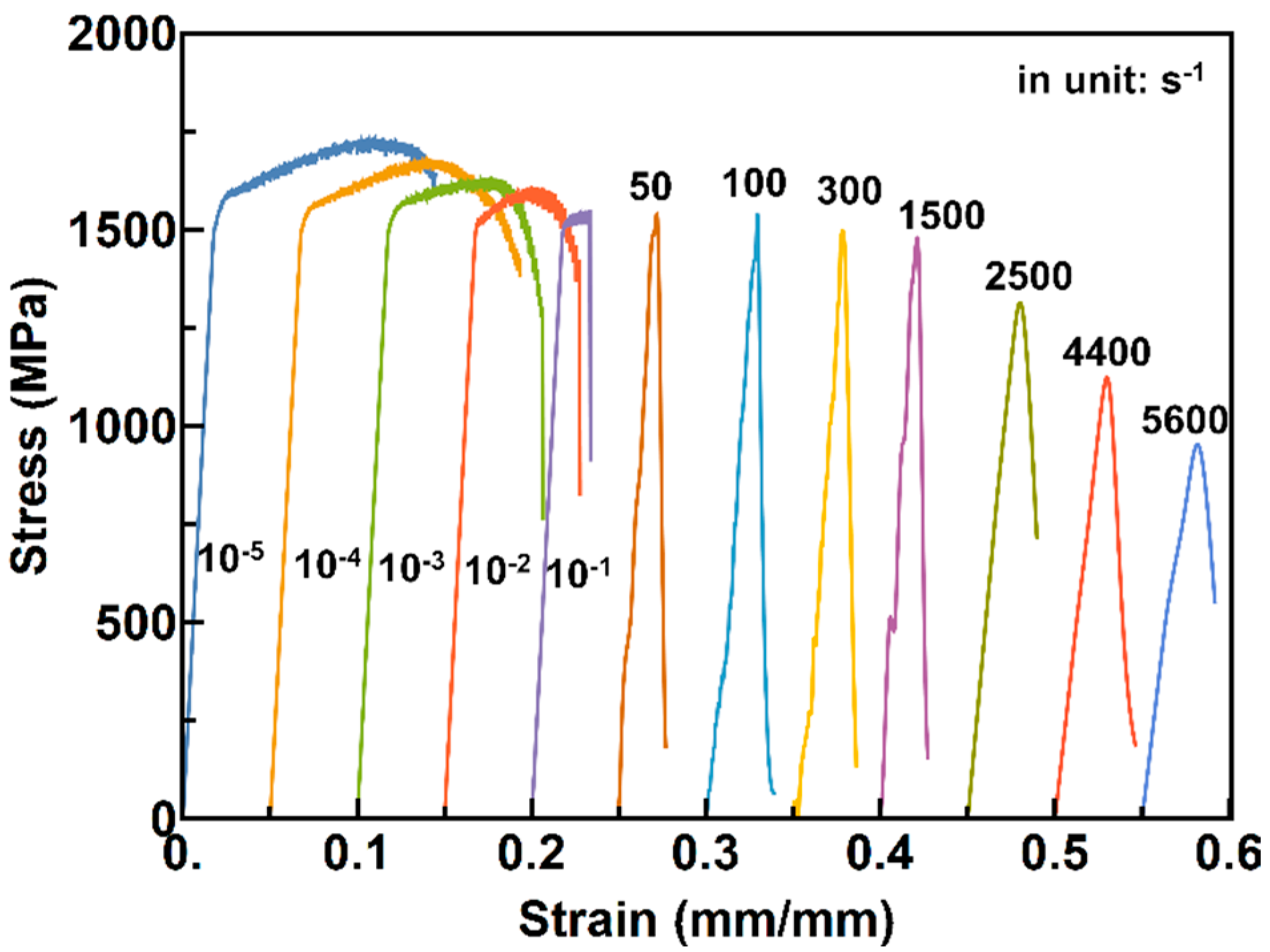

3.2. Stress-Strain Relationship at Different Strain Rates

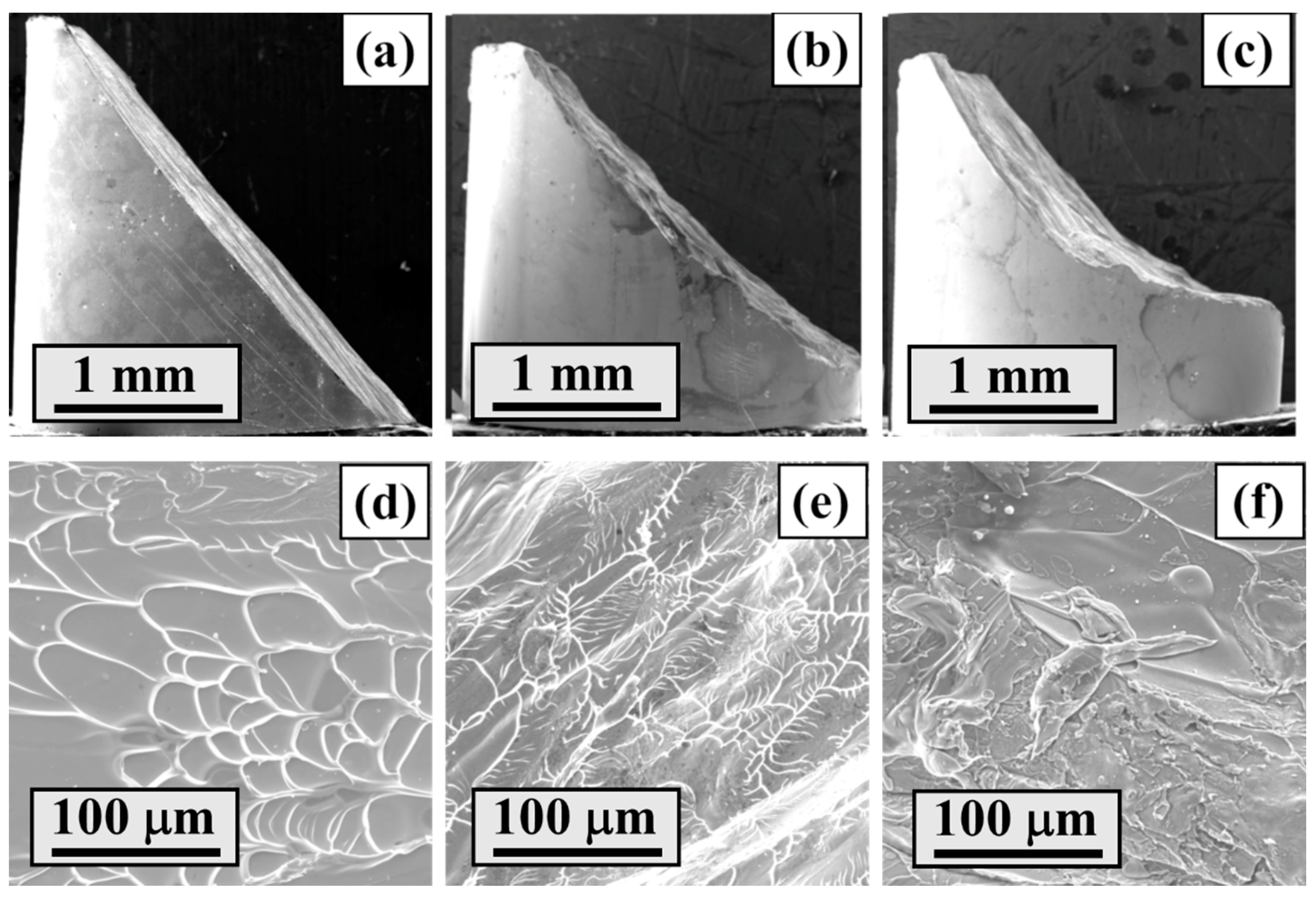

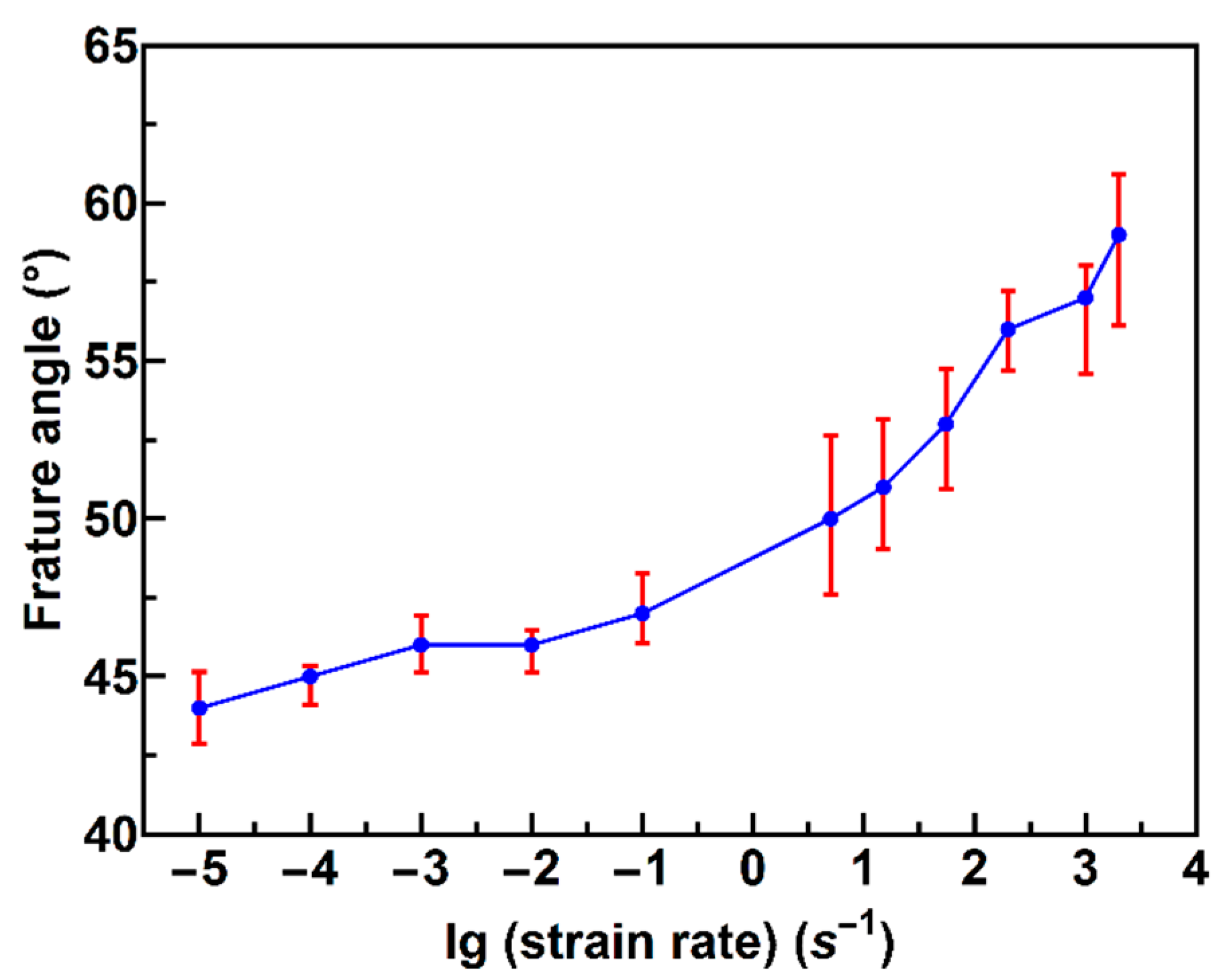

3.3. Fracture Morphology at Different Strain Rates

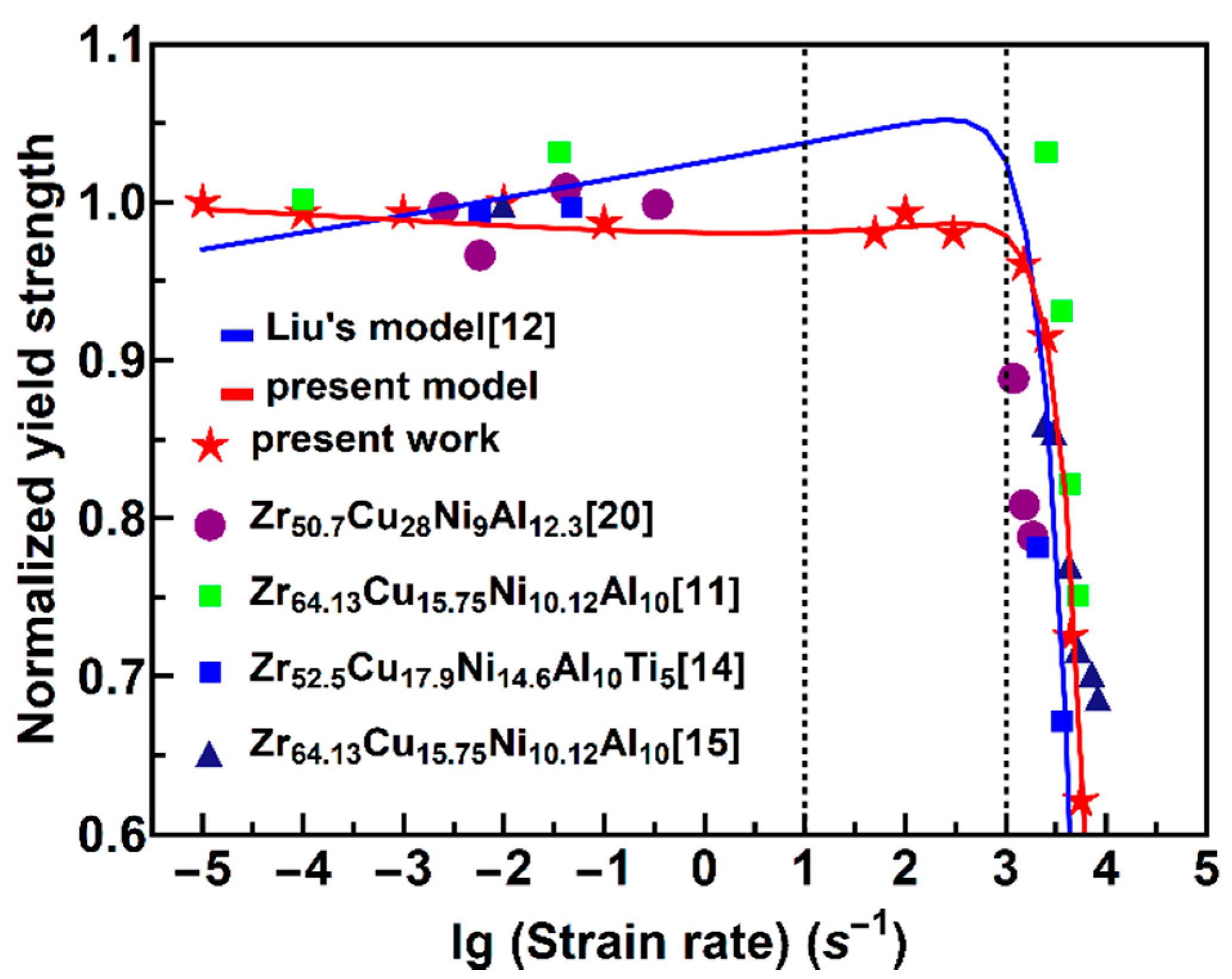

3.4. Model Prediction of Yield Strength at Different Strain Rates

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Johnson, W.L. Bulk Glass-Forming Metallic Alloys: Science and Technology. MRS Bull. 1999, 24, 42–56. [Google Scholar] [CrossRef]

- Inoue, A. Bulk Glassy Alloys: Historical Development and Current Research. Engineering 2015, 1, 185–191. [Google Scholar] [CrossRef]

- Plummer, J.; Johnson, W.L. Is metallic glass poised to come of age? Nat. Mater. 2015, 14, 553–555. [Google Scholar] [CrossRef]

- Bruck, H.A.; Rosakis, A.J.; Johnson, W.L. The dynamic compressive behavior of beryllium bearing bulk metallic glasses. J. Mater. Res. 1996, 11, 503–511. [Google Scholar] [CrossRef]

- Hufnagel, T.C.; Jiao, T.; Li, Y.; Xing, L.Q.; Ramesh, K.T. Deformation and Failure of Zr57Ti5Cu20Ni8Al10 Bulk Metallic Glass Under Quasi-static and Dynamic Compression. J. Mater. Res. 2002, 17, 1441–1445. [Google Scholar] [CrossRef]

- Mukai, T.; Nieh, T.G.; Kawamura, Y.; Inoue, A.; Higashi, K. Effect of strain rate on compressive behavior of a Pd40Ni40P20 bulk metallic glass. Intermetallics 2002, 10, 1071–1077. [Google Scholar] [CrossRef]

- Subhash, G.; Dowding, R.J.; Kecskes, L.J. Characterization of uniaxial compressive response of bulk amorphous Zr–Ti–Cu–Ni–Be alloy. Mater. Sci. Eng. A 2002, 334, 33–40. [Google Scholar] [CrossRef]

- Li, H.; Subhash, G.; Gao, X.L.; Kecskes, L.J.; Dowding, R.J. Negative strain rate sensitivity and compositional dependence of fracture strength in Zr/Hf based bulk metallic glasses. Scr. Mater. 2003, 49, 1087–1092. [Google Scholar] [CrossRef]

- Sunny, G.; Lewandowski, J.; Prakash, V. Effects of annealing and specimen geometry on dynamic compression of a Zr-based bulk metallic glass. J. Mater. Res. 2007, 22, 389–401. [Google Scholar] [CrossRef]

- Sunny, G.; Yuan, F.; Prakash, V.; Lewandowski, J. Effect of high strain rates on peak stress in a Zr-based bulk metallic glass. J. Appl. Phys. 2008, 104, 093522. [Google Scholar] [CrossRef]

- Liu, W.D.; Liu, K.X.; Xia, X.X.; Wang, W.H. The failure stress of bulk metallic glasses under very high strain rate. J. Mater. Res. 2010, 25, 1230–1234. [Google Scholar] [CrossRef]

- Liu, W.D.; Liu, K.X. Notable internal thermal effect on the yielding of metallic glasses. Appl. Phys. Lett. 2012, 100, 141904. [Google Scholar] [CrossRef]

- Fan, J.; Yang, L. Damage mechanisms of bulk metallic glasses under high-rate compression. Int. J. Impact Eng. 2017, 106, 217–222. [Google Scholar] [CrossRef]

- Li, M.C.; Jiang, M.Q.; Yang, S.; Jiang, F.; He, L.; Sun, J. Effect of strain rate on yielding strength of a Zr-based bulk metallic glass. Mater. Sci. Eng. A 2017, 680, 21–26. [Google Scholar] [CrossRef]

- Fan, J. Rate dependency of a Zr-based bulk metallic glass: Strength and fracture characteristic. Mater. Lett. 2018, 216, 176–178. [Google Scholar] [CrossRef]

- Zhou, D.; Li, B.; Zhang, S.; Hou, B.; Li, Y. Rate-dependent shear banding and fracture behavior in a ductile bulk metallic glass. Mater. Sci. Eng. A 2018, 730, 270–279. [Google Scholar] [CrossRef]

- Zhou, D.; Hou, B.; Li, B.; Zhang, S.; Dai, L.; Li, Y. A comparative study of the rate effect on deformation mode in ductile and brittle bulk metallic glasses. Intermetallics 2018, 96, 94–103. [Google Scholar] [CrossRef]

- Yang, R.Q.; Fan, J.T.; Li, S.X.; Zhang, Z.F. Fracture behavior of Zr55Cu30Al10Ni5 bulk metallic glass under quasi-static and dynamic compression. J. Mater. Res. 2008, 23, 1744–1750. [Google Scholar] [CrossRef]

- Xue, Y.F.; Cai, H.N.; Wang, L.; Wang, F.C.; Zhang, H.F. Effect of loading rate on failure in Zr-based bulk metallic glass. Mater. Sci. Eng. A 2008, 473, 105–110. [Google Scholar] [CrossRef]

- Zheng, W.; Huang, Y.J.; Wang, G.Y.; Liaw, P.K.; Shen, J. Influence of Strain Rate on Compressive Deformation Behavior of a Zr-Cu-Ni-Al Bulk Metallic Glass at Room Temperature. Metall. Mater. Trans. A 2011, 42, 1491–1498. [Google Scholar] [CrossRef]

- Pan, Y.; Chen, W.; Song, B. Upper limit of constant strain rates in a split Hopkinson pressure bar experiment with elastic specimens. Exp. Mech. 2005, 45, 440–446. [Google Scholar] [CrossRef]

- Argon, A.S. Plastic deformation in metallic glasses. Acta Metall. 1979, 27, 47–58. [Google Scholar] [CrossRef]

- Steif, P.S.; Spaepen, F.; Hutchinson, J.W. Strain localization in amorphous metals. Acta Metall. 1982, 30, 447–455. [Google Scholar] [CrossRef]

- Johnson, W.L.; Samwer, K. A Universal Criterion for Plastic Yielding of Metallic Glasses with a (T/Tg)2/3 Temperature Dependence. Phys. Rev. Lett. 2005, 95, 195501. [Google Scholar] [CrossRef]

- Zhao, H.; Gary, G. A new method for the separation of waves. Application to the SHPB technique for an unlimited duration of measurement. J. Mech. Phys. Solids 1997, 45, 1185–1202. [Google Scholar] [CrossRef]

- Kolsky, H. An Investigation of the Mechanical Properties of Materials at very High Rates of Loading. Proc. Phys. Soc. Sect. B 1949, 62, 676. [Google Scholar] [CrossRef]

- Song, B.; Chen, W.W.; Lu, W.-Y. Mechanical characterization at intermediate strain rates for rate effects on an epoxy syntactic foam. Int. J. Mech. Sci. 2007, 49, 1336–1343. [Google Scholar] [CrossRef]

- Gary, G.; Mohr, D. Modified Kolsky Formulas for an Increased Measurement Duration of SHPB Systems. Exp. Mech. 2013, 53, 713–717. [Google Scholar] [CrossRef]

- Zhao, H. Material behaviour characterisation using SHPB techniques, tests and simulations. Comput. Struct. 2003, 81, 1301–1310. [Google Scholar] [CrossRef]

- Frew, D.J.; Forrestal, M.J.; Chen, W. Pulse shaping techniques for testing brittle materials with a split hopkinson pressure bar. Exp. Mech. 2002, 42, 93–106. [Google Scholar] [CrossRef]

- Liu, J.; He, S.; Zhao, H.; Li, G.; Wang, M. Experimental investigation on the dynamic behaviour of metal foam: From yield to densification. Int. J. Impact Eng. 2018, 114, 69–77. [Google Scholar] [CrossRef]

- Park, S.W.; Zhou, M. Separation of elastic waves in split Hopkinson bars using one-point strain measurements. Exp. Mech. 1999, 39, 287–294. [Google Scholar] [CrossRef]

- Song, B.; Antoun, B.R.; Nie, X.; Chen, W. High-rate Characterization of 304 L Stainless Steel at Elevated Temperatures for Recrystallization Investigation. Exp. Mech. 2010, 50, 553–560. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Geng, T.; Ge, S.; Zhu, Z.; Zhang, L.; Li, Z.; Fu, H.; Zhang, H.; Li, H.; Wang, A.; et al. Effect of Strain Rate on Compressive Behavior of a Zr-Based Metallic Glass under a Wide Range of Strain Rates. Materials 2020, 13, 2861. https://doi.org/10.3390/ma13122861

Li W, Geng T, Ge S, Zhu Z, Zhang L, Li Z, Fu H, Zhang H, Li H, Wang A, et al. Effect of Strain Rate on Compressive Behavior of a Zr-Based Metallic Glass under a Wide Range of Strain Rates. Materials. 2020; 13(12):2861. https://doi.org/10.3390/ma13122861

Chicago/Turabian StyleLi, Wenqing, Tieqiang Geng, Shaofan Ge, Zhengwang Zhu, Long Zhang, Zhengkun Li, Huameng Fu, Hongwei Zhang, Hong Li, Aimin Wang, and et al. 2020. "Effect of Strain Rate on Compressive Behavior of a Zr-Based Metallic Glass under a Wide Range of Strain Rates" Materials 13, no. 12: 2861. https://doi.org/10.3390/ma13122861

APA StyleLi, W., Geng, T., Ge, S., Zhu, Z., Zhang, L., Li, Z., Fu, H., Zhang, H., Li, H., Wang, A., & Zhang, H. (2020). Effect of Strain Rate on Compressive Behavior of a Zr-Based Metallic Glass under a Wide Range of Strain Rates. Materials, 13(12), 2861. https://doi.org/10.3390/ma13122861