Compressive Behavior Characteristics of High-Performance Slurry-Infiltrated Fiber-Reinforced Cementitious Composites (SIFRCCs) under Uniaxial Compressive Stress

Abstract

1. Introduction

2. Mechanical Properties of Fiber-Reinforced Concrete

3. Experimental

3.1. Materials

3.1.1. Cement

3.1.2. Silica Fume

3.1.3. Aggregates

3.1.4. Admixture

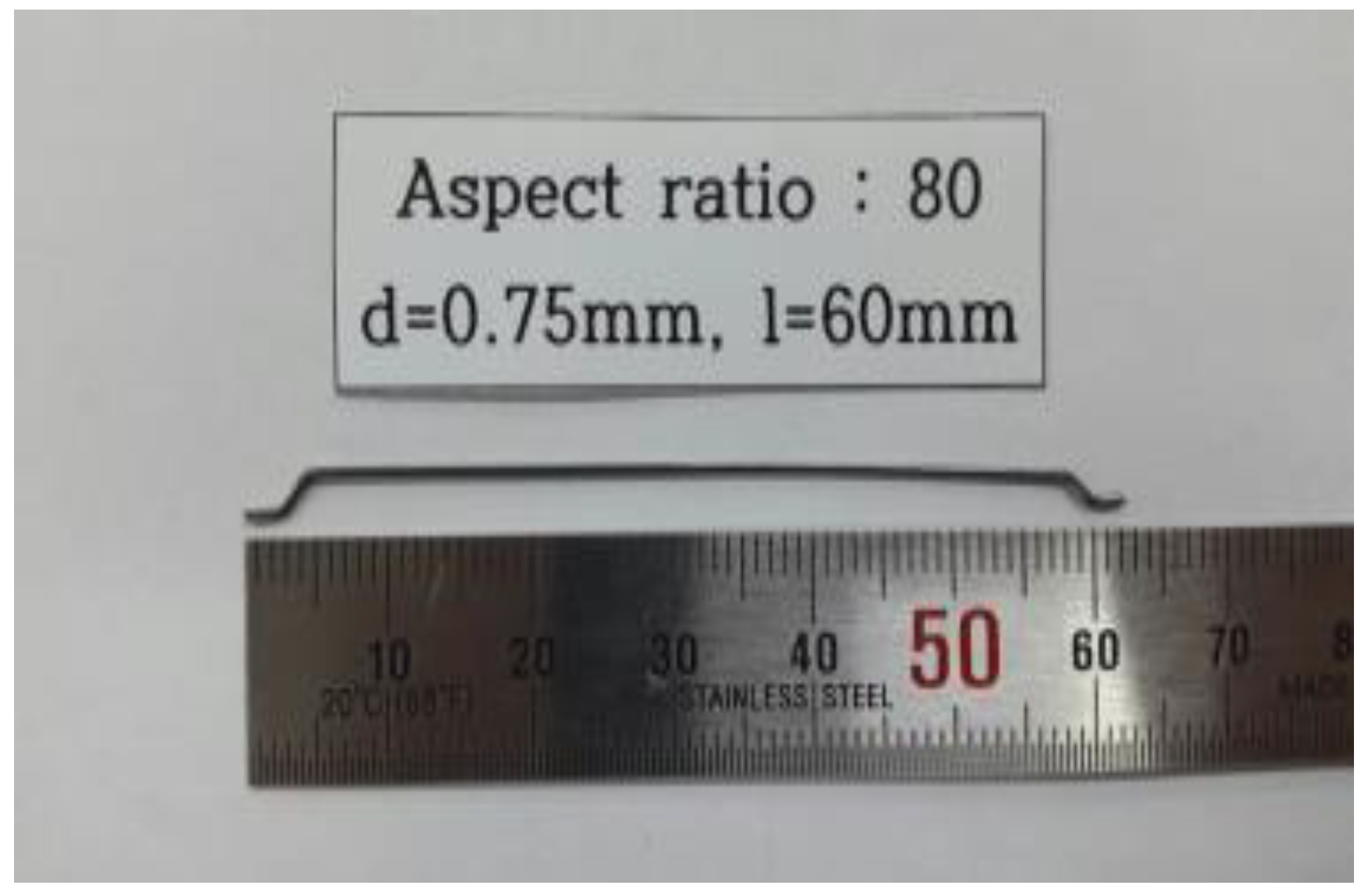

3.1.5. Steel Fibers

3.2. SIFRCCs

3.3. Mixing and Fabrication of Specimens

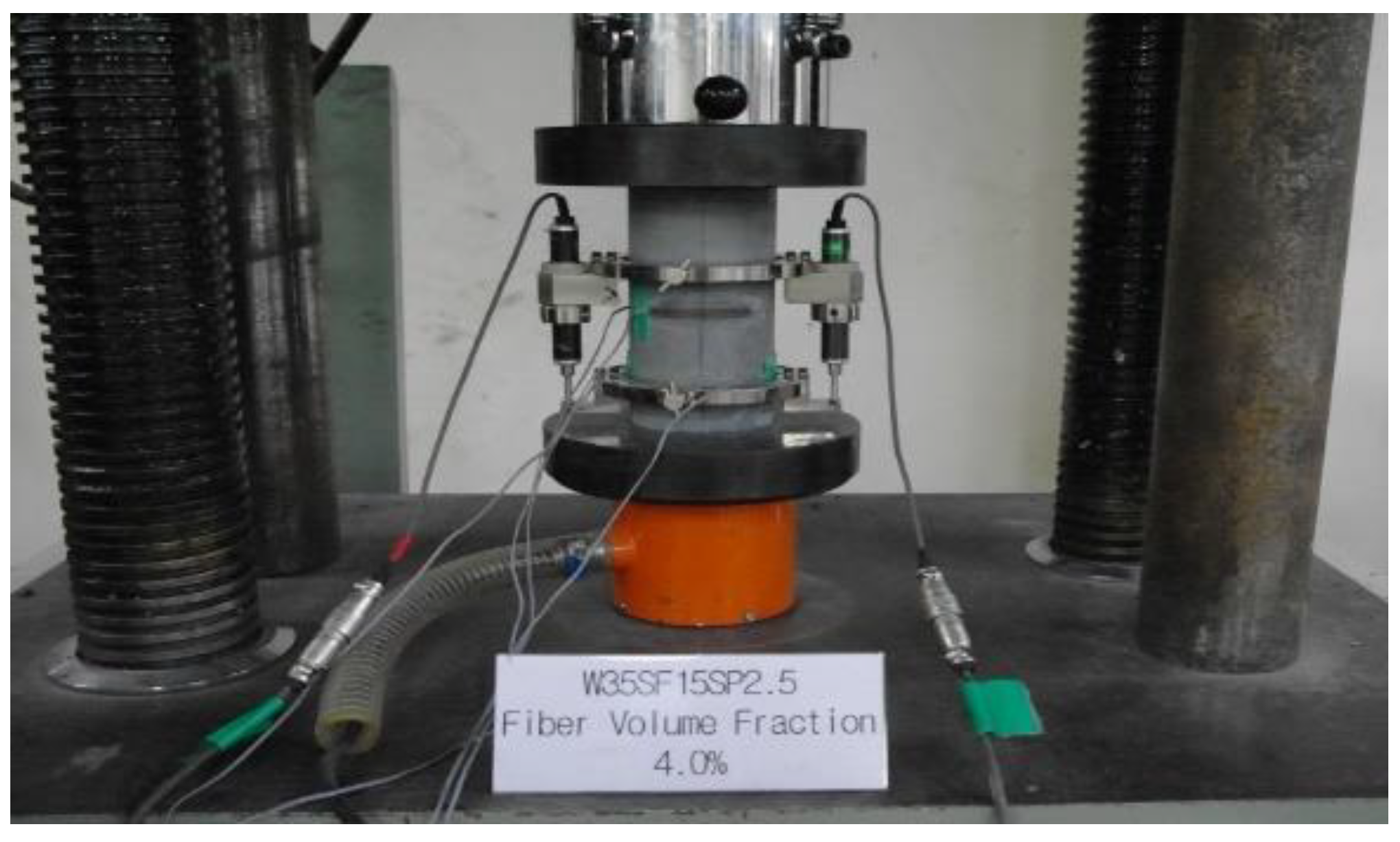

3.4. Compression Test of SIFRCCs

4. Experiment Results and Analysis

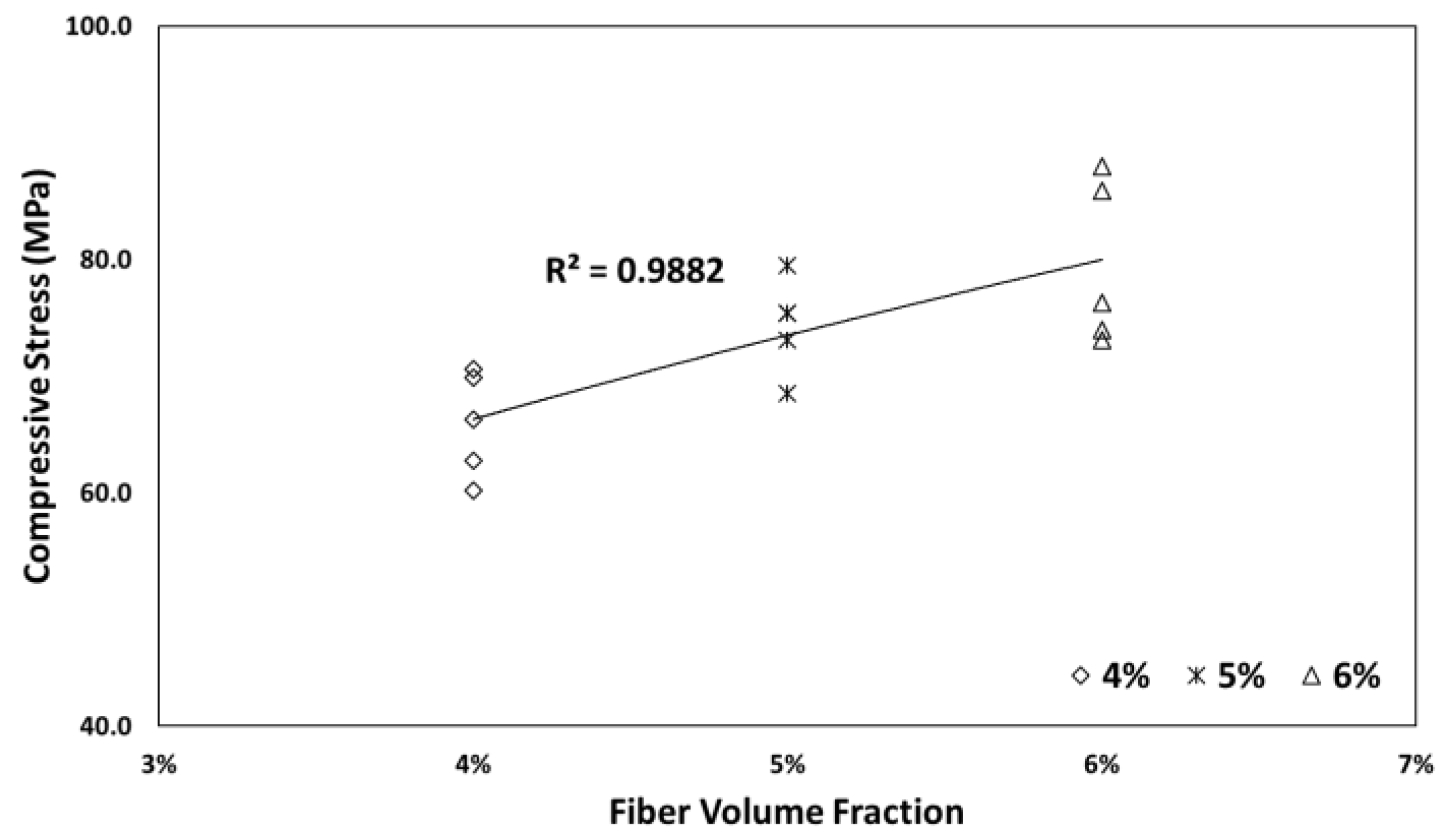

4.1. Compressive Stress

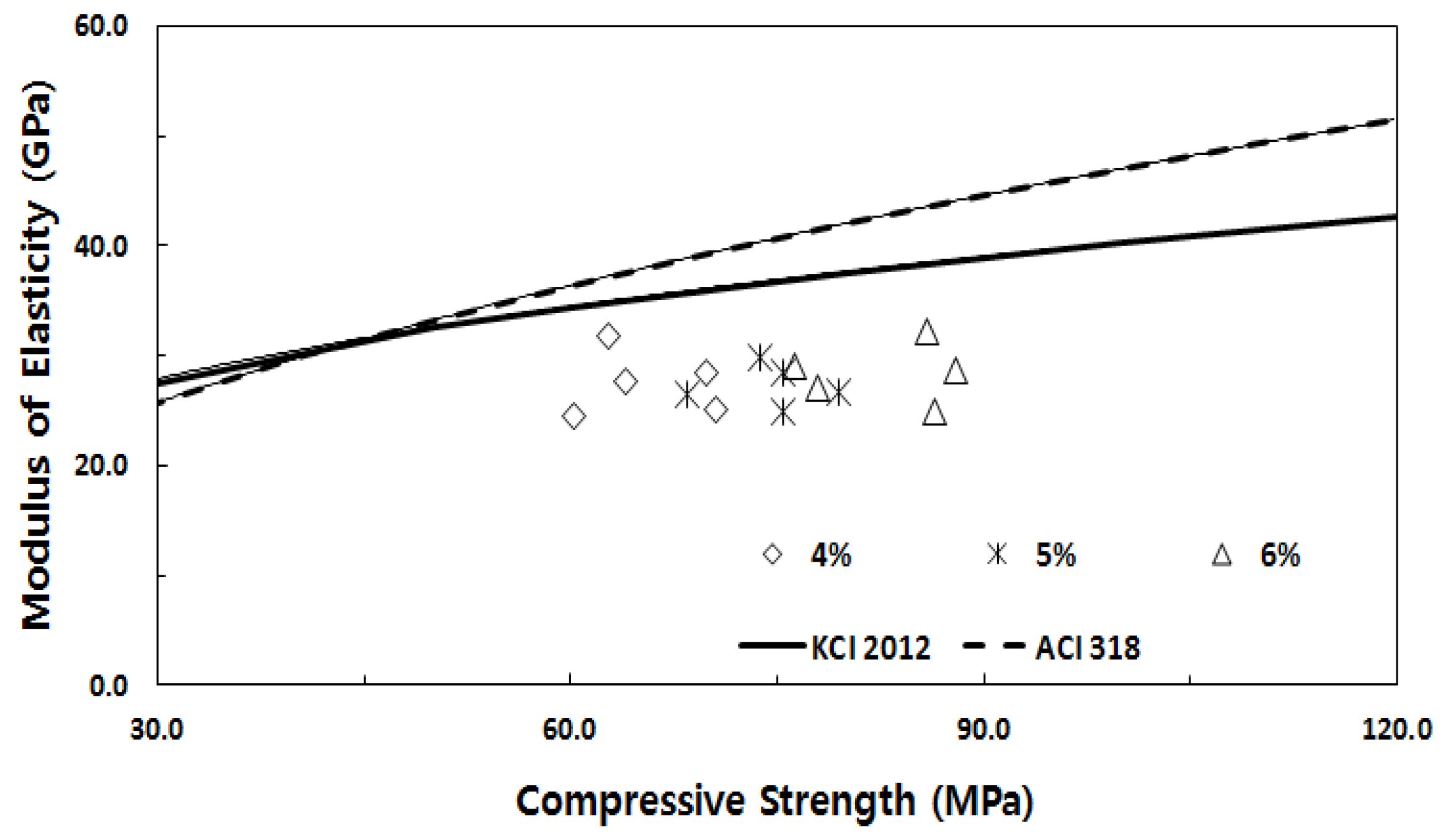

4.2. Elastic Modulus

4.3. Poisson’s Ratio

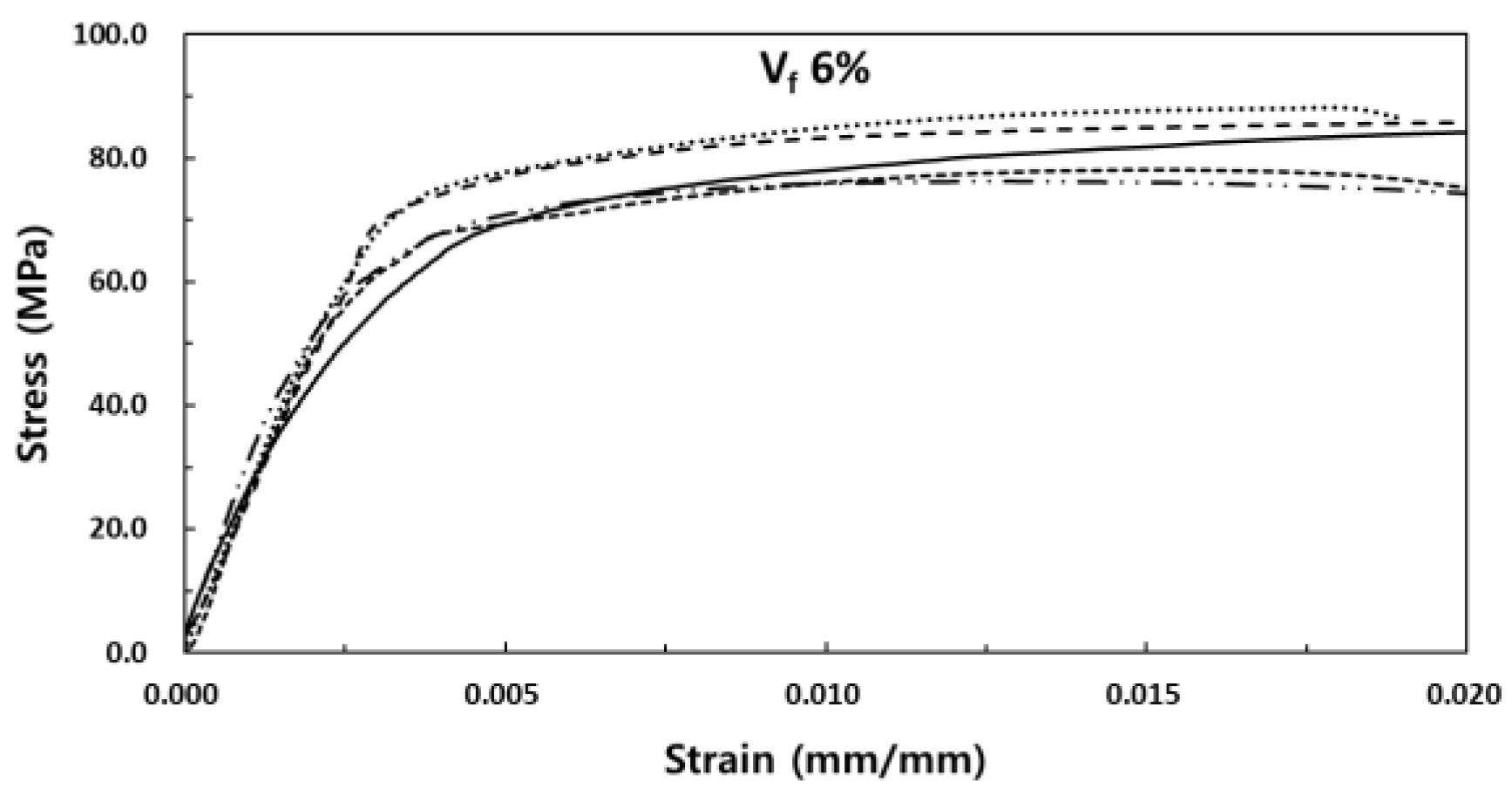

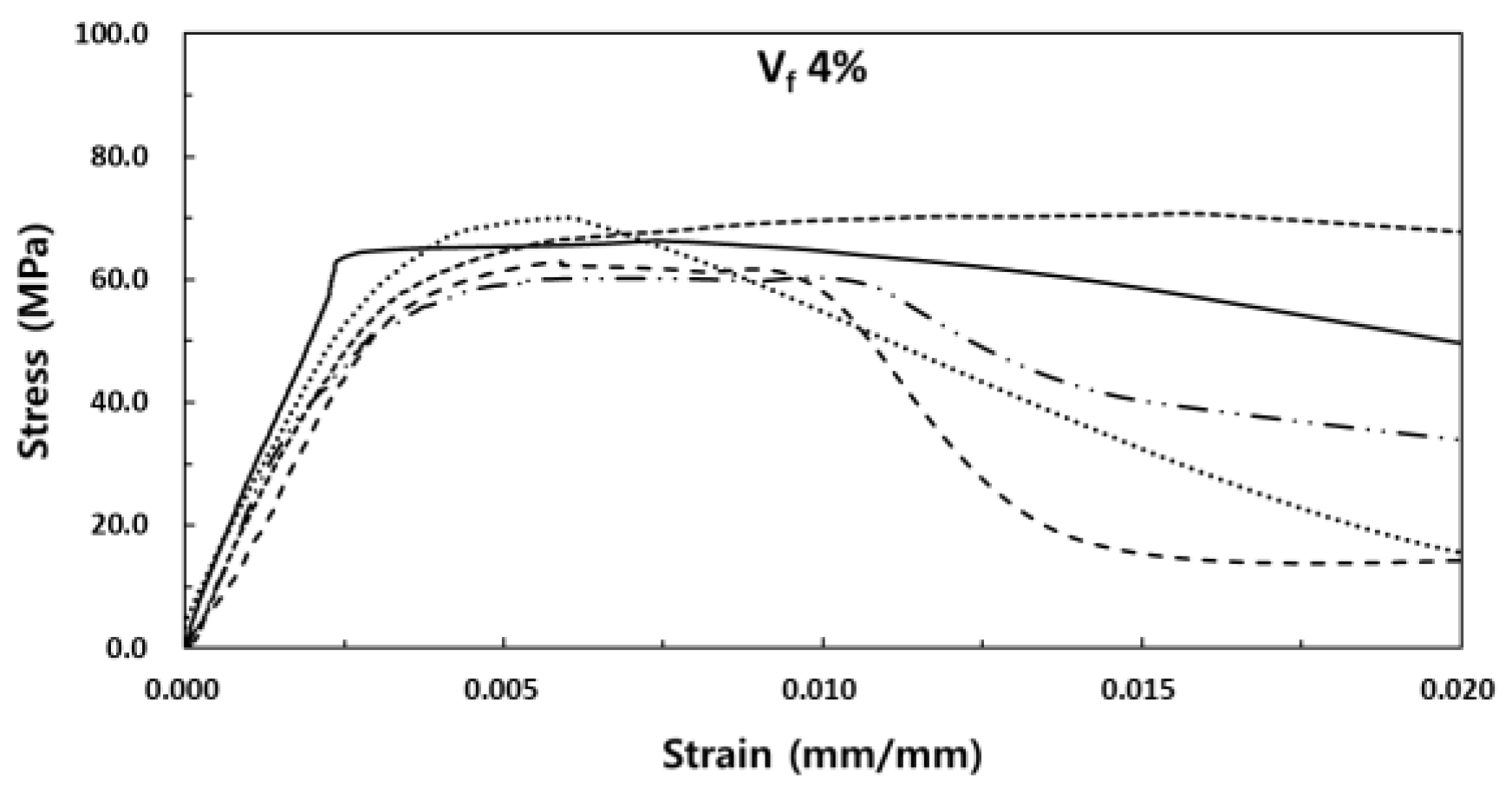

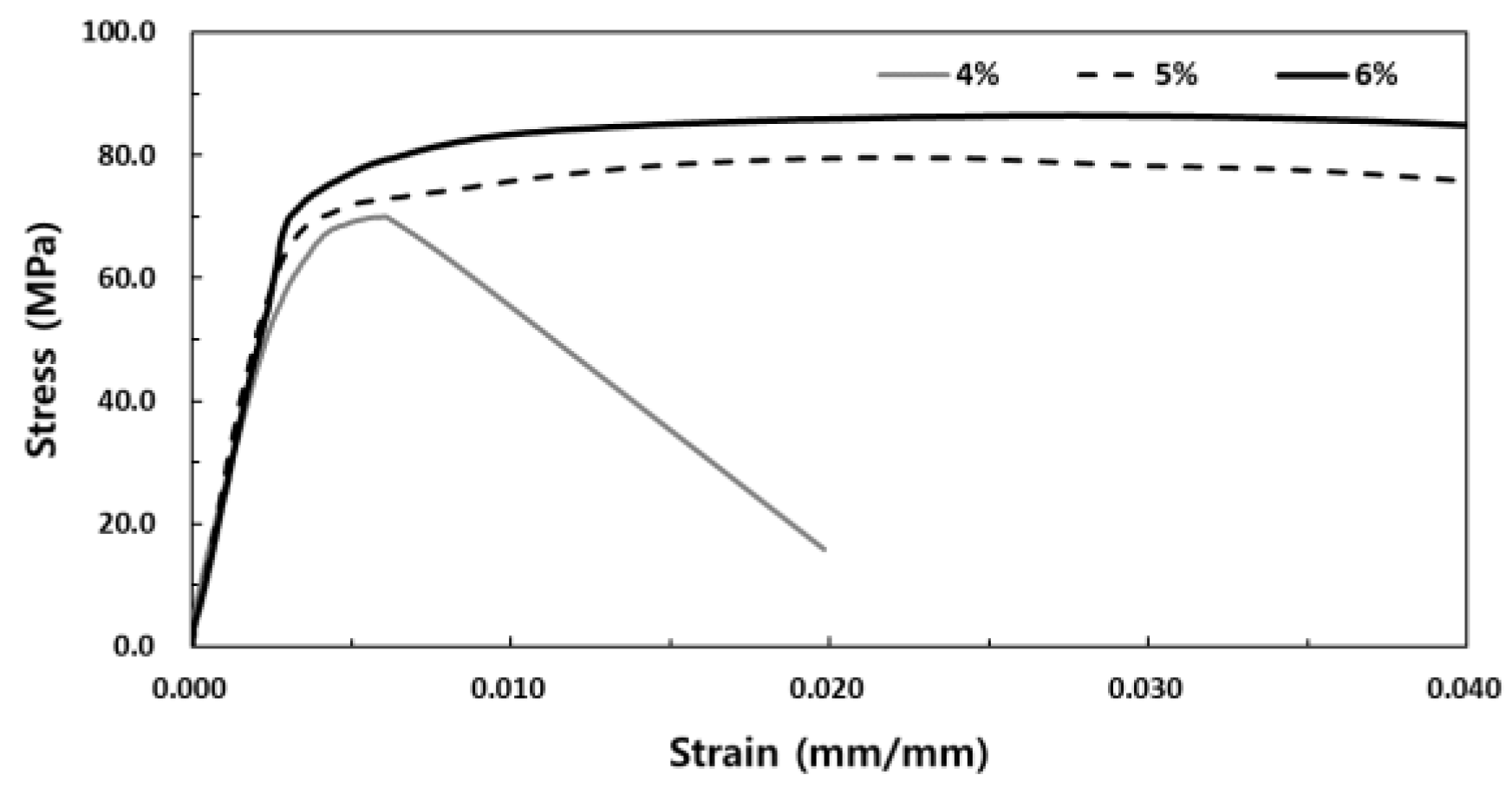

4.4. Stress-Strain Relationship

5. Conclusions

- (1)

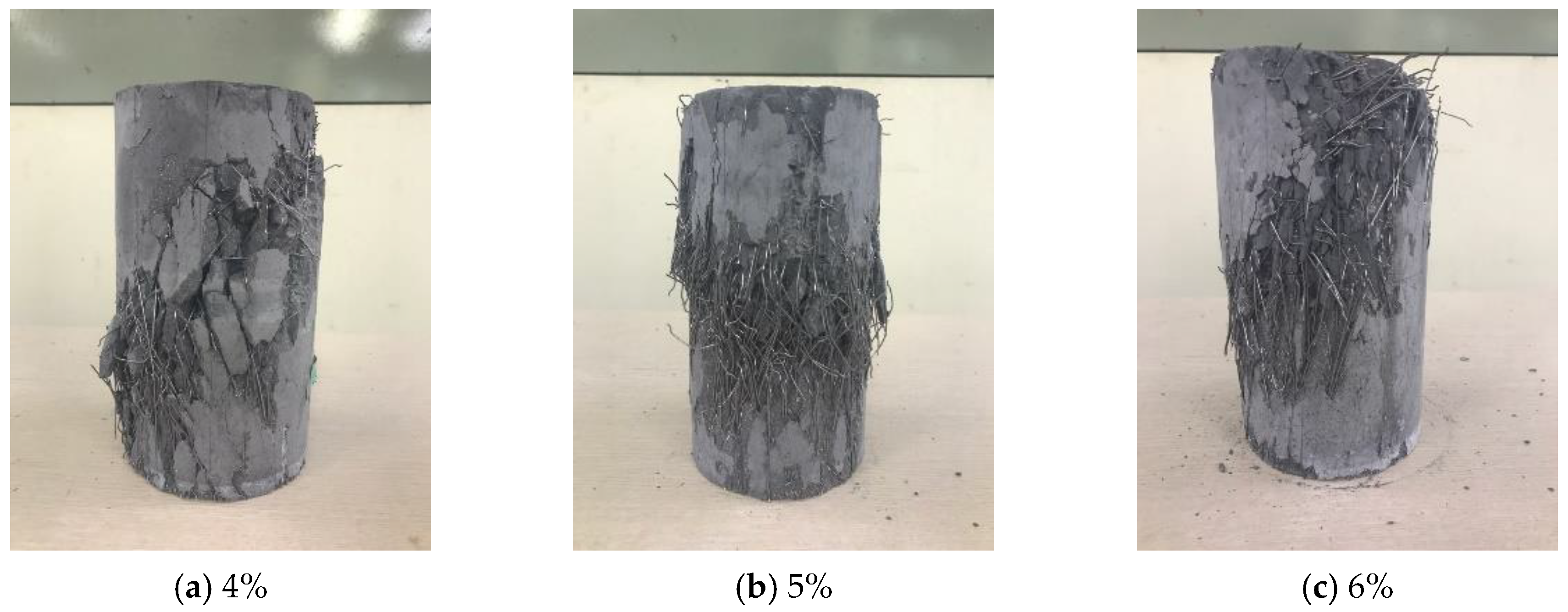

- The static compressive behavior characteristics with respect to the fiber volume fraction of SIFRCCs showed that the compressive stress increased in proportion to the increasing fiber volume fraction. The micro-cracks in conventional concrete and fiber-reinforced concrete were caused by the interface properties of coarse aggregates and cement paste. By contrast, SIFRCCs could reduce cracks at the interface because it was a composite made of fine particles with no coarse aggregates. Furthermore, the filling slurry and steel fibers improved the adhesion performance and reflected the effects of the fiber volume fraction and steel fibers instead of the compressive stress characteristics caused by matrix fracture. In addition, the high volume fraction of the steel fibers generated a restraining effect in the compressive stress test specimen, thereby affecting the increase in compressive stress.

- (2)

- The elastic modulus experiment results showed that the elastic modulus did not increase with the increasing fiber volume fraction, unlike the compressive stress experiment results. However, for strain under compressive stress, the increased rate of the strain at peak stress showed a difference of up to 2.7 times depending on the fiber volume fraction. This means that with increasing fiber volume fraction, the post-peak behavior after peak stress showed a strain hardening behavior, implying that the energy absorption capacity improved at a higher fiber volume fraction.

- (3)

- The characteristics of the strain increase rate were attributed to the restraining effect of the high fiber volume fraction in which many steel fibers resisted the expansion force generated vertically to the specimen axis that caused longitudinal split cracks. Furthermore, the reinforcing effect of steel fibers was considered to increase the peak stress and strain at peak stress in all compressive stress areas.

- (4)

- Poisson’s ratio experiment results showed insignificant differences in the elastic modulus with the fiber volume fraction. Similarly, Poisson’s ratio showed insignificant differences with the fiber volume fraction. However, Poisson’s ratio was ~0.3 for every variable; this was similar to that of steel. This was caused by the improved interface adhesion performance between the high-strength filling slurry matrix and the steel fibers. Therefore, the SIFRCCs with a high fiber volume fraction could suppress brittle fracture, a disadvantage of conventional concrete, and exhibit sufficient energy absorption capacity owing to its homogeneity.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Kang, S.-T. Bond Strength of Steel Fiber Incorporated in Ultra High Performance Fiber-Reinforced Concrete. J. Korea Concr. Inst. 2013, 25, 547–554. [Google Scholar] [CrossRef]

- Ku, D.-O.; Kim, S.-D.; Kim, H.-S.; Choi, K.-K. Flexural Performance Characteristics of Amorphous Steel Fiber-Reinforced Concrete. J. Korea Concr. Inst. 2014, 26, 483–489. [Google Scholar] [CrossRef][Green Version]

- Bindiganavile, V.; Banthia, N. Generating dynamic crack growth resistance curves for fiber-reinforced concrete. Exp. Mech. 2005, 45, 112–122. [Google Scholar] [CrossRef]

- Kim, S.; Park, C. Flexural Behavior of High-Volume Steel Fiber Cementitious Composite Externally Reinforced with Basalt FRP Sheet. J. Eng. 2016, 2016, 2857270. [Google Scholar] [CrossRef]

- Malvar, L.J.; Crawford, J.E.; Morrill, K.B. Use of Composites to Resist Blast. J. Compos. Constr. 2007, 11, 601–610. [Google Scholar] [CrossRef]

- Otter, D.E.; Naaman, A.E. Strain rate effects on compressive properties of fiber reinforced concrete. In Proceedings of the International Symposium on Fibre Reinforced Concrete, Madras, India, 16–19 December 1987; Volume 2, pp. 225–235. [Google Scholar]

- Jung, H.; Park, S.; Kim, S.; Park, C. Performance of SIFCON based HPFRCC under Field Blast Load. Procedia Eng. 2017, 210, 401–408. [Google Scholar] [CrossRef]

- Choi, H.-K.; Bae, B.-I.; Choi, C.-S. Mechanical Characteristics of Ultra High Strength Concrete with Steel Fiber Under Uniaxial Compressive Stress. J. Korea Concr. Inst. 2015, 27, 521–530. [Google Scholar] [CrossRef]

- Gopalaratnam, V.S.; Shah, S. Failure mechanism and fracture of fibre reinforced concrete. J. Am. Concr. Inst. 1987, 105, 1–26. [Google Scholar]

- Propovics, S. A Numerical Approach to the Complete Stress-Strain Curve of Concrete. Cement Concr. Res. 1973, 3, 583–599. [Google Scholar] [CrossRef]

- Sargin, M. Stress-Strain Relationship for Concrete and the Analysis of Structural Concrete Sections; University of Waterloo: Waterloo, ON, Canada, 1971; p. 167. [Google Scholar]

- Carreira, D.J.; Chu, K.D. Stress-Strain Relationship for Plain Concrete in Compression. ACI J. 1985, 82, 797–804. [Google Scholar]

- Collins, M.P.; Mitchell, D.; Macgregor, J.G. Structural Design Considerations for High-Strength Concrete. Concr. Int. Des. Const. 1993, 15, 27–34. [Google Scholar]

- Wee, T.H.; Chin, M.S.; Mansur, M.A. Stress-Strain Relationship of High-Strength Concrete in Compression. J. Mater. Civ. Eng. 1996, 8, 70–76. [Google Scholar] [CrossRef]

- Wang, P.T.; Shah, S.P.; Naaman, A.E. Stress-Strain Curves of Normal and Lightweight Concrete in Compression. ACI J. Proc. 1978, 75, 603–611. [Google Scholar]

- Attard, M.M.; Setunge, S. Stress-strain relationship of confined and unconfined concrete. ACI Mater. J. 1996, 93, 432–442. [Google Scholar]

- Graybeal, B.A. Compressive Behavior of Ultra-High-Performance Fiber-Reinforced Concrete. ACI Mater. J. 2007, 104, 146–152. [Google Scholar]

- Gilani, A.M. Various Durability Aspect of Slurry Infiltrated Fiber Concrete. Ph.D. Thesis, Middle East Technical University, Ankara, Turkey, 7 September 2007. [Google Scholar]

- Romualdi, J.P.; Batson, G.B. Mechanics of crack arrest in concrete. J. Eng. Mech. 1963, 89, 147–168. [Google Scholar]

- Romualdi, J.P.; Mandel, J.A. Tensile strength of concrete affected by uniformly distributed and closely space short length of wire reinforcement. ACI J. 1964, 61, 657–672. [Google Scholar]

- Snyder, M.L.; Landkard, D.R. Factors affecting the strength of steel fibrous concrete. ACI J. Proc. 1972, 69, 96–100. [Google Scholar]

- American Society for Testing and Materials (ASTM). Standard Specification for Portland Cement; ASTM C150/C150M-19a; ASTM: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Kim, S.; Jung, H.; Kim, Y.; Park, C. Effect of steel fiber volume fraction and aspect ratio type on the mechanical properties of SIFCON-based HPFRCC. Struct. Eng. Mech. 2018, 65, 163–171. [Google Scholar]

- Kim, S.W.; Cho, H.M.; Lee, H.Y.; Park, C.W. Flexural Performance Characteristics of High Performance Slurry Infiltrated Fiber Reinforced Cementitious Composite according to Fiber Volume Fraction. J. Korea Inst. Struct. Maint. Insp. 2015, 19, 109–115. [Google Scholar]

- Kim, S.W.; Park, C.W.; Kim, S.W.; Cho, H.M.; Jeon, S.P.; Ju, M.K. Optimum Mix Proportions of In-fill Slurry for High Performance Steel Fiber Reinforced Cementitious Composite. J. Korean Rec. Conct. Resources Inst. 2014, 2, 196–201. [Google Scholar]

- Kim, S.; Kim, Y.; Kim, S.W.; Kim, Y.J.; Park, C. Strengthening Effect of Externally Reinforced RC Structure with SIFRCC on Impact Load. In Proceedings of the ICPS5, Poznan, Poland, 19–23 August 2018; pp. 522–528. [Google Scholar]

- American Society for Testing and Materials (ASTM). Standard Test Method for Compressive Strength of Concrete Cylinders Cast in Place in Cylindrical Molds; ASTM C873/C873M-15; ASTM: West Conshohocken, PA, USA, 2015. [Google Scholar]

- American Society for Testing and Materials (ASTM). Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression; ASTM C469/C469M-14; ASTM: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Shah, S.P.; Rangan, B.V. Fiber Reinforced Concrete Properties. Am. Concr. Inst. J. Proc. 1971, 68, 126–137. [Google Scholar]

- Korea Concrete Institute (KCI). Concrete Design Code and Commentary; Kimoondang Publishing Company: Seoul, Korea, 2012. [Google Scholar]

- ACI Committee; International Organization for Standardization. Building Code Requirements for Structural Concrete (ACI 318-11) and Commentary; American Concrete Institute: Farmington Hills, MI, USA, 2008. [Google Scholar]

| Physical Properties | |||||

|---|---|---|---|---|---|

| Specific Gravity | Blaine (cm2/g) | Stability (%) | Setting Time (min) | Loss on Ignition (%) | |

| Initial | Final | ||||

| 3.15 | 3400 | 0.10 | 230 | 410 | 2.58 |

| Chemical Composition (%, mass) | |||||

| SiO2 | CaO | MgO | SO3 | Al2O3 | |

| 21.95 | 60.12 | 3.32 | 2.11 | 6.59 | |

| Physical Properties | ||||

| Specific Gravity | Blaine (cm2/g) | |||

| 2.10 | 200,000 | |||

| Chemical Composition (%, mass) | ||||

| SiO2 | CaO | MgO | SO3 | Al2O3 |

| 96.00 | 0.38 | 0.10 | - | 0.25 |

| Principal Component | Specific Gravity | pH | Alkali Content (%) | Chloride Content (%) |

|---|---|---|---|---|

| Polycarboxylate | 1.05 ± 0.05 | 5.0 ± 1.5 | <0.01 | <0.01 |

| Fiber (% vol.) | W/B (Water-Binder Ratio) | Unit Material Quantity (kg/m3) | |||||

|---|---|---|---|---|---|---|---|

| Water | Cement | Fine Aggregate | Silica Fume | Superplasticizer | Steel Fiber | ||

| 4% | 0.35 | 407.4 | 962.8 | 566.4 | 169.9 | 28.3 | 312 |

| 5% | 390 | ||||||

| 6% | 468 | ||||||

| Variables () | (MPa) | (MPa) | (×10−6) | |

|---|---|---|---|---|

| 4% | 69.9 | 28,430 | 5.74 | 0.289 |

| 70.6 | 25,098 | 16.08 | 0.233 | |

| 62.8 | 31,826 | 5.86 | 0.333 | |

| 64.0 | 27,667 | 7.40 | 0.336 | |

| 60.2 | 24,493 | 6.67 | 0.239 | |

| Average | 65.5 | 27,503 | 8.37 | 0.286 |

| 5% | 73.7 | 29,853 | 8.16 | 0.360 |

| 68.5 | 26,548 | 11.52 | 0.231 | |

| 79.5 | 26,617 | 21.36 | 0.343 | |

| 75.4 | 24,804 | 3.84 | 0.305 | |

| 75.4 | 28,481 | 29.16 | 0.358 | |

| Average | 74.5 | 27,261 | 14.81 | 0.319 |

| 6% | 88.0 | 28,551 | 18.18 | 0.237 |

| 78.0 | 26,967 | 15.02 | 0.253 | |

| 86.4 | 24,886 | 27.38 | 0.267 | |

| 85.9 | 32,182 | 38.02 | 0.373 | |

| 76.3 | 29,071 | 13.20 | 0.367 | |

| Average | 82.9 | 28,331 | 22.36 | 0.300 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; Han, S.; Park, C.; Yun, K.-K. Compressive Behavior Characteristics of High-Performance Slurry-Infiltrated Fiber-Reinforced Cementitious Composites (SIFRCCs) under Uniaxial Compressive Stress. Materials 2020, 13, 159. https://doi.org/10.3390/ma13010159

Kim S, Han S, Park C, Yun K-K. Compressive Behavior Characteristics of High-Performance Slurry-Infiltrated Fiber-Reinforced Cementitious Composites (SIFRCCs) under Uniaxial Compressive Stress. Materials. 2020; 13(1):159. https://doi.org/10.3390/ma13010159

Chicago/Turabian StyleKim, Seungwon, Seungyeon Han, Cheolwoo Park, and Kyong-Ku Yun. 2020. "Compressive Behavior Characteristics of High-Performance Slurry-Infiltrated Fiber-Reinforced Cementitious Composites (SIFRCCs) under Uniaxial Compressive Stress" Materials 13, no. 1: 159. https://doi.org/10.3390/ma13010159

APA StyleKim, S., Han, S., Park, C., & Yun, K.-K. (2020). Compressive Behavior Characteristics of High-Performance Slurry-Infiltrated Fiber-Reinforced Cementitious Composites (SIFRCCs) under Uniaxial Compressive Stress. Materials, 13(1), 159. https://doi.org/10.3390/ma13010159