Atmospheric and Marine Corrosion of PEO and Composite Coatings Obtained on Al-Cu-Mg Aluminum Alloy

Abstract

1. Introduction

2. Materials and Methods

2.1. Samples Preparation

2.2. Electrochemical Measurements

2.3. Surface Morphology and Phase Analysis

2.4. Scratch Adhesion Test

2.5. Corrosion Tests

3. Results and Discussion

3.1. Coatings Properties

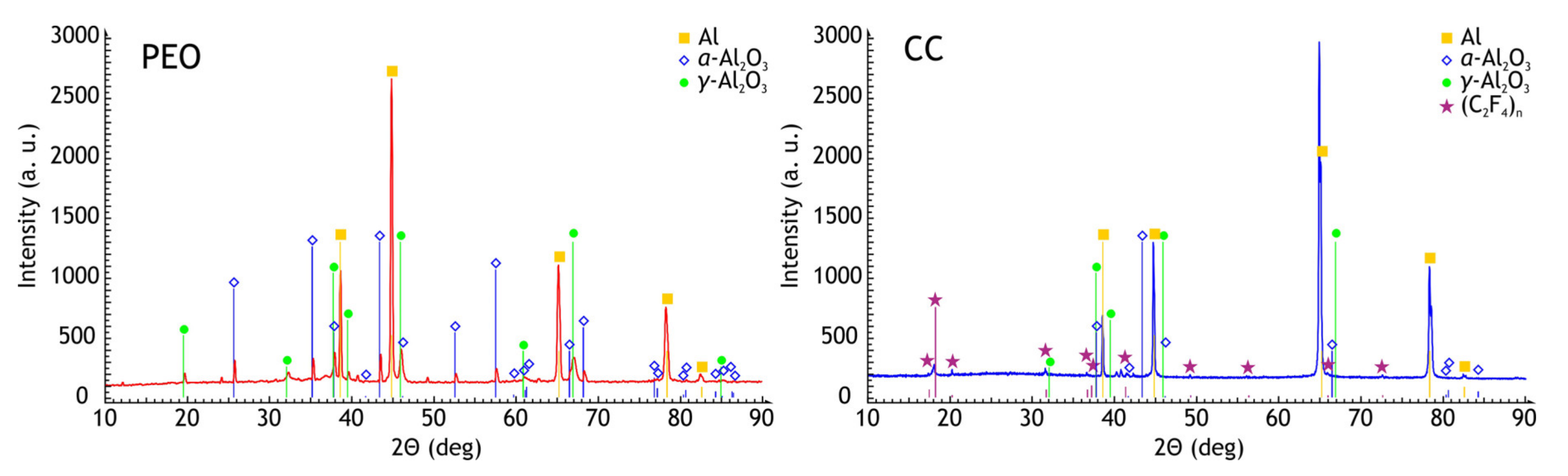

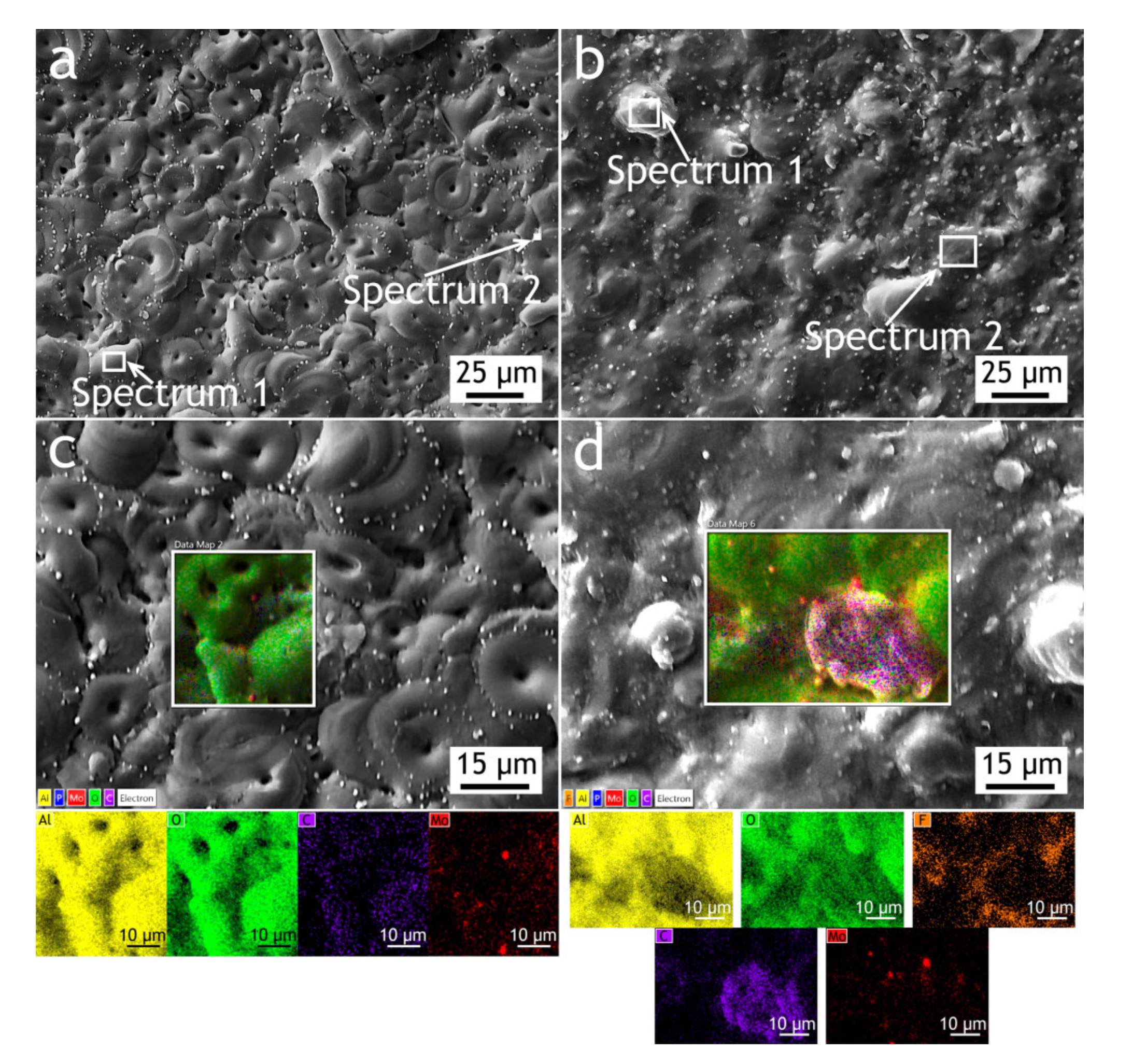

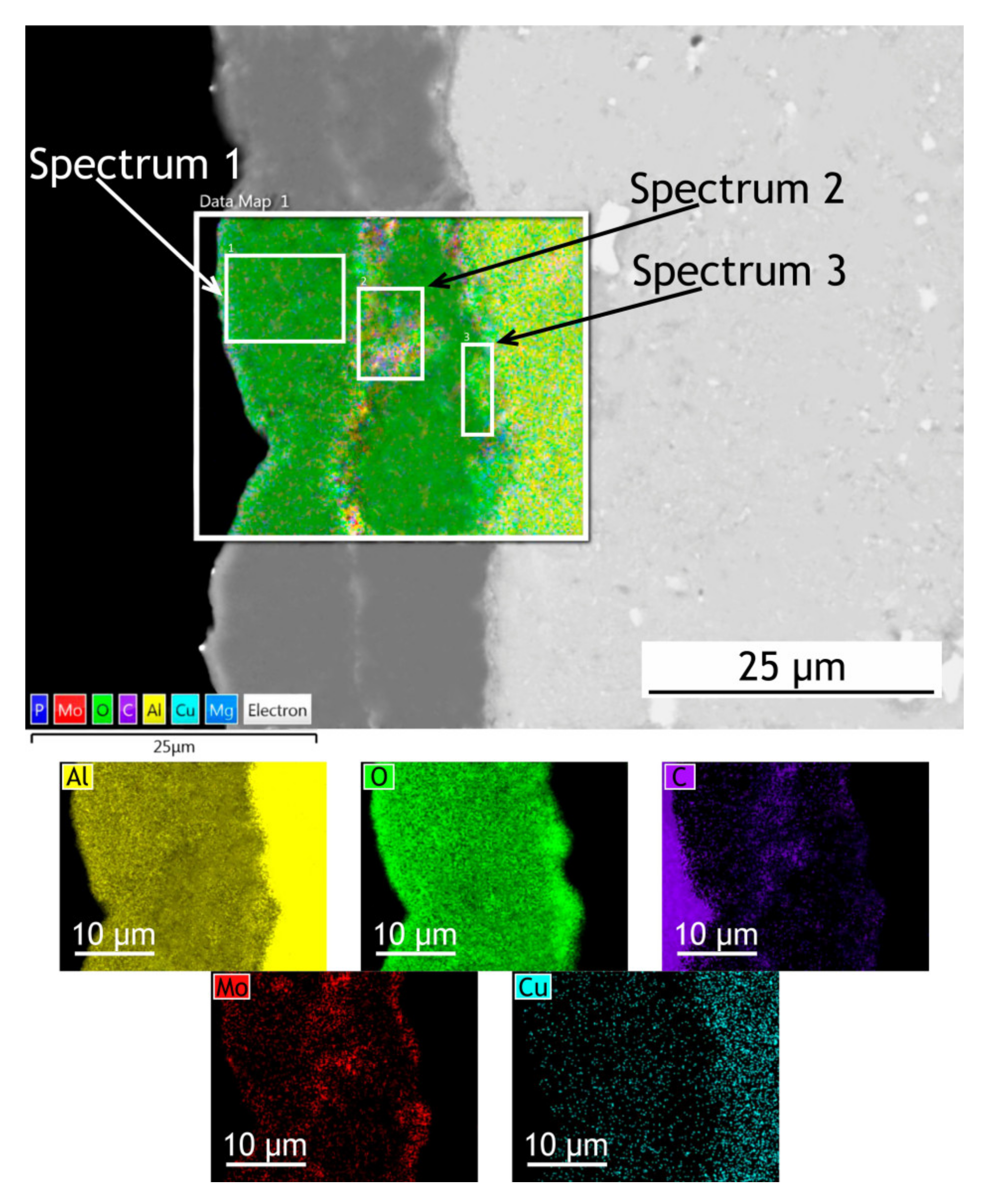

3.1.1. Surface Morphology and Phase Analysis

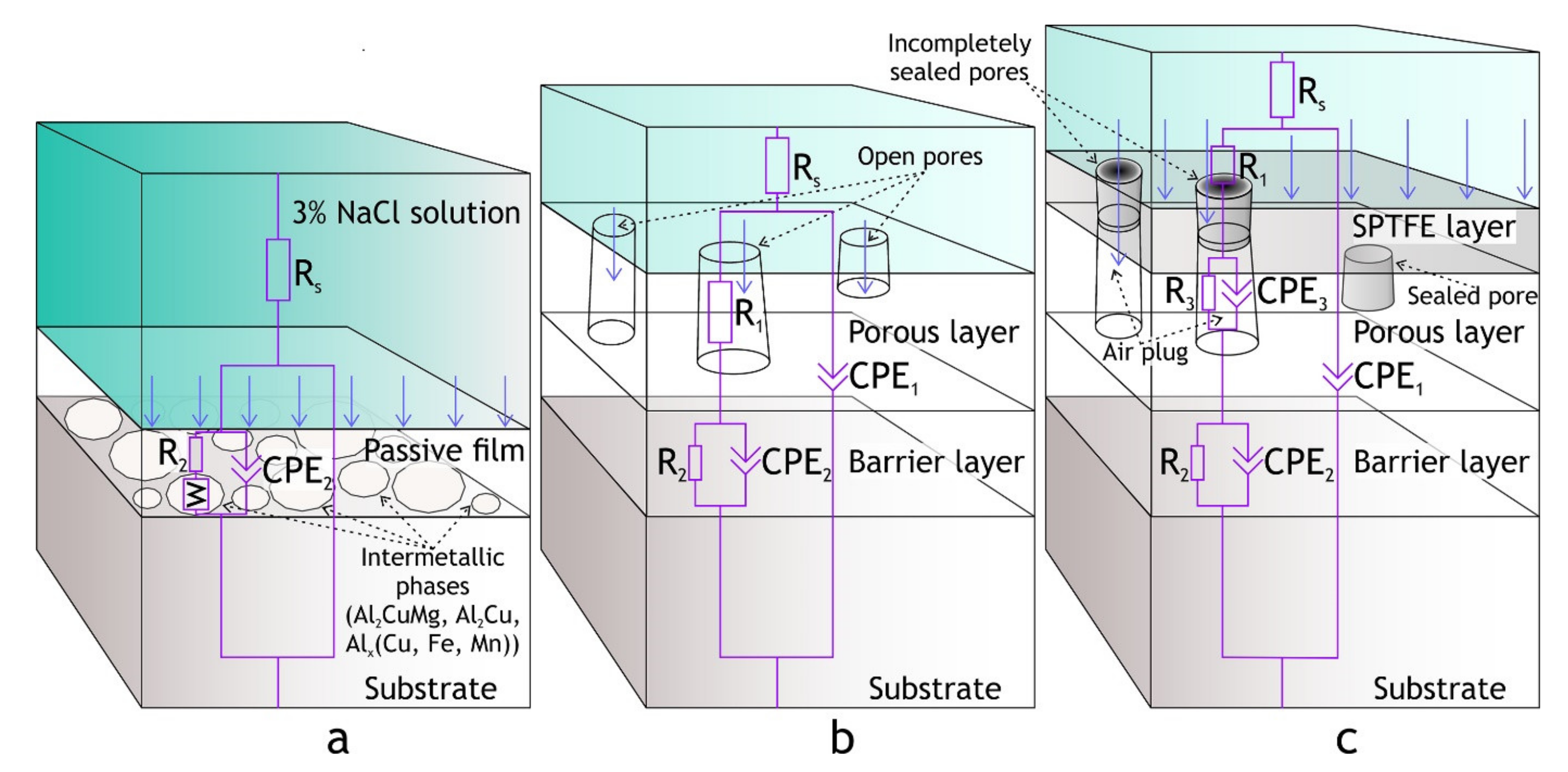

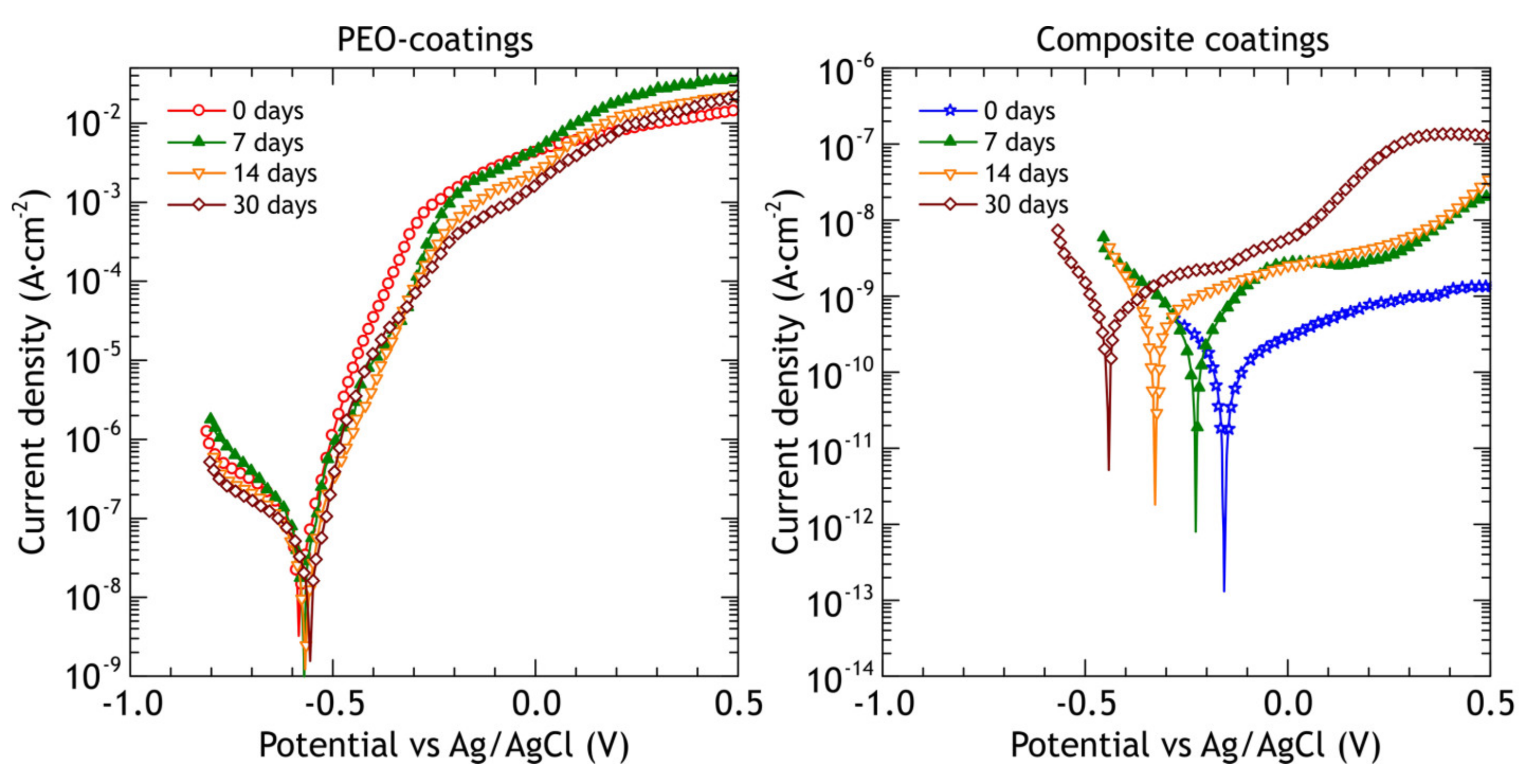

3.1.2. Electrochemical Measurements

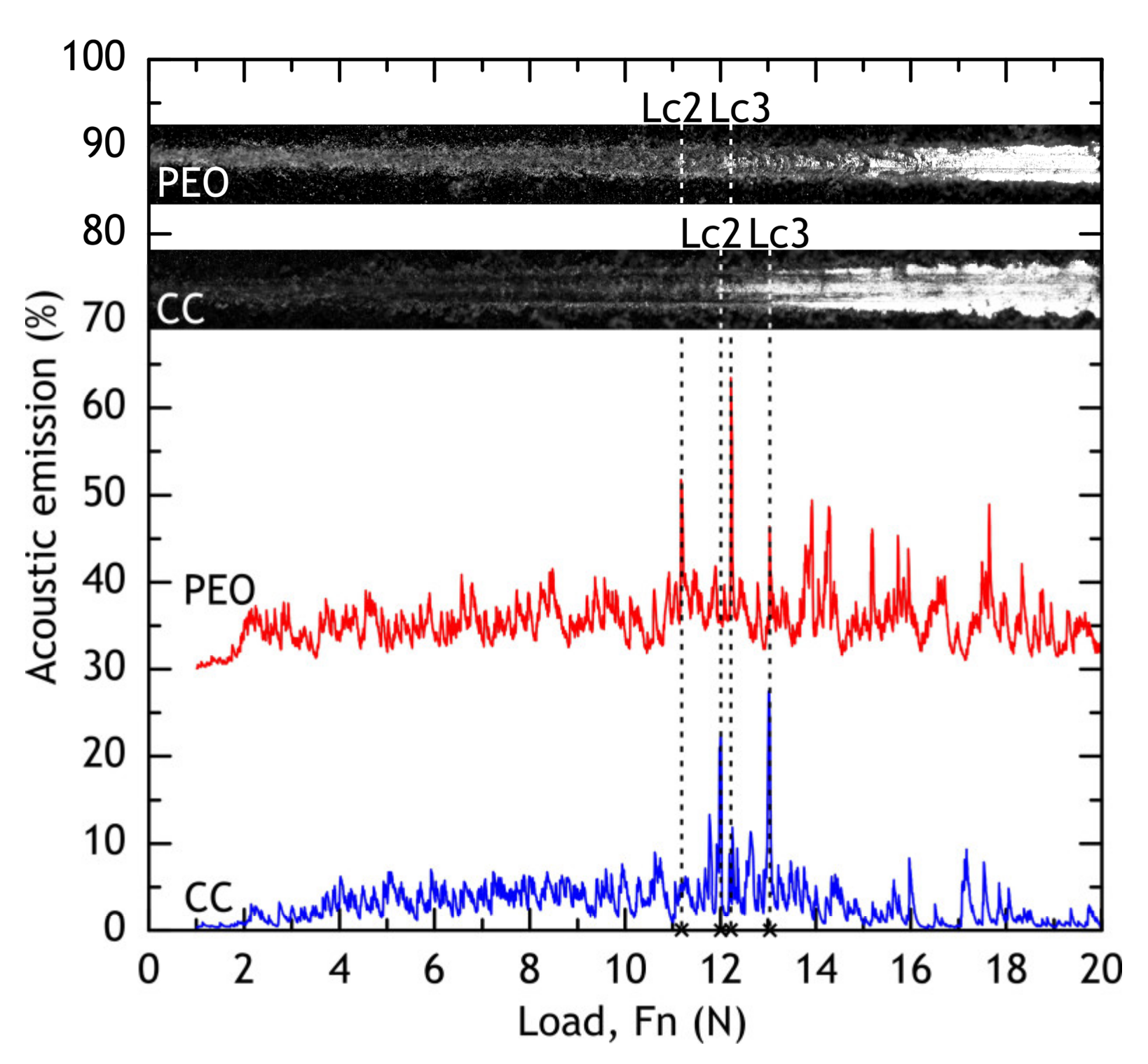

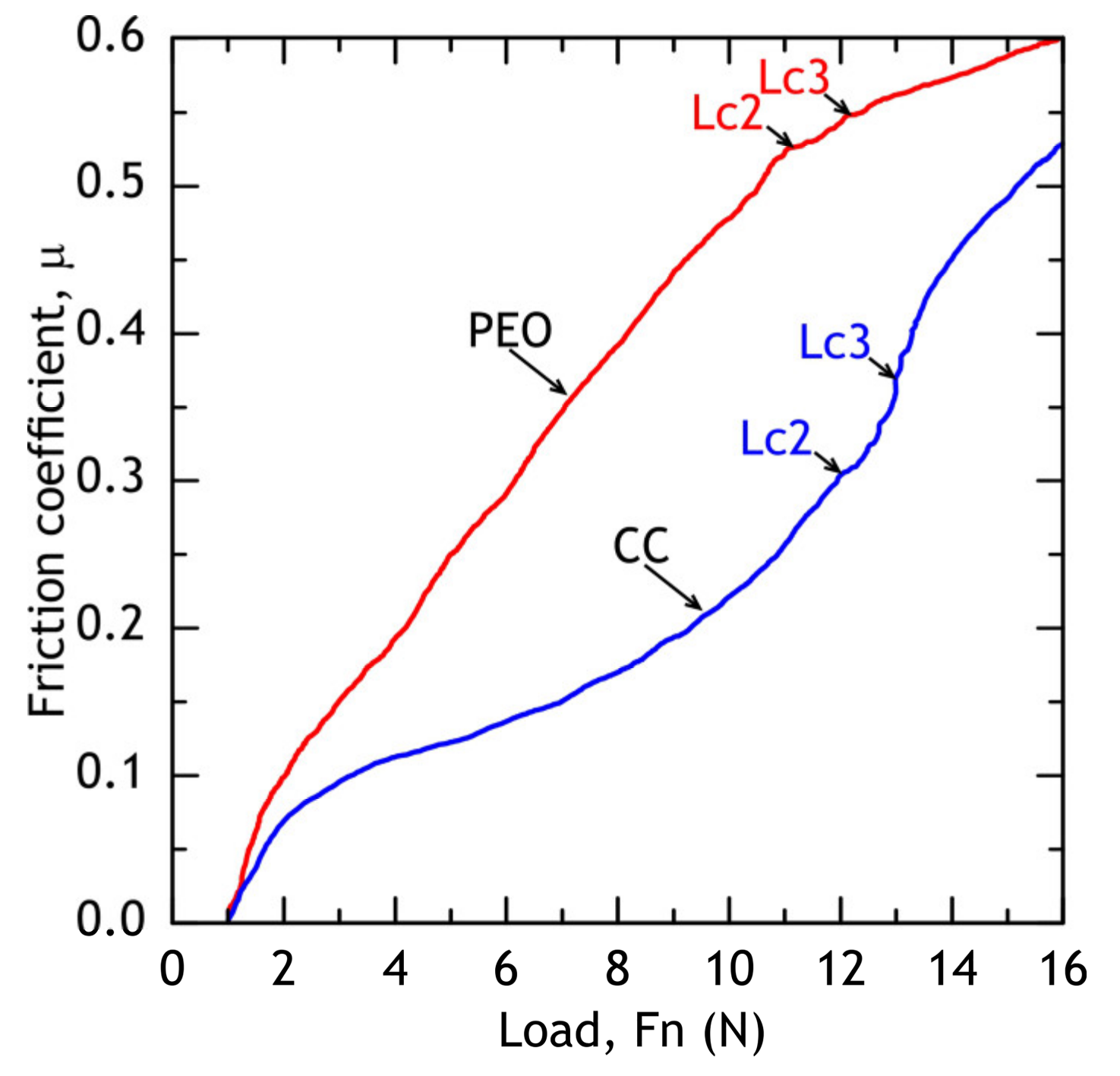

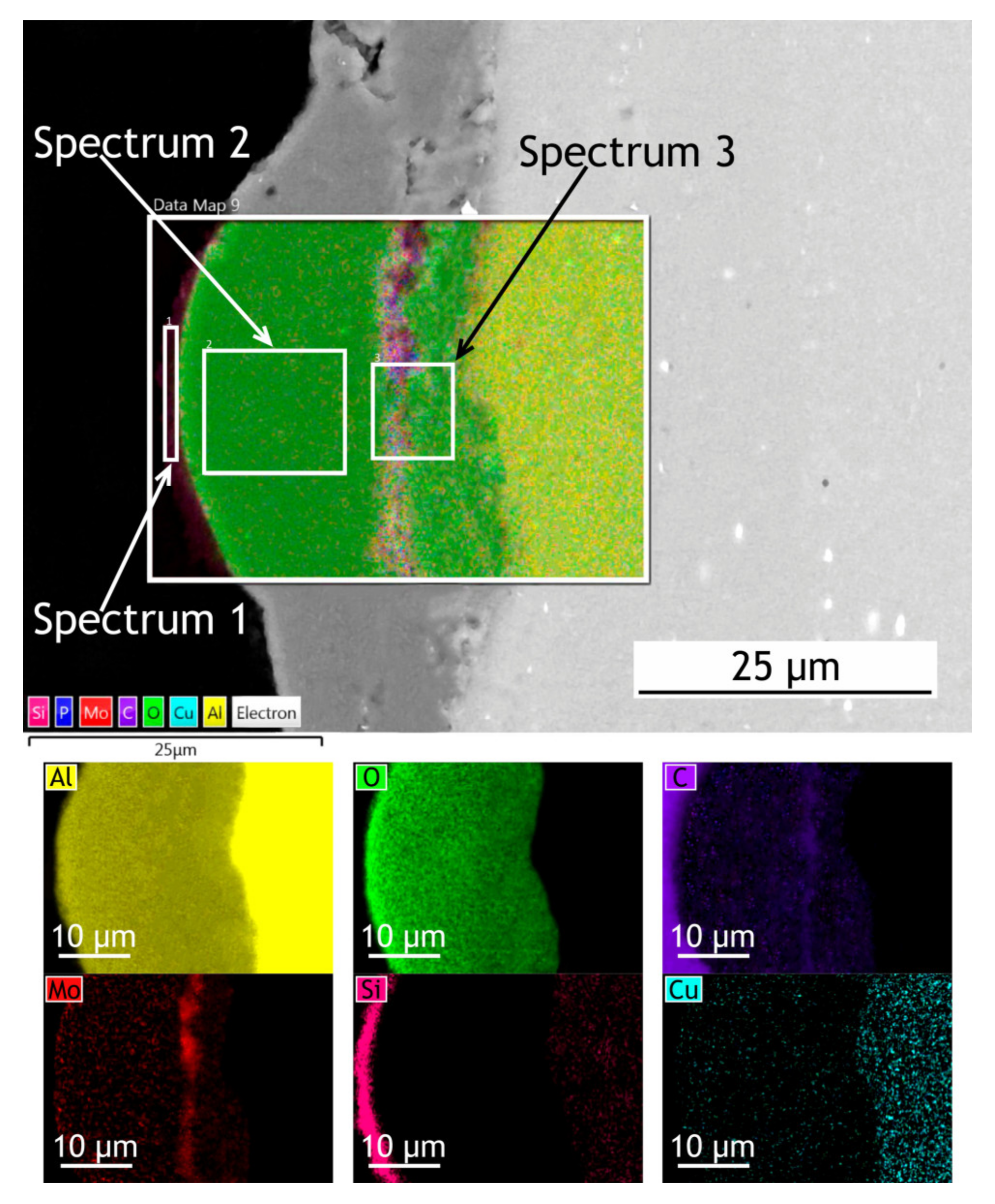

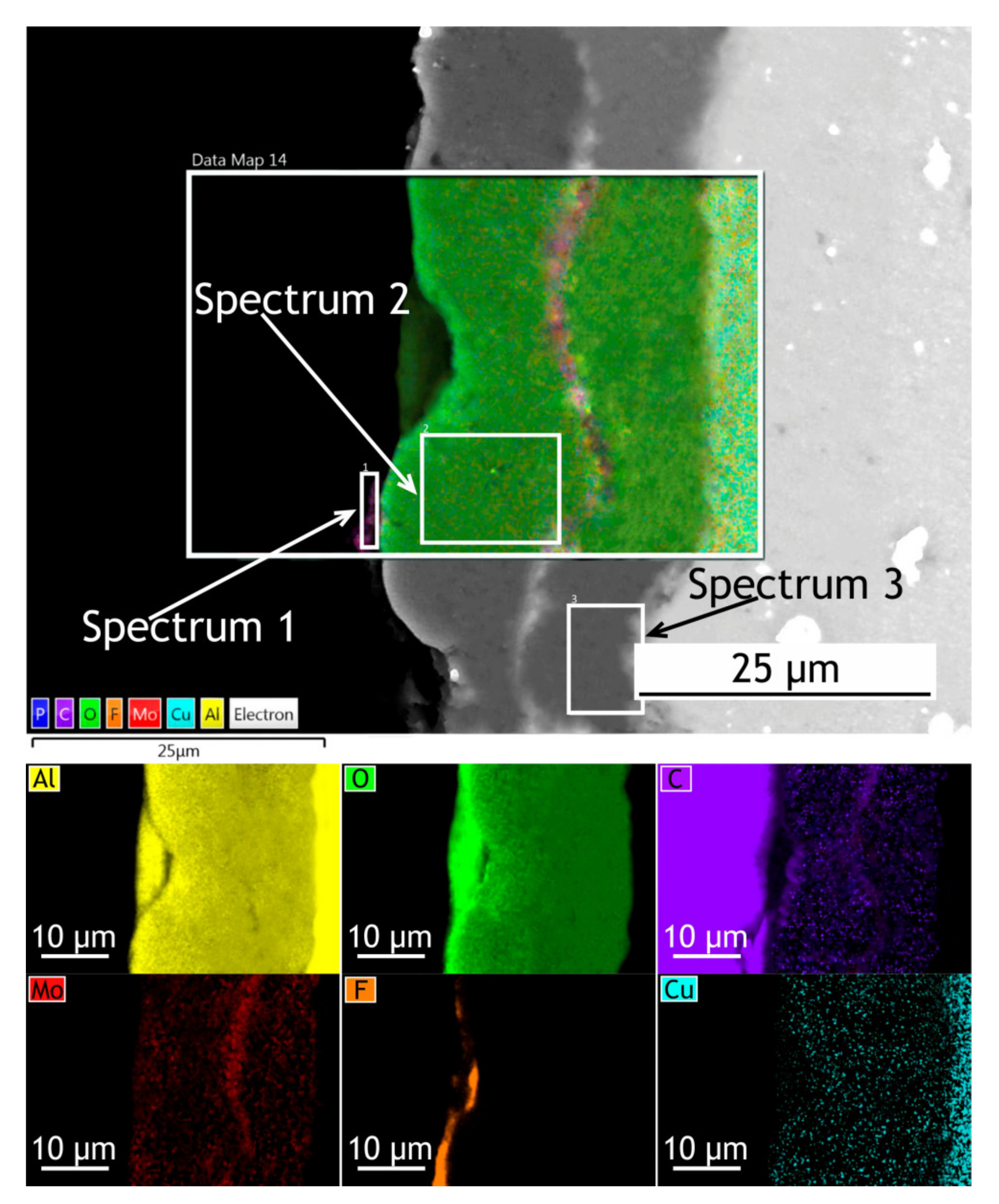

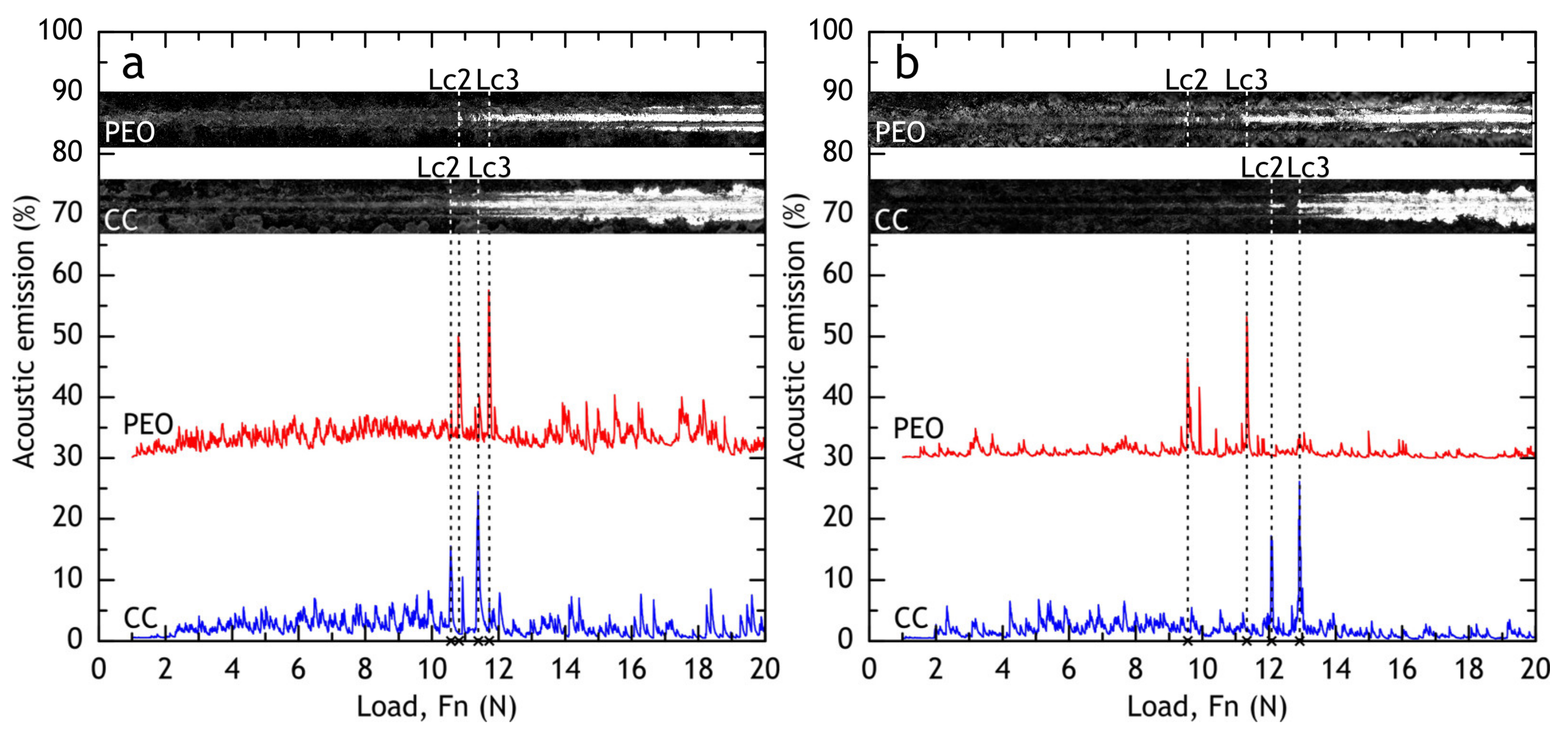

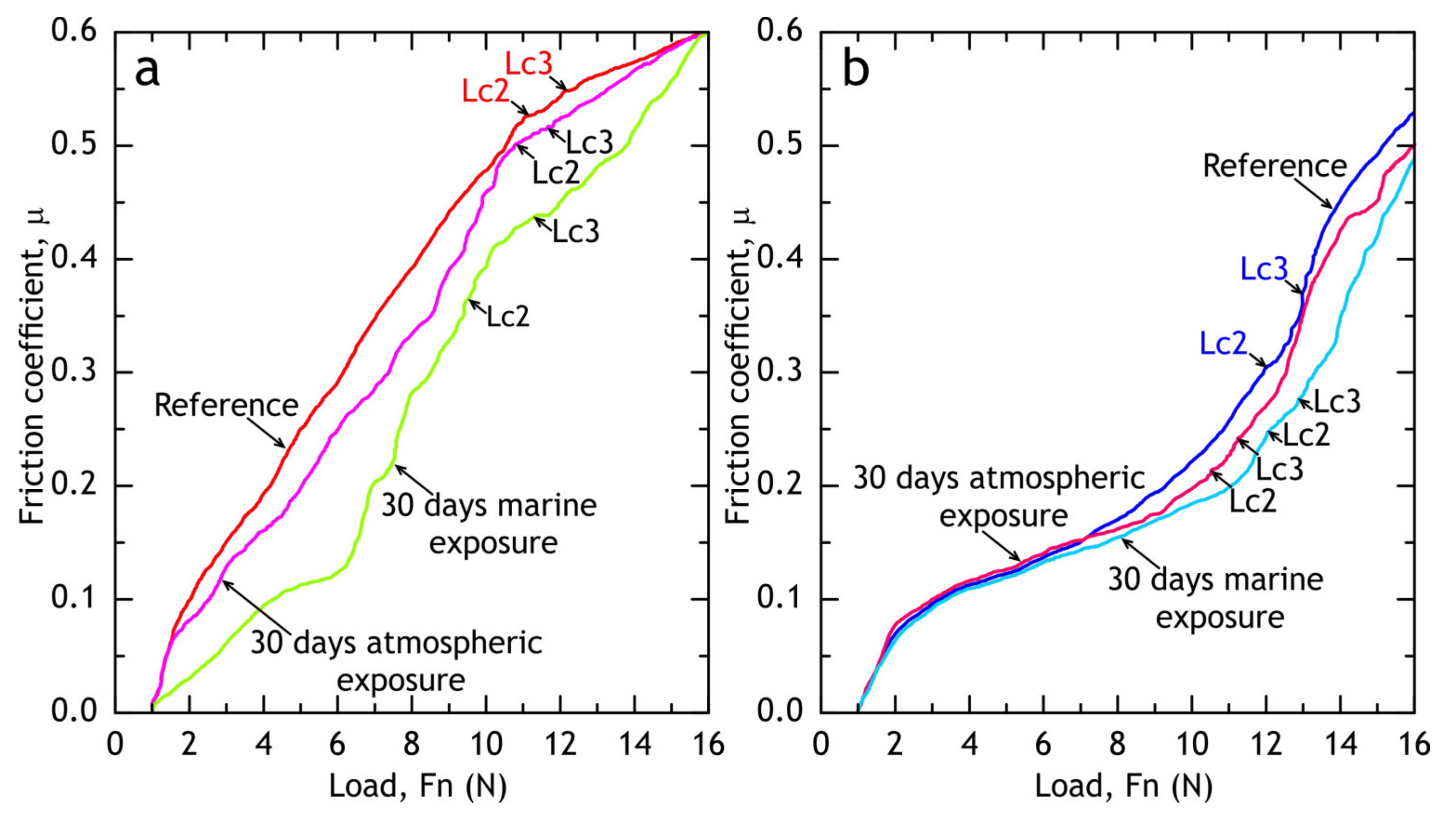

3.1.3. Scratch Test

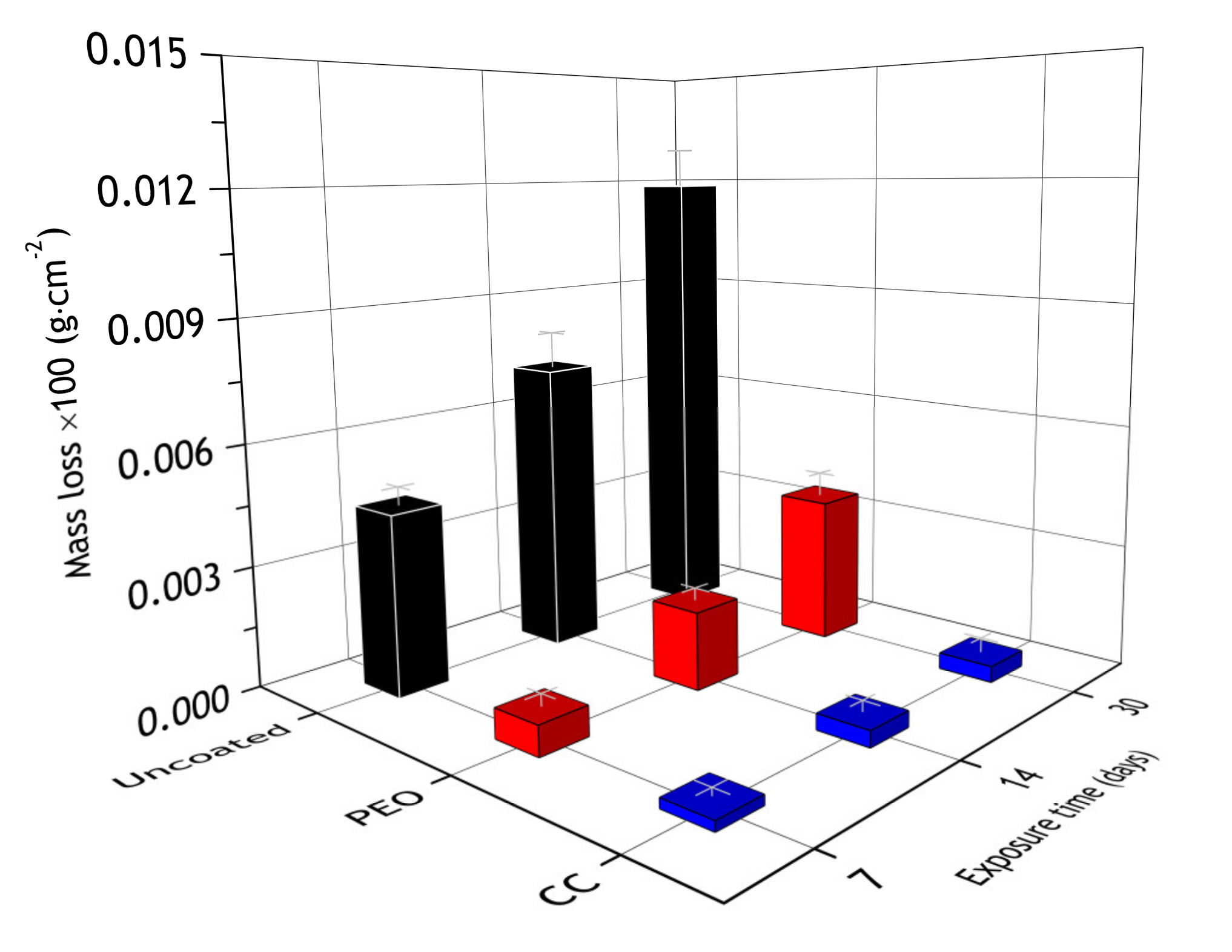

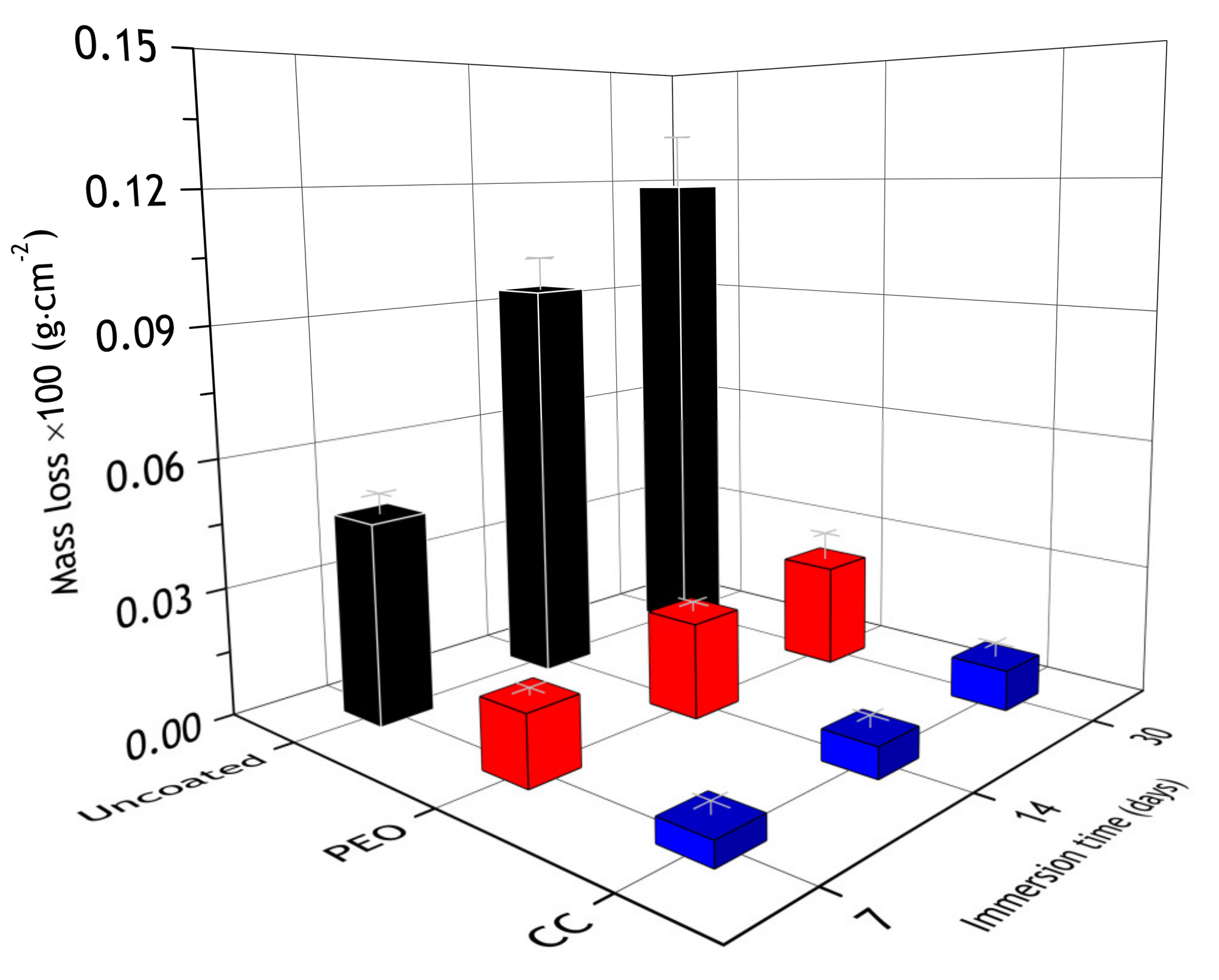

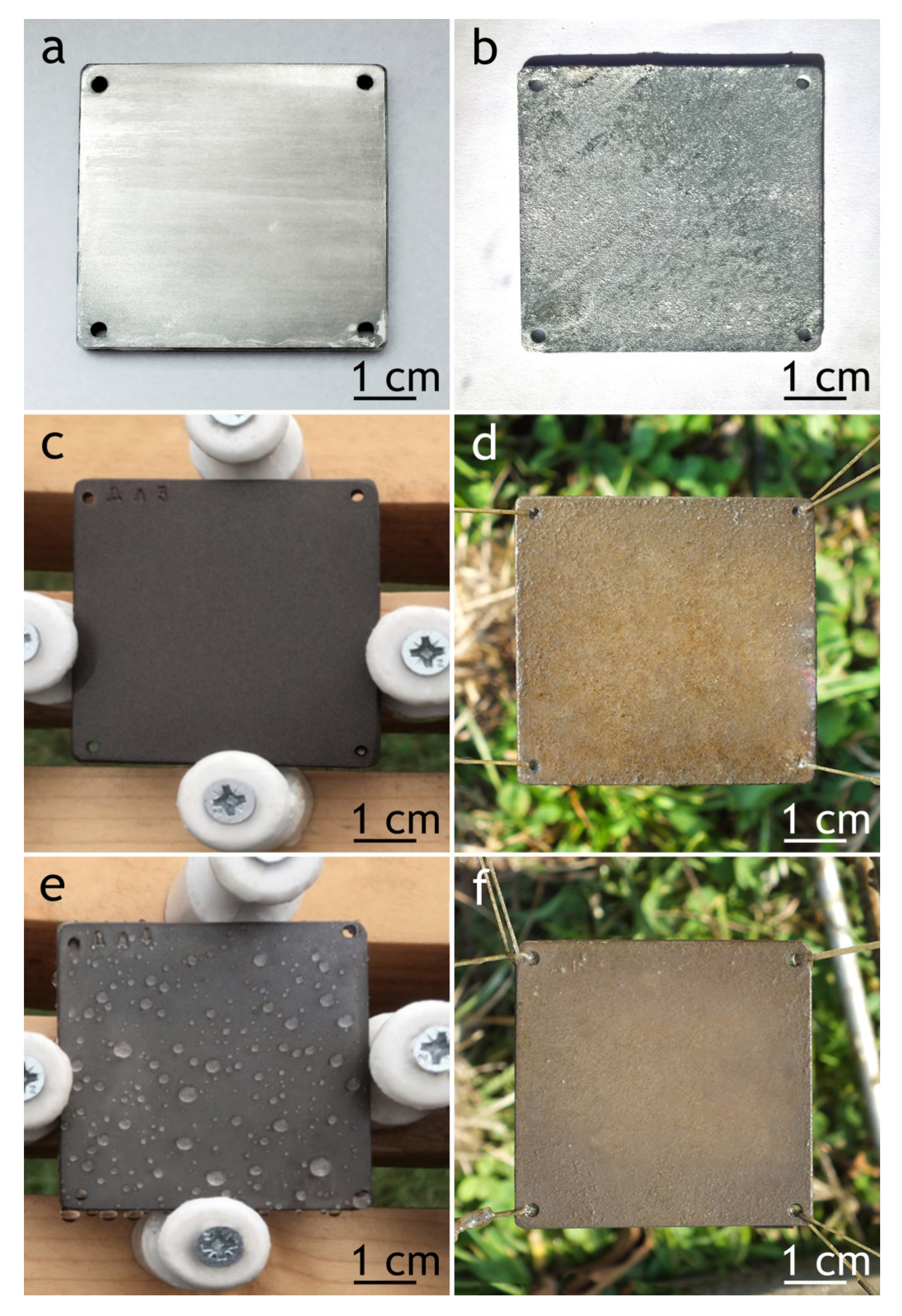

3.2. Atmospheric Corrosion

3.3. Marine Corrosion

3.4. Scratch Test of Coatings after Atmospheric Exposure and Marine Immersion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Shen, Y.; Sahoo, P.K.; Pan, Y. Microarc oxidation coatings on aluminum alloy drill pipe. Mater. Perform. 2017, 56, 42–44. [Google Scholar]

- López-Ortega, A.; Arana, J.L.; Rodríguez, E.; Bayón, R. Corrosion, wear and tribocorrosion performance of a thermally sprayed aluminum coating modified by plasma electrolytic oxidation technique for offshore submerged components protection. Corros. Sci. 2018, 143, 258–280. [Google Scholar] [CrossRef]

- López-Ortega, A.; Areitioaurtena, O.; Alves, S.A.; Goitandia, A.M.; Elexpe, I.; Arana, J.L.; Bayón, R. Development of a superhydrophobic and bactericide organic topcoat to be applied on thermally sprayed aluminum coatings in offshore submerged components. Prog. Org. Coat. 2019, 137, 105376. [Google Scholar] [CrossRef]

- Rao, Y.; Wang, Q.; Oka, D.; Ramachandran, C.S. On the PEO treatment of cold sprayed 7075 aluminum alloy and its effects on mechanical, corrosion and dry sliding wear performances thereof. Surf. Coat. Technol. 2020, 383, 125271. [Google Scholar] [CrossRef]

- Momber, A.W.; Marquardt, T. Protective coatings for offshore wind energy devices (OWEAs): A review. J. Coat. Technol. Res. 2018, 15, 13–40. [Google Scholar] [CrossRef]

- Javidi, M.; Fadaee, H. Plasma electrolytic oxidation of 2024-T3 aluminum alloy and investigation on microstructure and wear behavior. Appl. Surf. Sci. 2013, 286, 212–219. [Google Scholar] [CrossRef]

- Jiang, B.L.; Wang, Y.M. Plasma electrolytic oxidation treatment of aluminium and titanium alloys. In Surface Engineering of Light Alloys; Woodhead Publishing Limited: Cambridge, UK, 2010; pp. 110–154. ISBN 9781845695378. [Google Scholar]

- Toorani, M.; Aliofkhazraei, M.; Golabadi, M.; Rouhaghdam, A.S. Effect of lanthanum nitrate on the microstructure and electrochemical behavior of PEO coatings on AZ31 Mg alloy. J. Alloys Compd. 2017, 719, 242–255. [Google Scholar] [CrossRef]

- Allahyarzadeh, M.H.; Aliofkhazraei, M.; Rouhaghdam, A.R.S.; Torabinejad, V. Electrochemical tailoring of ternary Ni-W-Co(Al2O3) nanocomposite using pulse reverse technique. J. Alloys Compd. 2017, 705, 788–800. [Google Scholar] [CrossRef]

- Aliofkhazraei, M.; Taheri, P.; Rouhaghdam, A.S.; Dehghanian, C. Systematic study of nanocrystalline plasma electrolytic nitrocarburising of 316L austenitic stainless steel for corrosion protection. J. Mater. Sci. Technol. 2007, 23, 665–671. [Google Scholar]

- Gnedenkov, S.V.; Sinebryukhov, S.L.; Zavidnaya, A.G.; Egorkin, V.S.; Puz’, A.V.; Mashtalyar, D.V.; Sergienko, V.I.; Yerokhin, A.L.; Matthews, A. Composite hydroxyapatite–PTFE coatings on Mg–Mn–Ce alloy for resorbable implant applications via a plasma electrolytic oxidation-based route. J. Taiwan Inst. Chem. Eng. 2014, 45, 3104–3109. [Google Scholar] [CrossRef]

- Gnedenkov, S.V.; Egorkin, V.S.; Sinebryukhov, S.L.; Vyaliy, I.E.; Pashinin, A.S.; Emelyanenko, A.M.; Boinovich, L.B. Formation and electrochemical properties of the superhydrophobic nanocomposite coating on PEO pretreated Mg–Mn–Ce magnesium alloy. Surf. Coat. Technol. 2013, 232, 240–246. [Google Scholar] [CrossRef]

- Gnedenkov, S.V.; Sinebryukhov, S.L.; Mashtalyar, D.V.; Egorkin, V.S.; Sidorova, M.V.; Gnedenkov, A.S. Composite polymer-containing protective coatings on magnesium alloy MA8. Corros. Sci. 2014, 85, 52–59. [Google Scholar] [CrossRef]

- Gnedenkov, A.S.; Sinebryukhov, S.L.; Mashtalyar, D.V.; Gnedenkov, S.V. Features of the corrosion processes development at the magnesium alloys surface. Surf. Coat. Technol. 2013, 225, 112–118. [Google Scholar] [CrossRef]

- Zhang, R.H.; Zhao, J.; Liang, J. A novel multifunctional PTFE/PEO composite coating prepared by one-step method. Surf. Coat. Technol. 2016, 299, 90–95. [Google Scholar] [CrossRef]

- Lu, C.; Feng, X.; Yang, J.; Jia, J.; Yi, G.; Xie, E.; Sun, Y. Influence of surface microstructure on tribological properties of PEO-PTFE coating formed on aluminum alloy. Surf. Coat. Technol. 2019, 364, 127–134. [Google Scholar] [CrossRef]

- Forooshani, H.M.; Aliofkhazraei, M.; Rouhaghdam, A.S. Superhydrophobic aluminum surfaces by mechanical/chemical combined method and its corrosion behavior. J. Taiwan Inst. Chem. Eng. 2017, 72, 220–235. [Google Scholar] [CrossRef]

- Godja, N.; Kiss, N.; Löcker, C.; Schindel, A.; Gavrilovic, A.; Wosik, J.; Mann, R.; Wendrinsky, J.; Merstallinger, A.; Nauer, G. Preparation and characterization of spark-anodized Al-alloys: Physical, chemical and tribological properties. Tribol. Int. 2010, 43, 1253–1261. [Google Scholar] [CrossRef]

- Shchedrina, I.; Rakoch, A.G.; Henrion, G.; Martin, J. Non-destructive methods to control the properties of MAO coatings on the surface of 2024 aluminium alloy. Surf. Coat. Technol. 2014, 238, 27–44. [Google Scholar] [CrossRef]

- Dehnavi, V.; Liu, X.Y.; Luan, B.L.; Shoesmith, D.W.; Rohani, S. Phase transformation in plasma electrolytic oxidation coatings on 6061 aluminum alloy. Surf. Coat. Technol. 2014, 251, 106–114. [Google Scholar] [CrossRef]

- Wei, T.; Yan, F.; Tian, J. Characterization and wear- and corrosion-resistance of microarc oxidation ceramic coatings on aluminum alloy. J. Alloys Compd. 2005, 389, 169–176. [Google Scholar] [CrossRef]

- Venugopal, A.; Panda, R.; Manwatkar, S.; Sreekumar, K.; Krishna, L.R.; Sundararajan, G. Effect of micro arc oxidation treatment on localized corrosion behaviour of AA7075 aluminum alloy in 3.5 NaCl solution. Trans. Nonferrous Met. Soc. China 2012, 22, 700–710. [Google Scholar] [CrossRef]

- Fadaee, H.; Javidi, M. Investigation on the corrosion behaviour and microstructure of 2024-T3 Al alloy treated via plasma electrolytic oxidation. J. Alloys Compd. 2014, 604, 36–42. [Google Scholar] [CrossRef]

- Cui, S.; Han, J.; Li, W.; Kang, S.-B.; Lee, J.-M. Study on wear behavior of plasma electrolytic oxidation coatings on aluminum alloy. Rare Met. 2006, 25, 141–145. [Google Scholar] [CrossRef]

- Yerokhin, A.L.; Shatrov, A.; Samsonov, V.; Shashkov, P.; Pilkington, A.; Leyland, A.; Matthews, A. Oxide ceramic coatings on aluminium alloys produced by a pulsed bipolar plasma electrolytic oxidation process. Surf. Coat. Technol. 2005, 199, 150–157. [Google Scholar] [CrossRef]

- Wang, K.; Koo, B.H.; Lee, C.G.; Kim, Y.J.; Lee, S.H.; Byon, E. Effects of electrolytes variation on formation of oxide layers of 6061 Al alloys by plasma electrolytic oxidation. Trans. Nonferrous Met. Soc. China 2009, 19, 866–870. [Google Scholar] [CrossRef]

- Liu, R.; Wu, J.; Xue, W.; Qu, Y.; Yang, C.; Wang, B.; Wu, X. Discharge behaviors during plasma electrolytic oxidation on aluminum alloy. Mater. Chem. Phys. 2014, 148, 284–292. [Google Scholar] [CrossRef]

- Wen, L.; Wang, Y.; Zhou, Y.; Ouyang, J.H.; Guo, L.; Jia, D. Corrosion evaluation of microarc oxidation coatings formed on 2024 aluminium alloy. Corros. Sci. 2010, 52, 2687–2696. [Google Scholar] [CrossRef]

- Lampke, T.; Meyer, D.; Alisch, G.; Nickel, D.; Scharf, I.; Wagner, L.; Raab, U. Alumina coatings obtained by thermal spraying and plasma anodising—A comparison. Surf. Coat. Technol. 2011, 206, 2012–2016. [Google Scholar] [CrossRef]

- Li, Q.; Liang, J.; Liu, B.; Peng, Z.; Wang, Q. Effects of cathodic voltages on structure and wear resistance of plasma electrolytic oxidation coatings formed on aluminium alloy. Appl. Surf. Sci. 2014, 297, 176–181. [Google Scholar] [CrossRef]

- Wu, X.; Qin, W.; Guo, Y.; Xie, Z. Self-lubricative coating grown by micro-plasma oxidation on aluminum alloys in the solution of aluminate-graphite. Appl. Surf. Sci. 2008, 254, 6395–6399. [Google Scholar] [CrossRef]

- Parvizi, R.; Tan, M.Y.; Hughes, A.E. Recent Insights into Corrosion Initiation at the Nanoscale. In Fundamentals of Aluminium Metallurgy; Woodhead Publishing: Cambridge, UK, 2018; pp. 525–551. ISBN 9780081020630. [Google Scholar]

- Kablov, E.N.; Startsev, O.V.; Medvedev, I.M.; Panin, S.V. Corrosivity of a Marine Atmosphere. 1. Environmental Factors Influence (a Review). Korroz. Mater. Zashchita 2013, 12, 6–18. [Google Scholar]

- Cerchier, P.; Pezzato, L.; Moschin, E.; Coelho, L.B.; Olivier, M.G.M.; Moro, I.; Magrini, M. Antifouling properties of different Plasma Electrolytic Oxidation coatings on 7075 aluminium alloy. Int. Biodeterior. Biodegrad. 2018, 133, 70–78. [Google Scholar] [CrossRef]

- Ivanova, A.O.; Vakhromov, R.O.; Grigoriev, M.V.; Senatorova, O.G. Investigation of Effect of Silver Small Additives on Structure and Properties of Resource Al–Cu–Mg Alloys. Proc. VIAM 2014, 1. [Google Scholar] [CrossRef]

- ISO 9223:2012. Corrosion of Metals and Alloys—Corrosivity of Atmospheres—Clasification, Determination and Estimation, 2nd ed.; International Organization for Standardization: Geneva, Switzerland, 2012.

- Gnedenkov, S.V.; Khrisanfova, O.A.; Zavidnaya, A.G.; Sinebryukhov, S.L.; Egorkin, V.S.; Nistratova, M.V.; Yerokhin, A.; Matthews, A. PEO coatings obtained on an Mg-Mn type alloy under unipolar and bipolar modes in silicate-containing electrolytes. Surf. Coat. Technol. 2010, 204, 2316–2322. [Google Scholar] [CrossRef]

- Quintero, D.; Galvis, O.; Calderón, J.A.; Gómez, M.A.; Castaño, J.G.; Echeverría, F.; Habazaki, H. Control of the physical properties of anodic coatings obtained by plasma electrolytic oxidation on Ti6Al4V alloy. Surf. Coat. Technol. 2015, 283, 210–222. [Google Scholar] [CrossRef]

- Oleynik, S.V.; Rudnev, V.S.; Kuzenkov, Y.A.; Jarovaja, T.P.; Trubetskaja, L.F.; Nedozorov, P.M. Protective properties of PEO coatings modified by corrosion inhibitors on aluminum alloys. Int. J. Corros. Scale Inhib. 2017, 6, 91–111. [Google Scholar] [CrossRef]

- Riyad, O.; Derek, O. Production of Anti-Corrosion Coatings on Light Alloys (Al, Mg, Ti) by Plasma-Electrolytic Oxidation (PEO). In Developments in Corrosion Protection; InTech: London, UK, 2014. [Google Scholar]

- Hussein, R.O.; Northwood, D.O.; Nie, X. Coating growth behavior during the plasma electrolytic oxidation process. J. Vac. Sci. Technol. A Vacuum Surf. Film. 2010, 28, 766–773. [Google Scholar] [CrossRef]

- Liu, X.; Wang, S.; Du, N.; Li, X.; Zhao, Q. Evolution of the Three-Dimensional Structure and Growth Model of Plasma Electrolytic Oxidation Coatings on 1060 Aluminum Alloy. Coatings 2018, 8, 105. [Google Scholar] [CrossRef]

- Gnedenkov, S.V.; Khrisanfova, O.A.; Zavidnaya, A.G.; Sinebrukhov, S.L.; Kovryanov, A.N.; Scorobogatova, T.M.; Gordienko, P.S. Production of hard and heat-resistant coatings on aluminium using a plasma micro-discharge. Surf. Coat. Technol. 2000, 123, 24–28. [Google Scholar] [CrossRef]

- Egorkin, V.S.; Gnedenkov, S.V.; Sinebryukhov, S.L.; Vyaliy, I.E.; Gnedenkov, A.S.; Chizhikov, R.G. Increasing thickness and protective properties of PEO-coatings on aluminum alloy. Surf. Coat. Technol. 2018, 334, 29–42. [Google Scholar] [CrossRef]

- Gnedenkov, S.V.; Vovna, V.I.; Gordienko, P.S.; Sinebryukhov, S.L.; Cherednichenko, A.I.; Shchukarev, A.V. Chemical Composition of Antifriction Micro-arc Oxide Coatings on Titanium Alloy BT16. Prot. Met. 2001, 37, 168–172. [Google Scholar] [CrossRef]

- Hussein, R.O.; Nie, X.; Northwood, D.O. A spectroscopic and microstructural study of oxide coatings produced on a Ti–6Al–4V alloy by plasma electrolytic oxidation. Mater. Chem. Phys. 2012, 134, 484–492. [Google Scholar] [CrossRef]

- Locke, B.R.; Thagard, S.M. Analysis of Chemical Reactions in Gliding-Arc Reactors with Water Spray Into Flowing Oxygen. IEEE T. Plasma Sci. 2009, 37, 494–501. [Google Scholar] [CrossRef]

- Barik, R.C.; Wharton, J.A.; Wood, R.J.K.; Stokes, K.R.; Jones, R.L. Corrosion, erosion and erosion–corrosion performance of plasma electrolytic oxidation (PEO) deposited Al2O3 coatings. Surf. Coat. Technol. 2005, 199, 158–167. [Google Scholar] [CrossRef]

- Luo, C.; Zhou, X.; Thompson, G.E. Localized dissolution initiated at single and clustered intermetallic particles during immersion of Al—Cu—Mg alloy in sodium chloride solution. Trans. Nonferrous Met. Soc. China 2016, 26, 2800–2809. [Google Scholar] [CrossRef]

- Boag, A.; Taylor, R.J.; Muster, T.H.; Goodman, N.; Mcculloch, D.; Ryan, C.; Rout, B.; Jamieson, D.; Hughes, A.E. Stable pit formation on AA2024-T3 in a NaCl environment. Corros. Sci. 2010, 52, 90–103. [Google Scholar] [CrossRef]

- Buchheit, R.G.; Grant, R.P.; Hiava, P.F.; Mckenzie, B.; Zender, G. Local Dissolution Phenomena Associated with S Phase (Al2CuMg) Particles in Aluminum Alloy 2024-T3. J. Electrochem. Soc. 1997, 144, 2621–2628. [Google Scholar] [CrossRef]

- Bethencourt, M.; Botana, F.J.; Cano, M.J.; Marcos, M.; Sánchez-Amaya, J.M.; González-Rovira, L. Behaviour of the alloy AA2017 in aqueous solutions of NaCl. Part I: Corrosion mechanisms. Corros. Sci. 2009, 51, 518–524. [Google Scholar] [CrossRef]

- Yasakau, K.A.; Zheludkevich, M.L.; Lamaka, S.V.; Ferreira, M.G.S. Mechanism of corrosion inhibition of AA2024 by rare-earth compounds. J. Phys. Chem. B 2006, 110, 5515–5528. [Google Scholar] [CrossRef]

- Guillaumin, V.; Mankowski, G. Localized corrosion of 2024 T351 aluminium alloy in chloride media. Corros. Sci. 1998, 41, 421–438. [Google Scholar] [CrossRef]

- Zhang, X.; Hashimoto, T.; Lindsay, J.; Zhou, X. Investigation of the de-alloying behaviour of θ-phase (Al2Cu) in AA2024-T351 aluminium alloy. Corros. Sci. 2016, 108, 85–93. [Google Scholar] [CrossRef]

- Dimitrov, N.; Mann, J.A.; Sieradzki, K. Copper Redistribution during Corrosion of Aluminum Alloys. J. Electrochem. Soc. 1999, 146, 98–102. [Google Scholar] [CrossRef]

- Obispo, H.M.; Murr, L.E.; Arrowood, R.M.; Trillo, E.A. Copper deposition during the corrosion of aluminum alloy 2024 in sodium chloride solutions. J. Mater. Sci. 2000, 35, 3479–3495. [Google Scholar] [CrossRef]

- Prakashaiah, B.G.; Kumara, D.V.; Pandith, A.A.; Shetty, A.N.; Rani, B.E.A. Corrosion inhibition of 2024-T3 aluminum alloy in 3.5% NaCl by thiosemicarbazone derivatives. Corros. Sci. 2018, 136, 326–338. [Google Scholar] [CrossRef]

- Izadi, M.; Rad, A.R.; Shahrabi, T.; Mohammadi, I. The combined action of L-cysteine and L-histidine as a significant eco-friendly protective system to enhance the corrosion protection performance of AA2024-T3 alloy in 0.1 M NaCl solution: Electrochemical and surface studies. Mater. Chem. Phys. 2020, 250, 122997. [Google Scholar] [CrossRef]

- Snihirova, D.; Taryba, M.; Lamaka, S.V.; Montemor, M.F. Corrosion inhibition synergies on a model Al-Cu-Mg sample studied by localized scanning electrochemical techniques. Corros. Sci. 2016, 112, 408–417. [Google Scholar] [CrossRef]

- Coelho, L.B.; Taryba, M.; Alves, M.; Montemor, M.F.; Olivier, M.G. Unveiling the effect of the electrodes area on the corrosion mechanism of a graphite—AA2024-T3 galvanic couple by localised electrochemistry. Electrochim. Acta 2018, 277, 9–19. [Google Scholar] [CrossRef]

- Zheludkevich, M.L.; Yasakau, K.A.; Poznyak, S.K.; Ferreira, M.G.S. Triazole and thiazole derivatives as corrosion inhibitors for AA2024 aluminium alloy. Corros. Sci. 2005, 47, 3368–3383. [Google Scholar] [CrossRef]

- Matter, E.A.; Kozhukharov, S.; Machkova, M.; Kozhukharov, V. Comparison between the inhibition efficiencies of Ce(III) and Ce(IV) ammonium nitrates against corrosion of AA2024 aluminum alloy in solutions of low chloride concentration. Corros. Sci. 2012, 62, 22–33. [Google Scholar] [CrossRef]

- Gnedenkov, S.V.; Sinebryukhov, S.L.; Mashtalyar, D.V.; Nadaraia, K.V.; Gnedenkov, A.S.; Bouznik, V.M. Composite fluoropolymer coatings on the MA8 magnesium alloy surface. Corros. Sci. 2016, 111, 175–185. [Google Scholar] [CrossRef]

- Escudero, E.; López, V.; Otero, E.; Bartolomé, M.J.; González, J.A. Behaviour of anodised aluminium in very long-term atmospheric exposure. Surf. Coat. Technol. 2007, 201, 7303–7309. [Google Scholar] [CrossRef]

- Wang, R.; Wang, L.; He, C.; Lu, M.; Sun, L. Studies on the sealing processes of corrosion resistant coatings formed on 2024 aluminium alloy with tartaric-sulfuric anodizing. Surf. Coat. Technol. 2019, 360, 369–375. [Google Scholar] [CrossRef]

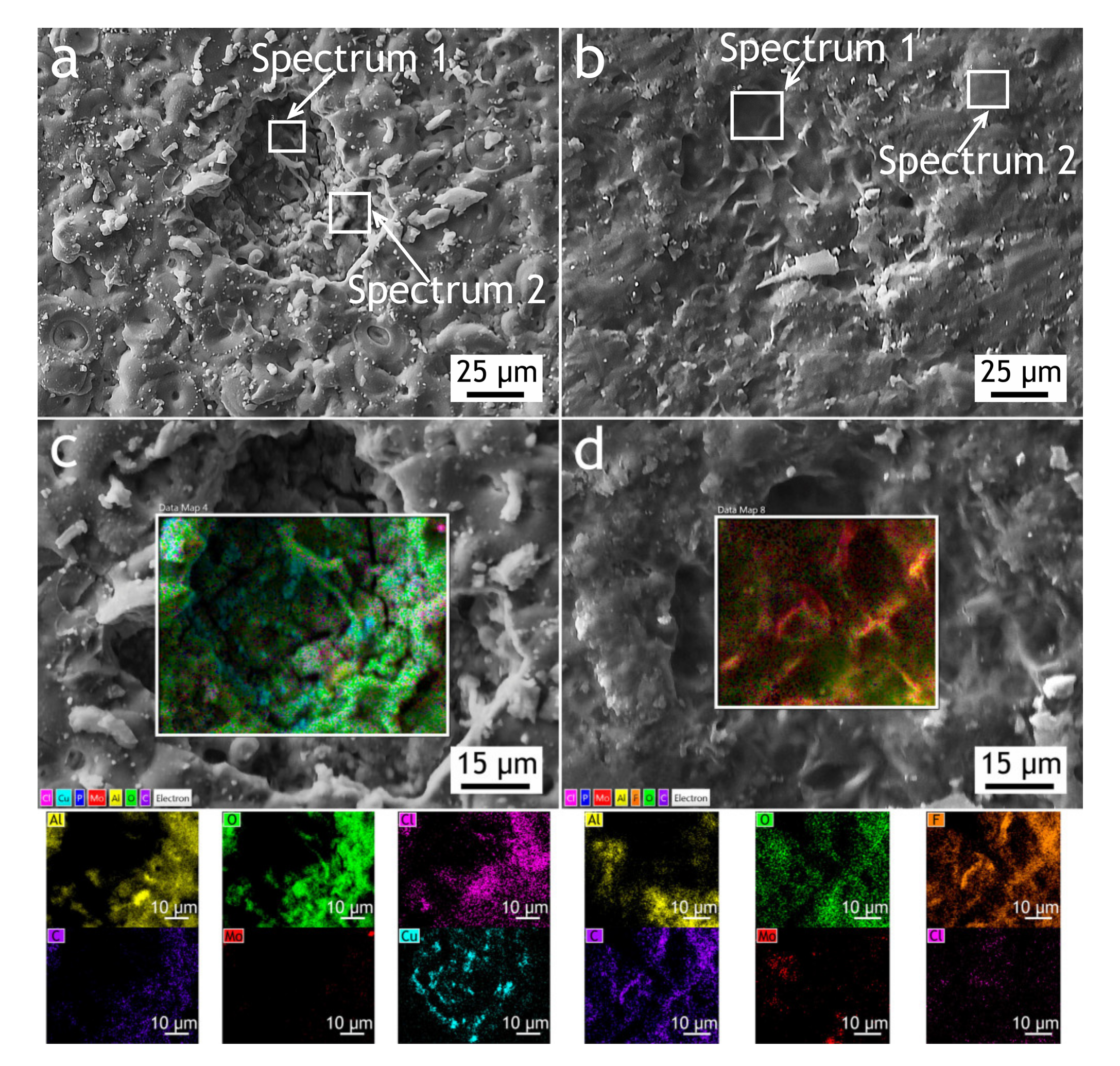

| PEO | CC | ||||||

|---|---|---|---|---|---|---|---|

| Spectrum 1 | Spectrum 2 | Spectrum 1 | Spectrum 2 | ||||

| Element | wt. (%) | Element | wt. (%) | Element | wt. (%) | Element | wt. (%) |

| O | 45.0 | Mo | 70.8 | O | 45.2 | O | 31.3 |

| Al | 33.0 | O | 21.5 | Al | 31.2 | Al | 29.0 |

| C | 11.7 | Al | 5.0 | C | 19.1 | C | 25.3 |

| Mo | 4.8 | P | 2.7 | F | 2.6 | F | 10.5 |

| P | 3.3 | - | - | Mo | 1.9 | Mo | 3.3 |

| Na | 1.7 | - | - | - | - | P | 0.6 |

| K | 0.5 | - | - | - | - | - | - |

| PEO | CC | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Top (Spectrum 1) | Middle (Spectrum 2) | Bottom (Spectrum 3) | Top (Spectrum 1) | Middle (Spectrum 2) | Bottom (Spectrum 3) | ||||||

| Element | wt. (%) | Element | wt. (%) | Element | wt. (%) | Element | wt. (%) | Element | wt. (%) | Element | wt. (%) |

| O | 54.3 | O | 52.6 | O | 51.4 | O | 33.4 | O | 57.7 | O | 51.2 |

| Al | 38.3 | Al | 32.2 | Al | 35.3 | C | 29.5 | Al | 33.4 | Al | 32.6 |

| C | 5.2 | C | 12.2 | C | 5.6 | F | 20.2 | C | 6.3 | C | 8.1 |

| Mo | 1.3 | Mo | 1.9 | Mo | 4.3 | Al | 14.8 | Mo | 2.6 | Mo | 4.2 |

| P | 0.9 | P | 0.6 | P | 1.8 | Mo | 2.1 | Cu | 0.6 | P | 2.8 |

| - | - | Cu | 0.5 | Cu | 1.2 | - | - | - | - | Cu | 1.1 |

| - | - | - | - | Mg | 0.4 | - | - | - | - | - | - |

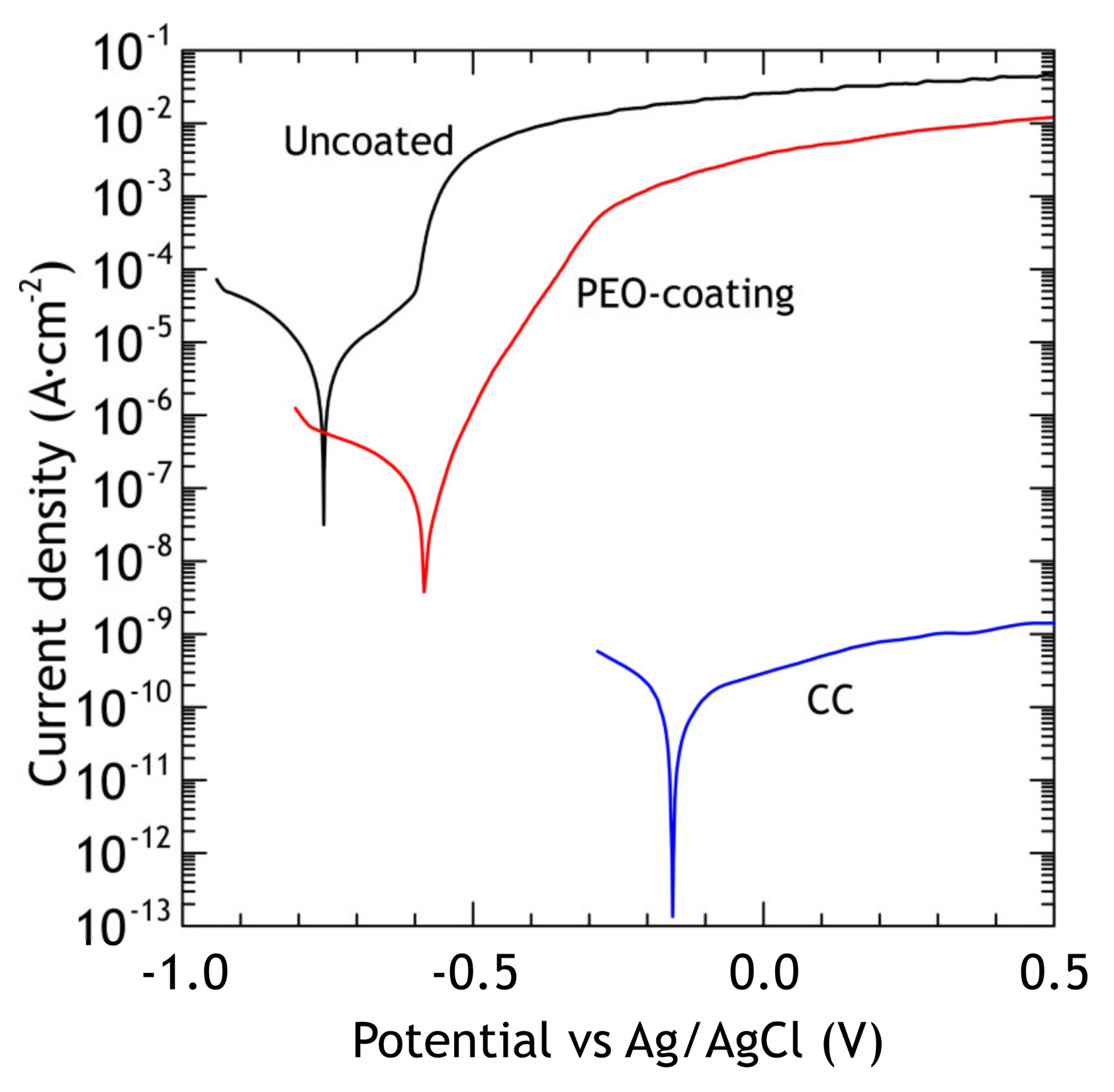

| Sample | βa (mV) | −βc (mV) | jc (A·cm−2) | Ec (mV) | Rp (Ω cm2) | |Z|f = 0.02 Hz (Ω cm2) |

|---|---|---|---|---|---|---|

| Bare alloy | 307 | 211 | 4.5 × 10−6 | −757 | 1.2 × 104 | 1.1 × 104 |

| PEO-coating | 65 | 208 | 1.2 × 10−7 | −583 | 1.8 × 105 | 1.1 × 105 |

| Composite coating | 174 | 80 | 1.1 × 10−10 | −160 | 2.2 × 108 | 1.8 × 108 |

| PEO | CC | ||||||

|---|---|---|---|---|---|---|---|

| Spectrum 1 | Spectrum 2 | Spectrum 1 | Spectrum 2 | ||||

| Element | wt. (%) | Element | wt. (%) | Element | wt. (%) | Element | wt. (%) |

| Al | 38.8 | O | 49.7 | C | 42.6 | F | 31.2 |

| O | 38.1 | Al | 35.1 | F | 27.2 | C | 26.5 |

| Cu | 13.2 | C | 11.2 | O | 20.6 | Al | 20.8 |

| C | 8.5 | Cu | 1.4 | Al | 7.3 | O | 20.3 |

| Cl | 1.3 | Mo | 1.3 | Mo | 1.8 | Mo | 1.2 |

| - | - | Cl | 1.0 | Cl | 0.6 | - | - |

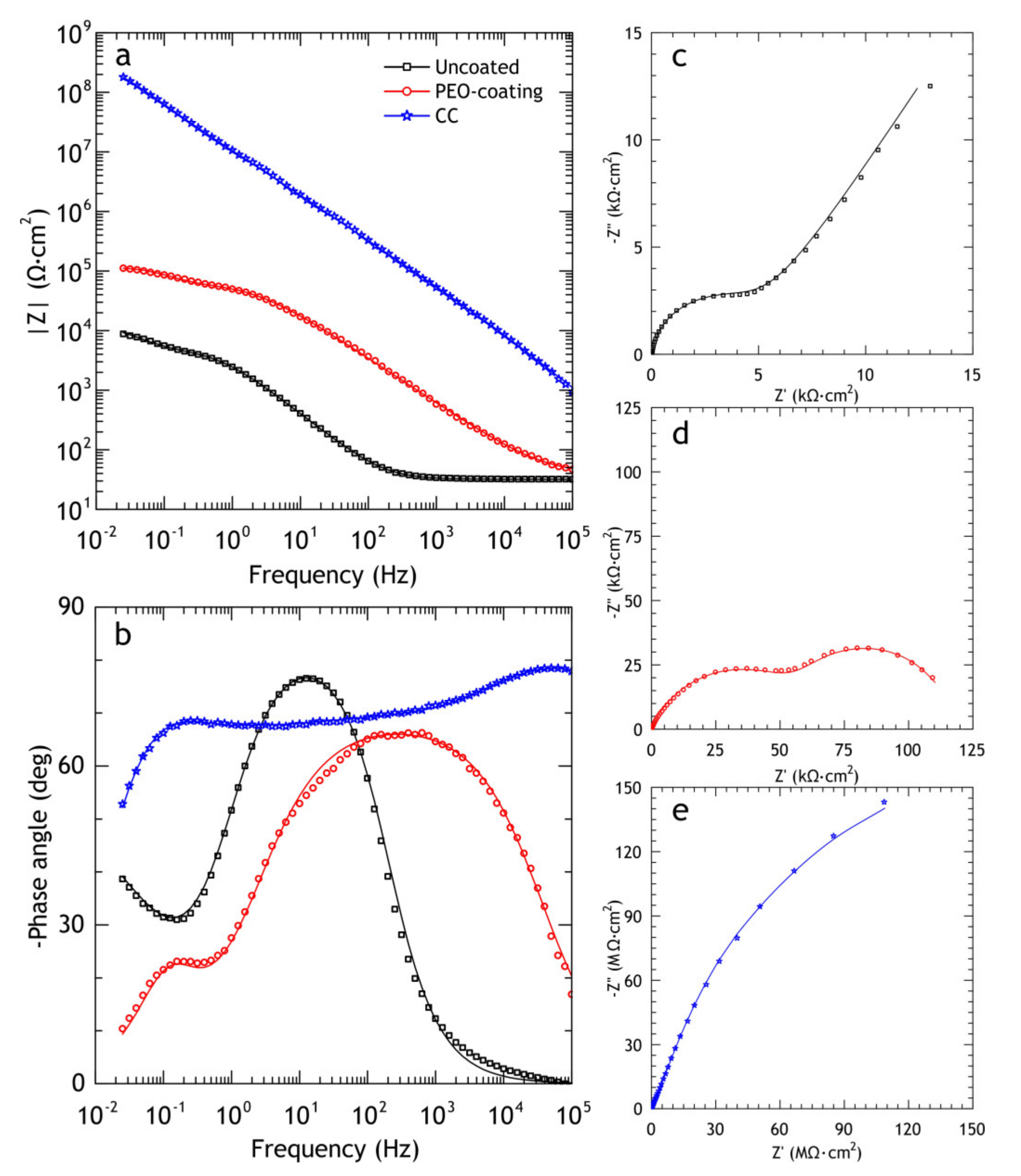

| Sample | CPE1 | R1 (Ω·cm2) | CPE2 | R2 (Ω·cm2) | W | CPE3 | R3 (Ω·cm2) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Q1 (Ω−1·cm−2 sn) | n1 | Q2 (Ω−1·cm−2 sn) | n2 | RW (Ω·cm2) | T (s) | P | Q3 (Ω−1·cm−2 sn) | n3 | ||||

| Bare alloy | – | – | – | 6.4 × 10−5 | 0.90 | 4.2 × 103 | 2.8 × 103 | 1.15 | 0.32 | – | – | – |

| PEO-coating | 2.0 × 10−6 | 0.77 | 6.2 × 104 | 2.5 × 10−5 | 0.79 | 6.6 × 104 | – | – | – | – | – | – |

| Composite coating | 9.4 × 10−9 | 0.86 | 4.0 × 105 | 2.4 × 10−8 | 0.60 | 7.5 × 107 | – | – | – | 1.5 × 10−8 | 0.86 | 4.3 × 108 |

| PEO | CC | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Top (Spectrum 1) | Middle (Spectrum 2) | Bottom (Spectrum 3) | Top (Spectrum 1) | Middle (Spectrum 2) | Bottom (Spectrum 3) | ||||||

| Element | wt. (%) | Element | wt. (%) | Element | wt. (%) | Element | wt. (%) | Element | wt. (%) | Element | wt. (%) |

| O | 48.7 | O | 55.8 | O | 48.8 | O | 38.8 | O | 55.0 | O | 42.5 |

| Al | 33.9 | Al | 43.1 | Al | 38.0 | Al | 18.2 | Al | 37.4 | Al | 35.8 |

| C | 8.4 | Mo | 0.6 | C | 6.7 | C | 21.4 | C | 5.6 | C | 9.7 |

| Si | 7.1 | P | 0.5 | Mo | 4.9 | F | 20.9 | Mo | 1.6 | F | 8.1 |

| Mo | 1.2 | - | - | P | 1.6 | Mo | 0.7 | P | 0.4 | Mo | 3.9 |

| P | 0.7 | - | - | - | - | - | - | - | - | - | - |

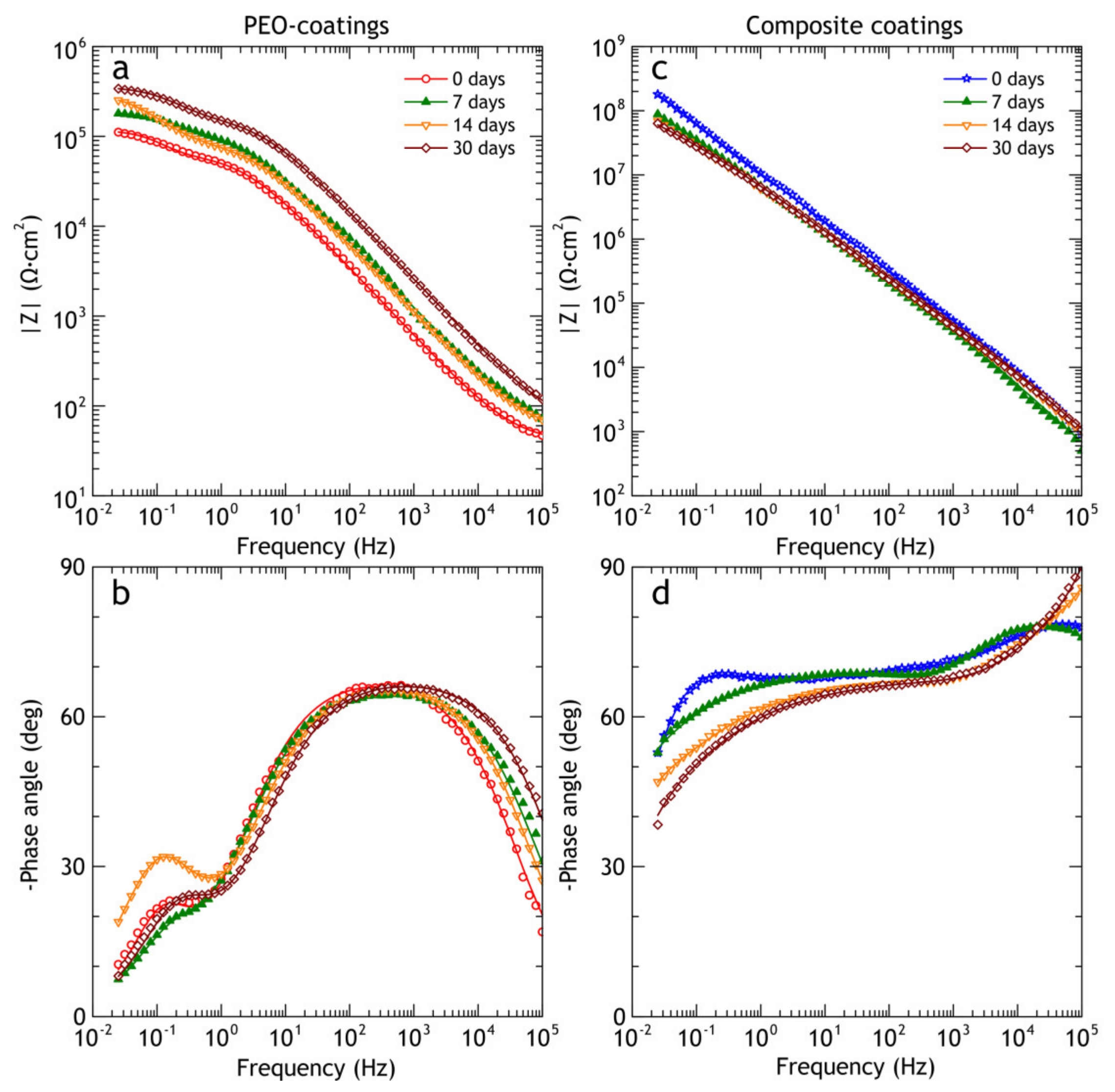

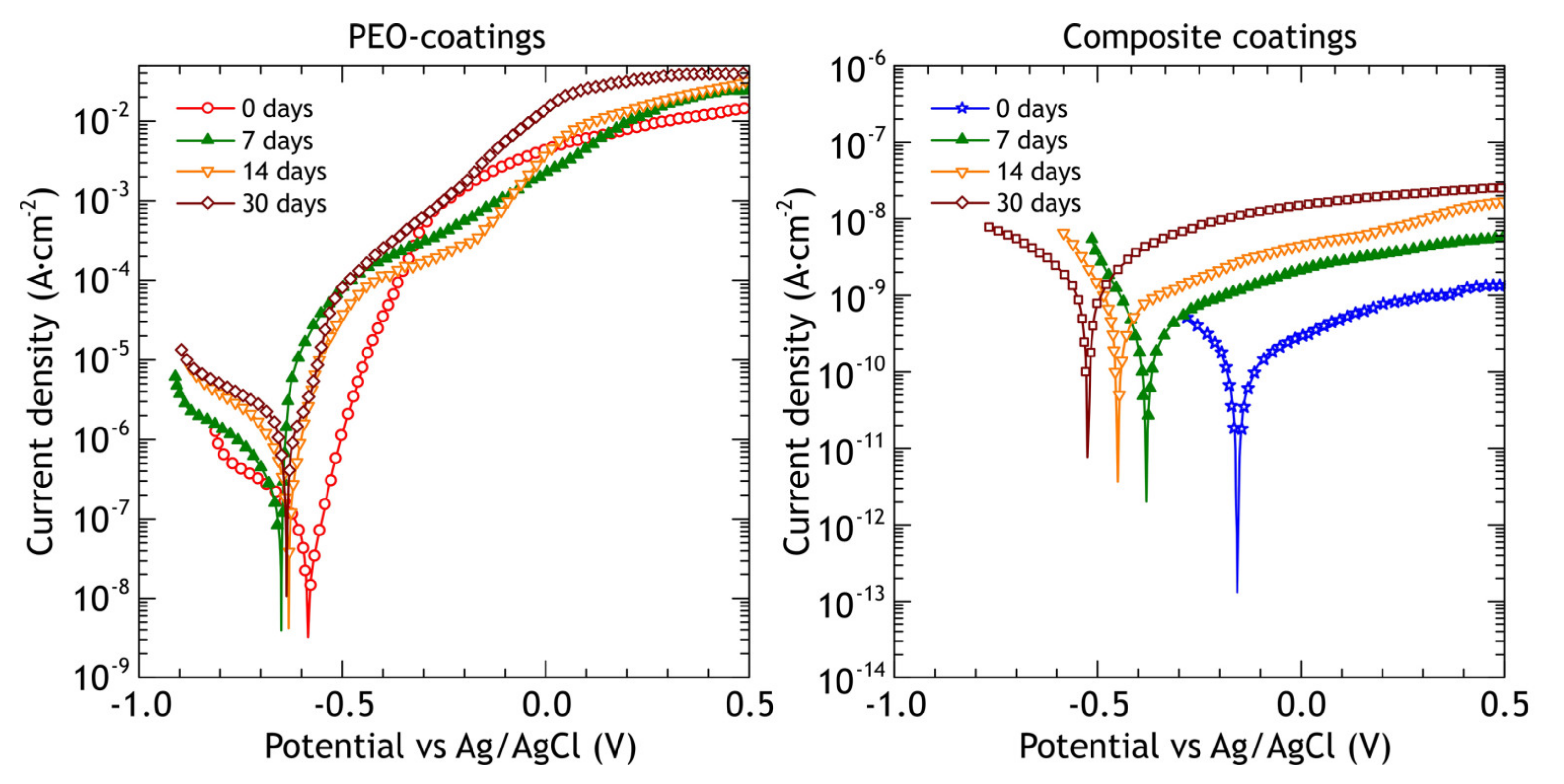

| Coating | Exposure, Days | βa (mV) | −βc (mV) | jc (A·cm−2) | Ec (mV) | Rp (Ω·cm2) | |Z|f = 0.02 Hz, (Ω cm2) |

|---|---|---|---|---|---|---|---|

| PEO | 0 | 65 | 208 | 1.2 × 10−7 | −583 | 1.8 × 105 | 1.1 × 105 |

| 7 | 72 | 143 | 5.7 × 10−8 | −572 | 3.6 × 105 | 1.8 × 105 | |

| 14 | 62 | 145 | 4.2 × 10−8 | −569 | 4.5 × 105 | 2.5 × 105 | |

| 30 | 56 | 190 | 3.9 × 10−8 | −576 | 4.8 × 105 | 3.4 × 105 | |

| CC | 0 | 174 | 80 | 1.1 × 10−10 | −160 | 2.2 × 108 | 1.8 × 108 |

| 7 | 234 | 89 | 3.2 × 10−10 | −225 | 8.8 × 107 | 8.3 × 107 | |

| 14 | 243 | 95 | 5.3 × 10−10 | −327 | 5.7 × 107 | 5.4 × 107 | |

| 30 | 255 | 102 | 7.6 × 10−10 | −441 | 4.2 × 107 | 3.6 × 107 |

| Sample | Exposure Time, Days | CPE1 | R1 (Ω·cm2) | CPE2 | R2 (Ω·cm2) | CPE3 | R3 (Ω·cm2) | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Q1 (Ω−1·cm−2 sn) | n1 | Q2 (Ω−1·cm−2 sn) | n2 | Q3 (Ω−1·cm−2 sn) | n3 | |||||

| PEO | 0 | 2.0 × 10−6 | 0.77 | 6.2 × 104 | 2.5 × 10−5 | 0.79 | 6.6 × 104 | - | - | |

| 7 | 1.2 × 10−6 | 0.74 | 1.2 × 105 | 1.6 × 10−5 | 0.85 | 7.2 × 104 | - | - | ||

| 14 | 1.3 × 10−6 | 0.75 | 9.3 × 104 | 1.1 × 10−5 | 0.86 | 2.1 × 105 | - | - | ||

| 30 | 5.3 × 10−7 | 0.76 | 1.7 × 105 | 6.0 × 10−6 | 0.83 | 1.9 × 105 | - | - | ||

| Composite coating | 0 | 9.4 × 10−9 | 0.86 | 4.0 × 105 | 2.4 × 10−8 | 0.60 | 7.5 × 107 | 1.5 × 10−8 | 0.86 | 4.3 × 108 |

| 7 | 2.8 × 10−9 | 0.92 | 7.7 × 103 | 1.6 × 10−7 | 0.44 | 5.1 × 107 | 7.3 × 10−8 | 0.92 | 2.8 × 108 | |

| 14 | 5.2 × 10−9 | 0.88 | 3.8 × 104 | 1.9 × 10−7 | 0.51 | 2.1 × 106 | 1.1 × 10−7 | 0.98 | 1.7 × 108 | |

| 30 | 4.2 × 10−9 | 0.84 | 3.1 × 103 | 0.7 × 10−7 | 0.52 | 2.0 × 106 | 1.2 × 10−7 | 0.79 | 1.0 × 108 | |

| PEO | CC | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Top (Spectrum 1) | Middle (Spectrum 2) | Bottom (Spectrum 3) | Top (Spectrum 1) | Middle (Spectrum 2) | Bottom (Spectrum 3) | ||||||

| Element | wt. (%) | Element | wt. (%) | Element | wt. (%) | Element | wt. (%) | Element | wt. (%) | Element | wt. (%) |

| O | 53.5 | O | 48.8 | O | 54.2 | O | 25.4 | O | 54.1 | O | 46.4 |

| Al | 39.2 | Al | 35.6 | Al | 38.6 | Al | 8.7 | Al | 36.7 | Al | 39.9 |

| C | 5.4 | C | 11.4 | C | 3.9 | C | 34.4 | C | 4.7 | C | 8.8 |

| Mo | 1.3 | Mo | 3.9 | Mo | 1.7 | Mo | 0.9 | Mo | 3.4 | Mo | 3.5 |

| P | 0.4 | P | 0.3 | P | 1.3 | F | 30.6 | P | 0.7 | Cu | 0.6 |

| Cl | 0.2 | Cu | 0.3 | Mg | 0.4 | Mg | 0.5 | ||||

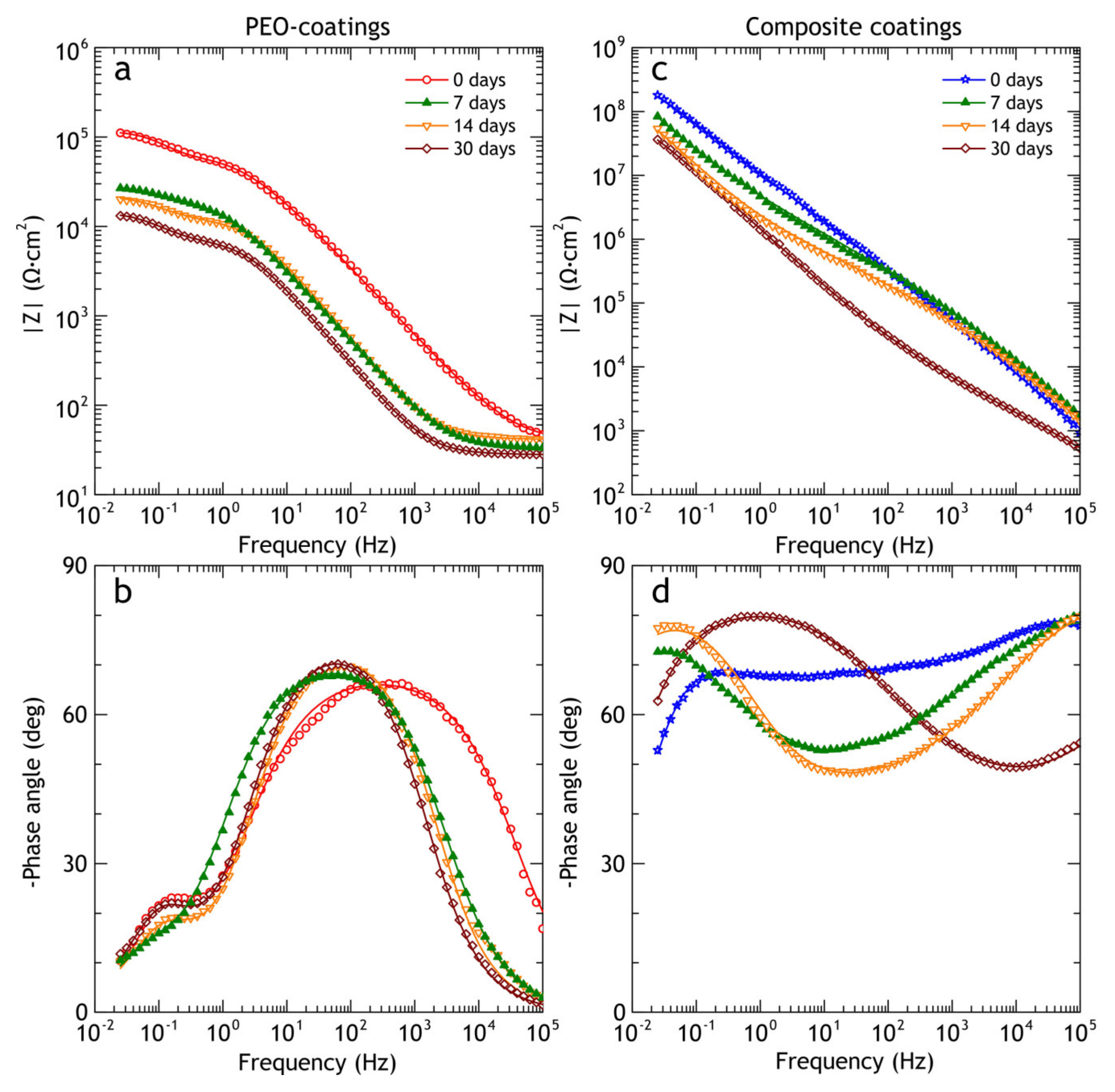

| Sample | Exposure Time, Days | βa (mV) | −βc (mV) | jc (A·cm−2) | Ec (mV) | Rp (Ω·cm2) | |Z|f = 0.02 Hz, (Ω cm2) |

|---|---|---|---|---|---|---|---|

| PEO | 0 | 65 | 208 | 1.2 × 10−7 | −583 | 1.8 × 105 | 1.1 × 105 |

| 7 | 60 | 215 | 3.8 × 10−7 | −650 | 3.8 × 104 | 5.6 × 104 | |

| 14 | 58 | 220 | 6.5 × 10−7 | −644 | 3.1 × 104 | 3.0 × 104 | |

| 30 | 60 | 245 | 1.2 × 10−6 | −646 | 1.8 × 104 | 1.4 × 104 | |

| Composite coating | 0 | 174 | 80 | 1.1 × 10−10 | −160 | 2.2 × 108 | 1.8 × 108 |

| 7 | 59 | 406 | 2.5 × 10−10 | −384 | 9.0 × 107 | 8.7 × 107 | |

| 14 | 63 | 440 | 5.8 × 10−10 | −451 | 4.1 × 107 | 2.7 × 107 | |

| 30 | 72 | 314 | 1.3 × 10−9 | −583 | 2.0 × 107 | 7.2 × 106 |

| Sample | Exposure Time, Days | CPE1 | R1 (Ω·cm2) | CPE2 | R2 (Ω·cm2) | CPE3 | R3 (Ω·cm2) | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Q1 (Ω−1·cm−2 sn) | n1 | Q2 (Ω−1·cm−2 sn) | n2 | Q3 (Ω−1·cm−2 sn) | n3 | |||||

| PEO | 0 | 2.0 × 10−6 | 0.77 | 6.2 × 104 | 2.5 × 10−5 | 0.79 | 6.6 × 104 | - | - | - |

| 7 | 1.5 × 10−5 | 0.92 | 1.8 × 104 | 3.7 × 10−4 | 0.71 | 1.5 × 104 | - | - | - | |

| 14 | 1.3 × 10−5 | 0.88 | 1.5 × 104 | 1.2 × 10−4 | 0.67 | 5.5 × 104 | - | - | - | |

| 30 | 1.3 × 10−5 | 0.89 | 2.5 × 104 | 7.2 × 10−5 | 0.74 | 1.1 × 105 | - | - | - | |

| CC | 0 | 9.4 × 10−9 | 0.86 | 4.0 × 105 | 2.4 × 10−8 | 0.60 | 7.5 × 107 | 1.5 × 10−8 | 0.86 | 4.3 × 108 |

| 7 | 2.8 × 10−9 | 0.92 | 7.7 × 103 | 1.6 × 10−7 | 0.44 | 5.1 × 107 | 7.3 × 10−8 | 0.92 | 2.7 × 108 | |

| 14 | 5.2 × 10−9 | 0.88 | 3.8 × 104 | 1.9 × 10−7 | 0.51 | 2.1 × 106 | 1.1 × 10−7 | 0.98 | 5.7 × 107 | |

| 30 | 4.2 × 10−9 | 0.84 | 3.1 × 103 | 0.7 × 10−7 | 0.52 | 2.0 × 106 | 1.2 × 10−7 | 0.79 | 2.3 × 107 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Egorkin, V.S.; Medvedev, I.M.; Sinebryukhov, S.L.; Vyaliy, I.E.; Gnedenkov, A.S.; Nadaraia, K.V.; Izotov, N.V.; Mashtalyar, D.V.; Gnedenkov, S.V. Atmospheric and Marine Corrosion of PEO and Composite Coatings Obtained on Al-Cu-Mg Aluminum Alloy. Materials 2020, 13, 2739. https://doi.org/10.3390/ma13122739

Egorkin VS, Medvedev IM, Sinebryukhov SL, Vyaliy IE, Gnedenkov AS, Nadaraia KV, Izotov NV, Mashtalyar DV, Gnedenkov SV. Atmospheric and Marine Corrosion of PEO and Composite Coatings Obtained on Al-Cu-Mg Aluminum Alloy. Materials. 2020; 13(12):2739. https://doi.org/10.3390/ma13122739

Chicago/Turabian StyleEgorkin, Vladimir S., Ivan M. Medvedev, Sergey L. Sinebryukhov, Igor E. Vyaliy, Andrey S. Gnedenkov, Konstantine V. Nadaraia, Nikolaj V. Izotov, Dmitriy V. Mashtalyar, and Sergey V. Gnedenkov. 2020. "Atmospheric and Marine Corrosion of PEO and Composite Coatings Obtained on Al-Cu-Mg Aluminum Alloy" Materials 13, no. 12: 2739. https://doi.org/10.3390/ma13122739

APA StyleEgorkin, V. S., Medvedev, I. M., Sinebryukhov, S. L., Vyaliy, I. E., Gnedenkov, A. S., Nadaraia, K. V., Izotov, N. V., Mashtalyar, D. V., & Gnedenkov, S. V. (2020). Atmospheric and Marine Corrosion of PEO and Composite Coatings Obtained on Al-Cu-Mg Aluminum Alloy. Materials, 13(12), 2739. https://doi.org/10.3390/ma13122739