Assessment of Rational Design of Self-Compacting Concrete Incorporating Fly Ash and Limestone Powder in Terms of Long-Term Durability

Abstract

1. Introduction

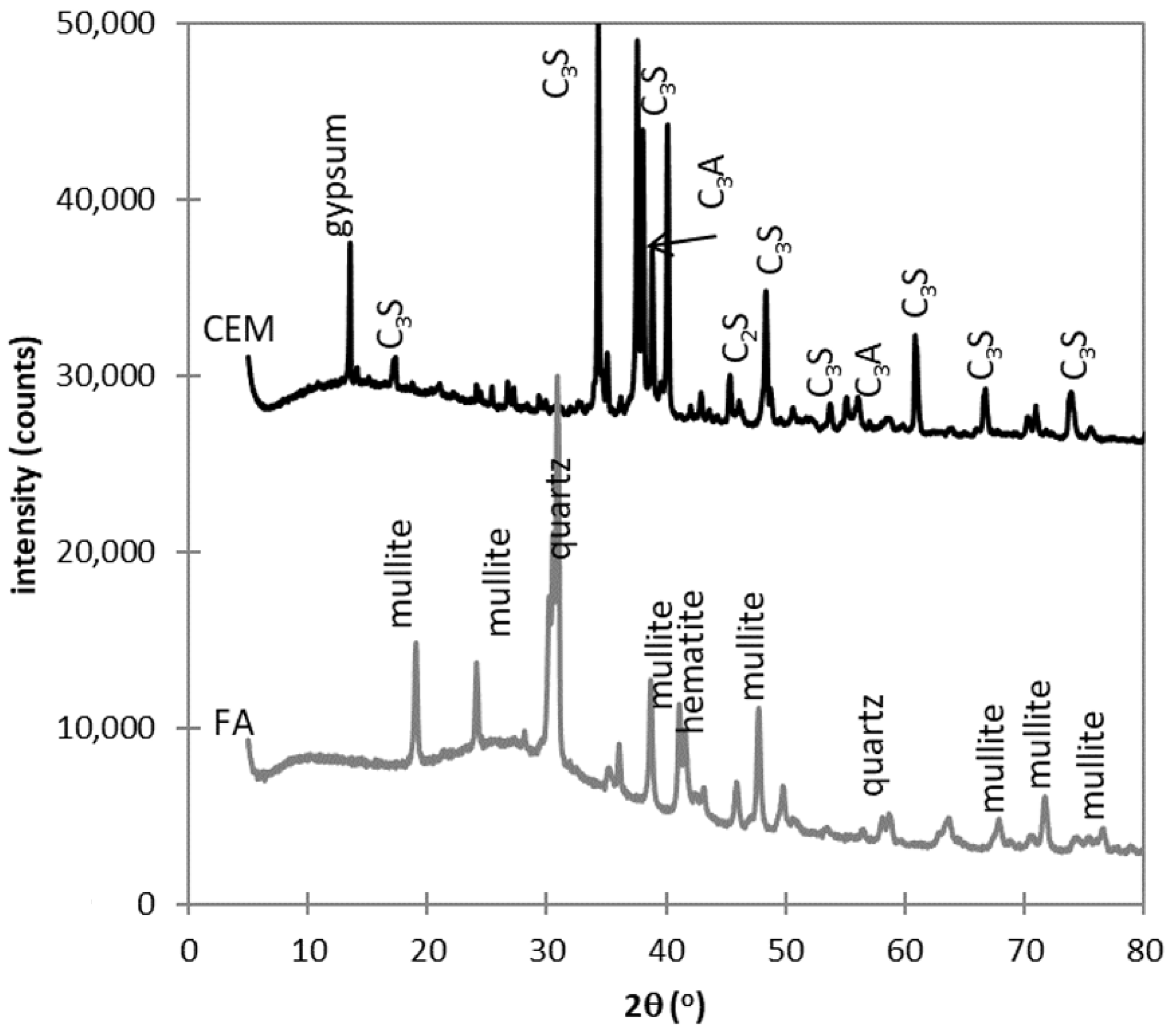

2. Materials and Methods

3. Results

3.1. Fresh Concrete

3.2. Hardened Concrete

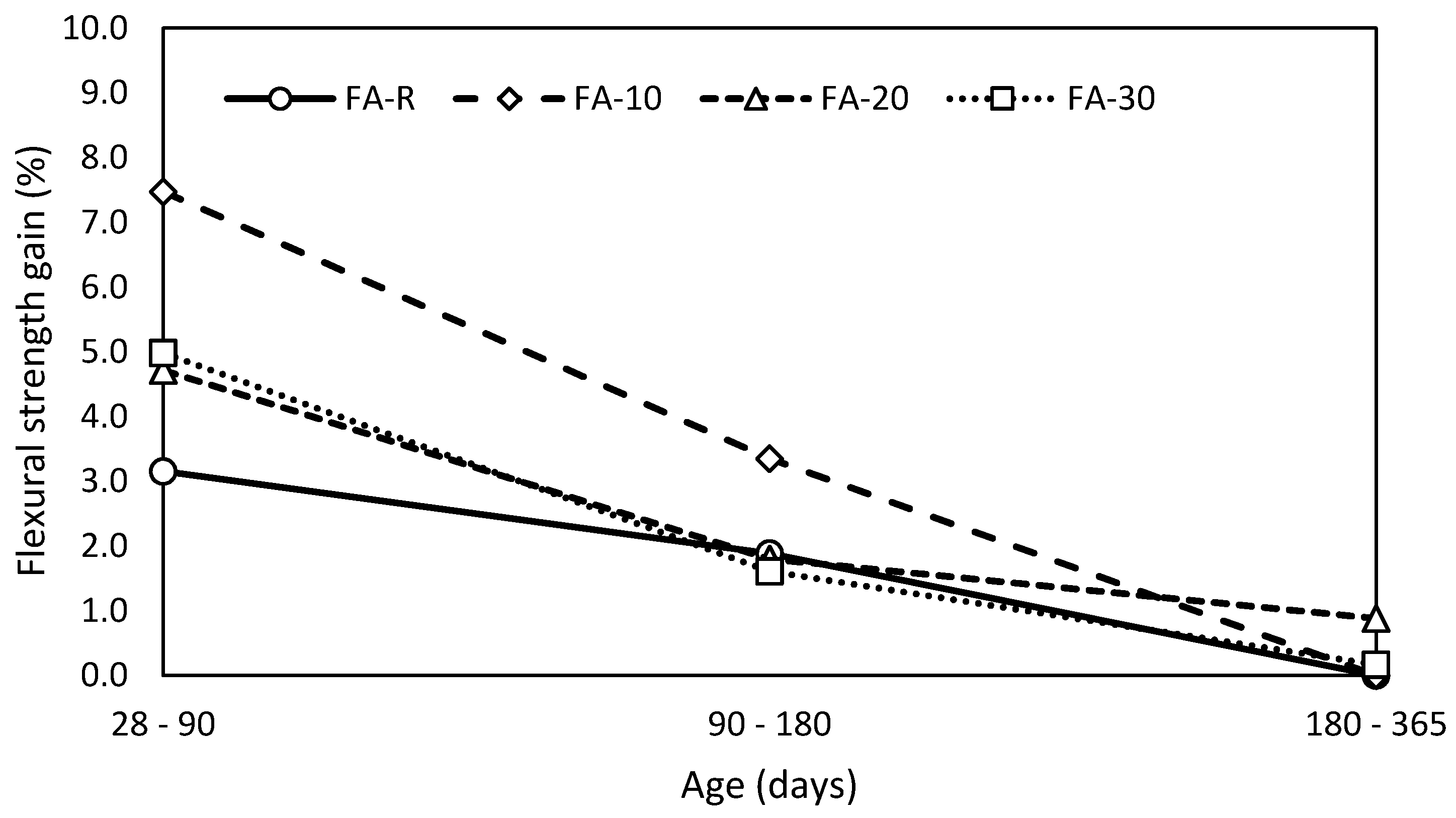

3.2.1. Mechanical Properties

3.2.2. Frost Resistance

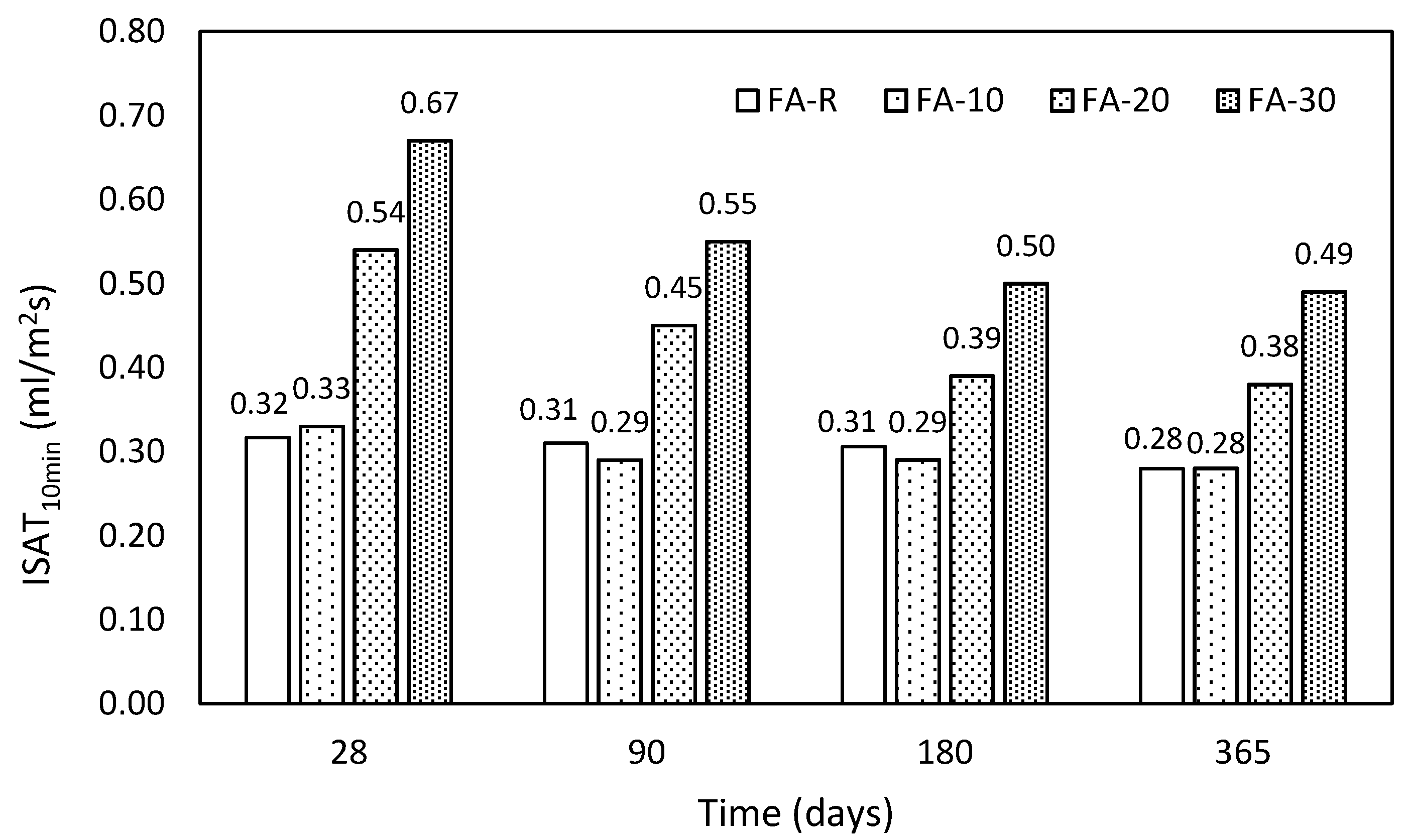

3.2.3. Initial Surface Adsorption Test (ISAT)

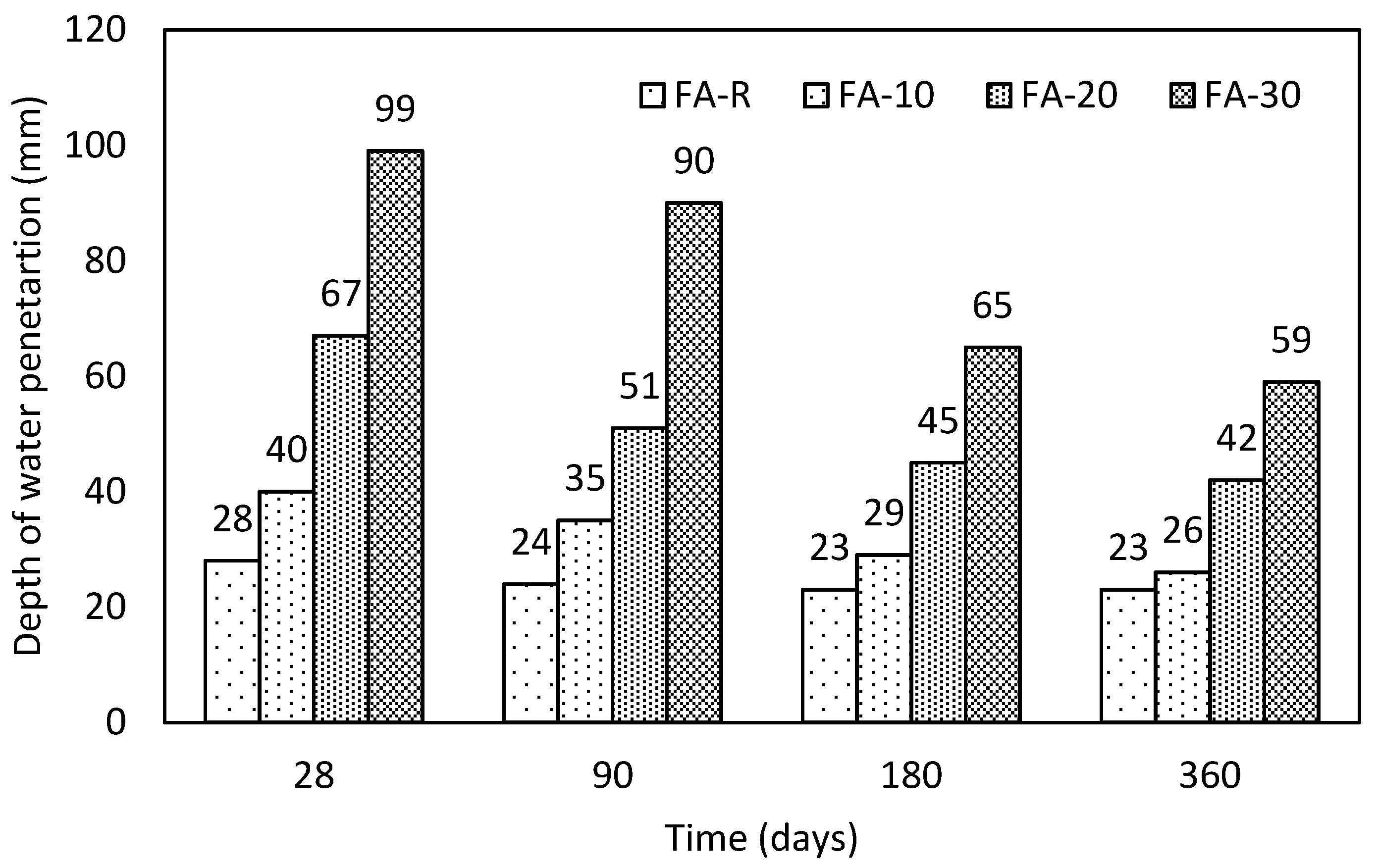

3.2.4. Depth of Water Penetration Test

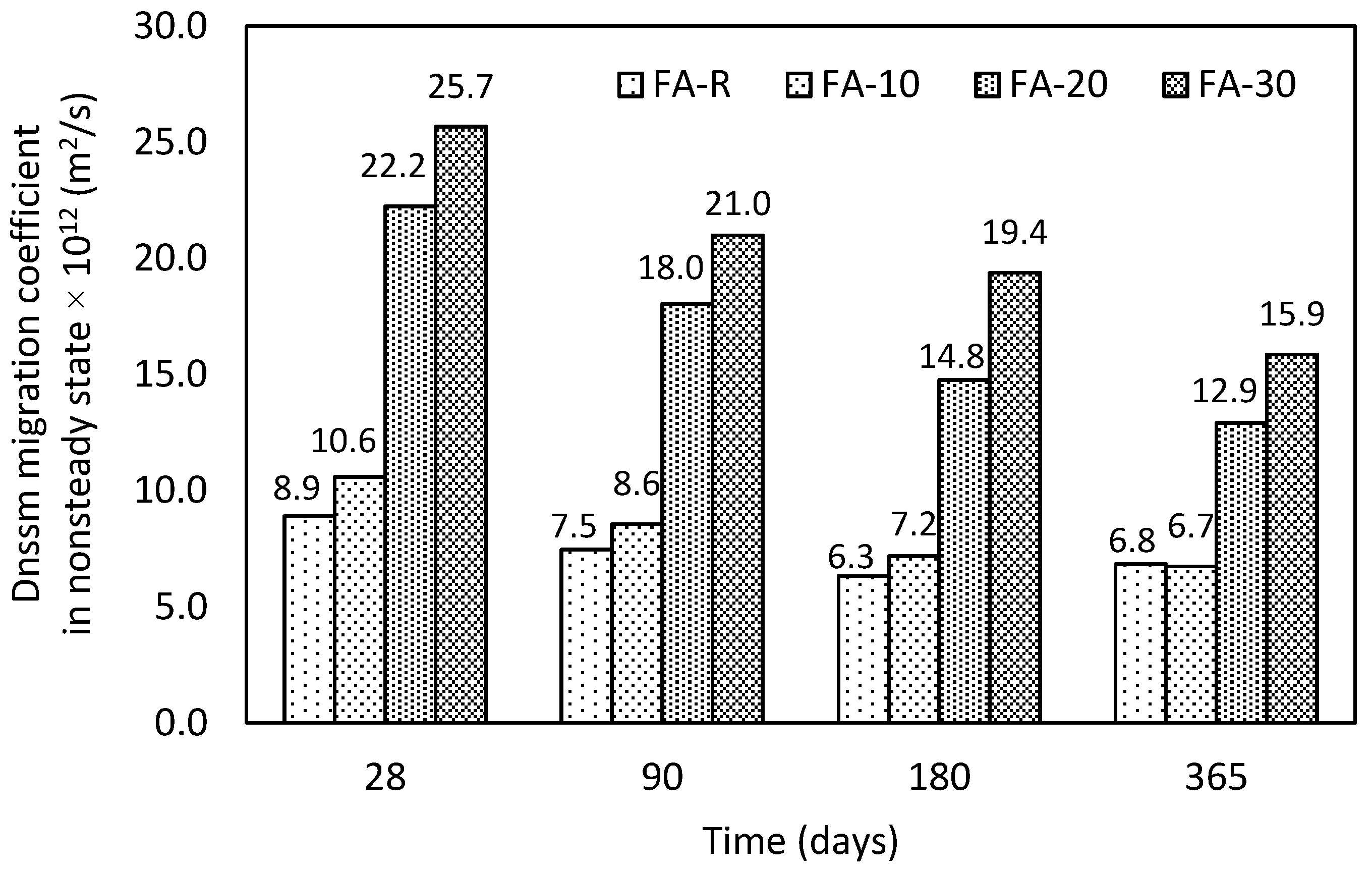

3.2.5. Chloride Migration Test

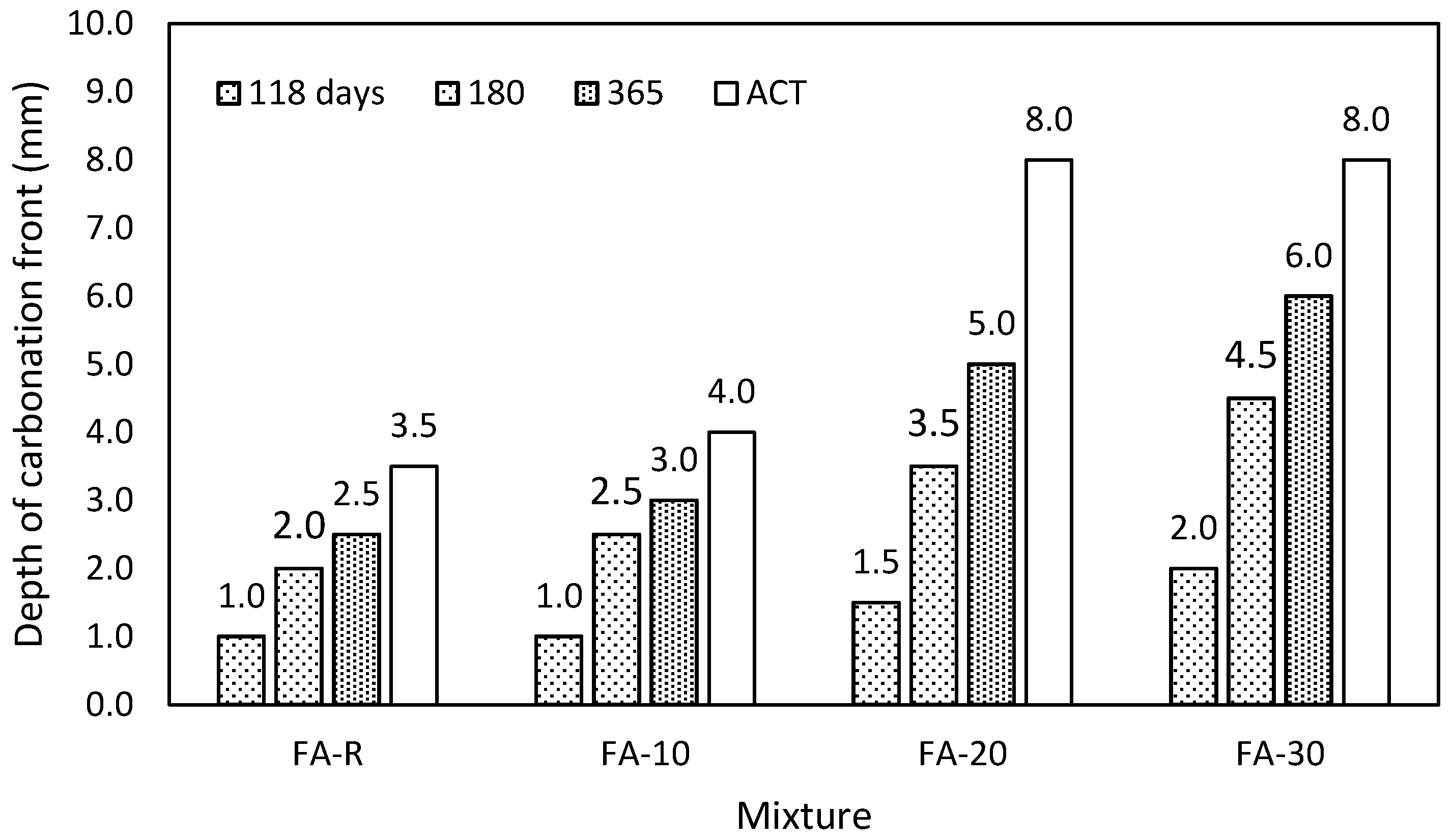

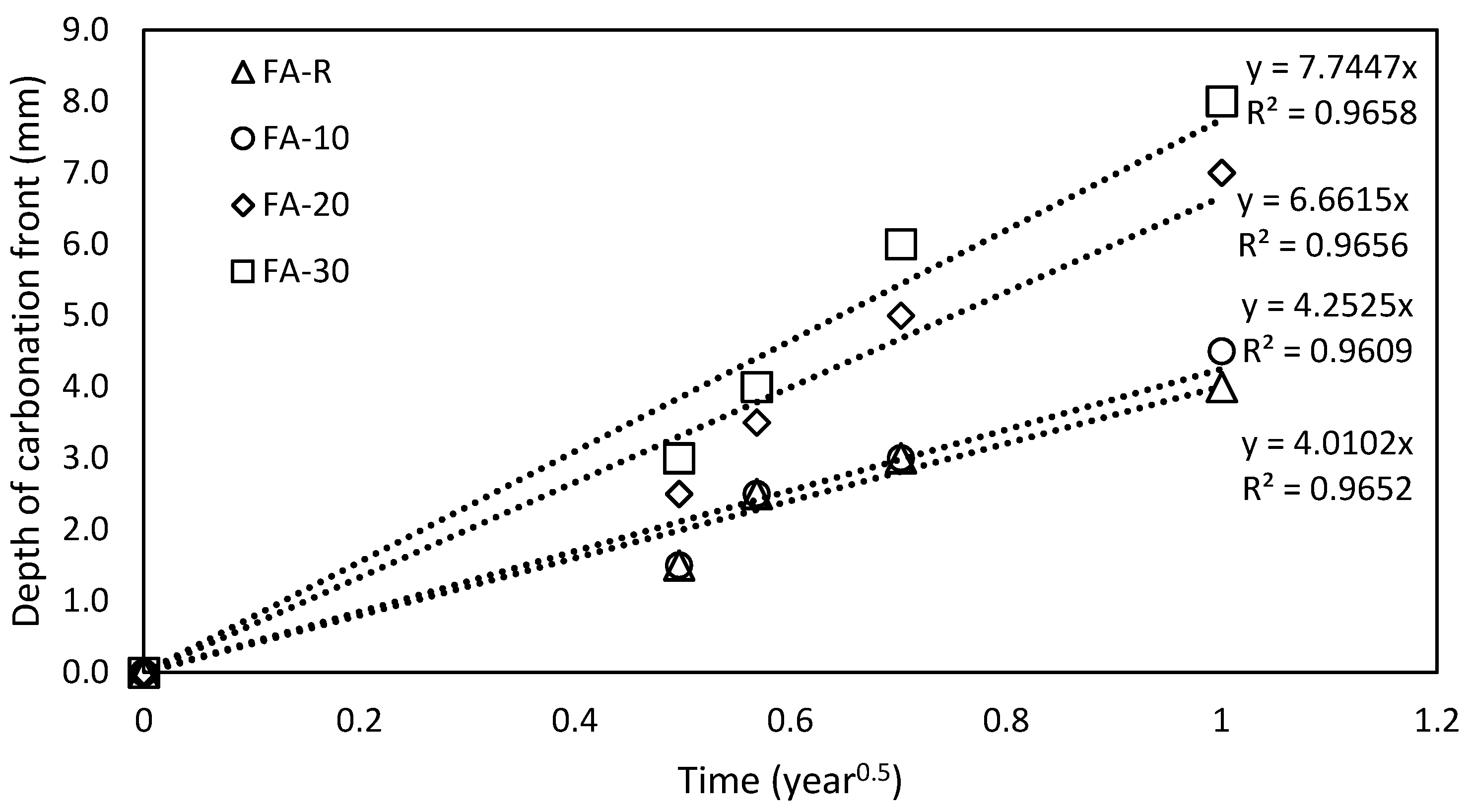

3.2.6. Carbonation

3.2.7. Shrinkage

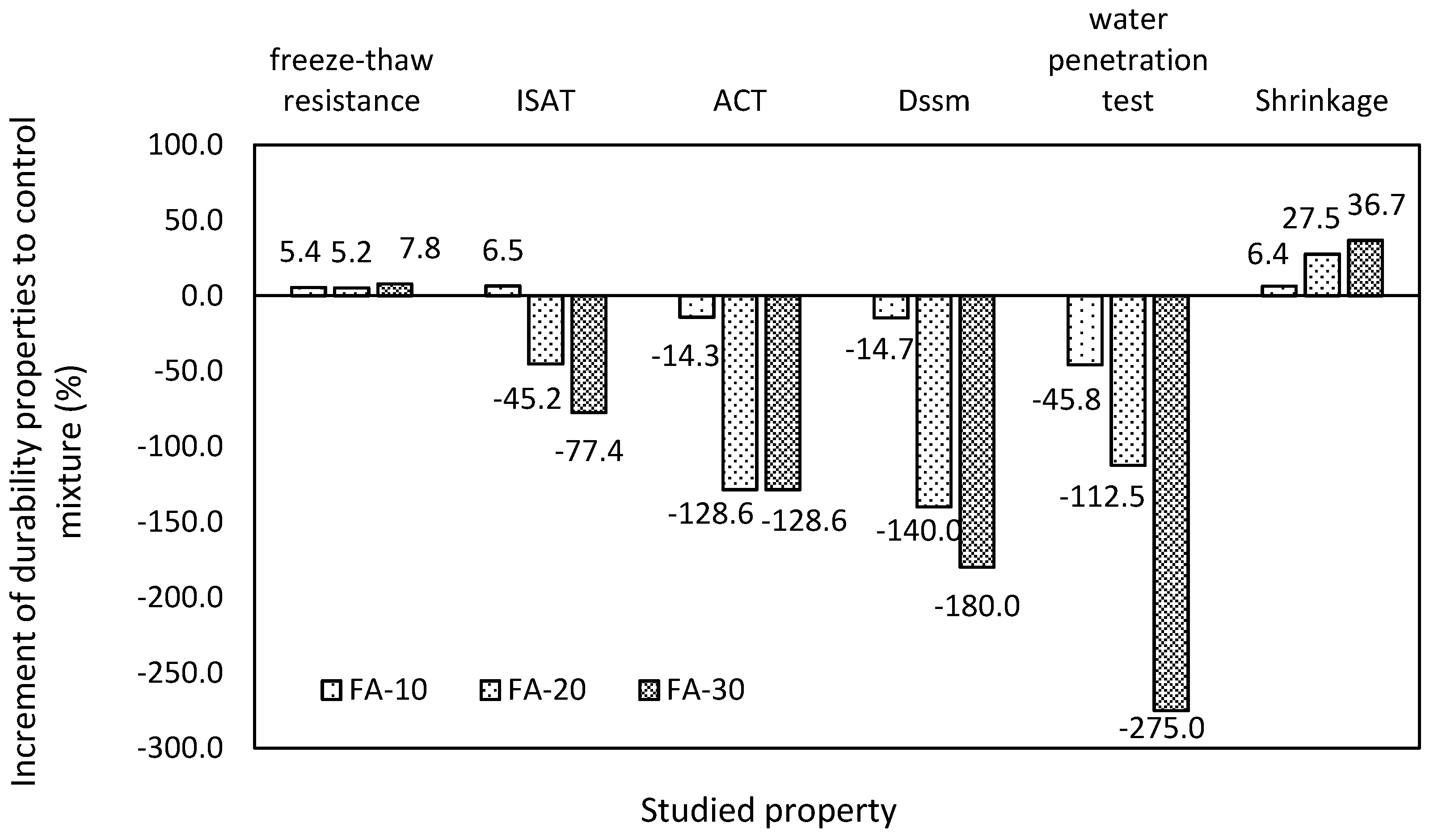

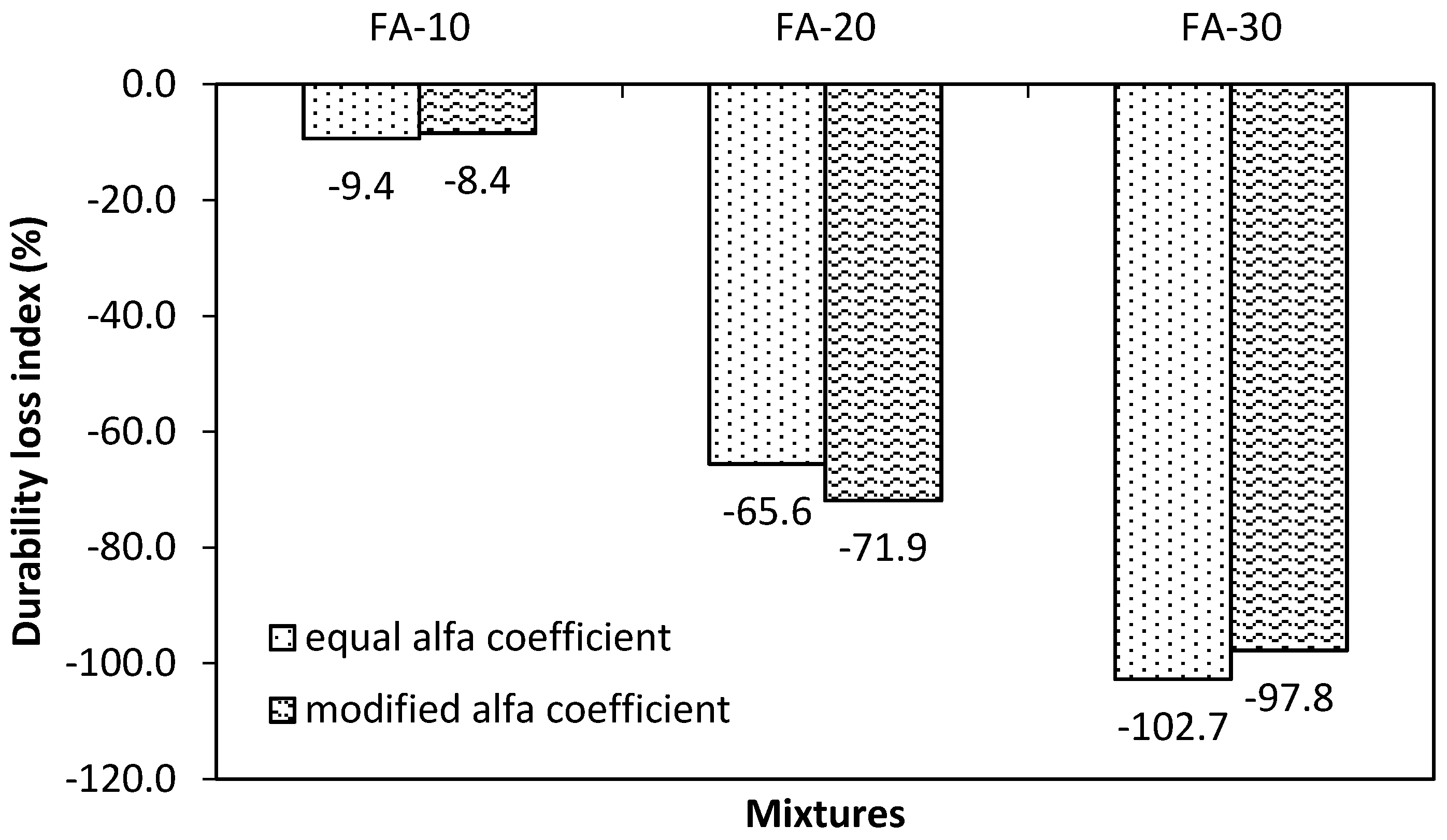

3.2.8. Durability Loss Index (DLI)

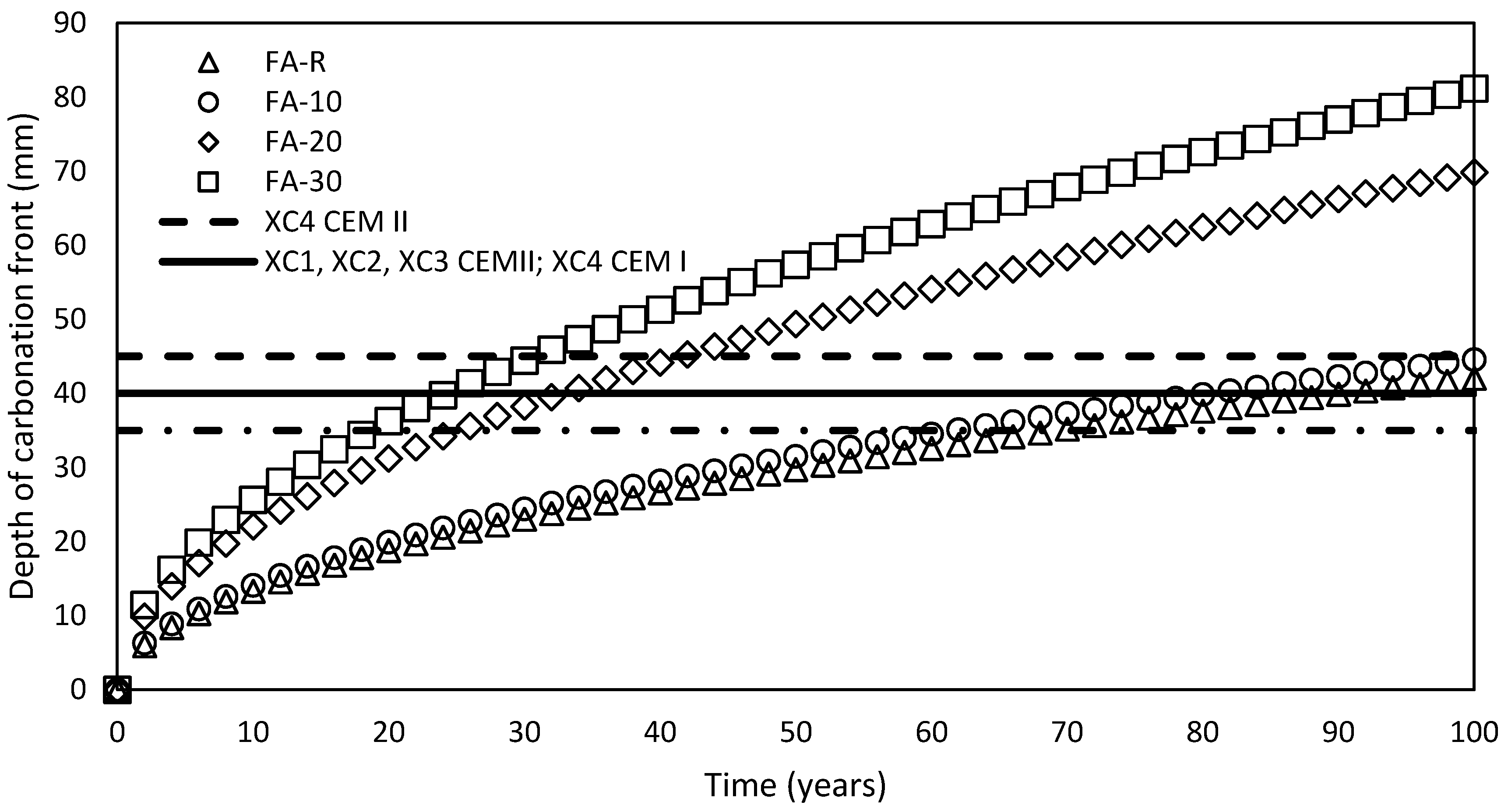

3.2.9. Service Life Prediction.

4. Conclusions

- (1)

- Mixtures designed in terms of proposed concept reached similar workability as control mixture; all mixtures satisfied self-compacting criteria without additional dosage of chemical admixtures. However, the lowest applied fly ash replacement exhibited a slight increase in workability due to higher air-entraining.

- (2)

- The proposed design of the binding system ensures similar or slightly higher values of compressive strength, especially from the long-term point of view.

- (3)

- An increase of mechanical performance was negligible after 180 days of curing. Mixtures containing fly ash exhibited higher flexural strength in comparison with the control mixture. The lowest dose of fly ash led to the increment of compressive strength by approximately 10%, while additional increase of fly ash replacement maintained compressive strength equal to the control mixture.

- (4)

- The gradual increase of cement replacement by fly ash led to a significant reduction of shrinkage and improvement of freeze-thaw resistance.

- (5)

- Replacement by fly ash in proposed procedure indicated a significant increase of permeability controlling carbonation, water penetration and chloride migration, which increases the risk of embedded steel corrosion. It was caused by gradual substitution of finer limestone filler by coarser fly ash.

- (6)

- SCC mixture with the lowest applied cement replacement exhibited reduced, but still acceptable, durability performance. Despite increased water penetration, this mixture obtained similar absolute values in terms of chloride migration and carbonation depth.

- (7)

- Final derived values of DLI of individual concrete mixtures were dominantly affected by the results of carbonation tests.

- (8)

- DLI offers a useful tool for the evaluation of concrete mixtures in terms of various criteria. In addition, the choice of the values of weight factors for single criterion allows the assessment of different exposures or experimental setups. The calculation of DLI indicates that optimal proportion of ternary binding system should kept the level of fly ash for these type mixtures below 13 wt.%.

Author Contributions

Funding

Conflicts of Interest

References

- Assi, L.; Carter, K.; Deaver, E.; Anay, R.; Ziehl, P. Sustainable concrete: Building a greener future. J. Clean. Prod. 2018, 198, 1641–1651. [Google Scholar] [CrossRef]

- Andrew, R. Global CO2 emissions from cement production. Earth Syst. Sci. Data 2017. [Google Scholar] [CrossRef]

- Habert, G. Assessing the Environmental Impact of Conventional and ‘green’ Cement Production. In Eco-efficient Construction and Building Materials; Elsevier: Amsterdam, The Netherlands, 2014; pp. 199–238. [Google Scholar] [CrossRef]

- Schneider, M.; Romer, M.; Tschudin, M.; Bolio, H. Sustainable Cement Production—Present and Future. Cem. Concr. Res. 2011, 41, 642–650. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Proce, L.; Lin, E. Emerging energy-efficiency and CO2 emission-reduction technologies for cement and concrete production: A technical review. Renew. Sust. Energ. Rev. 2012, 16, 6220–6238. [Google Scholar] [CrossRef]

- Reiterman, P.; Holčapek, O.; Davidová, V.; Jaskulski, R.; Keppert, M. Estimation of Hydration Degree of Blended Cements with the Help of K-Values. Materials 2019, 12, 2420. [Google Scholar] [CrossRef]

- Al-Mansour, A.; Chow, C.L.; Feo, L.; Penna, R.; Lau, D. Green Concrete: By-Products Utilization and Advanced Approaches. Sustainability 2019, 11, 5145. [Google Scholar] [CrossRef]

- Wilińska, I.; Pacewska, B. Influence of Selected Activating Methods on Hydration Processes of Mixtures Containing High and Very High Amount of Fly Ash. J. Therm. Anal. Calorim. 2018, 133, 823–843. [Google Scholar] [CrossRef]

- Pavlíková, M.; Zemanová, L.; Pokorný, J.; Záleská, M.; Jankovský, O.; Lojka, M.; Sedmidubský, D.; Pavlík, Z. Valorization of Wood Chips Ash as an Eco-Friendly Mineral Admixture in Mortar Mix Design. Waste Manag. 2018, 80, 89–100. [Google Scholar] [CrossRef]

- Ishak, S.A.; Hashim, H. Low Carbon Measures for Cement Plant—A Review. J. Clean. Prod. 2015, 103, 260–274. [Google Scholar] [CrossRef]

- Dvorak, K.; Dolak, D.; Vsiansky, D.; Dobrovolny, P. Evaluation of the Grindability of Recycled Glass in the Production of Blended Cements. Mater. Tehnol. 2016, 50, 729–734. [Google Scholar] [CrossRef]

- Lothenbach, B.; Scrivener, K.; Hooton, R.D. Supplementary Cementitious Materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- Haider, U.; Bittnar, Z.; Kopecky, L.; Šmilauer, V.; Pokorny, J.; Zaleska, M.; Prošek, Z.; Hrbek, V. Determining the role of individual fly ash particles in the overall physical, morphological, and chemical properties of fly ash. Acta Polytech. 2016, 56, 265–282. [Google Scholar] [CrossRef]

- Kubissa, W.; Jaskulski, R.; Reiterman, P. Ecological Concrete Based on Blast-Furnace Cement with Incorporated Coarse Recycled Concrete Aggregate and Fly Ash Addition. J. Renew. Mater. 2017, 5, 53–61. [Google Scholar] [CrossRef]

- Yang, J.; Huang, J.; Su, Y.; He, X.; Tan, H.; Yang, W.; Strnadel, B. Eco-Friendly Treatment of Low-Calcium Coal Fly Ash for High Pozzolanic Reactivity: A Step towards Waste Utilization in Sustainable Building Material. J. Clean. Prod. 2019, 238, 117962. [Google Scholar] [CrossRef]

- BS EN 450 1: Fly Ash for Concrete. Definition, Specifications and Conformity Criteria; British Standards Institution: London, UK, 2012.

- Pacewska, B.; Blonkowski, G.; Wilińska, I. Investigations of the Influence of Different Fly Ashes on Cement Hydration. J. Therm. Anal. Calorim. 2006, 86, 179–186. [Google Scholar] [CrossRef]

- Pacewska, B.; Blonkowski, G.; Wilińska, I. Studies on the Pozzolanic and Hydraulic Properties of Fly Ashes in Model Systems. J. Therm. Anal. Calorim. 2008, 94, 469–476. [Google Scholar] [CrossRef]

- Turgut, P.; Demir, F. The Influence of Disposed Fly Ash on Ca2+ Leaching and Physico-Mechanical Properties of Mortars. J. Clean. Prod. 2019, 226, 270–281. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Saffari, M.; Milani, D.; Montoya, A.; Valix, M.; Abbas, A. Sustainable Transformation of Fly Ash Industrial Waste into a Construction Cement Blend via CO2 Carbonation. J. Clean. Prod. 2017, 156, 660–669. [Google Scholar] [CrossRef]

- Drochytka, R.; Černý, V. Influence of Fluidized Bed Combustion Fly Ash Admixture on Hydrothermal Synthesis of Tobermorite in the Mixture with Quartz Sand, High Temperature Fly Ash and Lime. Constr. Build. Mater. 2020, 230, 117033. [Google Scholar] [CrossRef]

- Hlaváček, P.; Šulc, R.; Šmilauer, V.; Rößler, C.; Snop, R. Ternary Binder Made of CFBC Fly Ash, Conventional Fly Ash, and Calcium Hydroxide: Phase and Strength Evolution. Cem. Concr. Compos. 2018, 90, 100–107. [Google Scholar] [CrossRef]

- Pacewska, B.; Wilińska, I. Comparative Investigations of Influence of Chemical Admixtures on Pozzolanic and Hydraulic Activities of Fly Ash with the Use of Thermal Analysis and Infrared Spectroscopy. J. Therm. Anal. Calorim. 2014, 120, 119–127. [Google Scholar] [CrossRef]

- Siddique, R. Properties of Self-Compacting Concrete Containing Class F Fly Ash. Mater. Des. 2011, 32, 1501–1507. [Google Scholar] [CrossRef]

- Altoubat, S.; Talha Junaid, M.; Leblouba, M.; Badran, D. Effectiveness of Fly Ash on the Restrained Shrinkage Cracking Resistance of Self-Compacting Concrete. Cem. Concr. Compos. 2017, 79, 9–20. [Google Scholar] [CrossRef]

- Davidova, V.; Reiterman, P. Shrinkage of various types of Portland clinker-based cements with respect to their hydration degree. Acta Polytech. 2020, 60, 88–97. [Google Scholar] [CrossRef]

- Yazıcı, H. The Effect of Silica Fume and High-Volume Class C Fly Ash on Mechanical Properties, Chloride Penetration and Freeze-thaw Resistance of Self-Compacting Concrete. Constr. Build. Mater. 2008, 22, 456–462. [Google Scholar] [CrossRef]

- Kledyński, Z.; Machowska, A.; Pacewska, B.; Wilińska, I. Investigation of Hydration Products of Fly Ash–slag Pastes. J. Therm. Anal. Calorim. 2017, 130, 351–363. [Google Scholar] [CrossRef]

- De Weerdt, K.; Kjellsen, K.O.; Sellevold, E.; Justnes, H. Synergy between Fly Ash and Limestone Powder in Ternary Cements. Cem. Concr. Compos. 2011, 33, 30–38. [Google Scholar] [CrossRef]

- Celik, K.; Jackson, M.D.; Mancio, M.; Meral, C.; Emwas, A.-H.; Mehta, P.K.; Monteiro, P.J.M. High-Volume Natural Volcanic Pozzolan and Limestone Powder as Partial Replacements for Portland Cement in Self-Compacting and Sustainable Concrete. Cem. Concr. Compos. 2014, 45, 136–147. [Google Scholar] [CrossRef]

- CSN EN 206-1 Concrete—Specification, Performance, Production and Conformity; Czech Standard Institute: Prague, Czech Republic, 2014.

- Matschei, T.; Lothenbach, B.; Glasser, F.P. The Role of Calcium Carbonate in Cement Hydration. Cem. Concr. Res. 2007, 37, 551–558. [Google Scholar] [CrossRef]

- Poppe, A.M.; De Schutter, G. Cement Hydration in the Presence of High Filler Contents. Cem. Concr. Res. 2005, 35, 2290–2299. [Google Scholar] [CrossRef]

- Bonavetti, V.; Donza, H.; Rahhal, V.; Irassar, E. Influence of Initial Curing on the Properties of Concrete Containing Limestone Blended Cement. Cem. Concr. Res. 2000, 30, 703–708. [Google Scholar] [CrossRef]

- Lothenbach, B.; Le Saout, G.; Gallucci, E.; Scrivener, K. Influence of Limestone on the Hydration of Portland Cements. Cem. Concr. Res. 2008, 38, 848–860. [Google Scholar] [CrossRef]

- Ipavec, A.; Gabrovšek, R.; Vuk, T.; Kaučič, V.; Maček, J.; Meden, A. Carboaluminate Phases Formation during the Hydration of Calcite-Containing Portland Cement. J. Am. Ceram. Soc. 2010, 94, 1238–1242. [Google Scholar] [CrossRef]

- Felekoğlu, B.; Tosun, K.; Baradan, B.; Altun, A.; Uyulgan, B. The Effect of Fly Ash and Limestone Fillers on the Viscosity and Compressive Strength of Self-Compacting Repair Mortars. Cem. Concr. Res. 2006, 36, 1719–1726. [Google Scholar] [CrossRef]

- Gesoğlu, M.; Güneyisi, E.; Kocabağ, M.E.; Bayram, V.; Mermerdaş, K. Fresh and Hardened Characteristics of Self Compacting Concretes Made with Combined Use of Marble Powder, Limestone Filler, and Fly Ash. Constr. Build. Mater. 2012, 37, 160–170. [Google Scholar] [CrossRef]

- Bentz, D.P.; Peltz, M.A.; Winpigler, J. Early-Age Properties of Cement-Based Materials. II: Influence of Water-to-Cement Ratio. J. Mater. Civil Eng. 2009, 21, 512–517. [Google Scholar] [CrossRef]

- Singh, N.; Kumar, P.; Goyal, P. Reviewing the Behaviour of High Volume Fly Ash Based Self Compacting Concrete. J. Build. Eng. 2019, 26, 100882. [Google Scholar] [CrossRef]

- Aslani, F.; Maia, L. Creep and Shrinkage of High-Strength Self-Compacting Concrete: Experimental and Analytical Analysis. Mag. Concr. Res. 2013, 65, 1044–1058. [Google Scholar] [CrossRef]

- Jiang, L.; Lin, B.; Cai, Y. A Model for Predicting Carbonation of High-Volume Fly Ash Concrete. Cem. Concr. Res. 2000, 30, 699–702. [Google Scholar] [CrossRef]

- Bentz, D.P.; Sato, T.; de la Varga, I.; Weiss, W.J. Fine Limestone Additions to Regulate Setting in High Volume Fly Ash Mixtures. Cem. Concr. Compos. 2012, 34, 11–17. [Google Scholar] [CrossRef]

- Bederina, M.; Makhloufi, Z.; Bouziani, T. Effect of Limestone Fillers the Physic-Mechanical Properties of Limestone Concrete. Phys. Procedia 2011, 21, 28–34. [Google Scholar] [CrossRef]

- Duran-Herrera, A.; De-León-Esquivel, J.; Bentz, D.P.; Valdez-Tamez, P. Self-Compacting Concretes Using Fly Ash and Fine Limestone Powder: Shrinkage and Surface Electrical Resistivity of Equivalent Mortars. Constr. Build. Mater. 2019, 199, 50–62. [Google Scholar] [CrossRef]

- Boel, V.; Audenaert, K.; De Schutter, G.; Heirman, G.; Vandewalle, L.; Desmet, B.; Vantomme, J. Transport Properties of Self Compacting Concrete with Limestone Filler or Fly Ash. Mater. Struct. 2006, 40, 507–516. [Google Scholar] [CrossRef]

- Gesoğlu, M.; Güneyisi, E.; Özbay, E. Properties of Self-Compacting Concretes Made with Binary, Ternary, and Quaternary Cementitious Blends of Fly Ash, Blast Furnace Slag, and Silica Fume. Constr. Build. Mater. 2009, 23, 1847–1854. [Google Scholar] [CrossRef]

- Doebelin, N.; Kleeberg, R. Profex: A Graphical User Interface for the Rietveld Refinement program BGMN. J. Appl. Crystallogr. 2015, 48, 1573–1580. [Google Scholar] [CrossRef]

- Keppert, M.; Urbanová, M.; Brus, J.; Čáchová, M.; Fořt, J.; Trník, A.; Scheinherrová, L.; Záleská, M.; Černý, R. Rational Design of Cement Composites Containing Pozzolanic Additions. Constr. Build. Mater. 2017, 148, 411–418. [Google Scholar] [CrossRef]

- CSN EN 12350-8: Testing Fresh Concrete—Part 8: Self-Compacting Concrete. Slump-Flow Test; Czech Standard Institute: Prague, Czech Republic, 2010.

- CSN EN 12350-12: Testing Fresh Concrete—Part 12: Self-Compacting Concrete. J-Ring Test; Czech Standard Institute: Prague, Czech Republic, 2010.

- CSN EN 12350-10: Testing Fresh Concrete—Part 10: Self-Compacting Concrete. L-Box Test; Czech Standard Institute: Prague, Czech Republic, 2010.

- CSN EN 12350-7: Testing Fresh Concrete—Part 7: Air Content Pressure Methods; Czech Standard Institute: Prague, Czech Republic, 2009.

- CSN EN 12390-3: Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens; Czech Standard Institute: Prague, Czech Republic, 2009.

- CSN EN 12390-5: Testing Hardened Concrete—Part 5: Flexural Strength of Test Specimens; Czech Standard Institute: Prague, Czech Republic, 2009.

- Chan, S.Y.; Ji, X. Comparative Study of the Initial Surface Absorption and Chloride Diffusion of High Performance Zeolite, Silica Fume and PFA Concretes. Cem. Concr. Compos. 1999, 21, 293–300. [Google Scholar] [CrossRef]

- Claisse, P.A. Surface Tests to Determine Transport Properties of Concrete I: The Tests. In Transport Properties of Concrete; Elsevier: Cambridge, UK, 2014; pp. 26–42. [Google Scholar] [CrossRef]

- CSN EN 12390-8: Testing Hardened Concrete—Part 8: Depth of Penetration of Water under Pressure; Czech Standard Institute: Prague, Czech Republic, 2009.

- Nordtest Method NT Build 492. Concrete, Mortar and Cement-Based Repair Materials: Chloride Migration Coefficient from non-Steady-State Migration Experiments; NORDTEST: Espoo, Finland, 1999.

- CSN 731322–Determination of frost resistance of concrete; Czech Standard Institute: Prague, Czech Republic, 2003.

- CSN EN 13295: Products and Systems for the Protection and Repair of Concrete Structures—Test Methods—Determination of Resistance to Carbonation; Czech Standard Institute: Prague, Czech Republic, 2004.

- Reiterman, P.; Holčapek, O.; Jaskulski, R.; Kubissa, W. Long-Term Behaviour of Ceramic Powder Containing Concrete for Pavement Blocks. Int. J. Pavement Eng. 2020, 1–8. [Google Scholar] [CrossRef]

- EHE-08 Instrucción Hormigón Estructural; Ministerio de Fomento: Madrid, Spain, 2008.

- Sáez del Bosque, I.F.; Van den Heede, P.; De Belie, N.; Sánchez de Rojas, M.I.; Medina, C. Carbonation of Concrete with Construction and Demolition Waste Based Recycled Aggregates and Cement with Recycled Content. Constr. Build. Mater. 2020, 234, 117336. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Nosouhian, F.; Nazari-Monfared, H. Influence of Magnesium Sulphate Concentration on Durability of Concrete Containing Micro-Silica, Slag and Limestone Powder Using Durability Index. Constr. Build. Mater. 2016, 117, 107–120. [Google Scholar] [CrossRef]

- Sun, Z.; Scherer, G.W. Effect of Air Voids on Salt Scaling and Internal Freezing. Cem. Concr. Res. 2010, 40, 260–270. [Google Scholar] [CrossRef]

- Puthipad, N.; Ouchi, M.; Rath, S.; Attachaiyawuth, A. Enhancement in Self-Compactability and Stability in Volume of Entrained Air in Self-Compacting Concrete with High Volume Fly Ash. Constr. Build. Mater. 2016, 128, 349–360. [Google Scholar] [CrossRef]

- Rath, S.; Ouchi, M.; Puthipad, N.; Attachaiyawuth, A. Improving the Stability of Entrained Air in Self-Compacting Concrete by Optimizing the Mix Viscosity and Air Entraining Agent Dosage. Constr. Build. Mater. 2017, 148, 531–537. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Algin, Z. Performance of Self-Compacting Concrete (SCC) with High-Volume Supplementary Cementitious Materials (SCMs). In Eco-Efficient Concrete; Elsevier: Amsterdam, The Netherlands, 2013; pp. 198–217. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. Influence of Recycled Aggregates and High Contents of Fly Ash on Concrete Fresh Properties. Cem. Concr. Compos. 2017, 84, 198–213. [Google Scholar] [CrossRef]

- Puthipad, N.; Ouchi, M.; Attachaiyawuth, A. Effects of Fly Ash, Mixing Procedure and Type of Air-Entraining Agent on Coalescence of Entrained Air Bubbles in Mortar of Self-Compacting Concrete at Fresh State. Constr. Build. Mater. 2018, 180, 437–444. [Google Scholar] [CrossRef]

- Jones, M.R.; Ozlutas, K.; Zheng, L. Stability and Instability of Foamed Concrete. Mag. Concr. Res. 2016, 68, 542–549. [Google Scholar] [CrossRef]

- Mendes, J.C.; Moro, T.K.; Figueiredo, A.S.; Silva, K.D.; Silva, G.C.; Silva, G.J.B.; Peixoto, R.A.F. Mechanical, Rheological and Morphological Analysis of Cement-Based Composites with a New LAS-Based Air Entraining Agent. Constr. Build. Mater. 2017, 145, 648–661. [Google Scholar] [CrossRef]

- Ghorbani, S.; Ghorbani, S.; Tao, Z.; de Brito, J.; Tavakkolizadeh, M. Effect of Magnetized Water on Foam Stability and Compressive Strength of Foam Concrete. Constr. Build. Mater. 2019, 197, 280–290. [Google Scholar] [CrossRef]

- Zhang, D.S. Air Entrainment in Fresh Concrete with PFA. Cem. Concr. Compos. 1996, 18, 409–416. [Google Scholar] [CrossRef]

- Jiang, L.; Malhotra, V. Reduction in Water Demand of Non-Air-Entrained Concrete Incorporating Large Volumes of Fly Ash. Cem. Concr. Res. 2000, 30, 1785–1789. [Google Scholar] [CrossRef]

- De Matos, P.R.; Foiato, M.; Prudêncio, L.R., Jr. Ecological, Fresh State and Long-Term Mechanical Properties of High-Volume Fly Ash High-Performance Self-Compacting Concrete. Constr. Build. Mater. 2019, 203, 282–293. [Google Scholar] [CrossRef]

- Moghaddam, F.; Sirivivatnanon, V.; Vessalas, K. The Effect of Fly Ash Fineness on Heat of Hydration, Microstructure, Flow and Compressive Strength of Blended Cement Pastes. Case Stud. Constr. Mater. 2019, 10, e00218. [Google Scholar] [CrossRef]

- Esquinas, A.R.; Ledesma, E.F.; Otero, R.; Jiménez, J.R.; Fernández, J.M. Mechanical Behaviour of Self-Compacting Concrete Made with Non-Conforming Fly Ash from Coal-Fired Power Plants. Constr. Build. Mater. 2018, 182, 385–398. [Google Scholar] [CrossRef]

- Liu, M. Self-Compacting Concrete with Different Levels of Pulverized Fuel Ash. Constr. Build. Mater. 2010, 24, 1245–1252. [Google Scholar] [CrossRef]

- Yu, J.; Lu, C.; Leung, C.K.Y.; Li, G. Mechanical Properties of Green Structural Concrete with Ultrahigh-Volume Fly Ash. Constr. Build. Mater. 2017, 147, 510–518. [Google Scholar] [CrossRef]

- De Weerdt, K.; Haha, M.B.; Le Saout, G.; Kjellsen, K.O.; Justnes, H.; Lothenbach, B. Hydration Mechanisms of Ternary Portland Cements Containing Limestone Powder and Fly Ash. Cem. Concr. Res. 2011, 41, 279–291. [Google Scholar] [CrossRef]

- Shaikh, F.U.A.; Supit, S.W.M. Mechanical and Durability Properties of High Volume Fly Ash (HVFA) Concrete Containing Calcium Carbonate (CaCO3) Nanoparticles. Constr. Build. Mater. 2014, 70, 309–321. [Google Scholar] [CrossRef]

- Shaikh, F.U.A.; Supit, S.W.M. Compressive Strength and Durability Properties of High Volume Fly Ash (HVFA) Concretes Containing Ultrafine Fly Ash (UFFA). Constr. Build. Mater. 2015, 82, 192–205. [Google Scholar] [CrossRef]

- Sahmaran, M.; Yildirim, G.; Erdem, T.K. Self-Healing Capability of Cementitious Composites Incorporating Different Supplementary Cementitious Materials. Cem. Concr. Compos. 2013, 35, 89–101. [Google Scholar] [CrossRef]

- Soriano, L.; Monzó, J.; Bonilla, M.; Tashima, M.M.; Payá, J.; Borrachero, M.V. Effect of Pozzolans on the Hydration Process of Portland Cement Cured at Low Temperatures. Cem. Concr. Compos. 2013, 42, 41–48. [Google Scholar] [CrossRef]

- Reiterman, P.; Holčapek, O.; Zobal, O.; Keppert, M. Freeze-Thaw Resistance of Cement Screed with Various Supplementary Cementitious Materials. Rev. Adv. Mater. Sci. 2019, 58, 66–74. [Google Scholar] [CrossRef]

- De Belie, N.; Gruyaert, E.; Al-Tabbaa, A.; Antonaci, P.; Baera, C.; Bajare, D.; Darquennes, A.; Davies, R.; Ferrara, L.; Jefferson, T.; et al. A Review of Self-Healing Concrete for Damage Management of Structures. Adv. Mater. Interfaces 2018, 5, 1800074. [Google Scholar] [CrossRef]

- Da Silva, P.R.; de Brito, J. Experimental Study of the Porosity and Microstructure of Self-Compacting Concrete (SCC) with Binary and Ternary Mixes of Fly Ash and Limestone Filler. Constr. Build. Mater. 2015, 86, 101–112. [Google Scholar] [CrossRef]

- Li, K.; Zhang, D.; Li, Q.; Fan, Z. Durability for Concrete Structures in Marine Environments of HZM Project: Design, Assessment and beyond. Cem. Concr. Res. 2019, 115, 545–558. [Google Scholar] [CrossRef]

- Thomas, M. The durability of concrete for marine construction: Materials and properties. In Marine Concrete Structures; Alexander, M.G., Ed.; Woodhead Publishing: Cambridge, UK, 2016; pp. 151–170. [Google Scholar]

- Moffat, E.G.; Thomas, M.D.A.; Fahim, A. Performance of high-volume fly ash concrete in marine environment. Cem. Concr. Res. 2017, 102, 127–135. [Google Scholar] [CrossRef]

- Celik, K.; Meral, C.; Gursel, A.P.; Mehta, P.K.; Horvath, A.; Monteiro, P.J.M. Mechanical properties, durability and life-cycle assessment of self-consolidating concrete mixtures made with blended Portland cements containing fly ash and limestone powder. Cem. Concr. Compos. 2015, 56, 59–72. [Google Scholar] [CrossRef]

- Singh, N.; Singh, S.P. Carbonation Resistance and Microstructural Analysis of Low and High Volume Fly Ash Self Compacting Concrete Containing Recycled Concrete Aggregates. Constr. Build. Mater. 2016, 127, 828–842. [Google Scholar] [CrossRef]

- Esquinas, A.R.; Álvarez, J.I.; Jiménez, J.R.; Fernández, J.M. Durability of Self-Compacting Concrete Made from Non-Conforming Fly Ash from Coal-Fired Power Plants. Constr. Build. Mater. 2018, 189, 993–1006. [Google Scholar] [CrossRef]

- Silva, P.; de Brito, J. Experimental Study of the Mechanical Properties and Shrinkage of Self-Compacting Concrete with Binary and Ternary Mixes of Fly Ash and Limestone Filler. Eur. J. Environ. Civ. Eng. 2016, 21, 430–453. [Google Scholar] [CrossRef]

- Rahimi-Aghdam, S.; Masoero, E.; Rasoolinejad, M.; Bažant, Z.P. Century-Long Expansion of Hydrating Cement Counteracting Concrete Shrinkage due to Humidity Drop from Selfdesiccation or External Drying. Mater. Struct. 2019, 52. [Google Scholar] [CrossRef]

- Wang, X.H.; Val, D.V.; Zheng, L.; Jones, M.R. Carbonation of Loaded RC Elements Made of Different Concrete Types: Accelerated Testing and Future Predictions. Constr. Build. Mater. 2020, 243, 118259. [Google Scholar] [CrossRef]

- Singh, N.; Singh, S.P. Carbonation and Electrical Resistance of Self Compacting Concrete Made with Recycled Concrete Aggregates and Metakaolin. Constr. Build. Mater. 2016, 121, 400–409. [Google Scholar] [CrossRef]

- Pacheco Torgal, F.; Miraldo, S.; Labrincha, J.A.; De Brito, J. An Overview on Concrete Carbonation in the Context of Eco-Efficient Construction: Evaluation, Use of SCMs And/Or RAC. Constr. Build. Mater. 2012, 36, 141–150. [Google Scholar] [CrossRef]

- Marques, P.F.; Chastre, C.; Nunes, Â. Carbonation Service Life Modelling of RC Structures for Concrete with Portland and Blended Cements. Cem. Concr. Compos. 2013, 37, 171–184. [Google Scholar] [CrossRef]

- Reiterman, P.; Keppert, M. Effect of Various de-Icers Containing Chloride Ions on Scaling Resistance and Chloride Penetration Depth of Highway Concrete. Roads Bridges Drog. Mosty 2020, 19, 51–64. [Google Scholar] [CrossRef]

| Binding Component | SiO2 (%) | Al2O3 (%) | Fe2O3 (%) | CaO (%) | MgO (%) | Na2O (%) | SO3 (%) | K2O (%) | TiO2 (%) | LOI (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| Cement | 18.1 | 6.4 | 2.4 | 64.9 | 1.0 | 0.3 | 4.9 | 1.2 | 0.8 | 1.1 |

| Fly ash | 52.4 | 35.9 | 4.9 | 1.2 | 0.8 | - | 0.2 | 1.4 | 2.4 | 2.8 |

| Amorphous Components | 60.0 |

| Quartz | 7.9 |

| Mullite | 28.8 |

| Magnesioferrite | 1.5 |

| Anhydrite | 0.7 |

| Hematite | 1.2 |

| Components | FA-R | FA-10 | FA-20 | FA-30 |

|---|---|---|---|---|

| CEM I 52.5 R (kg/m3) | 355.0 | 319.5 | 284.0 | 248.5 |

| Milled limestone (kg/m3) | 95 | 71.3 | 47.7 | 24.0 |

| Fly ash (kg/m3) | 0 | 59.2 | 118.3 | 177.5 |

| Sand 0–4 mm (kg/m3) | 1030 | 1030 | 1030 | 1030 |

| Crushed agg. 4–8 mm (kg/m3) | 270 | 270 | 270 | 270 |

| Crushed agg. 4–8 mm (kg/m3) | 400 | 400 | 400 | 400 |

| Plasticizer (kg/m3) | 3.8 | 3.8 | 3.8 | 3.8 |

| Retarding agent (kg/m3) | 1.5 | 1.5 | 1.5 | 1.5 |

| Water (kg/m3) | 190 | 190 | 190 | 190 |

| PC-FA-LS (%) | 79.0-0-21.0 | 71.0-13.1-15.9 | 63.1-26.2-10.6 | 55.2-39.4-5.3 |

| w/(PC + FA + LS) | 0.42 | 0.42 | 0.42 | 0.42 |

| w/(PC + FA) | 0.54 | 0.50 | 0.47 | 0.45 |

| ISAT10 min (g·m−2s−1) | Permeability Classification of Concrete | ||

| Low | Average | High | |

| <0.25 | 0.25–0.50 | >0.50 | |

| Freeze-Thaw Resistance | ISAT | ACT | Dssm | Water Penetration Test | Shrinkage |

|---|---|---|---|---|---|

| 0.25 | 0.10 | 0.25 | 0.20 | 0.10 | 0.10 |

| Properties of Fresh Concrete | FA-R | FA-10 | FA-20 | FA-30 |

|---|---|---|---|---|

| Air content (%) | 5.0 | 5.3 | 5.2 | 4.9 |

| Slump-flow test (mm) | 620 | 690 | 650 | 620 |

| J-Ring test (mm) | 590 | 680 | 620 | 590 |

| L-Box test (-) | 0.92 | 0.95 | 0.96 | 0.95 |

| Mixture | Depassivation Time (Years) | Minimum Cover for 100 Years (mm) | ||

|---|---|---|---|---|

| CEM I XC1, XC2, XC3 | CEM I XC4 CEM II XC1, XC2, XC3 | CEM II XC4 | ||

| FA-R | 69 | 91 | 115 | 42 |

| FA-10 | 62 | 81 | 102 | 45 |

| FA-20 | 25 | 33 | 42 | 70 |

| FA-30 | 19 | 24 | 31 | 81 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reiterman, P.; Jaskulski, R.; Kubissa, W.; Holčapek, O.; Keppert, M. Assessment of Rational Design of Self-Compacting Concrete Incorporating Fly Ash and Limestone Powder in Terms of Long-Term Durability. Materials 2020, 13, 2863. https://doi.org/10.3390/ma13122863

Reiterman P, Jaskulski R, Kubissa W, Holčapek O, Keppert M. Assessment of Rational Design of Self-Compacting Concrete Incorporating Fly Ash and Limestone Powder in Terms of Long-Term Durability. Materials. 2020; 13(12):2863. https://doi.org/10.3390/ma13122863

Chicago/Turabian StyleReiterman, Pavel, Roman Jaskulski, Wojciech Kubissa, Ondřej Holčapek, and Martin Keppert. 2020. "Assessment of Rational Design of Self-Compacting Concrete Incorporating Fly Ash and Limestone Powder in Terms of Long-Term Durability" Materials 13, no. 12: 2863. https://doi.org/10.3390/ma13122863

APA StyleReiterman, P., Jaskulski, R., Kubissa, W., Holčapek, O., & Keppert, M. (2020). Assessment of Rational Design of Self-Compacting Concrete Incorporating Fly Ash and Limestone Powder in Terms of Long-Term Durability. Materials, 13(12), 2863. https://doi.org/10.3390/ma13122863