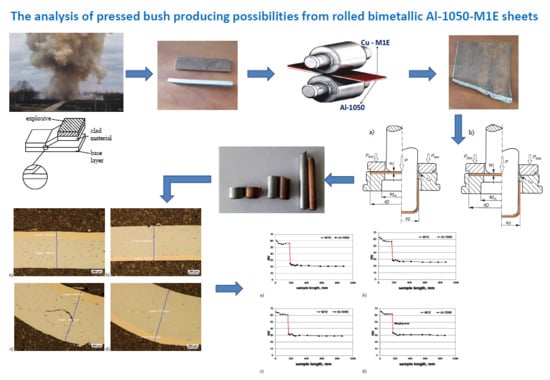

The Analysis of Pressed Cups Producing Possibilities from Rolled Bimetallic Al-1050 + Cu-M1E Sheets

Abstract

1. Introduction

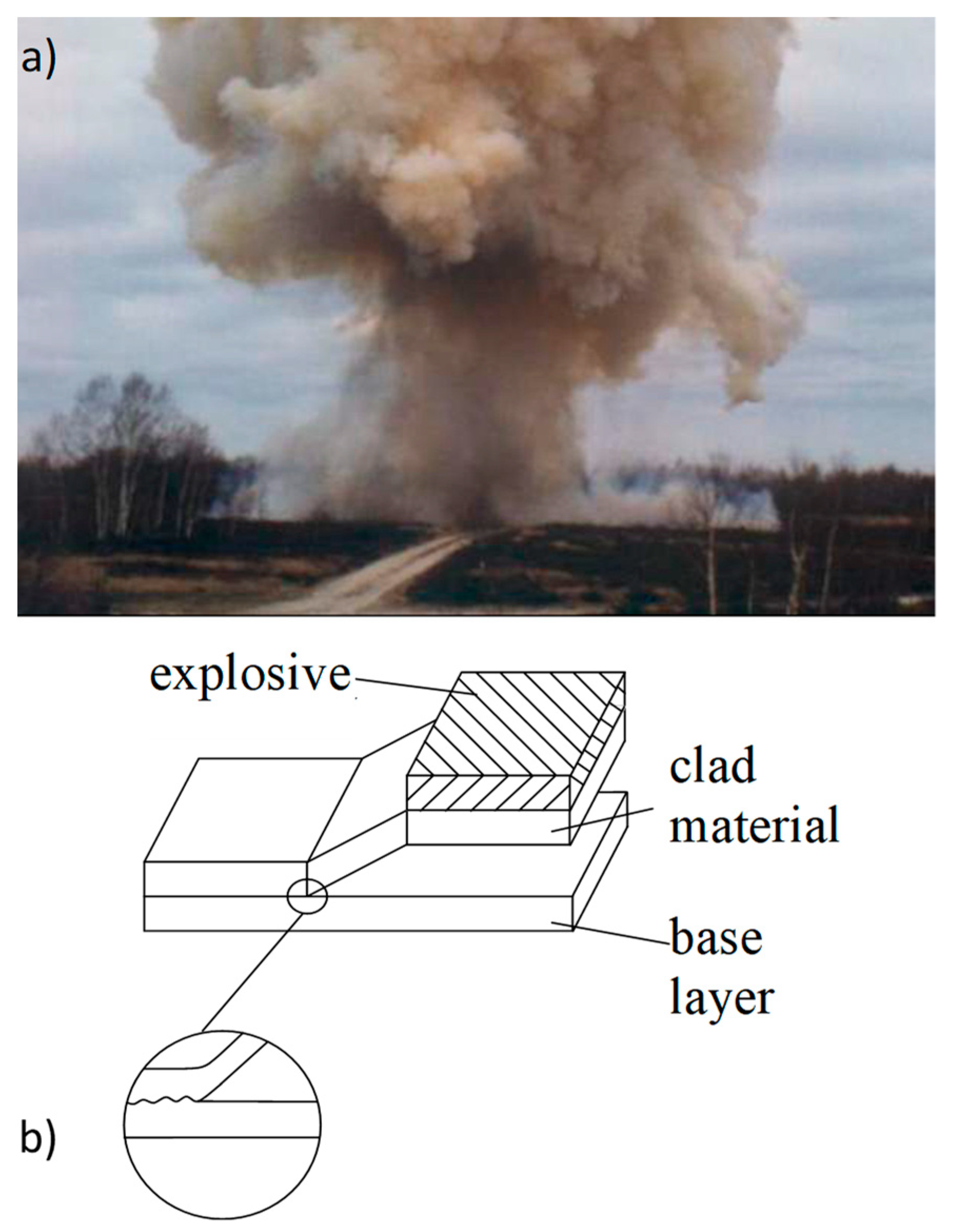

2. Material Selection and Scope of the Research

- HM0 and HM—the height before and after deformation of soft layer;

- HT0 and HT—the height of the hard layer;

- V0 M and V0 T—the velocity of soft and hard layer.

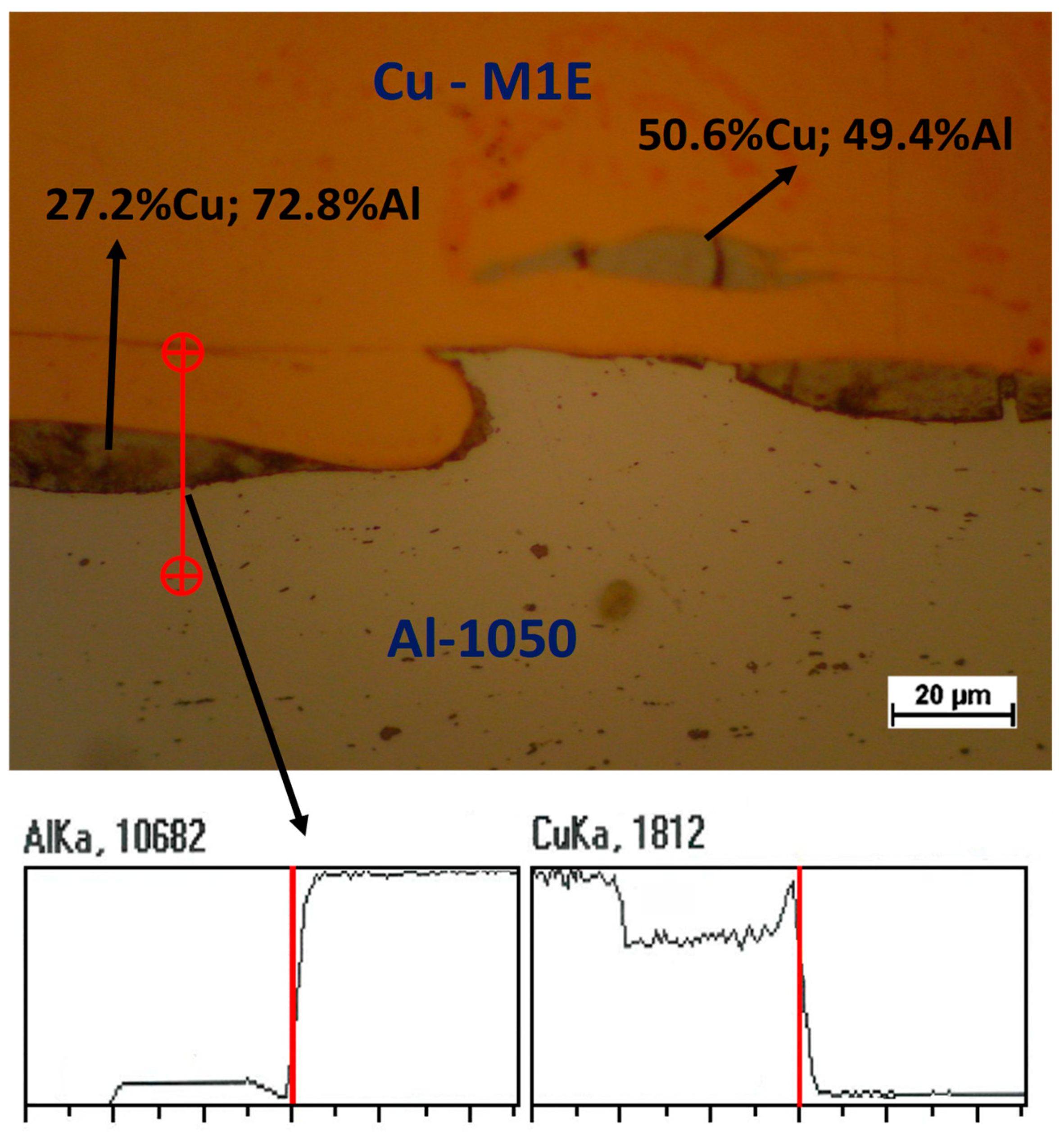

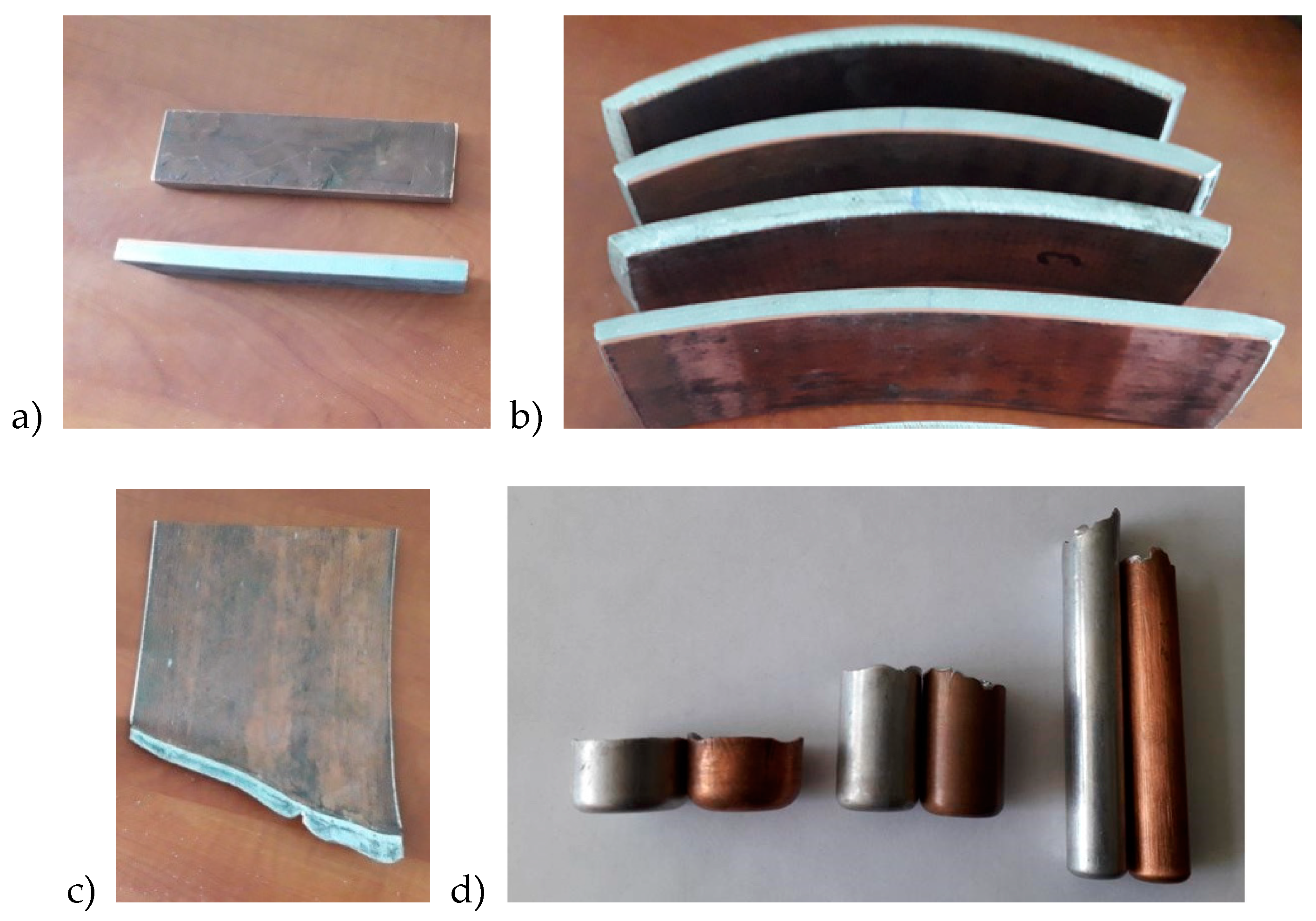

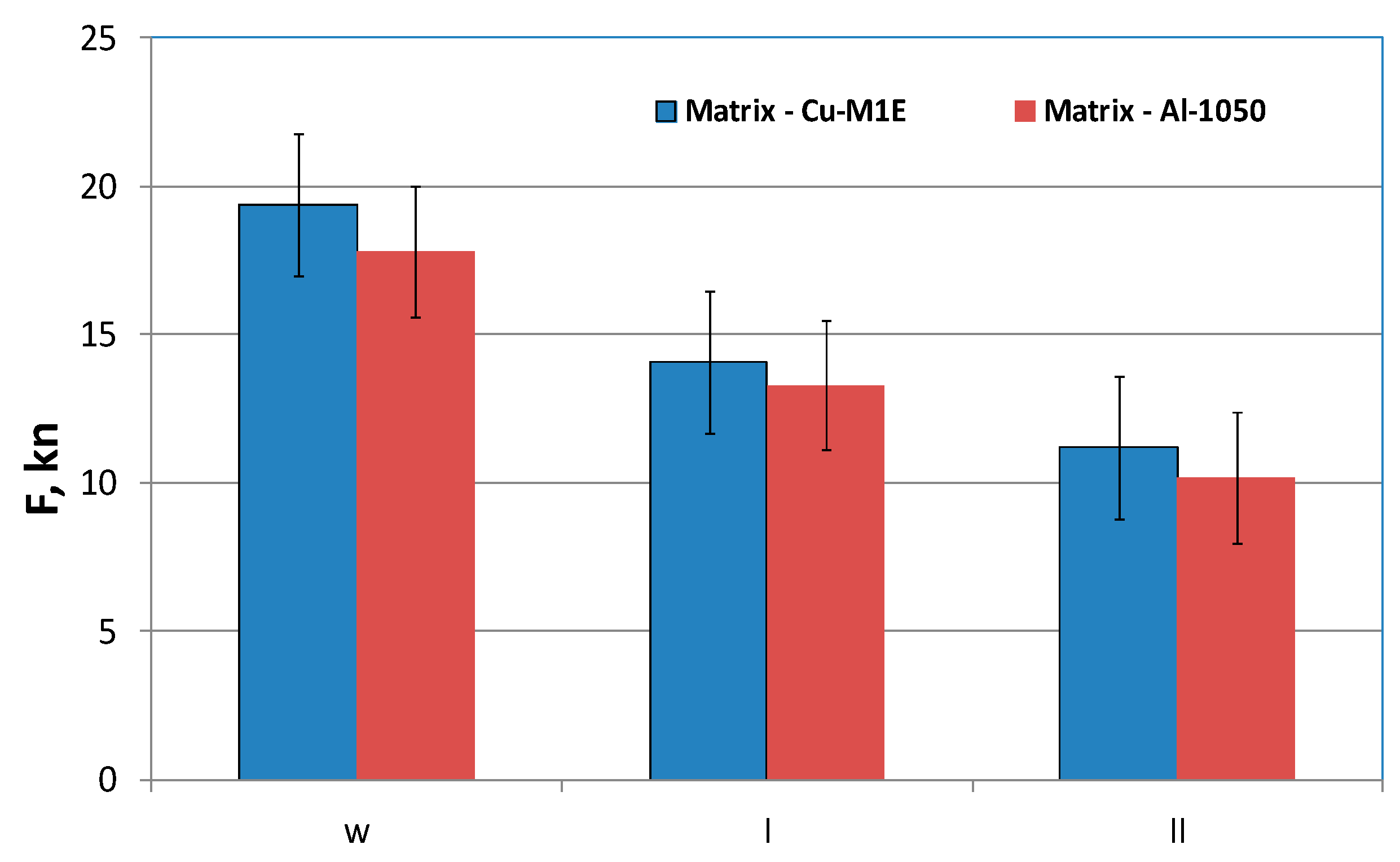

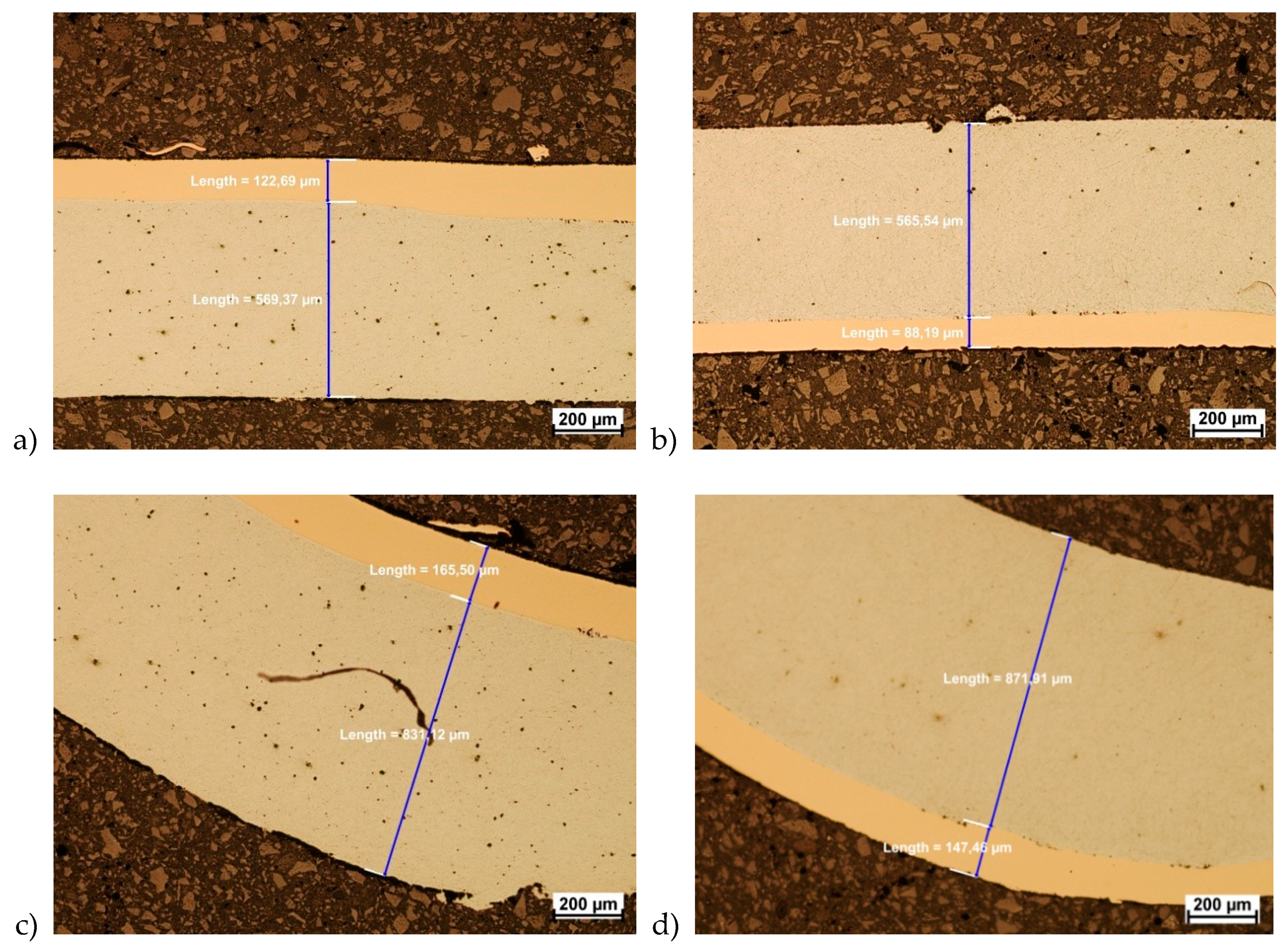

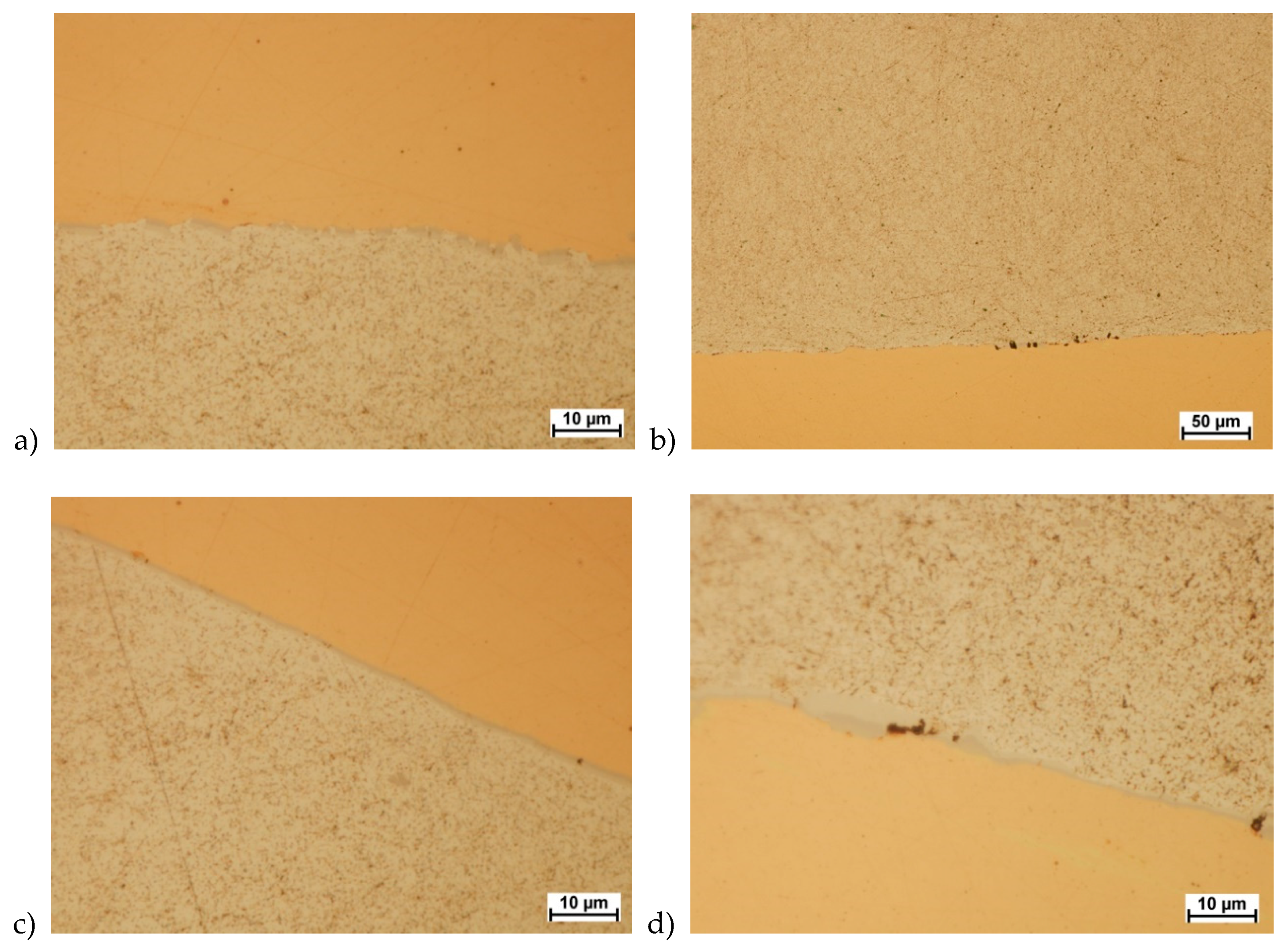

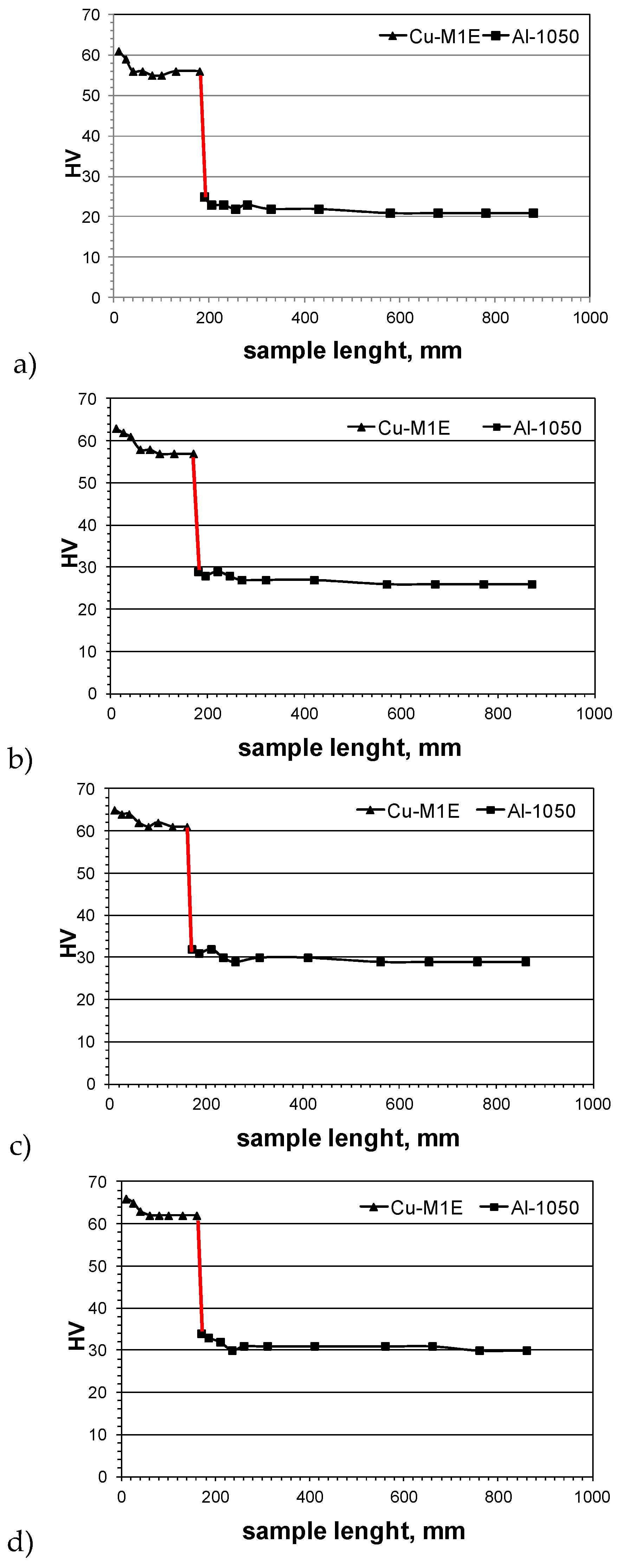

3. Research Results and Their Analysis

4. Summary

Author Contributions

Funding

Conflicts of Interest

References

- Erbel, S.; Kuczyński, K.; Marciniak, Z. Techniki Wytwarzania. Obróbka Plastyczna; Polish Scientific Publishers PWN: Warszawa, Poland, 1981. [Google Scholar]

- Available online: https://www.ergom.com/pl/cms/produkty/koncowki-kablowe-tulejkowe-miedziano-aluminiowe-hma.html (accessed on 4 April 2020).

- Pater, Z.; Samołyk, G. Podstawy Technologii Obróbki Plastycznej Metali; Publishing House of the Lublin University of Technology: Lublin, Poland, 2013. [Google Scholar]

- Dyl, T.; Starosta, R. Determining the effect of the geometry and type of inserts on the geometric structure of turned composite coatings. Inżynieria Materiałowa 2012, 6, 701–704. [Google Scholar]

- Miłek, T. Ocena Tłoczności Blach Metodami Engelhardta i Erichsena; Scientific Notebooks of the Rzeszow University of Technology 298: Mechanics 90; Rzeszow University of Technology: Rzeszów, Poland, 2018; pp. 195–204. [Google Scholar]

- Kocańda, A.; Jasiński, C. Extended evaluation of Erichsen cupping test results by means of laser speckle. Arch. Civ. Mech. Eng. 2016, 16, 211–216. [Google Scholar] [CrossRef]

- Tamimi, S.; Sivaswamy, G.; Violatos, I.; Moturu, S.; Rahimi, S.; Blackwell, P. Modelling and experimentation of the evolution of texture In an Al-Mg alloy during earing cupping test. Procedia Eng. 2017, 207, 1–6. [Google Scholar] [CrossRef]

- Hattalli, V.L.; Srivatsa, S.R. Sheet metal forming processes—Recent technological advances. Mater. Today 2018, 5, 2564–2574. [Google Scholar] [CrossRef]

- Rydz, D.; Kubik, K. Analiza procesu wytwarzania bimetalowych blach cienkich. Rudy i Metale Nieżelazne Recykling 2018, 11, 26–29. [Google Scholar] [CrossRef]

- Rydz, D.; Torbus, N.; Korn, K. Research of Area Connections of Al-Cu Bimetallic Plate. In Proceedings of the XIV International Scientific Conference. New Technologies and Achievements in Metallurgy, Materials Engineering and Production Engineering; Anna Kawałek, C., Ed.; Publishing House of the Faculty of Process, Materials Engineering and Applied Physics of the Czestochowa University of Technology: Czestochowa, Poland, 2013; pp. 260–263. [Google Scholar]

- Yoshida, F.; Hino, R. Forming limit of stainless steel-clad aluminium sheets under plane stress condition. J. Mater. Process. Technol. 1997, 63, 66–71. [Google Scholar] [CrossRef]

- Lee, D.N.; Kim, Y.K. Tensile properties of stainless steel-clad aluminum sandwich sheet metals. J. Mater. Sci. 1988, 23, 1436–1442. [Google Scholar] [CrossRef]

- Lee, D.N.; Kim, Y.K. On the rule of mixtures for flow stresses in stainless-steel-clad aluminum sandwich sheet metals. J. Mater. Sci. 1988, 23, 558–564. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Piehler, H.R. Deformation of sandwich sheet materials in uniaxial tension. Metall. Trans. A Phys. Metall. Mater. Sci. 1979, 10, 85–96. [Google Scholar] [CrossRef]

- Choi, S.-H.; Kim, K.-H.; Oh, K.H.; Lee, D.N. Tensile deformation behavior of stainless steel clad aluminum bilayer sheet. Mater. Sci. Eng. A 1997, 222, 158–165. [Google Scholar] [CrossRef]

- Lamik, A.; Leitner, H.; Eichlseder, W.; Riemelmoser, F. A study of the fatigue behaviour of an aluminum clad steel material compound. Strain 2008, 44, 440–445. [Google Scholar] [CrossRef]

- Dyja, H.; Mróz, S.; Rydz, D. Technologia i Modelowanie Procesów Walcowania Wyrobów Bimetalowych; Publishing House of the Faculty of Process, Materials Engineering and Applied Physics of the Czestochowa University of Technology: Czestochowa, Poland, 2003. [Google Scholar]

- Dyja, H.; Mróz, S.; Stradomski, G.; Lesik, L.; Maranda, A.; Nowaczewski, J. Wytwarzanie bimetalowych prętów miedź-stop Al metodą wybuchową. Inżynieria Mater. 2002, 23, 21–25. [Google Scholar]

- Tavoosi, M. The Kirkendall void formation in Al/Ti interface during solid-state reactive diusion between Al and Ti. Surf. Interfaces 2017, 9, 96–200. [Google Scholar]

- Luo, J.; Aco, V.L. Using cold roll bonding and annealing to process Ti/Al multi-layered composites from elemental foils. Mater. Sci. Eng. A 2004, 379, 164–172. [Google Scholar] [CrossRef]

- Assari, A.H.; Eghbali, B. Solid state diffusion bonding characteristics at the interfaces of Ti and Al layers. J. Alloys Compd. 2019, 773, 50–58. [Google Scholar] [CrossRef]

- Sun, Y.; Wan, Z.; Hu, L.; Wu, B.; Deng, T. Characterization on Solid Phase Diffusion Reaction Behavior and Diffusion Reaction Kinetic of Ti/Al. Rare Metal Mater. Eng. 2017, 46, 2080–2086. [Google Scholar]

- Wypart, J.; Rydz, D.; Stradomski, G.; Dyja, H. Analysis of bimetallic plate rolling after explosive welding joining. In XII International Symposium on Explosive Production of New Materials: Science, Technology, and Innovations; Deribas, A.A., Scheck, B.Y., Eds.; Publishing House of the UST: Cracow, Poland, 2014; pp. 1571–1573. [Google Scholar]

- Mróz, S.; Stradomski, G.; Dyja, H.; Galka, A. Using the explosive cladding method for production of Mg-Al bimetallic bars. Arch. Civ. Mech. Eng. 2015, 15, 317–323. [Google Scholar] [CrossRef]

- Mróz, S.; Szota, P.; Stefanik, A. The theoretical and experimental analysis of the possibility of employing the groove rolling process for the manufacture of Mg/Al bimetallic bars. Metalurgija 2016, 55, 628–630. [Google Scholar]

- Ren, L.; Wang, T.; Chen, Z.; Li, Y.; Qian, L. Self-Lubricating PEO–PTFE Composite Coating on Titanium. Metals 2019, 9, 170. [Google Scholar] [CrossRef]

- Paul, H.; Faryna, M.; Prażmowski, M.; Bański, R. Changes In The Bonding Zone of Explosively Welded Sheets. Zmiany w warstwie połączenia płyt zgrzewanych wybuchowo. Arch. Metall. Mater. 2011, 56, 463–474. [Google Scholar] [CrossRef]

- Young, G. Explosion welding, technical growth and commercial history. In Stainless Steel World; KCI Publishing BV: Zutphen, The Netherlands, 2004; pp. 1–6. [Google Scholar]

- Saravanan, S.; Raghukandan, K. Thermal kinetics in explosive cladding of dissimilar metals. Sci. Technol. Weld. Join. 2012, 17, 99–103. [Google Scholar] [CrossRef]

- Akbari Mousavi, S.A.A.; Farhadi Satrangi, P. Experimental investigation of explosive welding of titanium/ AISI 304 stainless steel. Mater. Des. 2009, 30, 459–468. [Google Scholar] [CrossRef]

- Saravanan, S.; Raghukandan, K. Influence of Interlayer in Explosive Cladding of Dissimilar Metals. Mater. Manuf. Process. 2013, 28, 589–594. [Google Scholar] [CrossRef]

- Shapoval, A.A.; Mos’pan, D.V.; Dragobetskii, V.V. Ensuring High Performance Characteristics For Explosion-Welded Bimetals. Metallurgist 2016, 60, 313–317. [Google Scholar] [CrossRef]

- Dyja, H.; Pietrzyk, M. On the Theory of the Process of Bimetal Plate and Sheet Hot Rolling. J. Mech. Work. Technol. 1983, 8, 309–325. [Google Scholar] [CrossRef]

- Wijata, E.; Rydz, D. Analiza złączy bimetalowych blach zgrzewanych wybuchowo i poddanych procesowi walcowania. In Proceedings of the XI International Scientific Conference, New Technologies and Achievements in Metallurgy and Material Engineering, Czestochowa, Poland, 27–30 May 2010; pp. 381–384. [Google Scholar]

| Material | Cu | Al | Fe | Si | Zn | Ti | Mg | Mn |

|---|---|---|---|---|---|---|---|---|

| M1E | 99.9 | – | max 0.005 | max 0.002 | max 0.003 | max 0.002 | – | – |

| Al-1050 | max 0.05 | 99.5 | max 0.4 | max 0.25 | max 0.07 | max 0.05 | max 0.05 | max 0.05 |

| Pass No | Total Thickness, mm | Total Deformation % | Layer Thickness Cu, mm | Layer Thickness Al, mm | Layer Thickness Ratio gCu/gAl | Asymmetry Coefficient av |

|---|---|---|---|---|---|---|

| 0 | 12.00 | - | 2.00 | 10.00 | 0.20 | - |

| 1 | 10.10 | 15.83 | 1.81 | 8.29 | 0.22 | 0.92 |

| 2 | 8.50 | 29.70 | 1.61 | 6.89 | 0.23 | 0.91 |

| 3 | 6.90 | 42.50 | 1.33 | 5.57 | 0.24 | 0.89 |

| 4 | 5.05 | 57.92 | 0.98 | 4.07 | 0.24 | 0.80 |

| 5 | 3.80 | 68.33 | 0.72 | 3.08 | 0.24 | 0.78 |

| 6 | 2.70 | 77.50 | 0.53 | 2.17 | 0.24 | 0.80 |

| 7 | 2.00 | 83.33 | 0.40 | 1.60 | 0.25 | 0.79 |

| 8 | 1.30 | 89.17 | 0.26 | 1.04 | 0.25 | 0.73 |

| 9 | 1.00 | 91.67 | 0.20 | 0.80 | 0.25 | 0.80 |

| Variant | Place of Measurement | Variant Matrix–Al1050-M1E | Variant Matrix–M1E-Al1050 | ||

|---|---|---|---|---|---|

| Thickness Al1050, mm | Thickness Cu-M1E, mm | Thickness Al1050, mm | Thickness Cu-M1E, mm | ||

| Drawing | Top | 0.82 | 0.18 | 0.82 | 0.18 |

| Rounding | 0.81 | 0.19 | 0.81 | 0.19 | |

| Bottom | 0.82 | 0.18 | 0.82 | 0.18 | |

| Pressing I | Top | 0.64 | 0.16 | 0.65 | 0.15 |

| Rounding | 0.81 | 0.18 | 0.81 | 0.17 | |

| Bottom | 0.82 | 0.18 | 0.81 | 0.19 | |

| Pressing II | Top | 0.40 | 0.10 | 0.40 | 0.10 |

| Rounding | 0.81 | 0.18 | 0.8 | 0.17 | |

| Bottom | 0.78 | 0.19 | 0.78 | 0.18 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rydz, D.; Stradomski, G.; Szarek, A.; Kubik, K.; Kordas, P. The Analysis of Pressed Cups Producing Possibilities from Rolled Bimetallic Al-1050 + Cu-M1E Sheets. Materials 2020, 13, 2413. https://doi.org/10.3390/ma13102413

Rydz D, Stradomski G, Szarek A, Kubik K, Kordas P. The Analysis of Pressed Cups Producing Possibilities from Rolled Bimetallic Al-1050 + Cu-M1E Sheets. Materials. 2020; 13(10):2413. https://doi.org/10.3390/ma13102413

Chicago/Turabian StyleRydz, Dariusz, Grzegorz Stradomski, Arkadiusz Szarek, Katarzyna Kubik, and Piotr Kordas. 2020. "The Analysis of Pressed Cups Producing Possibilities from Rolled Bimetallic Al-1050 + Cu-M1E Sheets" Materials 13, no. 10: 2413. https://doi.org/10.3390/ma13102413

APA StyleRydz, D., Stradomski, G., Szarek, A., Kubik, K., & Kordas, P. (2020). The Analysis of Pressed Cups Producing Possibilities from Rolled Bimetallic Al-1050 + Cu-M1E Sheets. Materials, 13(10), 2413. https://doi.org/10.3390/ma13102413