Reliability Modeling Method for Lithium-ion Battery Packs Considering the Dependency of Cell Degradations Based on a Regression Model and Copulas

Abstract

:1. Introduction

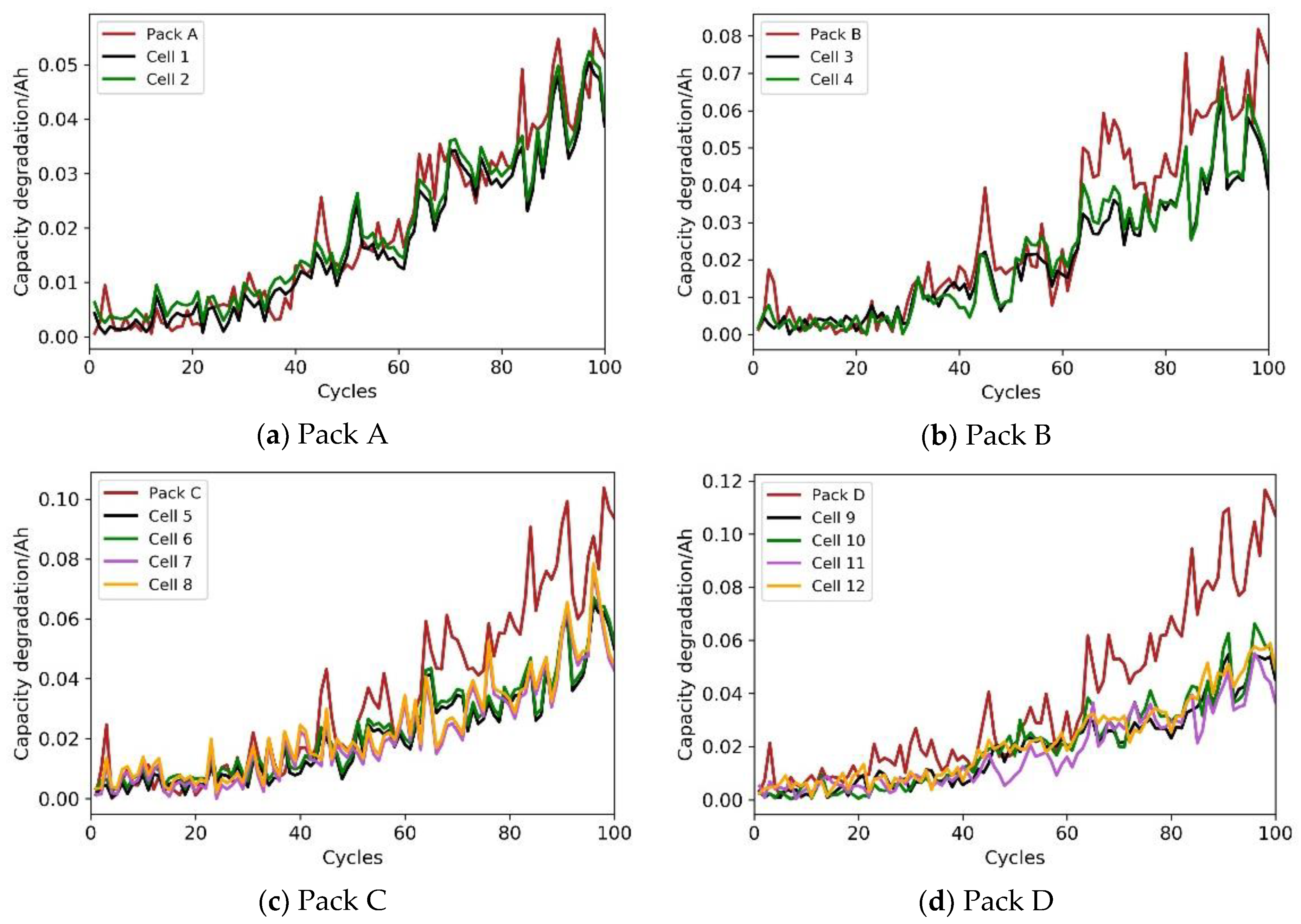

2. The Dependency Phenomenon and its Influence on a Lithium-Ion Battery Pack

2.1. Degradation Test

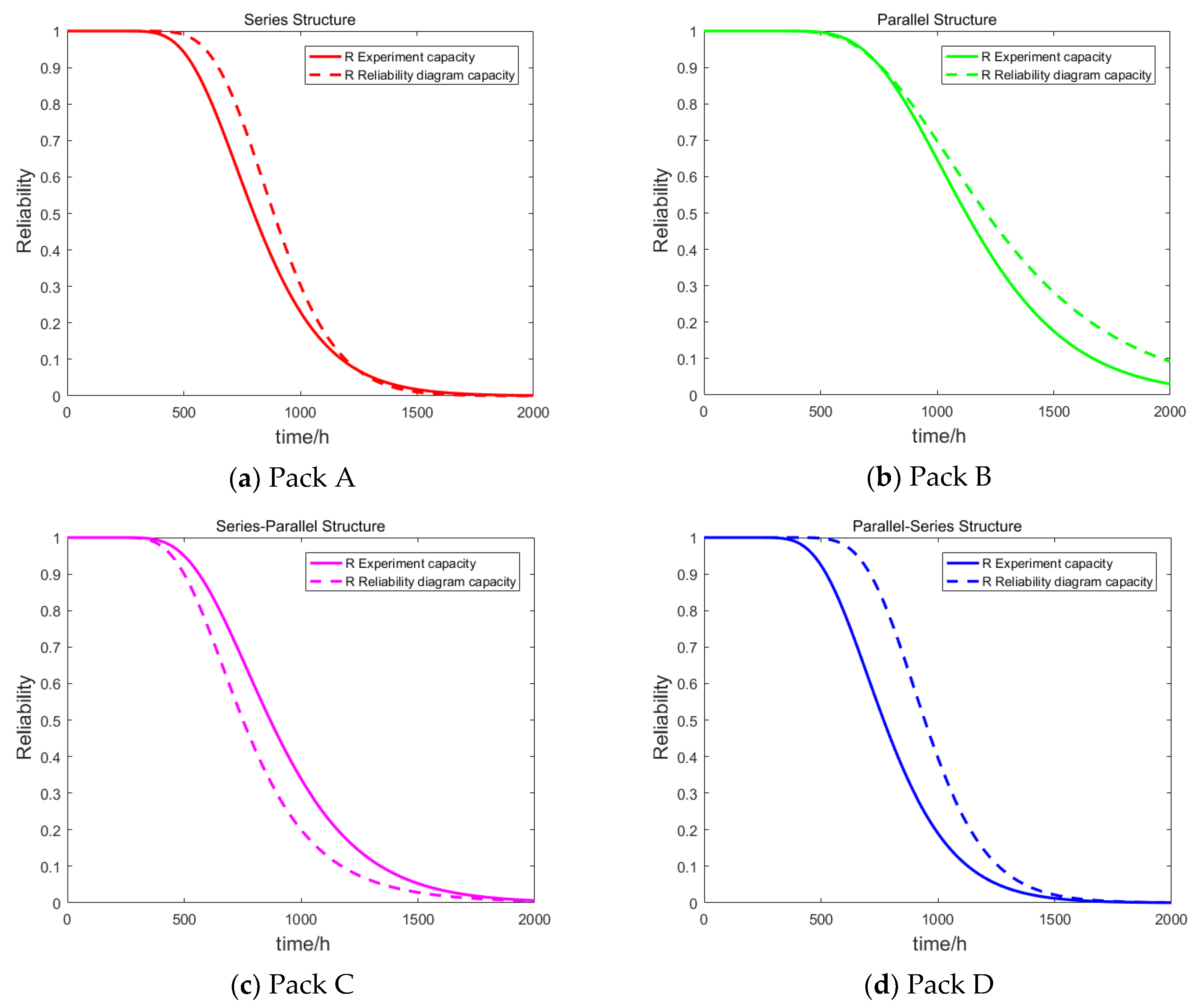

2.2. Reliability Analysis of a Lithium Ion Battery Pack

3. Method of Modeling the Reliability While Considering the Dependency

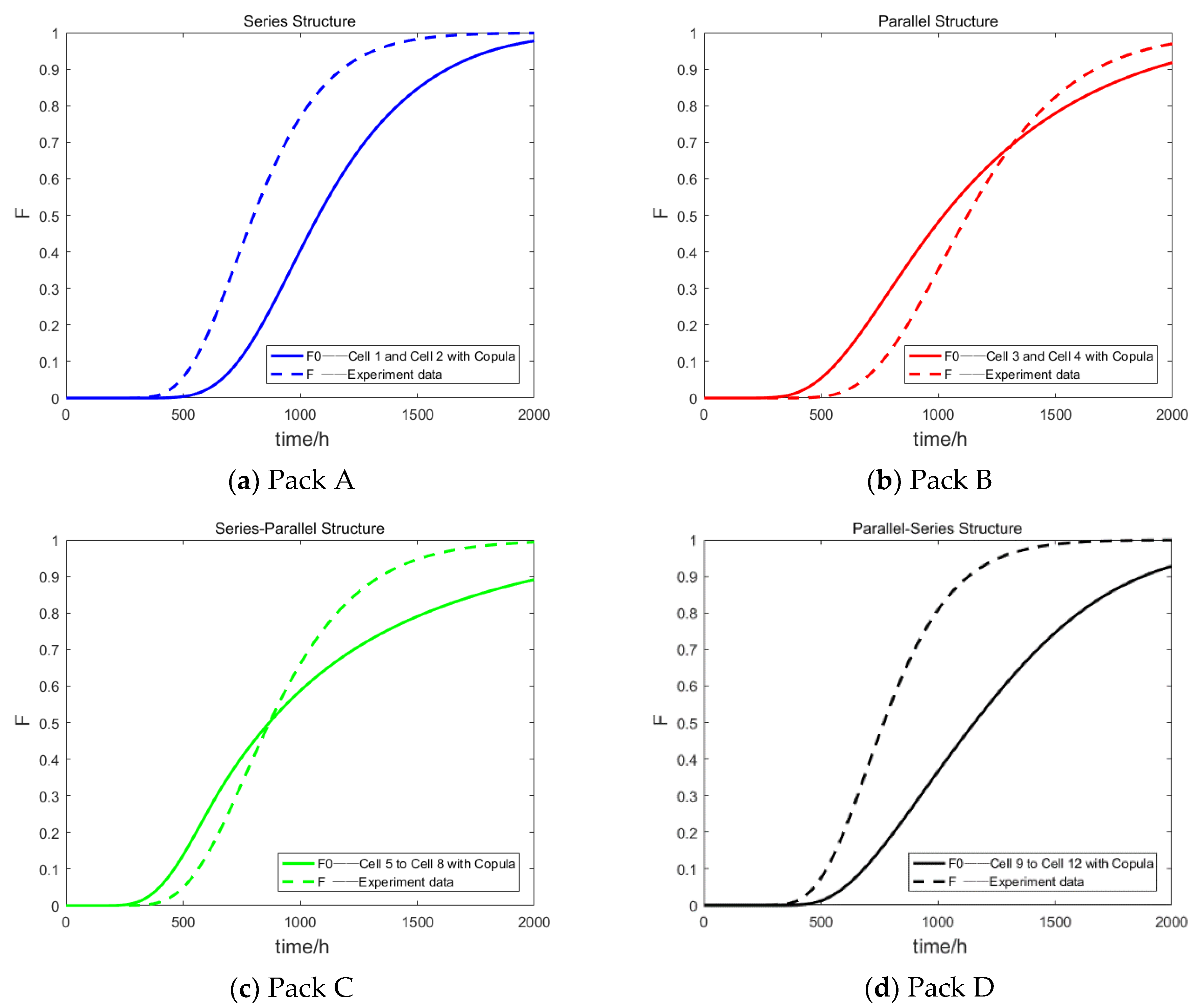

3.1. A Copula-Based Approach to Quantifying Dependency

3.2. Reliability Models of the Lithium-ion Battery Considering the Dependency

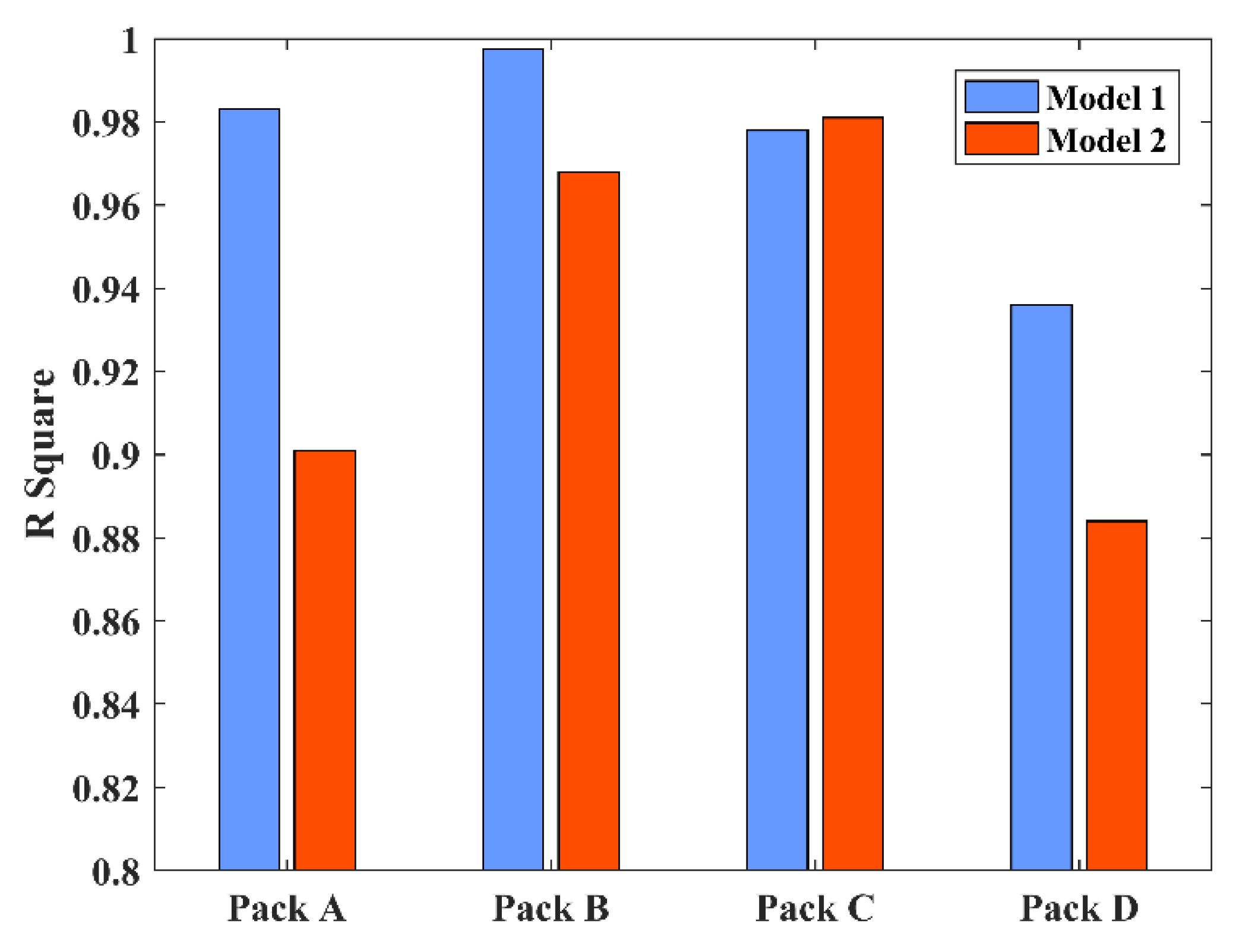

3.3. Model Comparison and Discussion

4. Application in Battery Group Design

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tyagi, A.; Tripathi, K.M.; Gupta, R.K. Recent progress in micro-scale energy storage devices and future aspects. J. Mater. Chem. A 2015, 3, 22507–22541. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Wang, Z.; Wang, L.; Wang, Z.; Guo, H. Dependency analysis and degradation process-dependent modeling of lithium-ion battery packs. J. Power Sources 2019, 414, 318–326. [Google Scholar] [CrossRef]

- Hendricks, C.; Williard, N.; Mathew, S.; Pecht, M. A failure modes, mechanisms, and effects analysis (FMMEA) of lithium-ion batteries. J. Power Sources 2015, 297, 113–120. [Google Scholar] [CrossRef] [Green Version]

- Liu, M.; Li, W.; Wang, C.; Polis, M.P.; Wang, L.Y.; Li, J. Reliability evaluation of large scale battery energy storage systems. IEEE Trans. Smart Grid 2017, 8, 2733–2743. [Google Scholar] [CrossRef]

- Li, J.; Tan, F.; Zhang, C.; Sun, F. Capacity fade diagnosis of Lithium ion battery pack in electric vehicle base on fuzzy neural network. Energy Procedia 2014, 61, 2066–2070. [Google Scholar] [CrossRef]

- Zheng, Y.; Gao, W.; Ouyang, M.; Lu, L.; Zhou, L.; Han, X. State-of-charge inconsistency estimation of lithium-ion battery pack using mean-difference model and extended kalman filter. J. Power Sources 2018, 383, 50–58. [Google Scholar] [CrossRef]

- Zhen-Po, W.; Peng, L.; Li-Fang, W. Analysis on the capacity degradation mechanism of a series lithium-ion power battery pack based on inconsistency of capacity. Chin. Phys. B 2013, 22, 746–755. [Google Scholar]

- Zhang, X.; Wang, Y.; Liu, C.; Chen, Z. A novel approach of remaining discharge energy prediction for large format lithium-ion battery pack. J. Power Sources 2017, 343, 216–225. [Google Scholar] [CrossRef]

- Ma, Y.; Duan, P.; Sun, Y.; Chen, H. Equalization of lithium-ion battery pack based on fuzzy logic control in electric vehicle. IEEE Tran. Ind. Electron. 2018, 65, 6762–6771. [Google Scholar] [CrossRef]

- Sakji-Nsibi, S.; Benazza-Benyahia, A. Copula-based statistical models for multicomponent image retrieval in thewavelet transform domain. In Proceedings of the 16th IEEE International Conference on Image Processing (ICIP), Cairo, Egypt, 7–10 November 2009. [Google Scholar]

- Nelsen, R.B. An Introduction to Copulas; Springer Science & Business Media: Berlin, Germany, 2007. [Google Scholar]

- Yi, W. Applying Copula to Study the Dependence of Reliability. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2005. [Google Scholar]

- Liu, Z.; Ma, X.; Yang, J.; Zhao, Y. Reliability modeling for systems with multiple degradation processes using inverse Gaussian process and copulas. Math. Probl. Eng. 2014, 2014, 1–10. [Google Scholar] [CrossRef]

- Hao, H.; Su, C. Bivariate Nonlinear Diffusion Degradation Process Modeling via Copula and MCMC. Math. Probl. Eng. 2014, 2014, 1–11. [Google Scholar] [CrossRef]

- Luo, X.; Shevchenko, P.V. The t copula with multiple parameters of degrees of freedom: Bivariate characteristics and application to risk management. Quant. Financ. 2010, 10, 1039–1054. [Google Scholar] [CrossRef]

- Bee, M. Copula-based multivariate models with applications to risk management and insurance. SSRN Electron. J. 2005. [Google Scholar] [CrossRef]

- Ghosh, I.; Ray, S. Some alternative bivariate Kumaraswamy-type distributions via copula with application in risk management. J. Stat. Theory Pract. 2016, 10, 693–706. [Google Scholar] [CrossRef]

- Tang, S.; Yu, C.; Wang, X.; Guo, X.; Si, X. Remaining useful life prediction of lithium-ion batteries based on the wiener process with measurement error. Energies 2014, 7, 520–547. [Google Scholar] [CrossRef]

- Sun, Y. Research on Equilibrium Control Based on SOC Estimation for Battery Pack of Electric Vehicle. Master’s thesis, Jilin University, Changchun, China, 2017. [Google Scholar]

- Liu, X.; Zou, J.; Zhang, X. Investigations on the reliability of storage battery array with high capability. In Proceedings of the International Conference on Condition Monitoring and Diagnosis, Beijing, China, 21–24 April 2008. [Google Scholar]

- Zeng, S. Reliability Design and Analysis; National Defence Industry Press: Beijing, China, 2011. [Google Scholar]

- Luciano, E.; Semeraro, P. Multivariate Variance Gamma and Gaussian Dependence: A Study with Copulas; Mathematical and Statistical Methods for Actuarial Sciences and Finance: Milano, Italy, 2010; pp. 193–203. [Google Scholar]

- Sklar, M. Fonctions de repartition an dimensions et leurs marges. Publ. Inst. Statist. Univ. Paris 1959, 8, 229–231. [Google Scholar]

- Louzada, F.; Ferreira, P.H. Modified inference function for margins for the bivariate clayton copula-based SUN Tobit Model. J. Appl. Stat. 2016, 43, 1–21. [Google Scholar] [CrossRef]

- Abdi, A.; Hassanzadeh, Y.; Talatahari, S.; Fakheri-Fard, A.; Mirabbasi, R. Parameter estimation of copula functions using an optimization-based method. Theor. Appl. Climatol. 2017, 129, 21–32. [Google Scholar] [CrossRef]

- Schmalstieg, J.; Käbitz, S.; Ecker, M.; Sauer, D.U. A holistic aging model for Li (NiMnCo) O2 based 18650 lithium-ion batteries. J. Power Sources 2014, 257, 325–334. [Google Scholar] [CrossRef]

- Nelder, J.A.; Wedderburn, R.W. Generalized linear models. J. R. Stat. Soc. Ser. A (Gen.) 1972, 135, 370–384. [Google Scholar] [CrossRef]

- Hocking, R.R.; Hocking, R.R. The Analysis of Linear Models; Brooks/Cole: Beijing, China, 1985. [Google Scholar]

- Beninger, P.G.; Boldina, I.; Katsanevakis, S. Strengthening statistical usage in marine ecology. J. Exp. Mar. Biol. Ecol. 2012, 426, 97–108. [Google Scholar] [CrossRef]

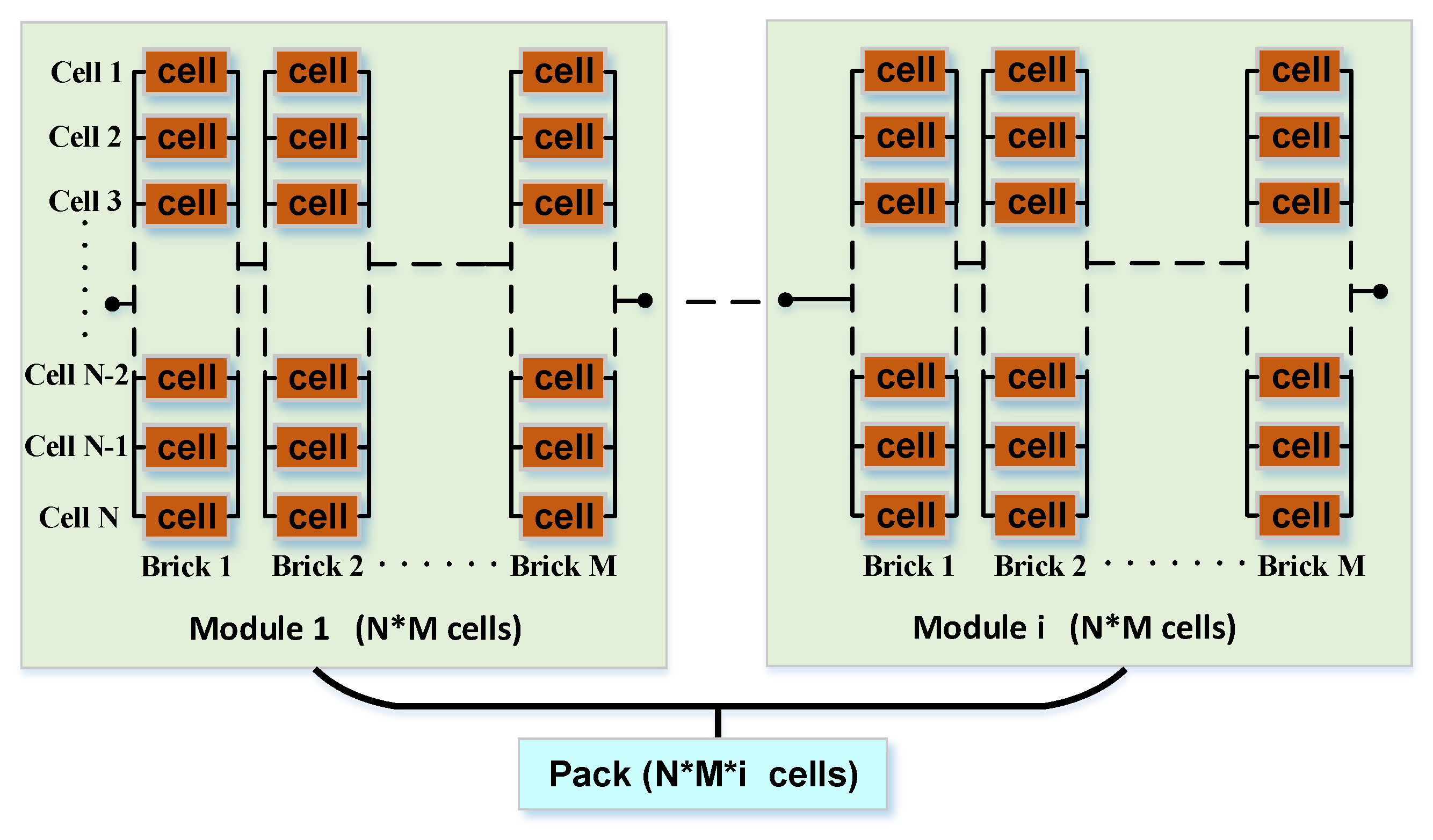

| Cell and Packs | Rated Capacity (Ah) | Failure Threshold Value w (Ah) |

|---|---|---|

| Cell | 2.15 | 0.43 |

| Pack A | 2.15 | 0.43 |

| Pack B | 4.30 | 0.86 |

| Pack C | 4.30 | 0.86 |

| Pack D | 4.30 | 0.86 |

| Pack | R |

|---|---|

| Pack A | |

| Pack B | |

| Pack C | |

| Pack D |

| Pack | Pack A | Pack B | Pack C | Pack D |

|---|---|---|---|---|

| RMSE | 0.0674 | 0.0648 | 0.0821 | 0.1377 |

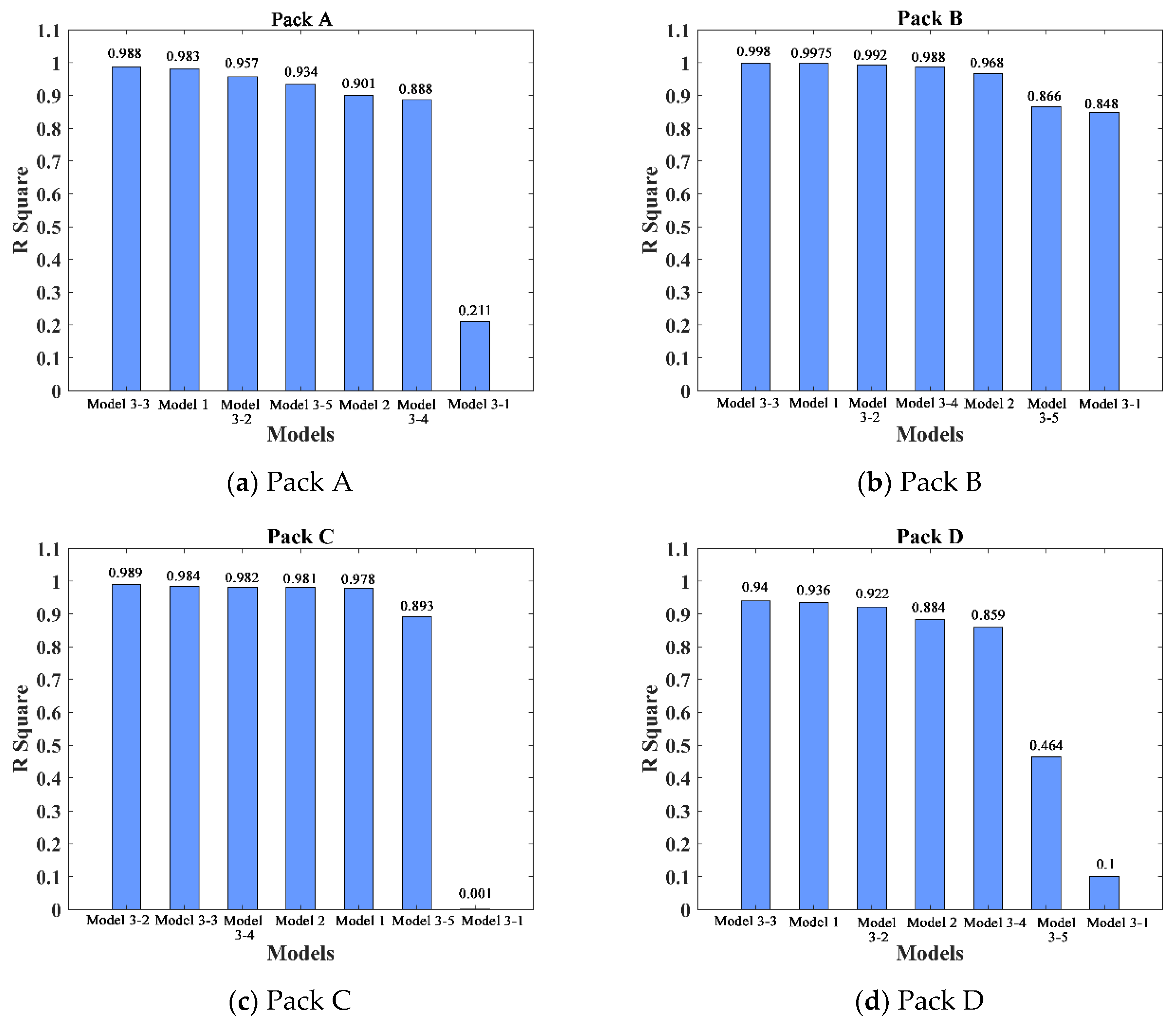

| Models | Pack | a | c | R2 | p-Value |

|---|---|---|---|---|---|

| Model 1 | Pack A | 0.953 | 0.061 | 0.983 | <0.01 |

| Pack B | 1.119 | 0.004 | 0.9975 | <0.01 | |

| Pack C | 0.984 | −0.047 | 0.978 | <0.01 | |

| Pack D | 0.927 | 0.121 | 0.936 | <0.01 | |

| Model 2 | Pack A | 1.02 | 0.139 | 0.901 | <0.001 |

| Pack B | 1.101 | −0.074 | 0.968 | <0.001 | |

| Pack C | 1.301 | −0.033 | 0.981 | <0.001 | |

| Pack D | 1.13 | 0.142 | 0.884 | <0.001 |

| Model 3 | Pack | a | b | c | R2 | p-Value |

|---|---|---|---|---|---|---|

| Model 3-1 | Pack A | −0.068 | / | 0.065 | 0.211 | <0.01 |

| Pack B | 0.121 | / | −0.007 | 0.848 | <0.01 | |

| Pack C | 0.007 | / | −0.06 | 0.001 | <0.01 | |

| Pack D | −0.1 | / | 0.124 | 0.1 | <0.01 | |

| Model 3-2 | Pack A | 0.5 | / | 0.092 | 0.957 | <0.01 |

| Pack B | 0.56 | / | −0.04 | 0.992 | <0.01 | |

| Pack C | 0.566 | / | −0.47 | 0.989 | <0.01 | |

| Pack D | 0.514 | / | 0.126 | 0.922 | <0.01 | |

| Model 3-3 | Pack A | 1.229 | −0.317 | 0.048 | 0.988 | <0.01 |

| Pack B | 1.003 | 0.117 | −0.006 | 0.998 | <0.01 | |

| Pack C | 0.401 | 0.732 | −0.046 | 0.984 | <0.01 | |

| Pack D | 1.181 | −0.328 | 0.121 | 0.94 | <0.01 | |

| Model 3-4 | Pack A | 1.017 | / | 0.148 | 0.888 | <0.01 |

| Pack B | 1.261 | / | 0.014 | 0.988 | <0.01 | |

| Pack C | 1.291 | / | −0.011 | 0.982 | <0.01 | |

| Pack D | 1.102 | / | 0.169 | 0.859 | <0.01 | |

| Model 3-5 | Pack A | 0.197 | 0.001 | −0.011 | 0.934 | <0.01 |

| Pack B | −0.018 | 0.26 | −0.011 | 0.866 | <0.01 | |

| Pack C | 0.507 | −0.363 | −0.03 | 0.893 | <0.01 | |

| Pack D | 1.187 | −1.338 | 0.139 | 0.464 | <0.01 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Sun, Y.; Wang, X.; Wang, Z.; Zhao, X. Reliability Modeling Method for Lithium-ion Battery Packs Considering the Dependency of Cell Degradations Based on a Regression Model and Copulas. Materials 2019, 12, 1054. https://doi.org/10.3390/ma12071054

Wang L, Sun Y, Wang X, Wang Z, Zhao X. Reliability Modeling Method for Lithium-ion Battery Packs Considering the Dependency of Cell Degradations Based on a Regression Model and Copulas. Materials. 2019; 12(7):1054. https://doi.org/10.3390/ma12071054

Chicago/Turabian StyleWang, Lizhi, Yusheng Sun, Xiaohong Wang, Zhuo Wang, and Xuejiao Zhao. 2019. "Reliability Modeling Method for Lithium-ion Battery Packs Considering the Dependency of Cell Degradations Based on a Regression Model and Copulas" Materials 12, no. 7: 1054. https://doi.org/10.3390/ma12071054

APA StyleWang, L., Sun, Y., Wang, X., Wang, Z., & Zhao, X. (2019). Reliability Modeling Method for Lithium-ion Battery Packs Considering the Dependency of Cell Degradations Based on a Regression Model and Copulas. Materials, 12(7), 1054. https://doi.org/10.3390/ma12071054