In-Situ Observation of Fracture Behavior of Ti-Aluminide Multi-Layered Composites Produced by a Hybrid Sintering Process

Abstract

1. Introduction

2. Materials and Methods

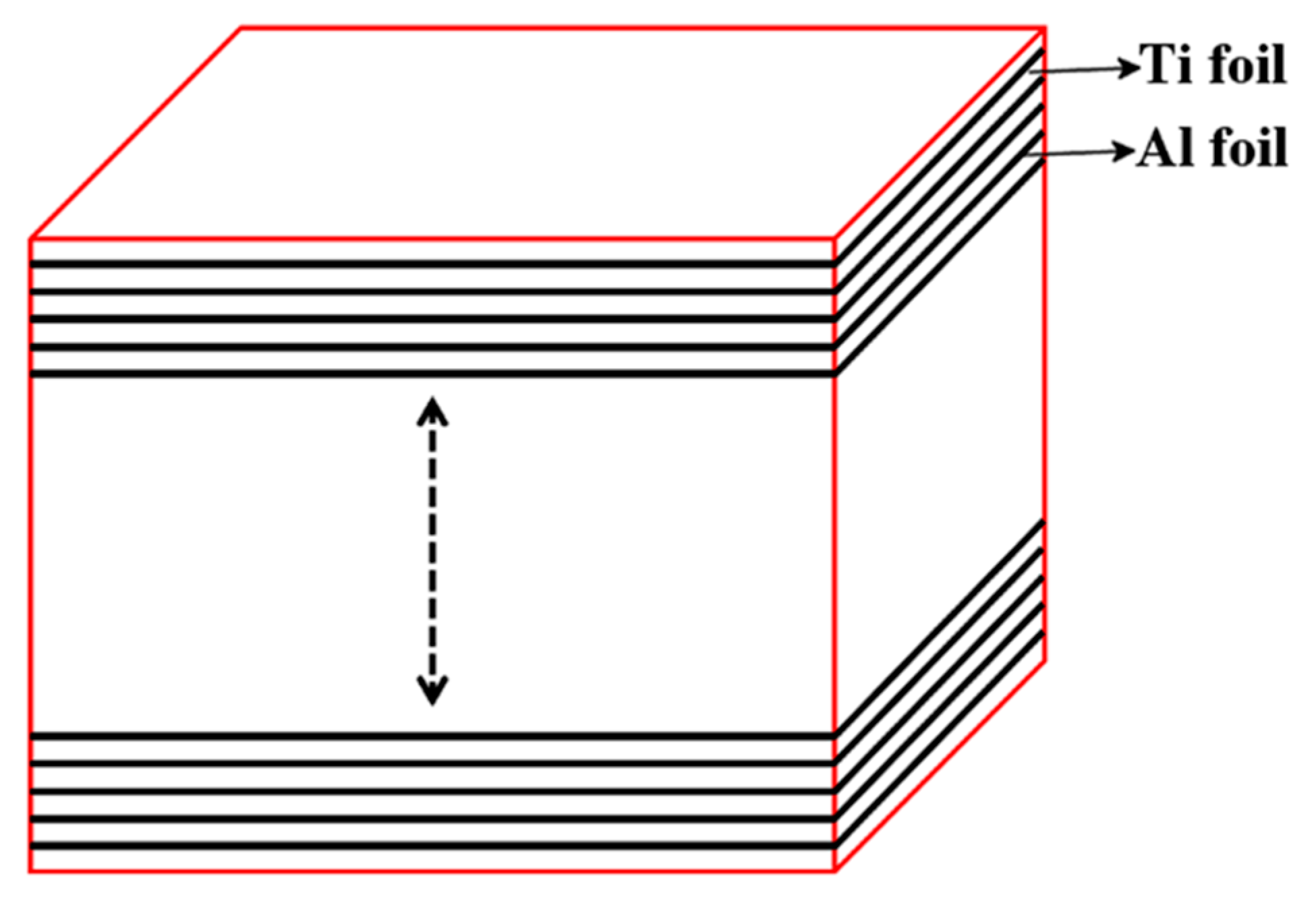

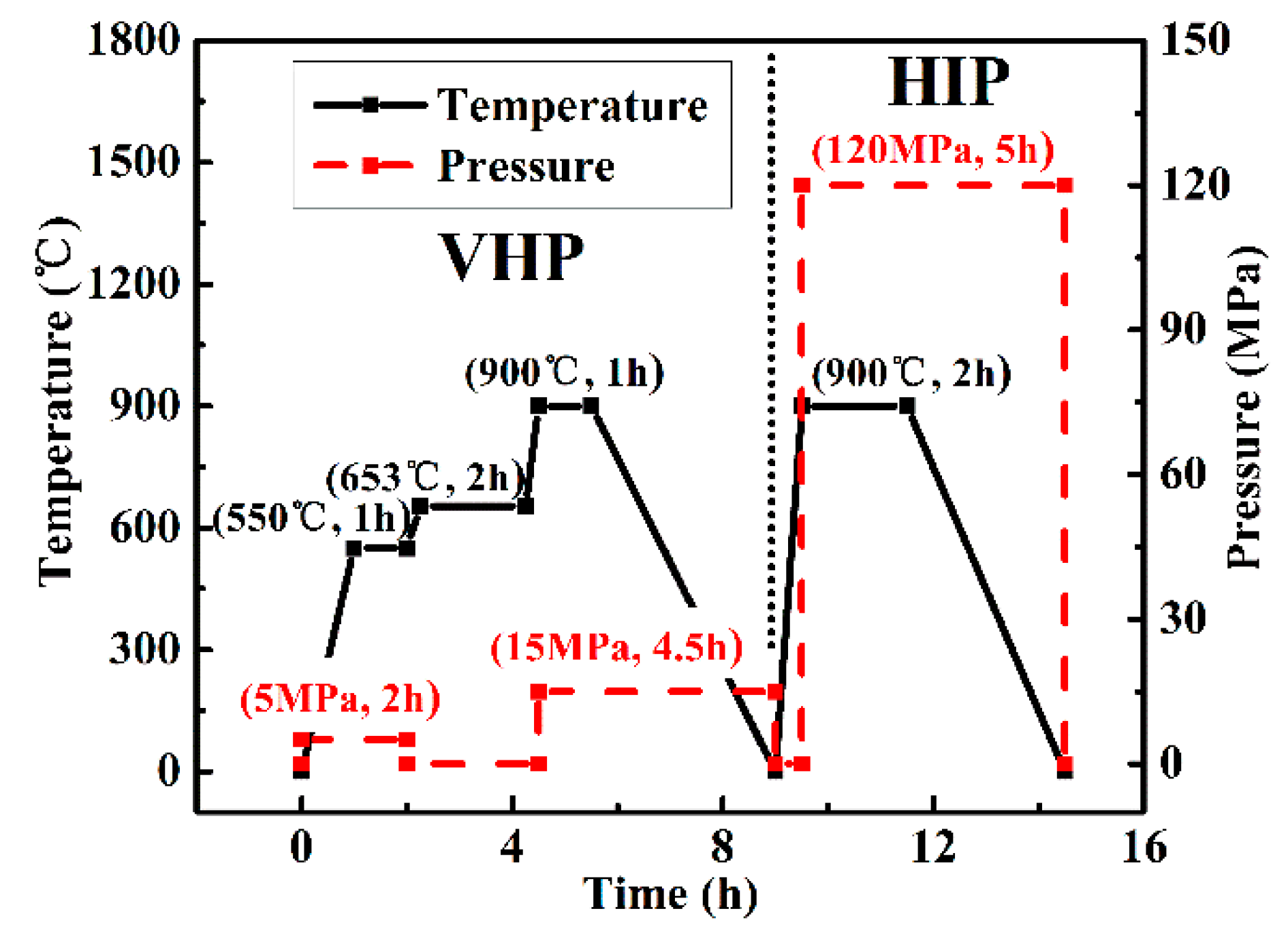

2.1. Materials and Specimens Preparation

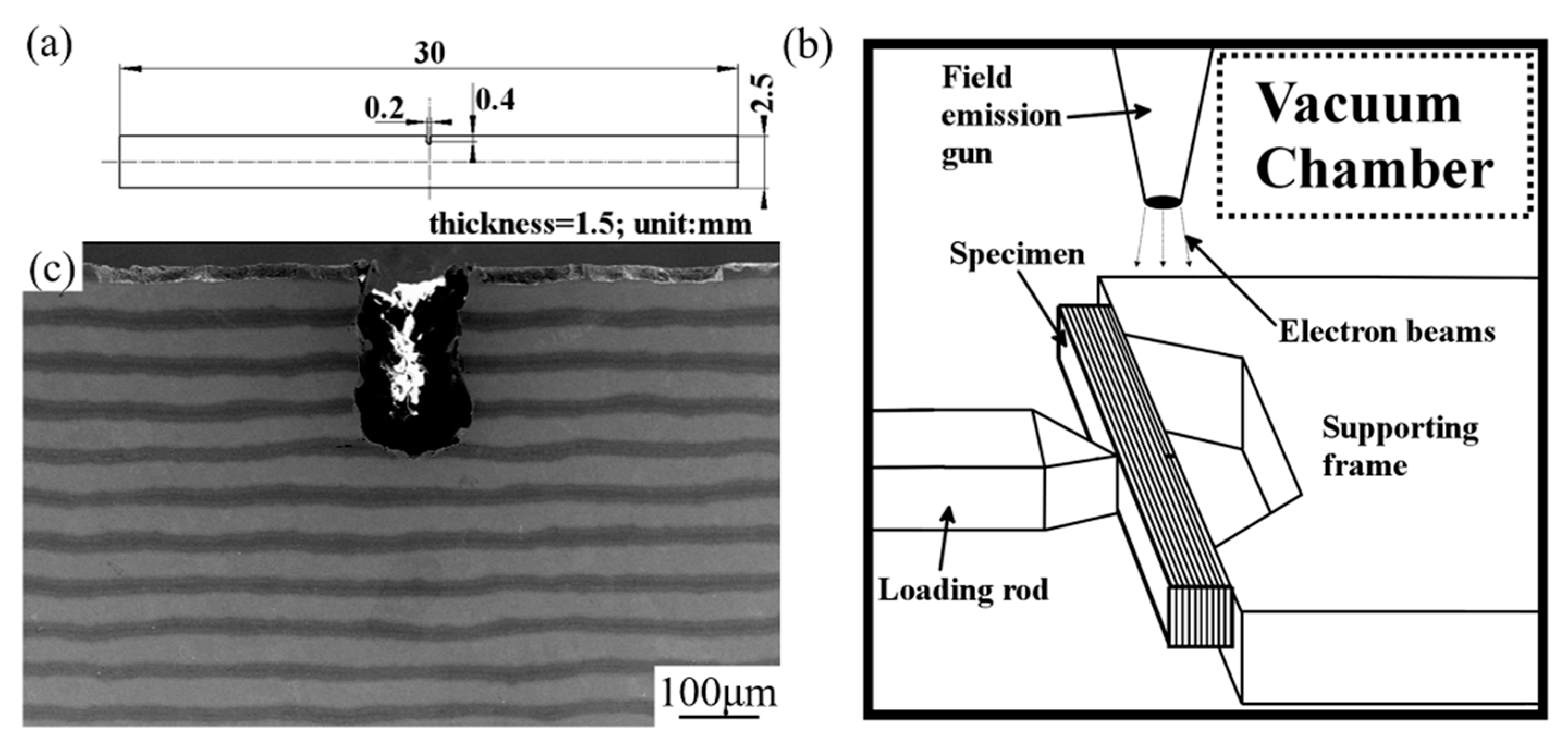

2.2. In-Situ Three-Point Bending Test

3. Results and Discussion

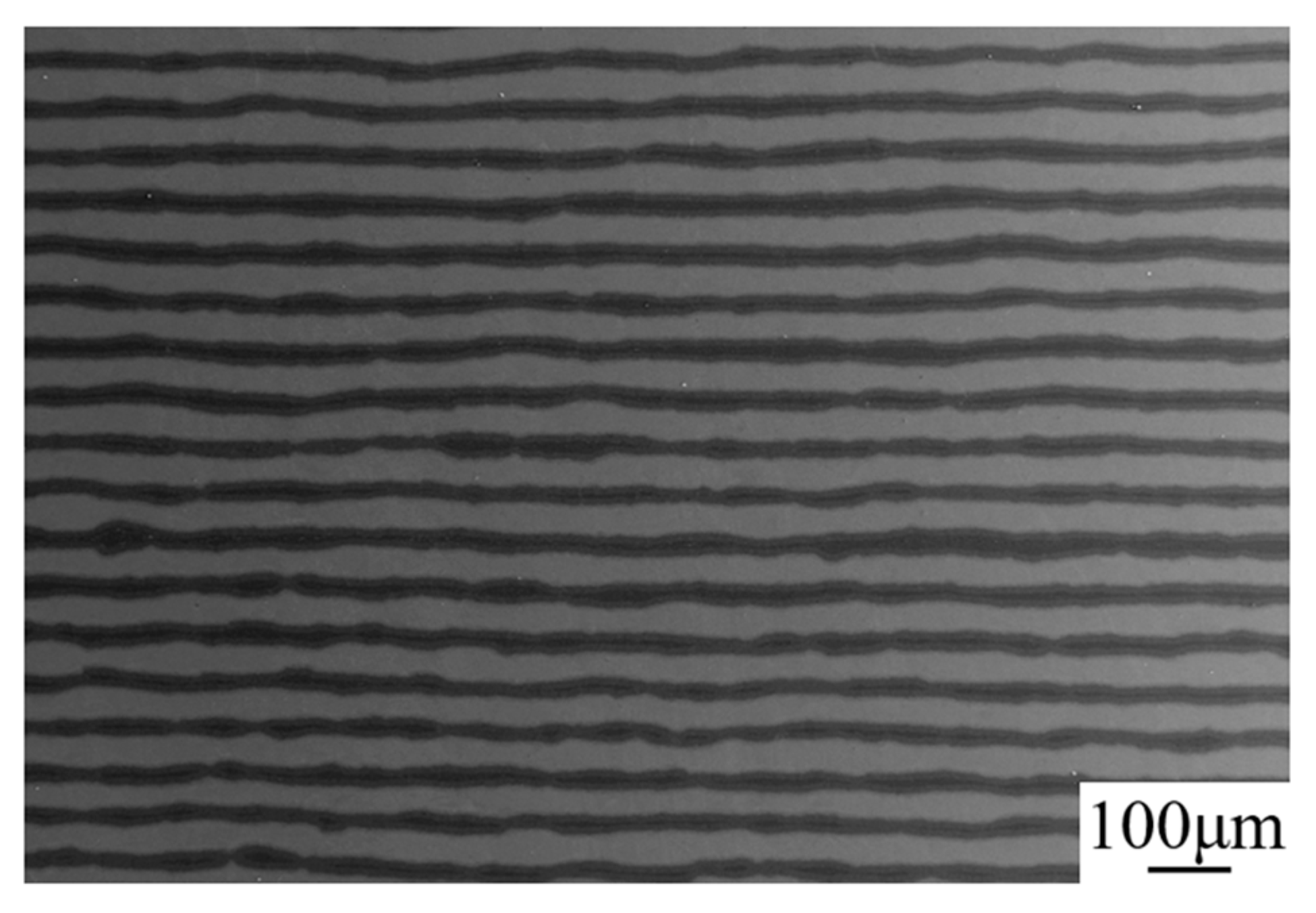

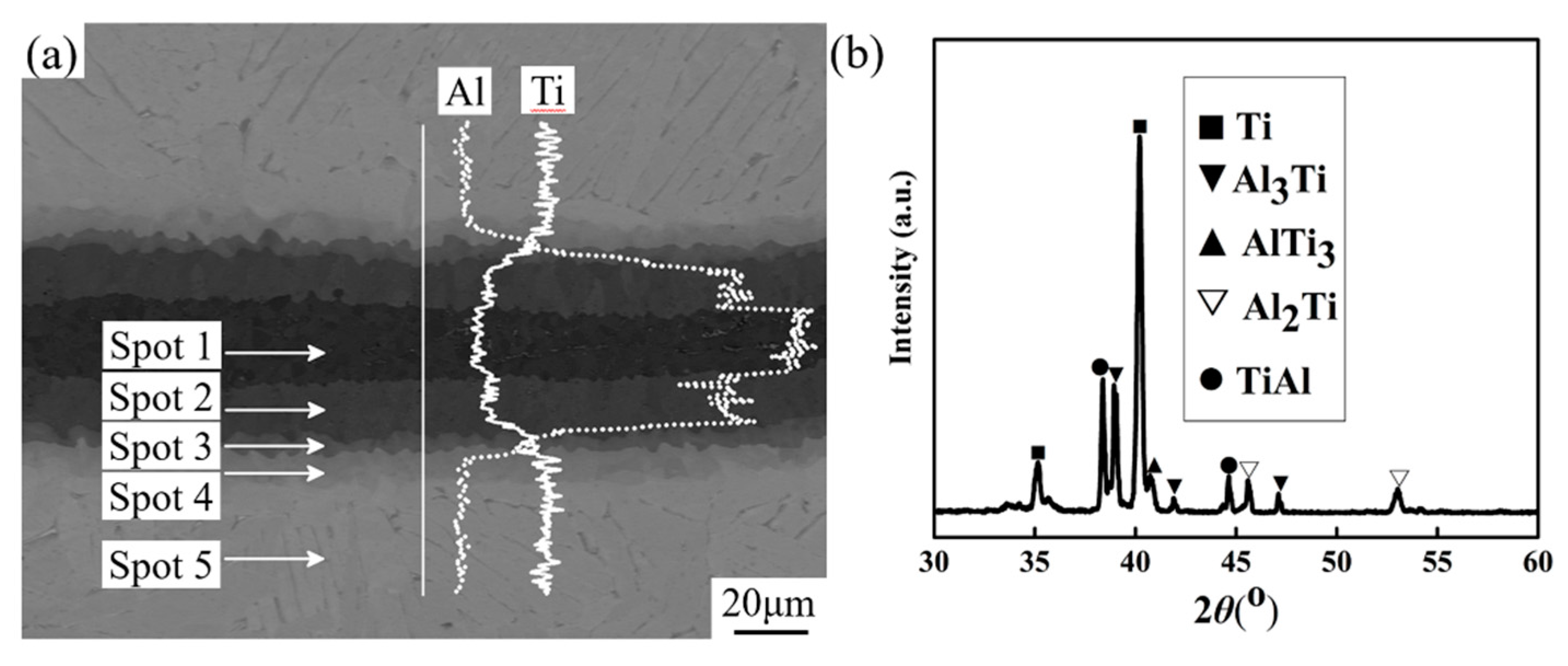

3.1. Microstructure Observation And Phase Identification

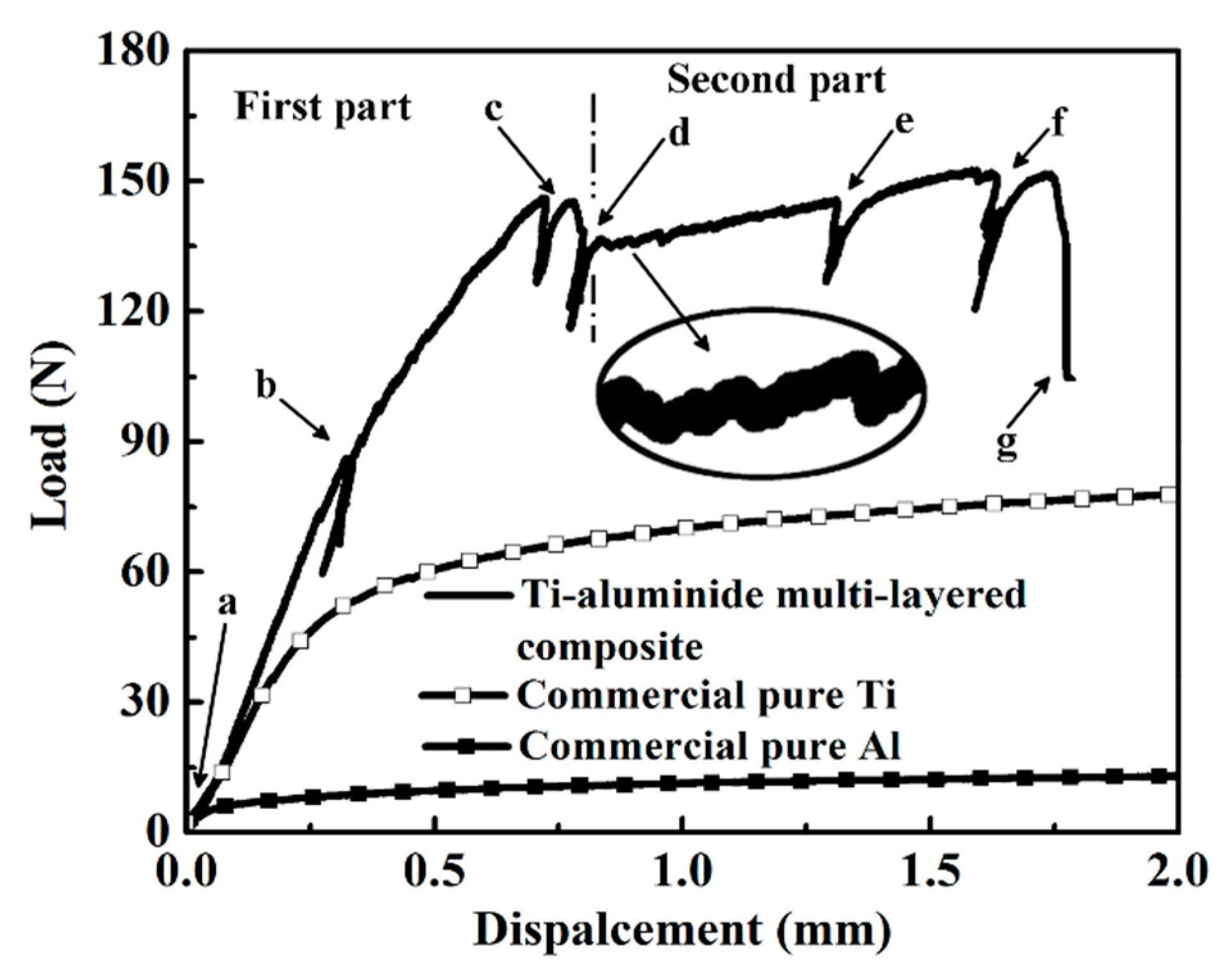

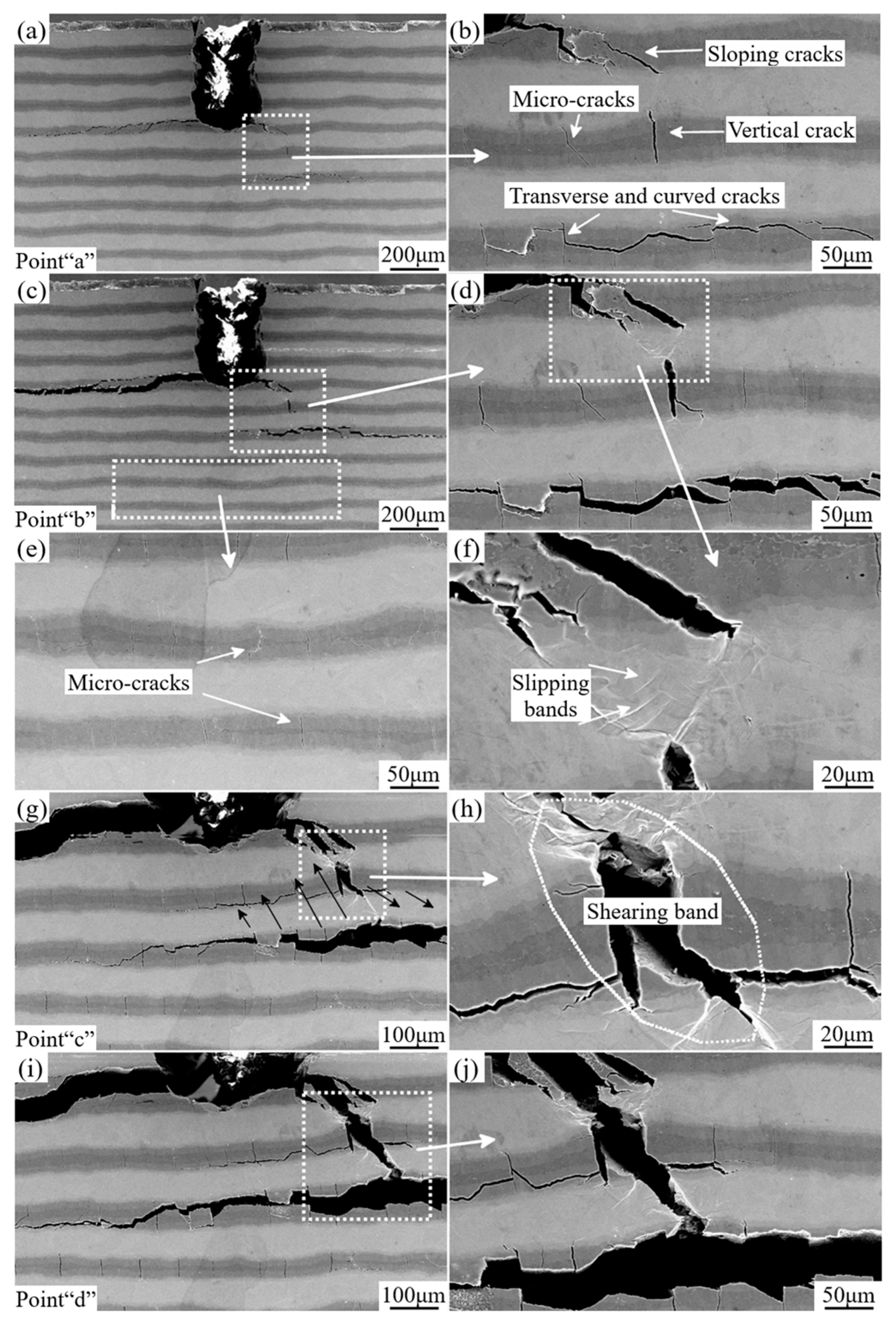

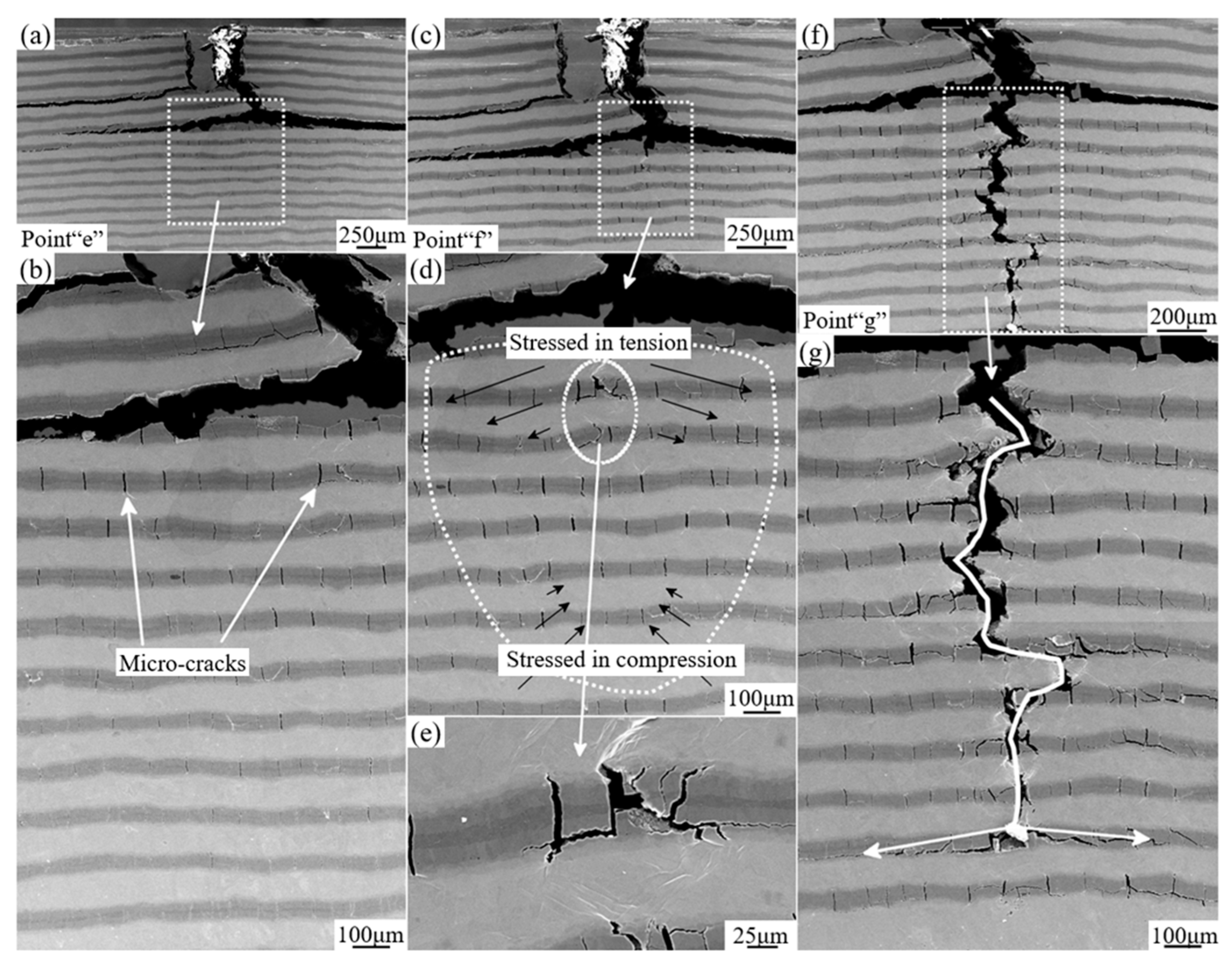

3.2. In-Situ Three-Point Bending Test Observation and Detailed Fracture Behavior

4. Conclusions

- (1)

- The Ti-aluminide multi-layered composites were successfully fabricated from sintering an assembly comprising alternatively stacked pure Ti and pure Al foils by a hybrid procedure composed of Vacuum Hot Pressing (VHP) and Hot Isostatic Pressing (HIP).

- (2)

- Microstructural observations indicated that all the pure Al foils were totally consumed to form a series of the Ti-Al compounds through the diffusive reaction between the adjacent Ti and Al foils, and none of the defects such as pores or voids were detected within the sample.

- (3)

- The failure mechanism and crack propagation behavior of Ti-aluminide multi-layered composites were carefully observed by in-situ three-point bending test on the notched sample. Furthermore, the observation indicated that the cracks mainly initiate and propagate along the intermetallic layers. Moreover, residual Ti layers also play an important role to blunt and bridge the cracks by their plastic deformation at the tip of those cracks to arrest the cracks propagation and enhance the toughness of this composite.

Author Contributions

Funding

Conflicts of Interest

References

- Munch, E.; Launey, M.E.; Alsem, D.H.; Saiz, E.; Tomsia, A.P.; Ritchie, R.O. Tough, Bio-Inspired Hybrid Materials. Science 2008, 322, 1516–1520. [Google Scholar] [CrossRef]

- Ritchie, R.O. The conflicts between strength and toughness. Nat. Mater. 2011, 10, 817–822. [Google Scholar] [CrossRef]

- Wegst, U.G.K.; Bai, H.; Saiz, E.; Tomsia, A.P.; Ritchie, R.O. Bioinspired structural materials. Nat. Mater. 2015, 14, 23–36. [Google Scholar] [CrossRef]

- Lu, K. Materials science. The future of metals. Science 2010, 328, 319–320. [Google Scholar] [CrossRef]

- Meyers, M.A.; Mishra, A.; Benson, D.J. Mechanical properties of nanocrystalline materials. Prog. Mater Sci. 2006, 51, 427–556. [Google Scholar] [CrossRef]

- Lu, K.; Lu, L.; Suresh, S. Strengthening Materials by Engineering Coherent Internal Boundaries at the Nanoscale. Science 2009, 324, 349–352. [Google Scholar] [CrossRef]

- Chen, P.Y.; McKittrick, J.; Meyers, M.A. Biological materials: Functional adaptations and bioinspired designs. Prog. Mater Sci. 2012, 57, 1492–1704. [Google Scholar] [CrossRef]

- Li, X.D.; Chang, W.C.; Chao, Y.J.; Wang, R.Z.; Chang, M. Nanoscale structural and mechanical characterization of a natural nanocomposite material: The shell of red abalone. Nano Lett. 2004, 4, 613–617. [Google Scholar] [CrossRef]

- Mayer, G. Rigid biological systems as models for synthetic composites. Science 2005, 310, 1144–1147. [Google Scholar] [CrossRef]

- Srivastava, V.C.; Singh, T.; Chowdhury, S.G.; Jindal, V. Microstructural Characteristics of Accumulative Roll-Bonded Ni-Al-Based Metal-Intermetallic Laminate Composite. J. Mater. Eng. Perform. 2012, 21, 1912–1918. [Google Scholar] [CrossRef]

- Zhang, B.; Kou, Y.; Xia, Y.Y.; Zhang, X. Modulation of strength and plasticity of multiscale Ni/Cu laminated composites. Mater. Sci. Eng. A 2015, 636, 216–220. [Google Scholar] [CrossRef]

- Alman, D.E.; Rawers, J.C.; Hawk, J.A. Microstructural and Failure Characteristics of Metal-Intermetallic Layered Sheet Composites. Metall. Mater. Trans. A 1995, 26, 589–599. [Google Scholar] [CrossRef]

- Rawers, J.C.; Maupin, H.E. Metal Intermetallic Composites Formed by Reaction-Sintering Metal Foils. J. Mater. Sci. Lett. 1993, 12, 637–639. [Google Scholar] [CrossRef]

- Price, R.D.; Jiang, F.C.; Kulin, R.M.; Vecchio, K.S. Effects of ductile phase volume fraction on the mechanical properties of Ti-Al3Ti metal-intermetallic laminate (MIL) composites. Mater. Sci. Eng. A 2011, 528, 3134–3146. [Google Scholar] [CrossRef]

- Guo, Y.J.; Qiao, G.J.; Jian, W.Z.; Zhi, X.H. Microstructure and tensile behavior of Cu-Al multi-layered composites prepared by plasma activated sintering. Mater. Sci. Eng. A 2010, 527, 5234–5240. [Google Scholar] [CrossRef]

- Fei, Y.; Ai, T.; Niu, Q.; Li, W.; Yuan, X.; Jing, R.; Dong, H. The Flexural Strength and Fracture Toughness of TC4-Based Laminated Composites Reinforced with Ti Aluminide and Carbide. Materials 2017, 10, 1175. [Google Scholar] [CrossRef]

- Lu, Z.C.; Wei, N.X.; Li, P.; Guo, C.H.; Jiang, F.C. Microstructure and mechanical properties of intermetallic Al3Ti alloy with residual aluminum. Mater. Des. 2016, 110, 466–474. [Google Scholar] [CrossRef]

- Lyu, S.Y.; Sun, Y.B.; Li, G.D.; Xiao, W.L.; Ma, C.L. Effect of layer sequence on the mechanical properties of Ti/TiAl laminates. Mater. Des. 2018, 143, 160–168. [Google Scholar] [CrossRef]

- Sun, Y.B.; Zhao, Y.Q.; Zhang, D.; Liu, C.Y.; Diao, H.Y.; Ma, C.L. Multilayered Ti-Al intermetallic sheets fabricated by cold rolling and annealing of titanium and aluminum foils. Trans. Nonferrous Met. Soc. China 2011, 21, 1722–1727. [Google Scholar] [CrossRef]

- Zhang, X.; Yu, Y.; Liu, B.; Zhao, Y.; Ren, J.; Yan, Y.; Cao, R.; Chen, J. In-Situ investigation of deformation behavior and fracture mechanism of laminated Al/Ti composites fabricated by hot rolling. J. Alloys Compd. 2019, 783, 55–65. [Google Scholar] [CrossRef]

- Yu, W.B.; Zhu, K.; Aman, Y.; Guo, Z.P.; Xiong, S.M. Bio-inspired design of SiCf-reinforced multi-layered Ti-intermetallic composite. Mater. Des. 2016, 101, 102–108. [Google Scholar] [CrossRef]

- Zhu, K.; Yu, W.B.; Aman, Y.; Jing, T. Synthesis, microstructure and mechanical properties of a bio-inspired Ti-intermetallic multi-layered/SiCf-reinforced Ti-matrix hybrid composite. J. Mater. Sci. 2016, 51, 8747–8760. [Google Scholar] [CrossRef]

- Rohatgi, A.; Harach, D.J.; Vecchio, K.S.; Harvey, K.P. Resistance-curve and fracture behavior of Ti-Al3Ti metallic-intermetallic laminate (MIL) composites. Acta Mater. 2003, 51, 2933–2957. [Google Scholar] [CrossRef]

- Sun, Y.B.; Chen, J.; Ma, F.M.; Ameyama, K.; Xiao, W.L.; Ma, C.L. Tensile and flexural properties of multilayered metal/intermetallics composites. Mater. Charact. 2015, 102, 165–172. [Google Scholar] [CrossRef]

- Han, B.-S.; Xu, Y.-J.; Guo, E.-Y.; Jing, T.; Hou, H.-L.; Luo, L.-S. Microstructure and Mechanical Properties of Tortoise Carapace Structure Bio-Inspired Hybrid Composite. Acta Metall. Sinica 2018, 31, 945–952. [Google Scholar] [CrossRef]

- Kattner, U.R.; Lin, J.C.; Chang, Y.A. Thermodynamic Assessment and Calculation of the Ti-Al System. Metall. Mater. Trans. A 1992, 23, 2081–2090. [Google Scholar] [CrossRef]

- Van Loo, F.; Rieck, G. Diffusion in the titanium-aluminium system—I. Interdiffusion between solid Al and Ti or Ti-Al alloys. Acta Metall. 1973, 21, 61–71. [Google Scholar] [CrossRef]

- Mishin, Y.; Herzig, C. Diffusion in the Ti-Al system. Acta Mater. 2000, 48, 589–623. [Google Scholar] [CrossRef]

- Adharapurapu, R.R.; Vecchio, K.S.; Jiang, F.C.; Rohatgi, A. Effects of ductile laminate thickness, volume fraction, and orientation on fatigue-crack propagation in Ti-Al3Ti metal-intermetallic laminate composites. Metall. Mater. Trans. A 2005, 36, 1595–1608. [Google Scholar] [CrossRef]

- Zhu, K.; Xu, Y.J.; Jing, T.; Hou, H.L. Fracture behavior of a composite composed by Ti-aluminide multi-layered and continuous-SiCf-reinforced Ti-matrix. Rare Met. 2017, 36, 925–933. [Google Scholar] [CrossRef]

- Li, T.; Jiang, F.; Olevsky, E.A.; Vecchio, K.S.; Meyers, M.A. Damage evolution in Ti6Al4V–Al3Ti metal-intermetallic laminate composites. Mater. Sci. Eng. A 2007, 443, 1–15. [Google Scholar] [CrossRef]

- Lyu, S.Y.; Sun, Y.B.; Ren, L.; Xiao, W.L.; Ma, C.L. Simultaneously achieving high tensile strength and fracture toughness of Ti/Ti-Al multilayered composites. Intermetallics 2017, 90, 16–22. [Google Scholar] [CrossRef]

- Rawers, J.; Perry, K. Crack initiation in laminated metal-intermetallic composites. J. Mater. Sci. 1996, 31, 3501–3506. [Google Scholar] [CrossRef]

- Peng, L.M.; Li, H.; Wang, J.H. Processing and mechanical behavior of laminated titanium-titanium tri-aluminide (Ti–Al3Ti) composites. Mater. Sci. Eng. A 2005, 406, 309–318. [Google Scholar] [CrossRef]

- Rawers, J.C.; Alman, D.E. Fracture characteristics of metalintermetallic laminar composites produced by reaction sintering and hot pressing. Compos. Sci. Technol. 1995, 54, 379–384. [Google Scholar] [CrossRef]

- Adharapurapu, R.R.; Vecchio, K.S.; Rohatgi, A.; Jiang, F.C. Fracture of Ti-Al3Ti metal-intermetallic laminate composites: Effects of lamination on resistance-curve behavior. Metall. Mater. Trans. A 2005, 36, 3217–3236. [Google Scholar] [CrossRef]

| Element | Spot 1 (at. %) | Spot 2 (at. %) | Spot 3 (at. %) | Spot 4 (at. %) | Spot 5 (at. %) |

|---|---|---|---|---|---|

| Ti | 24.77 | 32.89 | 48.72 | 74.59 | 96.33 |

| Al | 75.23 | 67.11 | 51.28 | 25.41 | 3.67 |

| Phase | Al3Ti | Al2Ti | TiAl | Ti3Al | Ti |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wan, X.; Zhu, K.; Xu, Y.; Han, B.; Jing, T. In-Situ Observation of Fracture Behavior of Ti-Aluminide Multi-Layered Composites Produced by a Hybrid Sintering Process. Materials 2019, 12, 1568. https://doi.org/10.3390/ma12091568

Wan X, Zhu K, Xu Y, Han B, Jing T. In-Situ Observation of Fracture Behavior of Ti-Aluminide Multi-Layered Composites Produced by a Hybrid Sintering Process. Materials. 2019; 12(9):1568. https://doi.org/10.3390/ma12091568

Chicago/Turabian StyleWan, Xiong, Kai Zhu, Yanjin Xu, Baoshuai Han, and Tao Jing. 2019. "In-Situ Observation of Fracture Behavior of Ti-Aluminide Multi-Layered Composites Produced by a Hybrid Sintering Process" Materials 12, no. 9: 1568. https://doi.org/10.3390/ma12091568

APA StyleWan, X., Zhu, K., Xu, Y., Han, B., & Jing, T. (2019). In-Situ Observation of Fracture Behavior of Ti-Aluminide Multi-Layered Composites Produced by a Hybrid Sintering Process. Materials, 12(9), 1568. https://doi.org/10.3390/ma12091568