Tests of Fiber Cement Materials Containing Recycled Cellulose Fibers

Abstract

1. Introduction

2. Survey of Literature

3. Tests of Principle Physical and Strength Properties

- mn—the mass of the water saturated sample [g];

- ms—the mass of the sample dried at 105 °C [g].

- mw—the mass of the sample with the current moisture content [g];

- ms—the mass of the sample dried at 105 °C [g].

- —the rupture force [N];

- —the spacing of the supports [mm];

- —the width of the tested specimen [mm];

- —the tested specimen’s mean thickness measured in four places (in the middle of each of the sides) [mm].

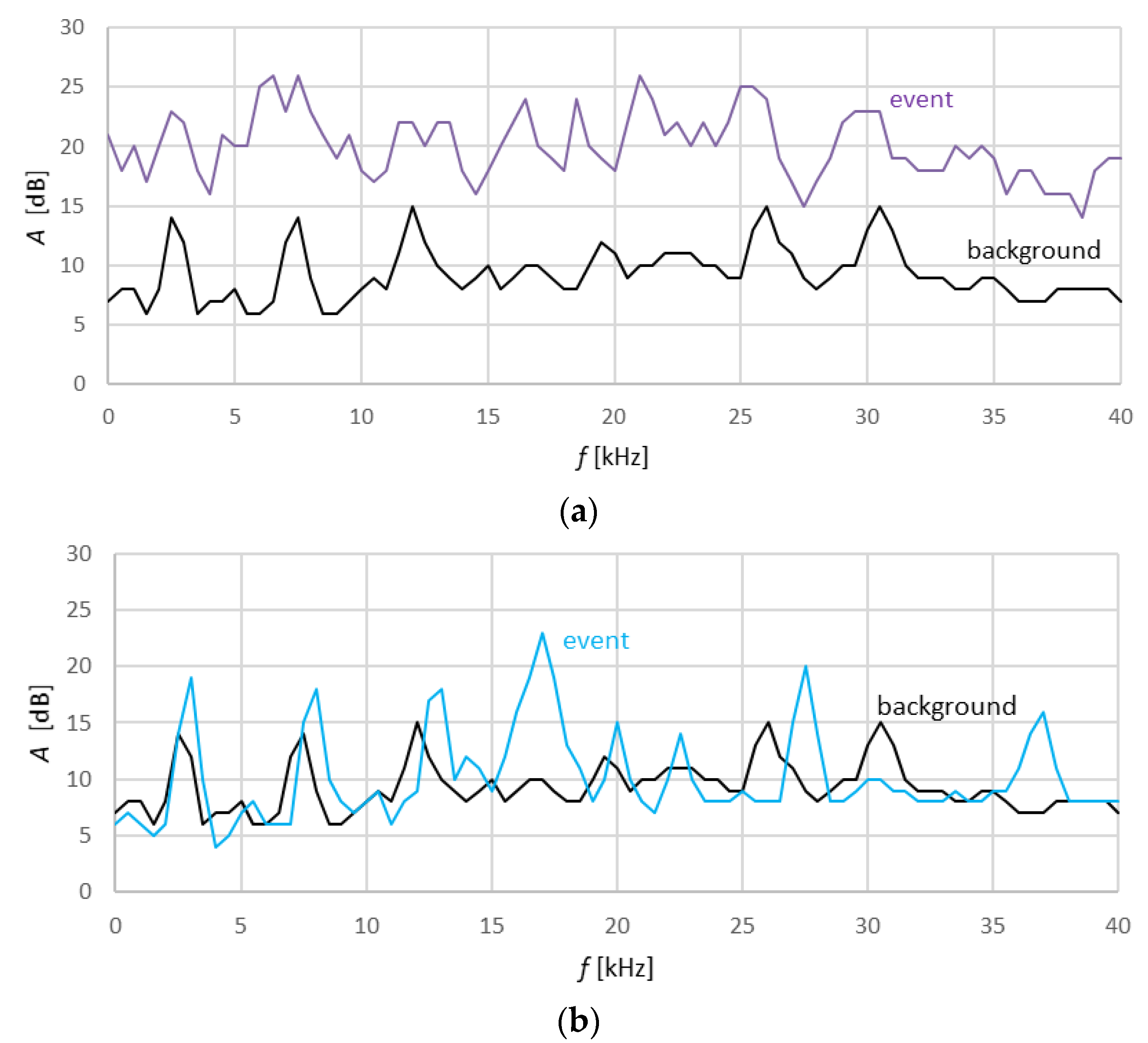

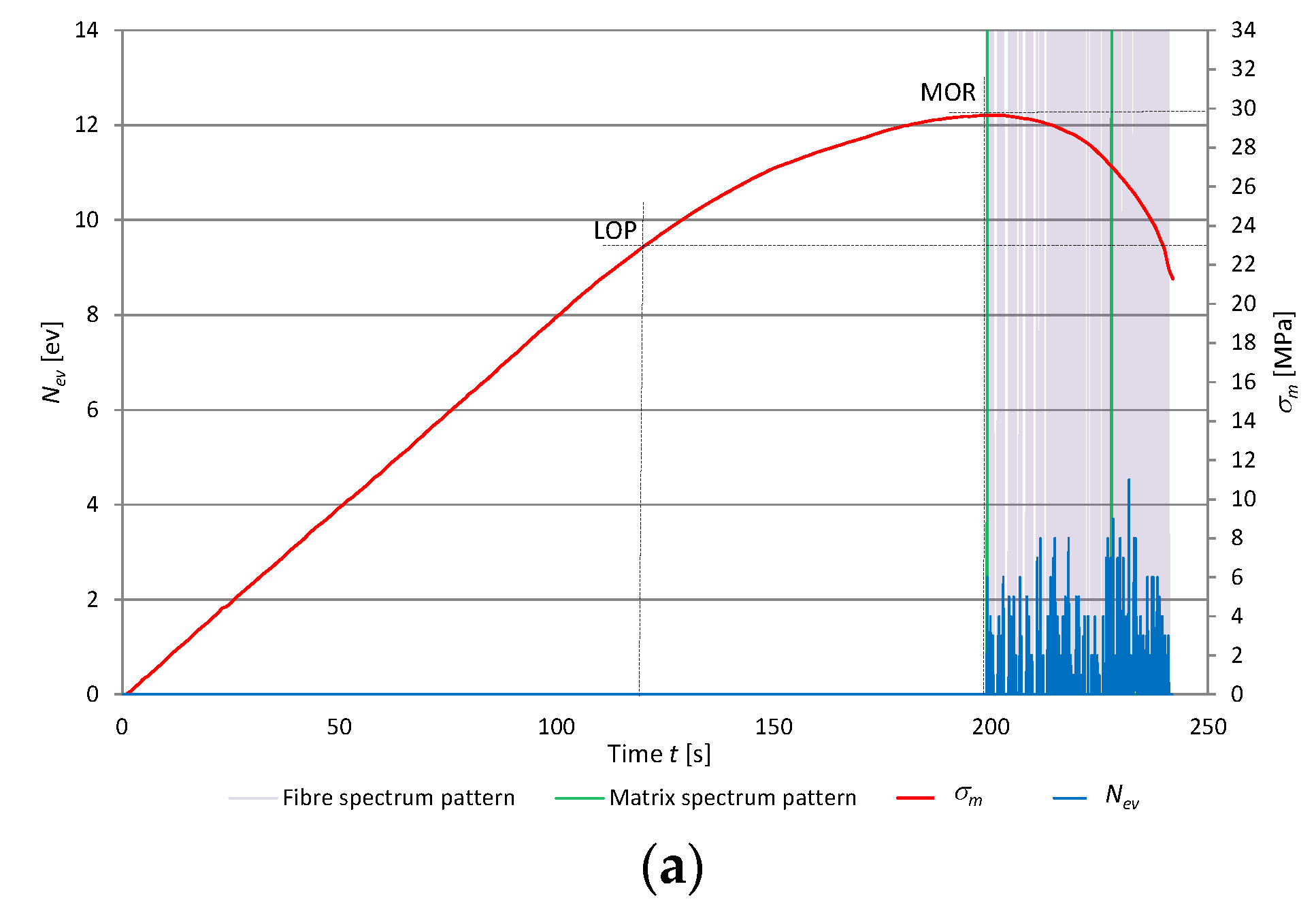

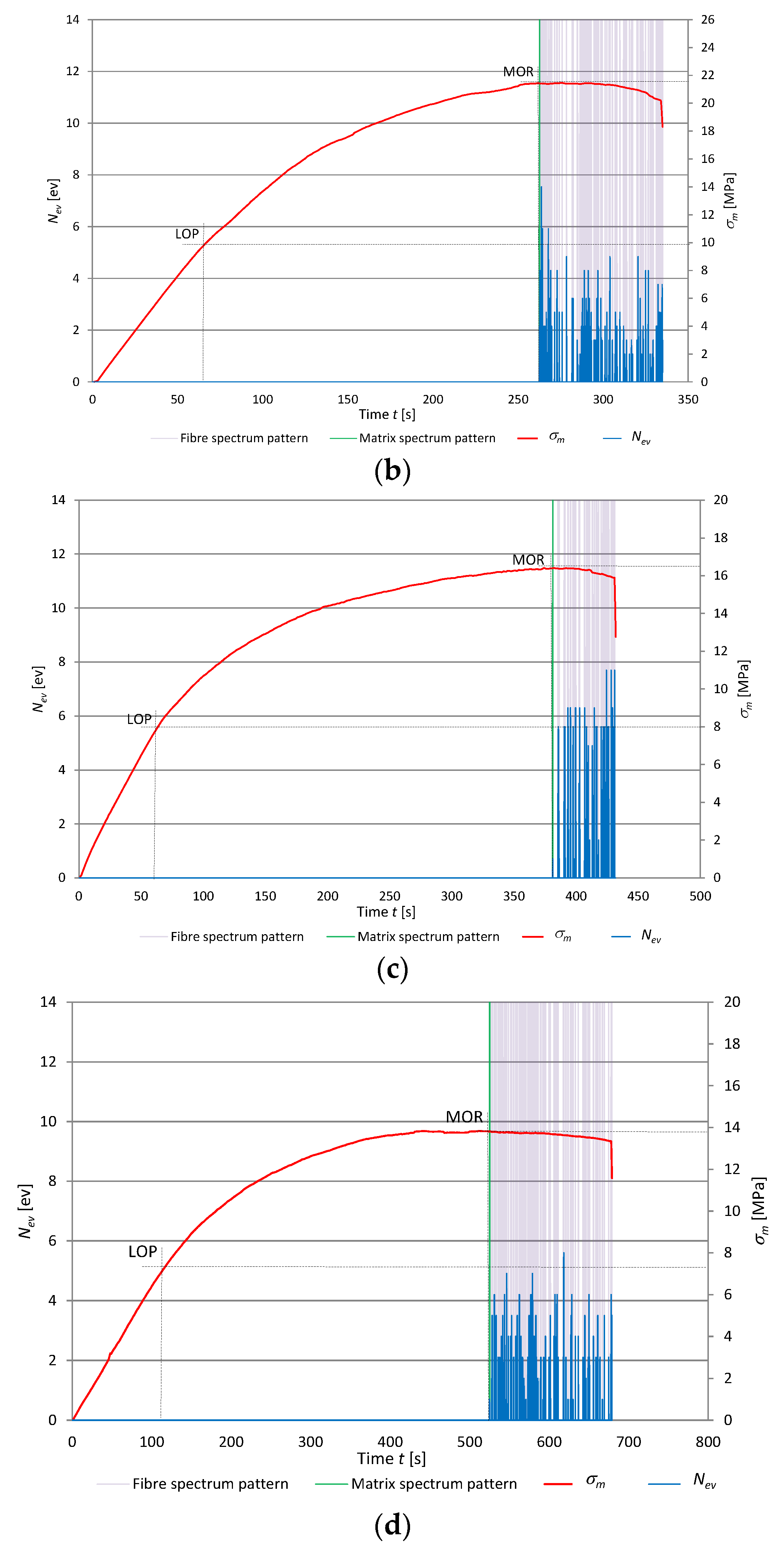

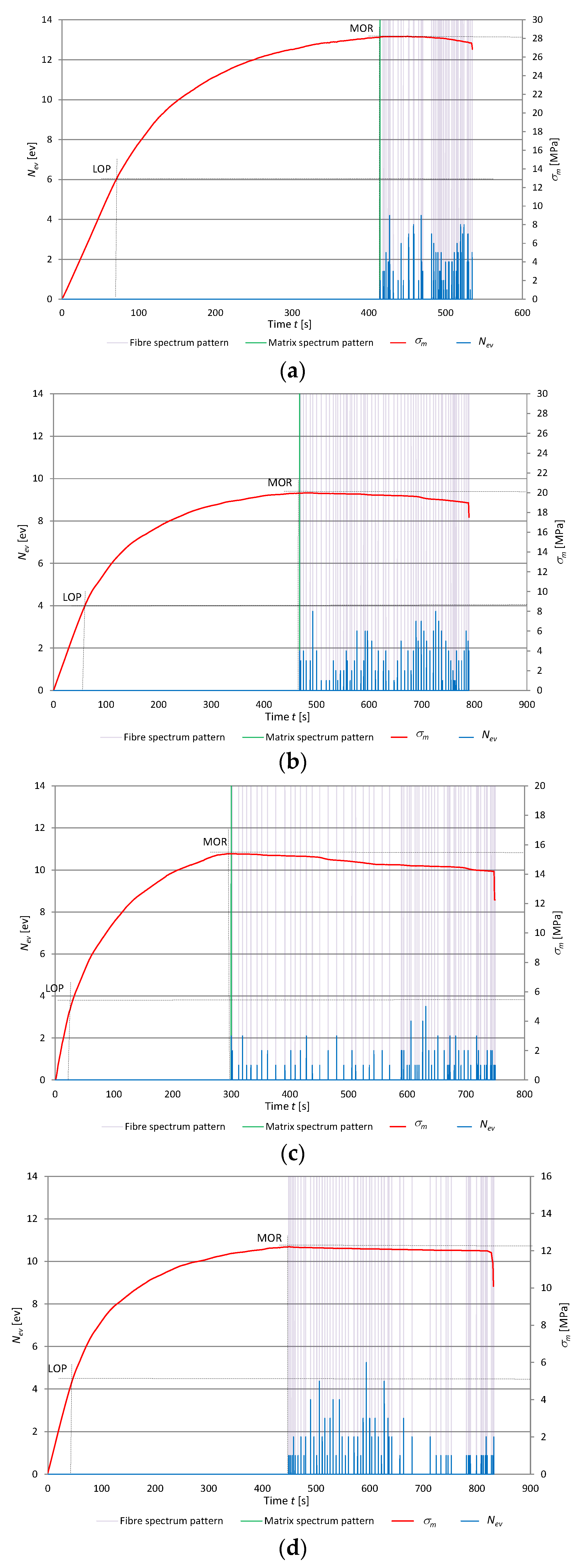

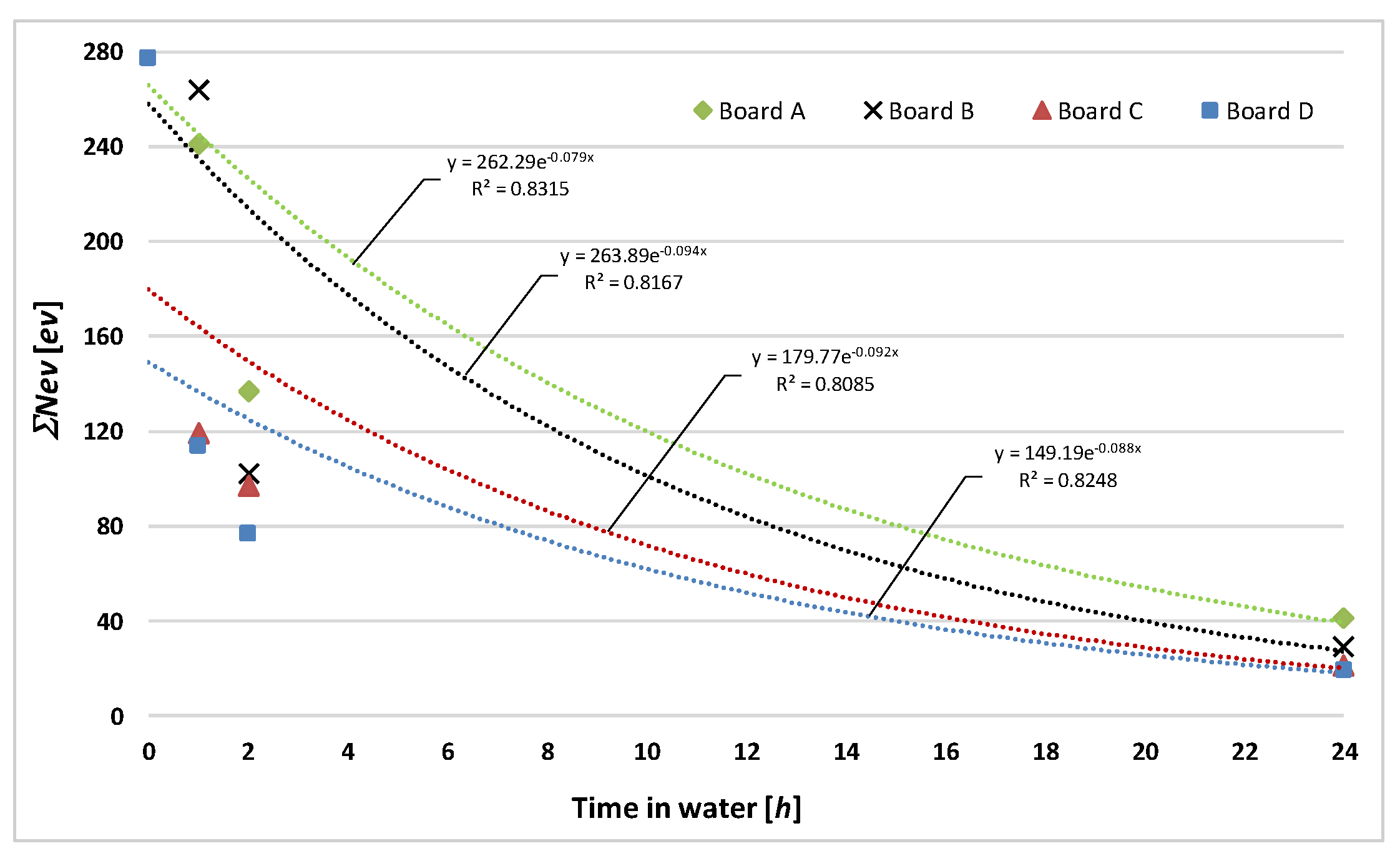

4. Testing by Means of Acoustic Emission and Artificial Neural Networks

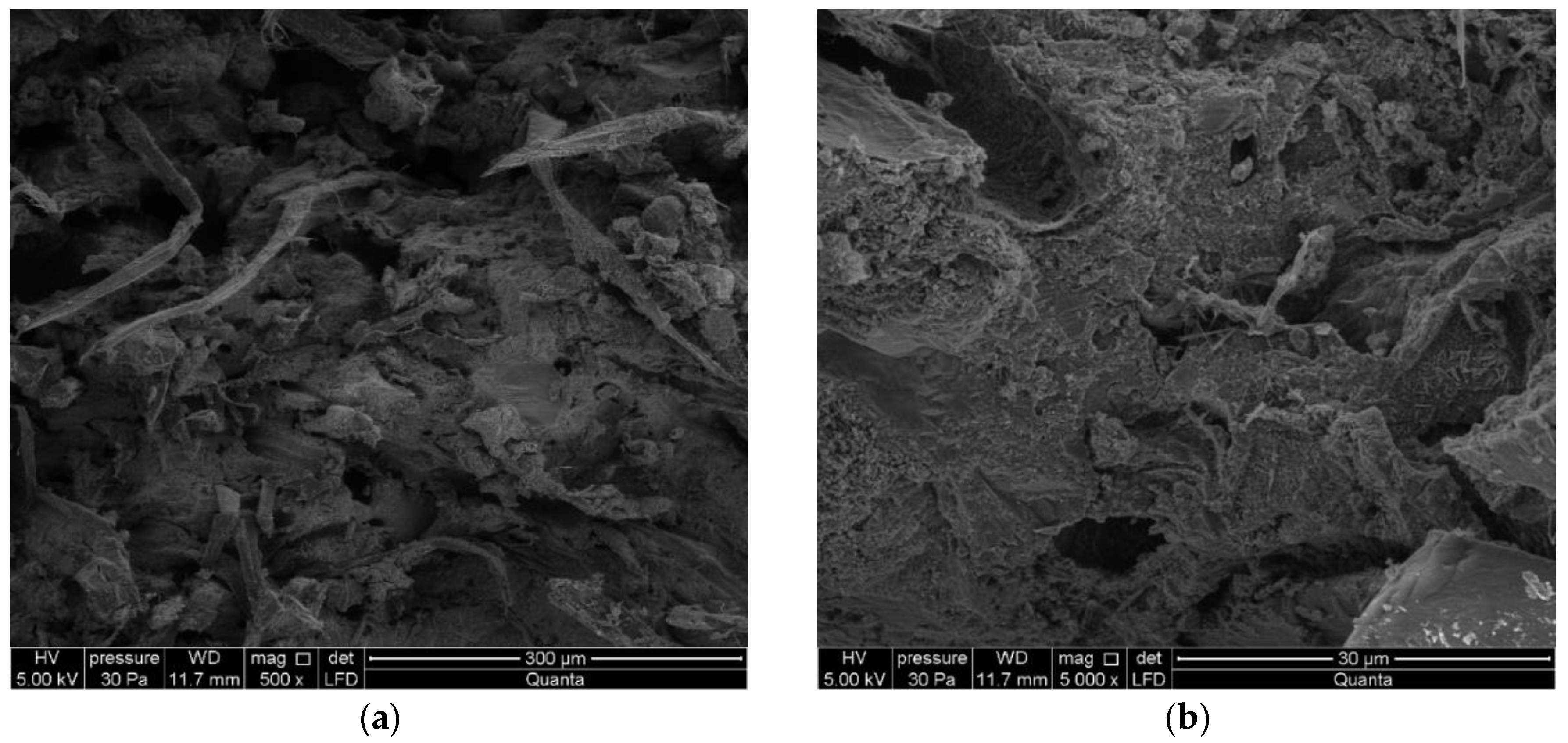

5. Scanning Electron Microscope (SEM) Examinations

6. Conclusions

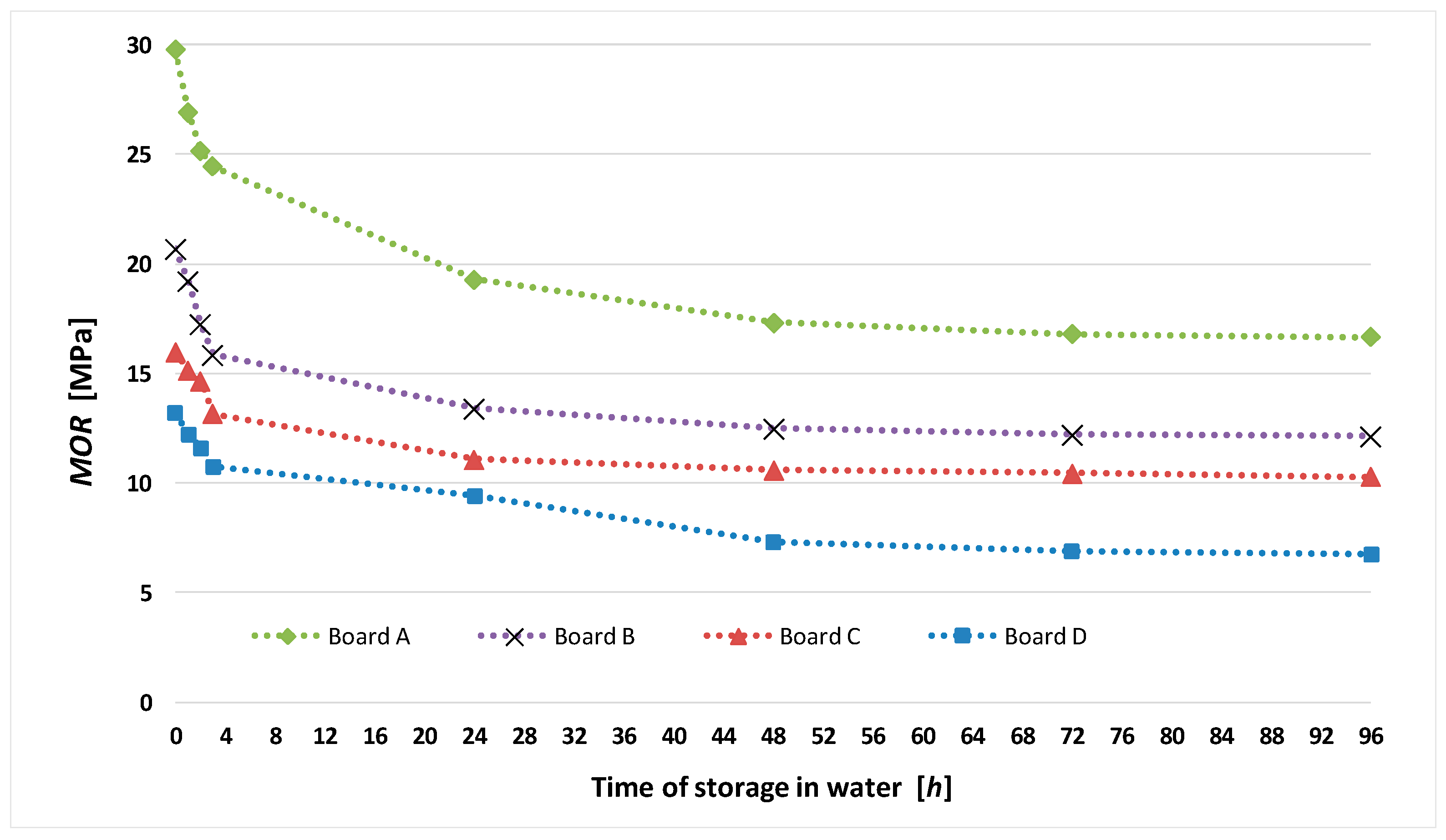

- The recycled cellulose fibers contained in the boards lower their modulus of rupture (MOR). The higher the percentage of recycled fibers in the board, the lower the MOR;

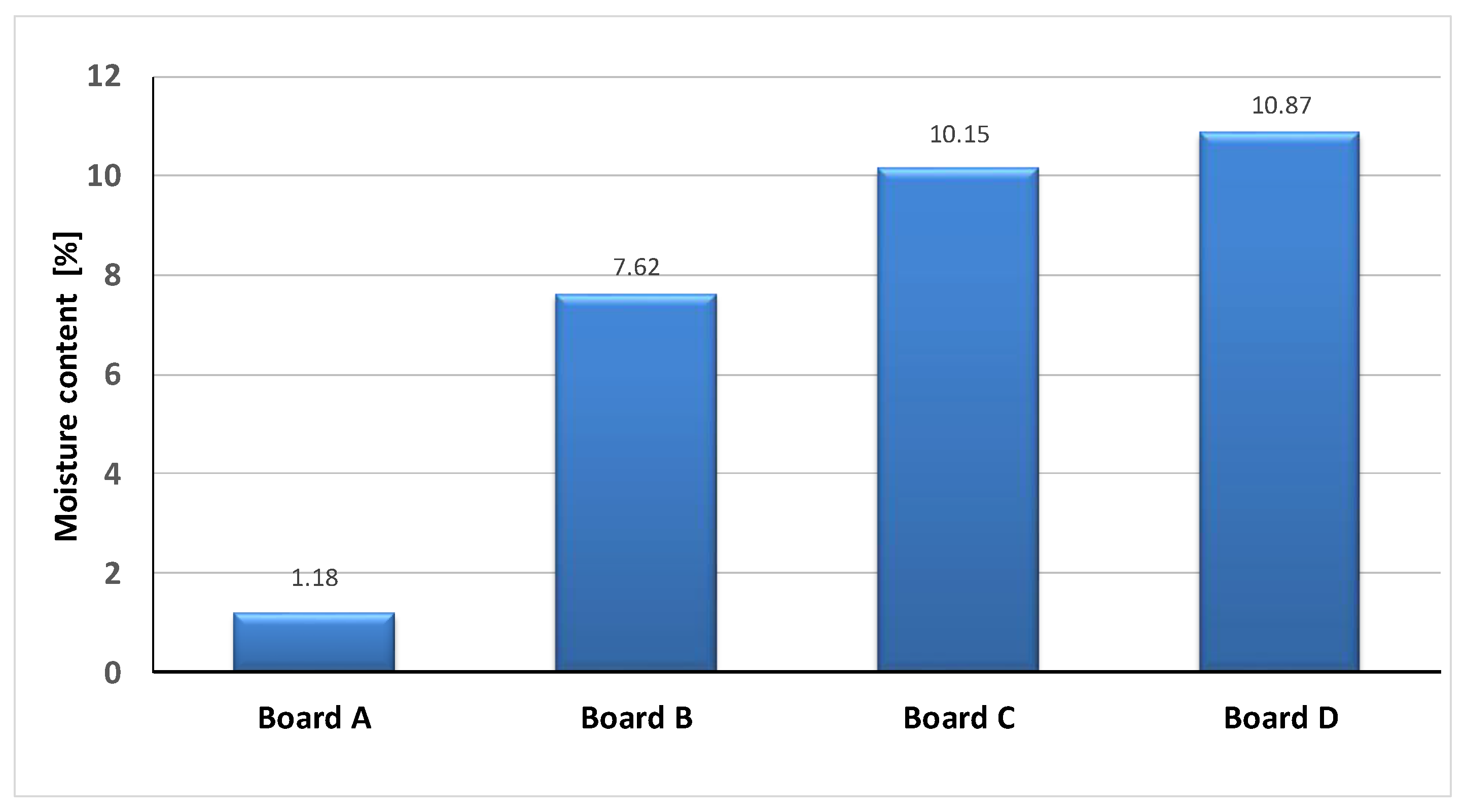

- Recycled cellulose fibers were found to adversely affect the fiber cement boards by increasing their absorbability. As the percentage of recycled fibers in the boards increased, so did their mass moisture content. As the time of storage of the boards in water increased, the modulus of rupture was found to decline evenly in all the tested fiber cement boards. In the case of the boards with a 50% recycled cellulose fiber content, the decrease in MOR due to moisture buildup for 96 h reached 50%, while for the reference board (series A) it amounted to 45%;

- The acoustic emission testing combined with artificial neural networks confirmed (on the basis of the count of recognized AE events accompanying the rupture of fibers) the significant effect of the recycled cellulose fibers on the properties of the fiber cement boards, reflected in the fall in the number or AE events registered during the bending test;

- Already, the storage of the boards in water for 1 h resulted in a significant decrease in the number of AE events recognized as accompanying the rupture of fibers. In the case of the boards containing more than 25% of recycled cellulose fibers, the fall in the number of AE events originating from the rupture of fibers exceeded 50%;

- Recycled cellulose fibers are more susceptible to moisture buildup, which results in the loss of the fiber cement boards’ strength and at the same time in the lowering of their acoustic activity during bending;

- The SEM examinations showed that in the boards stored in water most of the fibers had not ruptured during bending, but had been pulled out of the bugholes in the cement matrix without generating registrable AE events.

Author Contributions

Funding

Conflicts of Interest

References

- Schabowicz, K.; Gorzelańczyk, T. Fabrication of fibre cement boards. In The Fabrication, Testing and Application of Fibre Cement Boards, 1st ed.; Ranachowski, Z., Schabowicz, K., Eds.; Cambridge Scholars Publishing: Newcastle Upon Tyne, UK, 2018; pp. 7–39. ISBN 978-1-5276-6. [Google Scholar]

- Bentchikou, M.; Guidoum, A.; Scrivener, K.; Silhadi, K.; Hanini, S. Effect of recycled cellulose fibres on the properties of lightweight cement composite matrix. Constr. Build. Mater. 2012, 34, 451–456. [Google Scholar] [CrossRef]

- Savastano, H.; Warden, P.G.; Coutts, R.S.P. Microstructure and mechanical properties of waste fibre–cement composites. Cem. Concr. Compos. 2005, 27, 583–592. [Google Scholar] [CrossRef]

- Coutts, R.S.P. A Review of Australian Research into Natural Fibre Cement Composites. Cem. Concr. Compos. 2005, 27, 518–526. [Google Scholar] [CrossRef]

- Schabowicz, K.; Szymków, M. Ventilated facades made of fibre-cement boards (in Polish). Mater. Budowlane 2016, 4, 112–114. [Google Scholar]

- Schabowicz, K.; Jóźwiak-Niedźwiedzka, D.; Ranachowski, Z.; Kudela, S.; Dvorak, T. Microstructural characterization of cellulose fibres in reinforced cement boards. Arch. Civ. Mech. Eng. 2018, 4, 1068–1078. [Google Scholar] [CrossRef]

- Schabowicz, K.; Gorzelańczyk, T.; Szymków, M. Identification of the degree of fibre-cement boards degradation under the influence of high temperature. Autom. Constr. 2019, 101, 190–198. [Google Scholar] [CrossRef]

- Schabowicz, K.; Gorzelańczyk, T.; Szymków, M. Identification of the degree of degradation of fibre-cement boards exposed to fire by means of the acoustic emission method and artificial neural networks. Materials 2019, 12, 656. [Google Scholar] [CrossRef] [PubMed]

- Gorzelańczyk, T.; Schabowicz, K.; Szymków, M. Non-destructive testing of fibre-cement boards, using acoustic emission (in Polish). Przegląd Spaw. 2016, 88, 35–38. [Google Scholar] [CrossRef]

- Gorzelańczyk, T.; Schabowicz, K. Tests of fibre-cement boards containing recycled materials. Mater. Bud. 2015, 10, 27–29. (In Polish) [Google Scholar]

- Ardanuy, M.; Claramunt, J.; Toledo Filho, R.D. Cellulosic Fibre Reinforced Cement-Based Composites: A Review of Recent Research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef]

- EN 12467–Cellulose Fibre Cement Flat Sheets. Product Specification and Test Methods. 2018. Available online: https://standards.cen.eu/dyn/www/f?p=204:110:0::::FSP_PROJECT,FSP_ORG_ID:66671,6110&cs=1151E39EDCD9EF75E3C2D401EB5818ACD (accessed on 25 April 2018).

- Gorzelańczyk, T.; Schabowicz, K. Effect of freeze–thaw cycling on the failure of fibre-cement boards, assessed using acoustic emission method and artificial neural network. Materials 2019, 12, 2181. [Google Scholar] [CrossRef] [PubMed]

- Adamczak-Bugno, A.; Gorzelańczyk, T.; Krampikowska, A.; Szymków, M. Non-destructive testing of the structure of fibre-cement materials by means of a scanning electron microscope. Bad. Nieniszcz. Diagn. 2017, 3, 20–23. (In Polish) [Google Scholar] [CrossRef]

- Claramunt, J.; Ardanuy, M.; García-Hortal, J.A. Effect of drying and rewetting cycles on the structure and physicochemical characteristics of softwood fibres for reinforcement of cementitious composites. Carbohydr. Polym. 2010, 79, 200–205. [Google Scholar] [CrossRef]

- Mohr, B.J.; Nanko, H.; Kurtis, K.E. Durability of kraft pulp fibre-cement composites to wet/dry cycling. Cem. Concr. Compos. 2005, 27, 435–448. [Google Scholar] [CrossRef]

- Pizzol, V.D.; Mendes, L.M.; Savastano, H.; Frías, M.; Davila, F.J.; Cincotto, M.A.; John, V.M.; Tonoli, G.H.D. Mineralogical and microstructural changes promoted by accelerated carbonation and ageing cycles of hybrid fibre–cement composites. Constr. Build. Mater. 2014, 68, 750–756. [Google Scholar] [CrossRef]

- Adamczak-Bugno, A.; Świt, G.; Krampikowska, A. Time-frequency analysis of acoustic emission signals generated by cement-fiber boards during bending test. MATEC Web Conf. 2018, 174, 1–10. [Google Scholar] [CrossRef][Green Version]

- Li, Z.; Zhou, X.; Bin, S. Fibre-Cement extrudates with perlite subjected to high temperatures. J. Mater. Civ. Eng. 2004, 3, 221–229. [Google Scholar] [CrossRef]

- Kaczmarek, M.; Piwakowski, B.; Drelich, R. Noncontact Ultrasonic Nondestructive Techniques: State of the Art and Their Use in Civil Engineering. J. Infrastruct. Syst. 2017, 23, 45–56. [Google Scholar] [CrossRef]

- Stark, W. Non-destructive evaluation (NDE) of composites: Using ultrasound to monitor the curing of composites. In Non-destructive Evaluation (NDE) of Polymer Matrix Composites. Techniques and Applications, 1st ed.; Karbhari, V.M., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2013; pp. 136–181. ISBN 978-0-85709-344-8. [Google Scholar]

- Dębowski, T.; Lewandowski, M.; Mackiewicz, S.; Ranachowski, Z.; Schabowicz, K. Ultrasonic tests of fibre-cement boards (in Polish). Przegląd Spawalnictwa 2016, 10, 69–71. [Google Scholar] [CrossRef]

- Drelich, R.; Gorzelanczyk, T.; Pakuła, M.; Schabowicz, K. Automated control of cellulose fibre cement boards with a non-contact ultrasound scanner. Autom. Constr. 2015, 57, 55–63. [Google Scholar] [CrossRef]

- Schabowicz, K.; Gorzelańczyk, T. A non-destructive methodology for the testing of fibre cement boards by means of a non-contact ultrasound scanner. Constr. Build. Mater. 2016, 102, 200–207. [Google Scholar] [CrossRef]

- Chady, T.; Schabowicz, K.; Szymków, M. Automated multisource electromagnetic inspection of fibre-cement boards. Autom. Constr. 2018, 94, 383–394. [Google Scholar] [CrossRef]

- Chady, T.; Schabowicz, K. Non-destructive testing of fibre-cement boards, using terahertz spectroscopy in time domain. Bad. Nieniszcz. Diagn. 2016, 1–2, 62–66. (In Polish) [Google Scholar]

- Ranachowski, Z.; Ranachowski, P.; Dębowski, T.; Gorzelańczyk, T.; Schabowicz, K. Investigation of structural degradation of fibre cement boards due to thermal impact. Materials 2019, 12, 944. [Google Scholar] [CrossRef]

- Schabowicz, K.; Ranachowski, Z.; Jóźwiak-Niedźwiedzka, D.; Radzik, Ł.; Kudela, S.; Dvorak, T. Application of X-ray microtomography to quality assessment of fibre cement boards. Constr. Build. Mater. 2016, 110, 182–188. [Google Scholar] [CrossRef]

- Ranachowski, Z.; Schabowicz, K. The contribution of fibre reinforcement system to the overall toughness of cellulose fibre concrete panels. Constr. Build. Mater. 2017, 156, 1028–1034. [Google Scholar] [CrossRef]

- Ranachowski, Z. The application of neural networks to classify the acoustic emission waveforms emitted by the concrete under thermal stress. Arch. Acoust. 1996, 21, 89–98. [Google Scholar]

- Ranachowski, Z.; Jóźwiak-Niedźwiedzka, D.; Brandt, A.M.; Dębowski, T. Application of acoustic emission method to determine critical stress in fibre reinforced mortar beams. Arch. Acoust. 2012, 37, 261–268. [Google Scholar] [CrossRef]

- Yuki, H.; Homma, K. Estimation of acoustic emission source waveform of fracture using a neural network. NDT E Int. 1996, 29, 21–25. [Google Scholar] [CrossRef]

- Schabowicz, K. Neural networks in the NDT identification of the strength of concrete. Arch. Civ. Mech. Eng. 2005, 51, 371–382. [Google Scholar]

- Łazarska, M.; Woźniak, T.; Ranachowski, Z.; Trafarski, A.; Domek, G. Analysis of acoustic emission signals at austempering of steels using neural networks. Met. Mater. Int. 2017, 23, 426–433. [Google Scholar] [CrossRef]

- Woźniak, T.Z.; Ranachowski, Z.; Ranachowski, P.; Ozgowicz, W.; Trafarski, A. The application of neural networks for studying phase transformation by the method of acoustic emission in bearing steel. Arch. Civ. Mech. Eng. 2014, 59, 1705–1712. [Google Scholar] [CrossRef]

- Rucka, M.; Wilde, K. Experimental study on ultrasonic monitoring of splitting failure in reinforced concrete. J. Nondestr. Eval. 2013, 32, 372–383. [Google Scholar] [CrossRef]

- Rucka, M.; Wilde, K. Ultrasound monitoring for evaluation of damage in reinforced concrete. Bull. Pol. Acad. Sci.-Tech. 2015, 63, 65–75. [Google Scholar] [CrossRef]

- Schabowicz, K.; Ventilated, F. Fibre-Cement Board Production Technology and Testing Methods. Available online: http://www.oficyna.pwr.edu.pl/ksiazki/elewacje-wentylowane-technologia-produkcji-i-metody-badania-plyt-wloknisto-cementowych/ (accessed on 15 May 2020). (In Polish).

| Raw Material | Approximate Percentage |

|---|---|

| Cement | ~60 [%] |

| Cellulose (dry) | ~8 [%] |

| PVA | ~2 [%] |

| Kaolin or lime | ~30 [%] |

| Total | ~100 [%] |

| Additives and admixtures | |

| Hyperplasticizer | ~0.1 l/t *) |

| Didecyldimethylammonium (DDAC) or bromide chloride (DDAB) | ~0.1 l/t *) |

| Pearlite | ~1 kg/t *) |

| Mica | ~1 kg/t *) |

| Microsphere | ~1 kg/t *) |

| Antifoaming agent | ~0.26 l/t *) |

| Raw Material | Requirements | ||||

|---|---|---|---|---|---|

| Cellulose | Pulp | ||||

| Pulping Time | [min] | 0 | 40 | 70 | |

| Schopper Riegler degrees | [°SR] | 12.5 | 23.9 | 50.0 | |

| Apparent specific weight | [kg/m3] | 640 | 852 | 905 | |

| Tension coefficient | [Nm/g] | 49.9 | 106.5 | 112.1 | |

| Rupture coefficient | [kPa/m2/g] | 3.0 | 7.4 | 7.4 | |

| Flexibility | [%] | 2.0 | 3.1 | 2.9 | |

| Tear coefficient | [mN m2/g] | 23.7 | 20.1 | 19.7 | |

| Kappa number | 25 ± 3 | ||||

| Dryness | [%] | 80 | |||

| Min. fiber length | [mm] | 1.6–2.7 | |||

| Cement | Portland Cement CEM I 42.5 R Blain Fineness: 3200 cm2/g (range 3200–3700 cm2/g) | ||||

| Chemical Analysis | Recommended Values | ||||

| SiO2 | ~21.0% | ||||

| Al2O3 | ~6.3% | ||||

| Fe2O3 | ~3.0% | ||||

| CaO | ~66% | ||||

| MgO | ~1.0% | ||||

| SO3 | <3.2% | ||||

| L.O.I. | ~2.5% as little as possible | ||||

| Free CaO | <1.5% | ||||

| Mineralogical Composition | Recommended Values | ||||

| C3S | 40–70% | ||||

| C2S | <20% | ||||

| C3A | 7–10% | ||||

| C4AF | 5–15% | ||||

| PVA-polyvinyl acetate | Polyvinyl Acetate | ||||

| Fiber length | 6 mm | ||||

| Thickness | 1.6–2.0 dtex | ||||

| Dry tensile strength | 11.5 cN/dtex | ||||

| Dry E-modulus | 275 | ||||

| Elongation at dry rupture | 7.4% | ||||

| Kaolin | Specific weight 2.6 g/cm3 Weight density 0.35–0.45 g/cm3 Chemical Analysis: SiO2 46–49% Al2O3 35% Na2O 0.07% K2O 1.0% MgO 0.2% L.O.I. max. 10% | ||||

| Lime | CaCO3 Specific weight 2.73 g/cm3 | ||||

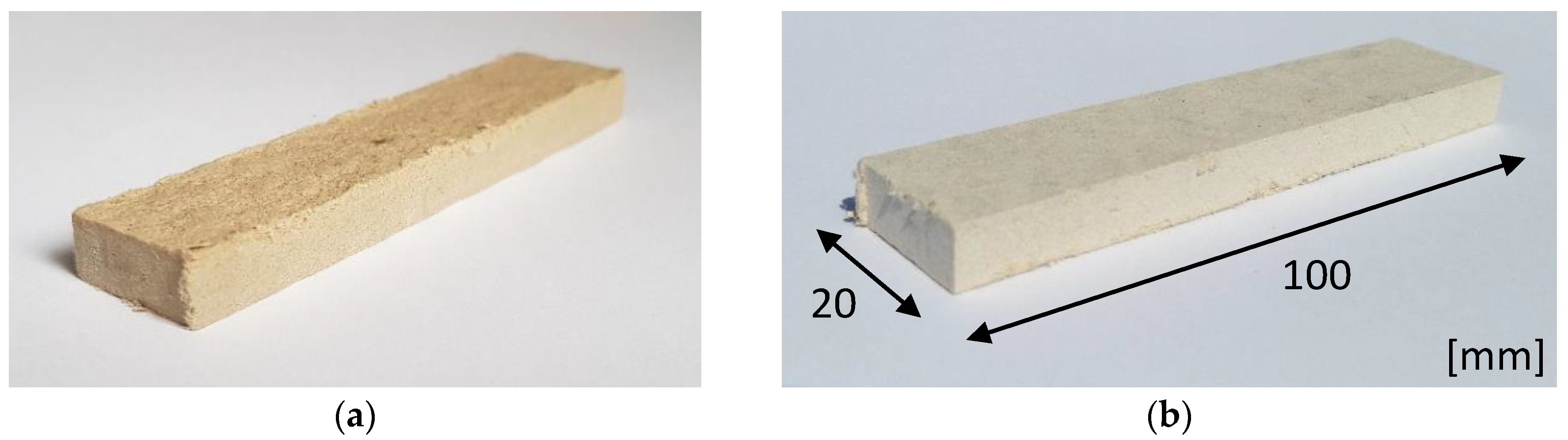

| Board Denotation | Type of Board | Board Thickness [mm] | View of Board |

|---|---|---|---|

| A | Board without recycled cellulose fibers | 8.0 |  |

| B | Board with 10% recycled cellulose fibers content | 8.0 |  |

| C | Board with 25% recycled cellulose fibers content | 8.0 |  |

| D | Board with 50% recycled cellulose fibers content | 8.0 |  |

| Board Denotation | Absorbability nw [%] After Storage in Water for: | Moisture Content | ||||||

|---|---|---|---|---|---|---|---|---|

| 1 h | 2 h | 3 h | 24 h | 48 h | 72 h | 96 h | wm [%] | |

| A | 6.40 | 7.15 | 7.73 | 8.02 | 10.88 | 11.90 | 11.91 | 1.18 |

| B | 9.14 | 11.08 | 11.72 | 14.22 | 19.05 | 20.51 | 16.51 | 7.62 |

| C | 11.24 | 11.89 | 12.34 | 16.78 | 21.45 | 22.20 | 22.21 | 10.15 |

| D | 12.89 | 13.74 | 14.54 | 18.38 | 22.86 | 23.64 | 23.65 | 10.87 |

| Board Denotation | Mean MOR [MPa] (In Two Directions) Acc. to [12] After Storage in Water for: | |||||||

|---|---|---|---|---|---|---|---|---|

| 0 h (dry) | 1 h | 2 h | 3 h | 24 h | 48 h | 72 h | 96 h | |

| A | 29.79 | 26.91 | 25.16 | 24.44 | 19.28 | 17.34 | 16.80 | 16.65 |

| B | 20.71 | 19.18 | 17.23 | 15.87 | 13.41 | 12.50 | 12.20 | 12.12 |

| C | 16.00 | 15.11 | 14.67 | 13.15 | 11.07 | 10.59 | 10.47 | 10.27 |

| D | 13.18 | 12.22 | 11.56 | 10.76 | 9.45 | 7.28 | 6.87 | 6.76 |

| Board Denotation | Count of AE Events Recognized as Accompanying Rupture of Fibers | |||

|---|---|---|---|---|

| 0 h (dry) | 1 h | 2 h | 24 h | |

| A | 429 | 241 | 137 | 41 |

| B | 456 | 264 | 102 | 29 |

| C | 364 | 119 | 97 | 21 |

| D | 277 | 114 | 77 | 19 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gorzelańczyk, T.; Schabowicz, K.; Szymków, M. Tests of Fiber Cement Materials Containing Recycled Cellulose Fibers. Materials 2020, 13, 2758. https://doi.org/10.3390/ma13122758

Gorzelańczyk T, Schabowicz K, Szymków M. Tests of Fiber Cement Materials Containing Recycled Cellulose Fibers. Materials. 2020; 13(12):2758. https://doi.org/10.3390/ma13122758

Chicago/Turabian StyleGorzelańczyk, Tomasz, Krzysztof Schabowicz, and Mateusz Szymków. 2020. "Tests of Fiber Cement Materials Containing Recycled Cellulose Fibers" Materials 13, no. 12: 2758. https://doi.org/10.3390/ma13122758

APA StyleGorzelańczyk, T., Schabowicz, K., & Szymków, M. (2020). Tests of Fiber Cement Materials Containing Recycled Cellulose Fibers. Materials, 13(12), 2758. https://doi.org/10.3390/ma13122758