Antistatic Fibers for High-Visibility Workwear: Challenges of Melt-Spinning Industrial Fibers

Abstract

1. Introduction

2. Materials and Methods

2.1. Polymers and Compounds

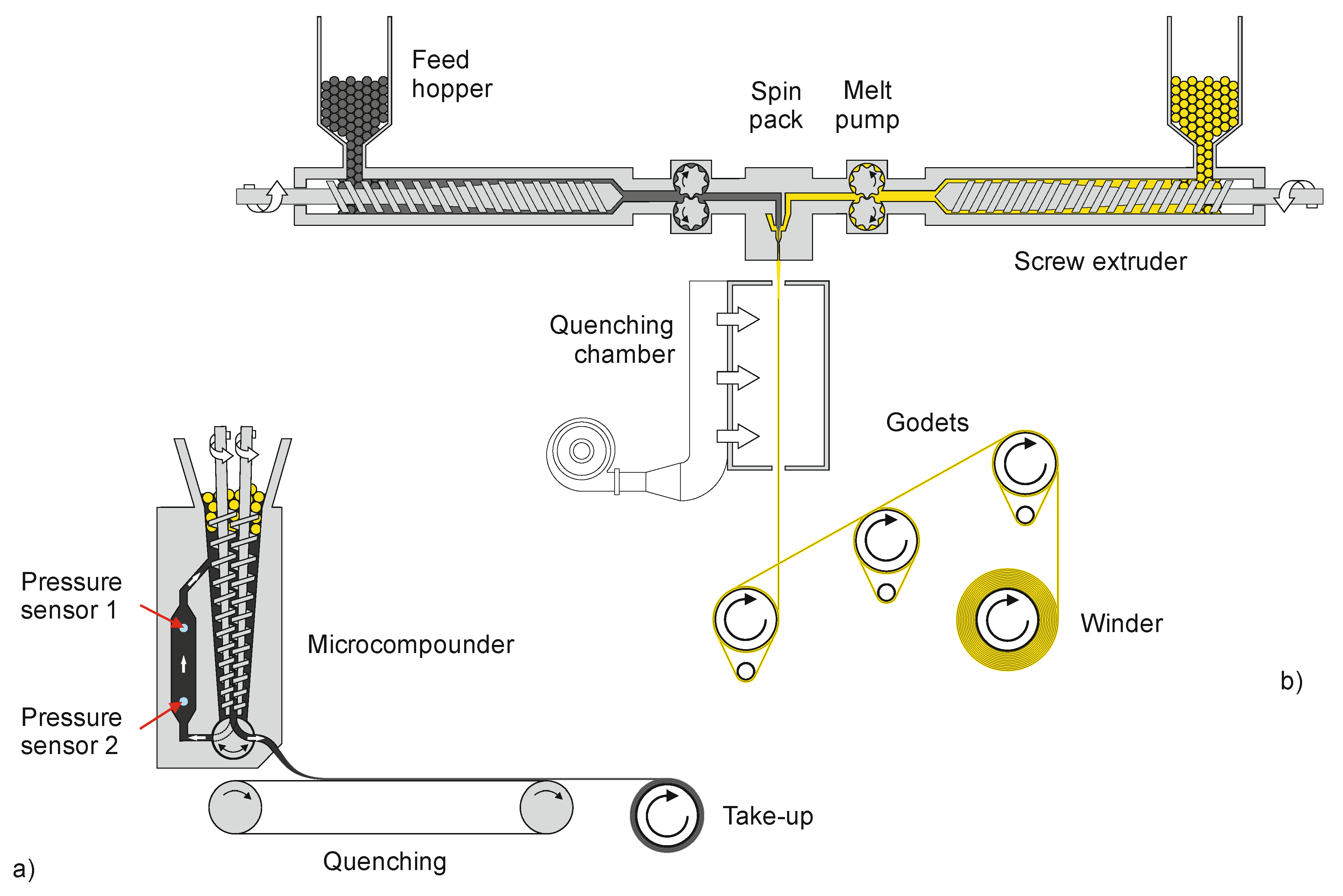

2.2. Extrusion and Melt-Spinning

2.3. Physical Properties

3. Results and Discussion

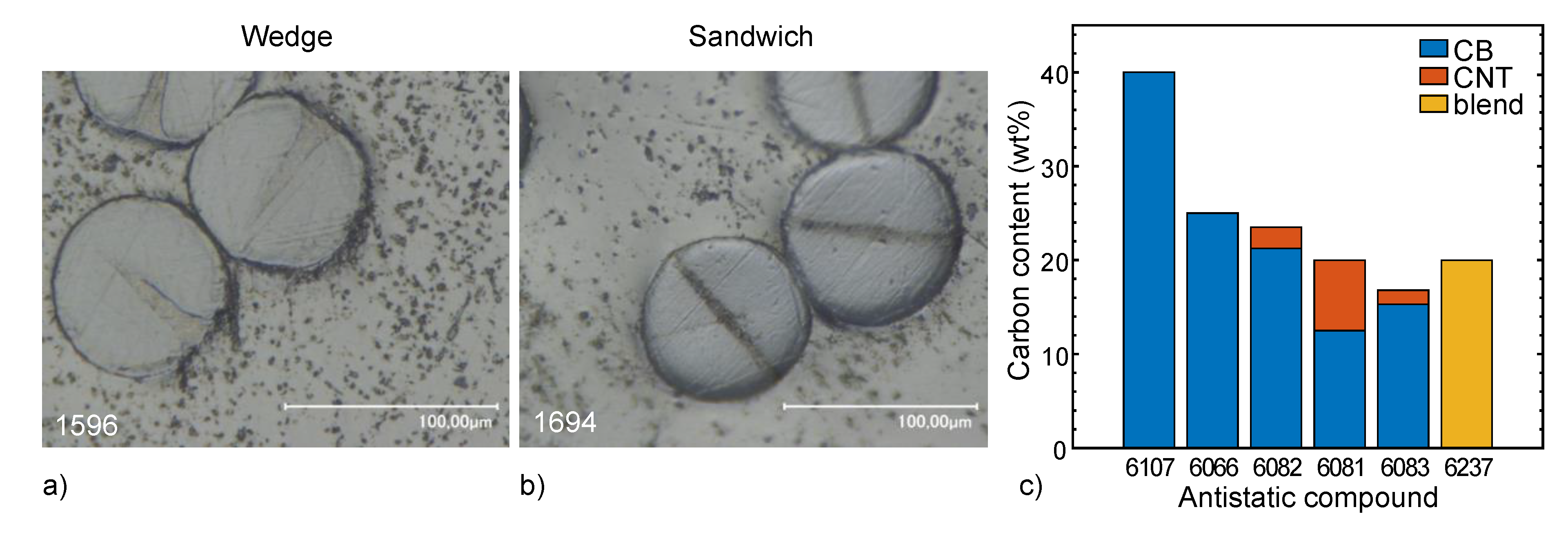

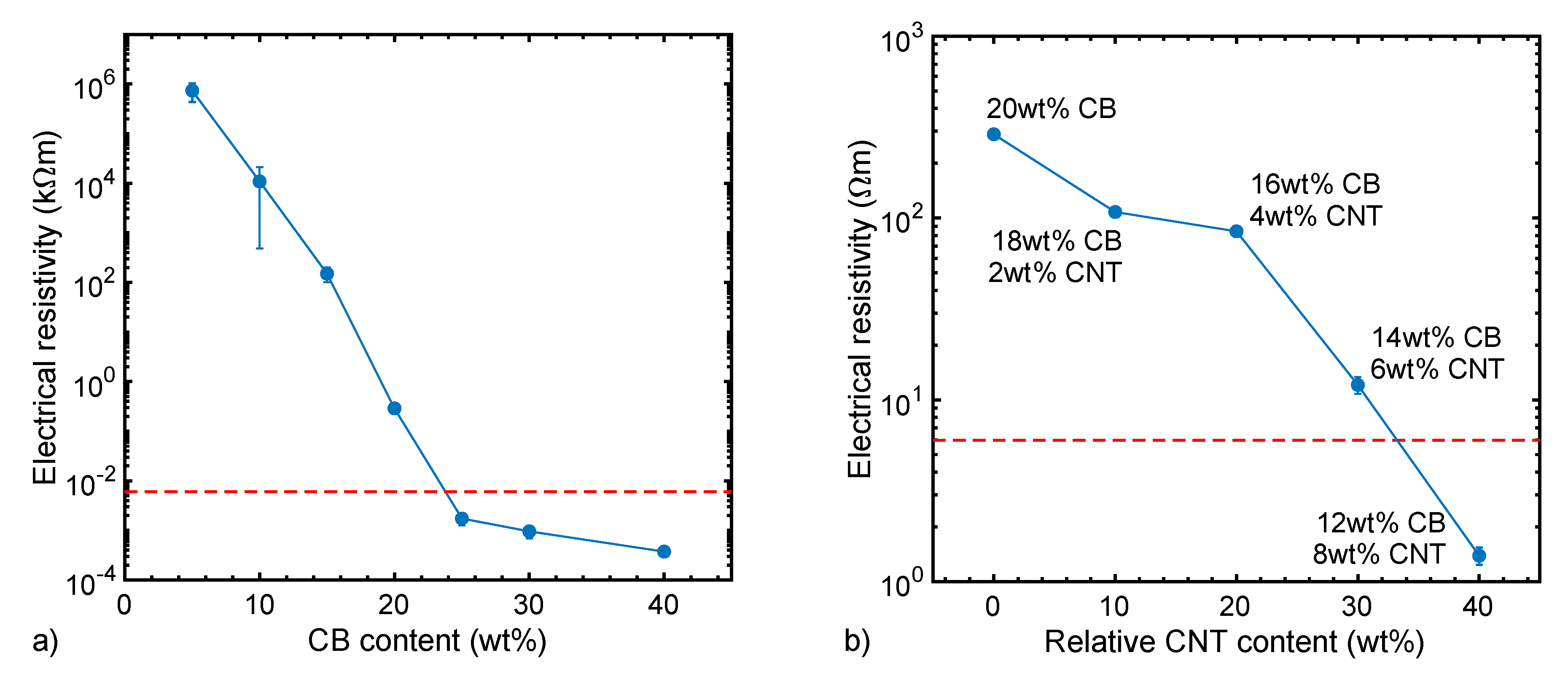

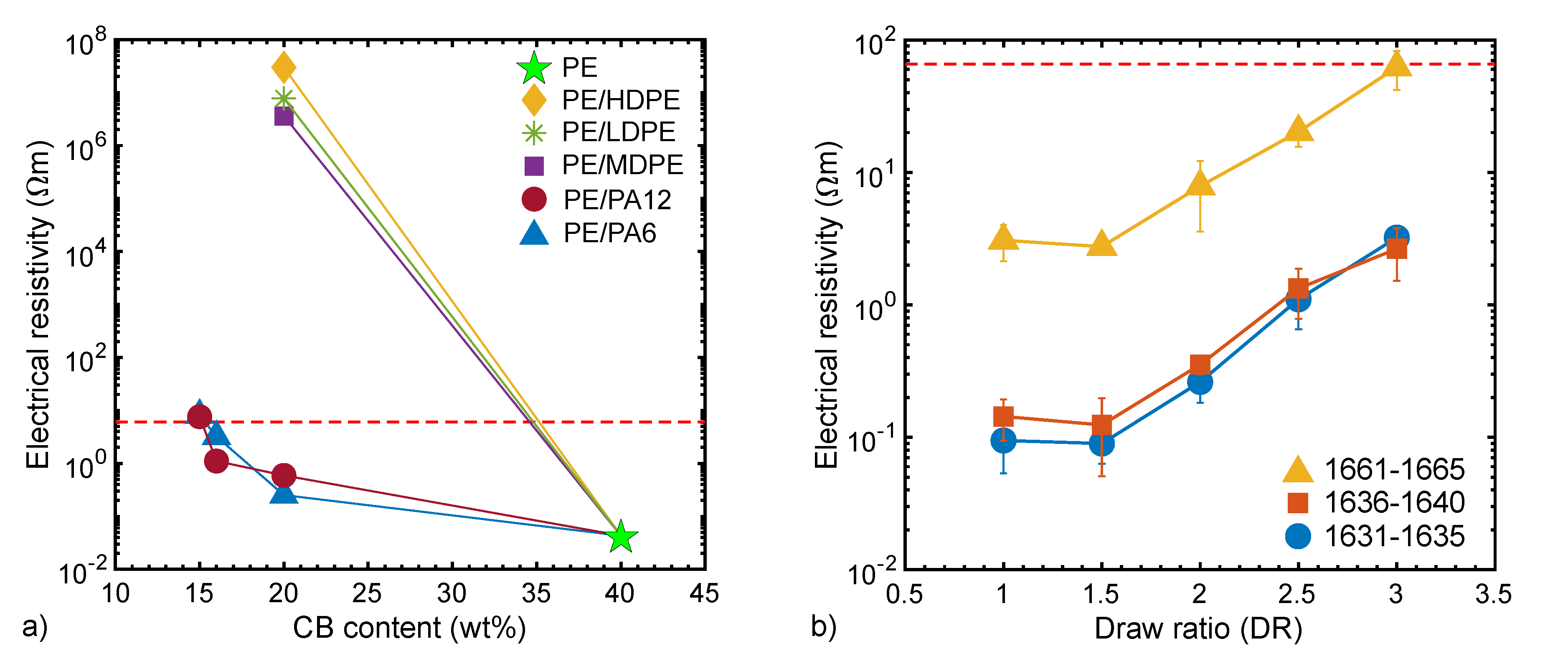

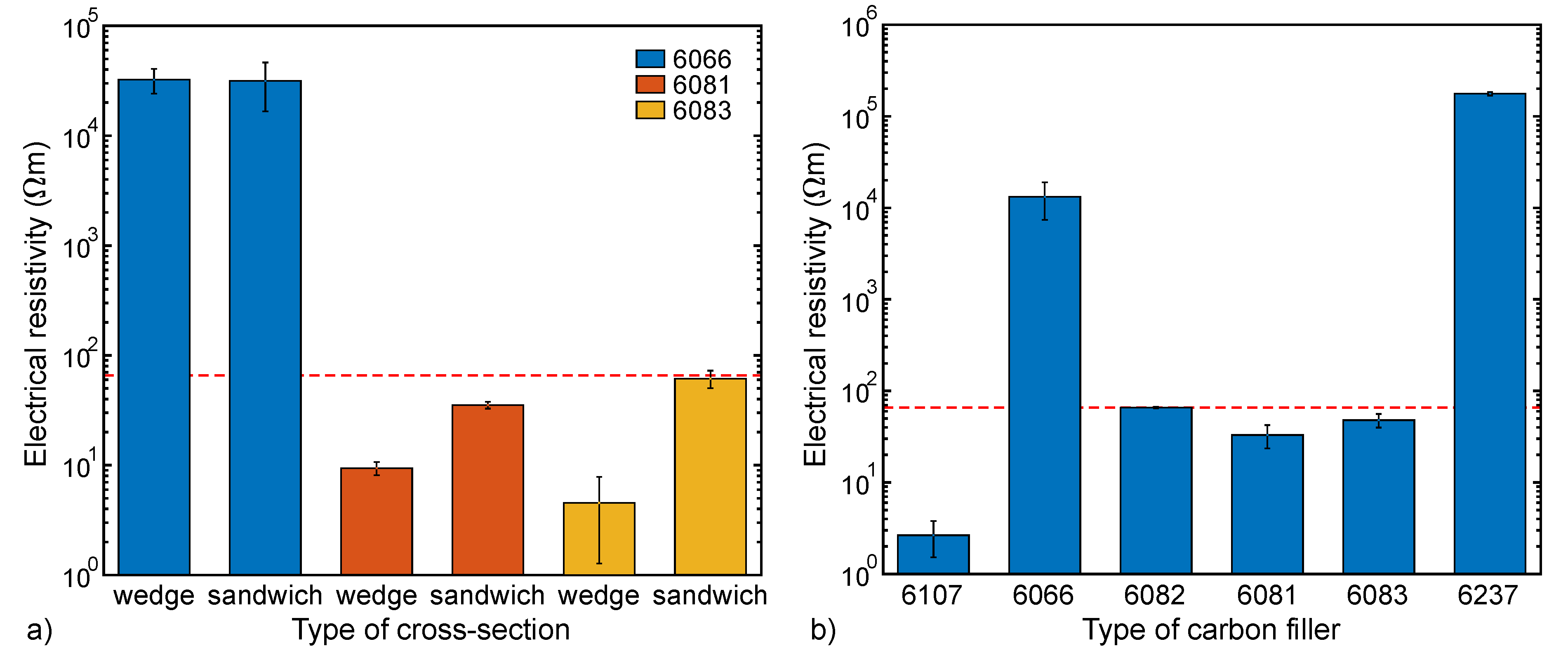

3.1. Assessment of Different Approaches to Reduce the Resistivity of Compounds

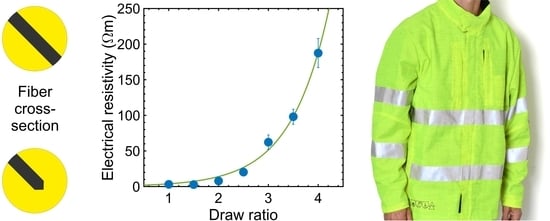

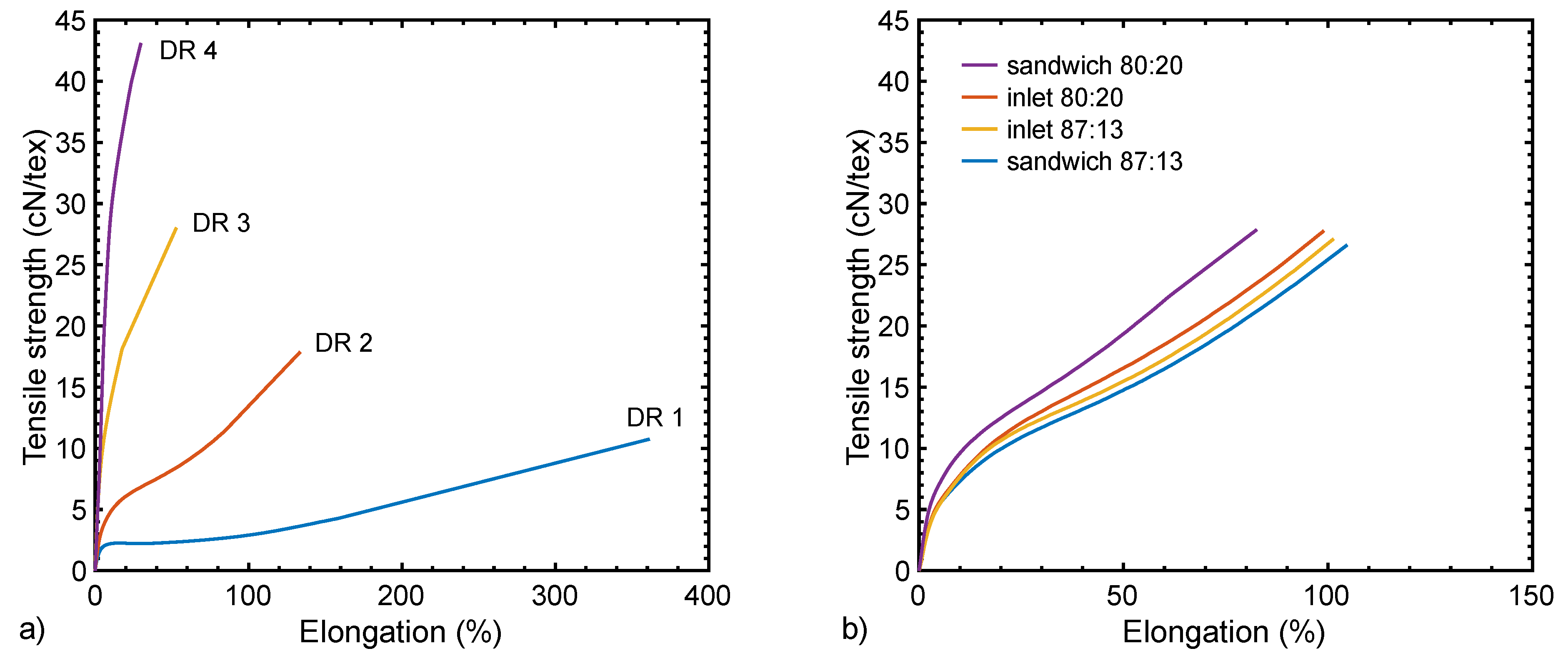

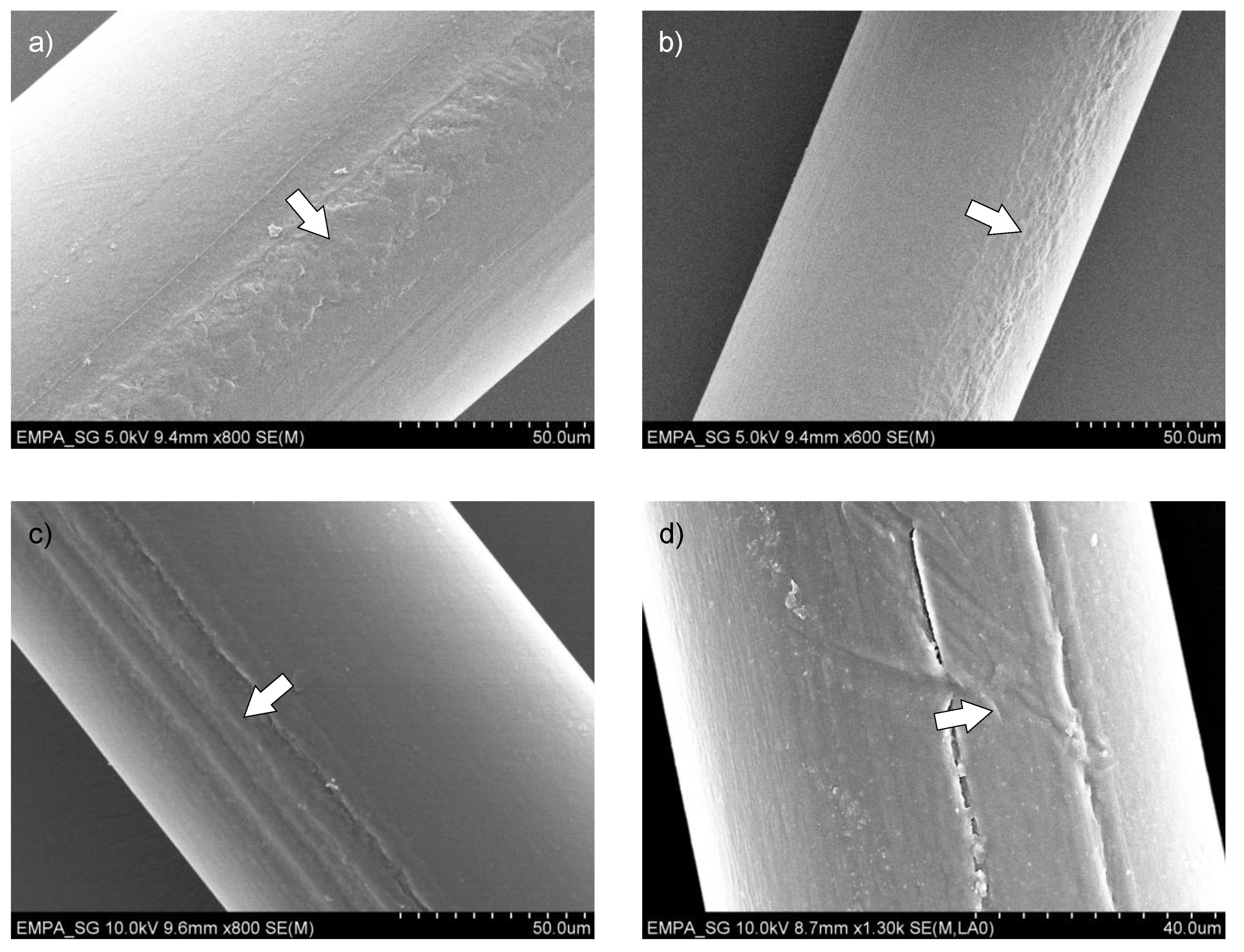

3.2. Physical Properties of Bicomponent Fibers

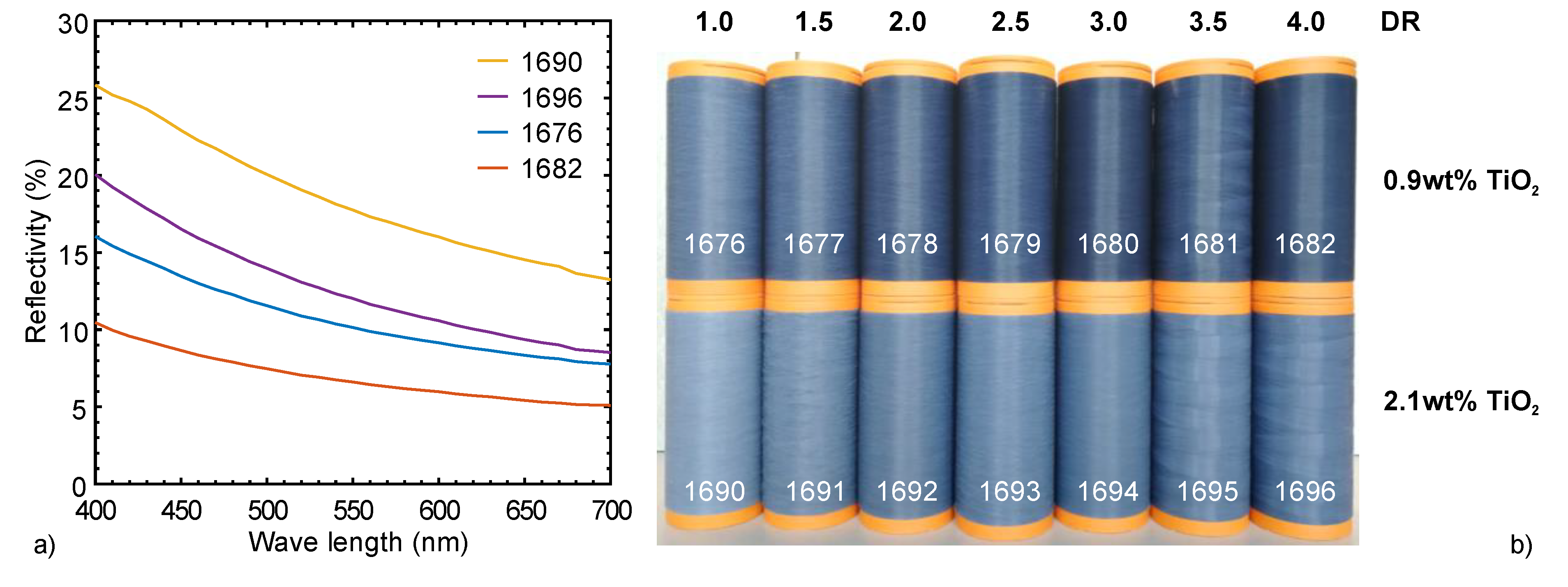

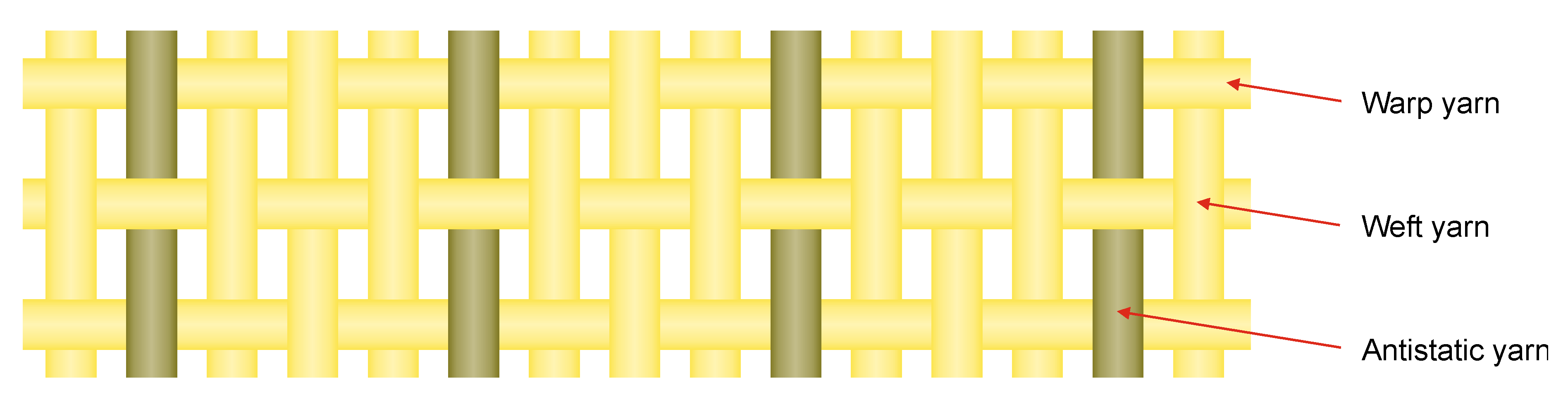

3.3. Prototype Production of Antistatic Hi-Viz Workwear

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fu, K.; Padbury, R.; Toprakci, O.; Dirican, M.; Zhang, X. 13-Conductive textiles. In Engineering of High-Performance Textiles; Miao, M., Xin, J.H., Eds.; Woodhead Publishing: Cambridge, UK, 2018; pp. 305–334. [Google Scholar]

- Molina, J. Graphene-based fabrics and their applications: A review. RSC Adv. 2016, 6, 68261–68291. [Google Scholar] [CrossRef]

- Shakespeare Conductive Fibers. Available online: http://www.resistat.com/pdf/rsum2.pdf (accessed on 12 May 2020).

- Stoppa, M.; Chiolerio, A. Wearable Electronics and Smart Textiles: A Critical Review. Sensors 2014, 14, 11957–11992. [Google Scholar] [CrossRef] [PubMed]

- Kong, L.B.; Boey, F.; Huang, Y.; Xu, Z.J.; Zhou, K.; Li, S.; Que, W.; Huang, H.; Zhang, T. Graphene-Based Fibers. Carbon Nanomater. Based Graphene Nanosheets 2017, 27, 303–383. [Google Scholar] [CrossRef]

- Hufenus, R.; Yan, Y.; Dauner, M.; Yao, D.; Kikutani, T. Bicomponent Fibers. In Handbook of Fibrous Materials; Wiley: Hoboken, NJ, USA, 2020; Volume 1, pp. 281–313. [Google Scholar]

- Hu, C.; Chang, S.-S.; Liang, N.-Y. Fabrication of antistatic fibers with core/sheath and segmented-pie configurations. J. Ind. Text. 2016, 47, 569–586. [Google Scholar] [CrossRef]

- Japan KBS Belltron. Available online: http://www.kbs-belltron.com/en/index.html (accessed on 12 May 2020).

- Perlon Nextrusion Monofil GmbH. Available online: https://www.perlon.com/wp-content/uploads/2019/05/PER_PB_AntiStat_19_en_web.pdf (accessed on 12 May 2020).

- Deng, H.; Lin, L.; Ji, M.; Zhang, S.; Yang, M.; Fu, Q. Progress on the morphological control of conductive network in conductive polymer composites and the use as electroactive multifunctional materials. Prog. Polym. Sci. 2014, 39, 627–655. [Google Scholar] [CrossRef]

- Gulrez, S.K.; Mohsin, M.A.; Shaikh, H.; Anis, A.; Pulose, A.M.; Yadav, M.K.; Qua, E.H.P.; Al-Zahrani, S. A review on electrically conductive polypropylene and polyethylene. Polym. Compos. 2013, 35, 900–914. [Google Scholar] [CrossRef]

- Kaur, G.; Adhikari, R.; Cass, P.; Bown, M.; Gunatillake, P. Electrically conductive polymers and composites for biomedical applications. RSC Adv. 2015, 5, 37553–37567. [Google Scholar] [CrossRef]

- Gooneie, A.; Sapkota, J.; Shirole, A.; Holzer, C. Length controlled kinetics of self-assembly of bidisperse nanotubes/nanorods in polymers. Polymers 2017, 118, 236–248. [Google Scholar] [CrossRef]

- Gooneie, A.; Hufenus, R. Hybrid Carbon Nanoparticles in Polymer Matrix for Efficient Connected Networks: Self-Assembly and Continuous Pathways. Macromolecules 2018, 51, 3547–3562. [Google Scholar] [CrossRef]

- Sadeghi, S.; Arjmand, M.; Navas, I.O.; Yazdi, A.Z.; Sundararaj, U. Effect of Nanofiller Geometry on Network Formation in Polymeric Nanocomposites: Comparison of Rheological and Electrical Properties of Multiwalled Carbon Nanotube and Graphene Nanoribbon. Macromolecules 2017, 50, 3954–3967. [Google Scholar] [CrossRef]

- Majidian, M.; Grimaldi, C.; Forró, L.; Magrez, A. Role of the particle size polydispersity in the electrical conductivity of carbon nanotube-epoxy composites. Sci. Rep. 2017, 7, 12553. [Google Scholar] [CrossRef] [PubMed]

- Sapkota, J.; Gooneie, A.; Shirole, A.; Garcia, J.C.M. A refined model for the mechanical properties of polymer composites with nanorods having different length distributions. J. Appl. Polym. Sci. 2017, 134, 45279. [Google Scholar] [CrossRef]

- Ma, P.-C.; Liu, M.-Y.; Zhang, H.; Wang, S.-Q.; Wang, R.; Wang, K.; Wong, Y.-K.; Tang, B.-Z.; Hong, S.H.; Paik, K.-W.; et al. Enhanced Electrical Conductivity of Nanocomposites Containing Hybrid Fillers of Carbon Nanotubes and Carbon Black. ACS Appl. Mater. Interfaces 2009, 1, 1090–1096. [Google Scholar] [CrossRef] [PubMed]

- Gubbels, F.; Jerome, R.; Teyssié, P.; Vanlathem, E.; Deltour, R.; Calderone, A.; Parente, V.; Bredas, J.L. Selective Localization of Carbon Black in Immiscible Polymer Blends: A Useful Tool to Design Electrical Conductive Composites. Macromolecules 1994, 27, 1972–1974. [Google Scholar] [CrossRef]

- Sumita, M.; Sakata, K.; Hayakawa, Y.; Asai, S.; Miyasaka, K.; Tanemura, M. Double percolation effect on the electrical conductivity of conductive particles filled polymer blends. Colloid Polym. Sci. 1992, 270, 134–139. [Google Scholar] [CrossRef]

- Katada, A.; Buys, Y.F.; Tominaga, Y.; Asai, S.; Sumita, M. Relationship between electrical resistivity and particle dispersion state for carbon black filled poly (ethylene-co-vinyl acetate)/poly (L-lactic acid) blend. Colloid Polym. Sci. 2005, 284, 134–141. [Google Scholar] [CrossRef]

- Hufenus, R.; Reifler, F.A.; Maniura-Weber, K.; Spierings, A.; Zinn, M. Biodegradable Bicomponent Fibers from Renewable Sources: Melt-Spinning of Poly(lactic acid) and Poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)]. Macromol. Mater. Eng. 2011, 297, 75–84. [Google Scholar] [CrossRef]

- Rwei, S.-P.; Rwei, S.-P.; Cheng, K.-C. Dispersion of carbon black in a continuous phase: Electrical, rheological, and morphological studies. Colloid Polym. Sci. 2002, 280, 1110–1115. [Google Scholar] [CrossRef]

- Ravindren, R.; Mondal, S.; Nath, K.; Das, N.C. Synergistic effect of double percolated co-supportive MWCNT-CB conductive network for high-performance EMI shielding application. Polym. Adv. Technol. 2019, 30, 1506–1517. [Google Scholar] [CrossRef]

- Goldel, A.; Marmur, A.; Kasaliwal, G.R.; Pötschke, P.; Heinrich, G. Shape-Dependent Localization of Carbon Nanotubes and Carbon Black in an Immiscible Polymer Blend during Melt Mixing. Macromolecules 2011, 44, 6094–6102. [Google Scholar] [CrossRef]

- Sumita, M.; Sakata, K.; Asai, S.; Miyasaka, K.; Nakagawa, H. Dispersion of fillers and the electrical conductivity of polymer blends filled with carbon black. Polym. Bull. 1991, 25, 265–271. [Google Scholar] [CrossRef]

- Mamunya, Y.P. Morphology and percolation conductivity of polymer blends containing carbon black. J. Macromol. Sci. Part B 1999, 38, 615–622. [Google Scholar] [CrossRef]

- Huang, J.-C. Carbon black filled conducting polymers and polymer blends. Adv. Polym. Technol. 2002, 21, 299–313. [Google Scholar] [CrossRef]

- Baudouin, A.-C.; Devaux, J.; Bailly, C. Localization of carbon nanotubes at the interface in blends of polyamide and ethylene–acrylate copolymer. Polymer 2010, 51, 1341–1354. [Google Scholar] [CrossRef]

- Cayla, A.; Campagne, C.; Rochery, M.; Devaux, É. Electrical, rheological properties and morphologies of biphasic blends filled with carbon nanotubes in one of the two phases. Synth. Met. 2011, 161, 1034–1042. [Google Scholar] [CrossRef]

- Gooneie, A.; Nazockdast, H.; Shahsavan, F. Effect of selective localization of carbon nanotubes in PA6 dispersed phase of PP/PA6 blends on the morphology evolution with time, part 1: Droplet deformation under simple shear flows. Polym. Eng. Sci. 2015, 55, 1504–1519. [Google Scholar] [CrossRef]

- Feng, J.; Chan, C. Carbon black-filled immiscible blends of poly(vinylidene fluoride) and high density polyethylene: Electrical properties and morphology. Polym. Eng. Sci. 1998, 38, 1649–1657. [Google Scholar] [CrossRef]

- Zoldan, J.; Siegmann, A.; Narkis, M.; Alig, I. Dielectric Spectroscopy of Anisotropic Polypropylene/Nylon-66 Blends Containing Carbon Black. J. Macromol. Sci. Part B 2006, 45, 61–83. [Google Scholar] [CrossRef]

- Tchoudakov, R.; Breuer, O.; Narkis, M.; Siegmann, A. Conductive polymer blends with low carbon black loading: Polypropylene/polyamide. Polym. Eng. Sci. 1996, 36, 1336–1346. [Google Scholar] [CrossRef]

- Huang, J.-C.; Wu, C.-L.; Grossman, S.J. Carbon Black-Filled Conductive Polymers of Polypropylene, Ethylene Vinyl Acetate Copolymer, and Their Ternary Blends. J. Polym. Eng. 2000, 20. [Google Scholar] [CrossRef]

- Tan, Y.; Song, Y.; Cao, Q.; Zheng, Q. Characterization of carbon black-filled immiscible polypropylene/polystyrene blends. Polym. Int. 2011, 60, 823–832. [Google Scholar] [CrossRef]

- Yu, G.; Zhang, M.Q.; Zeng, H.M.; Hou, Y.H.; Zhang, H.B. Conductive polymer blends filled with carbon black: Positive temperature coefficient behavior. Polym. Eng. Sci. 1999, 39, 1678–1688. [Google Scholar] [CrossRef]

- Pan, Y.; Liu, X.; Hao, X.; Starý, Z.; Schubert, D.W. Enhancing the electrical conductivity of carbon black-filled immiscible polymer blends by tuning the morphology. Eur. Polym. J. 2016, 78, 106–115. [Google Scholar] [CrossRef]

- Xu, Z.; Zhao, C.; Gu, A.; Fang, Z.; Tong, L. Effect of morphology on the electric conductivity of binary polymer blends filled with carbon black. J. Appl. Polym. Sci. 2007, 106, 2008–2017. [Google Scholar] [CrossRef]

- Chen, G.; Yang, B.; Guo, S. Nylon 6 induced morphological developments and electrical conductivity improvements of polypropylene/carbon black composites. J. Appl. Polym. Sci. 2009, 114, 1848–1855. [Google Scholar] [CrossRef]

- Wu, G.; Li, B.; Jiang, J. Carbon black self-networking induced co-continuity of immiscible polymer blends. Polymer 2010, 51, 2077–2083. [Google Scholar] [CrossRef]

- Bobeth, W. Textile Faserstoffe: Beschaffenheit und Eigenschaften; Springer: Berlin/Heidelberg, Germany, 1993. [Google Scholar]

- Loy, W. Chemiefasern für Technische Textilprodukte: Standardtypen; Deutscher Fachverlag: Modifikationen, Einsatzgebiete, 2008. [Google Scholar]

- Moniruzzaman, M.; Winey, K.I. Polymer Nanocomposites Containing Carbon Nanotubes. Macromolecules 2006, 39, 5194–5205. [Google Scholar] [CrossRef]

- Huang, Y.Y.S.; Ahir, S.V.; Terentjev, E.M. Dispersion rheology of carbon nanotubes in a polymer matrix. Phys. Rev. B 2006, 73, 125422. [Google Scholar] [CrossRef]

- European Standard. Protective Clothing—Electrostatic Properties—Part 5: Material Performance and Design Requirements; DIN EN 1149-5; Beuth Verlag: Berlin, Germany, 2008. [Google Scholar]

- European Standard. High-Visibility Warning Clothing for Professional Use—Test Methods and Requirements; DIN EN 471; Beuth Verlag: Berlin, Germany, 2006. [Google Scholar]

- Underwriters Laboratories. Tests for Flammability of Plastic Materials for Parts in Devices and Appliances; UL94; Underwriters Laboratories: Northbrook, IL, USA, 1990. [Google Scholar]

| Code/No. | Product Name | Provider | Base Polymer | CB Content (wt%) | CNT Content (wt%) | TiO2 Content (wt%) |

|---|---|---|---|---|---|---|

| LDPE | LDPE 1700 MN 18 C | Total | LDPE | - | - | - |

| MDPE | MDPE 1020 FE 30 | Arkema | MDPE | - | - | - |

| HDPE | HDPE 2055 MN | Total | HDPE | - | - | - |

| 887 | Sabic LDPE | Sabic | LDPE | - | - | - |

| 5432 | Grilon A26 | EMS-CHEMIE | PA6 | - | - | - |

| 5528 | Grilon F 34 NL | EMS-CHEMIE | PA6 | - | - | - |

| 5793 | Grilamid L 20 | EMS-CHEMIE | PA12 | - | - | - |

| 6065 | PlastiCyl PA1502 | Nanocyl | PA12 | - | 15 | - |

| 6066 | Grilamid L 20 EC | EMS-CHEMIE | PA12 | 25 | - | - |

| 6067 | Grilamid FE 11384 | EMS-CHEMIE | PA12 | 17 | - | - |

| 6081 | L-2597 KTI-2 | EMS-CHEMIE | PA12 | 12.5 | 7.5 | - |

| 6082 | L-2598 KTI-3 | EMS-CHEMIE | PA12 | 21.25 | 2.25 | - |

| 6083 | L-2599 KTI-5 | EMS-CHEMIE | PA12 | 15.3 | 1.5 | - |

| 6107 | Palamid Black 00-6405 | BASF | PA6 | 40 | - | - |

| 6111 | ColColor RKK E 40/FP | Evonik | PE | 40 | - | - |

| 6183 | Palamid White 00-2305 | BASF | PA6 | - | - | 30 |

| 6237 | - | - | PE/PA6 | 20 | - | - |

| 6739 | - | - | PE/PE | 20 | - | - |

| Blend Composition | Distribution Tendency of CB | Reference | ||

|---|---|---|---|---|

| PMMA | PP | CB | Interface | Sumita et al. [20] |

| PMMA | HDPE | CB | Interface | Sumita et al. [20] |

| LDPE | PP | CB | LDPE | Mamunya [27] |

| LDPE | POM | CB | Interface | Mamunya [27] |

| HDPE | PVDF | CB | HDPE | Feng et al. [32] |

| PA66 | PP | CB | PA66 | Zoldan et al. [33] |

| PA6/6-9 | PP | CB | PA6/6-9 | Tchoudakov et al. [34] |

| PP | EVA | CB | EVA | Huang et al. [35] |

| PP | PS | CB | PS | Tan et al. [36] |

| LDPE | EVA | CB | LDPE | Yu et al. [37] |

| PS | PMMA | CB | PS | Pan et al. [38] |

| HDPE | PP | CB | HDPE | Xu et al. [39] |

| PP | PA6 | CB | PA6 | Chen et al. [40] |

| ABS | PA6 | CB | PA6 | Wu et al. [41] |

| PS | PA6 | CB | PA6 | Xu et al. [39] |

| PMMA | PA6 | CB | PA6 | Xu et al. [39] |

| PE | PA12 | CB | PE | This study |

| PE | PA6 | CB | Interface | This study |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hufenus, R.; Gooneie, A.; Sebastian, T.; Simonetti, P.; Geiger, A.; Parida, D.; Bender, K.; Schäch, G.; Clemens, F. Antistatic Fibers for High-Visibility Workwear: Challenges of Melt-Spinning Industrial Fibers. Materials 2020, 13, 2645. https://doi.org/10.3390/ma13112645

Hufenus R, Gooneie A, Sebastian T, Simonetti P, Geiger A, Parida D, Bender K, Schäch G, Clemens F. Antistatic Fibers for High-Visibility Workwear: Challenges of Melt-Spinning Industrial Fibers. Materials. 2020; 13(11):2645. https://doi.org/10.3390/ma13112645

Chicago/Turabian StyleHufenus, Rudolf, Ali Gooneie, Tutu Sebastian, Pietro Simonetti, Andreas Geiger, Dambarudhar Parida, Klaus Bender, Gunther Schäch, and Frank Clemens. 2020. "Antistatic Fibers for High-Visibility Workwear: Challenges of Melt-Spinning Industrial Fibers" Materials 13, no. 11: 2645. https://doi.org/10.3390/ma13112645

APA StyleHufenus, R., Gooneie, A., Sebastian, T., Simonetti, P., Geiger, A., Parida, D., Bender, K., Schäch, G., & Clemens, F. (2020). Antistatic Fibers for High-Visibility Workwear: Challenges of Melt-Spinning Industrial Fibers. Materials, 13(11), 2645. https://doi.org/10.3390/ma13112645