Temperature Stable Cold Sintered (Bi0.95Li0.05)(V0.9Mo0.1)O4-Na2Mo2O7 Microwave Dielectric Composites

Abstract

:1. Introduction

2. Experimental Section

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Reaney, I.M.; Iddles, D. Microwave dielectric ceramics for resonators and filters in mobile phone networks. J. Am. Ceram. Soc. 2006, 89, 2063–2072. [Google Scholar] [CrossRef]

- Sebastian, M.T.; Wang, H.; Jantunen, H. Low temperature co-fired ceramics with ultra-low sintering temperature: A review. Curr. Opi. Solid State Mater. Sci. 2016, 20, 151–170. [Google Scholar] [CrossRef]

- Zhou, D.; Pang, L.; Wang, D.; Reaney, I.M. BiVO4 based high k microwave dielectric materials: A review. J. Mater. Chem. C 2018, 6, 9290–9313. [Google Scholar] [CrossRef]

- Zhou, D.; Pang, L.; Wang, D.; Qi, Z.; Reaney, I.M. High quality factor, ultralow sintering temperature Li6B4O9 microwave dielectric ceramics with ultralow density for antenna substrates. ACS Sustainable Chem. Eng. 2018, 6, 11138–11143. [Google Scholar] [CrossRef]

- Pang, L.; Zhou, D.; Wang, D.; Zhao, J.; Liu, W.; Yue, Z.; Reaney, I.M. Temperature stable K0.5(Nd1−xBix)0.5MoO4 microwave dielectrics ceramics with ultra-low sintering temperature. J. Am. Ceram. Soc. 2018, 101, 1806–1810. [Google Scholar] [CrossRef]

- Zhou, D.; Pang, L.; Wang, D.; Guo, H.; Yang, F.; Qi, Z.; Li, C.; Jin, B.; Reaney, I.M. Crystal structure, impedance and broadband dielectric spectra of ordered scheelite-structured Bi(Sc1/3Mo2/3)O4 ceramic. J. Euro. Ceram. Soc. 2018, 38, 1556–1561. [Google Scholar] [CrossRef]

- Pang, L.X.; Zhou, D.; Qi, Z.M.; Liu, W.G.; Yue, Z.X.; Reaney, I.M. Structure–property relationships of low sintering temperature scheelite-structured (1−x)BiVO4–xLaNbO4 microwave dielectric ceramics. J. Mater. Chem. C 2017, 5, 2695–2701. [Google Scholar] [CrossRef]

- Zhou, D.; Guo, D.; Li, W.B.; Pang, L.X.; Yao, X.; Wang, D.W.; Reaney, I.M. Novel temperature stable high-εr microwave dielectrics in the Bi2O3−TiO2−V2O5 system. J. Mater. Chem. C 2016, 4, 5357–5362. [Google Scholar] [CrossRef]

- Zhou, D.; Li, W.B.; Xi, H.H.; Pang, L.X.; Pang, G.S. Phase composition, crystal structure, infrared reflectivity and microwave dielectric properties of temperature stable composite ceramics (scheelite and zircon-type) in BiVO4-YVO4 system. J. Mater. Chem. C 2015, 3, 2582–2588. [Google Scholar] [CrossRef]

- Zhou, D.; Li, J.; Pang, L.X.; Chen, G.H.; Qi, Z.M.; Wang, D.W.; Reaney, I.M. Crystal structure, infrared spectra, and microwave dielectric properties of temperature-stable Zircon-yype (Y,Bi)VO4 solid solution ceramics. ACS Omega 2016, 1, 963–970. [Google Scholar] [CrossRef]

- Ma, J.L.; Fu, Z.F.; Liu, P.; Zhao, L.P.; Guo, B.C. Ultralow-fired Li2Mg3TiO6-Ca0.8Sr0.2TiO3 composite ceramics with temperature stable at microwave frequency. J. Alloys Comp. 2017, 709, 299–303. [Google Scholar] [CrossRef]

- Chen, G.H.; Gu, F.F.; Pan, M.; Yao, L.Q.; Li, M.; Chen, X.; Yang, Y.; Yang, T.; Yuan, C.L.; Zhou, C.R. Microwave dielectric properties of BiVO4/Li0.5Re0.5WO4 (Re = La, Nd) ultra-low firing ceramics. J. Mater. Sci. Mater. Electron. 2015, 26, 6511–6517. [Google Scholar] [CrossRef]

- Kahari, H.; Teirikangas, M.; Juuti, J.; Jantunen, H. Dielectric properties of lithium molybdate ceramic fabricated at room temperature. J. Am. Ceram. Soc. 2014, 97, 3378–3379. [Google Scholar] [CrossRef]

- Kähäri, H.; Teirikangas, M.; Juuti, J.; Jantunen, H. Room-temperature fabrication of microwave dielectric Li2MoO4–TiO2 composite ceramics. Ceram. Inter. 2016, 42, 11442–11446. [Google Scholar] [CrossRef]

- Väätäjä, M.; Kähäri, H.; Juuti, J.; Jantunen, H. Li2MoO4-based composite ceramics fabricated from temperature- and atmosphere-sensitive MnZn ferrite at room temperature. J. Am. Ceram. Soc. 2017, 100, 3626–3635. [Google Scholar]

- Väätäjä, M.; Kähäri, H.; Ohenoja, K.; Sobocinski, M.; Juuti, J.; Jantunen, H. 3D printed dielectric ceramic without a sintering stage. Sci. Rep. 2018, 8, 15955. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Guo, H.; Baker, A.L.; Lanagan, M.T.; Kupp, E.R.; Messing, G.L.; Randall, C.A. Cold sintering: A paradigm shift for processing and integration of ceramics. Angew. Chem. Int. Ed. 2016, 55, 11457–11461. [Google Scholar] [CrossRef]

- Guo, J.; Baker, A.L.; Guo, H.; Lanagan, M.T.; Randall, C.A. Cold sintering process: A new era for ceramic packaging and microwave device development. J. Am. Ceram. Soc. 2017, 100, 669–677. [Google Scholar] [CrossRef]

- Guo, J.; Berbano, S.S.; Guo, H.; Baker, A.L.; Lanagan, M.T.; Randall, C.A. Cold sintering process of composites: bridging the processing temperature gap of ceramic and polymer materials. Adv. Funct. Mater. 2016, 26, 7115–7121. [Google Scholar] [CrossRef]

- Hong, W.; Li, L.; Cao, M.; Chen, X.M. Plastic deformation and effects of water in room-temperature cold sintering of NaCl microwave dielectric ceramics. J. Am. Ceram. Soc. 2018, 101, 4038–4043. [Google Scholar] [CrossRef]

- Induja, I.J.; Sebastian, M.T. Microwave dielectric properties of mineral sillimanite obtained by conventional and cold sintering process. J. Euro. Ceram. Soc. 2017, 37, 2143–2147. [Google Scholar] [CrossRef]

- Wang, D.; Zhou, D.; Zhang, S.; Vardaxoglou, Y.; Whittow, W.G.; Cadman, D.; Reaney, I.M. Cold-sintered temperature stable Na0.5Bi0.5MoO4–Li2MoO4 microwave composite ceramics. ACS Sustainable Chem. Eng. 2018, 6, 2438–2444. [Google Scholar] [CrossRef]

- Faouri, S.S.; Mostaed, A.; Dean, J.S.; Wang, D.; Sinclair, D.C.; Zhang, S.; Whittow, W.G.; Vardaxoglou, Y.; Reaney, I.M. High quality factor cold sintered Li2MoO4–BaFe12O19 composites for microwave applications. Acta Mater. 2019, 166, 202–207. [Google Scholar] [CrossRef]

- Zhou, D.; Pang, L.; Wang, D.; Reaney, I.M. Novel water-assisting low firing MoO3 microwave dielectric ceramics. J. Euro. Ceram. Soc. 2019, 39, 2374–2378. [Google Scholar] [CrossRef]

- Zhang, G.Q.; Wang, H.; Guo, J.; He, L.; Wei, D.D.; Yuan, Q.B. Ultra-low sintering temperature microwave dielectric ceramics based on Na2O-MoO3 binary system. J. Am. Ceram. Soc. 2015, 98, 528–533. [Google Scholar] [CrossRef]

- Zhou, D.; Qu, W.G.; Randall, C.A.; Pang, L.X.; Wang, H.; Wu, X.G.; Guo, J.; Zhang, G.Q.; Shui, L.; Wang, Q.P.; Liu, H.C.; Yao, X. Ferroelastic phase transition compositional dependence for solid-solution [(Li0.5Bi0.5)xBi1−x][MoxV1−x]O4 scheelite-structured microwave dielectric ceramics. Acta Mater. 2011, 59, 1502–1509. [Google Scholar] [CrossRef]

- Zhou, D.; Pang, L.X.; Qu, W.G.; Randall, C.A.; Guo, J.; Qi, Z.M.; Shao, T.; Yao, X. Dielectric behavior, band gap, in situ X-ray diffraction, Raman and infrared study on (1−x)BiVO4−x(Li0.5Bi0.5)MoO4 solid solution. RSC Adv. 2013, 3, 5009–5014. [Google Scholar] [CrossRef]

- Zhou, D.; Randall, C.A.; Wang, H.; Pang, L.X.; Yao, X. Ultra-low firing high-k scheelite structures based on [(Li0.5Bi0.5)xBi1–x][MoxV1–x]O4 microwave dielectric ceramics. J. Am. Ceram. Soc. 2010, 93, 2147–2150. [Google Scholar] [CrossRef]

- Saraiva, G.D.; Paraguassu, W.; Maczka, M.; Freire, P.T.C.; de Sousad, F.F.; Mendes Filho, J. Temperature-dependent Raman scattering studies on Na2Mo2O7 disodium dimolybdate. J. Raman Spectrosc. 2011, 42, 1114–1119. [Google Scholar] [CrossRef]

- Pang, L.X.; Wang, H.; Zhou, D.; Yao, X. A new temperature stable microwave dielectric with low-firing temperature in Bi2MoO6–TiO2 system. J. Alloys Comp. 2010, 493, 626–629. [Google Scholar] [CrossRef]

- Wang, D.; Zhou, D.; Song, K.; Feteira, A.; Randall, C.A.; Reaney, I.M. Cold Sintered C0G Multilayer Ceramic Capacitors. Adv. Electro. Mater. 2019. [Google Scholar] [CrossRef]

- Ibn-Mohammed, T.; Randall, C.A.; Mustapha, K.B.; Guo, J.; Walker, J.; Berbano, S.; Koh, S.C.L.; Sinclair, D.C.; Reaney, I.M. Decarbonising ceramic manufacturing: A techno-economic analysis of energy efficient sintering technologies in the functional materials sector. J. Euro. Ceram. Soc. 2019. submitted. [Google Scholar]

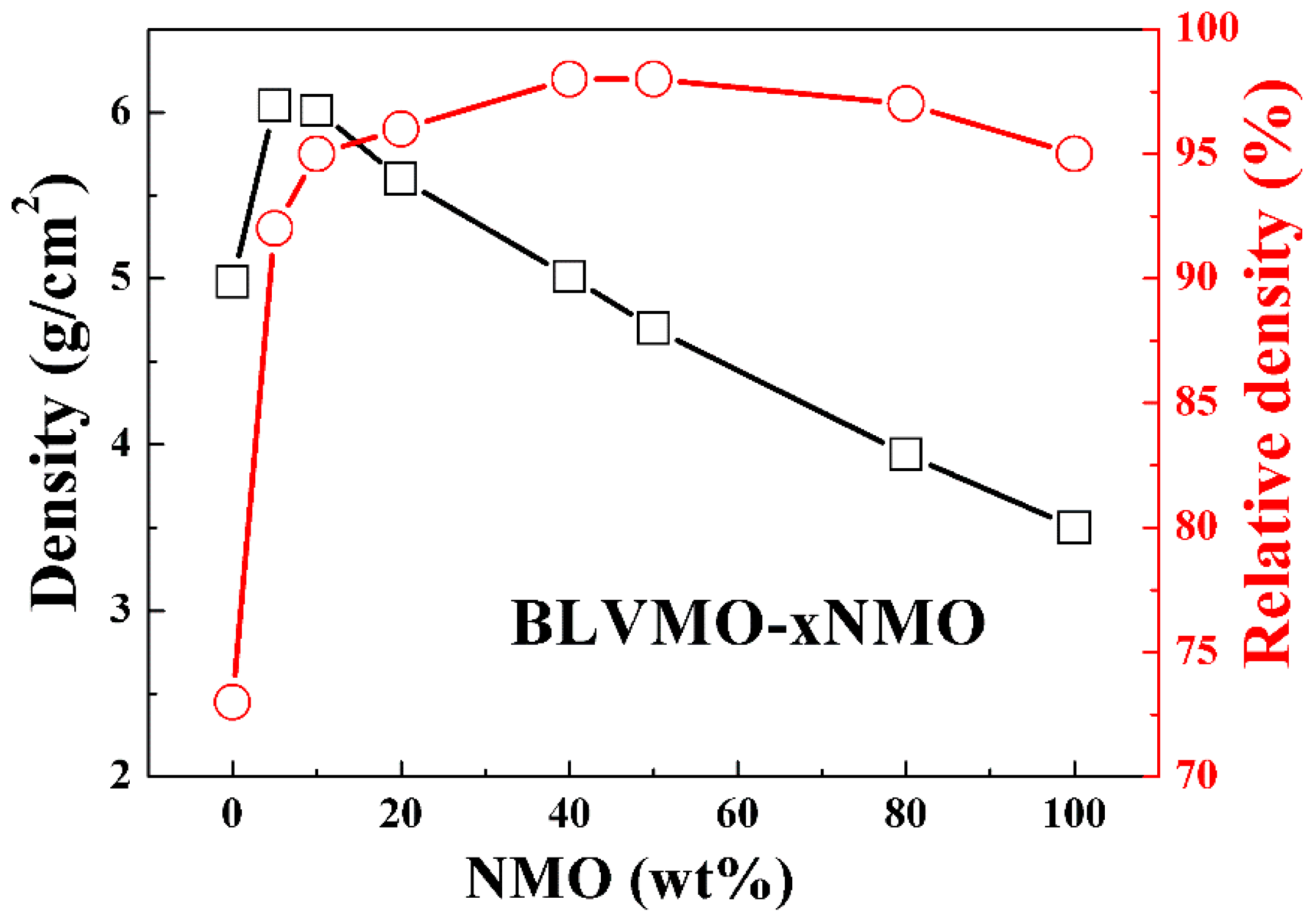

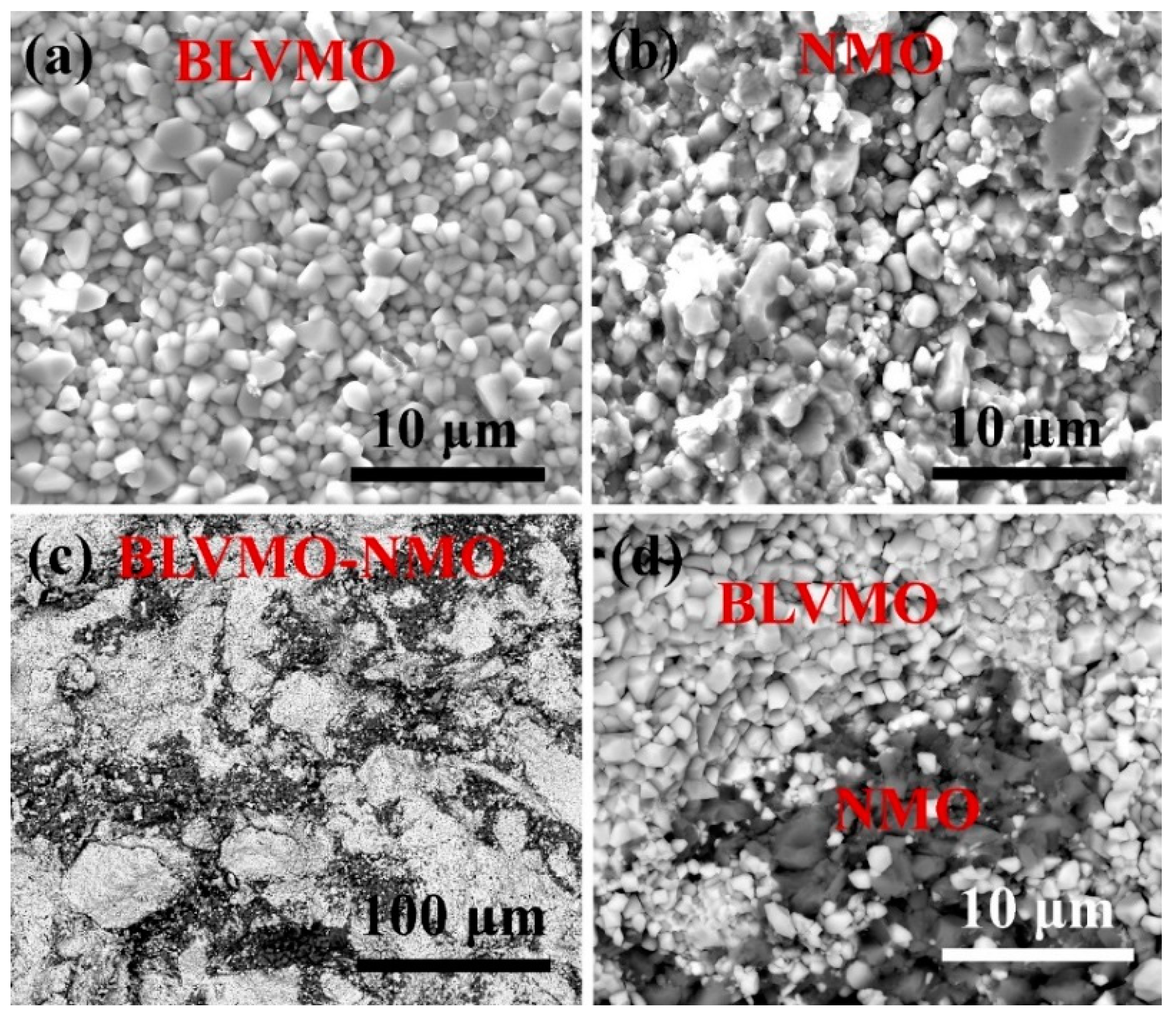

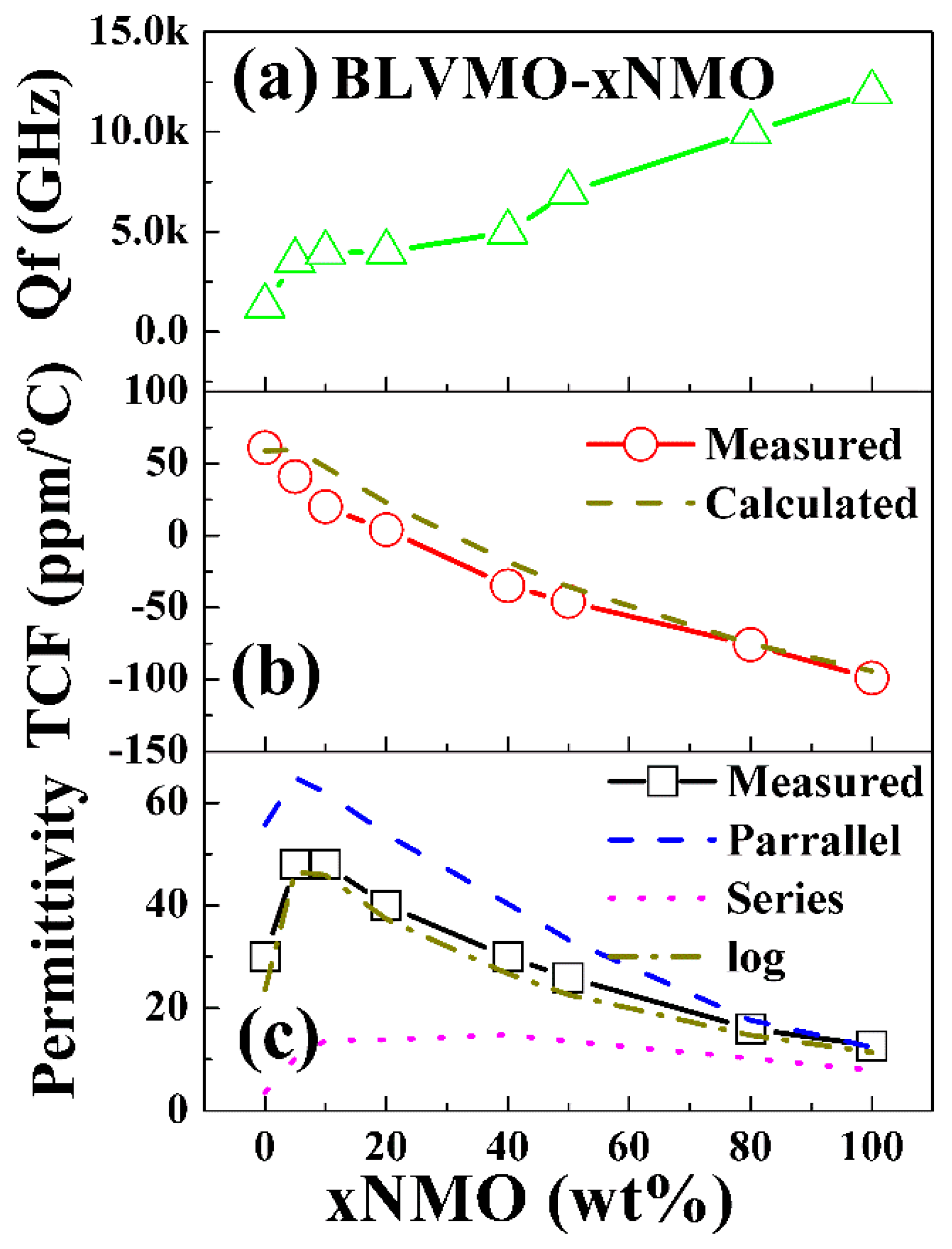

| Composition | ST (°C) | ρr (%) | εr | tanδ (%) | Qf (GHz) | TCF (ppm/°C) |

|---|---|---|---|---|---|---|

| BLVMO | 150 | 73 | 30 | 0.003 | 1300 | +61 |

| 5% NMO | 150 | 92 | 48 | 0.0014 | 3565 | +41 |

| 10% NMO | 150 | 95 | 48 | 0.0012 | 3959 | +20 |

| 20% NMO | 150 | 96 | 40 | 0.0012 | 4000 | +4 |

| 40% NMO | 150 | 98 | 30 | 0.001 | 5000 | −35 |

| 50% NMO | 150 | 98 | 26 | 0.001 | 7000 | −46 |

| 80% NMO | 150 | 97 | 16 | 0.0007 | 10000 | −76 |

| NMO | 150 | 95 | 12.7 | 0.0005 | 12000 | −99 |

| BLVMO | 690 | 96 | 76 | 0.0006 | 7000 | +81 |

| NMO | 610 | 87 | 11.6 | 0.0005 | 19000 | −78 |

| Compound | ρr (%) | εr | Qf (GHz) | TCF (ppm/oC) | Reference |

|---|---|---|---|---|---|

| PTFE | 100 | 2.12 | 135,700 | +60 | * |

| Polystyrene | 100 | 2.53 | 24,320 | −5 | * |

| Al2SiO5-NaCl | / | 4.52 | 22,350 | −24 | [21] |

| KCl | 98 | 4.74 | 7738 | −149 | * |

| LMO | 95.5 | 5.1–5.61 | 10,200-30,500 | −170 | [13,14,15,16,17,18,19,22] |

| NaCl | 97–99 | 5.22–5.55 | 12,000-49,600 | −100 | [20,21] |

| LMO-15%BF12 | 94.1 | 5.8 | 17,430 | - | [23] |

| K2MoO4 | 100 | 6.37 | 26,500 | −70 | * |

| AgNaMoO4 | 90.8 | 9.3 | 7078 | −120 | * |

| K2Mo2O7 | 94.1–96 | 9.35–9.8 | 12,000–16,000 | −63 | [17], * |

| MoO3 | 83.7 | 9.91 | 11,800 | −39 | [24] |

| Na2Mo2O7 | 93.7–95 | 12.7–13.4 | 12,000–14,900 | −99 | [17], * |

| NBMO-20%LMO | 93.6 | 17.4 | 7470 | −4.7 | [22] |

| NBMO-10%LMO | 92.6 | 24.1 | 2240 | +15 | [22] |

| (LiBi)0.5MoO4 | 88 | 33.7–37 | 1700–2300 | +180 | [18] |

| BLVMO-20%NMO | 96 | 40 | 4000 | +4 | this work |

| BLVMO-10%NMO | 95 | 48 | 3959 | +20 | this work |

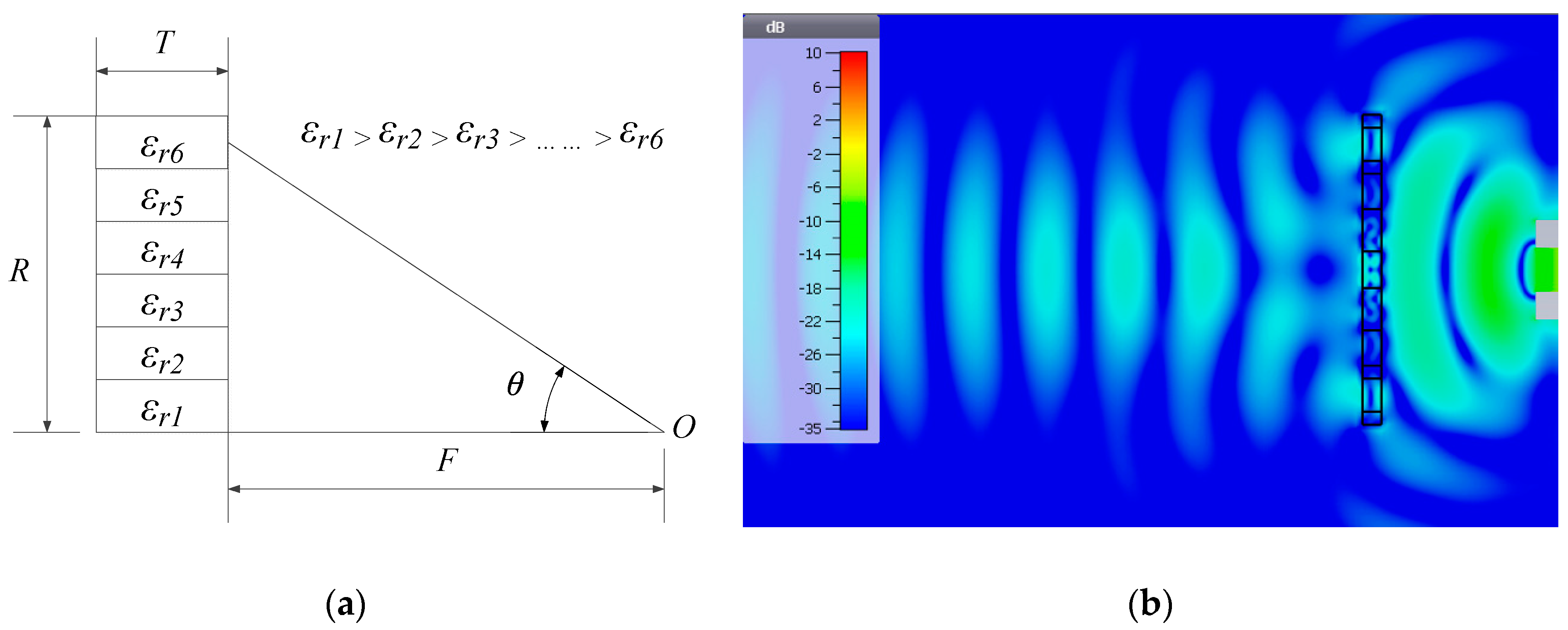

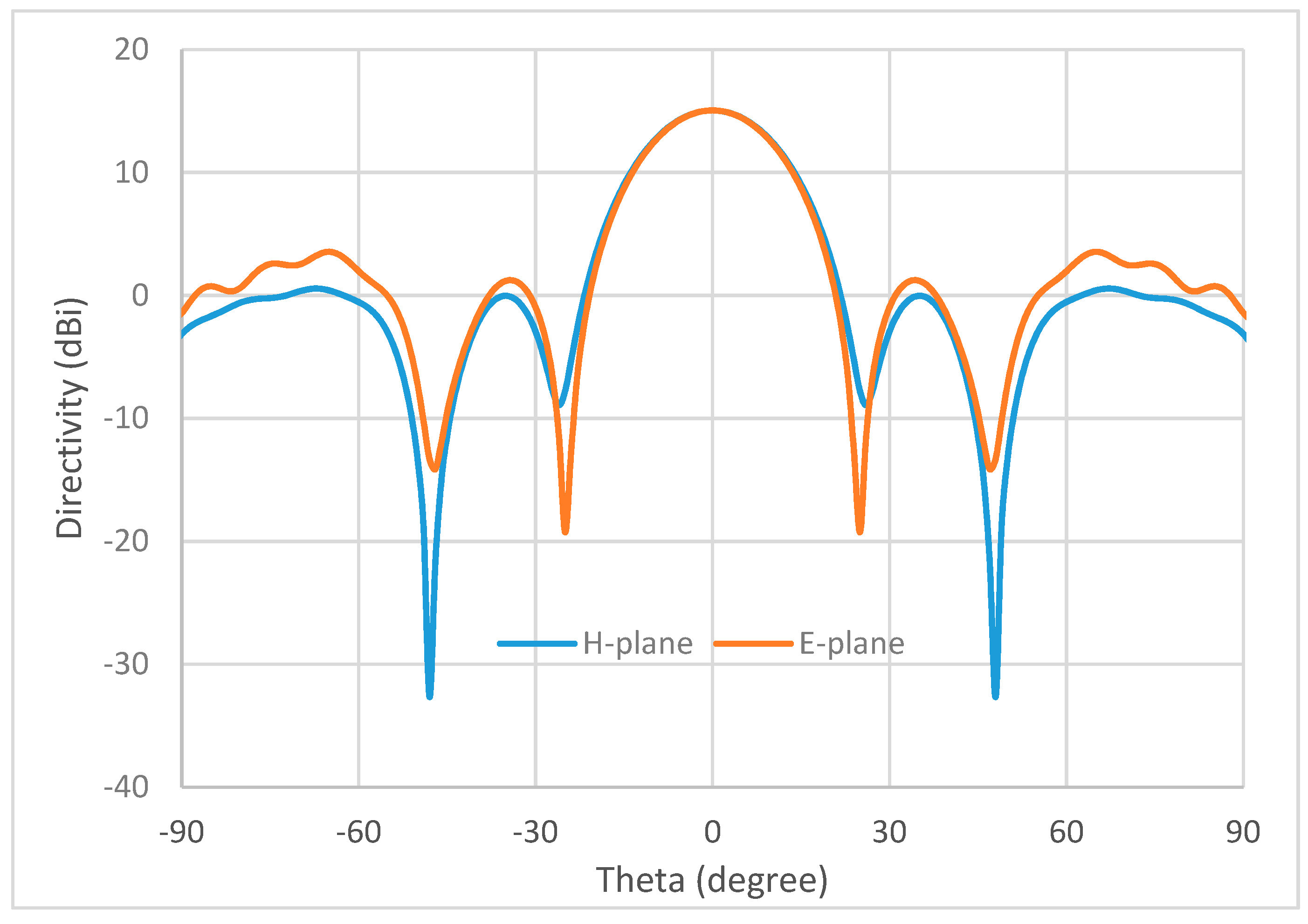

| Parameter | Value |

|---|---|

| Diameter | R = 12.5 mm |

| Focal length | F = 12.5 mm |

| Thickness | T = 1.53 mm |

| Ring No. | εr | Ring Outer Radius(mm) |

|---|---|---|

| 1 | 48 | 1.1 |

| 2 | 40 | 4.9 |

| 3 | 30 | 7.8 |

| 4 | 26 | 8.8 |

| 5 | 16 | 11.5 |

| 6 | 12.7 | 12.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Zhang, S.; Zhou, D.; Song, K.; Feteira, A.; Vardaxoglou, Y.; Whittow, W.; Cadman, D.; Reaney, I.M. Temperature Stable Cold Sintered (Bi0.95Li0.05)(V0.9Mo0.1)O4-Na2Mo2O7 Microwave Dielectric Composites. Materials 2019, 12, 1370. https://doi.org/10.3390/ma12091370

Wang D, Zhang S, Zhou D, Song K, Feteira A, Vardaxoglou Y, Whittow W, Cadman D, Reaney IM. Temperature Stable Cold Sintered (Bi0.95Li0.05)(V0.9Mo0.1)O4-Na2Mo2O7 Microwave Dielectric Composites. Materials. 2019; 12(9):1370. https://doi.org/10.3390/ma12091370

Chicago/Turabian StyleWang, Dawei, Shiyu Zhang, Di Zhou, Kaixin Song, Antonio Feteira, Yiannis Vardaxoglou, Will Whittow, Darren Cadman, and Ian M. Reaney. 2019. "Temperature Stable Cold Sintered (Bi0.95Li0.05)(V0.9Mo0.1)O4-Na2Mo2O7 Microwave Dielectric Composites" Materials 12, no. 9: 1370. https://doi.org/10.3390/ma12091370

APA StyleWang, D., Zhang, S., Zhou, D., Song, K., Feteira, A., Vardaxoglou, Y., Whittow, W., Cadman, D., & Reaney, I. M. (2019). Temperature Stable Cold Sintered (Bi0.95Li0.05)(V0.9Mo0.1)O4-Na2Mo2O7 Microwave Dielectric Composites. Materials, 12(9), 1370. https://doi.org/10.3390/ma12091370