Superelastic Behavior of Ti-Nb Alloys Obtained by the Laser Engineered Net Shaping (LENS) Technique

Abstract

1. Introduction

2. Materials and Methods

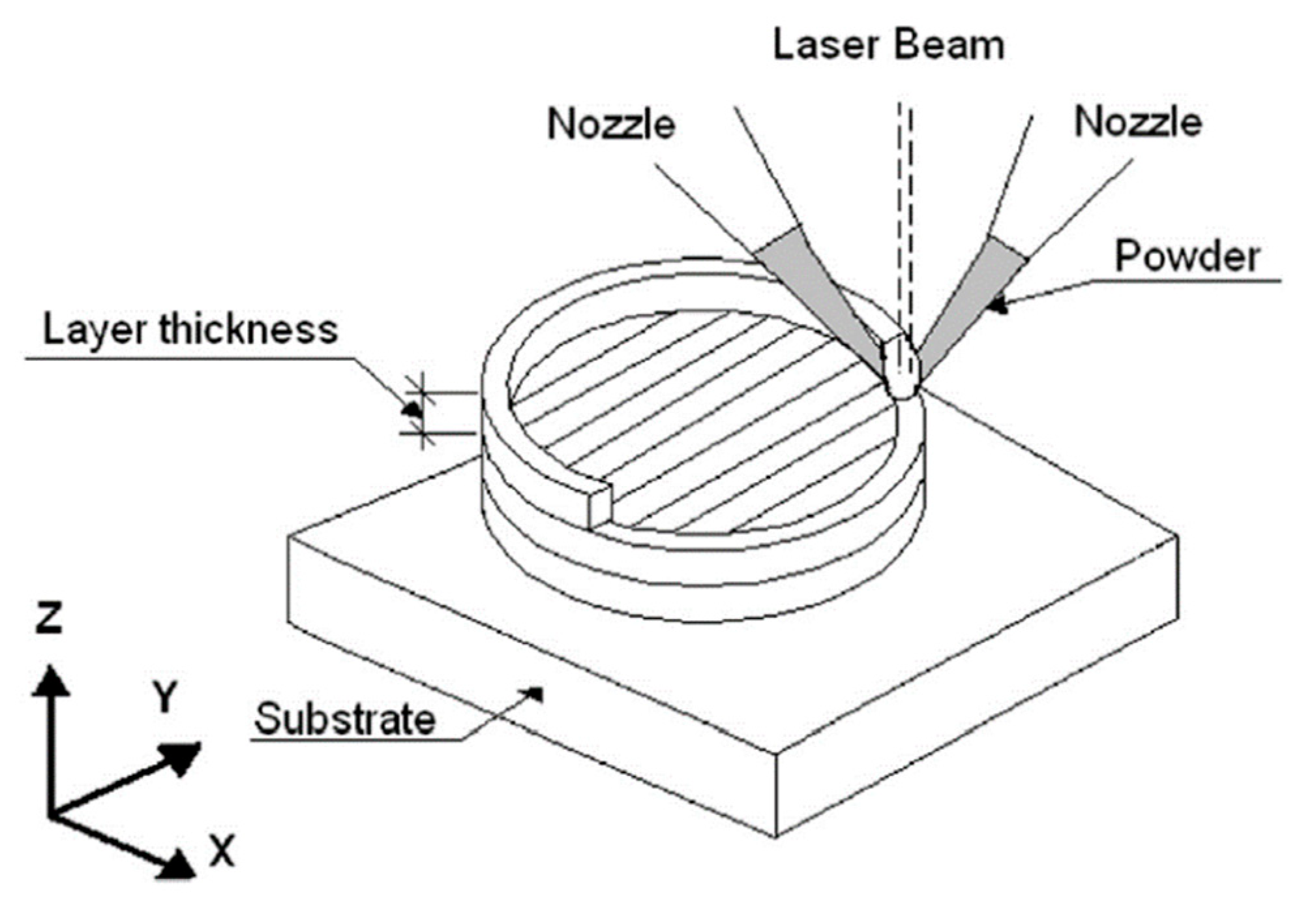

2.1. Material Fabrication

2.2. Material Characterization

3. Results and Discussion

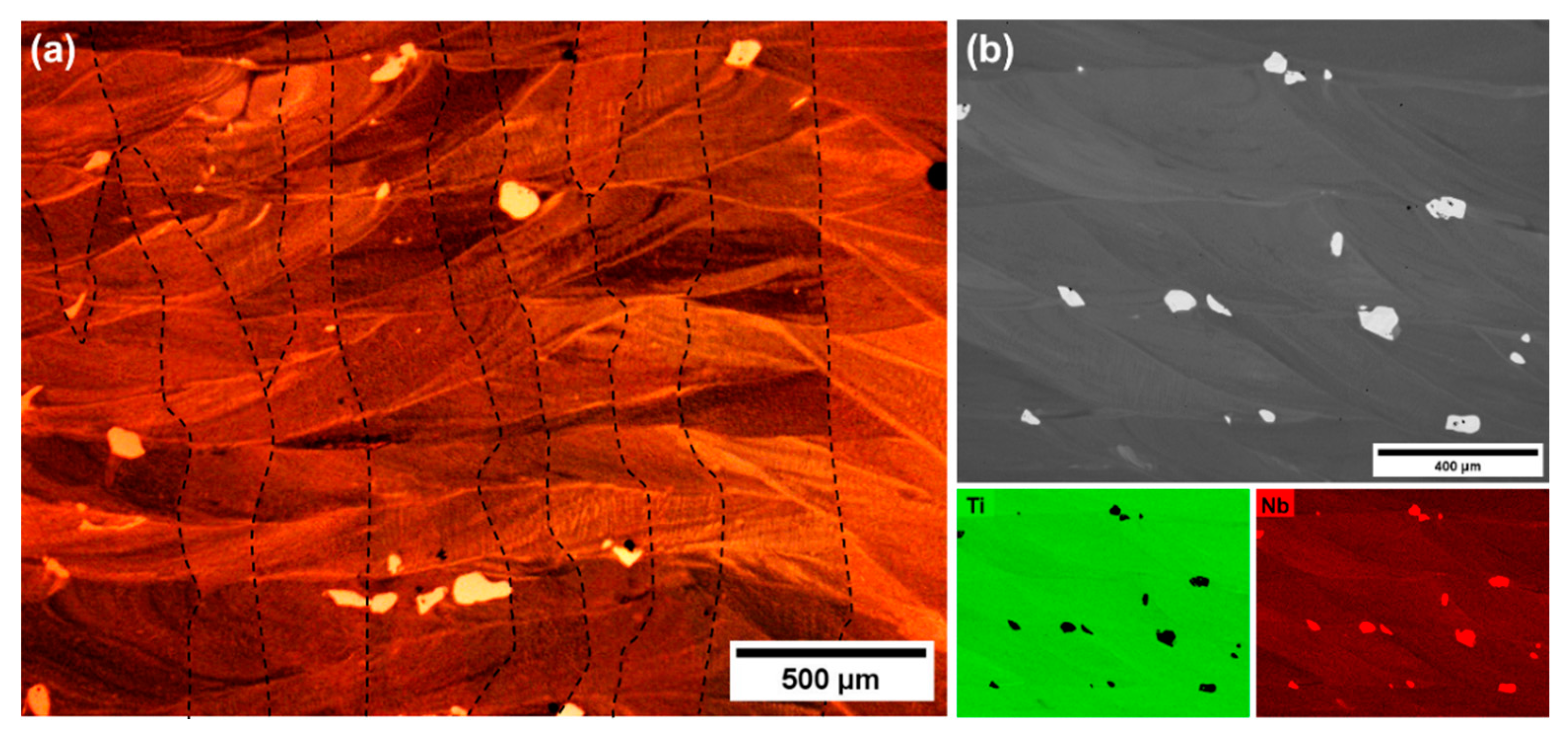

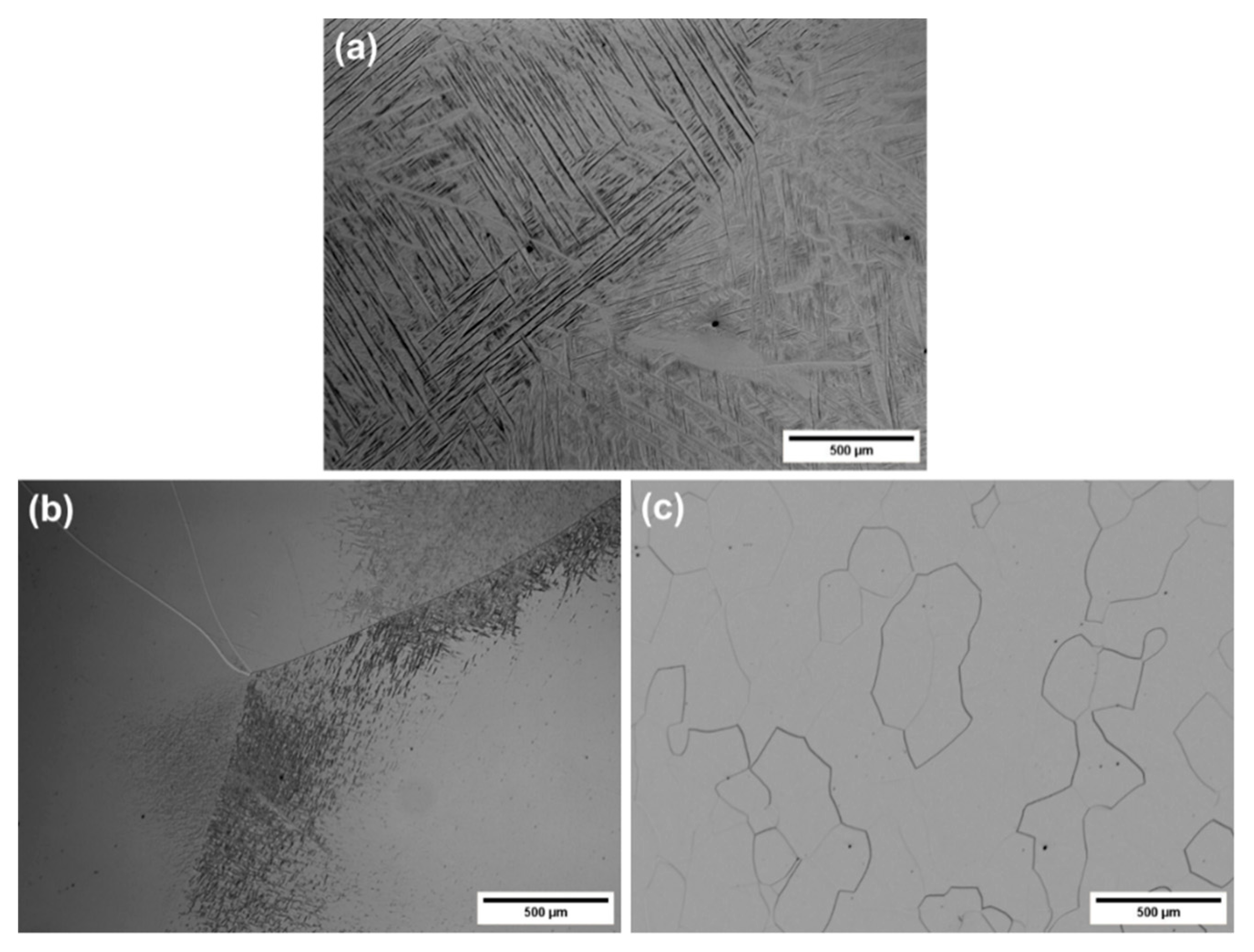

3.1. Microstructure of the As-Deposited Alloys

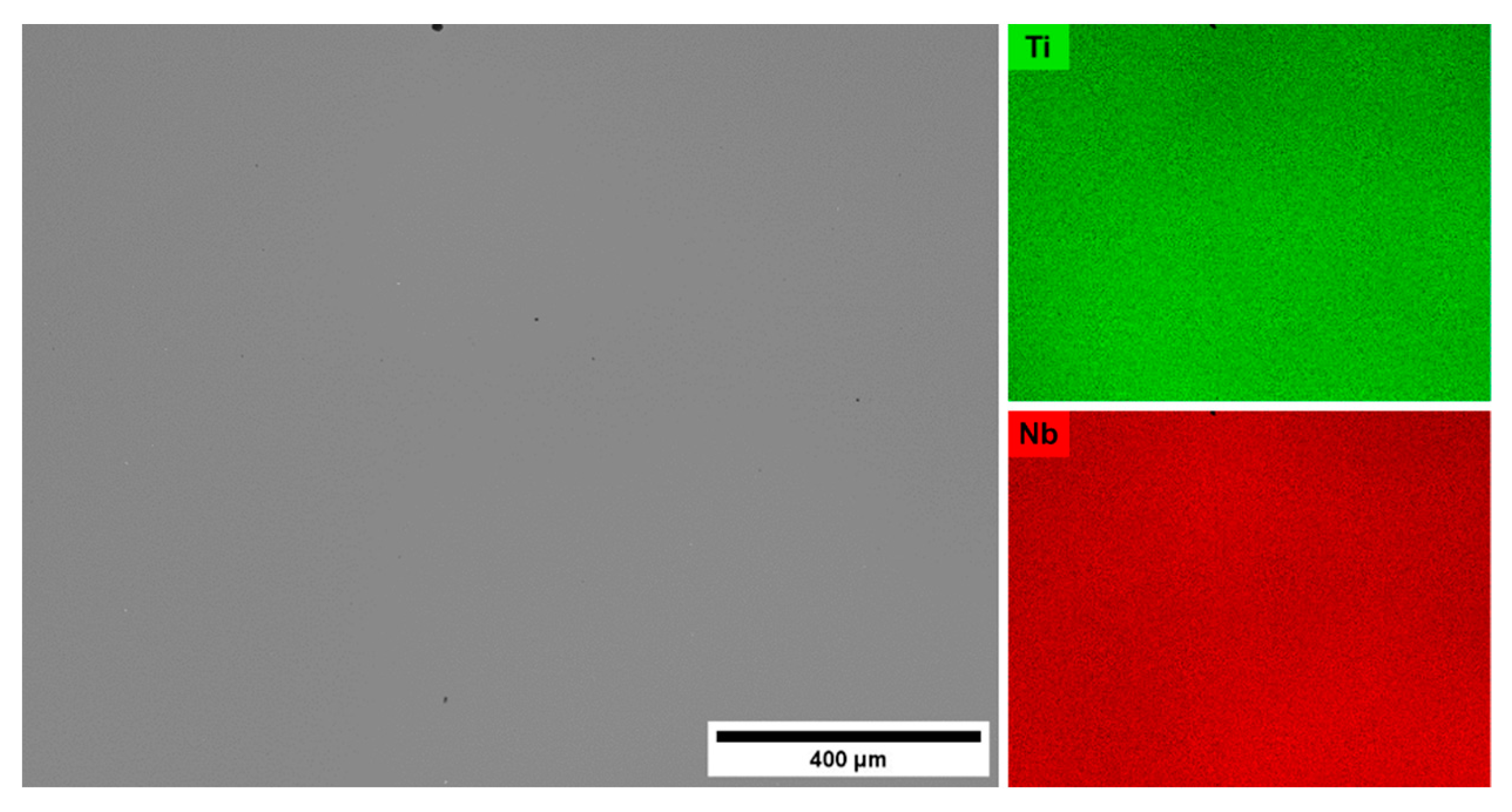

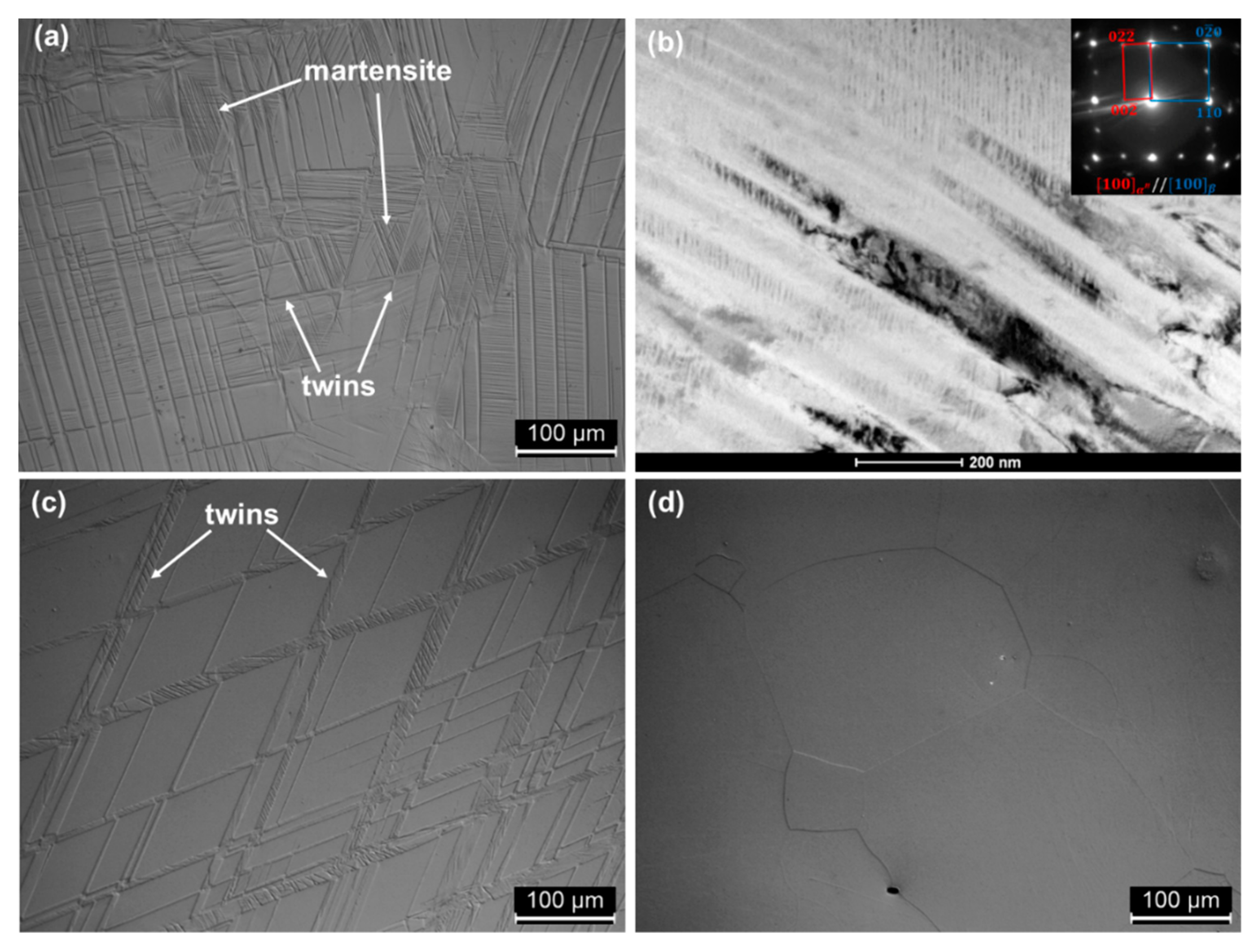

3.2. Microstructure of Solution-Treated Alloys

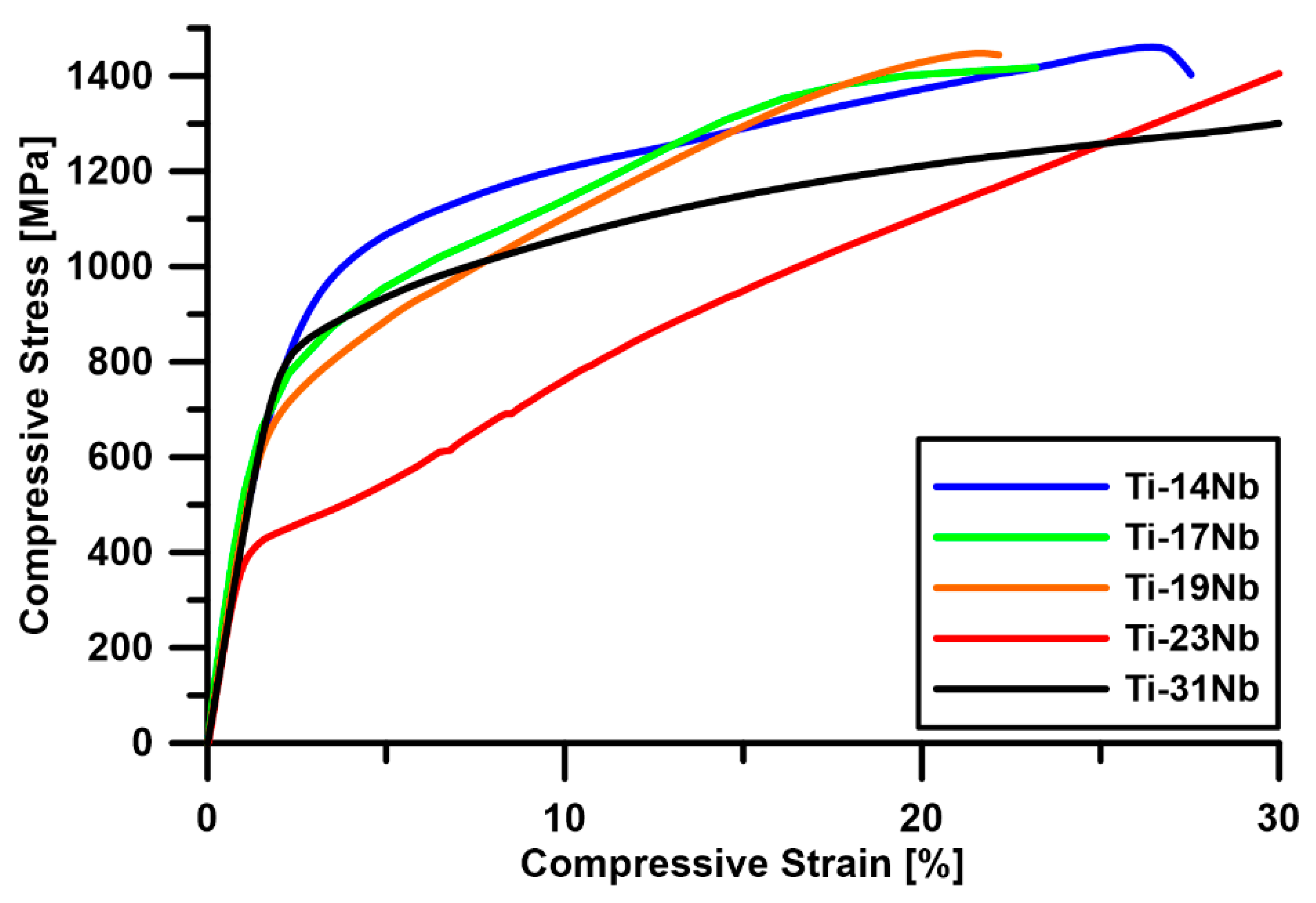

3.3. Mechanical Properties

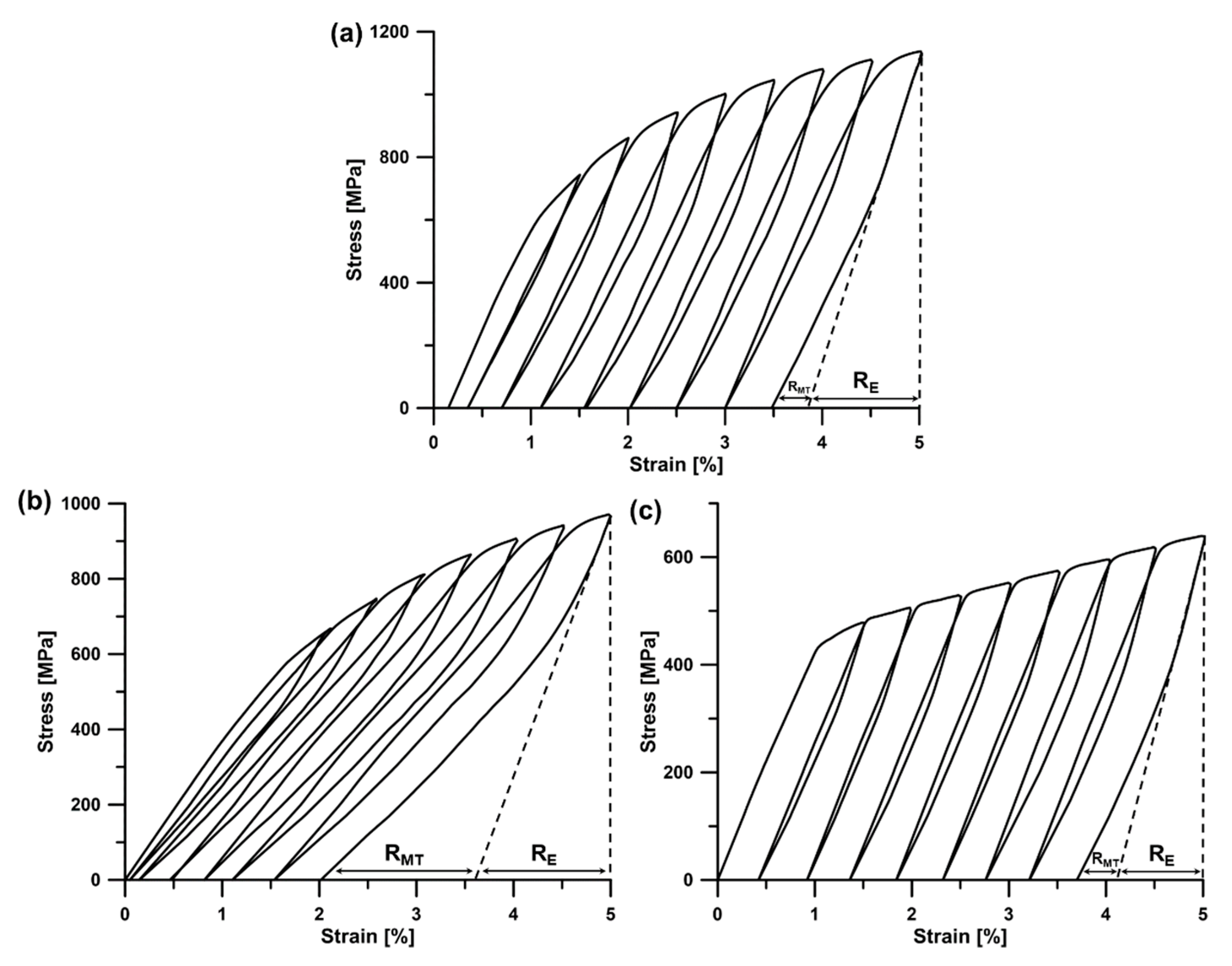

3.4. Superelastic Behavior

4. Conclusions

- The applied LENS fabrication parameters allowed the fabrication of almost fully dense materials with porosity of about 0.15 vol.%. However, the energy density was insufficient to melt the Nb particles. Additional annealing at 1250 °C for 24 h was necessary in order to ensure a suitable level of homogeneity.

- The phase composition of the investigated alloys changed from single α″ martensite (Ti-14Nb) to a mixture of α″ + β phases (Ti-17Nb, Ti-19Nb) and finally β + ωath (Ti-23Nb, Ti-31Nb).

- The observed changes in the mechanical properties of the investigated materials were associated with changes in the deformation modes. The SIMT and twinning mechanisms were observed in the Ti-17Nb and Ti-19Nb alloys, but it should be noted that with increasing Nb content the mechanism evolved to twinning in Ti-23Nb and slip in Ti-31Nb. Similar behavior was observed in cast alloys; however, in our case, the specific mechanism occurred at lower Nb concentration, which was associated with higher oxygen content. This leads to the conclusion that, although oxygen is considered as an α stabilizing element, it increases β phase stability in the β phase alloys.

- For the first time, superelastic behavior was observed in Ti–Nb alloys obtained using additive manufacturing techniques. The maximum recoverable strain, as high as 3%, was registered in the Ti-19Nb alloy. The obtained results allowed the statement to be made that oxygen has a significant influence on the superelasticity of alloys fabricated using AM techniques, which should be considered during the development of new compositions.

Author Contributions

Funding

Conflicts of Interest

References

- Wang, B.L.; Li, L.; Zheng, Y.F. In Vitro Cytotoxicity and Hemocompatibility Studies of Ti-Nb, Ti-Nb-Zr and Ti-Nb-Hf Biomedical Shape Memory Alloys. Biomed. Mater. 2010, 5, 044102. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.Y.; Ikehara, Y.; Kim, J.I.; Hosoda, H.; Miyazaki, S. Martensitic Transformation, Shape Memory Effect and Superelasticity of Ti-Nb Binary Alloys. Acta Mater. 2006, 54, 2419–2429. [Google Scholar] [CrossRef]

- Chen, Q.; Thouas, G.A. Metallic implant biomaterials. Mater. Sci. Eng. R Rep. 2015, 87, 1–57. [Google Scholar] [CrossRef]

- Zhang, L.C.; Chen, L.Y. A review on biomedical titanium alloys: Recent progress and prospect. Adv. Eng. Mater. 2019, 21, 1801215. [Google Scholar] [CrossRef]

- Noyama, Y.; Miura, T.; Ishimoto, T.; Itaya, T.; Niinomi, M.; Nakano, T. Bone loss and reduced bone quality of the human femur after total hip arthroplasty under stress-shielding effects by titanium-based implant. Mater. Trans. 2012, 53, 565–570. [Google Scholar] [CrossRef]

- Ziolkowski, A. Pseudoelasticity of Shape Memory Alloys: Theory and Experimental Studies; Butterworth-Heinemann: Waltham, MA, USA, 2015. [Google Scholar]

- Miyazaki, S.; Kim, H.Y.; Hosoda, H. Development and Characterization of Ni-Free Ti-Base Shape Memory and Superelastic Alloys. Mater. Sci. Eng. A 2006, 438, 18–24. [Google Scholar] [CrossRef]

- Kuroda, D.; Niinomi, M.; Morinaga, M.; Kato, Y.; Yashiro, T. Design and Mechanical Properties of New β Type Titanium Alloys for Implant Materials. Mater. Sci. Eng. A 1998, 243, 244–249. [Google Scholar] [CrossRef]

- Kim, H.Y.; Miyazaki, S. Several Issues in the Development of Ti-Nb-Based Shape Memory Alloys. Shape Mem. Superelast. 2016, 2, 380–390. [Google Scholar] [CrossRef]

- Rao, X.; Chu, C.L.; Zheng, Y.Y. Phase composition, microstructure, and mechanical properties of porous Ti–Nb–Zr alloys prepared by a two-step foaming powder metallurgy method. J. Mech. Behav. Biomed. 2014, 34, 27–36. [Google Scholar] [CrossRef]

- Liu, Y.J.; Li, S.J.; Wang, H.L.; Hou, W.T.; Hao, Y.L.; Yang, R.; Sercombe, T.B.; Zhang, L.C. Microstructure, defects and mechanical behavior of beta-type titanium porous structures manufactured by electron beam melting and selective laser melting. Acta Mater. 2016, 113, 56–67. [Google Scholar] [CrossRef]

- Kalita, D.; Rogal, Ł.; Czeppe, T.; Wójcik, A.; Kolano-Burian, A.; Zackiewicz, P.; Kania, B.; Dutkiewicz, J. Microstructure and Mechanical Properties of Ti-Nb Alloys Prepared by Mechanical Alloying and Spark Plasma Sintering. J. Mater. Eng. Perform. 2020, 29, 1145–1452. [Google Scholar] [CrossRef]

- Kim, H.Y.; Hashimoto, S.; Kim, J.I.; Hosoda, H.; Miyazaki, S. Mechanical properties and shape memory behavior of Ti-Nb alloys. Mater. Trans. 2004, 45, 2443–2448. [Google Scholar] [CrossRef]

- Kim, J.I.; Kim, H.Y.; Hosoda, H.; Miyazaki, S. Shape memory behavior of Ti–22Nb–(0.5–2.0) O (at%) biomedical alloys. Mater. Trans. 2005, 46, 852–857. [Google Scholar] [CrossRef]

- Lai, M.; Gao, Y.; Yuan, B.; Zhu, M. Remarkable Superelasticity of Sintered Ti-Nb Alloys by Ms Adjustment Via Oxygen Regulation. Mater. Des. 2015, 87, 466–472. [Google Scholar] [CrossRef]

- Hernandez, J.; Li, S.J.; Martinez, E.; Murr, L.E.; Pan, X.M.; Amato, K.N.; Cheng, X.Y.; Fang, F.; Terrazas, C.A.; Gaytan, S.M.; et al. Microstructures and Hardness Properties for β-Phase Ti–24Nb–4Zr–7.9Sn Alloy Fabricated by Electron Beam Melting. J. Mater. Sci. Technol. 2013, 29, 1011–1017. [Google Scholar] [CrossRef]

- Chen, W.; Chen, C.; Zi, X.; Cheng, X.; Zhang, X.; Lin, Y.C.; Zhou, K. Controlling the microstructure and mechanical properties of a metastable β titanium alloy by selective laser melting. Mater. Sci. Eng. A 2018, 726, 240–250. [Google Scholar] [CrossRef]

- Schwab, H.; Prashanth, K.G.; Löber, L.; Kühn, U.; Eckert, J. Selective laser melting of Ti-45Nb alloy. Metals 2015, 5, 686–694. [Google Scholar] [CrossRef]

- Schulze, C.; Weinmann, M.; Schweigel, C.; Keßler, O.; Bader, R. Mechanical properties of a newly additive manufactured implant material based on Ti-42Nb. Materials 2018, 11, 124. [Google Scholar] [CrossRef]

- Wang, J.C.; Liu, Y.J.; Qin, P.; Liang, S.X.; Sercombe, T.B.; Zhang, L.C. Selective laser melting of Ti–35Nb composite from elemental powder mixture: Microstructure, mechanical behavior and corrosion behavior, 2019. Mater. Sci. Eng. A 2019, 760, 214–224. [Google Scholar] [CrossRef]

- Fischer, M.; Joguet, D.; Robin, G.; Peltier, L.; Laheurte, P. In situ elaboration of a binary Ti–26Nb alloy by selective laser melting of elemental titanium and niobium mixed powders. Mater. Sci. Eng. C 2016, 62, 852–859. [Google Scholar] [CrossRef]

- Antolak-Dudka, A.; Płatek, P.; Durejko, T.; Baranowski, P.; Małachowski, J.; Sarzyński, M.; Czujko, T. Static and Dynamic Loading Behavior of Ti6Al4V Honeycomb Structures Manufactured by Laser Engineered Net Shaping (LENSTM) Technology. Materials 2019, 12, 1225. [Google Scholar] [CrossRef]

- Attar, H.; Ehtemam-Haghighi, S.; Kent, D.; Wu, X.; Dargusch, M.S. Comparative study of commercially pure titanium produced by laser engineered net shaping, selective laser melting and casting processes. Mater. Sci. Eng. A 2017, 705, 385–393. [Google Scholar] [CrossRef]

- Wei, J.; Sun, H.; Zhang, D.; Gong, L.; Lin, J.; Wen, C. Influence of Heat Treatments on Microstructure and Mechanical Properties of Ti–26Nb Alloy Elaborated In Situ by Laser Additive Manufacturing with Ti and Nb Mixed Powder. Materials 2019, 12, 61. [Google Scholar] [CrossRef] [PubMed]

- Banerjee, R.; Nag, S.; Samuel, S.; Fraser, H.L. Laser-deposited Ti-Nb-Zr-Ta orthopedic alloys. J. Biomed. Mater. Res. A 2006, 78, 298–305. [Google Scholar] [CrossRef] [PubMed]

- Schwendner, K.I.; Banerjee, R.; Collins, P.C.; Brice, C.A.; Fraser, H.L. Direct laser deposition of alloys from elemental powder blends. Scr. Mater. 2001, 45, 1123–1129. [Google Scholar] [CrossRef]

- Kunce, I.; Polanski, M.; Karczewski, K.; Plocinski, T.; Kurzydlowski, K.J. Microstructural characterisation of high-entropy alloy AlCoCrFeNi fabricated by laser engineered net shaping. J. Alloys Compd. 2015, 648, 751–758. [Google Scholar] [CrossRef]

- Durejko, T.; Łazińska, M.; Dworecka-Wójcik, J.; Lipiński, S.; Varin, R.A.; Czujko, T. The Tribaloy T-800 Coatings Deposited by Laser Engineered Net Shaping (LENSTM). Materials 2019, 12, 1366. [Google Scholar] [CrossRef]

- Tahara, M.; Kim, H.Y.; Inamura, T.; Hosoda, H.; Miyazaki, S. Lattice modulation and superelasticity in oxygen-added β-Ti alloys. Acta Mater. 2011, 59, 6208–6218. [Google Scholar] [CrossRef]

- Abdel-Hady, M.; Fuwa, H.; Hinoshita, K.; Kimura, H.; Shinzato, Y.; Morinaga, M. Phase stability change with Zr content in β-type Ti–Nb alloys. Scr. Mater. 2007, 57, 1000–1003. [Google Scholar] [CrossRef]

- Terayama, A.; Fuyama, N.; Yamashita, Y.; Ishizaki, I.; Kyogoku, H. Fabrication of Ti–Nb alloys by powder metallurgy process and their shape memory characteristics. J. Alloys Compd. 2013, 577, S408–S412. [Google Scholar] [CrossRef]

- Xue, Q.; Ma, Y.J.; Lei, J.F.; Yang, R.; Wang, C. Evolution of microstructure and phase composition of Ti-3Al-5Mo-4.5V alloy with varied β phase stability. J. Mater. Sci. Technol. 2018, 34, 2325–2330. [Google Scholar] [CrossRef]

- Banerjee, S.; Tewari, R.; Dey, G.K. Omega phase transformation—Morphologies and mechanisms. Int. J. Mater. Res. 2006, 97, 963–977. [Google Scholar] [CrossRef]

- De Fontaine, D. Mechanical instabilities in the bcc lattice and the beta to omega phase transformation. Acta Metall. 1970, 18, 275–279. [Google Scholar] [CrossRef]

- Sukedai, E.; Hashimoto, H.; Hida, M.; Mabuchi, H. Formation of ω phase in Ti–Mo alloys after aging and deforming. Mater. Sci. Technol. 1992, 8, 1–9. [Google Scholar] [CrossRef]

- Lai, M.J.; Tasan, C.C.; Zhang, J.; Grabowski, B.; Huang, L.F.; Raabe, D. Origin of Shear Induced β to ω Transition in Ti-Nb-Based Alloys. Acta Mater. 2015, 92, 55–63. [Google Scholar] [CrossRef]

- Moffat, D.L.; Larbalestier, D.C. The Competition Between Martensite and Omega in Quenched Ti-Nb Alloys. Metall. Trans. A 1988, 19, 1677–1686. [Google Scholar] [CrossRef]

- Cai, S.; Schaffer, J.E.; Ren, Y. Deformation of a Ti-Nb alloy containing α”-martensite and omega phases. Appl. Phys. Lett. 2015, 106, 131907. [Google Scholar] [CrossRef]

- Ping, D.H.; Cui, C.Y.; Yin, F.X.; Yamabe-Mitarai, Y. TEM investigations on martensite in a Ti–Nb-based shape memory alloy. Scr. Mater. 2006, 54, 1305–1310. [Google Scholar] [CrossRef]

- Lee, S.; Park, C.; Hong, J.; Yeom, J.T. The role of nano-domains in {1–011} twinned martensite in metastable titanium alloys. Sci. Rep. 2018, 8, 1–9. [Google Scholar] [CrossRef]

- Kolli, R.P.; Joost, W.J.; Ankem, S. Phase Stability and Stress-Induced Transformations in Beta Titanium Alloys. Jom 2015, 67, 1273–1280. [Google Scholar] [CrossRef]

- Abdel-Hady, M.; Hinoshita, K.; Morinaga, M. General approach to phase stability and elastic properties of β-type Ti-alloys using electronic parameters. Scr. Mater. 2006, 55, 477–480. [Google Scholar] [CrossRef]

- Sun, F.; Zhang, J.Y.; Marteleur, M.; Gloriant, T.; Vermaut, P.; Laille, D.; Castany, P.; Curfs, C.; Jacques, P.J.; Prima, F. Investigation of early stage deformation mechanisms in a metastable β titanium alloy showing combined twinning-induced plasticity and transformation-induced plasticity effects. Acta Mater. 2013, 61, 6406–6417. [Google Scholar] [CrossRef]

- Yao, T.; Du, K.; Wang, H.; Huang, Z.; Li, C.; Li, L.; Hao, Y.; Yang, R.; Ye, H. In situ scanning and transmission electron microscopy investigation on plastic deformation in a metastable β titanium alloy. Acta Mater. 2017, 133, 21–29. [Google Scholar] [CrossRef]

- Sun, F.; Zhang, J.Y.; Marteleur, M.; Brozek, C.; Rauch, E.F.; Veron, M.; Vermaut, P.; Jacques, P.J.; Prima, F. A new titanium alloy with a combination of high strength, high strain hardening and improved ductility. Scr. Mater. 2015, 94, 17–20. [Google Scholar] [CrossRef]

- Bertrand, E.; Castany, P.; Péron, I.; Gloriant, T. Twinning system selection in a metastable β-titanium alloy by Schmid factor analysis. Scr. Mater. 2011, 64, 1110–1113. [Google Scholar] [CrossRef]

- Min, X.H.; Emura, S.; Sekido, N.; Nishimura, T.; Tsuchiya, K.; Tsuzaki, K. Effects of Fe addition on tensile deformation mode and crevice corrosion resistance in Ti–15Mo alloy. Mater. Sci. Eng. A 2010, 527, 2693–2701. [Google Scholar] [CrossRef]

- Kolli, R.P.; Devaraj, A. A review of metastable beta titanium alloys. Metals 2018, 8, 506. [Google Scholar] [CrossRef]

- Hao, Y.L.; Yang, R.; Niinomi, M.; Kuroda, D.; Zhou, Y.L.; Fukunaga, K.; Suzuki, A. Young’s modulus and mechanical properties of Ti-29Nb-13Ta-4.6 Zr in relation to α ″martensite. Metall. Mater. Trans. A 2002, 33, 3137–3144. [Google Scholar] [CrossRef]

- Hon, Y.H.; Wang, J.Y.; Pan, Y.N. Composition/phase structure and properties of titanium-niobium alloys. Mater. Trans. 2003, 44, 2384–2390. [Google Scholar] [CrossRef]

- Besse, M.; Castany, P.; Gloriant, T. Mechanisms of deformation in gum metal TNTZ-O and TNTZ titanium alloys: A comparative study on the oxygen influence. Acta Mater. 2003, 59, 5982–5988. [Google Scholar] [CrossRef]

- Castany, P.; Ramarolahy, A.; Prima, F.; Laheurte, P.; Curfs, C.; Gloriant, T. In situ synchrotron X-ray diffraction study of the martensitic transformation in superelastic Ti-24Nb-0.5 N and Ti-24Nb-0.5 O alloys. Acta Mater. 2015, 88, 102–111. [Google Scholar] [CrossRef]

- Tahara, M.; Kim, H.Y.; Hosoda, H.; Miyazaki, S. Cyclic deformation behavior of a Ti–26 at.% Nb alloy. Acta Mater. 2009, 57, 2461–2469. [Google Scholar] [CrossRef]

- Sun, F.; Hao, Y.L.; Nowak, S.; Gloriant, T.; Laheurte, P.; Prima, F. A thermo-mechanical treatment to improve the superelastic performances of biomedical Ti–26Nb and Ti–20Nb–6Zr (at.%) alloys. J. Mech. Behav. Biomed. 2011, 4, 1864–1872. [Google Scholar] [CrossRef] [PubMed]

- Nagase, T.; Hori, T.; Todai, M.; Sun, S.H.; Nakano, T. Additive manufacturing of dense components in beta-titanium alloys with crystallographic texture from a mixture of pure metallic element powders. Mater. Des. 2019, 173, 107771. [Google Scholar] [CrossRef]

- Kreitcberg, A.; Brailovski, V.; Prokoshkin, S. New biocompatible near-beta Ti-Zr-Nb alloy processed by laser powder bed fusion: Process optimization. J. Mater. Process. Technol. 2018, 252, 821–829. [Google Scholar] [CrossRef]

- Liu, Y.J.; Wang, H.L.; Li, S.J.; Wang, S.G.; Wang, W.J.; Hou, W.T.; Hao, Y.L.; Yang, R.; Zhang, L.C. Compressive and fatigue behavior of beta-type titanium porous structures fabricated by electron beam melting. Acta Mater. 2017, 126, 58–66. [Google Scholar] [CrossRef]

- Fischer, M.; Laheurte, P.; Acquier, P.; Joguet, D.; Peltier, L.; Petithory, T.; Anselme, K.; Mille, P. Synthesis and characterization of Ti-27.5 Nb alloy made by CLAD® additive manufacturing process for biomedical applications. Mater. Sci. Eng. C 2017, 75, 341–348. [Google Scholar] [CrossRef] [PubMed]

| Chemical Composition | Sample | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Ti [at.%] | 90.2 | 89.0 | 87.9 | 85.7 | 80.5 |

| Nb [at.%] | 9.8 | 11.0 | 12.1 | 14.3 | 19.5 |

| Chemical Composition | Sample | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Ti [at.%] | 85.8 | 82.1 | 80.7 | 77.2 | 69.2 |

| Nb [at.%] | 14.2 | 17.2 | 19.3 | 22.8 | 30.8 |

| Alloy Composition [at.%] | |||||

|---|---|---|---|---|---|

| Ti–14Nb | Ti–17Nb | Ti–19Nb | Ti–23Nb | Ti–31Nb | |

| YS [MPa] | 734 ± 12 | 695 ± 38 | 669 ± 36 | 418 ± 19 | 762 ± 22 |

| A [%] | 21 ± 3 | 23 ± 10 | 22 ± 4 | > 50 | > 50 |

| E [GPa] | 54 ± 6 | 49 ± 5 | 40 ± 6 | 49 ± 6 | 55 ± 2 |

| Alloy Composition | |||||

|---|---|---|---|---|---|

| Ti–14Nb | Ti–17Nb | Ti–19Nb | Ti–23Nb | Ti–31Nb | |

| RT [%] | 1.5 | 2.0 | 3.0 | 1.3 | 1.6 |

| RE [%] | 1.2 | 1.2 | 1.4 | 0.9 | 1.4 |

| RMT [%] | 0.3 | 0.8 | 1.6 | 0.4 | 0.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kalita, D.; Rogal, Ł.; Bobrowski, P.; Durejko, T.; Czujko, T.; Antolak-Dudka, A.; Cesari, E.; Dutkiewicz, J. Superelastic Behavior of Ti-Nb Alloys Obtained by the Laser Engineered Net Shaping (LENS) Technique. Materials 2020, 13, 2827. https://doi.org/10.3390/ma13122827

Kalita D, Rogal Ł, Bobrowski P, Durejko T, Czujko T, Antolak-Dudka A, Cesari E, Dutkiewicz J. Superelastic Behavior of Ti-Nb Alloys Obtained by the Laser Engineered Net Shaping (LENS) Technique. Materials. 2020; 13(12):2827. https://doi.org/10.3390/ma13122827

Chicago/Turabian StyleKalita, Damian, Łukasz Rogal, Piotr Bobrowski, Tomasz Durejko, Tomasz Czujko, Anna Antolak-Dudka, Eduard Cesari, and Jan Dutkiewicz. 2020. "Superelastic Behavior of Ti-Nb Alloys Obtained by the Laser Engineered Net Shaping (LENS) Technique" Materials 13, no. 12: 2827. https://doi.org/10.3390/ma13122827

APA StyleKalita, D., Rogal, Ł., Bobrowski, P., Durejko, T., Czujko, T., Antolak-Dudka, A., Cesari, E., & Dutkiewicz, J. (2020). Superelastic Behavior of Ti-Nb Alloys Obtained by the Laser Engineered Net Shaping (LENS) Technique. Materials, 13(12), 2827. https://doi.org/10.3390/ma13122827