Mechanical Behaviors of Flax Fiber-Reinforced Composites at Different Strain Rates and Rate-Dependent Constitutive Model

Abstract

:1. Introduction

2. Materials and Methods

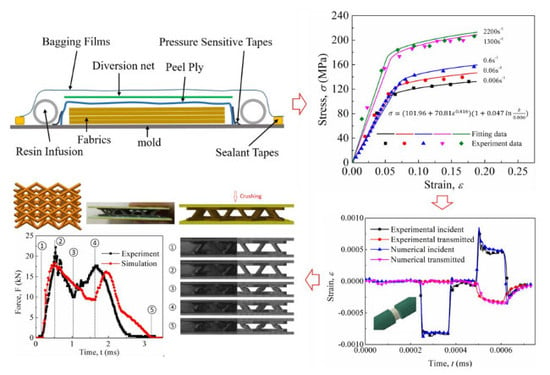

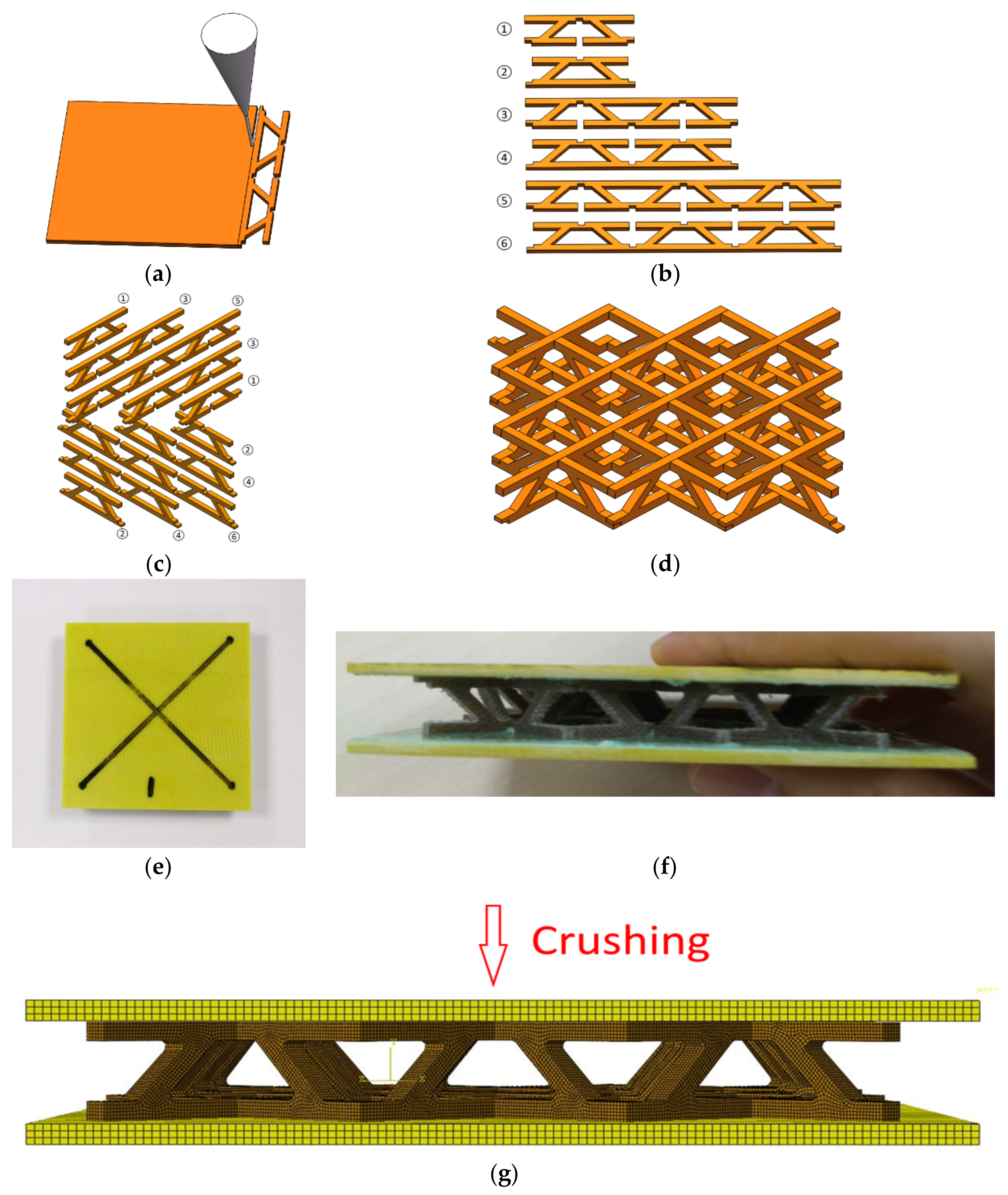

2.1. Fabrication

- ◇

- First, the mold surface is cleaned with acetone to achieve a perfect surface quality.

- ◇

- Secondly, the layers of woven fiber dried at 70 for 3 h in an oven are laid on a mold sheet and other supplementary materials as shown in Figure 1a.

- ◇

- Third, the resin is injected into the mold with atmospheric pressure after vacuuming and checking the sealing.

- ✧

2.2. Experimental Set-Up

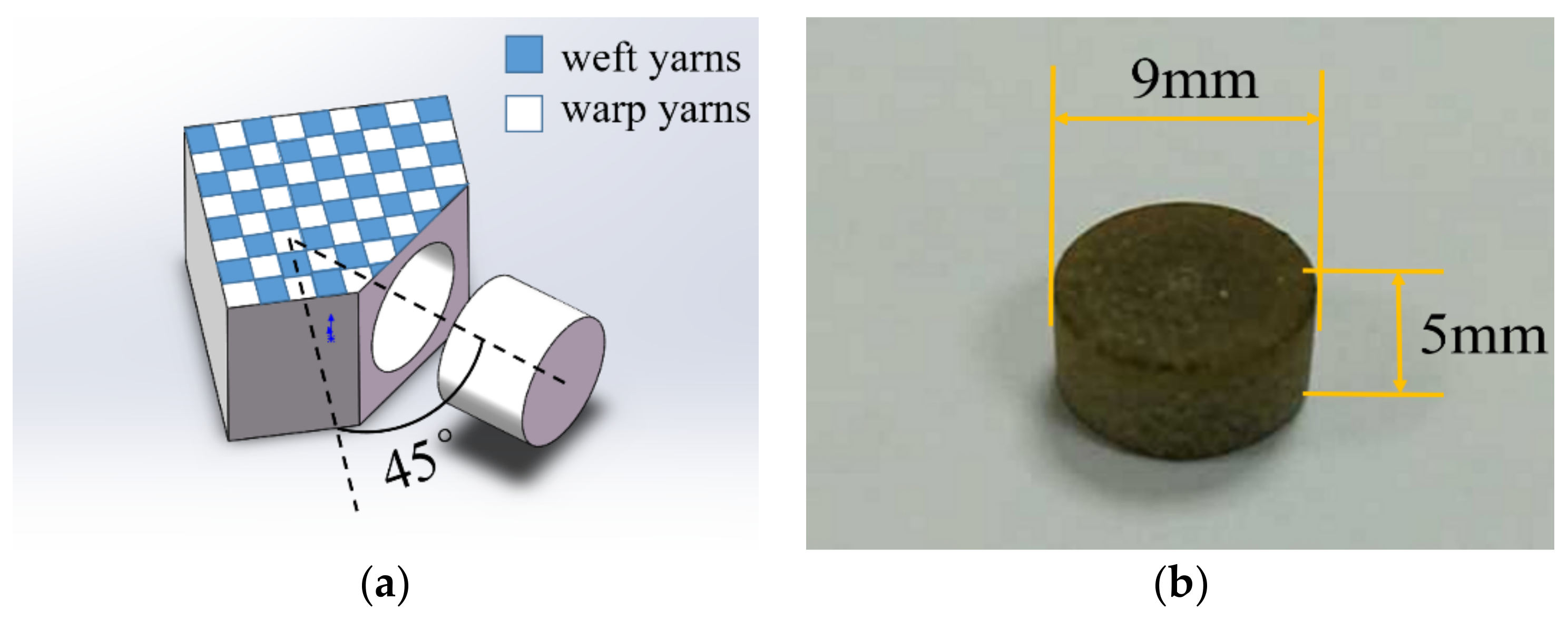

2.2.1 Quasi-Static Compression Experiment

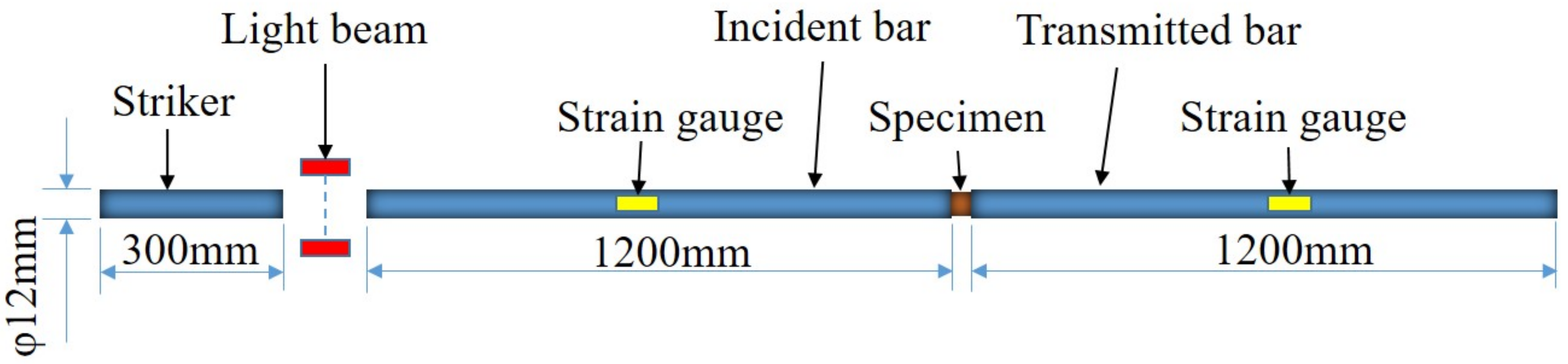

2.2.2. SHPB Experiment

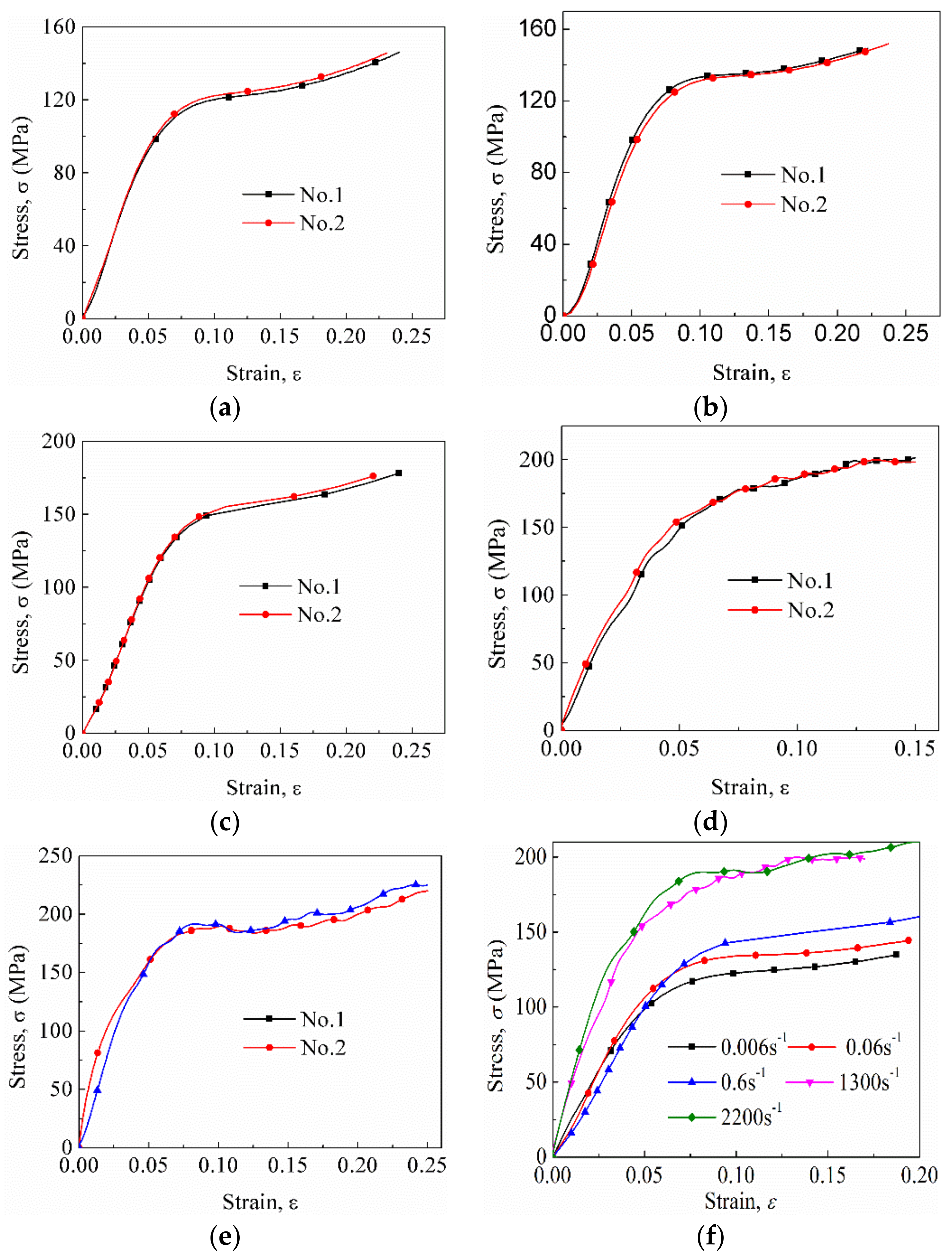

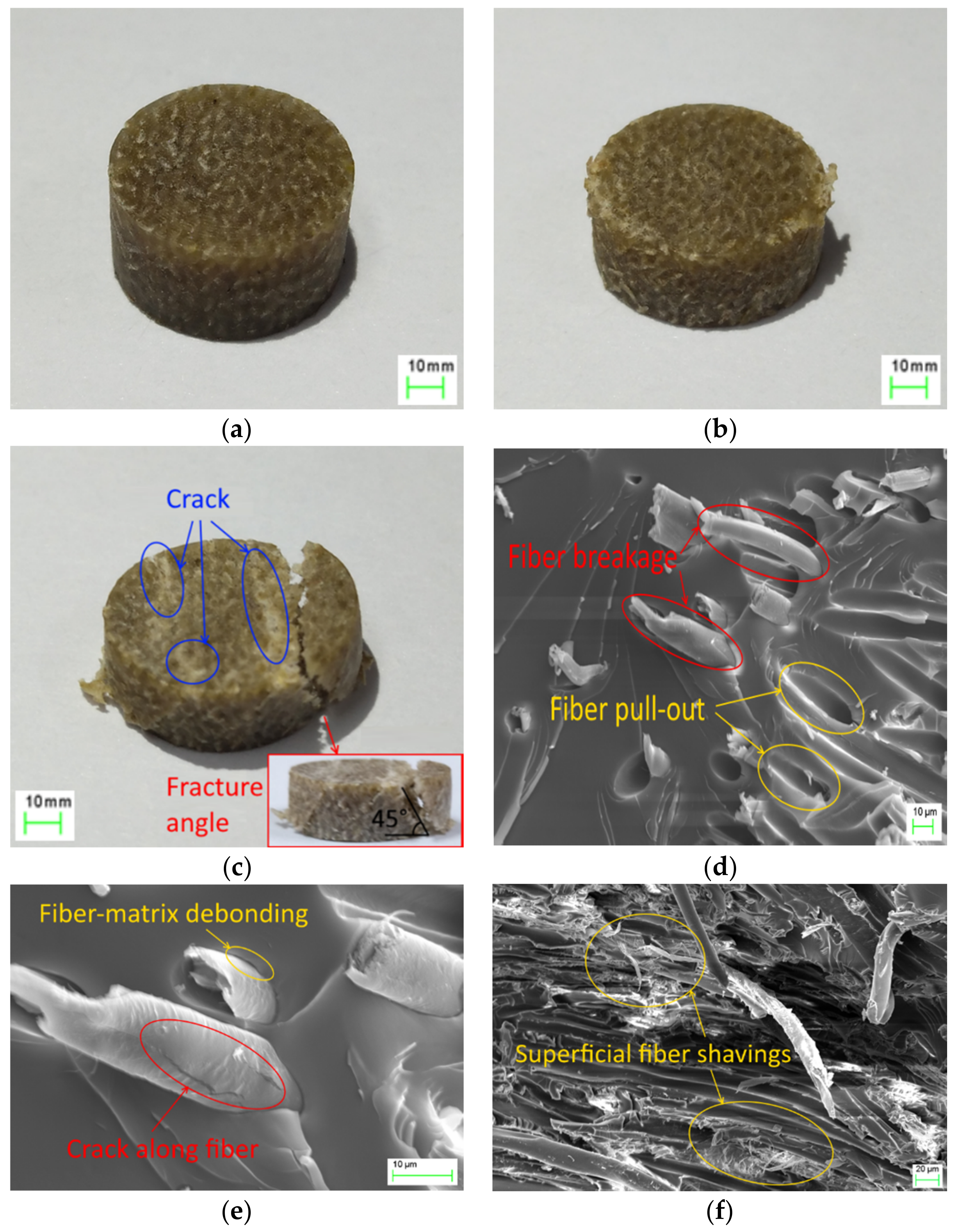

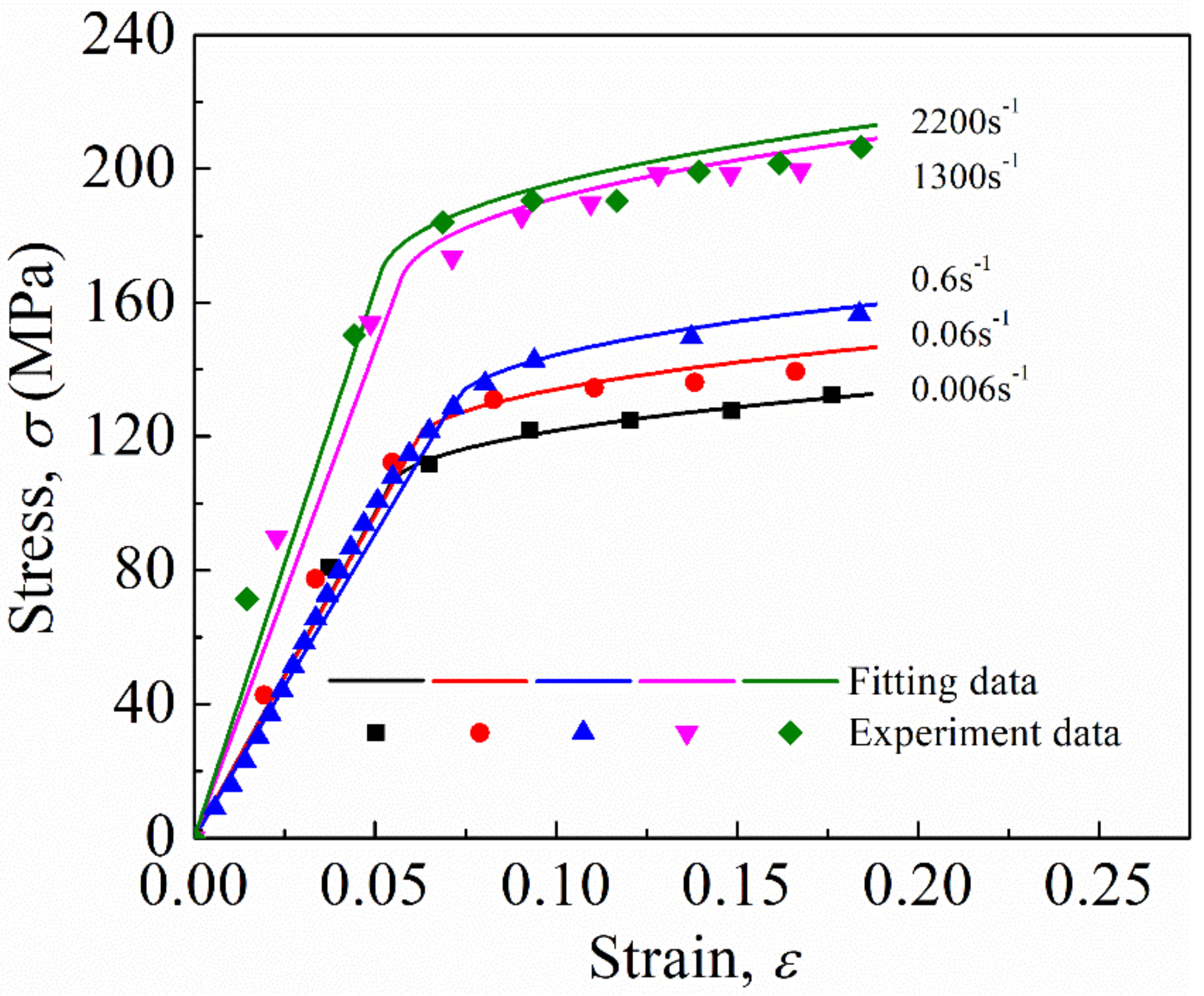

3. Experimental Results

4. Discussion

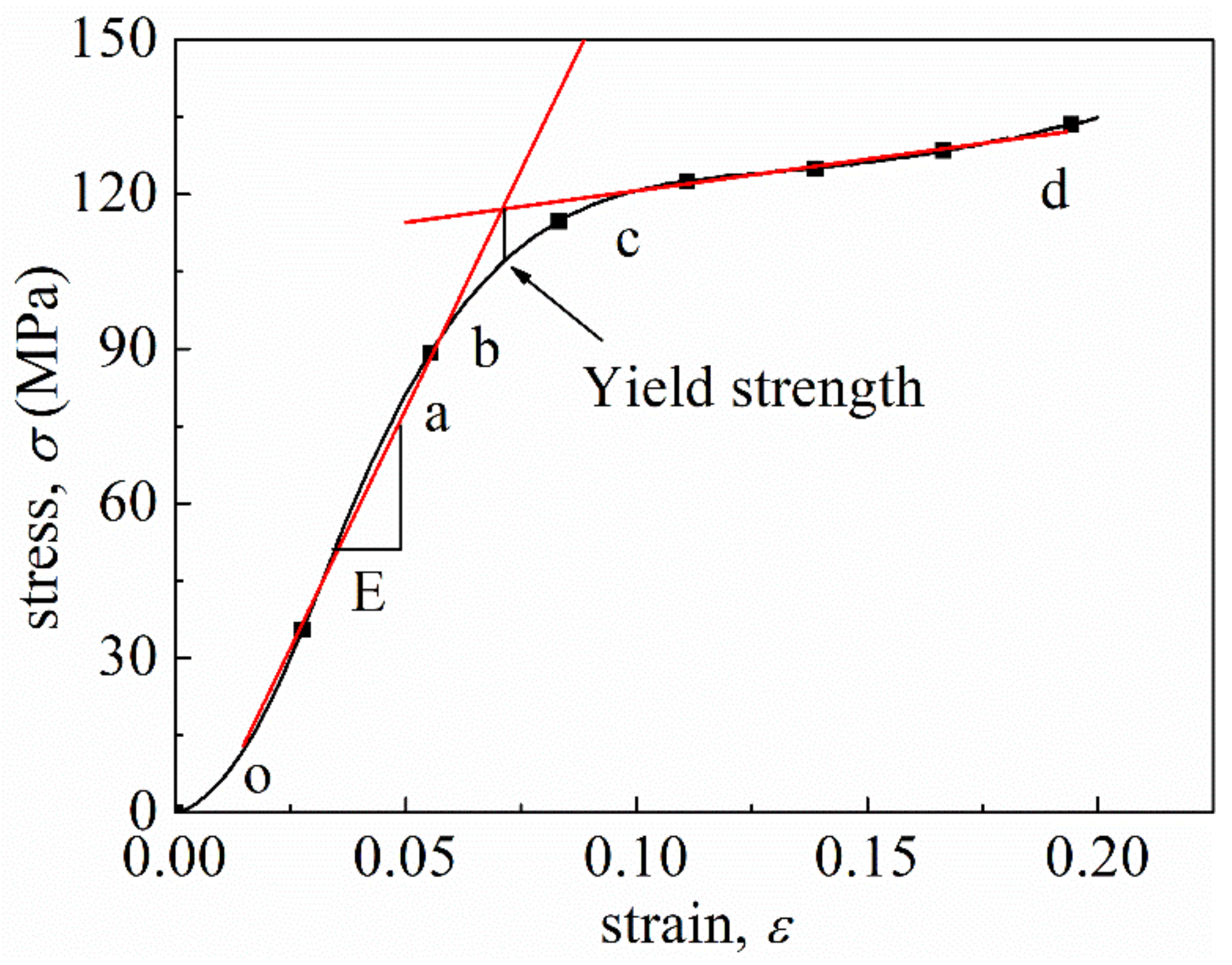

4.1. Simplified Johnson–Cook Model

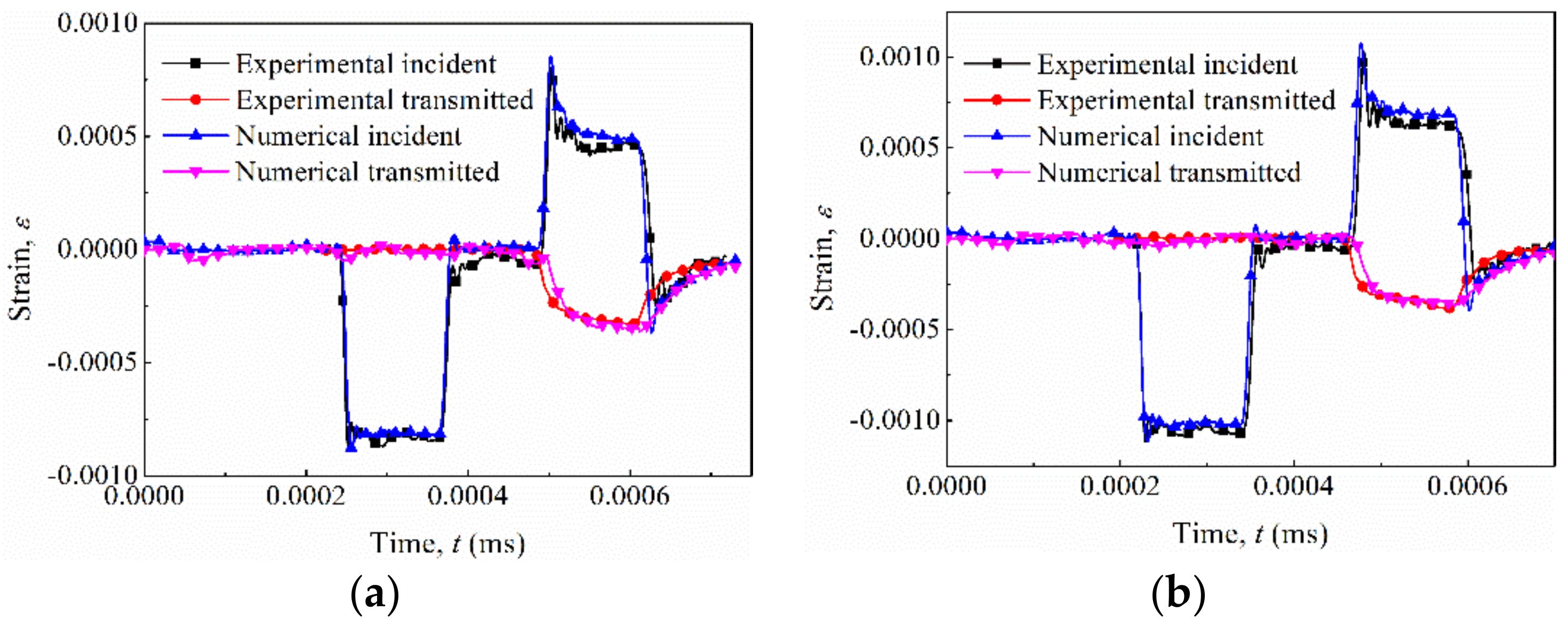

4.2. Dynamic Wave Verification

4.3. Prediction of the Crushing Peofrmance of Lattice Structures

4.3.1. Specimen and FEM Model

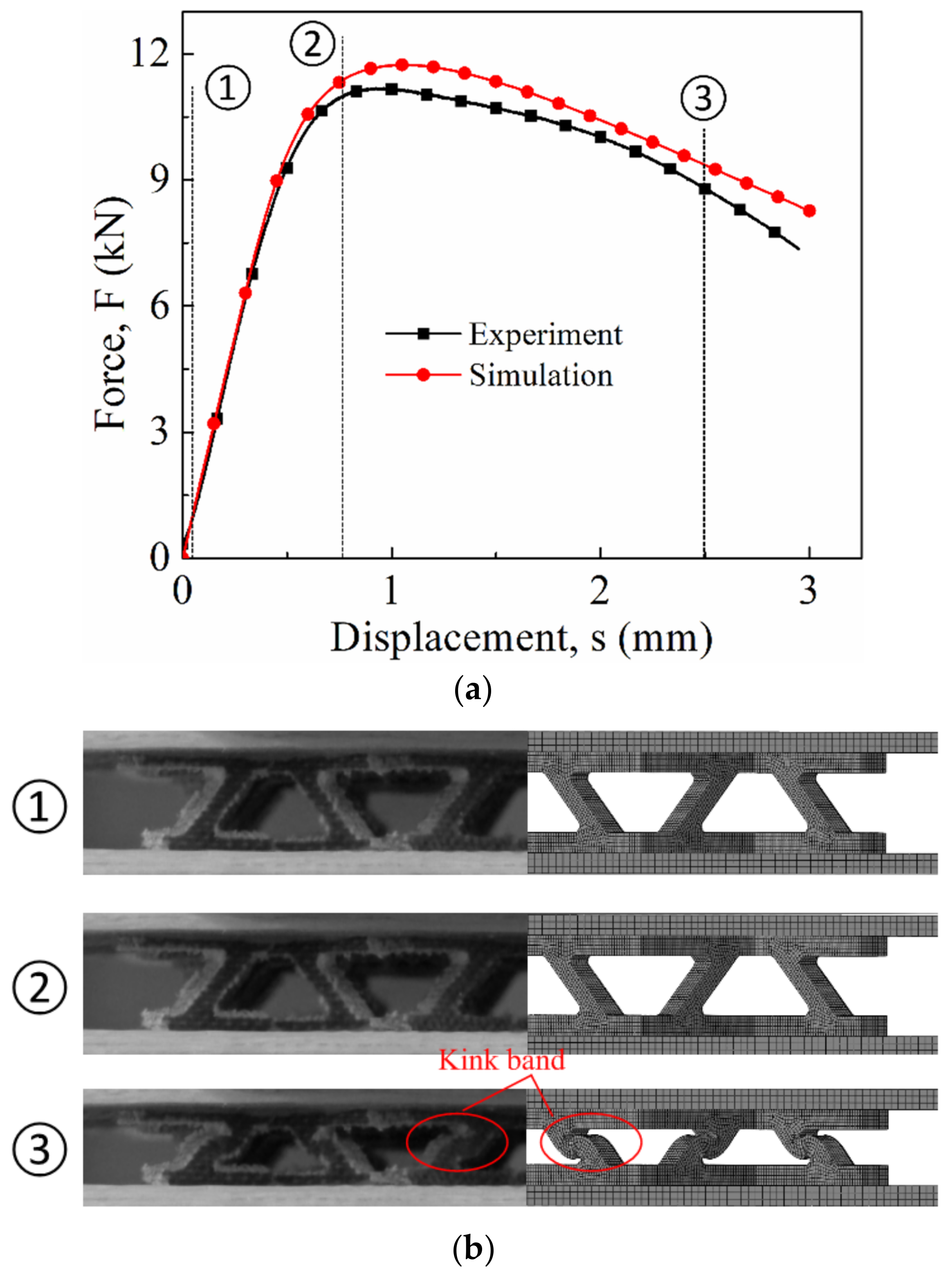

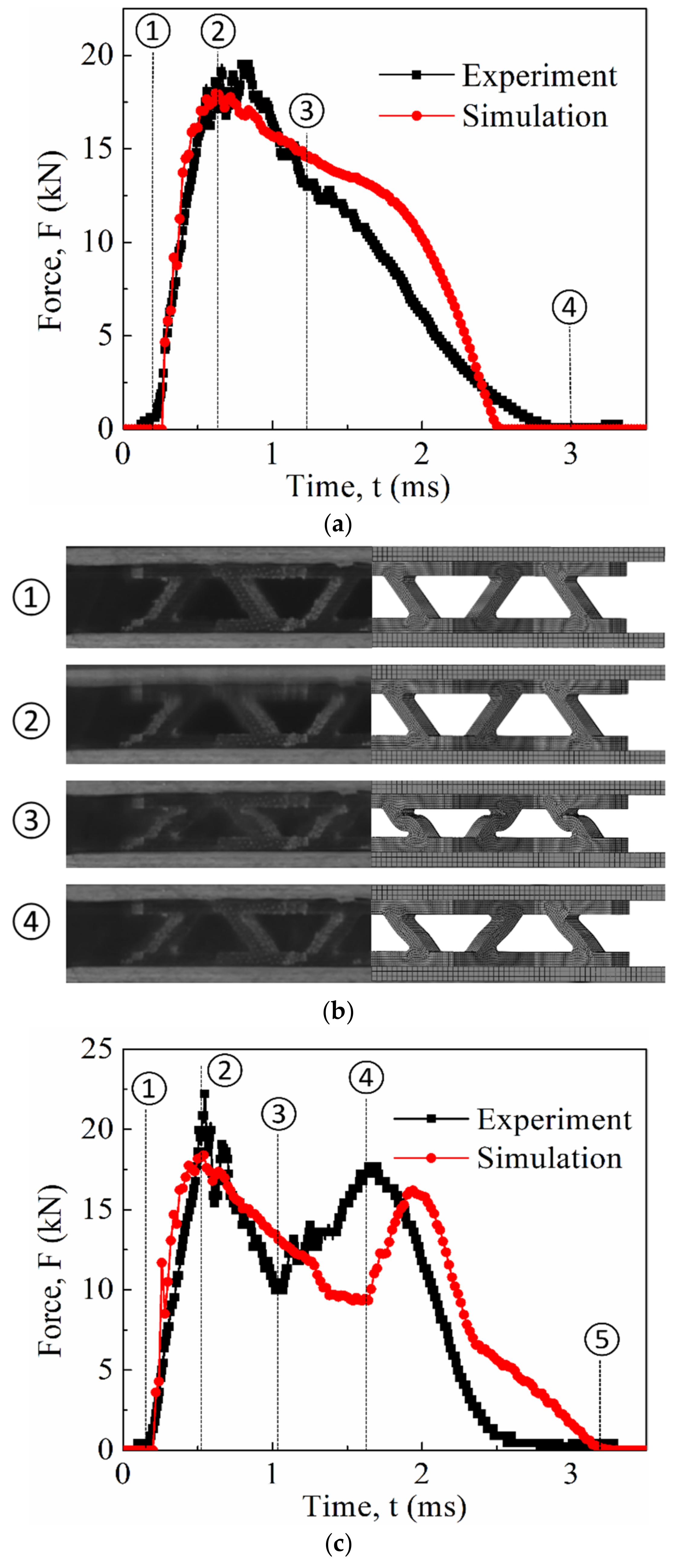

4.3.2. Quasi-Static and Impact Experiments

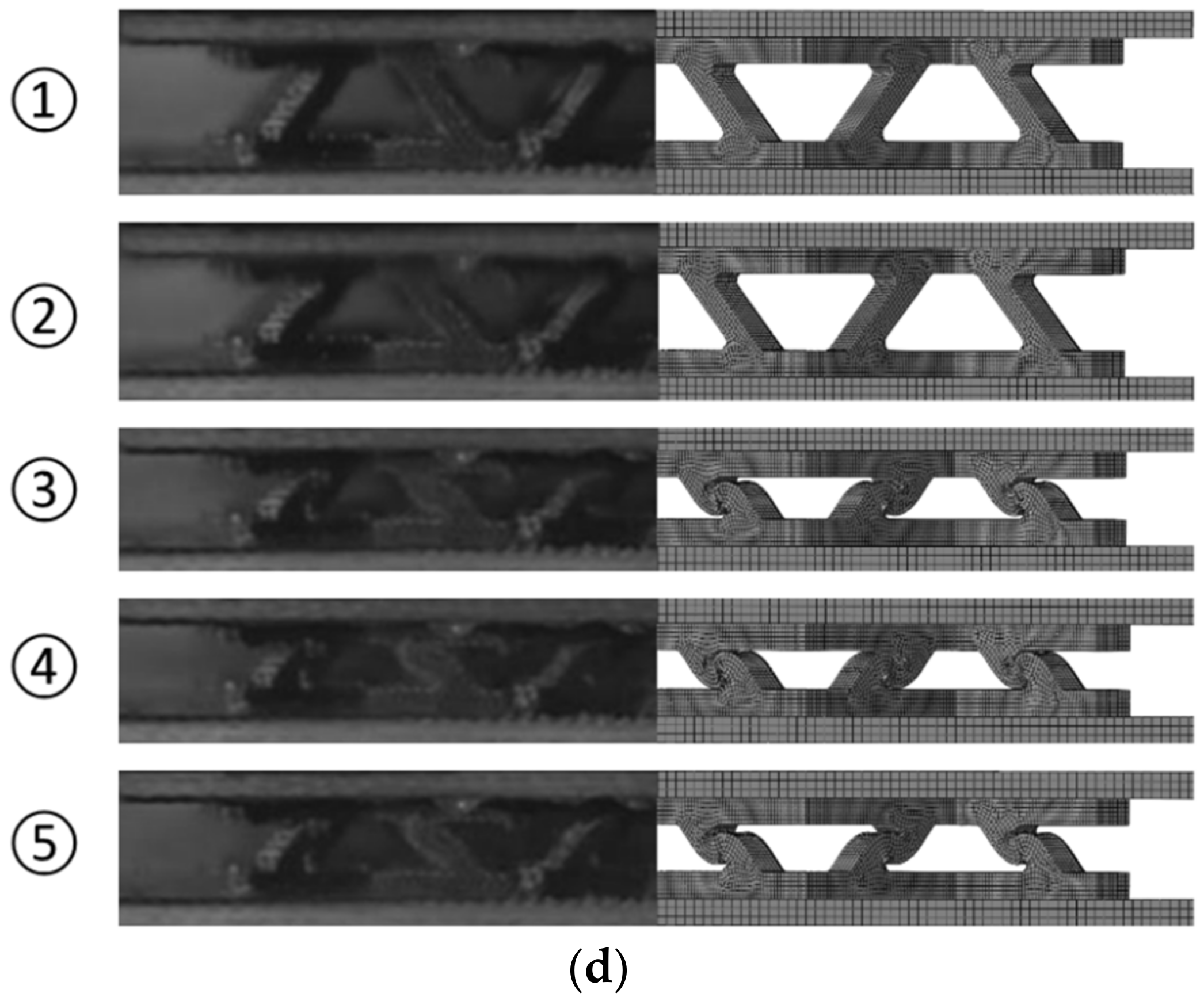

4.3.3. Numerical Simulation and Experiment Correlation

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Dittenber, D.B.; Gangarao, H.V.S. Critical review of recent publications on use of natural composites in infrastructure. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1419–1429. [Google Scholar] [CrossRef]

- Fragassa, C.; Pavlovic, A.; Santulli, C. Mechanical and impact characterisation of flax and basalt fibre vinylester composites and their hybrids. Compos. Part B Eng. 2018, 137, 247–259. [Google Scholar] [CrossRef]

- Campana, C.; Leger, R.; Sonnier, R.; Ferry, L.; Ienny, P. Effect of post curing temperature on mechanical properties of a flax fiber reinforced epoxy composite. Compos. Part A Appl. Sci. Manuf. 2018, 107, 171–179. [Google Scholar] [CrossRef]

- López-Alba, E.; Schmeer, S.; Díaz, F. Energy absorption capacity in natural fiber reinforcement composites structures. Materials 2018, 11, 418. [Google Scholar] [CrossRef]

- Claramunt, J.; Ventura, H.; Fernández-Carrasco, L.; Ardanuy, M. Tensile and flexural properties of cement composites reinforced with flax nonwoven fabrics. Materials 2017, 10, 215. [Google Scholar] [CrossRef]

- Amenini, F.; Brocail, J.; Chauvin, M.; Thuillier, S. Dynamical properties of flax fibre reinforced PA11 over a large frequency range. Compos. Sci. Technol. 2019, 171, 234–243. [Google Scholar] [CrossRef]

- Chilali, A.; Assarar, M.; Zouari, W.; Kebir, H.; Ayad, R. Analysis of the hydro-mechanical behaviour of flax fibre-reinforced composites: Assessment of hygroscopic expansion and its impact on internal stress. Compos. Struct. 2018, 206, 177–184. [Google Scholar] [CrossRef]

- Crawford, B.; Pakpour, S.; Kazemian, N.; Klironomos, J.; Stoeffler, K.; Rho, D.; Denault, J.; Milani, A.S. Effect of fungal deterioration on physical and mechanical properties of hemp and flax natural fiber composites. Materials 2017, 10, 1252. [Google Scholar] [CrossRef]

- Ventura, H.; Claramunt, J.; Navarro, A.; Rodriguez-Perez, M.A.; Ardanuy, M. Effects of wet/dry-cycling and plasma treatments on the properties of flax nonwovens intended for composite reinforcing. Materials 2016, 9, 93. [Google Scholar] [CrossRef]

- Joshi, S.V.; Drzal, L.T.; Mohanty, A.K.; Arora, S. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos. Part A Appl. Sci. Manuf. 2004, 35, 371–376. [Google Scholar] [CrossRef]

- Koh, R.; Madsen, B. Strength failure criteria analysis for a flax fibre reinforced composite. Mech. Mater. 2018, 124, 26–32. [Google Scholar] [CrossRef]

- Ramesh, M. Flax (Linum usitatissimum L.) fibre reinforced polymer composite materials: A review on preparation, properties and prospects. Prog. Mater. Sci. 2019, 102, 109–166. [Google Scholar] [CrossRef]

- Alkbir, M.F.M.; Sapuan, S.M.; Nuraini, A.A.; Ishak, M.R. Fibre properties and crashworthiness parameters of natural fibre-reinforced composite structure: A literature review. Compos. Struct. 2016, 148, 59–73. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. Effect of triggering and polyurethane foam-filler on axial crushing of natural flax/epoxy composite tubes. Mater. Des. 2014, 56, 528–541. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N. Crashworthiness characteristics of flax fibre reinforced epoxy tubes for energy absorption application. Mater. Des. 2013, 51, 629–640. [Google Scholar] [CrossRef]

- Yan, L.; Kasal, B.; Huang, L. A review of recent research on the use of cellulosic fibres, their fibre fabric reinforced cementitious, geo-polymer and polymer composites in civil engineering. Compos. Part B Eng. 2016, 92, 94–132. [Google Scholar] [CrossRef]

- Ravandi, M.; Teo, W.S.; Tran, L.Q.N.; Yong, M.S.; Tay, T.E. Low velocity impact performance of stitched flax/epoxy composite laminates. Compos. Part B Eng. 2017, 117, 89–100. [Google Scholar] [CrossRef]

- Meredith, J.; Coles, S.R.; Powe, R.; Collings, E.; Cozien-Cazuc, S.; Weager, B.; Müssig, J.; Kirwan, K. On the static and dynamic properties of flax and Cordenka epoxy composites. Compos. Sci. Technol. 2013, 80, 31–38. [Google Scholar] [CrossRef]

- Shishevan, F.A.; Akbulut, H.; Mohtadi-Bonab, M.A. Low velocity impact behavior of basalt fiber-reinforced polymer composites. J. Mater. Eng. Perform. 2017, 26, 2890–2900. [Google Scholar] [CrossRef]

- Rahman, M.Z.; Jayaraman, K.; Mace, B.R. Impact energy absorption of flax fiber-reinforced polypropylene composites. Polym. Compos. 2018, 39, 4165–4175. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.Y.; Bennett, N.; Reis, P.N.B. Low-velocity impact response of non-woven hemp fibre reinforced unsaturated polyester composites: Influence of impactor geometry and impact velocity. Compos. Struct. 2012, 94, 2756–2763. [Google Scholar] [CrossRef]

- Rajaei, M.; Kim, N.K.; Bhattacharyya, D. Effects of heat-induced damage on impact performance of epoxy laminates with glass and flax fibres. Compos. Struct. 2018, 185, 515–523. [Google Scholar] [CrossRef]

- Shen, Y.; Zhong, J.J.; Cai, S.M.; Ma, H.; Qu, Z.H.; Guo, Y.C.; Li, Y. Effect of temperature and water absorption on low-velocity impact damage of composites with multi-layer structured flax fiber. Materials 2019, 12, 453. [Google Scholar] [CrossRef]

- Al-Hajaj, Z.; Sy, B.L.; Bougherara, H.; Zdero, R. Impact properties of a new hybrid composite material made from woven carbon fibres plus flax fibres in an epoxy matrix. Compos. Struct. 2019, 208, 346–356. [Google Scholar] [CrossRef]

- Hu, D.Y.; Meng, K.P.; Jiang, H.L.; Xu, J.; Liu, R.R. Strain rate dependent constitutive behavior investigation of AerMet 100 steel. Mater. Des. 2015, 87, 759–772. [Google Scholar] [CrossRef]

- Elanchezhian, C.; Ramnath, B.V.; Hemalatha, J. Mechanical behaviour of glass and carbon fibre reinforced composites at varying strain rates and temperatures. Procedia Mat. Sci. 2014, 6, 1405–1418. [Google Scholar] [CrossRef]

- Omar, M.F.; Akil, H.M.; Ahmad, Z.A.; Mazuki, A.A.M.; Yokoyama, T. Dynamic properties of pultruded natural fibre reinforced composites using Split Hopkinson Pressure Bar technique. Mater. Des. 2010, 31, 4209–4218. [Google Scholar] [CrossRef]

- Kim, W.; Argento, A.; Lee, E.; Flanigan, C.; Houston, D.; Harris, A.; Mielewski, D.F. High strain-rate behavior of natural fiber-reinforced polymer composites. J. Compos. Mater. 2012, 46, 1051–1065. [Google Scholar] [CrossRef]

- Rubio-López, A.; Olmedo, A.; Santiuste, C. Modelling impact behaviour of all-cellulose composite plates. Compos. Struct. 2015, 122, 139–143. [Google Scholar] [CrossRef]

- Poilâne, C.; Cherif, Z.E.; Richard, F.; Vivet, A.; Doudou, B.B.; Chen, J. Polymer reinforced by flax fibres as a viscoelastoplastic material. Compos. Struct. 2014, 112, 100–112. [Google Scholar] [CrossRef]

- Rubio-López, A.; Hoang, T.; Santiuste, C. Constitutive model to predict the viscoplastic behaviour of natural fibres based composites. Compos. Struct. 2016, 155, 8–18. [Google Scholar] [CrossRef]

- Jalón, E.; Hoang, T.; Rubio-López, A.; Santiuste, C. Analysis of low-velocity impact on flax/PLA composites using a strain rate sensitive model. Compos. Struct. 2018. [CrossRef]

- Holbery, J.; Dan, H. Natural-fiber-reinforced polymer composites in automotive applications. JOM 2006, 58, 80–86. [Google Scholar] [CrossRef]

- Gama, B.A.; Lopatnikov, S.L.; Gillespie, J.W. Hopkinson bar experimental technique: A critical review. Appl. Mech. Rev. 2004, 57, 223–250. [Google Scholar] [CrossRef]

- Liang, S.X.; Gning, P.-B.; Guillaumat, L. Quasi-static behaviour and damage assessment of flax/epoxy composites. Mater. Des. 2015, 67, 344–353. [Google Scholar] [CrossRef]

- Singh, N.K.; Cadoni, E.; Singha, M.K.; Gupta, N.K. Dynamic tensile behavior of multi phase high yield strength steel. Mater. Des. 2011, 32, 5091–5098. [Google Scholar] [CrossRef]

- Arbaoui, J.; Tarfaoui, M.; El Malki Alaoui, A. Mechanical behavior and damage kinetics of woven E-glass/vinylester laminate composites under high strain rate dynamic compressive loading: Experimental and numerical investigation. Int. J. Impact Eng. 2016, 87, 44–54. [Google Scholar] [CrossRef]

- Berger, J.B.; Wadley, H.N.G.; McMeeking, R.M. Mechanical metamaterials at the theoretical limit of isotropic elastic stiffness. Nature 2017, 543, 533. [Google Scholar] [CrossRef]

- Tankasala, H.C.; Deshpande, V.S.; Fleck, N.A. Tensile response of elastoplastic lattices at finite strain. J. Mech. Phys. Solids. 2017, 109, 307–330. [Google Scholar] [CrossRef]

| 0.006 s−1 | 0.06 s−1 | 0.6 s−1 | 1300 s−1 | 2200 s−1 | |

| 102.0 MPa | 112.3 MPa | 149.9 MPa | 152.0 MPa | 163.7 MPa |

| Simplified Johnson-Cook model | A (MPa) | B (MPa) | n | C | |

| Value | 102.0 | 70.8 | 0.416 | 0.047 | 0.006 |

| Impact Energy (J) | Peak Load (kN) | Deviation % | ||||

|---|---|---|---|---|---|---|

| Experiments | Simulation | |||||

| No. 1 | No. 2 | No. 3 | Mean | |||

| Quasi static | 10.89 | 11.18 | 11.27 | 11.11 ± 0.16 | 11.73 | 5.58 |

| 30 J | 15.13 | 18.74 | 12.79 | 15.55 ± 2.45 | 17.96 | 15.50 |

| 45 J | 16.70 | 14.06 | - | 15.83 ± 1.32 | 18.40 | 16.23 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, D.; Dang, L.; Zhang, C.; Zhang, Z. Mechanical Behaviors of Flax Fiber-Reinforced Composites at Different Strain Rates and Rate-Dependent Constitutive Model. Materials 2019, 12, 854. https://doi.org/10.3390/ma12060854

Hu D, Dang L, Zhang C, Zhang Z. Mechanical Behaviors of Flax Fiber-Reinforced Composites at Different Strain Rates and Rate-Dependent Constitutive Model. Materials. 2019; 12(6):854. https://doi.org/10.3390/ma12060854

Chicago/Turabian StyleHu, Dayong, Linwei Dang, Chong Zhang, and Zhiqiang Zhang. 2019. "Mechanical Behaviors of Flax Fiber-Reinforced Composites at Different Strain Rates and Rate-Dependent Constitutive Model" Materials 12, no. 6: 854. https://doi.org/10.3390/ma12060854

APA StyleHu, D., Dang, L., Zhang, C., & Zhang, Z. (2019). Mechanical Behaviors of Flax Fiber-Reinforced Composites at Different Strain Rates and Rate-Dependent Constitutive Model. Materials, 12(6), 854. https://doi.org/10.3390/ma12060854