1. Introduction

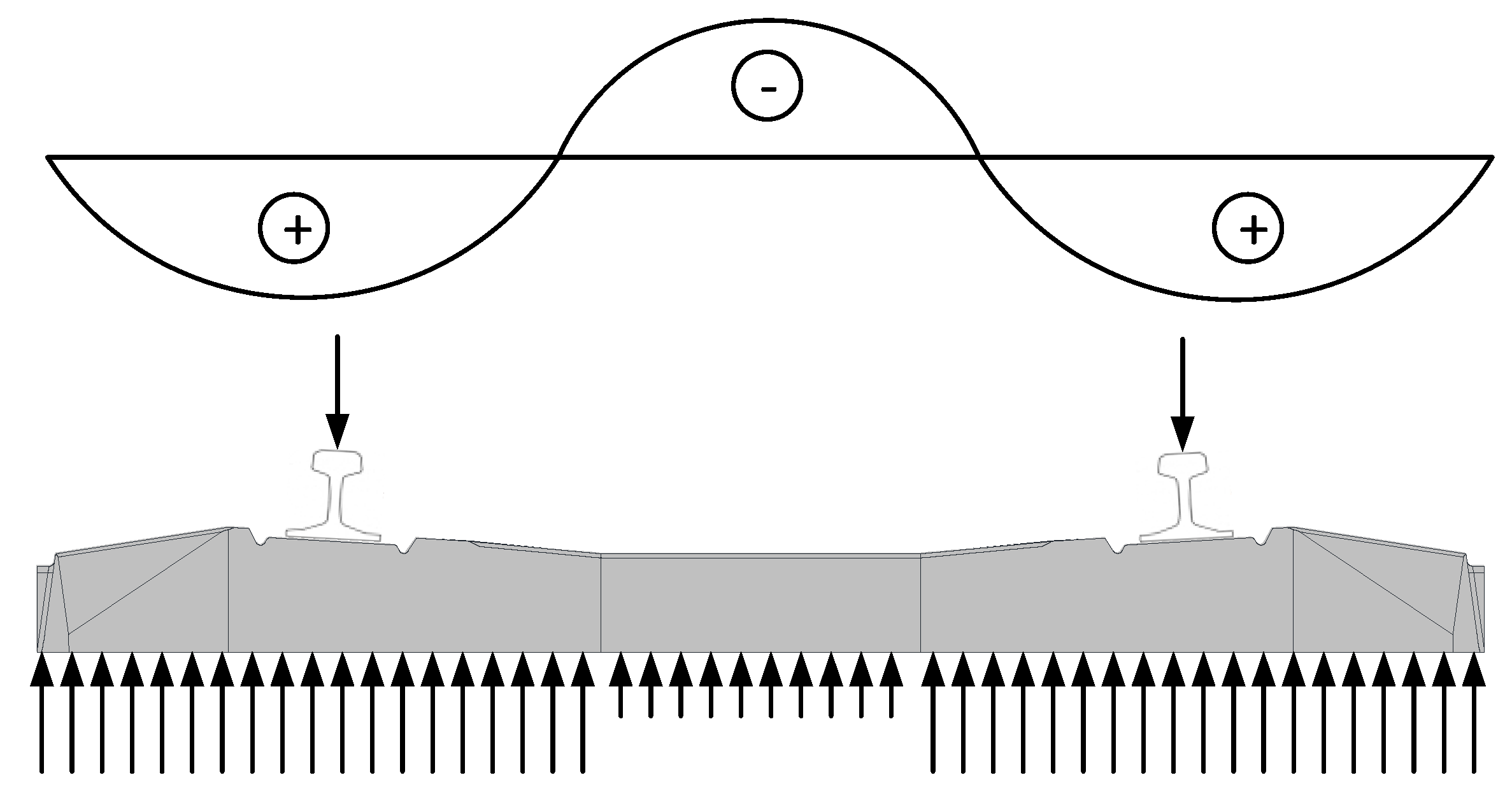

The railway track has the purpose to transfer adequately the trainload to the structure of railway track. During this transfer, it has to be ensured that the track components are not subjected to loads beyond their bearing capacity. Railway track consists of two main parts: superstructure and substructure. The superstructure consists of rails, rail pads, sleepers, and fastening systems while the substructure consists of ballast, sub-ballast, and subgrade. Each layer of the railway structure reduces the effect of the load on the underlying layer and thus distributes the load evenly between the layers. Furthermore, connecting the superstructure and substructure of the track, sleepers are the most affected part of the railway structure. They withstand static, cyclic, and impact loads of different types, directions and sizes caused by trains, and are affected by support reactions of the ballast [

1,

2,

3,

4]. Additionally, sleepers are affected by environmental influences (frost, humidity, temperature variation, aggressive materials) [

5] and production processes [

5,

6]. Furthermore, sleepers need to ensure adequate distance between the rails; evenly distribute loads from the rails to the ballast; maintain adequate inclination of the rails; act as support for the rail; restrict longitudinal, vertical, and horizontal rail displacement; and be resistant to wear. All of these factors, individually or together, affect the sleeper throughout its life cycle and can lead to damage of sleeper. Therefore, sleepers influence the global behavior of the track. Additionally, the behavior of sleepers depends on the characteristics of other track components, especially rail pads and ballast properties.

Ballast in railway track performs an important function to reduce the stress to a level which the structure of the railway track can safely withstand without any unacceptable settlement. Additionally, it provides a suitable foundation for the sleepers and also holds the sleepers in their correct level and position, preventing lateral or longitudinal displacement. The performance of a sleeper to withstand lateral and longitudinal load is dependent upon the sleeper’s size, shape, surface geometry, weight, and spacing.

The rail pad is one of the less visible parts of the fastening system. However, it has an essential function in damping the effect of vertical loading (particularly impact loading). This has two aspects: by providing an adjusting layer between the rail and the sleeper, the pad ensures even pressure on the rail seat area and by acting as a spring the pad reduces the transmission of vibration and impact from the rail into the sleeper.

Historically, timber, steel, and concrete sleepers were introduced in different countries taking into account climatic conditions and accessibility of local materials. However, nowadays new types of material are under consideration of using it in railway sleepers for a specific application or to obtain desired properties eliminating disadvantages of conventionality used timber, steel, or concrete sleepers. Composite sleepers are introduced to withstand harsh environmental impacts and eliminate damage of reinforcement due to corrosion of steel [

7]. High strength concrete instead of normal concrete can be used to increase sleeper resistance to cracking and bearing capacity [

8]. However, these types of sleepers have some disadvantages, have not yet been widely adopted, and are still under investigation.

The comparison of the behavior of timber, steel, and concrete sleepers showed that prestressed concrete sleepers have higher bearing capacity than timber and steel sleepers. Additionally, the deflection and ductility of prestressed concrete sleepers are lower and it provides more uniform load distribution under the sleeper compared to timber and steel sleepers [

9]. Therefore, nowadays, prestressed concrete sleepers are the most widely used sleepers in the world. The advantages of prestressed concrete sleepers such as rigidity, durability, improved geometric retention of track, and greater weight vital for high-speed and heavy freight lines, higher bearing capacity, resistance to environmental impacts and cracking, low cost of maintenance makes it the best choice for the heavily loaded railway tracks.

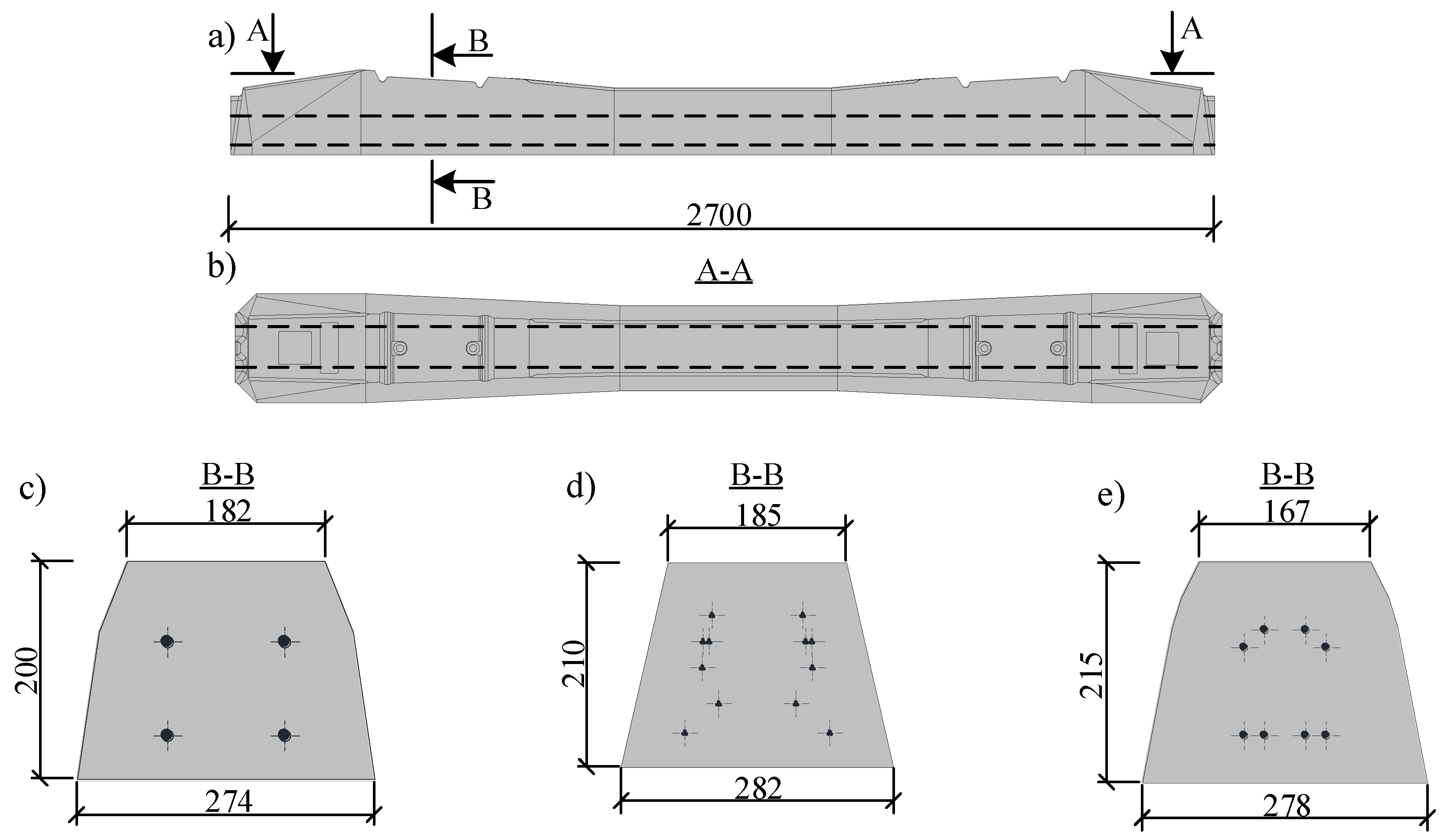

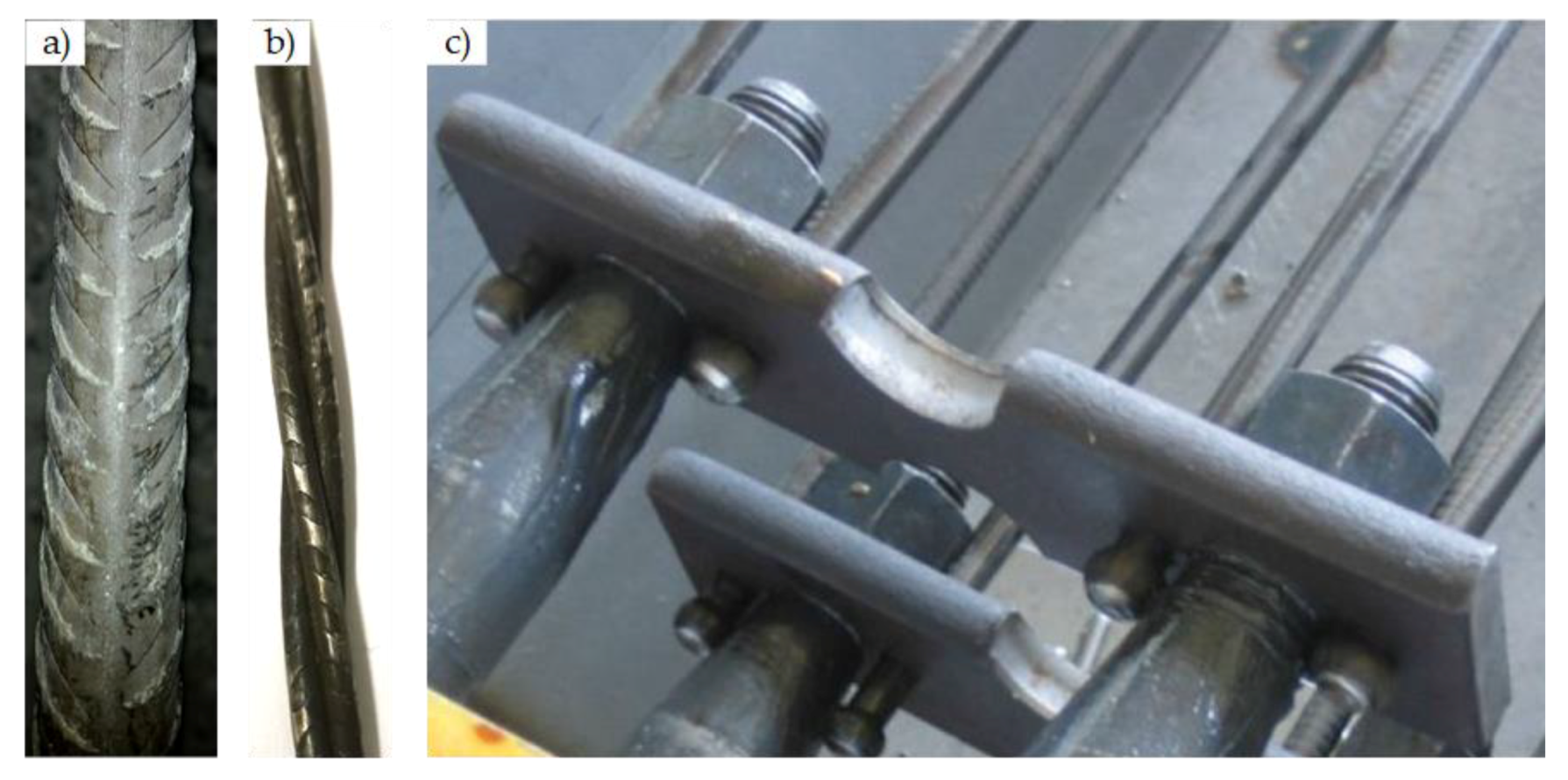

Many different types of sleepers have been designed and manufactured in recent decades. The quality of prestressed concrete sleepers is very important for the safety of the railway. Firstly, the quality of concrete sleepers is very dependent on the quality of manufacturing process. Two main manufacturing methods are currently used in the world that is a long line method and a single mold method [

6,

10]. In longline method 100–200 m long formwork tables are used which has 4–8 parallel sleeper molds. This method is based on pre-tensioning steel wires or strands to abutments before concrete is poured. After concrete reaches required strength the reinforcement is released and pretensioned force is transferred to concrete through bond between reinforcement and concrete. Therefore, utilization of pretension force, stiffness, and behavior of prestressed concrete sleeper are very dependent on the quality and strength of bond between reinforcement and concrete. In turn, bond of prestressed reinforcement is very dependent on surface roughness (indentations, helical shape, etc.) of reinforcement, concrete quality, and strength and Hoyer (wedge) effect at the end of the sleeper.

Single mold method uses one sleeper long molds with up to four parallel sleepers. As in the case of longline method, this method is based on pretensioning steel bars to molds before concrete is poured. Additionally, pretensioned bars are attached to the steel bearing plates by cold-formed buttons at their tips at each end of the mold. Therefore, the prestressing force is introduced to concrete through the steel bearing plates at the ends of the sleeper and bond between reinforcement and concrete. Usually, plain bars are used in this type of manufacturing method. Therefore, the bond portion is small. However, the bond can be increased by introducing indented bars.

The behavior and stiffness of the sleeper are very dependent on the ability to transfer prestressing force to concrete. Depending on the method of manufacturing of the sleepers the transfer of prestressing force to concrete can be ensured only through bond between reinforcement and concrete [

11,

12] (long line method) or through bearing steel plates at the ends of the sleeper and bond (single mold method). Therefore, it is very important to meet requirements for transfer length during the release of reinforcement and anchorage length in service [

13] in case of long line manufacturing method. However, the design of prestressed concrete sleepers leads to short distance between the center of the rail seat section and end of the sleeper. It means that smaller diameter reinforcement due to shorter transfer and anchorage length is used in prestressed concrete sleepers [

4,

5,

14,

15,

16,

17].

Monoblock prestressed concrete sleepers are used extensively throughout the world and are in use for all line types including high-speed lines and heavy haul lines. Despite the improvement in the quality of materials for sleepers, some sleepers are damaged in service and do not withstand expected service life [

1,

4,

18]. Hence, the sleeper design becomes a core factor in track safety. Additionally, the increasing traffic and heavier loads in railways raise the need for optimizing the design of prestressed concrete sleepers [

19].

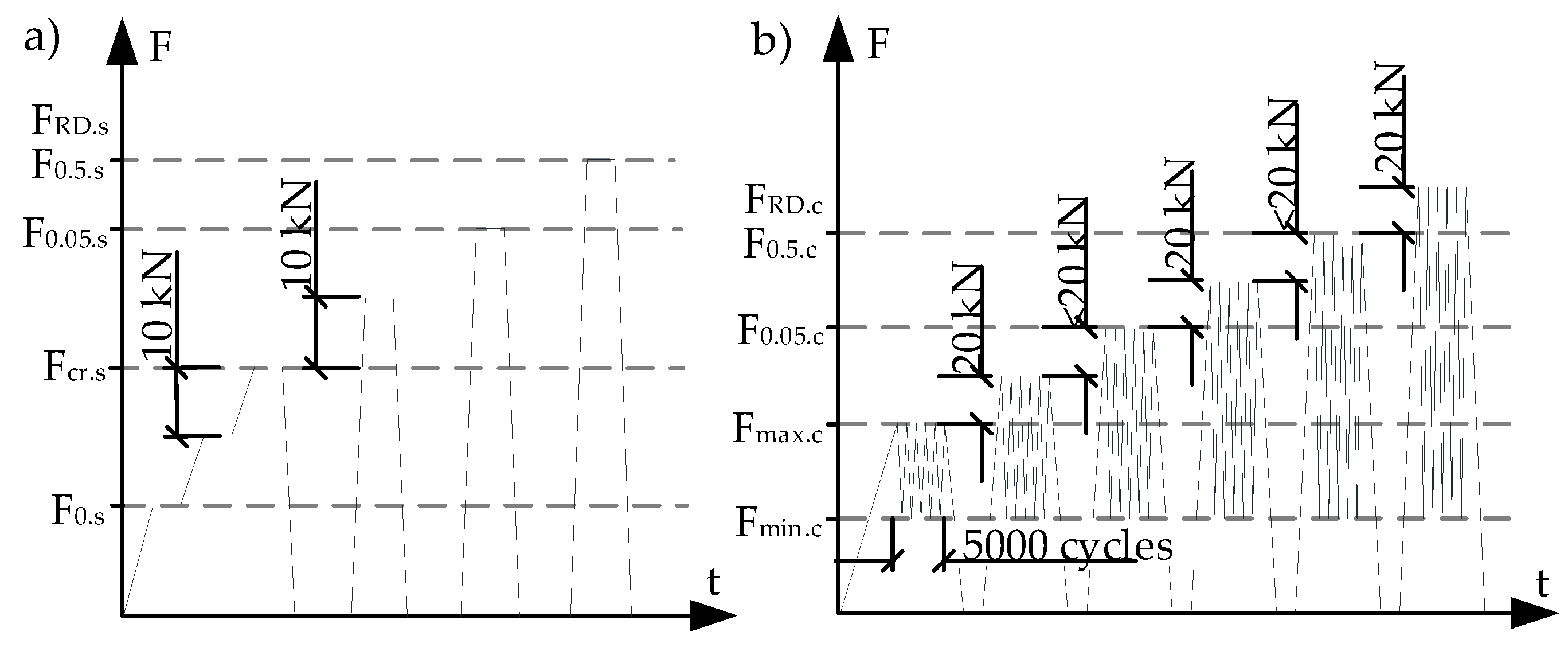

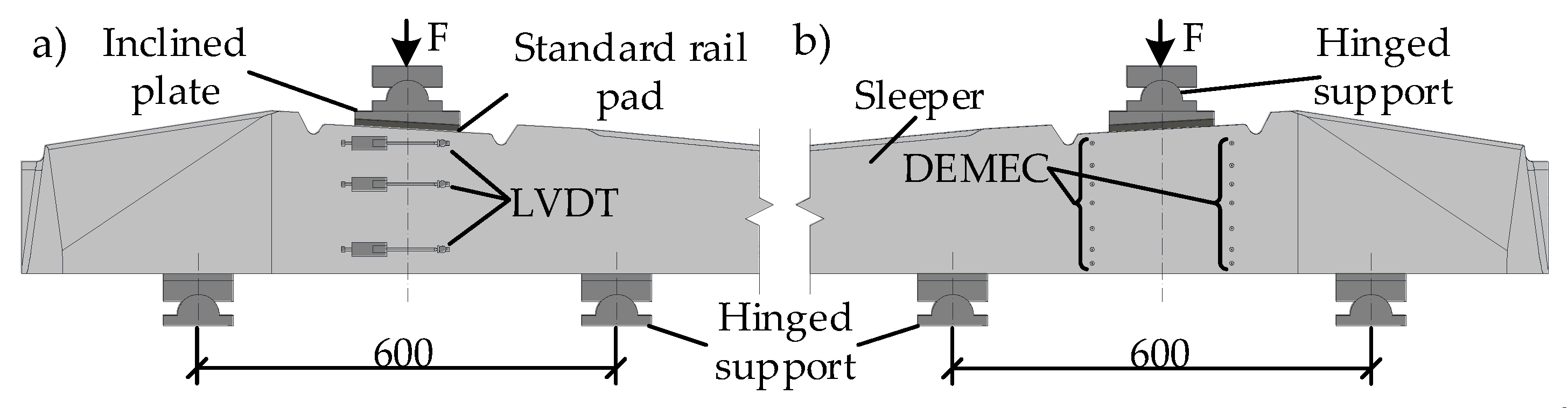

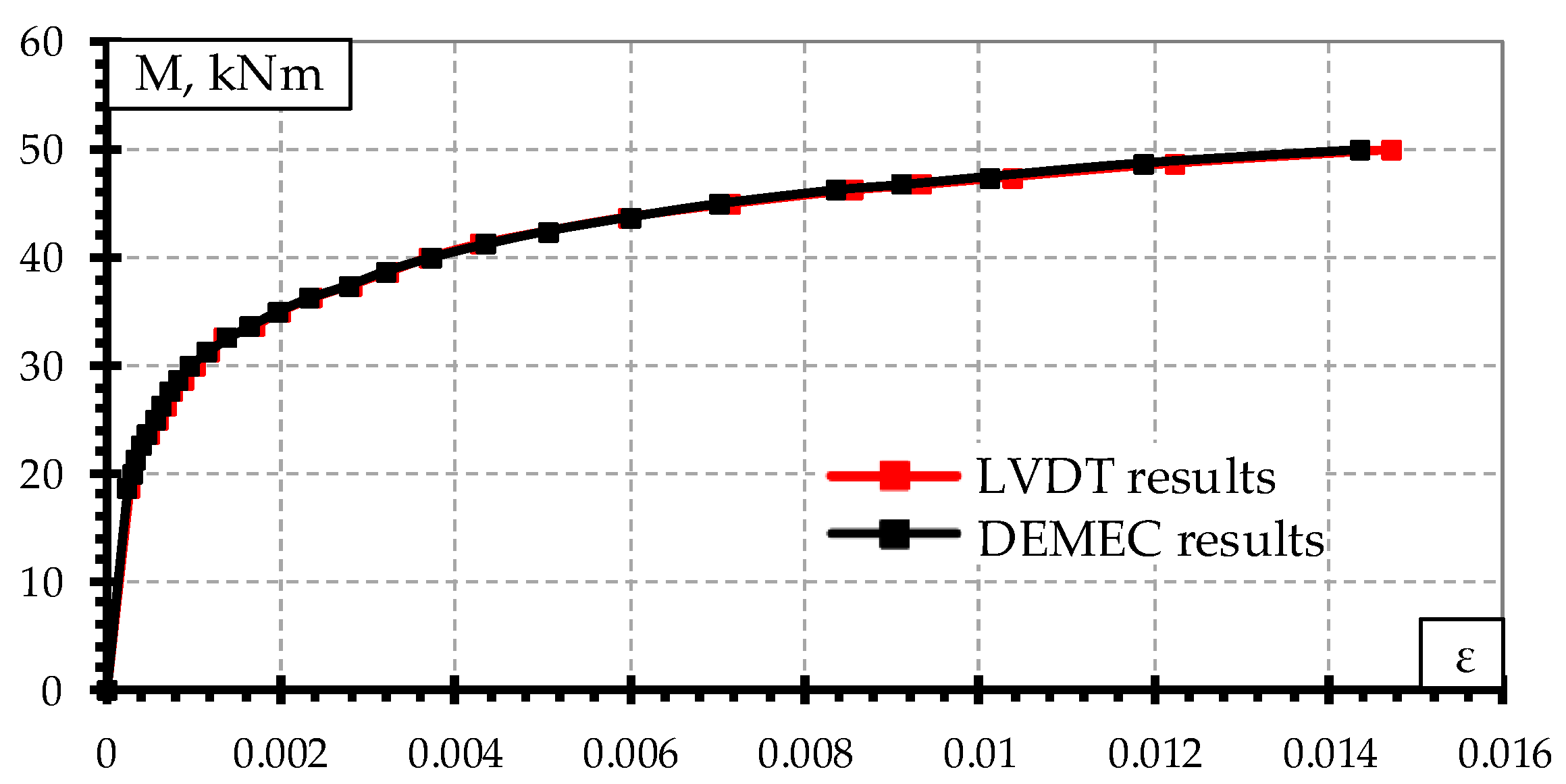

Data related to the comparison of different prestressed concrete sleepers is very important for the designing and manufacturing stage and service stage of the sleepers. Some studies were performed [

1,

4,

5,

14] comparing unexploited sleepers with damaged sleepers taken from the railway to determine the cause of deterioration of the sleeper. Other rstudies were conducted to compare the behavior of sleepers made out of different materials (concrete, timber, steel) [

9]. However, the behavior of prestressed concrete sleepers is complex not only due to various impacts affecting them in service but also due to different design approaches and manufacturing methods. As there are various types of monoblock prestressed concrete sleepers in Europe, there is a need for better understanding its behavior. However, there is a lack of qualitative data comparing the behavior of different types of sleepers. Therefore, this article presents a detailed comparative analysis of three types of sleepers under the influence of static and dynamic load. As the rail seat section is the most severely affected part of sleeper the influence of different diameter and type (strands, indented, and plain bars) of prestressed reinforcement were analyzed on the behavior of rail seat section of prestressed concrete sleepers. Tested sleepers were manufactured according to different methods (long line method and single mold method) and different reinforcement prestressing techniques were used. Therefore, the influence of different types of anchoring methods of prestressed reinforcement was also analyzed on the behavior of rail seat section of different types of prestressed concrete sleepers.

4. Conclusions

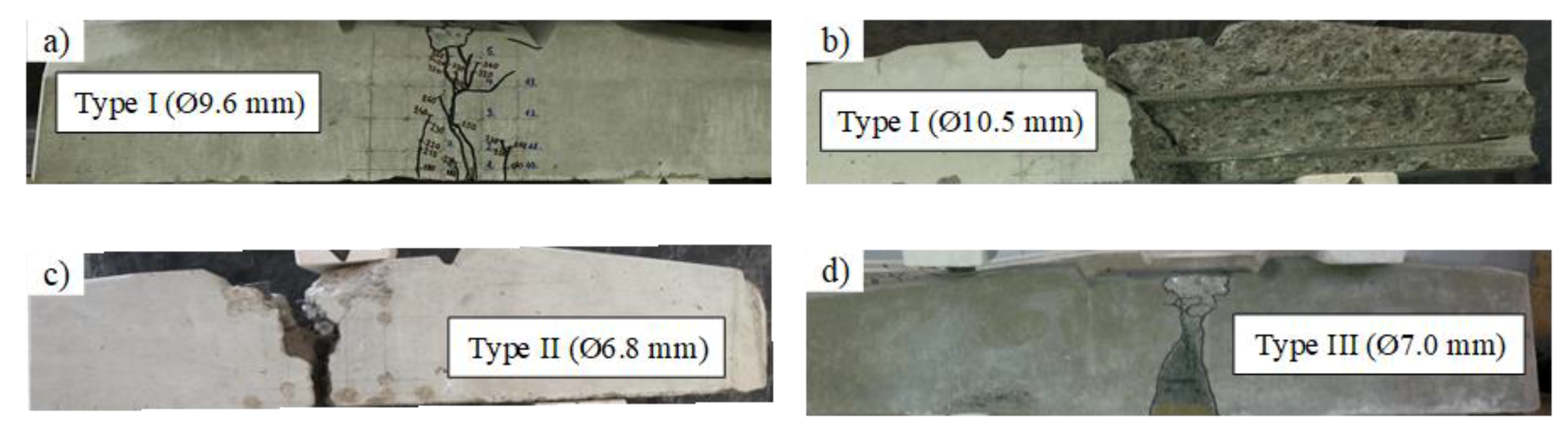

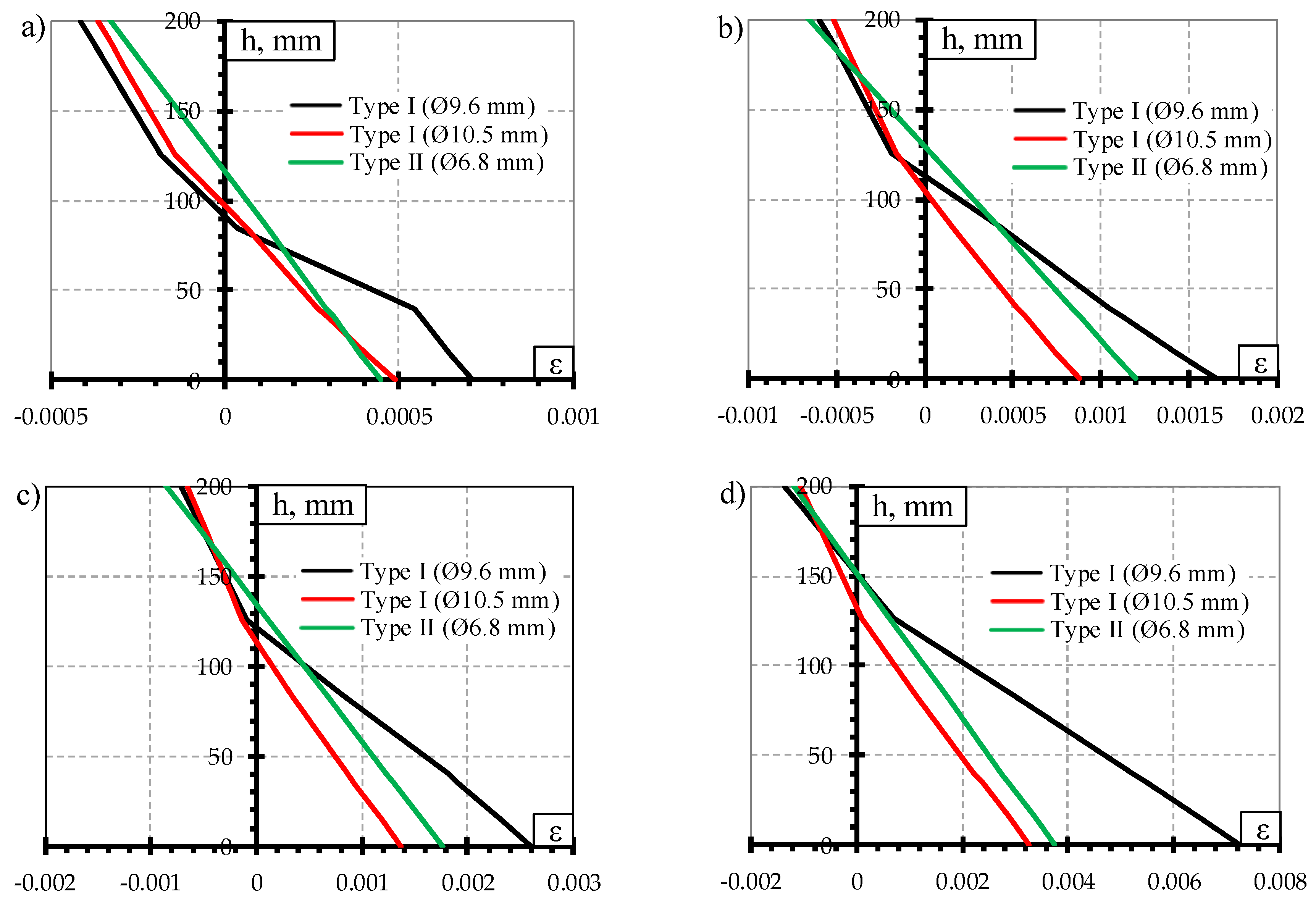

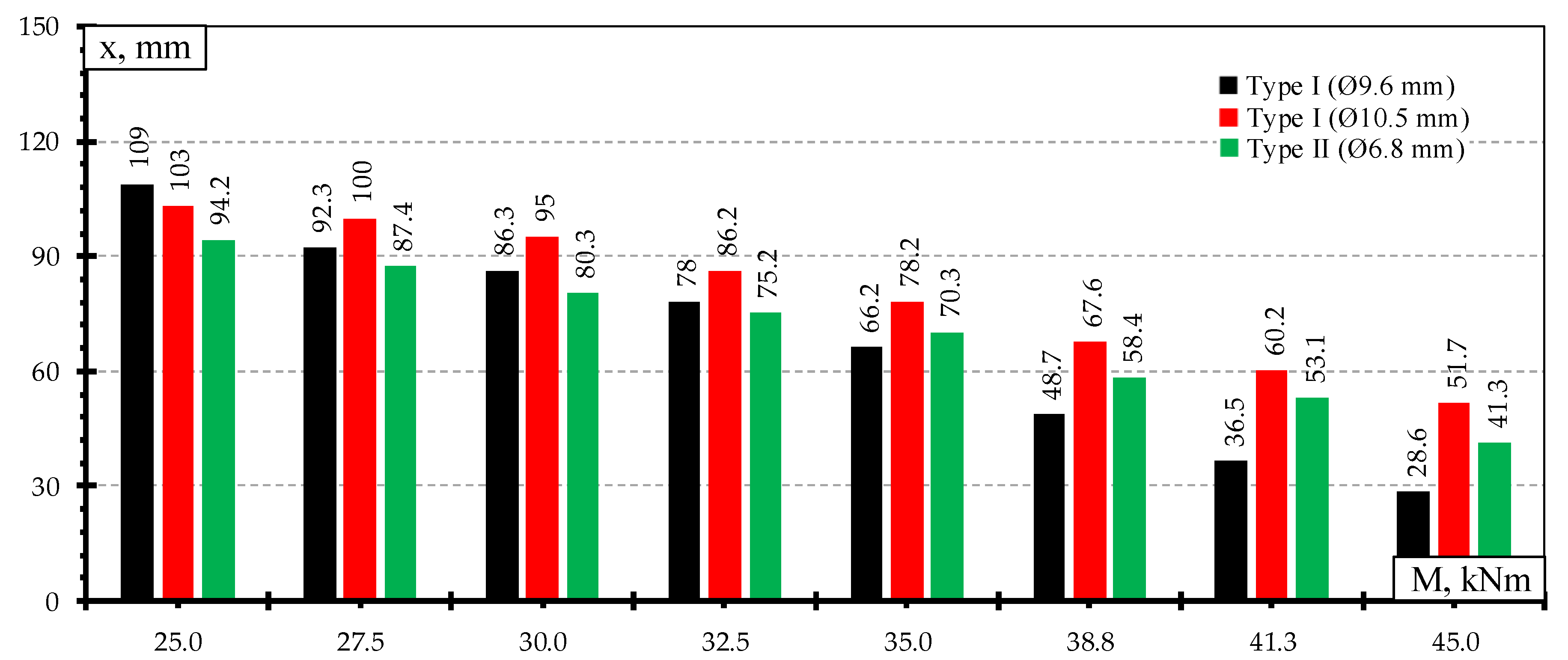

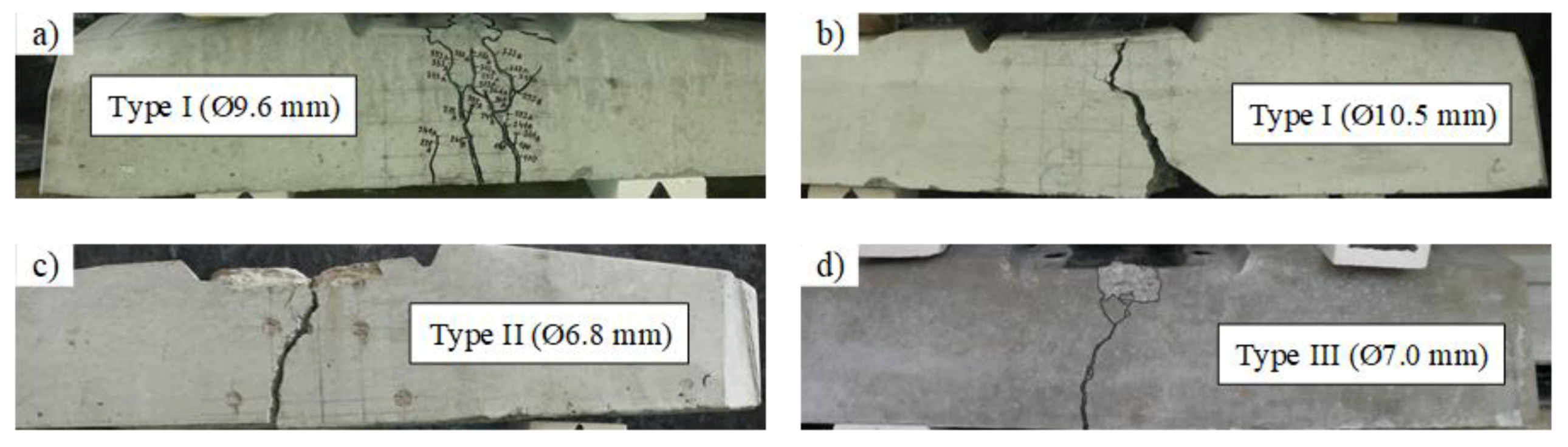

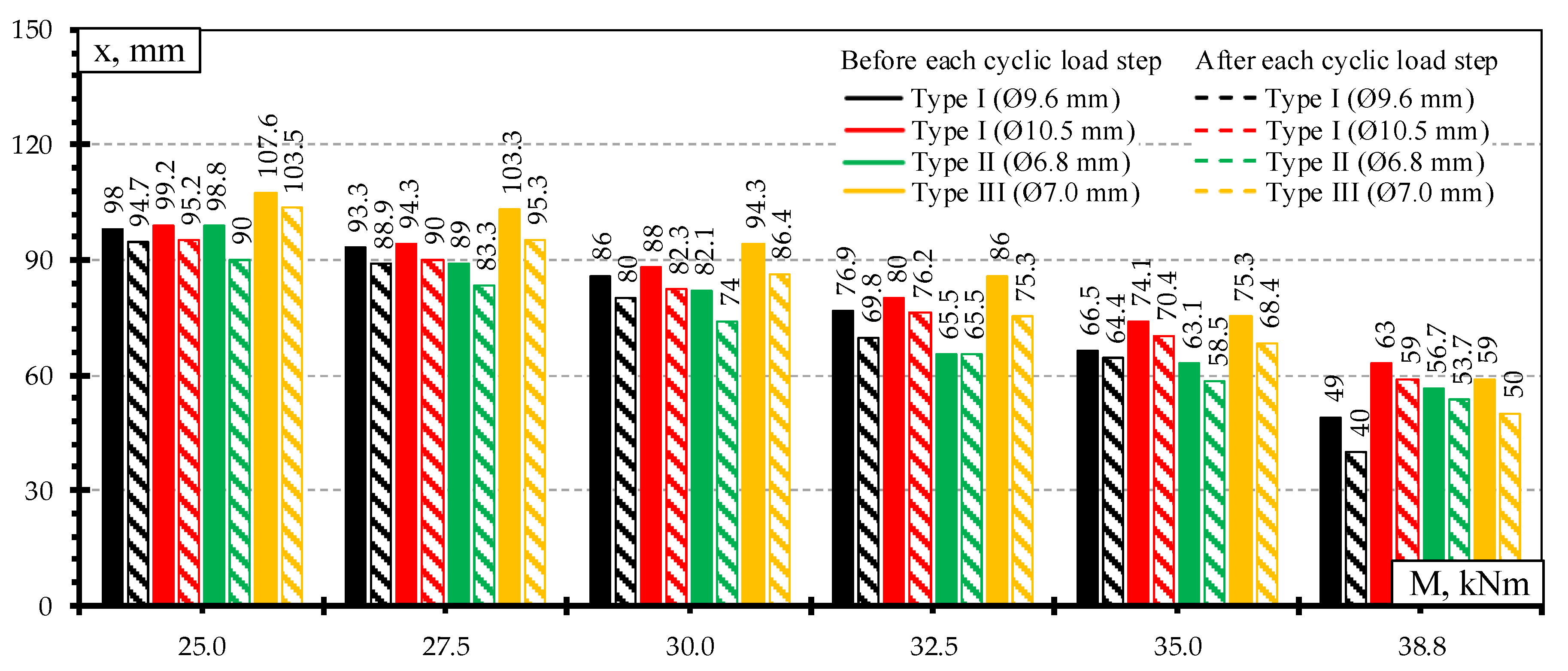

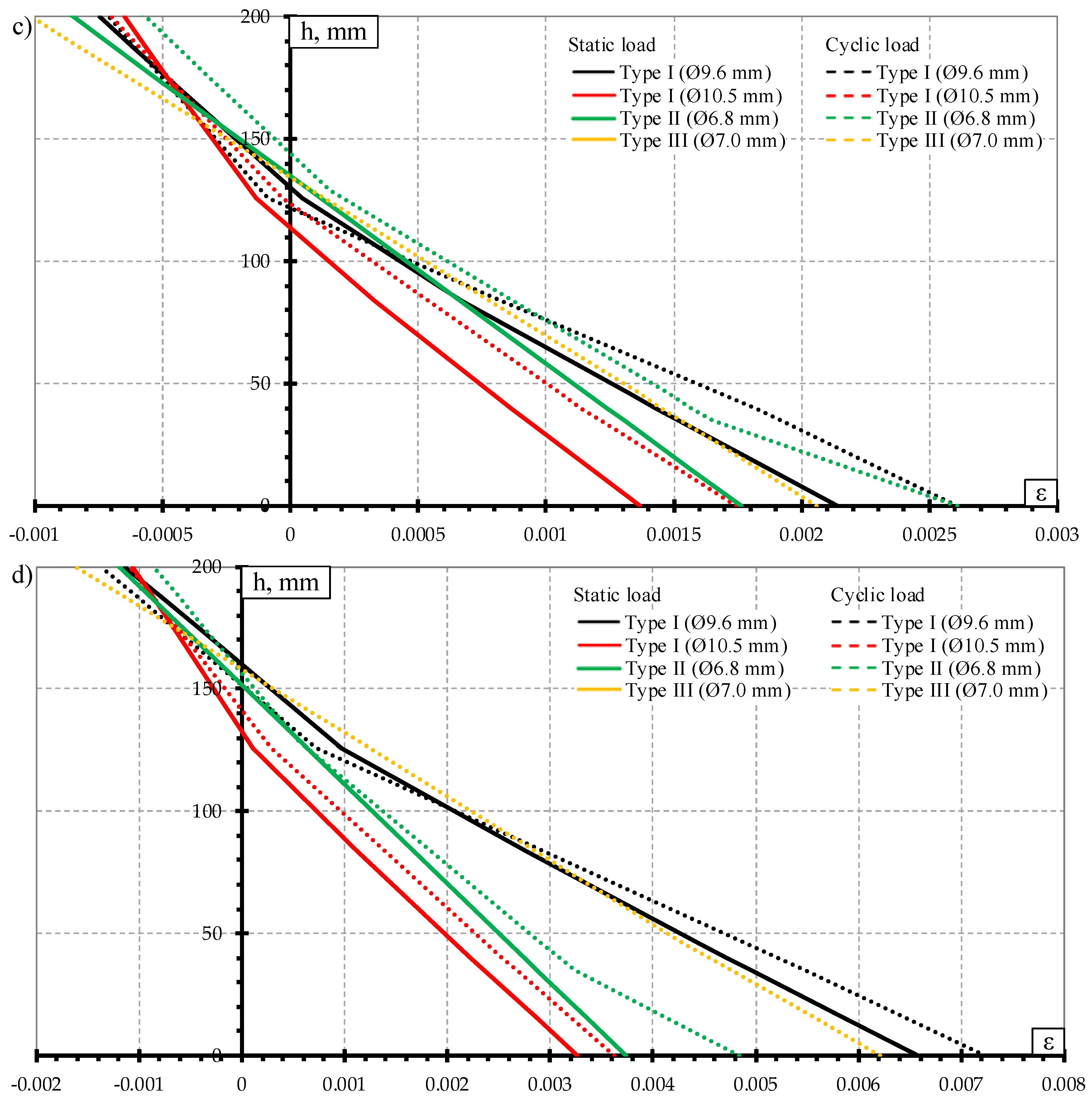

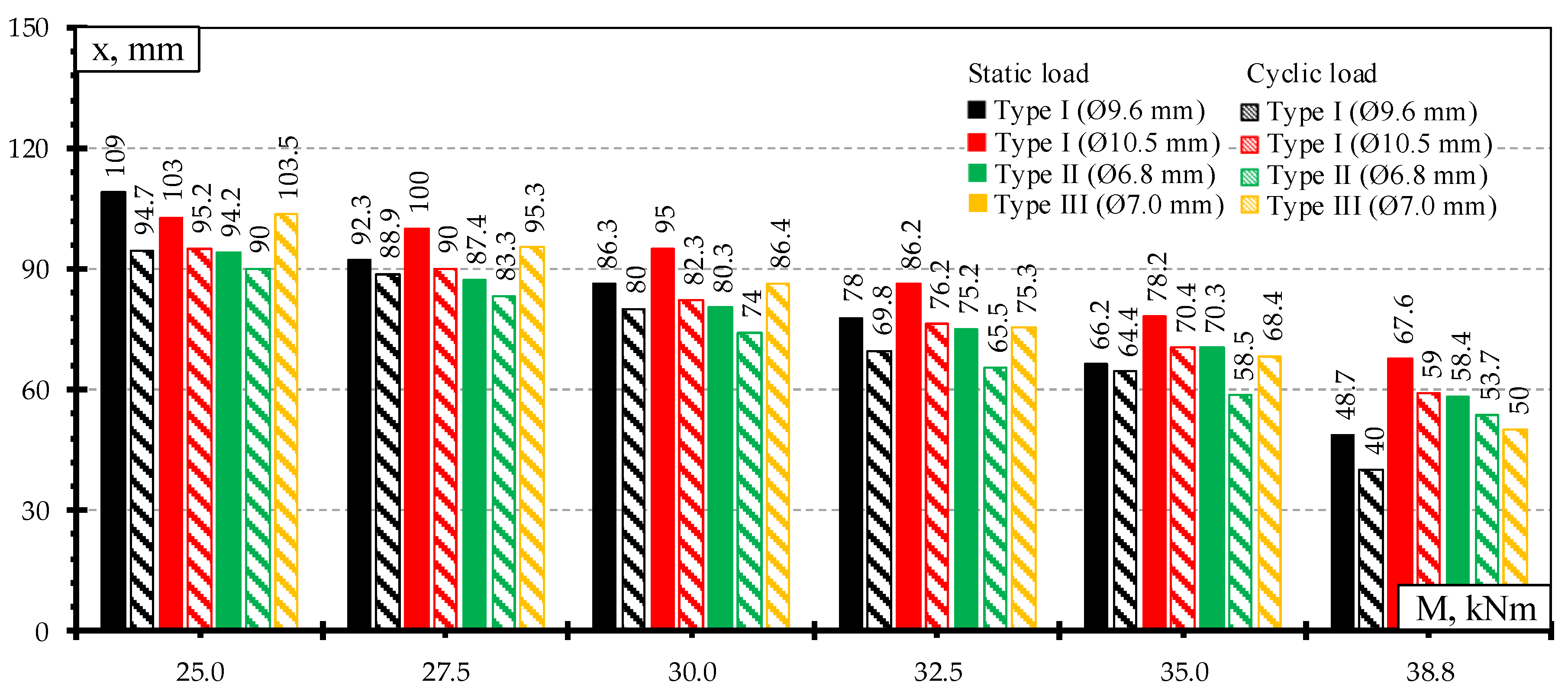

After analyzing the experimental results, it was found that slippage of reinforcing bars occurred at the end of Type I sleepers reinforced with Ø9.6 mm and Ø10.5 mm indented bars during the test. This indicates that the diameter of reinforcement (reinforcement) was selected incorrectly and anchorage length of prestressed bars was insufficient. Conversely, in Type II sleepers reinforced with three-wire strands, the bond between reinforcement and concrete was adequate and strands did not slip during the test. Additionally, the anchorage and consequently bond of plain bars were ensured by additional anchor plates at the ends of Type III sleepers.

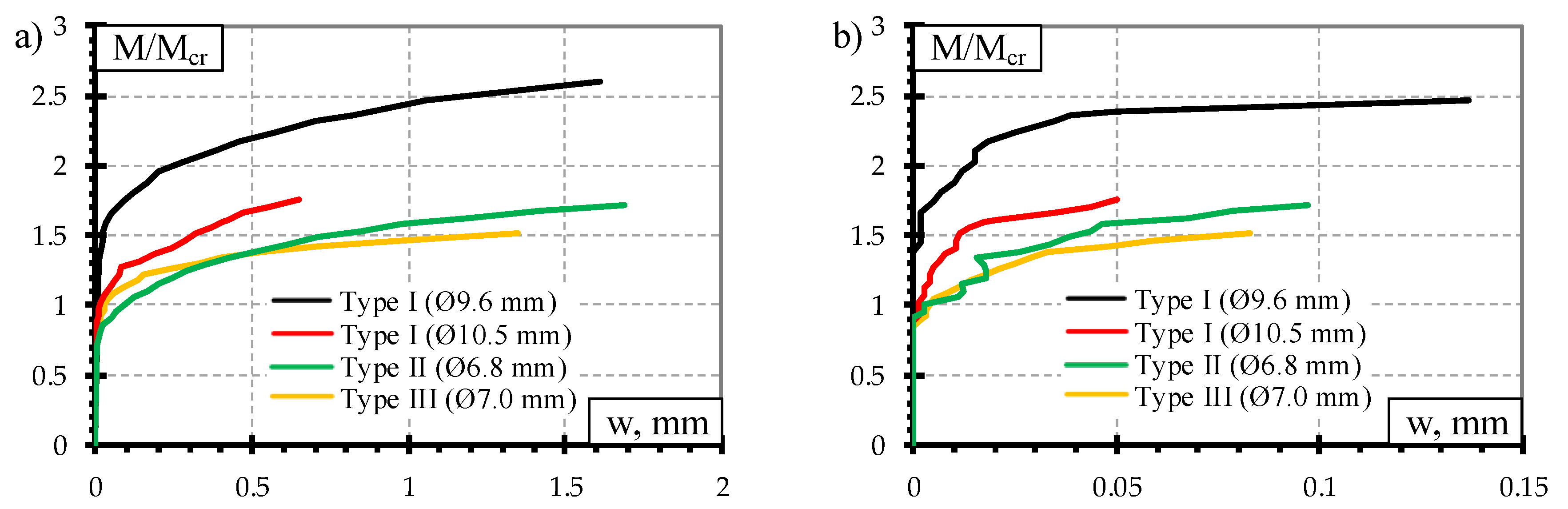

The research results showed that experimental cracking and failure moments of Type I sleepers were lower than design moments. This means that the structural solution of these type of sleepers was not suitable, because their behavior did not correspond to design evaluation of sleepers. The research has shown that failure occurred due to insufficient anchorage of reinforcement in concrete. In the case of Type II and Type III sleepers, the experimental values of cracking and failure moments were higher than the design ones, because anchorage of reinforcement in concrete was sufficient.

The research showed that reinforcement and rail seat section of Type III sleepers are chosen irrationally. During static and dynamic load tests, the sleepers failed in the concrete compression zone. This indicates that sleeper reinforcement does not match the selected cross-section of sleeper.

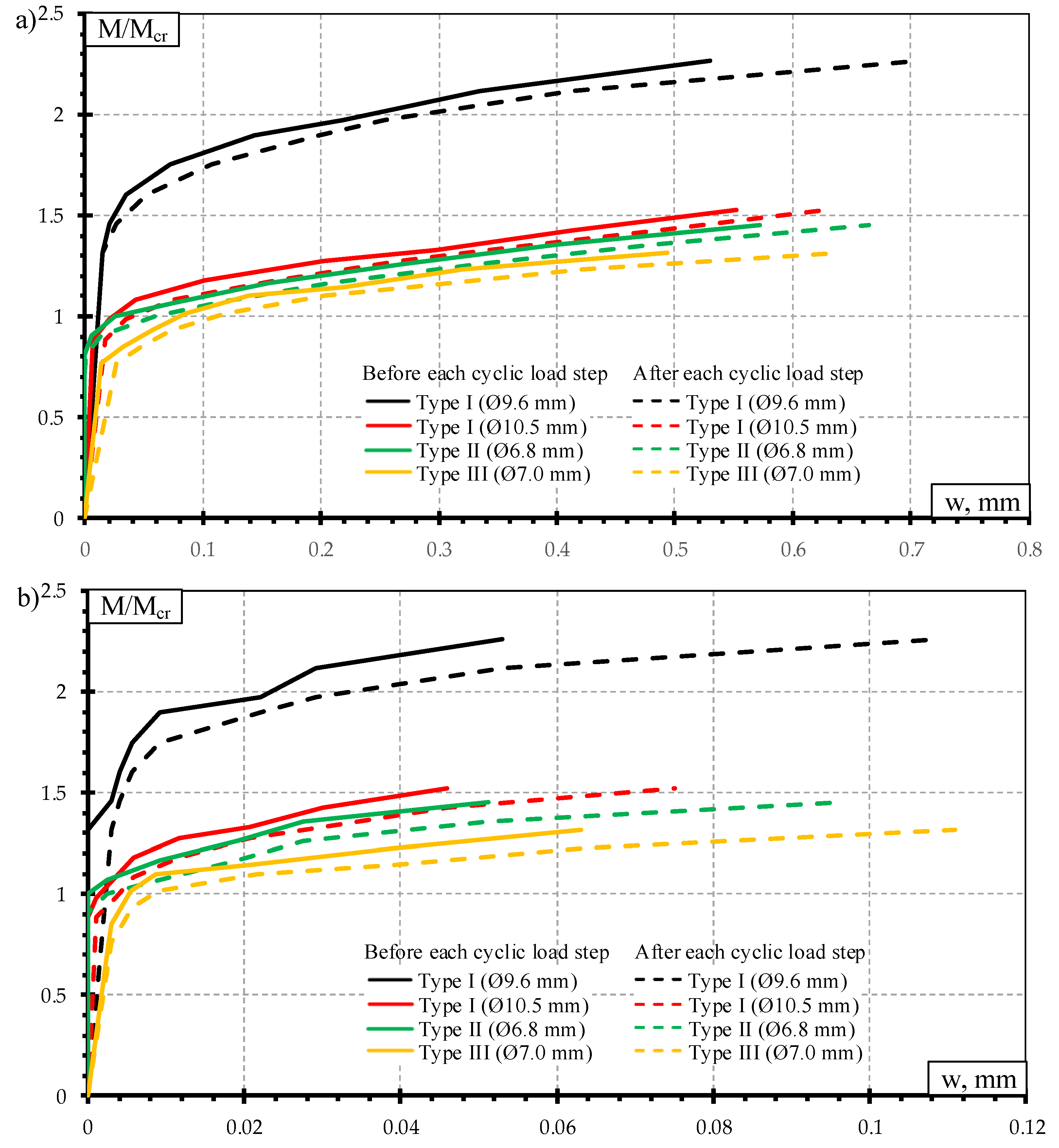

The use of higher diameter (Ø10.5 mm) prestressed bars improved the Type I sleeper’s resistance to cracking at rail seat section. Therefore, propagation of residual crack width was slower compared to sleepers reinforced with lower diameter (Ø9.6 mm) prestressed bars. However, a higher reinforcement ratio negatively influenced anchorage zone of sleeper and sleepers failed due to slip of reinforcement accompanied by longitudinal splitting of concrete. Therefore, confining reinforcement or anchors could be introduced at the ends of the sleeper to minimize the concrete splitting effect.

The distribution of crack width between each type of sleepers was more even under the influence of dynamic load compared to static load. Therefore, in contrast to static load test, crack widths of Type I sleepers reinforced with Ø10.5 mm bars were similar to crack widths of other types of sleepers under the influence of dynamic load. It means that Type I sleepers reinforced with Ø10.5 mm bars are more susceptible to dynamic load effect. Therefore, dynamic load reduces stiffness of this type of sleepers faster than for other types of sleepers.

It was found that the bearing capacity of Type I sleepers reinforced with Ø9.6 mm and Ø10.5 mm indented bars, Type II and Type III sleepers after the influence of dynamic load decreased by 15%, 9%, 10%, and 21% respectively compared with static test results. The greater degradation of prestressed concrete sleepers under the influence of dynamic load is related to higher deformation of reinforcement in the crack plane and greater damage on bond between reinforcement and concrete near the crack plane. Additionally, the character of failure of each type (Type I, Type II, and Type III) of the sleeper was the same after static and dynamic load tests.