Heat Treatment of Corrosion Resistant Steel for Water Propellers Fabricated by Direct Laser Deposition

Abstract

1. Introduction

2. Materials and Methods

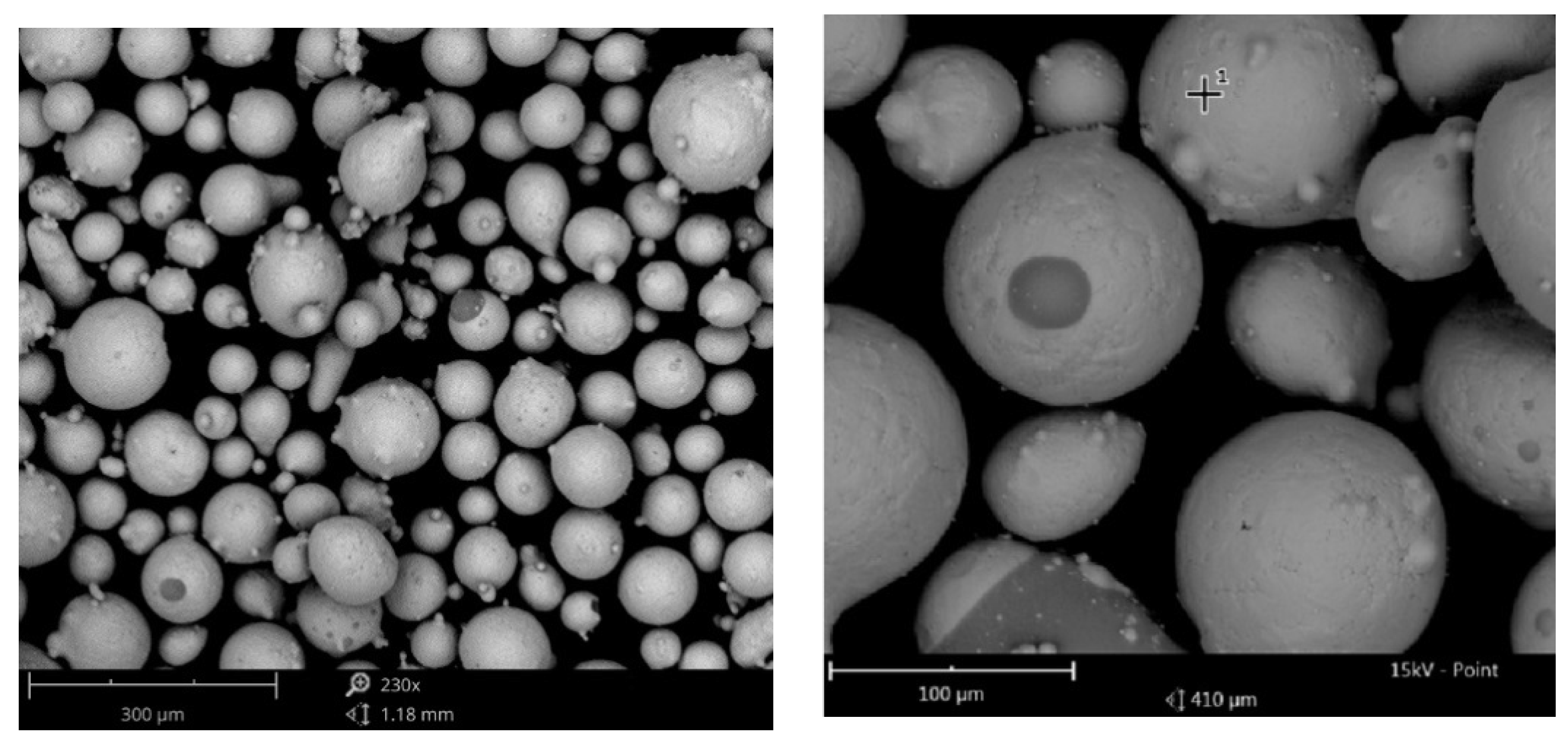

2.1. Materials

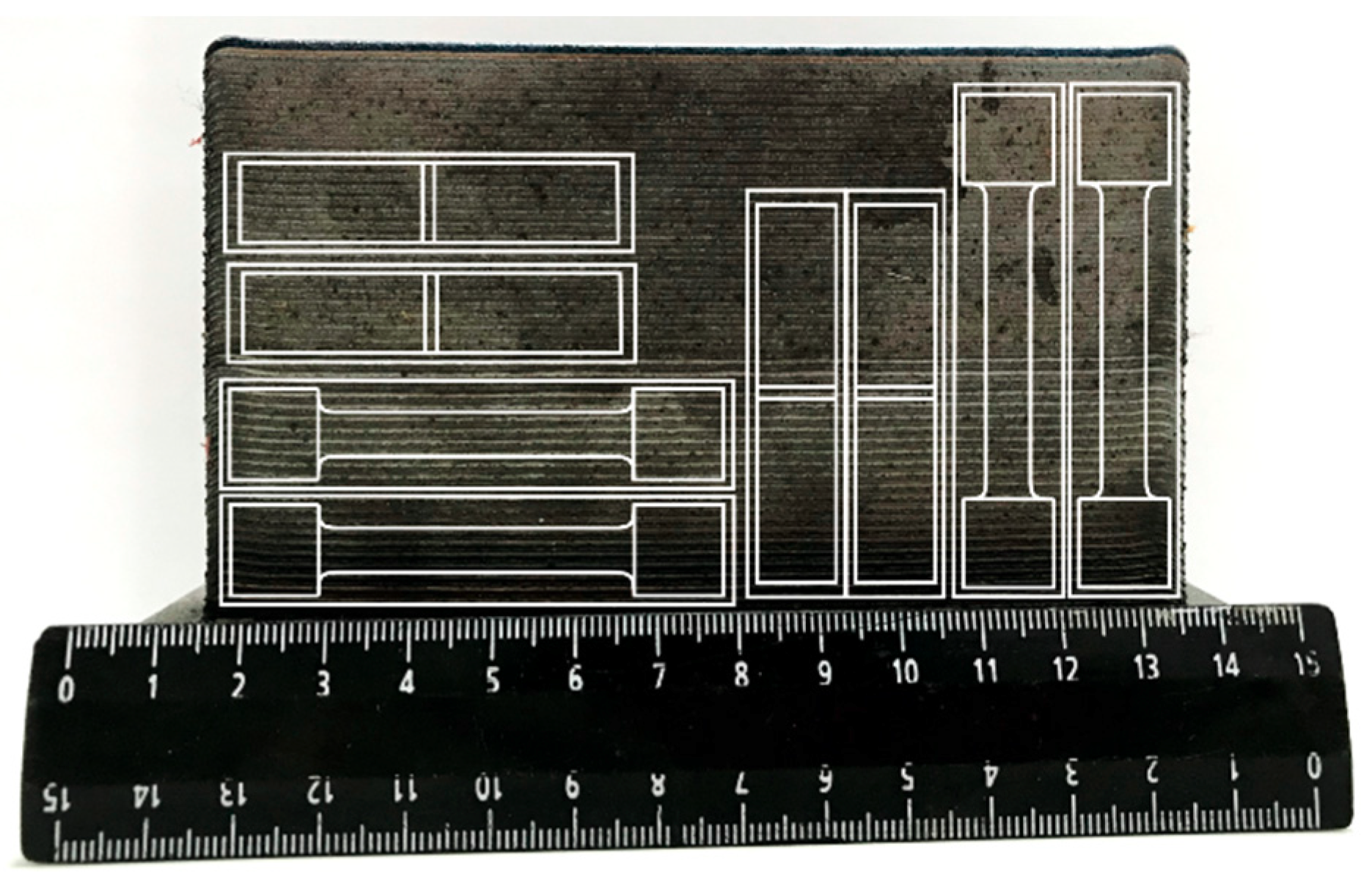

2.2. Fabrication of Samples Using DLD and Their Heat Treatment

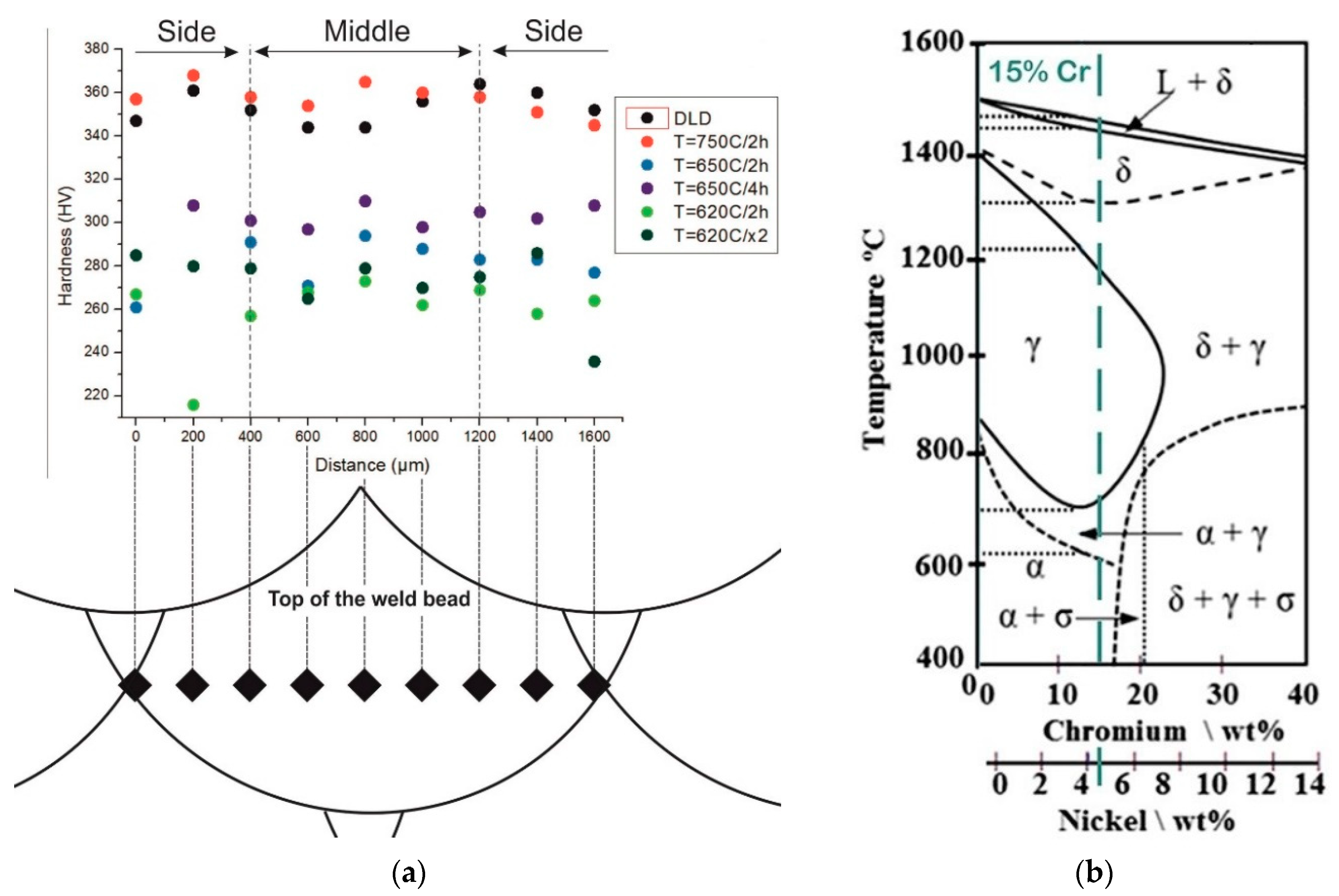

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Khodabakhshi, F.; Farshidianfar, M.; Gerlich, A.; Nosko, M.; Trembošová, V.; Khajepour, A. Microstructure, strain-rate sensitivity, work hardening, and fracture behavior of laser additive manufactured austenitic and martensitic stainless steel structures. Mater. Sci. Eng. A 2019, 756, 545. [Google Scholar] [CrossRef]

- Promakhov, V.; Zhukov, A.; Ziatdinov, M.; Zhukov, I.; Schulz, N.; Kovalchuk, S.; Dubkova, Y.; Korsmik, R.; Klimova-Korsmik, O.; Turichin, G.; et al. Inconel 625/TiB2 Metal Matrix Composites by Direct Laser Deposition. Metals 2019, 9, 141. [Google Scholar] [CrossRef]

- Winck, L.B.; Ferreira, J.; Araújo, J.; Manfrinato, M.D.; Silva, C. Surface nitriding influence on the fatigue life behavior of ASTM A743 steel type CA6NM. Surf. Coat. Technol. 2013, 232, 844. [Google Scholar] [CrossRef]

- Wen, P.; Cai, Z.; Feng, Z.; Wang, G. Microstructure and mechanical properties of hot wire laser clad layers for repairing precipitation hardening martensitic stainless steel. Opt. Laser Technol. 2015, 75, 207. [Google Scholar] [CrossRef]

- Promakhov, V.; Khmeleva, M.; Zhukov, I.A.; Platov, V.V.; Khrustalyov, A.; Vorozhtsov, A.B. Influence of Vibration Treatment and Modification of A356 Aluminum Alloy on Its Structure and Mechanical Properties. Metals 2019, 9, 87. [Google Scholar] [CrossRef]

- Mirakhorli, F.; Cao, X.; Pham, X.-T.; Wanjara, P.; Fihey, J. Phase structures and morphologies of tempered CA6NM stainless steel welded by hybrid laser-arc process. Mater. Charact. 2017, 123, 264. [Google Scholar] [CrossRef]

- Zhukov, I.A.; Kozulin, A.A.; Khrustalyov, A.; Matveev, A.E.; Platov, V.V.; Vorozhtsov, A.B.; Zhukova, T.V.; Promakhov, V. The Impact of Particle Reinforcement with Al2O3, TiB2, and TiC and Severe Plastic Deformation Treatment on the Combination of Strength and Electrical Conductivity of Pure Aluminum. Metals 2019, 9, 65. [Google Scholar] [CrossRef]

- Turichin, G.; Zemlyakov, E.; Babkin, K.; Ivanov, S.; Vildanov, A. Analysis of distortion during laser metal deposition of large parts. Procedia CIRP 2017, 74, 154. [Google Scholar] [CrossRef]

- Turichin, G.; Zemlyakov, E.; Kuznetsov, M.; Babkin, K.; Kurakin, A.; Vildanov, A. Direct laser deposition with transversal oscillating of laser radiation. In Proceedings of the International Conference Laser Optics, St. Petersburg, Russia, 4–8 June 2018; p. 124. [Google Scholar] [CrossRef]

- Turichin, G.; Kuznetsov, M.; Tsibulskiy, I.; Firsova, A. Hybrid Laser-Arc Welding of the High-Strength Shipbuilding Steels: Equipment and Technology. Phys. Procedia 2017, 89, 156. [Google Scholar] [CrossRef]

- Rahman, N.U.; Capuano, L.; Cabeza, S.; Feinaeugle, M.; Garcia-Junceda, A.; De Rooij, M.; Matthews, D.; Walmag, G.; Gibson, I.; Römer, G. Directed energy deposition and characterization of high-carbon high speed steels. Addit. Manuf. 2019, 30. [Google Scholar] [CrossRef]

- Zhao, X.; Dong, S.; Yan, S.; Liu, X.; Liu, Y.; Xia, D.; Lv, Y.; He, P.; Xu, B.; Han, H. The effect of different scanning strategies on microstructural evolution to 24CrNiMo alloy steel during direct laser deposition. Mater. Sci. Eng. A 2019. [Google Scholar] [CrossRef]

- Turichin, G.; Klimova, O.; Zemlyakov, E.; Babkin, K.; Kolodyazhnyy, D.; Shamray, F.; Travyanov, A.; Petrovskiy, P. Technological aspects of high speed direct laser deposition based on heterophase powder metallurgy. Phys. Procedia 2015, 78, 397. [Google Scholar] [CrossRef]

- Turichin, G.A.; Zemlyakov, E.V.; Klimova, O.G.; Babkin, K.D. Hydrodynamic instability in high-speed direct laser deposition for additive manufacturing. Phys. Procedia 2016, 83, 674. [Google Scholar] [CrossRef]

- Glukhov, V.; Turichin, G.; Klimova-Korsmik, O.; Zemlyakov, E.; Babkin, K. Quality Management of Metal Products Prepared by High-Speed Direct Laser Deposition Technology. Key Eng. Mater. 2016, 684, 461. [Google Scholar] [CrossRef]

- Turichin, G.; Kuznetsov, M.; Pozdnyakov, A.; Gook, S.; Gumenyuk, A.; Rethmeier, M. Influence of heat input and preheating on the cooling rate, microstructure and mechanical properties at the hybrid laser-arc welding of API 5L X80 steel. Procedia CIRP 2018, 74, 748. [Google Scholar] [CrossRef]

- Turichin, G.; Zemlyakov, E.; Babkin, K.; Ivanov, S.; Vildanov, A. Laser metal deposition of Ti-6Al-4V alloy with beam oscillation. Procedia CIRP 2018, 74, 184. [Google Scholar] [CrossRef]

- Klimova-Korsmik, O.; Turichin, G.; Zemlyakov, E.; Babkin, K.; Petrovsky, P.; Travyanov, A. Structure formation in Ni superalloys during high-speed direct laser deposition. Mater. Sci. Forum 2017, 879, 978. [Google Scholar] [CrossRef]

- Trudel, A.; Lévesque, M.; Brochu, M. Microstructural effects on the fatigue crack growth resistance of a stainless steel CA6NM weld. Eng. Fract. Mech. 2014, 115, 60. [Google Scholar] [CrossRef]

- Fang, J.; Dong, S.; Li, S.; Wang, Y.; Xu, B.; Li, J.; Liu, B.; Jiang, Y. Direct laser deposition as repair technology for a low transformation temperature alloy: Microstructure, residual stress, and properties. Mater. Sci. Eng. A 2019, 748, 119. [Google Scholar] [CrossRef]

- Guan, T.; Chen, S.; Chen, X.; Liang, J.; Liu, C.; Wang, M. Effect of laser incident energy on microstructures and mechanical properties of 12CrNi2Y alloy steel by direct laser deposition. J. Mater. Sci. Technol. 2019, 35, 395. [Google Scholar] [CrossRef]

- Wei, S.; Wang, G.; Yu, J.; Rong, Y. Competitive failure analysis on tensile fracture of laser-deposited material for martensitic stainless steel. Mater. Des. 2017, 118, 1. [Google Scholar] [CrossRef]

- Sarafan, S.; Wanjara, P.; Champliaud, H.; Thibault, D. Characteristics of an autogenous single pass electron beam weld in thick gage CA6NM steel. Int. J. Adv. Manuf. Technol. 2015, 78, 1523. [Google Scholar] [CrossRef]

- Barros, R.; Silva, F.J.G.; Gouveia, R.M.; Saboori, A.; Marchese, G.; Biamino, S.; Salmi, A.; Atzeni, E. Laser Powder Bed Fusion of Inconel 718: Residual Stress Analysis Before and After Heat Treatment. Materials 2020, 13, 2248. [Google Scholar] [CrossRef]

- Liu, Y.; Li, A.; Cheng, X.; Zhang, S.; Wang, H. Effects of heat treatment on microstructure and tensile properties of laser melting deposited AISI 431 martensitic stainless steel. Mater. Sci. Eng. A 2016, 666, 27. [Google Scholar] [CrossRef]

- Gouveia, R.M.; Silva, F.J.G.; Atzeni, E.; Sormaz, D.; Alves, J.L.; Pereira, A.B. Effect of Scan Strategies and Use of Support Structures on Surface Quality and Hardness of L-PBF AlSi10Mg Parts. Materials 2020, 13, 2248. [Google Scholar] [CrossRef]

- Rashid, R.A.R.; Nazari, K.; Barr, C.; Palanisamy, S.; Orchowski, N.; Matthews, N.; Dargusch, M. Effect of laser reheat post-treatment on the microstructural characteristics of laser-cladded ultra-high strength steel. Surf. Coat. Technol. 2019, 372, 93. [Google Scholar] [CrossRef]

- Tsukanov, V.V.; Tsyganko, L.K.; Petrov, S.N.; Shandyba, G.A.; Ziza, A.I. Structural transformations during heat treatment of cast corrosion-resistant martensitic steel. Metallobrabotka 2016, 3, 42. [Google Scholar]

- Folkhard, E.; Rabensteiner, G.; Perteneder, E. Welding Metallurgy of Stainless Steels; Springer: Vienna, Austria, 1988; p. 98. [Google Scholar]

- Korsmik, R.; Rodionov, A.; Korshunov, V.; Ponomarev, D.; Prosychev, I.; Promakhov, V. Topological optimization and manufacturing of vessel propeller via LMD-method. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

| Material Grade | Elements Mass Ratio, % | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Ni | Mo | S | P | Fe | Cu | |

| 06Cr15Ni4CuMo | ≤0.06 | 0.40 | 0.60–0.90 | 14.0–15.5 | 4.0–4.4 | 0.11–0.28 | 0.015 | 0.015 | Bal. | 1.0–1.5 |

| P (W) | V (mm/s) | Yield Strength, σв, (MPa) | Ultimate Strength, σ0.2, (MPa) | Relative Elongation, δs, (%) | Impact Toughness, KV−10, (J) | |

|---|---|---|---|---|---|---|

| Technical specifications | N/A | N/A | ≥790 | ≥620 | ≥19 | ≥40 |

| DLD | 2300 | 25 | 1088 | 792 | 8 | 17 |

| b/Т = 750 °С, t = 2 h | ||||||

| Mode 1 | 1840 | 20 | 1114 | 798 | 7.5 | 16 |

| c/Т = 650 °С, t = 2 h | ||||||

| Mode 2 | 1840 | 20 | 863 | 530 | 15 | 39 |

| d/Т = 650 °С, t = 4 h | ||||||

| Mode 3 | 2300 | 25 | 891.7 | 587.2 | 12 | 29 |

| e/Т = 620 °С, t = 2 h | ||||||

| Mode 4 | 2300 | 20 | 816.4 | 698.3 | 16 | 42 |

| f/Т = 620 °С, t = 2 h/x2 the cycle is repeated twice | ||||||

| Mode 5 | 2300 | 20 | 804.4 | 666.8 | 19 | 42 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mendagaliev, R.; Klimova-Korsmik, O.; Promakhov, V.; Schulz, N.; Zhukov, A.; Klimenko, V.; Olisov, A. Heat Treatment of Corrosion Resistant Steel for Water Propellers Fabricated by Direct Laser Deposition. Materials 2020, 13, 2738. https://doi.org/10.3390/ma13122738

Mendagaliev R, Klimova-Korsmik O, Promakhov V, Schulz N, Zhukov A, Klimenko V, Olisov A. Heat Treatment of Corrosion Resistant Steel for Water Propellers Fabricated by Direct Laser Deposition. Materials. 2020; 13(12):2738. https://doi.org/10.3390/ma13122738

Chicago/Turabian StyleMendagaliev, Ruslan, Olga Klimova-Korsmik, Vladimir Promakhov, Nikita Schulz, Alexander Zhukov, Viktor Klimenko, and Andrey Olisov. 2020. "Heat Treatment of Corrosion Resistant Steel for Water Propellers Fabricated by Direct Laser Deposition" Materials 13, no. 12: 2738. https://doi.org/10.3390/ma13122738

APA StyleMendagaliev, R., Klimova-Korsmik, O., Promakhov, V., Schulz, N., Zhukov, A., Klimenko, V., & Olisov, A. (2020). Heat Treatment of Corrosion Resistant Steel for Water Propellers Fabricated by Direct Laser Deposition. Materials, 13(12), 2738. https://doi.org/10.3390/ma13122738