Analysis of Microstructure and Properties of a Ti–AlN Composite Produced by Selective Laser Melting

Abstract

1. Introduction

2. Materials and Methods

2.1. Powder Preparation and Samples Fabrication

2.2. Powder and Sample Characterization

3. Results and Discussion

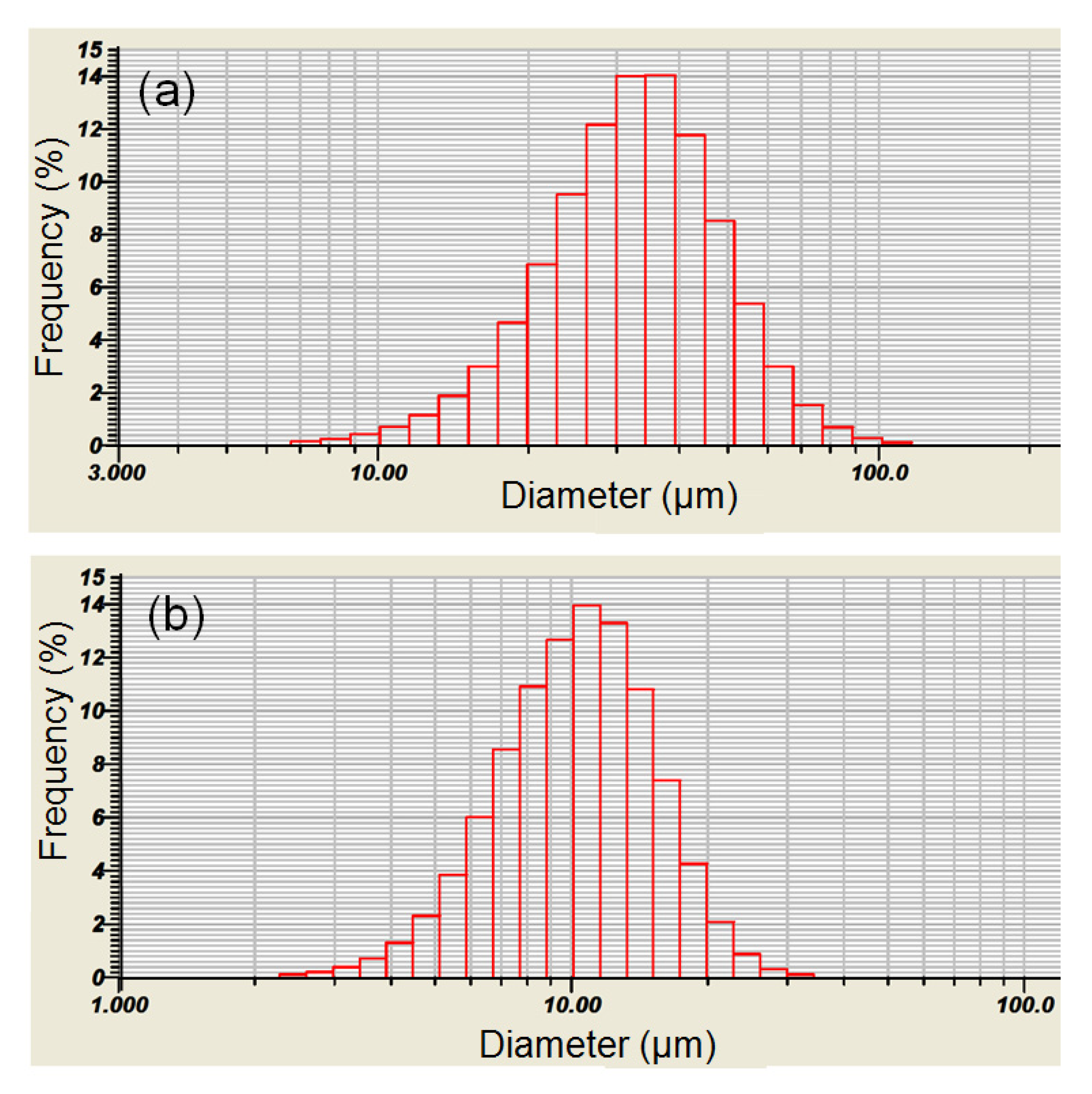

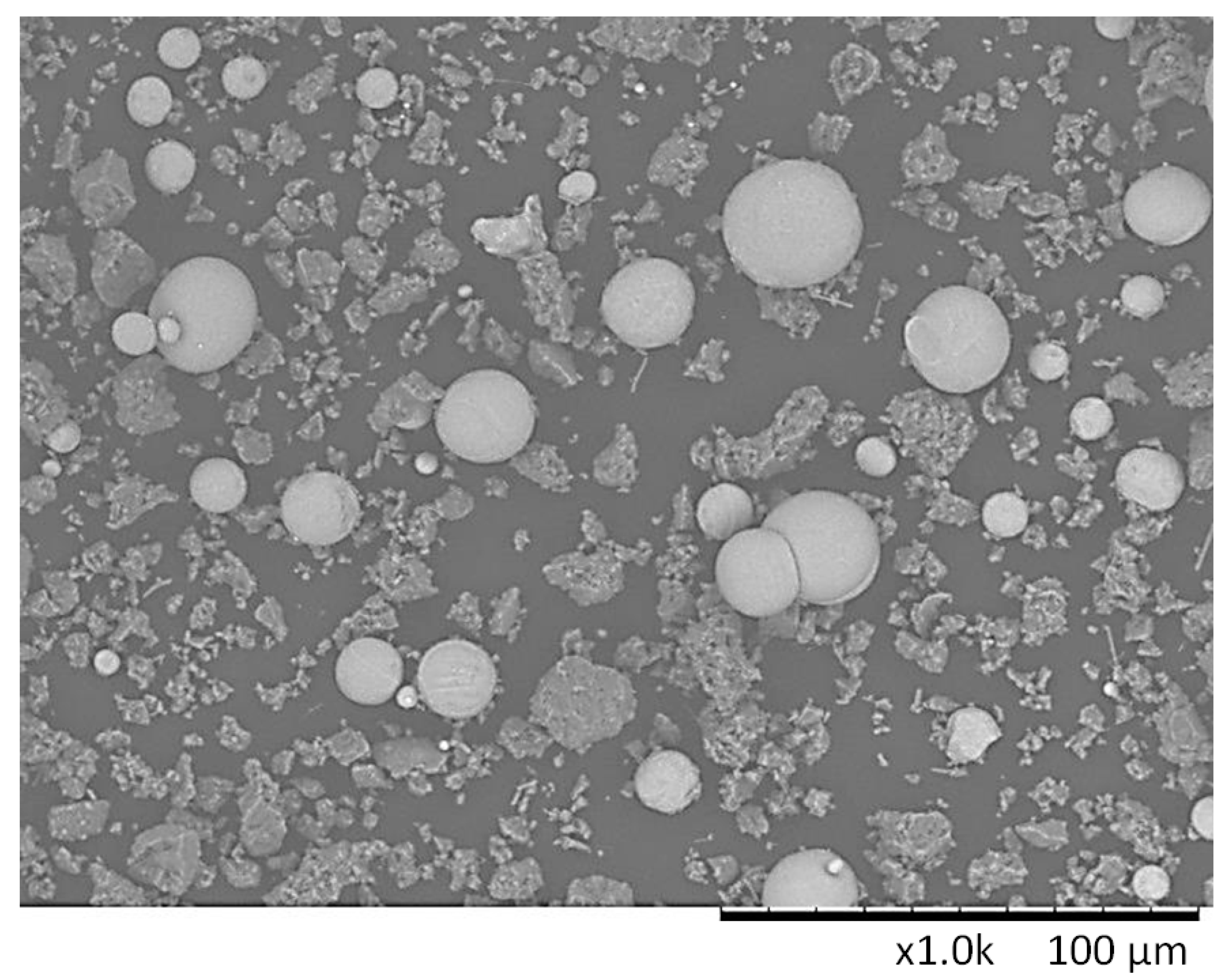

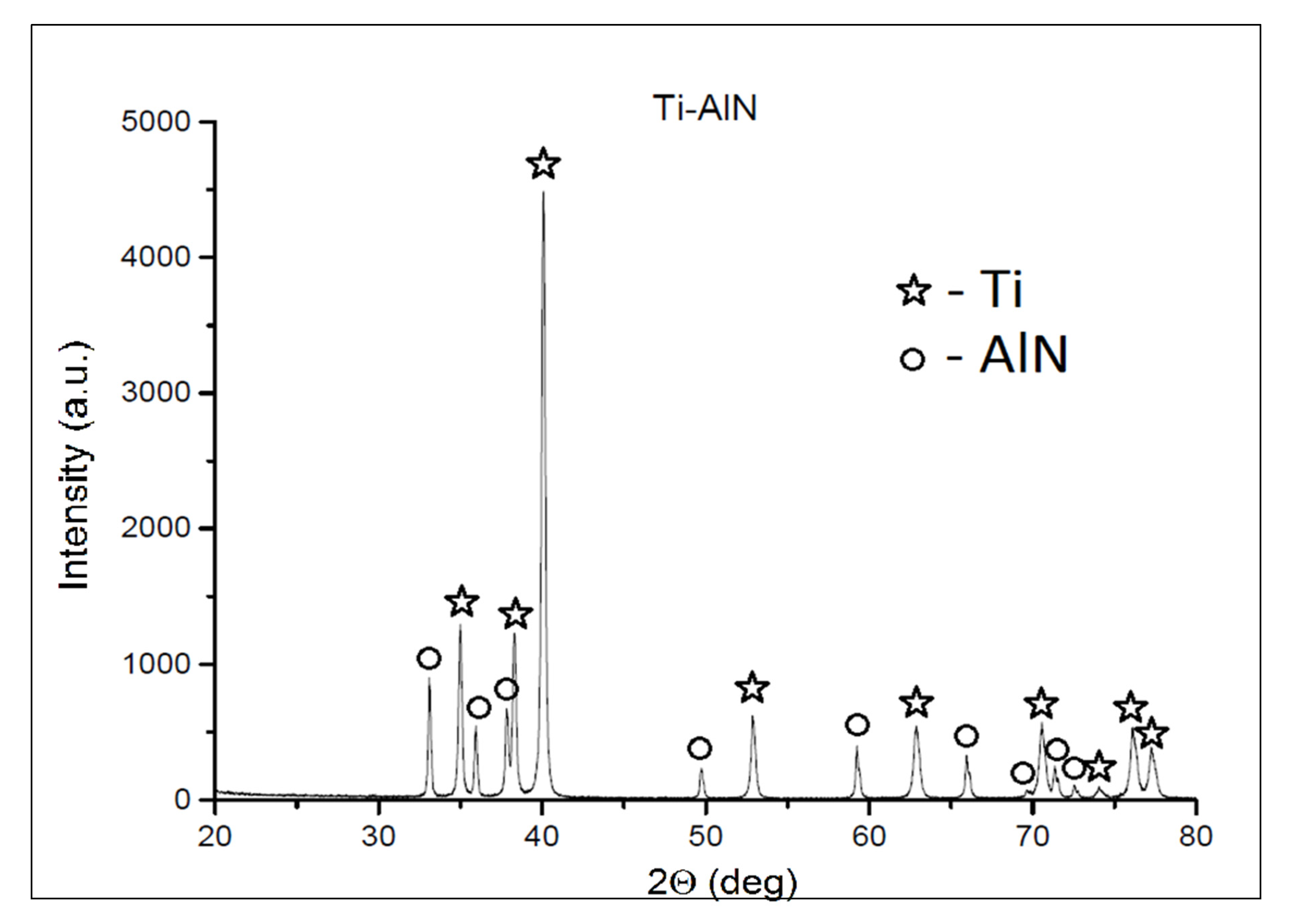

3.1. Analysis of Mixed Powders

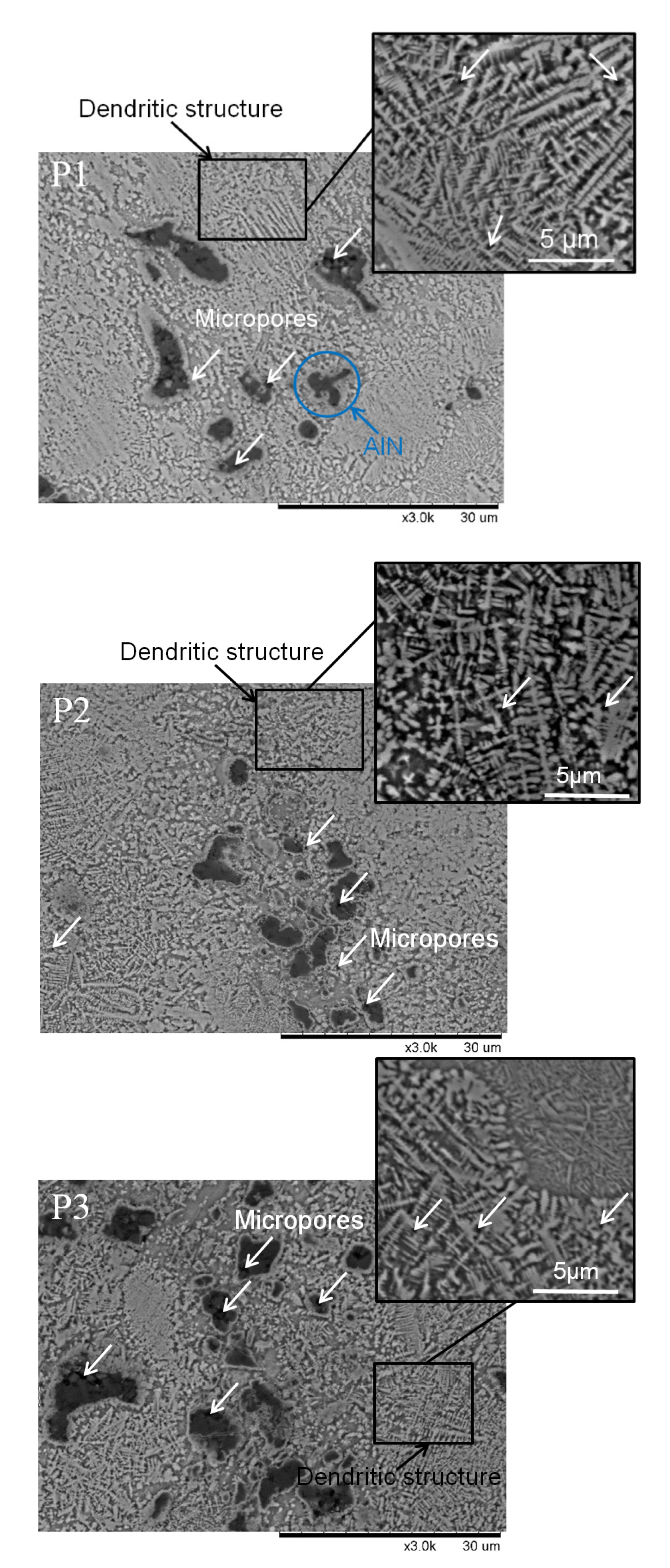

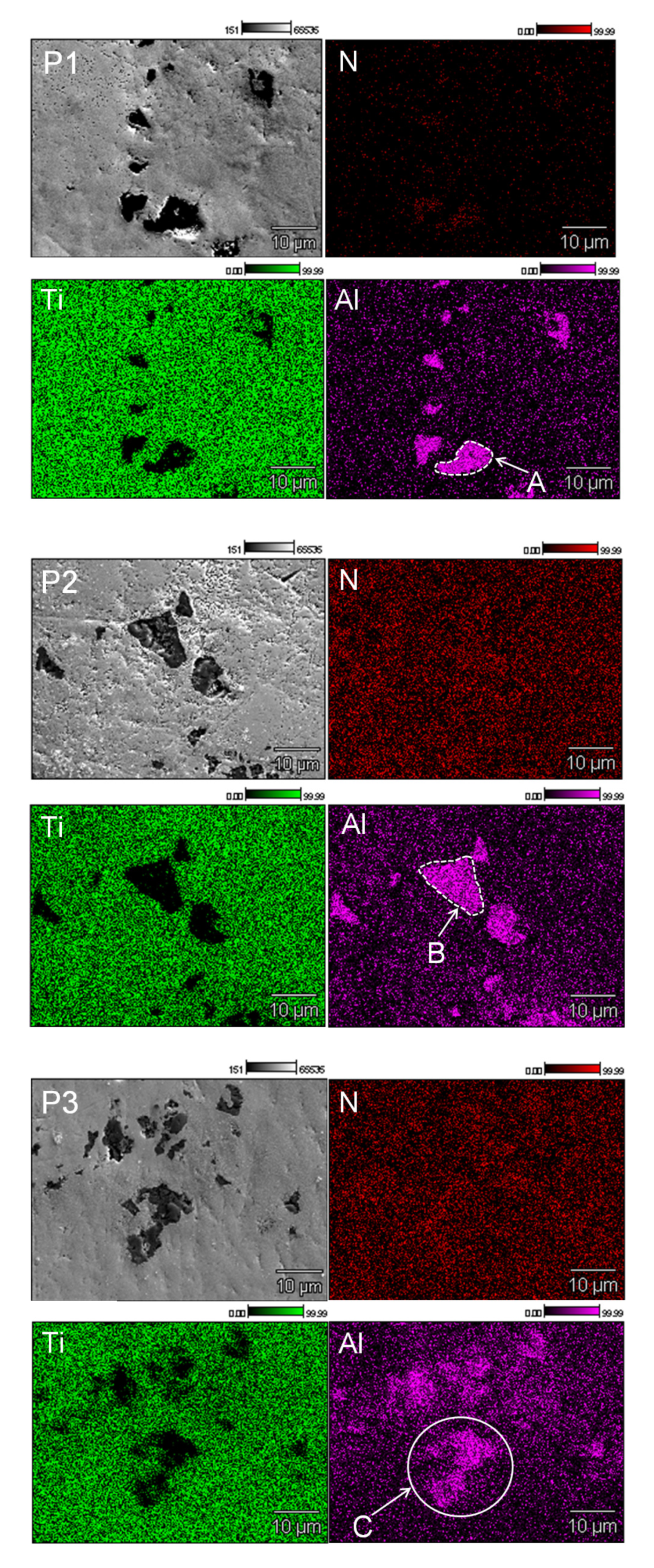

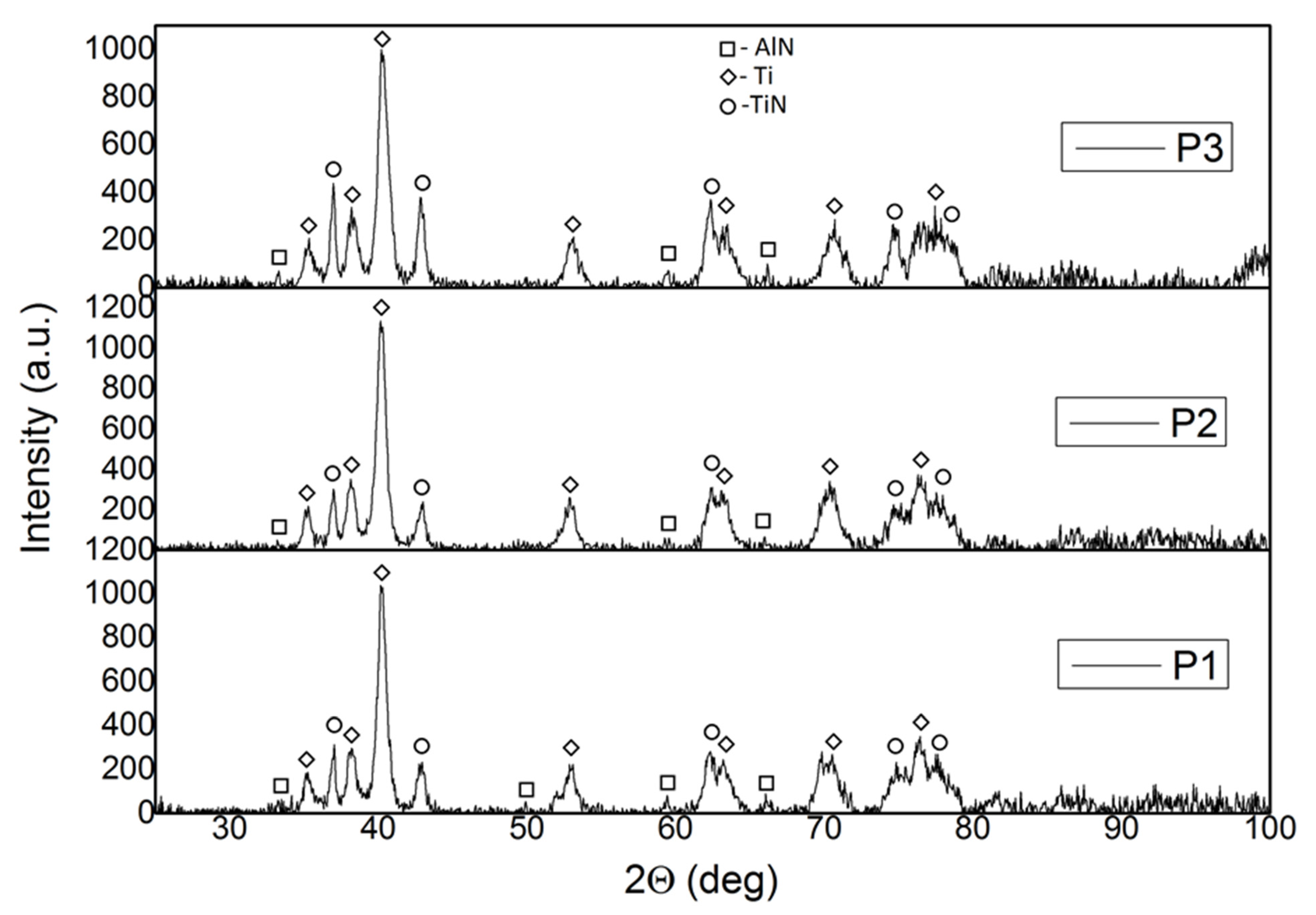

3.1.1. Microstructure Characterization of the Samples

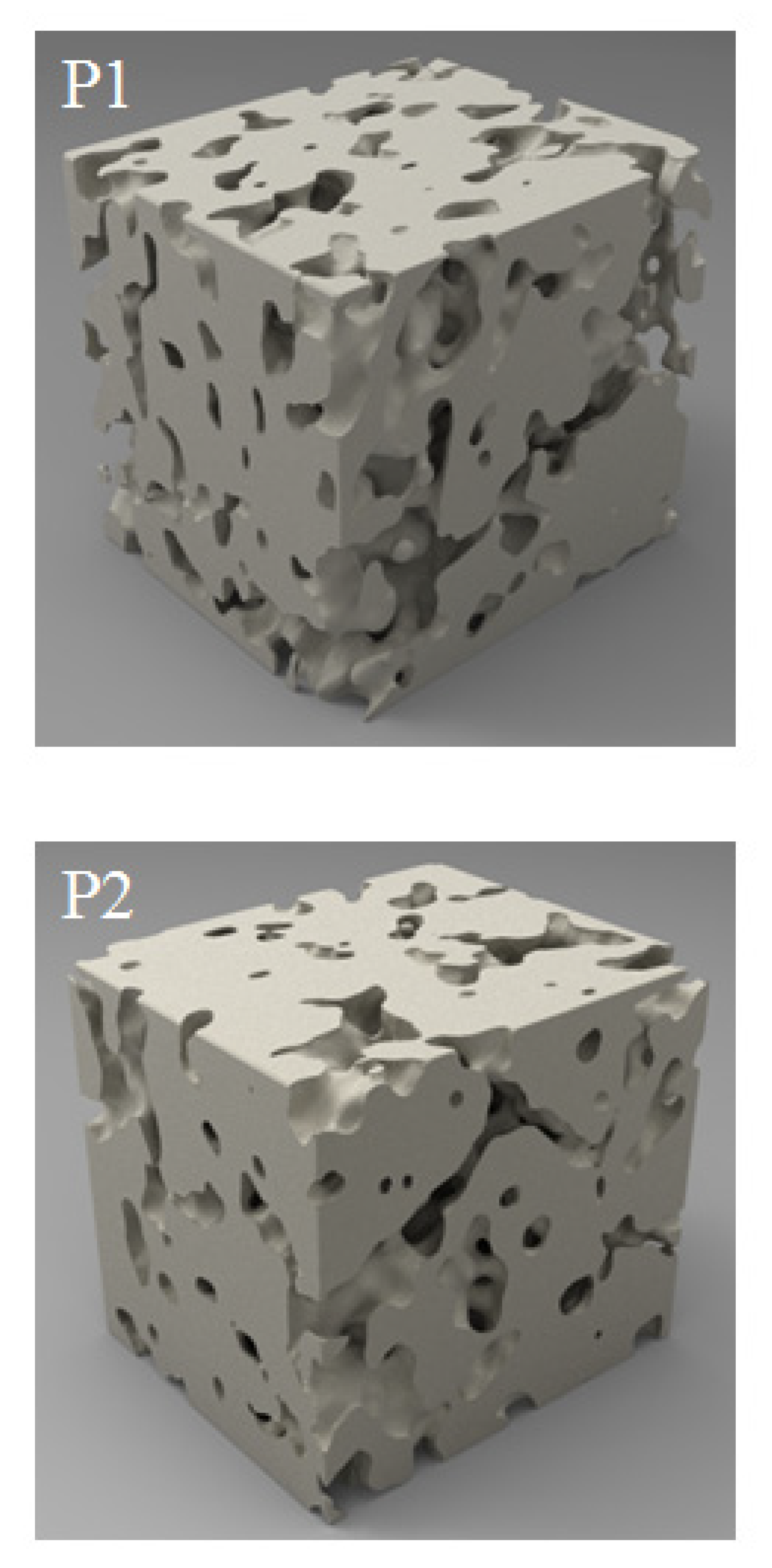

3.1.2. Analysis of the Samples’ Porosity

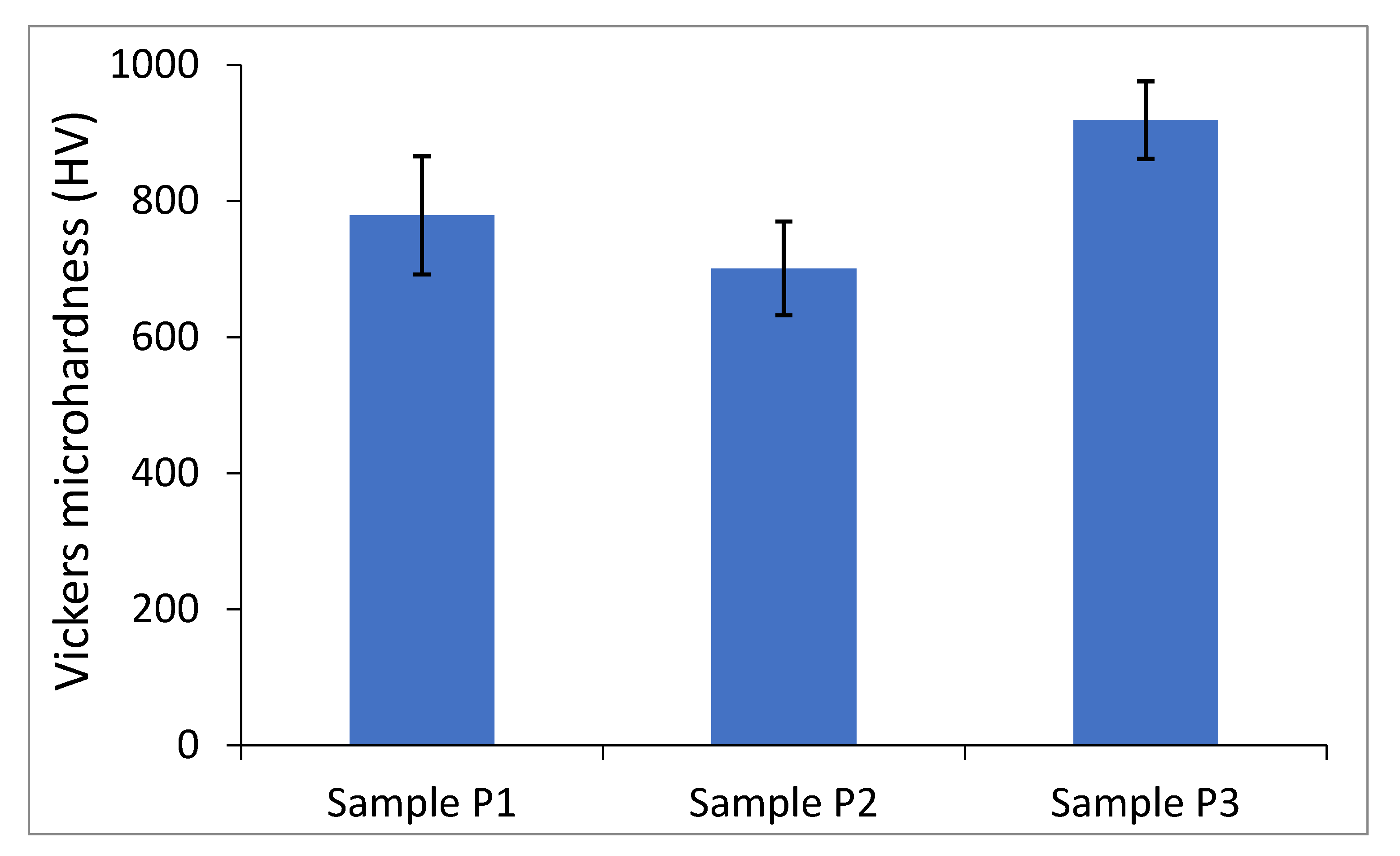

3.2. Influence of Manufacturing Process Parameters on Microhardness

4. Conclusions

- (1)

- The Selective Laser Melting method can be successfully applied to obtain a Ti–AlN composite.

- (2)

- The manufactured composites are characterized by considerable porosity and inhomogeneity (there are areas with a dendritic structure, and axial and nonmolten particles of aluminum nitride).

- (3)

- Increasing the density of energy supplied to the sample from 100.0 J/mm3 to 140.0 J/mm3 causes a decreased porosity of composite of about 10% and also reduces the hardness.

- (4)

- The work carried out is pioneering and constitutes an introduction to the discussion of the possibility of the manufacture and application of new composite materials from a Ti–Al–N system by using a Selective Laser Melting method.

Author Contributions

Funding

Conflicts of Interest

References

- He, B.; Wu, W.; Zhang, L.; Lu, L.; Yang, Q.; Long, Q.; Chang, K. Microstructural characteristic and mechanical property of Ti6Al4V alloy fabricated by selective laser melting. Vacuum 2018, 150, 79–83. [Google Scholar] [CrossRef]

- Koizumi, H.; Takeuchi, Y.; Imai, H.; Kawai, T.; Yoneyama, T. Application of titanium and titanium alloys to fixed dental prostheses. J. Prosthodont. Res. 2019, 63, 266–270. [Google Scholar] [CrossRef] [PubMed]

- Carradò, A.; Perrin-Schmitt, F.; Le, Q.; Giraudel, M.; Fischer, C.; Koenig, G.; Jacomine, L.; Behr, L.; Chalom, A.; Fiette, L.; et al. Nanoporous hydroxyapatite/sodium titanate bilayer on titanium implants for improved osteointegration. Dent. Mater. 2017, 33, 321–332. [Google Scholar] [CrossRef] [PubMed]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Van Humbeeck, J.; Kruth, J.-P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Trosch, T.; Strößner, J.; Völkl, R.; Glatzel, U. Microstructure and mechanical properties of selective laser melted Inconel 718 compared to forging and casting. Mater. Lett. 2016, 164, 428–431. [Google Scholar] [CrossRef]

- Chlebus, E.; Kuźnicka, B.; Dziedzic, R.; Kurzynowski, T. Titanium alloyed with rhenium by selective laser melting. Mater. Sci. Eng. A 2015, 620, 155–163. [Google Scholar] [CrossRef]

- Gu, D.; Hagedorn, Y.-C.; Meiners, W.; Wissenbach, K.; Poprawe, R. Nanocrystalline TiC reinforced Ti matrix bulk-form nanocomposites by Selective Laser Melting (SLM): Densification, growth mechanism and wear behavior. Compos. Sci. Technol. 2011, 71, 1612–1620. [Google Scholar] [CrossRef]

- Fischer, M.; Joguet, D.; Robin, G.; Peltier, L.; Laheurte, P. In situ elaboration of a binary Ti–26Nb alloy by selective laser melting of elemental titanium and niobium mixed powders. Mater. Sci. Eng. C 2016, 62, 852–859. [Google Scholar] [CrossRef]

- Baskut, S.; Cinar, A.; Turan, S. Directional properties and microstructures of spark plasma sintered aluminum nitride containing graphene platelets. J. Eur. Ceram. Soc. 2017, 37, 3759–3772. [Google Scholar] [CrossRef]

- Podsiadło, S. Nitrides; WNT: Warsaw, Poland, 1991. (In Polish) [Google Scholar]

- Shishkovsky, I.; Morozov, I.G.; Yadroitsev, I.; Smurov, I.Y. Titanium and aluminum nitride synthesis via layer by layer LA-CVD. Appl. Surf. Sci. 2009, 255, 9847–9850. [Google Scholar] [CrossRef]

- Castanho, J.; Vieira, M.; Vieira, M.T. Effect of ductile layers in mechanical behaviour of TiAlN thin coatings. J. Mater. Process. Technol. 2003, 143, 352–357. [Google Scholar] [CrossRef]

- Jindal, P.; Santhanam, A.; Schleinkofer, U.; Shuster, A. Performance of PVD TiN, TiCN, and TiAlN coated cemented carbide tools in turning. Int. J. Refract. Met. Hard Mater. 1999, 17, 163–170. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.; Beake, B.; Endrino, J.; Veldhuis, S.; Parkinson, R.; Shuster, L.; Migranov, M. Effect of mechanical properties measured at room and elevated temperatures on the wear resistance of cutting tools with TiAlN and AlCrN coatings. Surf. Coatings Technol. 2006, 200, 5738–5742. [Google Scholar] [CrossRef]

- Sitek, R.; Kaminski, J.; Borysiuk, J.; Matysiak, H.; Kubiak, K.; Kurzydlowski, K. Microstructure and properties of titanium aluminides on Ti6Al4V titanium alloy produced by chemical vapor deposition method. Intermetallics 2013, 36, 36–44. [Google Scholar] [CrossRef]

- Wysocki, B.; Maj, P.; Sitek, R.; Buhagiar, J.; Kurzydlowski, K.; Swieszkowski, W. Laser and Electron Beam Additive Manufacturing Methods of Fabricating Titanium Bone Implants. Appl. Sci. 2017, 7, 657. [Google Scholar] [CrossRef]

- Wysocki, B.; Maj, P.; Krawczynska, A.T.; Rożniatowski, K.; Zdunek, J.; Kurzydlowski, K.; Swieszkowski, W. Microstructure and mechanical properties investigation of CP titanium processed by selective laser melting (SLM). J. Mater. Process. Technol. 2017, 241, 13–23. [Google Scholar] [CrossRef]

- Garcia, I.; De La Fuente, J.; De-Damborenea, J. (Ti,Al)/(Ti,Al)N coatings produced by laser surface alloying. Mater. Lett. 2002, 53, 44–51. [Google Scholar] [CrossRef]

- Ly, S.; Rubenchik, A.M.; Khairallah, S.A.; Guss, G.; Matthews, M. Metal vapor micro-jet controls material redistribution in laser powder bed fusion additive manufacturing. Sci. Rep. 2017, 7, 4085. [Google Scholar] [CrossRef]

- Das, S.; Beama, J.J.; Wohlert, M.; Bourell, D.L. Direct laser freeform fabrication of high performance metal components. Rapid Prototyp. J. 1998, 4, 112–117. [Google Scholar] [CrossRef]

- Song, B.; Dong, S.; Liao, H.; Coddet, C. Process parameter selection for selective laser melting of Ti6Al4V based on temperature distribution simulation and experimental sintering. Int. J. Adv. Manuf. Technol. 2011, 61, 967–974. [Google Scholar] [CrossRef]

- Agarwala, M.; Bourell, D.; Beaman, J.; Marcus, H.; Barlow, J. Post-processing of selective laser sintered metal parts. Rapid Prototyp. J. 1995, 1, 36–44. [Google Scholar] [CrossRef]

- Gong, H.; Rafi, K.; Starr, T.; Stucker, B. The Effects of Processing Parameters on Defect Regularity in Ti-6Al-4V Parts Fabricated By Selective Laser Melting and Electron Beam Melting (2013) 424–439. In Proceedings of the Conference: 24th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 12–14 August 2013. [Google Scholar]

- Żrodowski, Ł.; Wysocki, B.; Wróblewski, R.; Krawczynska, A.T.; Adamczyk-Cieślak, B.; Zdunek, J.; Błyskun, P.; Ferenc, J.; Leonowicz, M.; Swieszkowski, W. New approach to amorphization of alloys with low glass forming ability via selective laser melting. J. Alloy. Compd. 2019, 771, 769–776. [Google Scholar] [CrossRef]

- Schloffer, M.; Iqbal, F.; Gabrisch, H.; Schwaighofer, E.; Schimansky, F.-P.; Mayer, S.; Stark, A.; Lippmann, T.; Göken, M.; Pyczak, F.; et al. Microstructure development and hardness of a powder metallurgical multi phase γ-TiAl based alloy. Intermetallics 2012, 22, 231–240. [Google Scholar] [CrossRef]

| Sample No. | Scanning Strategy | Energy Density [J/mm3] | Scanning Speed [mm/s] | Porosity [%] | Mean Pore Size [µm] |

|---|---|---|---|---|---|

| P1 | Alternating | 100.00 | 125.00 | 17.5% | 67 (SD 25) |

| P2 | Alternating | 140.00 | 90.00 | 7.0% | 62 (SD 22) |

| P3 | (1) Initial sintering followed by (2) alternating | (1) 70.00 (2) 100.00 | (1) 90.00 (2) 125.00 | 16.0% | 65 (SD 24) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sitek, R.; Szustecki, M.; Zrodowski, L.; Wysocki, B.; Jaroszewicz, J.; Wisniewski, P.; Mizera, J. Analysis of Microstructure and Properties of a Ti–AlN Composite Produced by Selective Laser Melting. Materials 2020, 13, 2218. https://doi.org/10.3390/ma13102218

Sitek R, Szustecki M, Zrodowski L, Wysocki B, Jaroszewicz J, Wisniewski P, Mizera J. Analysis of Microstructure and Properties of a Ti–AlN Composite Produced by Selective Laser Melting. Materials. 2020; 13(10):2218. https://doi.org/10.3390/ma13102218

Chicago/Turabian StyleSitek, Ryszard, Maciej Szustecki, Lukasz Zrodowski, Bartlomiej Wysocki, Jakub Jaroszewicz, Paweł Wisniewski, and Jaroslaw Mizera. 2020. "Analysis of Microstructure and Properties of a Ti–AlN Composite Produced by Selective Laser Melting" Materials 13, no. 10: 2218. https://doi.org/10.3390/ma13102218

APA StyleSitek, R., Szustecki, M., Zrodowski, L., Wysocki, B., Jaroszewicz, J., Wisniewski, P., & Mizera, J. (2020). Analysis of Microstructure and Properties of a Ti–AlN Composite Produced by Selective Laser Melting. Materials, 13(10), 2218. https://doi.org/10.3390/ma13102218