The Directional Solidification, Microstructural Characterization and Deformation Behavior of β-Solidifying TiAl Alloy

Abstract

:1. Introduction

2. Experimental

3. Results and Discussion

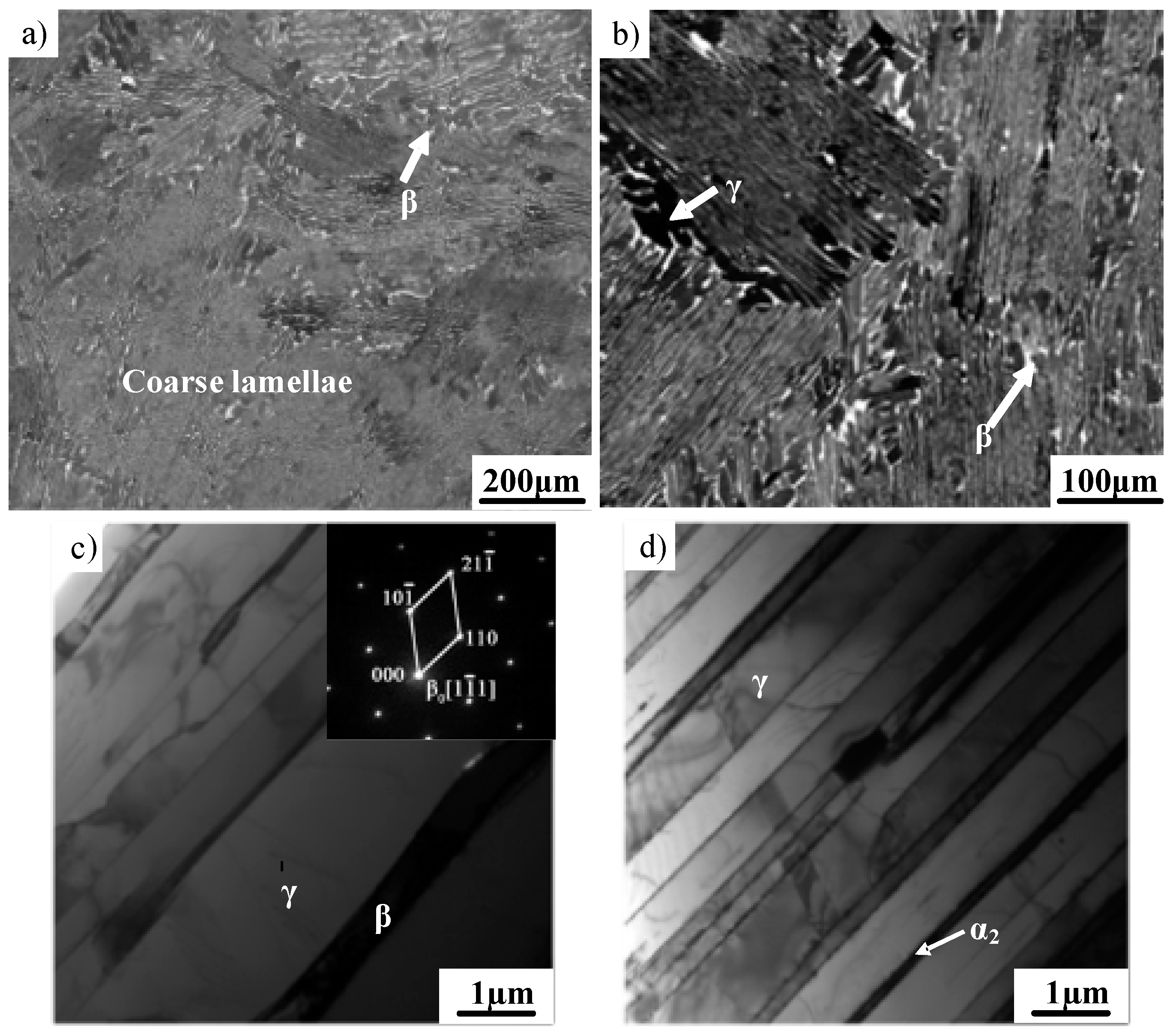

3.1. Initial As-Cast Microstructure of β-Solidifying TiAl Alloy

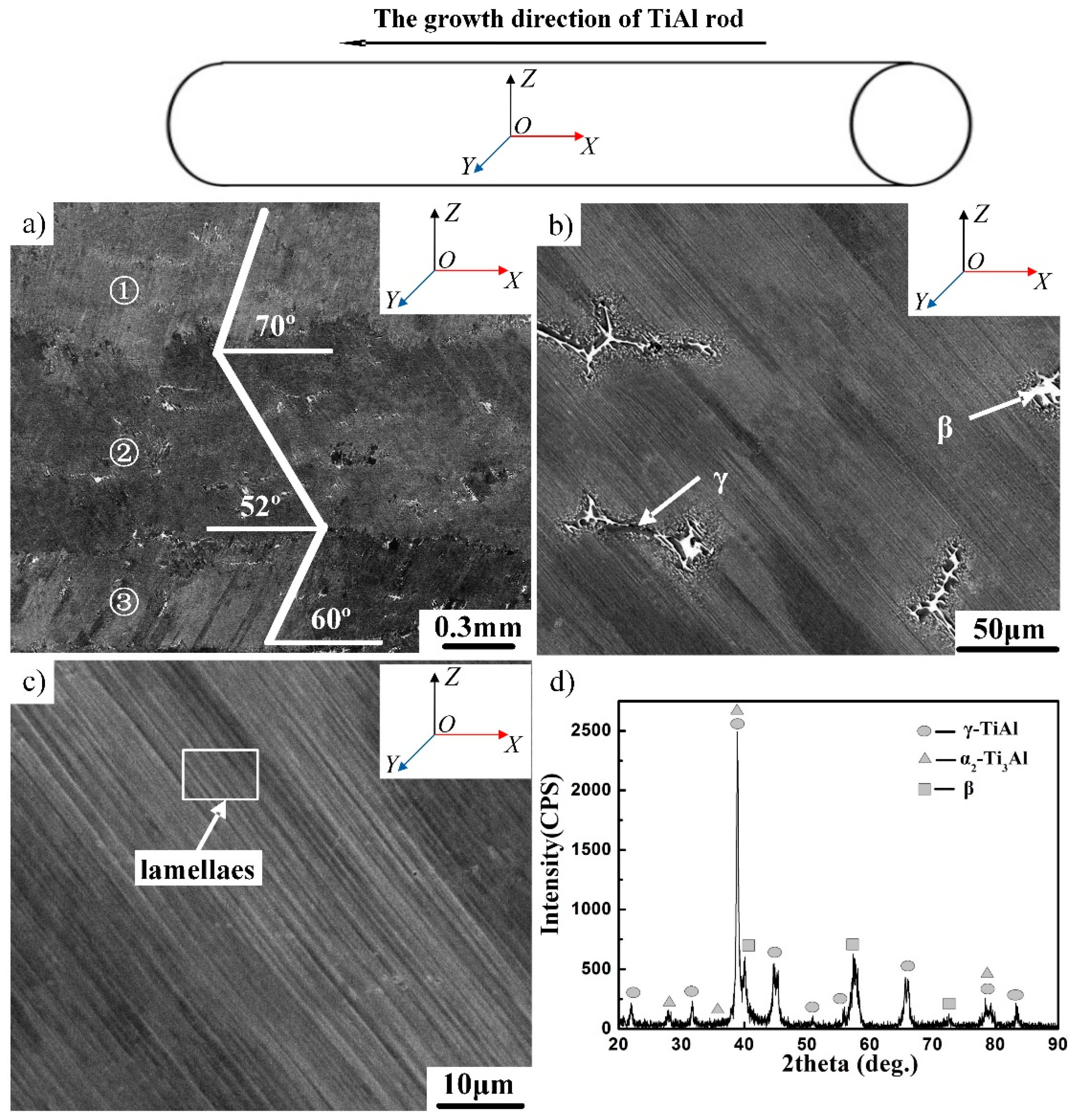

3.2. Directionally Solidified Microstructure of β-Solidifying TiAl Alloy

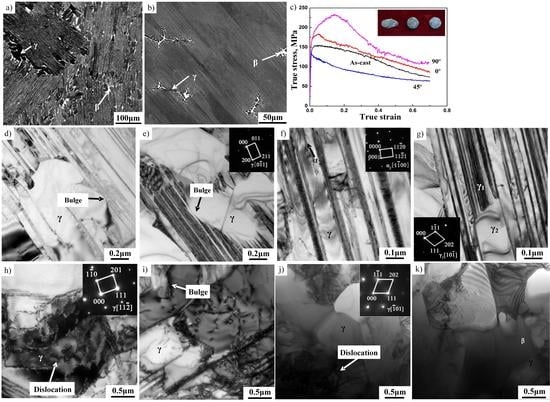

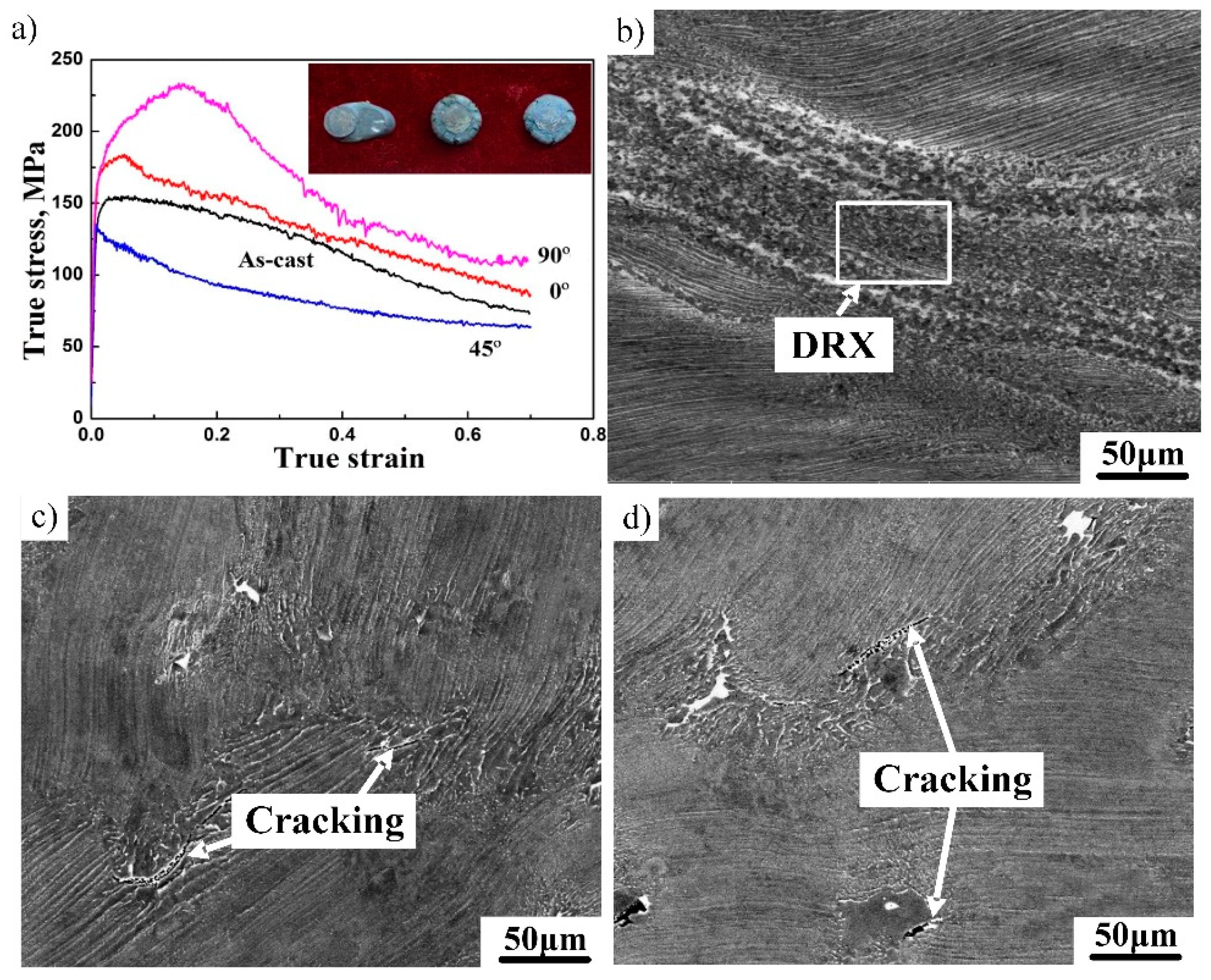

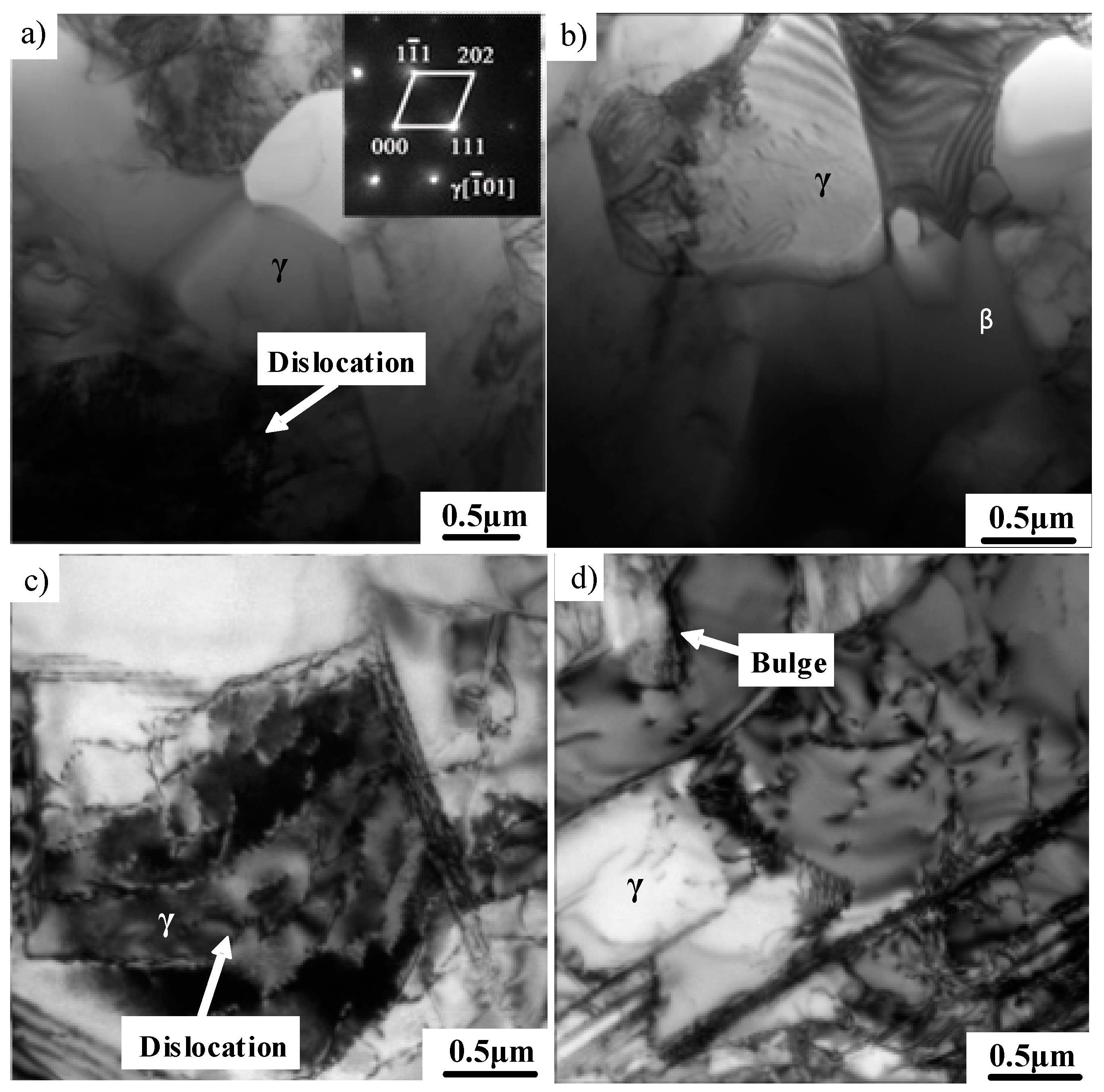

3.3. Deformation Resistance of β-Containing Lamellae

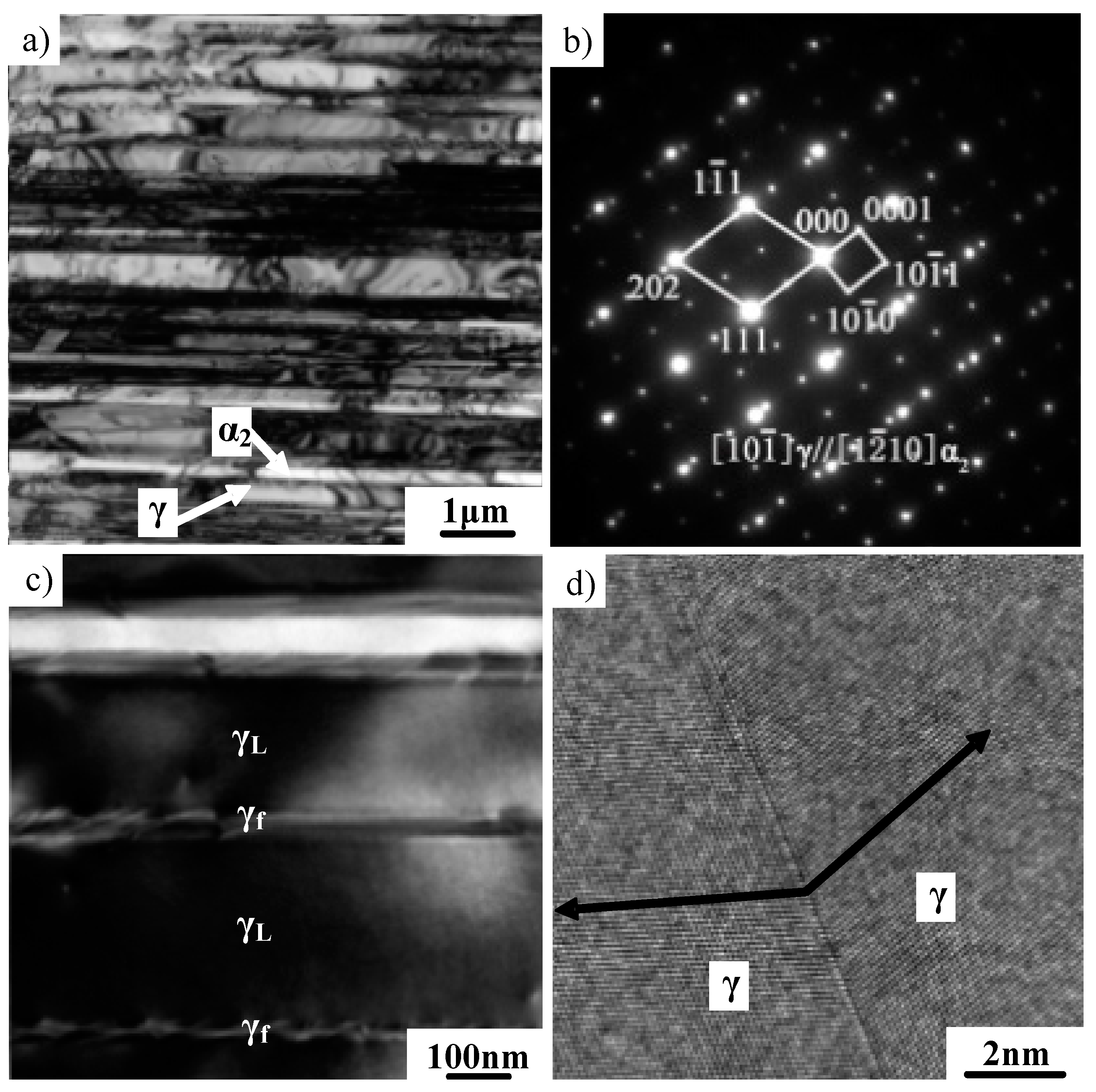

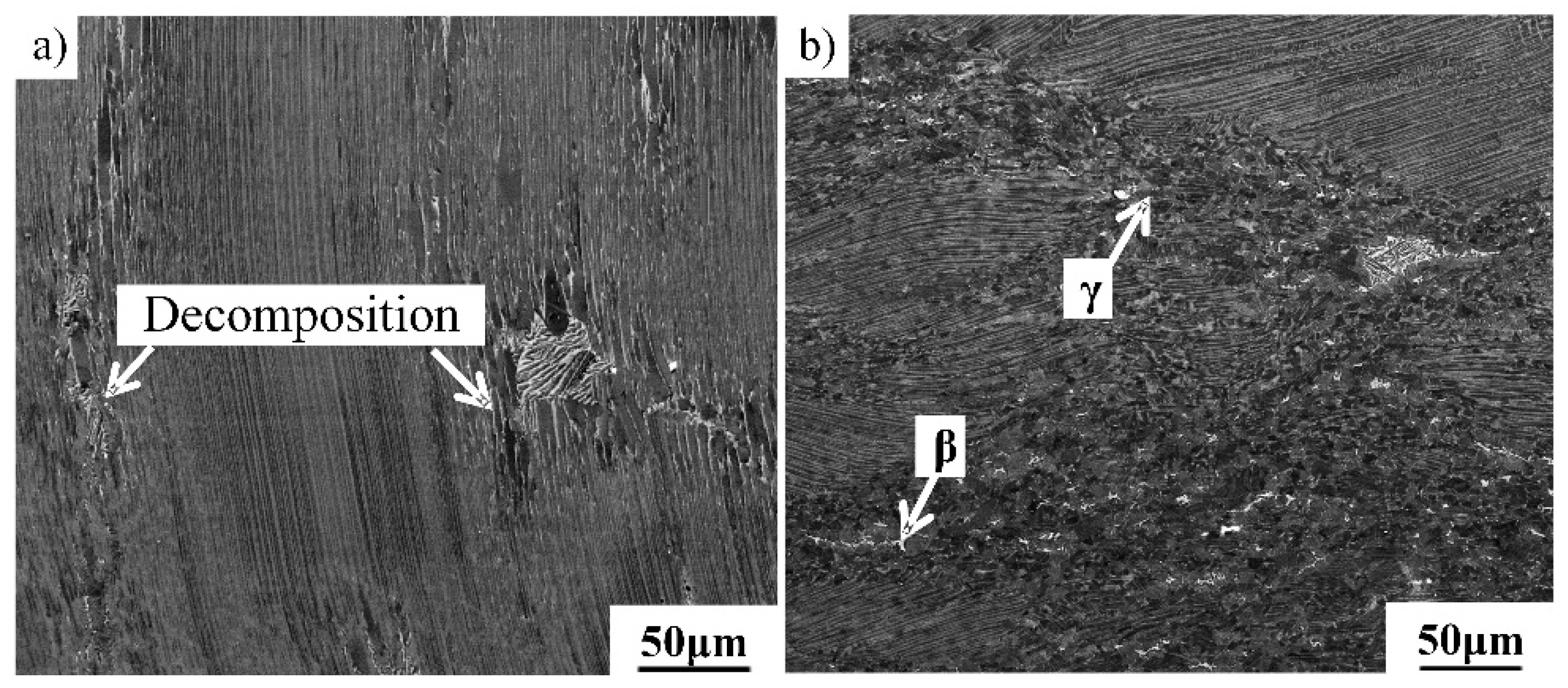

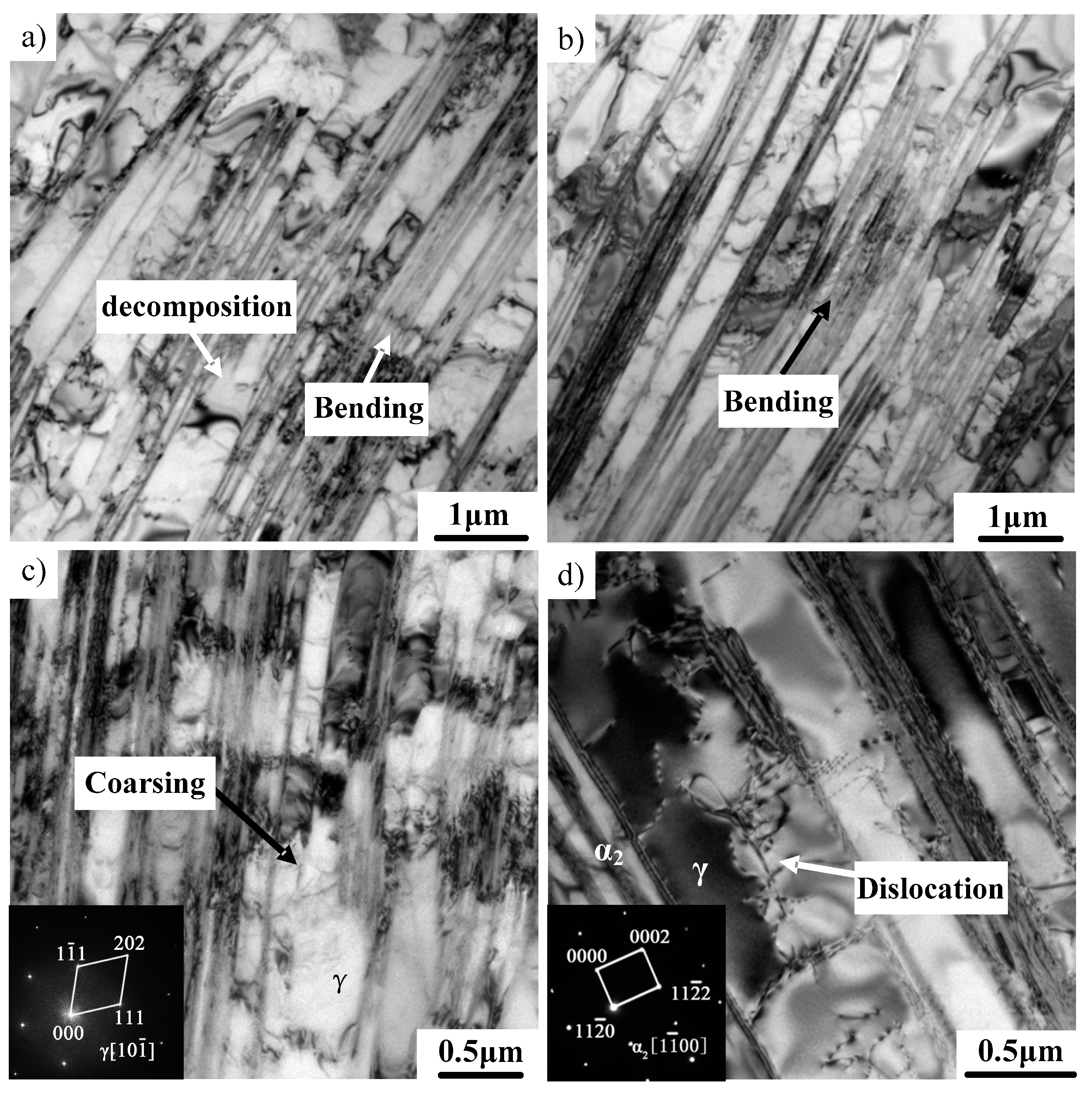

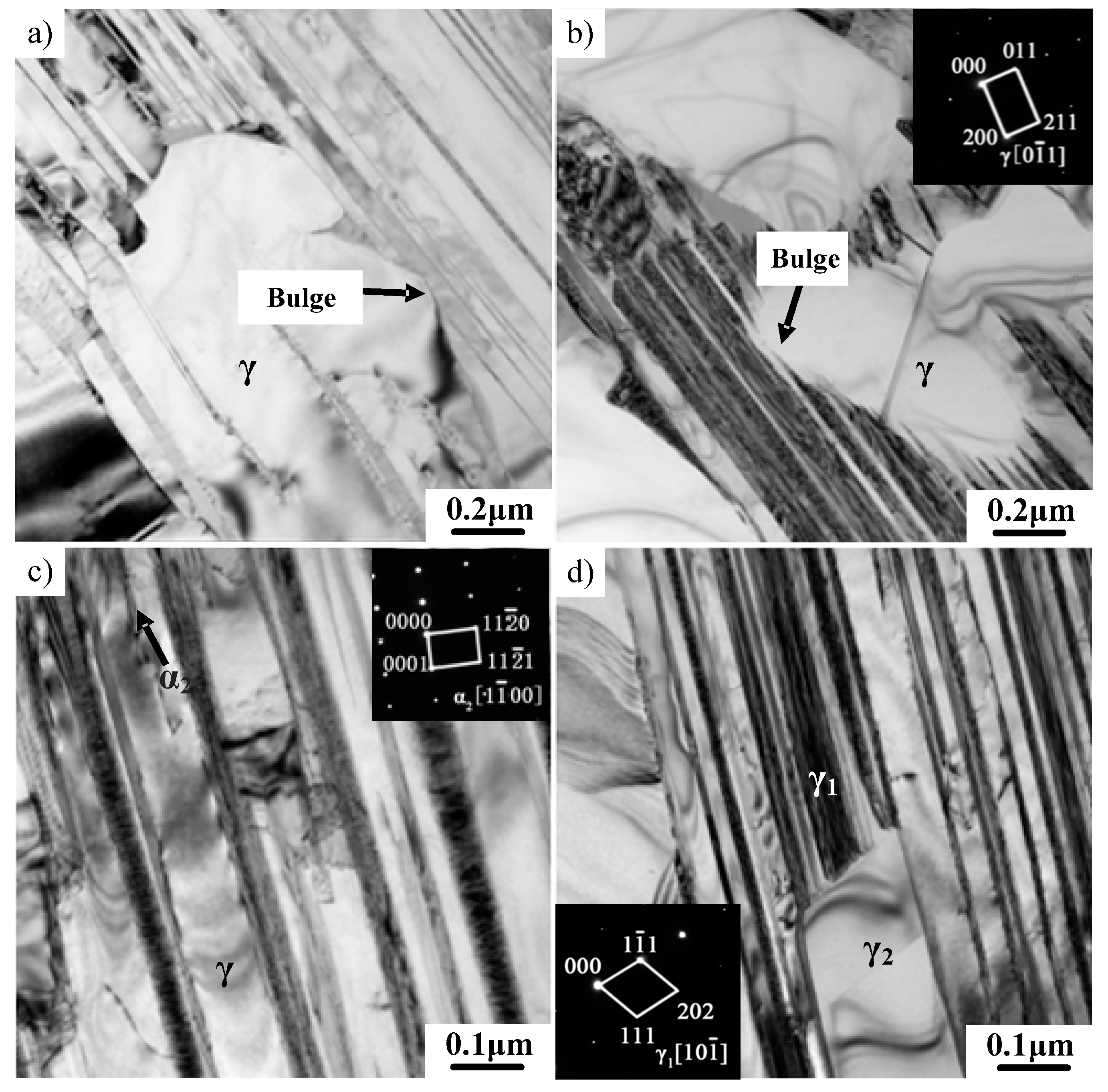

3.4. Microstructural Evolution of β-Containing Lamellae

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kim, Y.W.; Kim, S.L. Advances in gammalloy materials–processes–application technology: Successes, dilemmas, and future. JOM 2018, 5, 1–8. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Advanced Intermetallic TiAl Alloys. Mater. Sci. Forum 2017, 879, 113–118. [Google Scholar] [CrossRef]

- Kothari, K.; Radhakrishnan, R.; Wereley, N.M. Advances in gamma titanium aluminides and their manufacturing techniques. Prog. Aerosp. Sci 2012, 55, 1–16. [Google Scholar] [CrossRef]

- Ehtemam-Haghighi, S.; Attar, H.; Dargusch, M.S.; Kent, D. Microstructure, phase composition and mechanical properties of new, low cost Ti-Mn-Nb alloys for biomedical applications. J. Alloy. Compd. 2019. [Google Scholar] [CrossRef]

- Okulov, I.; Okulov, A.; Volegov, A.; Markmann, J. Tuning microstructure and mechanical properties of open porous TiNb and TiFe alloys by optimization of dealloying parameters. Scr. Mater. 2018, 154, 68–72. [Google Scholar] [CrossRef]

- Okulov, I.; Bönisch, M.; Okulov, A.; Volegov, A.; Attar, H.; Ehtemam-Haghighi, S.; Calin, M.; Wang, Z.; Hohenwarter, A.; Kaban, I. Phase formation, microstructure and deformation behavior of heavily alloyed TiNb-and TiV-based titanium alloys. Mater. Sci. Eng. A 2018, 733, 80–86. [Google Scholar] [CrossRef]

- Ehtemam-Haghighi, S.; Liu, Y.; Cao, G.; Zhang, L.-C. Phase transition, microstructural evolution and mechanical properties of Ti-Nb-Fe alloys induced by Fe addition. Mater. Des. 2016, 97, 279–286. [Google Scholar] [CrossRef]

- Appel, F.; Clemens, H.; Fischer, F. Modeling concepts for intermetallic titanium aluminides. Prog. Mater. Sci. 2016, 81, 55–124. [Google Scholar] [CrossRef]

- Kong, F.T.; Cui, N.; Chen, Y.Y.; Wang, X.P. A novel composition design method for beta-gamma TiAl alloys with excellent hot workability. Metall. Mater. Trans. A 2018, 49, 5574–5584. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Design, processing, microstructure, properties, and applications of advanced intermetallic TiAl alloys. Adv. Eng. Mater. 2013, 15, 191–215. [Google Scholar] [CrossRef]

- Zhao, E.T.; Niu, H.Z.; Zhang, S.Z.; Feng, L.; Yang, S.Y. Microstructural control and mechanical properties of a β-solidified γ-TiAl alloy Ti-46Al-2Nb-1.5V-1Mo-Y. Mater. Sci. Eng. A 2017, 701, 1–6. [Google Scholar] [CrossRef]

- Zhou, H.T.; Kong, F.T.; Wang, X.P.; Chen, Y.Y. Hot deformation behavior and microstructural evolution of as-forged Ti-44Al-8Nb-(W, B, Y) alloy with nearly lamellar microstructure. Intermetallics 2017, 81, 62–72. [Google Scholar] [CrossRef]

- Clemens, H.; Wallgram, W.; Kremmer, S.; Güther, V.; Otto, A.; Bartels, A. Design of novel β-solidifying TiAl alloys with adjustable β/B2-phase fraction and excellent hot-workability. Adv. Eng. Mater. 2008, 10, 707–713. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Johnson, D.; Lee, H.; Inui, H. Directional solidification of TiAl-base alloys. Intermetallics 2000, 8, 511–517. [Google Scholar] [CrossRef]

- Tetsui, T.; Ono, S. Endurance and composition and microstructure effects on endurance of TiAl used in turbochargers. Intermetallics 1999, 7, 689–697. [Google Scholar] [CrossRef]

- Ding, X.F.; Lin, J.P.; Zhang, L.Q.; Su, Y.Q.; Chen, G.L. Microstructural control of TiAl-Nb alloys by directional solidification. Acta Mater. 2012, 60, 498–506. [Google Scholar] [CrossRef]

- Cui, N.; Kong, F.T.; Wang, X.P.; Chen, Y.Y.; Zhou, H.T. Microstructural evolution, hot workability, and mechanical properties of Ti–43Al–2Cr–2Mn–0.2Y alloy. Mater. Des. 2016, 89, 1020–1027. [Google Scholar] [CrossRef]

- Tetsui, T.; Shindo, K.; Kobayashi, S.; Takeyama, M. A newly developed hot worked TiAl alloy for blades and structural components. Scr. Mater. 2002, 47, 399–403. [Google Scholar] [CrossRef]

- Kim, M.C.; Oh, M.H.; Lee, J.H.; Inui, H.; Yamaguchi, M.; Wee, D.M. Composition and growth rate effects in directionally solidified TiAl alloys. Mater. Sci. Eng. A 1997, 239, 570–576. [Google Scholar] [CrossRef]

- Takeyama, M.; Kobayashi, S. Physical metallurgy for wrought gamma titanium aluminides microstructure control through phase transformations. Intermetallics 2005, 13, 993–999. [Google Scholar] [CrossRef]

- Blackburn, M.J. Some aspects of phase transformations in titanium alloys. In The Science, Technology and Application of Titanium; Pergamon Press: Oxford, UK, 1970; pp. 633–643. [Google Scholar]

- Dey, S.R.; Bouzy, E.; Hazotte, A. Features of feathery γ structure in a near-γ TiAl alloy. Acta Mater. 2008, 56, 2051–2062. [Google Scholar] [CrossRef]

- Cui, N.; Kong, F.T.; Wang, X.P.; Chen, Y.Y.; Zhou, H.T. Hot deformation behavior and dynamic recrystallization of a β-solidifying TiAl alloy. Mater. Sci. Eng. A 2016, 652, 231–238. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Takeyama, M. Physical metallurgy of single crystal gamma titanium aluminide alloys: Orientation control and thermal stability of lamellar microstructure. Intermetallics 2005, 13, 965–970. [Google Scholar] [CrossRef]

- Shuleshova, O.; Woodcock, T.G.; Lindenkreuz, H.G.; Hermann, R.; Löser, W.; Büchner, B. Metastable phase formation in Ti-Al-Nb undercooled melts. Acta Mater. 2007, 55, 681–689. [Google Scholar] [CrossRef]

- Ding, H.S.; Nie, G.; Chen, R.R.; Guo, J.J.; Fu, H.Z. High temperature deformation behaviors of polysynthetically twinned (PST) Ti-47Al-2Cr-2Nb alloy. Mater. Sci. Eng. A 2012, 558, 747–754. [Google Scholar] [CrossRef]

- Gupta, A.; Wiezorek, J.M. Microstructural evolution of PST-TiAl during low-rate compressive micro-straining at 1023K in hard and soft orientations. Intermetallics 2003, 11, 589–600. [Google Scholar] [CrossRef]

- Kim, H.Y.; Maruyama, K. Stability of lamellar microstructure of hard orientated PST crystal of TiAl alloy. Acta Mater. 2003, 51, 2191–2204. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, N.; Wu, Q.; Wang, J.; Lv, B.; Kong, F. The Directional Solidification, Microstructural Characterization and Deformation Behavior of β-Solidifying TiAl Alloy. Materials 2019, 12, 1203. https://doi.org/10.3390/ma12081203

Cui N, Wu Q, Wang J, Lv B, Kong F. The Directional Solidification, Microstructural Characterization and Deformation Behavior of β-Solidifying TiAl Alloy. Materials. 2019; 12(8):1203. https://doi.org/10.3390/ma12081203

Chicago/Turabian StyleCui, Ning, Qianqian Wu, Jin Wang, Binjiang Lv, and Fantao Kong. 2019. "The Directional Solidification, Microstructural Characterization and Deformation Behavior of β-Solidifying TiAl Alloy" Materials 12, no. 8: 1203. https://doi.org/10.3390/ma12081203

APA StyleCui, N., Wu, Q., Wang, J., Lv, B., & Kong, F. (2019). The Directional Solidification, Microstructural Characterization and Deformation Behavior of β-Solidifying TiAl Alloy. Materials, 12(8), 1203. https://doi.org/10.3390/ma12081203