P-Type Lithium Niobate Thin Films Fabricated by Nitrogen-Doping

Abstract

1. Introduction

2. Experimental Details

2.1. Preparation of LN:N thin films

2.2. Instrumentation details

3. Results and Discussion

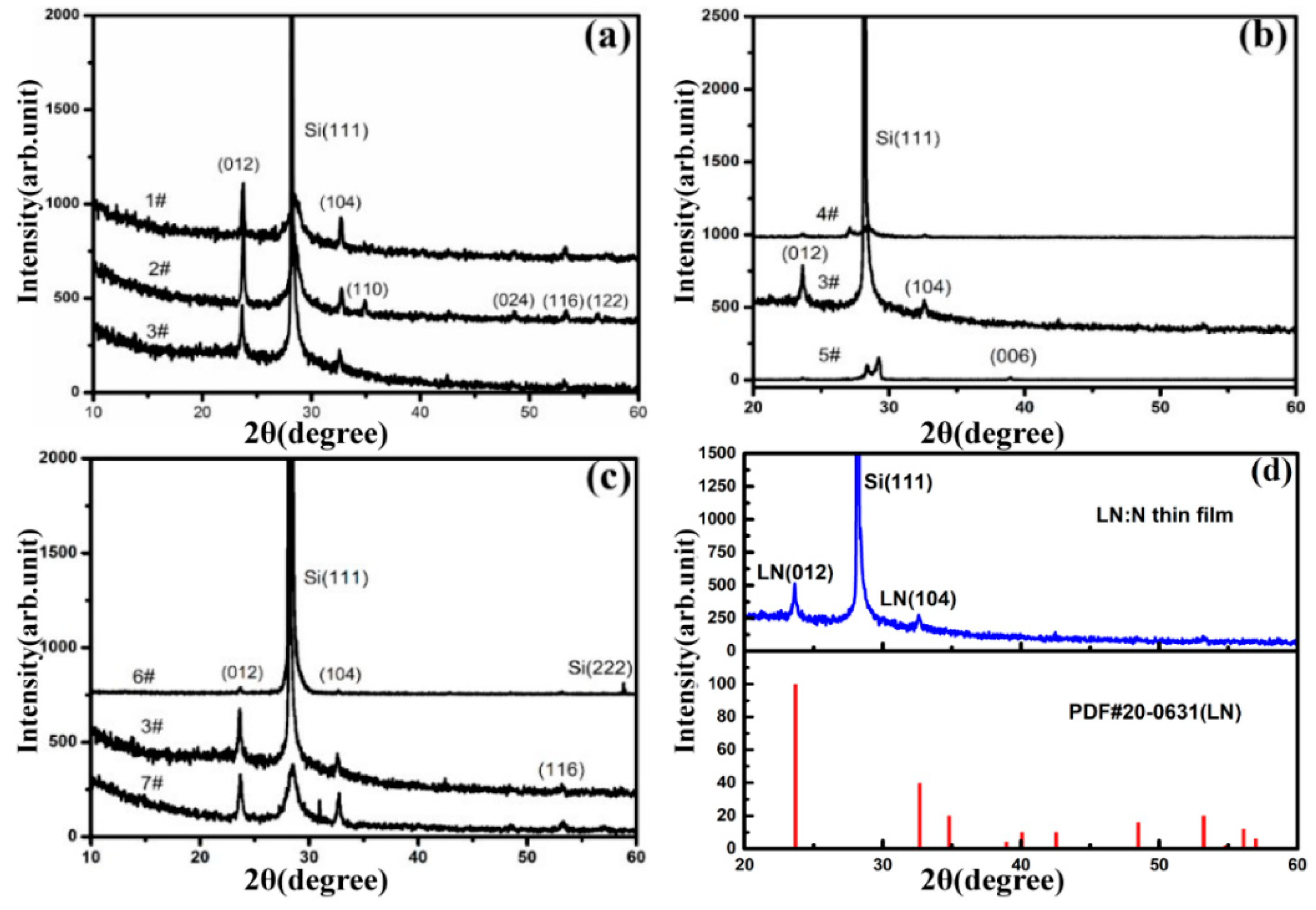

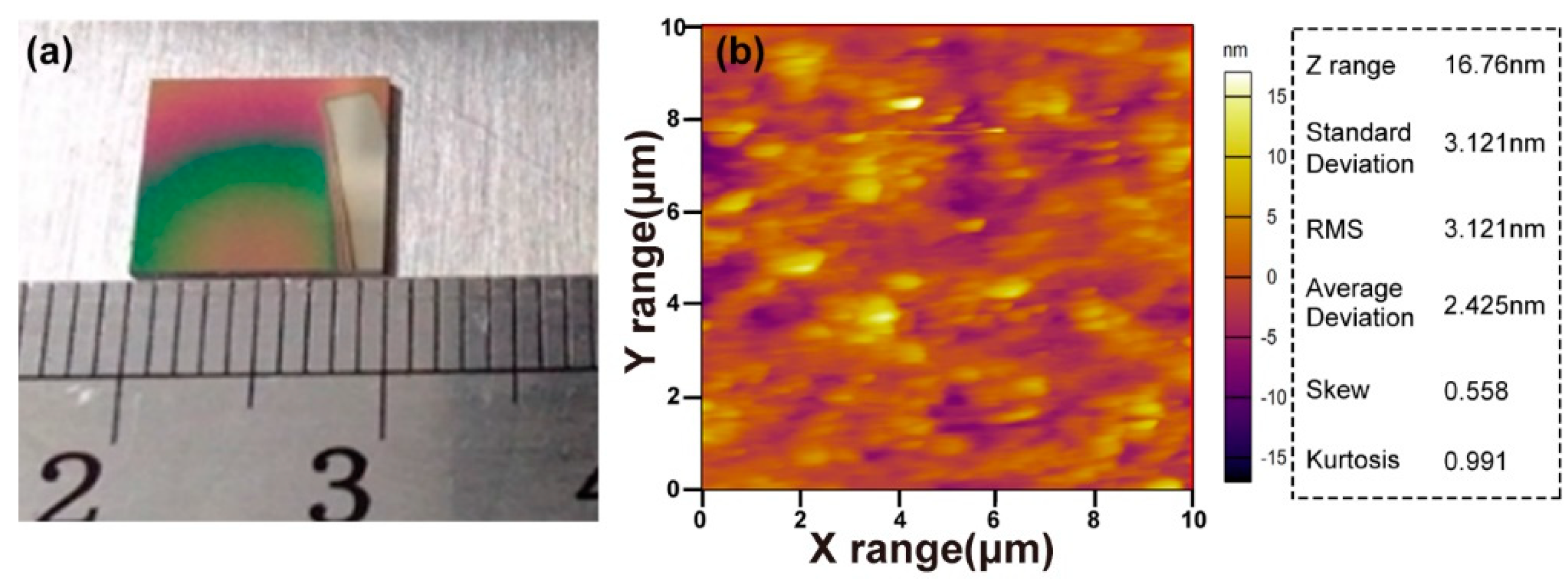

3.1. Structure of LN:N Films

3.2. Electrical Characterization of LN:N film

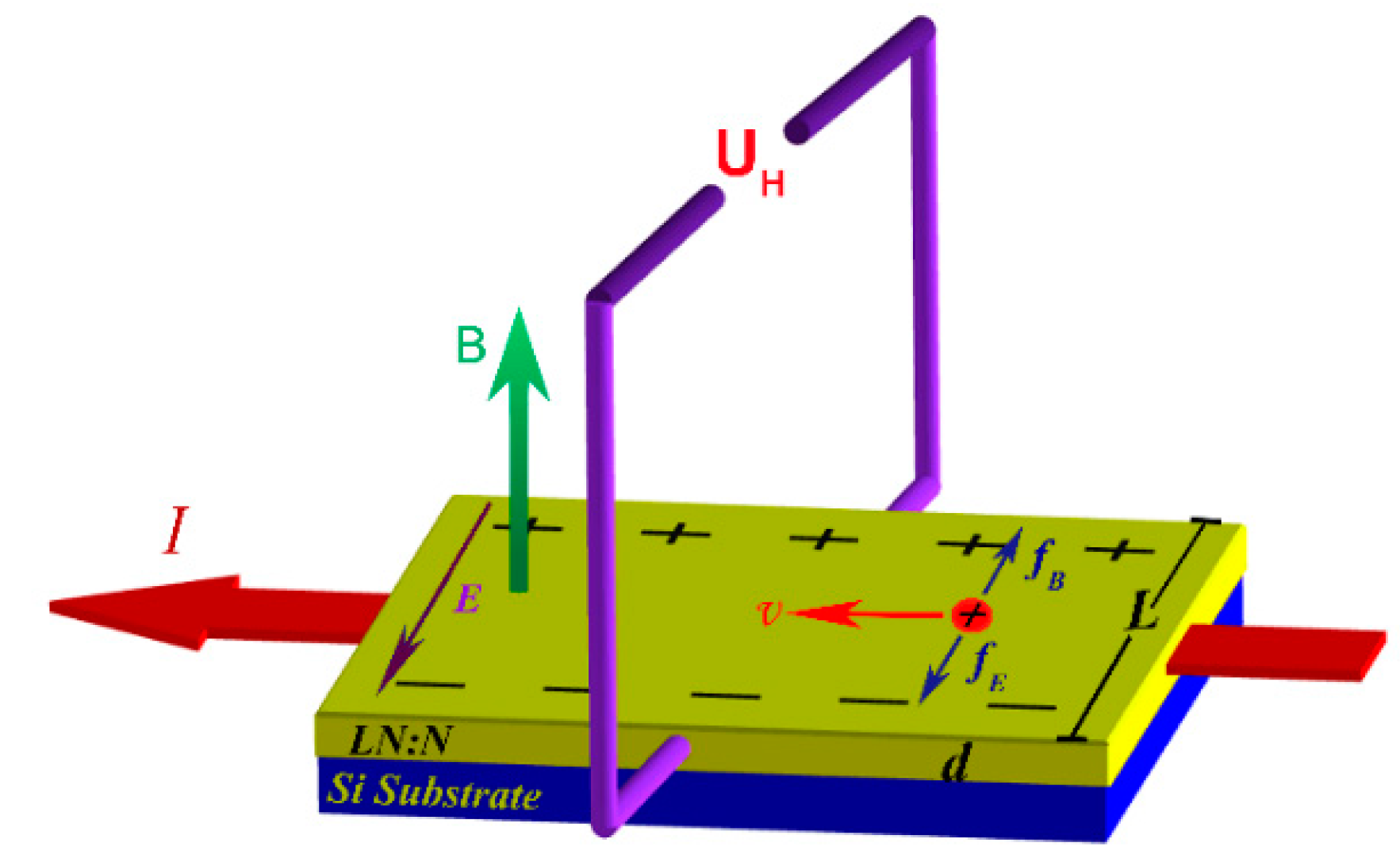

3.2.1. Hall-Effect Measurement

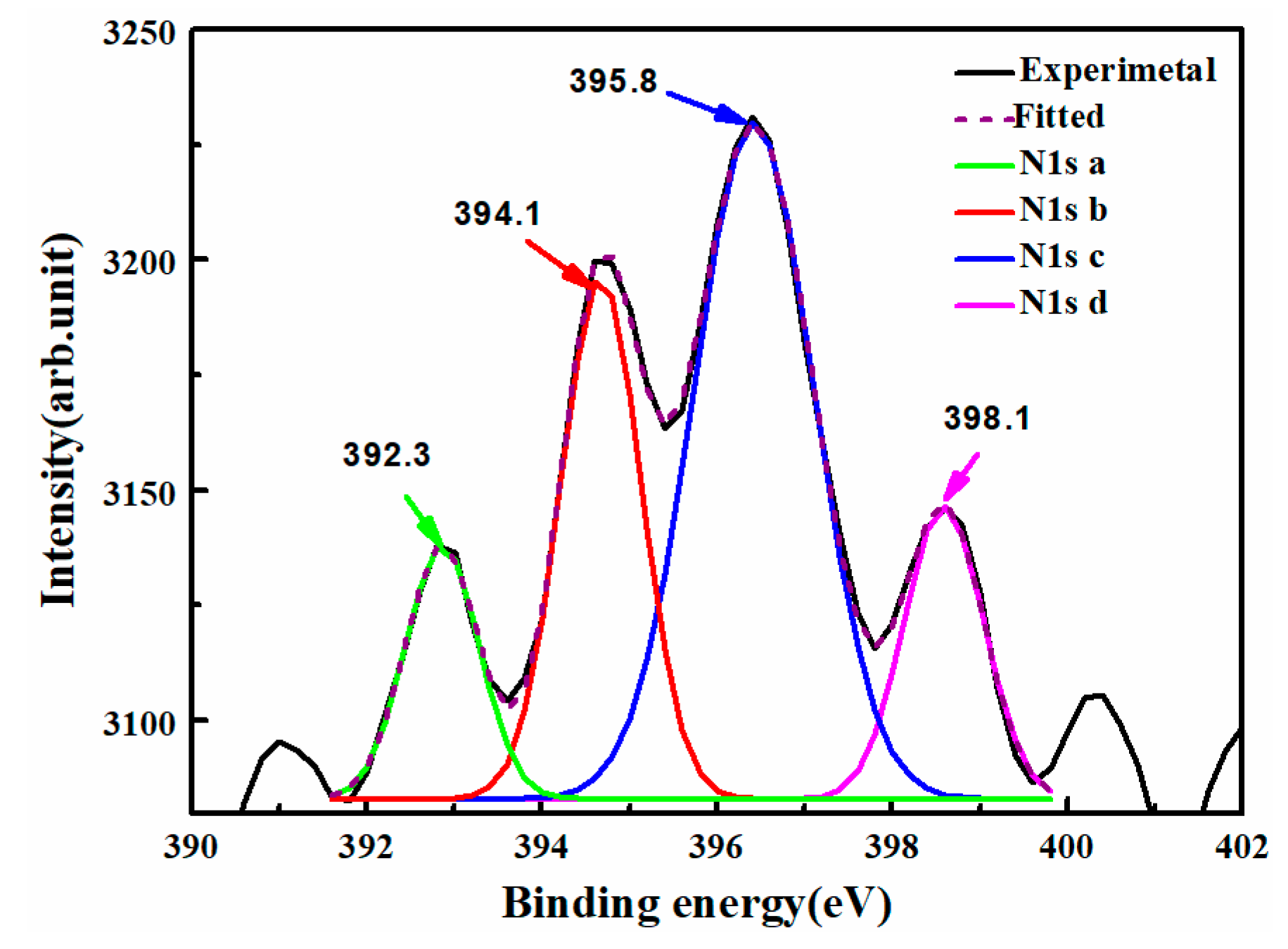

3.2.2. XPS measurement

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Li, W.; Ji, L.J. Perovskite Ferroelectrics Go Metal Free. Science 2018, 361, 132. [Google Scholar] [CrossRef] [PubMed]

- von Hoegen, A.; Mankowsky, R.; Fechner, M.; Forst, M.; Cavalleri, A. Probing the Interatomic Potential of Solids with Strong-Field Nonlinear Phononics. Nature 2018, 555, 79–82. [Google Scholar] [CrossRef] [PubMed]

- Wei, D.Z.; Wang, C.W.; Wang, H.J.; Hu, X.P.; Wei, D.; Fang, X.Y.; Zhang, Y.; Wu, D.; Hu, Y.L.; Li, J.W.; et al. Experimental Demonstration of a Three-Dimensional Lithium Niobate Nonlinear Photonic Crystal. Nat. Photonics 2018, 12, 596–600. [Google Scholar] [CrossRef]

- Courjal, N.; Benchabane, S.; Dahdah, J.; Ulliac, G.; Gruson, Y.; Laude, V. Acousto-Optically Tunable Lithium Niobate Photonic Crystal. Appl. Phys. Lett. 2010, 96, 131103. [Google Scholar] [CrossRef]

- Broderick, N.G.R.; Ross, G.W.; Offerhaus, H.L.; Richardson, D.J.; Hanna, D.C. Hexagonally poled lithium niobate: A two-dimensional nonlinear photonic crystal. Phys. Rev. Lett. 2000, 84, 4345–4348. [Google Scholar] [CrossRef] [PubMed]

- Guarino, A.; Poberaj, G.; Rezzonico, D.; Degl’Innocenti, R.; Gu¨nter, P. Electrooptically tunable microring resonators in lithium niobate. Nat. Photonics 2007, 1, 407–410. [Google Scholar] [CrossRef]

- Edon, V.; Rèmiensa, D.; Saada, S. Structural, Electrical and piezoelectric properties of LiNbO3 thin films for surface acoustic wave resonators applications. Appl. Surf. Sci. 2009, 256, 723–733. [Google Scholar] [CrossRef]

- Hasegawa, T.; Wang, X.; Suzuki, A. Retiming of picosecond pulses by a cascaded second-order nonlinear process in quasi-phase-matched LiNbO3 waveguides. Opt. Lett. 2004, 29, 2776–2778. [Google Scholar] [CrossRef] [PubMed]

- Lu, H.; Sadani, B.; Courjal, N.; Ulliac, G.; Smith, N.; Stenger, V.; Collet, M.; Baida, F.I.; Bernal, M.P. Enhanced electro-optical lithium niobate photonic crystal wire waveguide on a smart-cut thin film. Opt. Express 2012, 20, 2974–2981. [Google Scholar] [CrossRef] [PubMed]

- Tien, P.K.; Riva-Sanseverino, S.; Ballman, A.A. Light beam scanning and deflection in epitaxial LiNbO3 Electro-optic waveguides. Appl. Phys. Lett. 1974, 25, 563. [Google Scholar] [CrossRef]

- Yang, M.; Long, S.; Yang, X.; Lin, S.; Zhu, Y.; Ma, D.; Wang, B. Temperature-Dependent and Threshold Behavior of Sm3+ Ions on Fluorescence Properties of Lithium Niobate Single Crystals. Materials 2018, 11, 2058. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Yang, X.; Zhang, Q.; Wong, W.; Yu, D.; Pun, E. Y-B. Near-stoichiometric Ti-diffused LiNbO3 strip waveguide doped with Zr4+. Opt. Lett. 2015, 40, 5307–5310. [Google Scholar] [CrossRef] [PubMed]

- Staebler, D.L.; Amodei, J.J. Coupled-wave analysis of holographic storage in LiNbO3. J. Appl. Phys. 1972, 43, 1042–1049. [Google Scholar] [CrossRef]

- Kong, Y.; Wu, S.; Liu, S.; Chen, S.; Xu, J. Fast photorefractive response and high sensitivity of Zr and Fe codoped LiNbO3 crystals. Appl. Phys. Lett. 2008, 92, 251107. [Google Scholar] [CrossRef]

- Jungen, R.; Angelow, G.; Laeri, F.; Grabmaier, C. Efficient ultraviolet photorefraction in LiNbO3. Appl. Phys. A 1992, 55, 101. [Google Scholar] [CrossRef]

- Liu, F.; Kong, Y.; Li, W.; Liu, H.; Liu, S.; Chen, S.; Zhang, X.; Rupp, R.; Xu, J. High resistance against ultraviolet photorefraction in zirconium-doped lithium niobate crystals. Opt. Lett. 2010, 35, 10. [Google Scholar] [CrossRef] [PubMed]

- Yan, W.; Shi, L.; Chen, H.; Zhang, X.; Kong, Y. Investigations on the UV photorefractivity of LiNbO3:Hf. Opt. Lett. 2010, 35, 601. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Wen, J.; Li, J.; Wang, H.; Jing, J. Photoinduced hole carriers and enhanced resistance to photorefraction in Mg-doped LiNbO3 crystals. Appl. Phys. Lett. 1990, 57, 344. [Google Scholar] [CrossRef]

- Deng, J.; Wen, J.; Wu, Z.; Wang, H. Decay dynamics of laser-induced gratings in LiNbO3:Zn. App. Phys. Lett. 1994, 64, 2622. [Google Scholar] [CrossRef]

- Pei, Z.; Hu, Q.; Kong, Y.; Liu, S.; Chen, S.; Xu, J. Investigation on p-type lithium niobate crystals. AIP Adv. 2011, 1, 032171. [Google Scholar] [CrossRef]

- Zhang, S.B.; Wei, S.H.; Zunger, A. Intrinsic n-Type Versus p-Type Doping Asymmetry and the Defect Physics of ZnO. Phys. Rev. B 2001, 63, 075205. [Google Scholar] [CrossRef]

- Van de Walle, C.G. Hydrogen as a Cause of Doping in Zinc Oxide. Phys. Rev. Lett. 2000, 85, 1012–1015. [Google Scholar] [CrossRef] [PubMed]

- Jin, Y.; Zhang, N.; Zhang, B. Fabrication of p-Type ZnO:N Films by Oxidizing Zn3N2 Films in Oxygen Plasma at Low Temperature. Materials 2017, 10, 236. [Google Scholar] [CrossRef] [PubMed]

- Kaminska, E.; Piotrowska, A.; Kossut, J.; Butkut, R.; Dobrowolski, W.; ukasiewicz, R.; Barcz, A.; Jakiela, R.; Dynowska, E.; Przedziecka, E.; et al. P-Type Conducting ZnO: Fabrication and Characterisation. Phys. Status Solidi(c) 2005, 2, 1119–1124. [Google Scholar] [CrossRef]

- Look, D.C.; Reynolds, D.C.; Litton, C.W.; Jones, R.L.; Eason, D.B.; Cantwell, G. Characterization of Homoepitaxial P-Type Zno Grown by Molecular Beam Epitaxy. Appl. Phys. Lett. 2002, 81, 1830–1832. [Google Scholar] [CrossRef]

- Tsukazaki, A.; Ohtomo, A.; Onuma, T.; Ohtani, M.; Makino, T.; Sumiya, M.; Ohtani, K.; Chichibu, S.F.; Fuke, S.; Segawa, Y.; et al. Repeated Temperature Modulation Epitaxy for P-Type Doping and Light-Emitting Diode Based on ZnO. Nat. Mater. 2004, 4, 42–46. [Google Scholar] [CrossRef]

- Orlowski, R.; Kraetzig, E. Holographic method for the determination of photo-induced electron and hole transport in electro-optic crystals. Solid State Commun. 1978, 27, 1351. [Google Scholar] [CrossRef]

- Lim, D.G.; Jang, B.S.; Moon, S.I.; Won, C.Y.; Yi, J. Characteristics of LiNbO3 memory capacitors fabricated using a low thermal budget process. Solid State Electron. 2001, 45, 1159–1163. [Google Scholar] [CrossRef]

- Shandilya, S.; Tomar, M.; Sreenivas, K.; Gupta, V. Purely hopping conduction in c-axis oriented LiNbO3 thin films. J. Appl. Phys. 2009, 105, 094105. [Google Scholar] [CrossRef]

- Zhang, D.E.; Gong, J.Y.; Ma, J.J.; Han, G.Q.; Tong, Z.W. A facile method for synthesis of N-doped ZnO mesoporous nanospheres and enhanced photocatalytic activity. Dalton Trans. 2013, 42, 16556–16561. [Google Scholar] [CrossRef] [PubMed]

- Özgür, Ü.; Alivov, Y.I.; Liu, C.; Teke, A.; Reshchikov, M.A.; Doğan, S.; Avrutin, V.; Cho, S.J.; Morkoc, H. A comprehensive review of ZnO materials and devices. J. Appl. Phys. 2005, 98, 041301. [Google Scholar] [CrossRef]

| Sample | Pressure (Pa) | Gas Flow (sccm) | RF Current (mA) |

|---|---|---|---|

| 1# | 43 N2 | 87 | 18 |

| 2# | 53 N2 | 87 | 18 |

| 3# | 70 N2 | 87 | 18 |

| 4# | 70 N2 | 45 | 18 |

| 5# | 70 N2 | 100 | 18 |

| 6# | 70 N2 | 87 | 12 |

| 7# | 70 N2 | 87 | 20 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Cui, J.; Wang, W.; Zheng, D.; Jia, L.; Saeed, S.; Liu, H.; Rupp, R.; Kong, Y.; Xu, J. P-Type Lithium Niobate Thin Films Fabricated by Nitrogen-Doping. Materials 2019, 12, 819. https://doi.org/10.3390/ma12050819

Li W, Cui J, Wang W, Zheng D, Jia L, Saeed S, Liu H, Rupp R, Kong Y, Xu J. P-Type Lithium Niobate Thin Films Fabricated by Nitrogen-Doping. Materials. 2019; 12(5):819. https://doi.org/10.3390/ma12050819

Chicago/Turabian StyleLi, Wencan, Jiao Cui, Weiwei Wang, Dahuai Zheng, Longfei Jia, Shahzad Saeed, Hongde Liu, Romano Rupp, Yongfa Kong, and Jingjun Xu. 2019. "P-Type Lithium Niobate Thin Films Fabricated by Nitrogen-Doping" Materials 12, no. 5: 819. https://doi.org/10.3390/ma12050819

APA StyleLi, W., Cui, J., Wang, W., Zheng, D., Jia, L., Saeed, S., Liu, H., Rupp, R., Kong, Y., & Xu, J. (2019). P-Type Lithium Niobate Thin Films Fabricated by Nitrogen-Doping. Materials, 12(5), 819. https://doi.org/10.3390/ma12050819