FEP Encapsulated Crack-Based Sensor for Measurement in Moisture-Laden Environment

Abstract

1. Introduction

2. Experimental Section

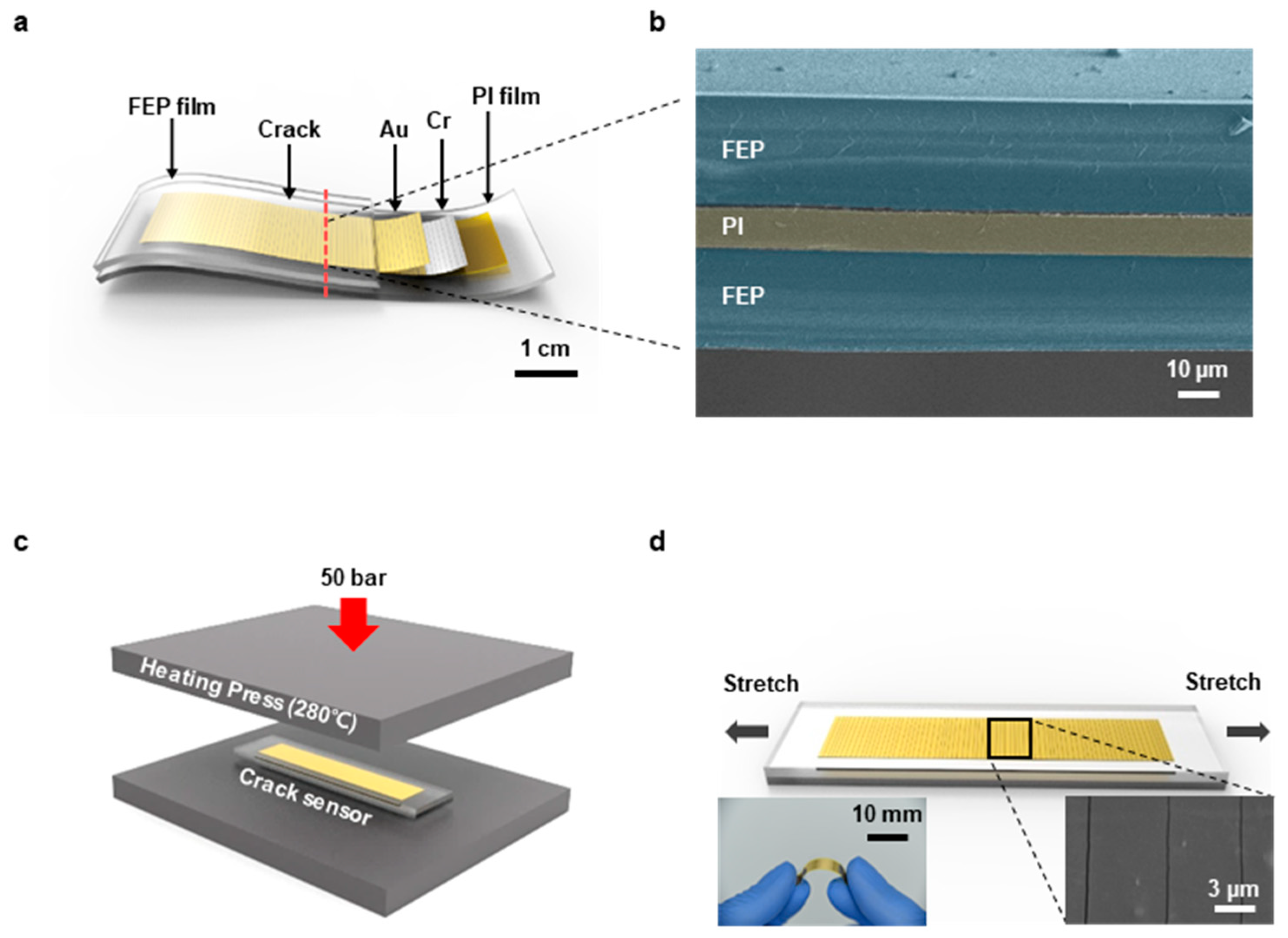

2.1. The Configuration and Fabrication of an FEP Encapsulated Crack-Based Sensor

2.2. Method and Test

3. Results and Discussion

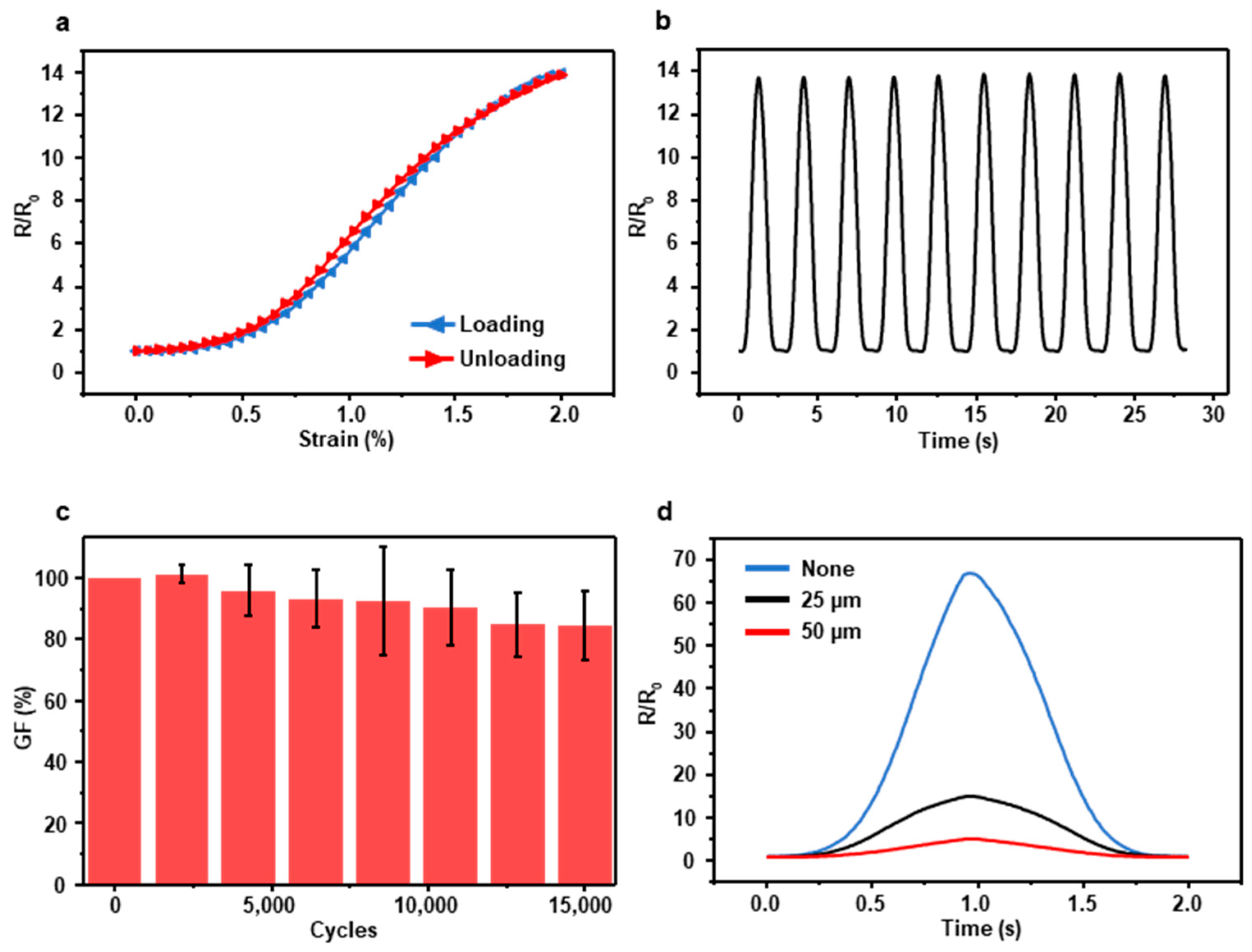

3.1. Basic Electrical Characteristics of FEP-Encapsulated Sensor

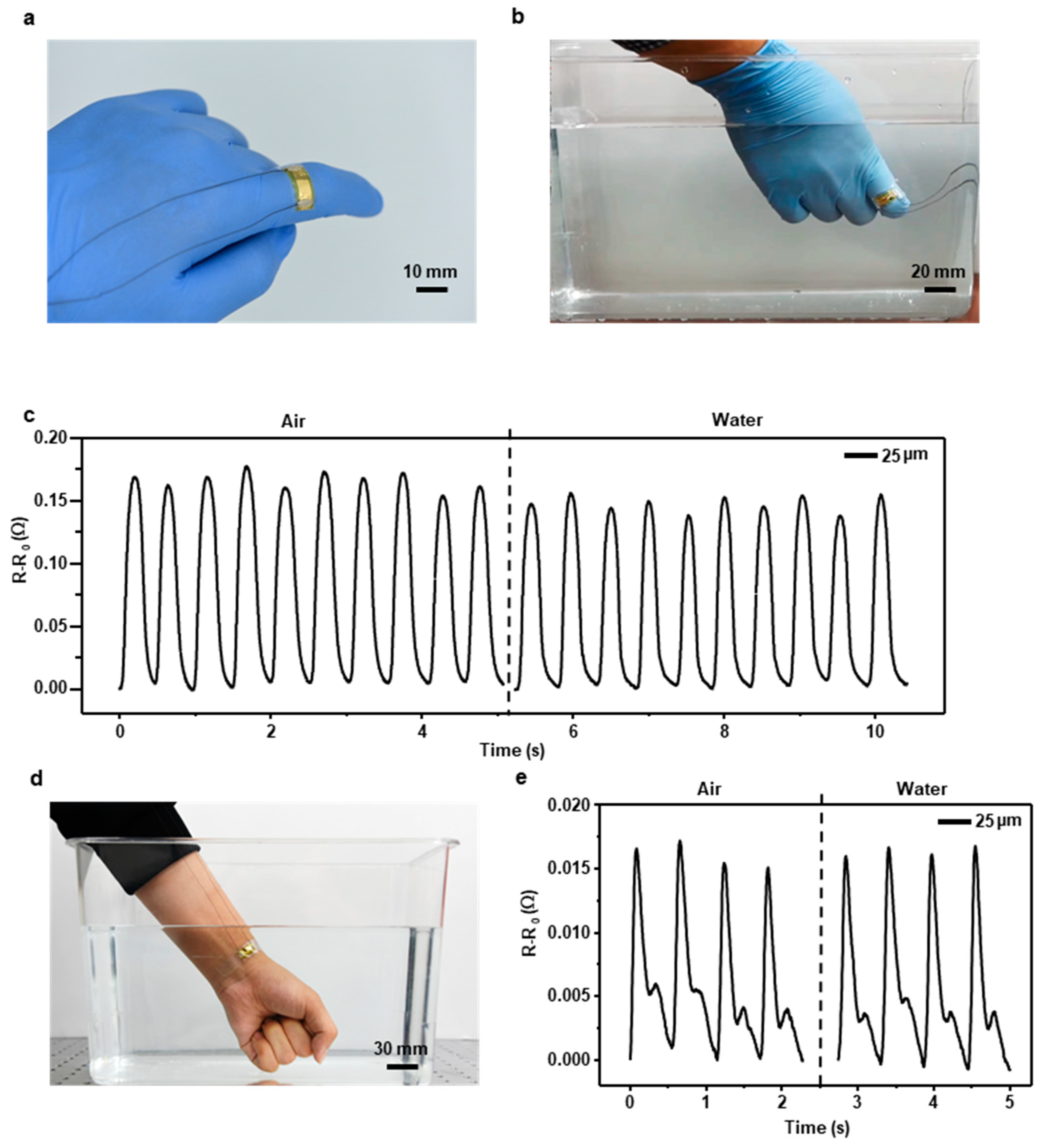

3.2. Water Permeability and Chemical Resistance of the FEP-Encapsulated Sensor

3.3. Underwater Motion Test

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Khan, H.; Razmjou, A.; Ebrahimi Warkiani, M.; Kottapalli, A.; Asadnia, M. Sensitive and Flexible Polymeric Strain Sensor for Accurate Human Motion Monitoring. Sensors 2018, 18, 418. [Google Scholar] [CrossRef] [PubMed]

- Kong, J.-H.; Jang, N.-S.; Kim, S.-H.; Kim, J.-M. Simple and rapid micropatterning of conductive carbon composites and its application to elastic strain sensors. Carbon 2014, 77, 199–207. [Google Scholar] [CrossRef]

- Slobodian, P.; Riha, P.; Benlikaya, R.; Svoboda, P.; Petras, D. A Flexible Multifunctional Sensor Based on Carbon Nanotube/Polyurethane Composite. IEEE Sens. J. 2013, 13, 4045–4048. [Google Scholar] [CrossRef]

- Sun, Q.; Seung, W.; Kim, B.J.; Seo, S.; Kim, S.-W.; Cho, J.H. Active Matrix Electronic Skin Strain Sensor Based on Piezopotential-Powered Graphene Transistors. Adv. Mater. 2015, 27, 3411–3417. [Google Scholar] [CrossRef]

- Wu, J.M.; Chen, C.-Y.; Zhang, Y.; Chen, K.-H.; Yang, Y.; Hu, Y.; He, J.-H.; Wang, Z.L. Ultrahigh Sensitive Piezotronic Strain Sensors Based on a ZnSnO3 Nanowire/Microwire. ACS Nano 2012, 6, 4369–4374. [Google Scholar] [CrossRef]

- Zhou, J.; Gu, Y.; Fei, P.; Mai, W.; Gao, Y.; Yang, R.; Bao, G.; Wang, Z.L. Flexible Piezotronic Strain Sensor. Nano Lett. 2008, 8, 3035–3040. [Google Scholar] [CrossRef]

- Aliane, A.; Fischer, V.; Galliari, M.; Tournon, L.; Gwoziecki, R.; Serbutoviez, C.; Chartier, I.; Coppard, R. Enhanced printed temperature sensors on flexible substrate. Microelectron. J. 2014, 45, 1621–1626. [Google Scholar] [CrossRef]

- Dagdeviren, C.; Shi, Y.; Joe, P.; Ghaffari, R.; Balooch, G.; Usgaonkar, K.; Gur, O.; Tran, P.L.; Crosby, J.R.; Meyer, M.; et al. Conformal piezoelectric systems for clinical and experimental characterization of soft tissue biomechanics. Nat. Mater. 2015, 14, 728. [Google Scholar] [CrossRef]

- Hong, S.; Myung, S. A flexible approach to mobility. Nat. Nanotechnol. 2007, 2, 207. [Google Scholar] [CrossRef] [PubMed]

- Jeon, J.; Lee, H.-B.-R.; Bao, Z. Flexible Wireless Temperature Sensors Based on Ni Microparticle-Filled Binary Polymer Composites. Adv. Mater. 2013, 25, 850–855. [Google Scholar] [CrossRef]

- Kim, D.-H.; Lu, N.; Ma, R.; Kim, Y.-S.; Kim, R.-H.; Wang, S.; Wu, J.; Won, S.M.; Tao, H.; Islam, A.; et al. Epidermal Electronics. Science 2011, 333, 838–843. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.-H.; Wang, S.; Keum, H.; Ghaffari, R.; Kim, Y.-S.; Tao, H.; Panilaitis, B.; Li, M.; Kang, Z.; Omenetto, F.; et al. Thin, Flexible Sensors and Actuators as ‘Instrumented’ Surgical Sutures for Targeted Wound Monitoring and Therapy. Small 2012, 8, 3263–3268. [Google Scholar] [CrossRef]

- Trung, T.Q.; Ramasundaram, S.; Hong, S.W.; Lee, N.-E. Flexible and Transparent Nanocomposite of Reduced Graphene Oxide and P(VDF-TrFE) Copolymer for High Thermal Responsivity in a Field-Effect Transistor. Adv. Funct. Mater. 2014, 24, 3438–3445. [Google Scholar] [CrossRef]

- Xu, S.; Zhang, Y.; Jia, L.; Mathewson, K.E.; Jang, K.-I.; Kim, J.; Fu, H.; Huang, X.; Chava, P.; Wang, R.; et al. Soft Microfluidic Assemblies of Sensors, Circuits, and Radios for the Skin. Science 2014, 344, 70–74. [Google Scholar] [CrossRef] [PubMed]

- Yan, C.; Wang, J.; Lee, P.S. Stretchable Graphene Thermistor with Tunable Thermal Index. ACS Nano 2015, 9, 2130–2137. [Google Scholar] [CrossRef] [PubMed]

- Yao, H.-B.; Ge, J.; Wang, C.-F.; Wang, X.; Hu, W.; Zheng, Z.-J.; Ni, Y.; Yu, S.-H. A Flexible and Highly Pressure-Sensitive Graphene–Polyurethane Sponge Based on Fractured Microstructure Design. Adv. Mater. 2013, 25, 6692–6698. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Zhu, R.; Nguyen, V.; Yang, R. Highly sensitive and flexible strain sensors based on vertical zinc oxide nanowire arrays. Sens. Actuators A Phys. 2014, 205, 164–169. [Google Scholar] [CrossRef]

- Kang, D.; Pikhitsa, P.V.; Choi, Y.W.; Lee, C.; Shin, S.S.; Piao, L.; Park, B.; Suh, K.-Y.; Kim, T.-I.; Choi, M. Ultrasensitive mechanical crack-based sensor inspired by the spider sensory system. Nature 2014, 516, 222. [Google Scholar] [CrossRef] [PubMed]

- Trung, T.Q.; Lee, N.-E. Flexible and Stretchable Physical Sensor Integrated Platforms for Wearable Human-Activity Monitoringand Personal Healthcare. Adv. Mater. 2016, 28, 4338–4372. [Google Scholar] [CrossRef]

- Lee, E.; Kim, T.; Suh, H.; Kim, M.; Pikhitsa, P.V.; Han, S.; Koh, J.-S.; Kang, D. Effect of Metal Thickness on the Sensitivity of Crack-Based Sensors. Sensors 2018, 18, 2872. [Google Scholar] [CrossRef]

- Lee, T.; Choi, Y.W.; Lee, G.; Kim, S.M.; Kang, D.; Choi, M. Crack-based strain sensor with diverse metal films by inserting an inter-layer. RSC Adv. 2017, 7, 34810–34815. [Google Scholar] [CrossRef]

- Lee, T.; Choi, Y.W.; Lee, G.; Pikhitsa, P.V.; Kang, D.; Kim, S.M.; Choi, M. Transparent ITO mechanical crack-based pressure and strain sensor. J. Mater. Chem. C 2016, 4, 9947–9953. [Google Scholar] [CrossRef]

- Park, B.; Kim, J.; Kang, D.; Jeong, C.; Kim, K.S.; Kim, J.U.; Yoo, P.J.; Kim, T.-I. Dramatically Enhanced Mechanosensitivity and Signal-to-Noise Ratio of Nanoscale Crack-Based Sensors: Effect of Crack Depth. Adv. Mater. 2016, 28, 8130–8137. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.; Lee, T.; Lee, G.; Choi, Y.W.; Kim, S.M.; Kang, D.; Choi, M. Polyimide Encapsulation of Spider-Inspired Crack-Based Sensors for Durability Improvement. Appl. Sci. 2018, 8, 367. [Google Scholar] [CrossRef]

- Park, B.; Lee, S.; Choi, H.; Kim, J.U.; Hong, H.; Jeong, C.; Kang, D.; Kim, T.-I. A semi-permanent and durable nanoscale-crack-based sensor by on-demand healing. Nanoscale 2018, 10, 4354–4360. [Google Scholar] [CrossRef] [PubMed]

- Bowman, L.; Meindl, J.D. The Packaging of Implantable Integrated Sensors. IEEE Trans. Biomed. Eng. 1986, 2, 248–255. [Google Scholar] [CrossRef]

- Kim, N.; Potscavage, W.J., Jr.; Domercq, B.; Kippelen, B.; Graham, S. A hybrid encapsulation method for organic electronics. Appl. Phys. Lett. 2009, 94, 163308. [Google Scholar] [CrossRef]

- Kinkeldei, T.; Munzenrieder, N.; Zysset, C.; Cherenack, K.; Tröster, G. Encapsulation for Flexible Electronic Devices. IEEE Electron Device Lett. 2011, 32, 1743–1745. [Google Scholar] [CrossRef]

- Linz, T.; Vieroth, R.; Dils, C.; Koch, M.; Braun, T.; Becker, K.F.; Kallmayer, C.; Hong, S.M. Embroidered Interconnections and Encapsulation for Electronics in Textiles for Wearable Electronics Applications. Adv. Sci. Technol. 2009, 60, 85–94. [Google Scholar] [CrossRef]

- Maydannik, P.S.; Kääriäinen, T.O.; Lahtinen, K.; Cameron, D.C.; Söderlund, M.; Soininen, P.; Johansson, P.; Kuusipalo, J.; Moro, L.; Zeng, X. Roll-to-roll atomic layer deposition process for flexible electronics encapsulation applications. J. Vacuum Sci. Technol. A 2014, 32, 051603. [Google Scholar] [CrossRef]

- Meyer, J.; Görrn, P.; Bertram, F.; Hamwi, S.; Winkler, T.; Johannes, H.-H.; Weimann, T.; Hinze, P.; Riedl, T.; Kowalsky, W. Al2O3/ZrO2 Nanolaminates as Ultrahigh Gas-Diffusion Barriers—A Strategy for Reliable Encapsulation of Organic Electronics. Adv. Mater. 2009, 21, 1845–1849. [Google Scholar] [CrossRef]

- Xie, X.; Rieth, L.; Merugu, S.; Tathireddy, P.; Solzbacher, F. Plasma-assisted atomic layer deposition of Al2O3 and parylene C bi-layer encapsulation for chronic implantable electronics. Appl. Phys. Lett. 2012, 101, 093702. [Google Scholar] [CrossRef] [PubMed]

- Forsythe, J.S.; Hill, D.J.T. The radiation chemistry of fluoropolymers. Prog. Polym. Sci. 2000, 25, 101–136. [Google Scholar] [CrossRef]

- Grover, W.H.; von Muhlen, M.G.; Manalis, S.R. Teflon films for chemically-inert microfluidic valves and pumps. Lab Chip 2008, 8, 913–918. [Google Scholar] [CrossRef]

- Gupta, B.D.; Chapiro, A. Preparation of ion-exchange membranes by grafting acrylic acid into pre-irradiated polymer films—1. Grafting into polyethylene. Eur. Polym. J. 1989, 25, 1137–1143. [Google Scholar] [CrossRef]

- Lahokallio, S.; Saarinen, K.; Frisk, L. Changes in water absorption and modulus of elasticity of flexible printed circuit board materials in high humidity testing. In Proceedings of the 18th European Microelectronics & Packaging Conference, Brighton, UK, 12–15 September 2011; pp. 1–6. [Google Scholar]

- Leivo, E.; Wilenius, T.; Kinos, T.; Vuoristo, P.; Mäntylä, T. Properties of thermally sprayed fluoropolymer PVDF, ECTFE, PFA and FEP coatings. Prog. Organ. Coat. 2004, 49, 69–73. [Google Scholar] [CrossRef]

- Sacher, E.; Susko, J.R. Water permeation of polymer films. II. Dual-mode absorption in teflon FEP. J. Appl. Polym. Sci. 1979, 24, 1997–2003. [Google Scholar] [CrossRef]

- Harris, F.; Wilson, D.; Stenzenberger, H.; Hergenrother, P. Polyimides; Wilson, D., Stenzenberger, H.D., Hergenrother, P.M., Eds.; Chapman and Hall: New York, NY, USA, 1990; pp. 23–96. [Google Scholar]

- Kitoh, M.; Honda, Y. Preparation and tribological properties of sputtered polyimide film. Thin Solid Films 1995, 271, 92–95. [Google Scholar] [CrossRef]

- Egitto, F.D.; Matienzo, L.J. Plasma modification of polymer surfaces for adhesion improvement. IBM J. Res. Dev. 1994, 38, 423–439. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, M.; Choi, H.; Kim, T.; Hong, I.; Roh, Y.; Park, J.; Seo, S.; Han, S.; Koh, J.-s.; Kang, D. FEP Encapsulated Crack-Based Sensor for Measurement in Moisture-Laden Environment. Materials 2019, 12, 1516. https://doi.org/10.3390/ma12091516

Kim M, Choi H, Kim T, Hong I, Roh Y, Park J, Seo S, Han S, Koh J-s, Kang D. FEP Encapsulated Crack-Based Sensor for Measurement in Moisture-Laden Environment. Materials. 2019; 12(9):1516. https://doi.org/10.3390/ma12091516

Chicago/Turabian StyleKim, Minho, Hyesu Choi, Taewi Kim, Insic Hong, Yeonwook Roh, Jieun Park, SungChul Seo, Seungyong Han, Je-sung Koh, and Daeshik Kang. 2019. "FEP Encapsulated Crack-Based Sensor for Measurement in Moisture-Laden Environment" Materials 12, no. 9: 1516. https://doi.org/10.3390/ma12091516

APA StyleKim, M., Choi, H., Kim, T., Hong, I., Roh, Y., Park, J., Seo, S., Han, S., Koh, J.-s., & Kang, D. (2019). FEP Encapsulated Crack-Based Sensor for Measurement in Moisture-Laden Environment. Materials, 12(9), 1516. https://doi.org/10.3390/ma12091516