Mechanical and Non-Destructive Testing of Plasterboards Subjected to a Hydration Process

Abstract

1. Introduction

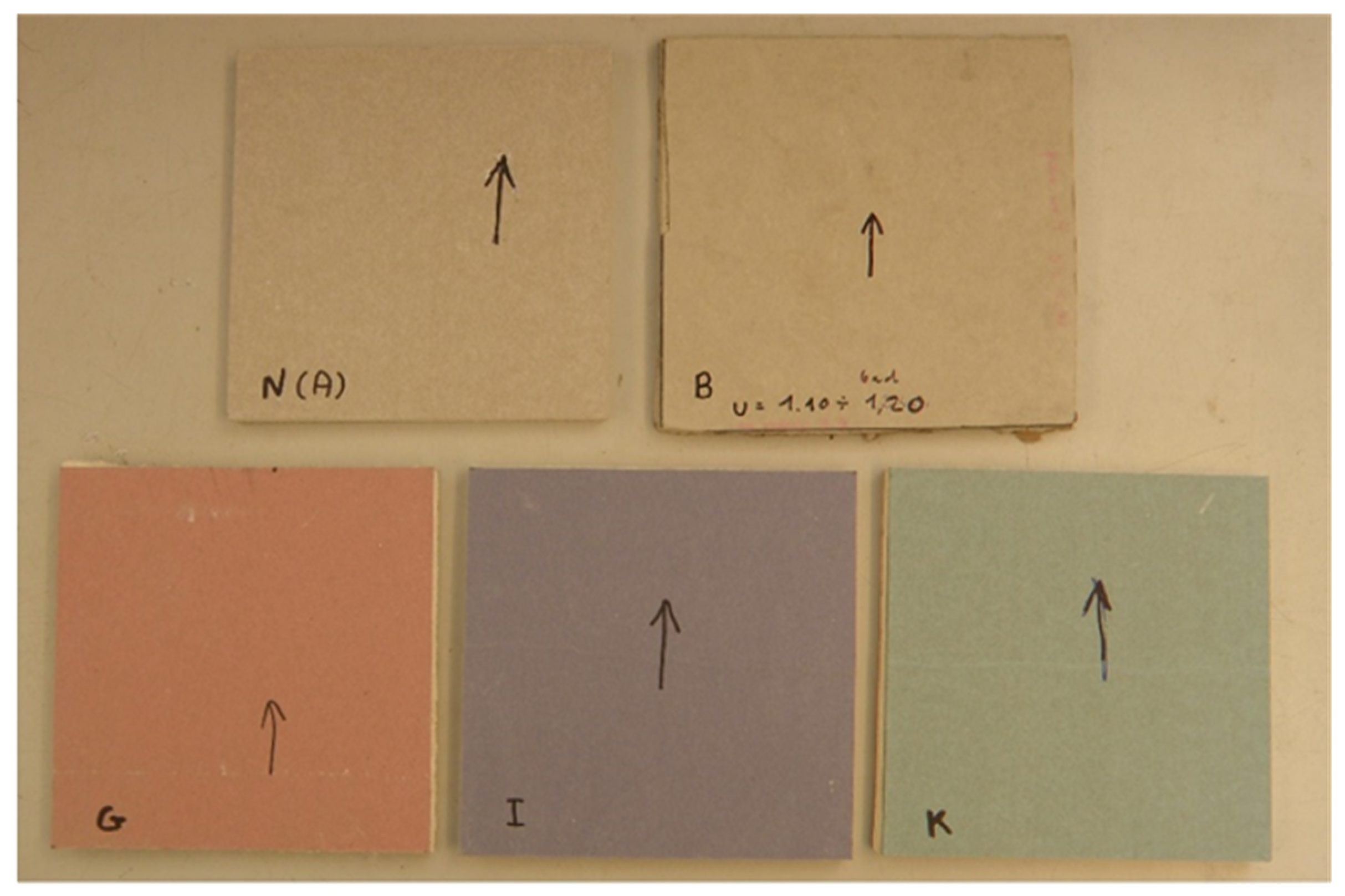

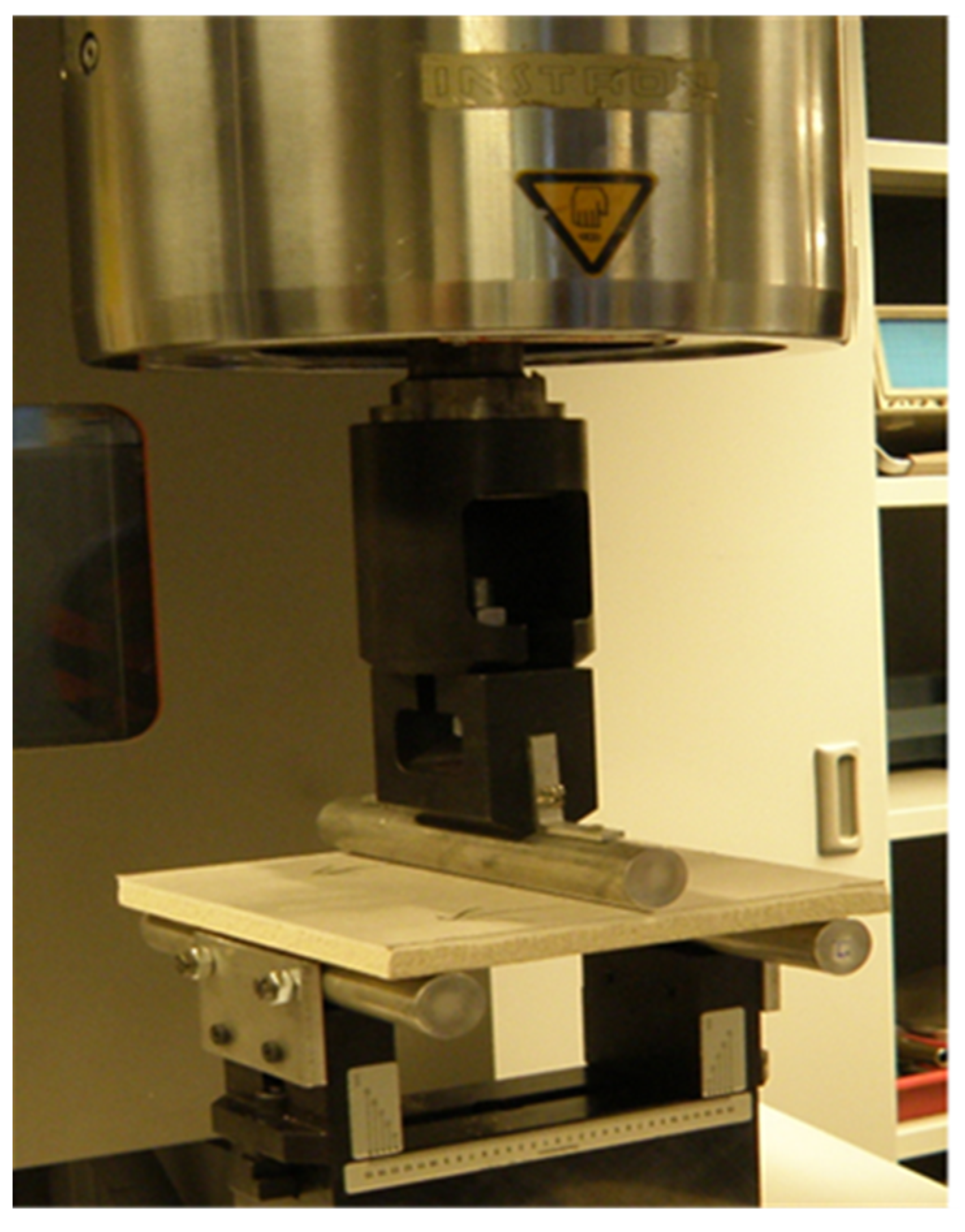

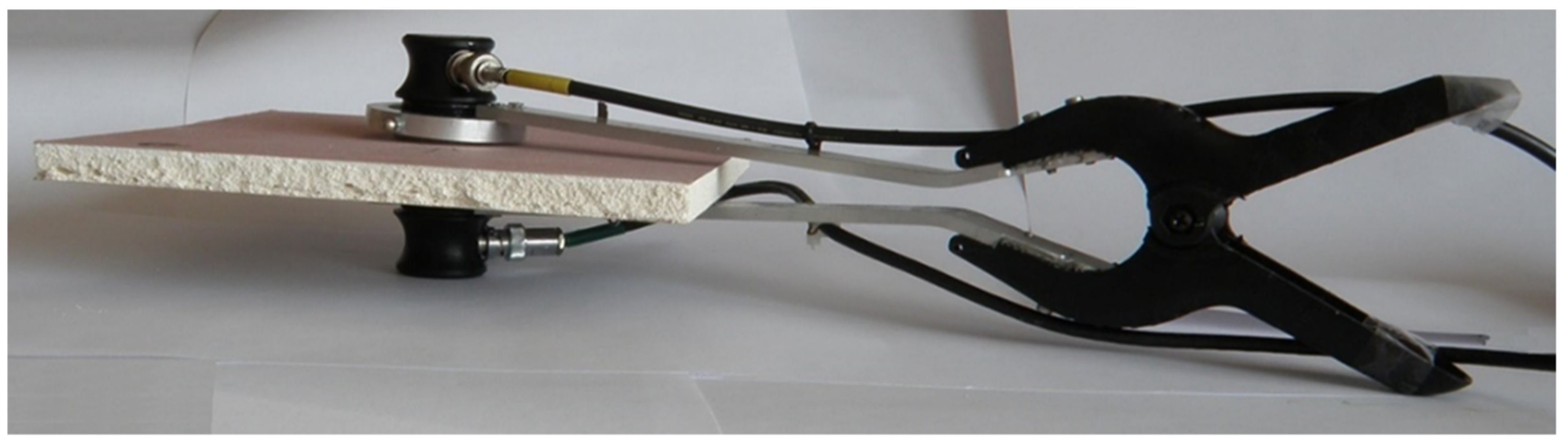

2. Materials and Methods

- A—Standard board for indoor installations;

- B—Low-quality, standard-type board rejected after quality control by the producer;

- G—Fire-resistant type;

- I—Acoustic-insulating type;

- K—Humidity-resistant type.

3. Results and Discussion

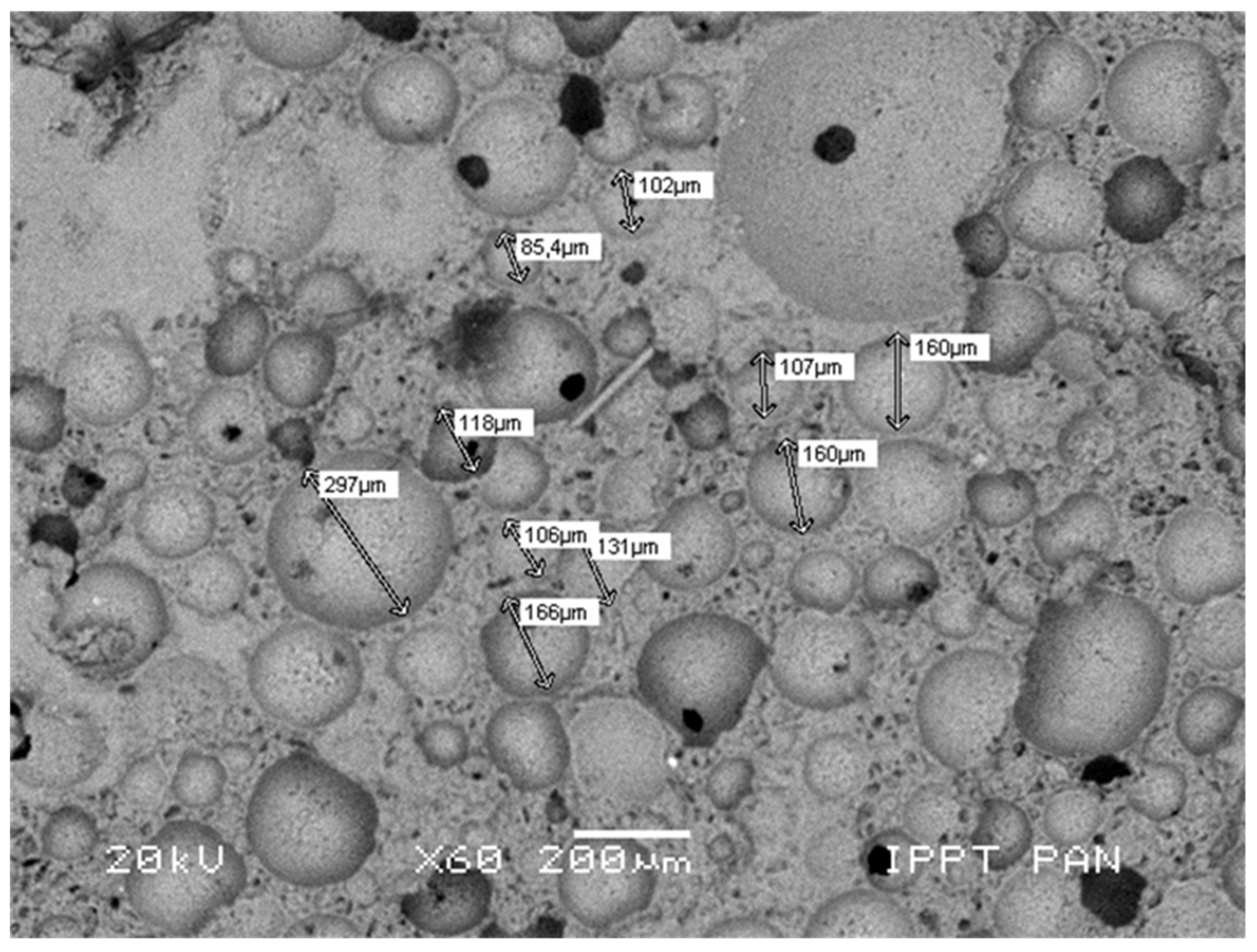

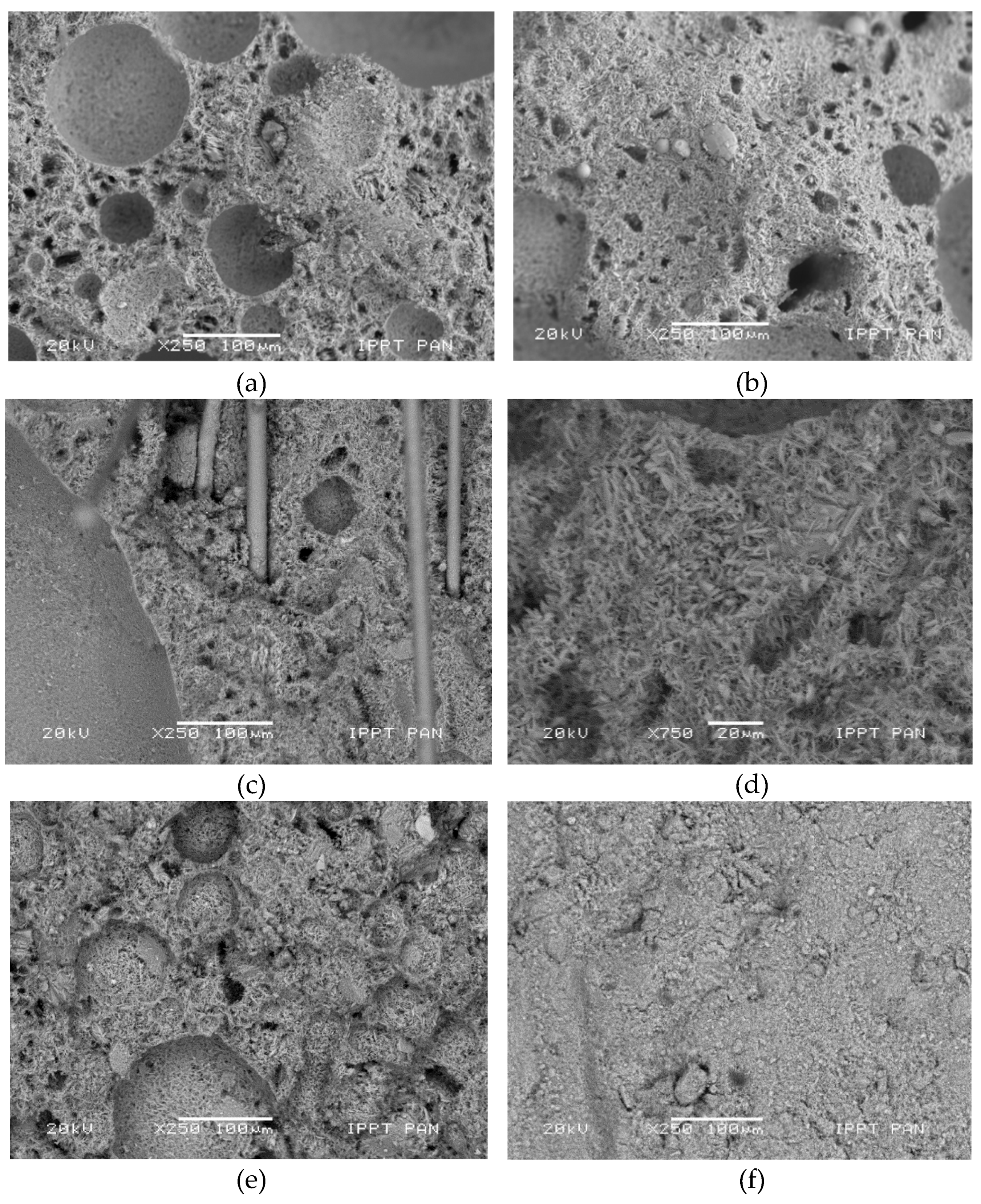

3.1. Microstructural Characterization of Plasterboards in the As-received Condition

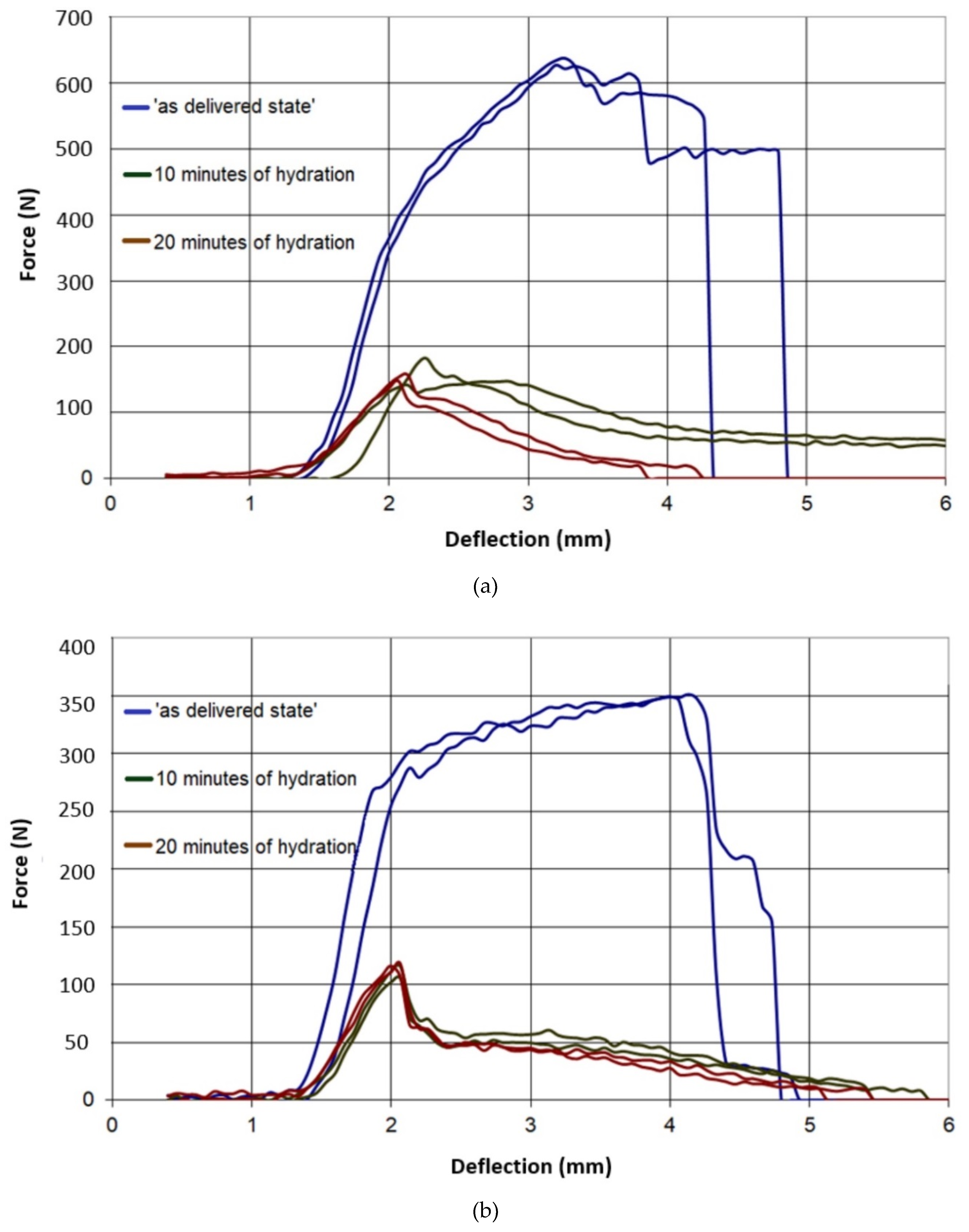

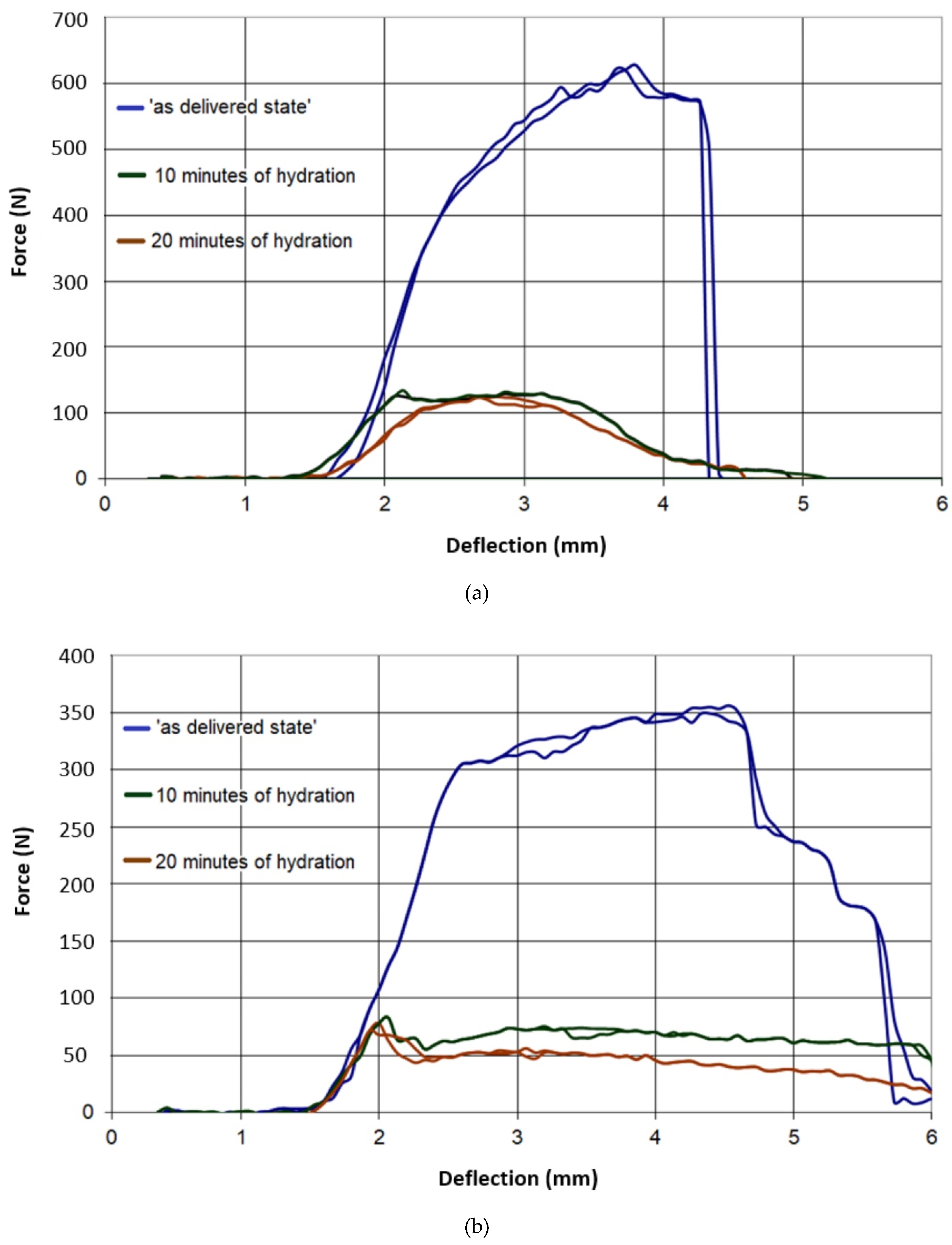

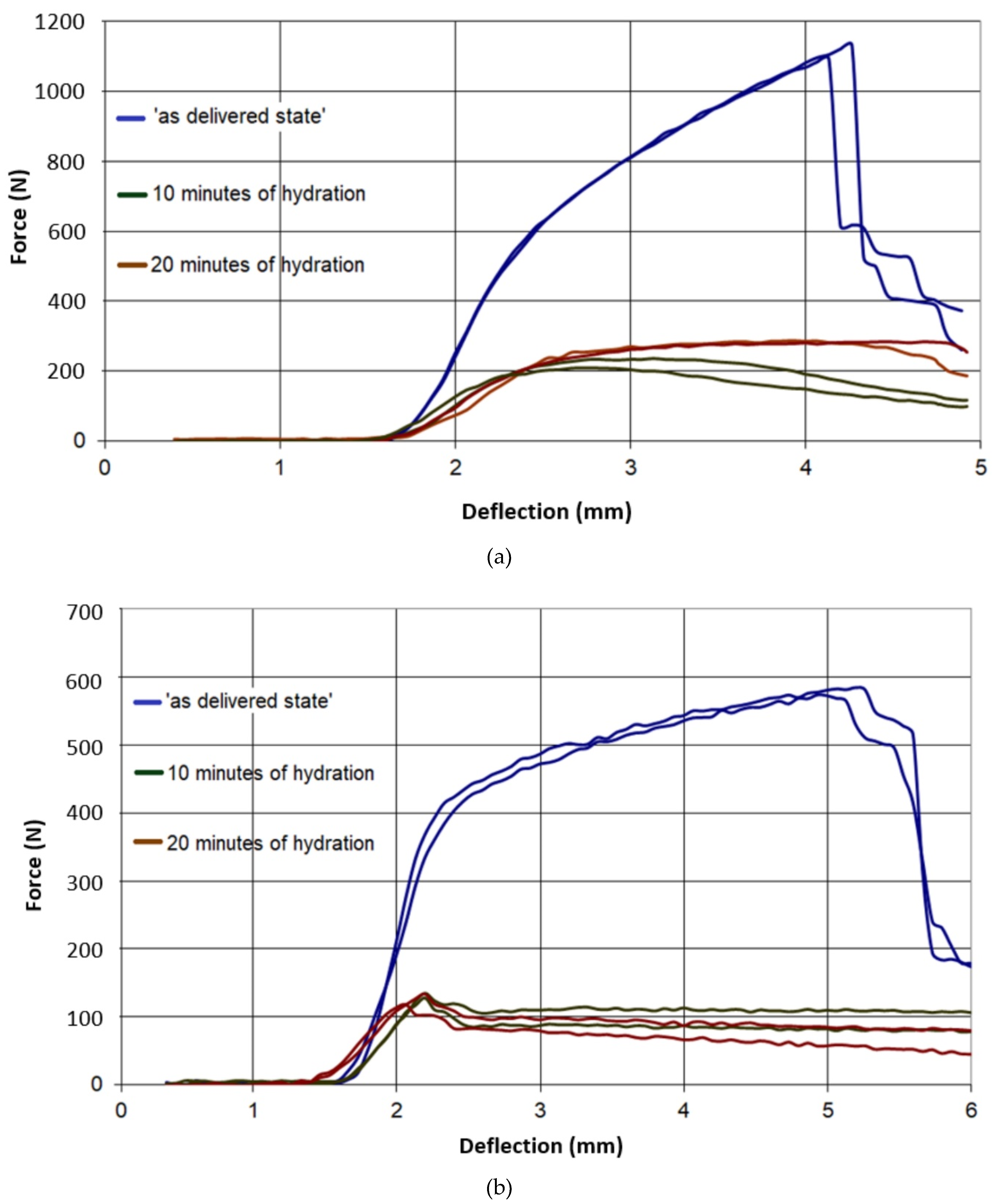

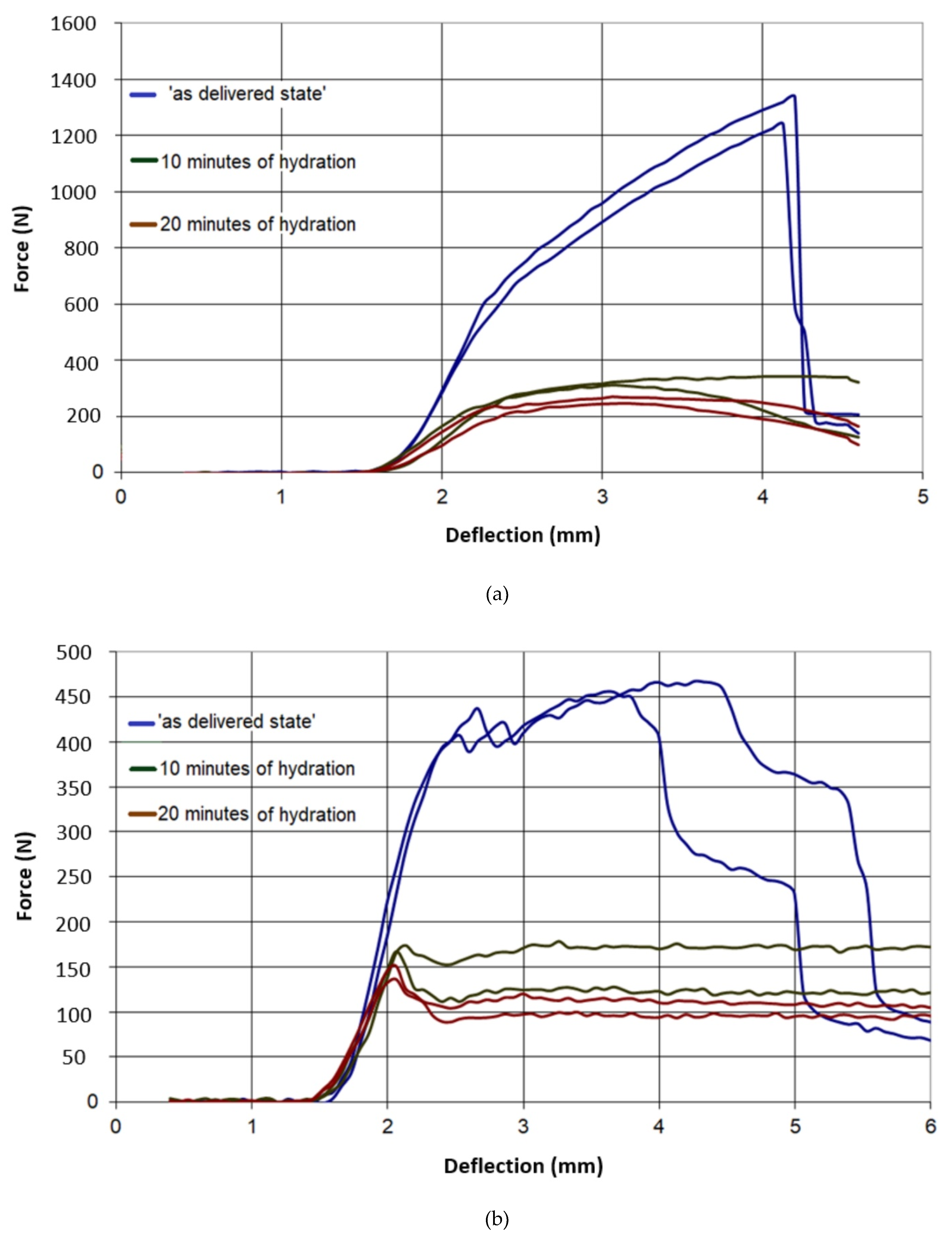

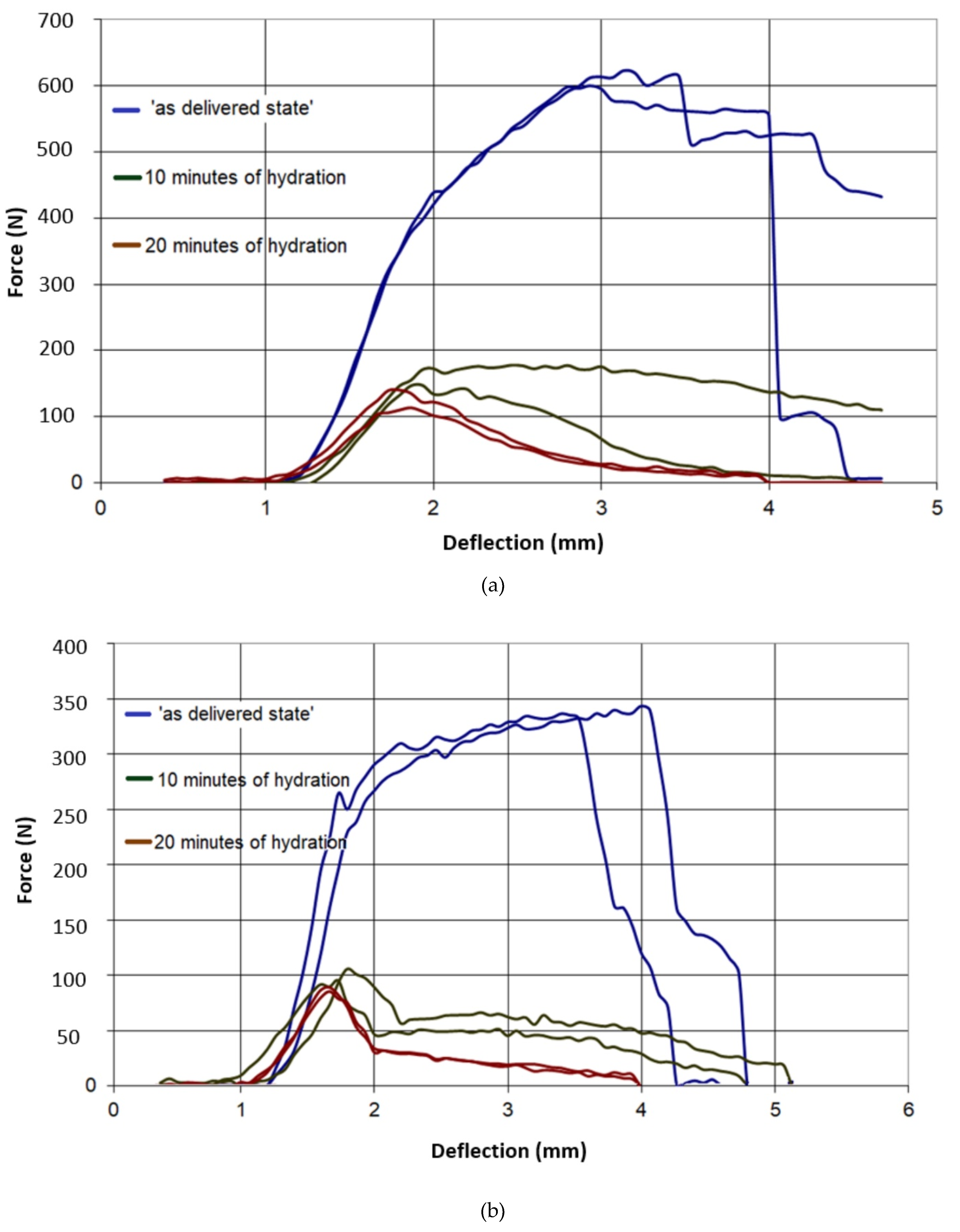

3.2. The Effect of Hydration on the Mechanical Properties of Plasterboards

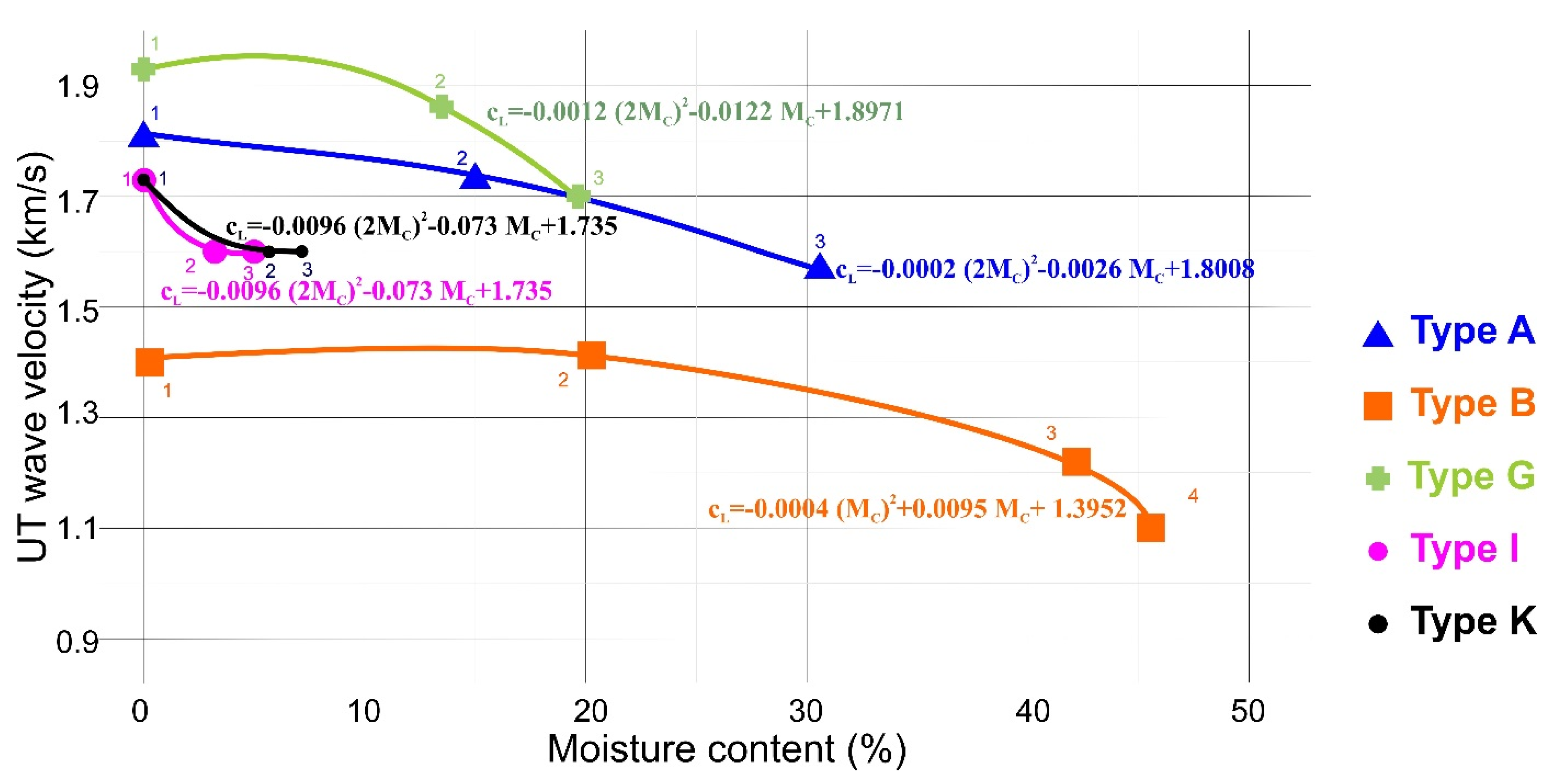

3.3. Assessment of Ultrasonic Wave Velocity cL Loss after Hydration Tests—Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Calcium Sulphate Consortium. Available online: http://www.eurogypsum.org/the-gypsum-industry/use-of-gypsum-in-buildings/ (accessed on 2 April 2020).

- Shirakawa, M.A.; Gaylarde, C.C.; Sahao, H.D.; Lima, J.R.B. Inhibition of Cladosporium growth on gypsum panels treated with nanosilver particles. Int. Biodeterior. Biodegrad. 2013, 85, 57–61. [Google Scholar] [CrossRef]

- Baux, C.; Melinge, Y.; Lanos, C.; Jauberthie, R. Enhanced gypsum panels for fire protection. J. Mater. Civ. Eng. 2008, 20, 71–77. [Google Scholar] [CrossRef]

- Kania, T.; Nowak, H. Gypsum partitions in medical rooms. MATEC Web Conf. 2018, 174. [Google Scholar] [CrossRef]

- Abuasi, H.A.; McCabe, J.F.; Carrick, T.E.; Wassel, R.W. Displacement rheometer: A method of measuring working time and setting time of elastic impression materials. J. Dent. 1993, 21, 360–366. [Google Scholar] [CrossRef]

- Winkler, M.M.; Monaghan, P.; Gilbert, J.L.; Lautenschlager, E.P. Comparison of four techniques for monitoring the setting kinetics of gypsum. J. Prosthet. Dent. 1998, 79, 532–536. [Google Scholar] [CrossRef]

- Van Driessche, A.E.S.; Stawski, T.M.; Benning, L.G.; Kellermeier, M. Calcium sulfate precipitation throughout its phase diagram. In New Perspectives on Mineral Nucleation and Growth; Van Driessche, A., Kellermeier, M., Benning, L., Gebauer, D., Eds.; Springer: Cham, Switzerland, 2017; Available online: https://www.springerprofessional.de/en/calcium-sulfate-precipitation-throughout-its-phase-diagram/11950112 (accessed on 12 May 2020).

- Clifton, J.R. Thermal analysis of calcium sulfate dihydrate and supposed and forms of calcium sulfate hemihydrate from 25 to 500 °C. J. Res. Natl. Bur. Stand. A Phys. Chem. 1972, 76A, 41–49. Available online: https://nvlpubs.nist.gov/nistpubs/Legacy/SP/nbsspecialpublication305supp4.pdf (accessed on 12 May 2020). [CrossRef]

- Gurgul, S.J.; Seng, G.; Wiliams, G.R. A kinetic and mechanistics study into the transformation of calcium sulfate hemihydrate to dehydrate. J. Synchrotron Radiat. 2019, 26, 774–784. [Google Scholar] [CrossRef]

- Isern, E.R.; Messing, G.L. Direct foaming and seeding of highly porous, lightweight gypsum. J. Mater. Res. 2016, 31, 2244–2251. [Google Scholar] [CrossRef]

- Gaiao, C.; de Brito, J.; Silvestre, J.D. Gypsum plasterboard walls: Inspection, pathological characterization and statistical survey using an expert system. Mater. Constr. 2012, 62, 285–297. [Google Scholar] [CrossRef]

- Gaiao, C.; de Brito, J.; Silvestre, J. Inspection and diagnosis of gypsum plasterboard walls. J. Perform. Constr. Facil. 2011, 25, 172–180. [Google Scholar] [CrossRef]

- Kaftanowicz, M.; Krzemiński, M. Multiple-criteria analysis of plasterboard systems. Procedia Eng. 2015, 111, 364–370. [Google Scholar] [CrossRef]

- Alagusankareswari, K.; Jenitha, G.; Sastha Arumuga Pandi, S. Experimental study on empty glass fibre reinforced gypsum panel. Indian J. Sci. Res. 2018, 17, 217–220. Available online: https://www.researchgate.net/profile/Jenitha_Ganapathy/publication/325711122_EXPERIMENTAL_STUDY_ON_EMPTY_GLASS_FIBRE_REINFORCED_GYPSUM_PANEL/links/5b1f77d3aca272277fa76954/EXPERIMENTAL-STUDY-ON-EMPTY-GLASS-FIBRE-REINFORCED-GYPSUM-PANEL.pdf (accessed on 12 May 2020).

- Wu, Y.-F. The structural behavior and design methodology for a new building system consisting of glass fiber reinforced gypsum panels. Constr. Build. Mater. 2009, 23, 2905–2913. [Google Scholar] [CrossRef]

- Erbs, A.; Nagalli, A.; Mymrine, V.; Carvalho, K.Q. Determination of physical and mechanical properties of recycled gypsum from the plasterboard sheets. Cerâmica 2015, 61, 360. [Google Scholar] [CrossRef]

- Petrone, C.; Magliulo, G.; Manfredi, G. Mechanical properties of plasterboards: Experimental tests and statistical analysis. J. Mater. Civ. Eng. 2016, 28, 1–12. [Google Scholar] [CrossRef]

- Petrone, C.; Magliulo, G.; Lopez, P.; Manfredi, G. Out-of-plane seismic performance of plasterboard partitions via quasi-static tests. Bull. N. Z. Soc. Earthq. Eng. 2016, 49, 125–137. Available online: https://discovery.ucl.ac.uk/id/eprint/1496935/1/Petrone%20et%20al%20-%20BNZSEE%20-%20accepted%20version.pdf (accessed on 12 May 2020). [CrossRef]

- Gencel, O.; del Coz Diaz, J.J.; Sutcu, M.; Koksal, F.; Rabanal, A.; Marinez Barrera, G.; Brostow, W. Properties of gypsum composites containing vermiculite and polypropylene fibers: Numerical and experimental results. Energy Build. 2014, 70, 135–144. [Google Scholar] [CrossRef]

- Oliver-Ramirez, A.; Garcia-Santos, A.; Neila-Gonzalez, F.J. Physical and mechanical characterization of gypsum boards containing phase change materials for latent heat storage. Mater. Constr. 2011, 61, 465–484. [Google Scholar] [CrossRef][Green Version]

- BSEN 520:2004 + A1 2009. Gypsum Plasterboards—Definitions, Requirements and test Methods. Available online: https://Infostore.saiglobal.com/en-us/Standards/EN-520-2004-A1-2009-346166_SAIG_CEN_CEN_791645/ (accessed on 2 April 2020).

- Ranachowski, Z.; Ranachowski, P.; Dębowski, T.; Gorzelańczyk, T.; Schabowicz, K. Investigation of structural degradation of fiber cement boards due to thermal impact. Materials 2019, 12, 944. [Google Scholar] [CrossRef]

- Schabowicz, K.; Gorzelańczyk, T.; Szymków, M. Identification of the degree of fibre-cement boards degradation under the influence of high temperature. Autom. Constr. 2019, 101, 190–198. [Google Scholar] [CrossRef]

- Berriman, J.; Purnell, P.; Hutchins, D.A.; Neild, A. Humidity and aggregate content correction factors for air-coupled ultrasonic evaluation of concrete. Ultrasonics 2005, 43, 211–217. [Google Scholar] [CrossRef] [PubMed]

- MISTRAS Products & Systems. Available online: http://www.eurosonic.com/en/products/ut-solutions/utc-110.html (accessed on 19 November 2018).

- Olympus Ultrasonic Transducers. Available online: http://www.olympus-ims.com/en/ultrasonic-transducers/contact-transducers/ (accessed on 2 April 2020).

- Zielinski, T.G. Microstructure-based calculations and experimental results for sound absorbing porous layers of randomly packed rigid spherical beads. J. Appl. Phys. 2014, 116, 034905. [Google Scholar] [CrossRef]

| Board Symbol | Remarks | Board Thickness [mm] |

|---|---|---|

| A | standard board for indoor installations | 12.5 |

| B | low quality board of standard type | 12.5 |

| G | fire resistant type | 12.5 |

| I | acoustic insulating type | 12.5 |

| K | humidity resistant type | 12.5 |

| Board Symbol | Apparent Density [kg/m3] | Flexural Strength Fmax [N], Declared by the Manufacturer— Parallel and Perpendicular to the Sheet Length |

|---|---|---|

| A | 648 | >550/>210 |

| B | 648 | – |

| G | 880 | >550/>210 |

| I | 1024 | >550/>210 |

| K | 672 | >550/>210 |

| wt. (%) | O | Si | S | Ca |

|---|---|---|---|---|

| A material | 55.32 | 0.74 | 19.15 | 23.49 |

| G material | 56.54 | 1.20 | 19.52 | 22.74 |

| Board Type | Max. Stress in the Initial State, || to Sheet Production Direction [MPa] | Max. stress in the Initial State, |_ to Sheet Production Direction [MPa] | Max. stress after First Hydration, || to Sheet Production Direction [MPa] | Max. Stress after First hydration, |_ to Sheet Production Direction [MPa] | Max. Stress after Second Hydration || to Sheet Production Direction [MPa] | Max. Stress after Second Hydration |_ to Sheet Production Direction [MPa] |

|---|---|---|---|---|---|---|

| A | 4.74 | 2.62 | 1.24 | 1.29 | 1.15 | 0.84 |

| B | 4.69 | 2.64 | 1.01 | 0.62 | 0.95 | 0.58 |

| G | 8.34 | 4.34 | 2.14 | 0.98 | 1.68 | 0.94 |

| I | 9.65 | 3.46 | 2.48 | 1.27 | 1.93 | 1.08 |

| K | 4.59 | 2.50 | 1.22 | 0.75 | 0.95 | 0.65 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ranachowski, Z.; Ranachowski, P.; Dębowski, T.; Brodecki, A.; Kopec, M.; Roskosz, M.; Fryczowski, K.; Szymków, M.; Krawczyk, E.; Schabowicz, K. Mechanical and Non-Destructive Testing of Plasterboards Subjected to a Hydration Process. Materials 2020, 13, 2405. https://doi.org/10.3390/ma13102405

Ranachowski Z, Ranachowski P, Dębowski T, Brodecki A, Kopec M, Roskosz M, Fryczowski K, Szymków M, Krawczyk E, Schabowicz K. Mechanical and Non-Destructive Testing of Plasterboards Subjected to a Hydration Process. Materials. 2020; 13(10):2405. https://doi.org/10.3390/ma13102405

Chicago/Turabian StyleRanachowski, Zbigniew, Przemysław Ranachowski, Tomasz Dębowski, Adam Brodecki, Mateusz Kopec, Maciej Roskosz, Krzysztof Fryczowski, Mateusz Szymków, Ewa Krawczyk, and Krzysztof Schabowicz. 2020. "Mechanical and Non-Destructive Testing of Plasterboards Subjected to a Hydration Process" Materials 13, no. 10: 2405. https://doi.org/10.3390/ma13102405

APA StyleRanachowski, Z., Ranachowski, P., Dębowski, T., Brodecki, A., Kopec, M., Roskosz, M., Fryczowski, K., Szymków, M., Krawczyk, E., & Schabowicz, K. (2020). Mechanical and Non-Destructive Testing of Plasterboards Subjected to a Hydration Process. Materials, 13(10), 2405. https://doi.org/10.3390/ma13102405