1. Introduction

The corrosion of steel is one of the main mechanisms limiting the service life of reinforced and pre-stressed concrete structures, both in buildings and civil infrastructure [

1]. The expansive character of the steel corrosion products is at the origin of the damage suffered by concrete [

2], whose early symptoms are micro- and macro-cracking [

3,

4], followed by the spalling or the delamination of the concrete cover. Further consequences of the corrosion of embedded steel are the following: loss of bonding between concrete and steel, loss of steel ductility, and loss of the cross-sectional area of steel [

5]. These phenomena contribute to the reduction of the serviceability and load-bearing capacity of the structures. Usually, the appearance of cracking is considered to be the limit state, with regard to the durability of concrete structures that are affected by steel reinforcement corrosion [

6,

7].

There is much interest in developing non-destructive appraisal techniques that are able to provide early warnings for corrosion initiation. These techniques would be very useful for the surveying and inspection of structures in the field of maintenance and repair of constructions affected by reinforcement corrosion. The so-called electrochemical techniques have been widely used for assessing the state and risk of corrosion of steel in concrete [

8,

9,

10,

11]. The measurement of the steel corrosion potential (E

corr) provides qualitative information on the corrosion state of steel, which is helpful for mapping the corrosion risk for a structural member. The corrosion rate indicates the steel corrosion activity, which is usually expressed in electrochemical units (µA/cm

2). This latter parameter can even be used in mathematical models for predicting the remaining service life of a structure that is affected by steel reinforcement corrosion [

7]. However, electrochemical techniques do not provide information about micro-cracking that is induced in concrete by the generation of the corrosion products of steel.

Several techniques, based on the use of elastic waves, have been used for assessing mechanical properties, and for the detection of damage in materials and structures. The waves propagating through a material can react to defects, voids, and discontinuities such as cracks [

12]. The ultrasonic pulse velocity (UPV) method has been widely used for the inspection of concrete structures. The UPV technique, based on the measurement of the speed of sound, is considered to be sensitive to the state of the interface between concrete and steel, and also to cracking [

13]. Nevertheless, the UPV measurements through concrete are less sensitive to the distributed micro-cracks appearing during the early stages of corrosion of steel in concrete [

14]. The impact echo (IE) technique, which is based on applying a mechanical impact, and then monitoring the signals that are received by sensors located on the concrete surface, has been scarcely used for detecting the damage induced by corrosion of embedded steel [

15]. Some authors have indicated that the reliability of the IE method decreases with an increase of the thickness of the concrete members [

12]. The acoustic emission (AE) technique has been commonly used for detecting active deformation processes: crack growth, void closures, plastic deformations, etc. [

12,

16]. There are specific recommendations for the application of the AE method toward the evaluation of damage in concrete [

17]. However, an important limitation of the AE technique is that it is not able to detect passive defects [

12], thus reducing the applicability of AE to occasional surveys of existing reinforced concrete structures.

Non-linear ultrasonic (NLU) techniques have been shown to be useful for the evaluation of material degradation [

18]. Specifically, they are helpful for detecting cracking at early stages [

19]. The NLU technique is based on the fact that the non-linear interaction of ultrasound with cracked materials generates higher acoustic harmonics [

14,

19,

20,

21,

22,

23].

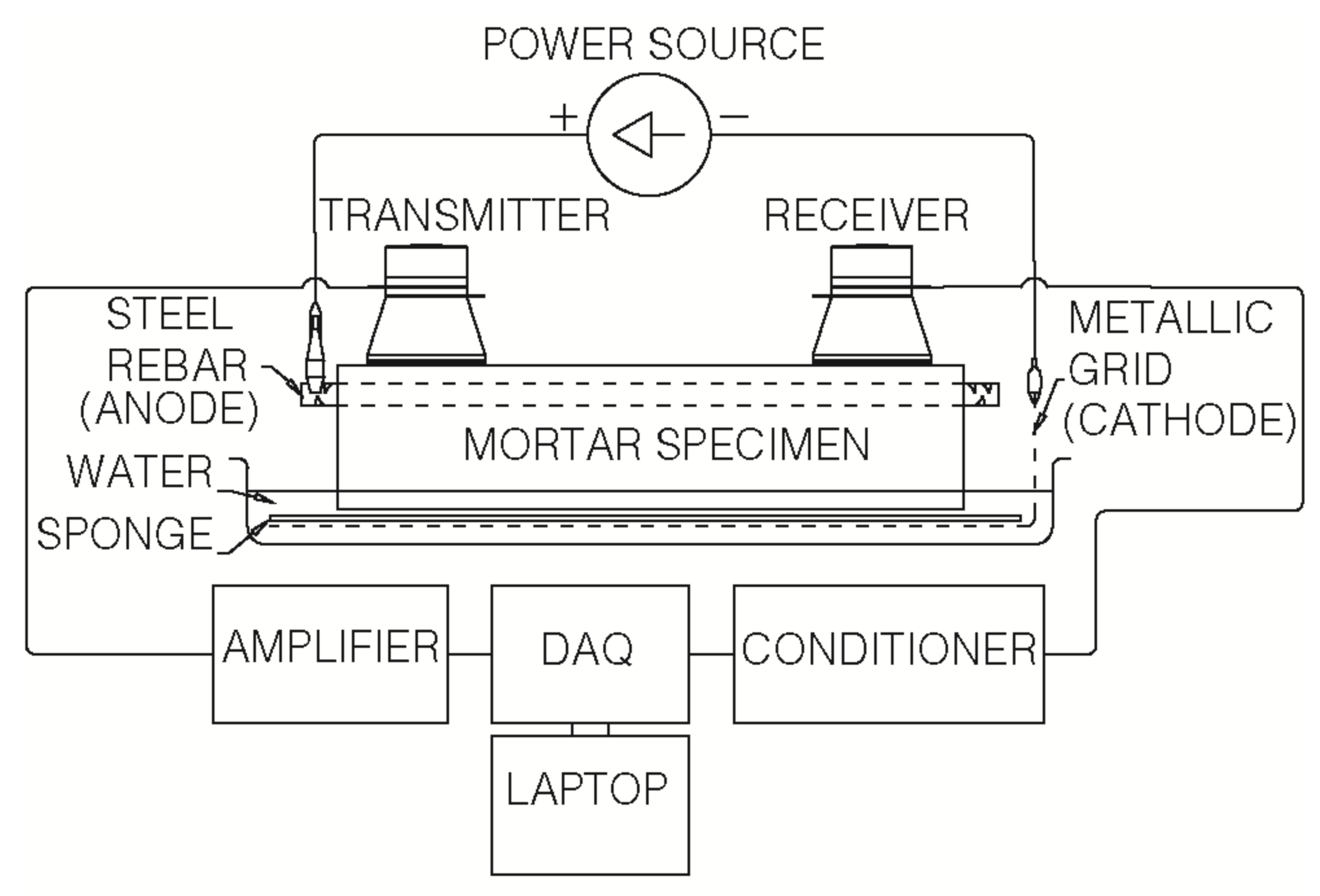

Many experimental techniques exist for detecting the micro-cracking of concrete [

24,

25]. Special mention should be given to methods based on digital image analysis, which have been used for investigating damage, cracks, and fracture mechanics parameters in concrete and other construction materials [

26,

27]. However, the aim of the present work is to study the possibility of using the NLU technique for the non-destructive evaluation of damage in concrete elements, due to the corrosion of embedded steel. To this end, NLU measurements have been performed on model-reinforced concrete specimens that are subjected to forced steel corrosion, due to the application of an electric field. The preliminary results suggest that it is possible to detect the micro-cracks that are generated by the expansion of steel corrosion products by using the NLU technique. The technique can be considered as a non-destructive methodology that is complementary to the classical electrochemical techniques, since these latter are not sensitive to the appearance of the abovementioned micro-cracking.

3. Results and Discussion

The surface cracking of reinforced concrete due to embedded steel corrosion in the presence of chloride ions, has been studied previously by a number of authors [

3,

4,

30,

31,

32]. The cracking process is usually considered as consisting of two steps. The first part, called the generation step, is the time that has elapsed since the onset of the corrosion process (the depassivation of steel), and the appearance of the first visible crack at the surface of the concrete [

3]. The second part, called the propagation step, is the period during which the crack width keeps growing [

3].

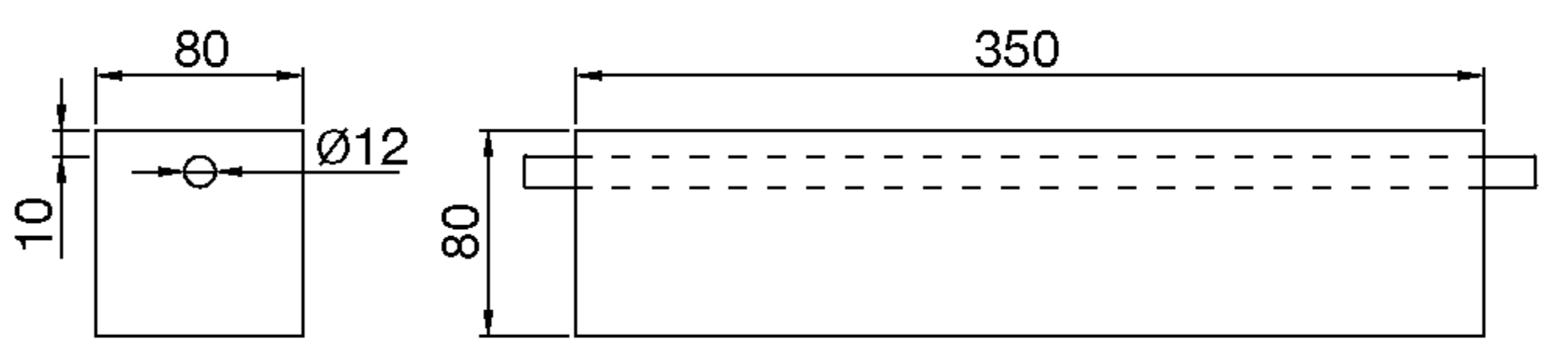

It is known that for an experimental setup similar to that used in this work, a small amount of loss of effective radius of the rebar of about 15 µm to 35 µm is enough to produce the first appearance of a visible crack at the concrete surface (a crack width that is equal to or less than 0.05 mm) [

3]. Regarding the propagation step, it is considered that the crack width increases linearly with the propagation of corrosion; i.e., it increases linearly with the loss of effective radius of the rebar [

3]. It is assumed that uniform corrosion products are formed around the steel surface to simplify the analysis, although corrosion takes place in chloride-contaminated concrete as pitting corrosion; therefore it is non-uniform. However, as pitting corrosion progresses, it appears as uniform corrosion, and the uniform corrosion assumption can be considered to be reasonable [

4]. Following this type of analysis, in this work, we have calculated the progress of the corrosion process; i.e., the theoretical loss of effective radius of the rebar, by applying the Faraday law with the relevant parameters of our tests, considering the corrosion process as a generalized and homogeneously distributed process [

30,

31,

32]. For a constant anodic current density (I

corr), the loss of the effective radius of the steel rebar (x) can be calculated as [

31]:

where x is expressed in µm, I

corr is expressed in µA/cm

2, and t is the time elapsed since the beginning of the forced corrosion test, in days. The value 0.0319 contains all of the relevant physical constants and unit change factors that are needed for the calculation. In other works, x is termed as the penetration of corrosion, and designated by the symbol P

x [

32].

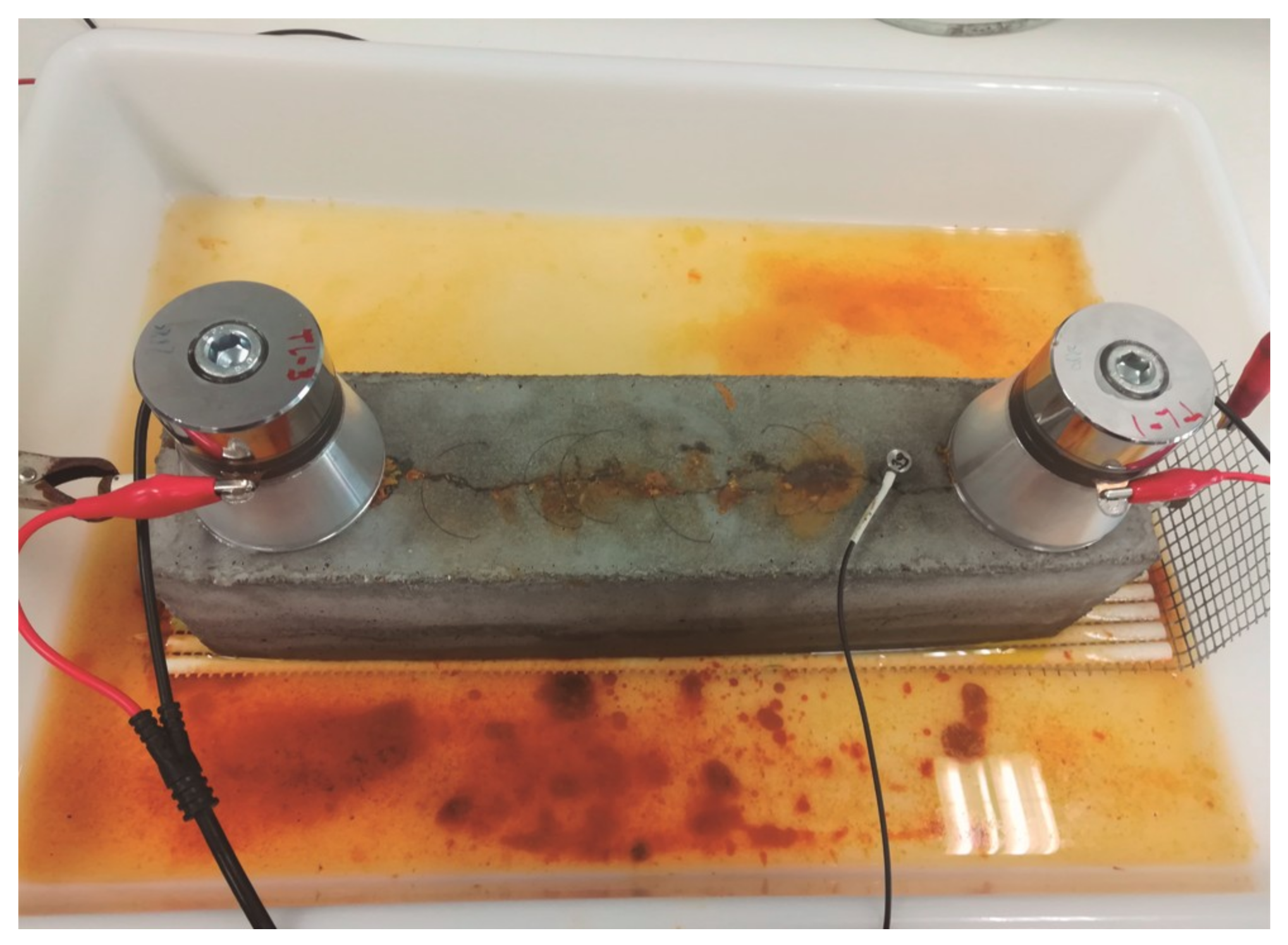

Figure 5 shows a photo of the M3-reinforced mortar specimen near the end of the forced corrosion test. An appreciable pattern of cracking occurred at the upper surface of the specimen. This cracking was longitudinal to the steel rebar, and some liquid-containing products of the corrosion of steel leaked out of the mortar specimen through the open cracks. The pH of this liquid was measured, obtaining a value of 3, in good agreement with the previous findings of other authors [

30].

At the end of the forced corrosion test, the mortar specimens were broken, and the steel bar was extracted.

Figure 6 shows a photo that was taken just after breaking the M1 specimen. It is appreciable that the corrosion process had affected the whole steel bar. However, some spots of more intense corrosion (pits), were also observed. These pits were more clearly appreciable after cleaning the corroded bar to remove the corrosion products; see Experimental Procedures. The appearance of the steel bars after the corrosion tests of the other specimens was similar to that shown in

Figure 6.

Since the mix that was used for the reinforced cement mortar specimens contained 2% Cl− relative to the cement weight, it was important to quantify the spontaneous corrosion that was suffered by steel before the forced corrosion test, i.e., during the curing period, and the time elapsed before starting the forced corrosion test. This was done by measuring the spontaneous corrosion rate by using a portable corrosion rate meter, see Experimental Procedure, with a typical frequency of one measurement every two days. The recorded corrosion rate values were always in the range from 0.7 µA/cm2 to 3 µA/cm2. Since the impressed anodic current density during the forced corrosion test was 100 µA/cm2, the spontaneous corrosion prior to the forced corrosion test, was considered as negligible, thus allowing for the use of Equation (3) for the estimation of the progress of the corrosion process. Nevertheless, a further check of the validity of this assumption was obtained by measuring the experimental mass loss of the steel rebar at the end of the corrosion test (∆mG), comparing it with the theoretical weight loss, or electrochemical weight loss (∆mT), calculated according to the application of the Faraday law with the relevant parameters of the tests. See the Experimental Procedure. For an anodic current density of 100 µA/cm2, an exposed steel surface of 120 cm2, and a duration of the forced corrosion test of 23 days, the theoretical weight loss was 6.90 g.

Table 2 shows the comparison between the experimentally determined mass losses and the theoretical mass loss of the steel bars in these tests. The results indicate a good concordance between the experimental and theoretical values, which confirms the validity of assuming that the corrosion of steel before the forced corrosion test is negligible. Another consideration that can be derived from the data of

Table 2 is that the accelerated (forced) corrosion processes have been developed, with a current efficiency that is close to 100%, which is typical of cases of accelerated corrosion tests that are performed on specimens of reinforced concrete that are contaminated with chlorides and with no limitation of water in the system [

33].

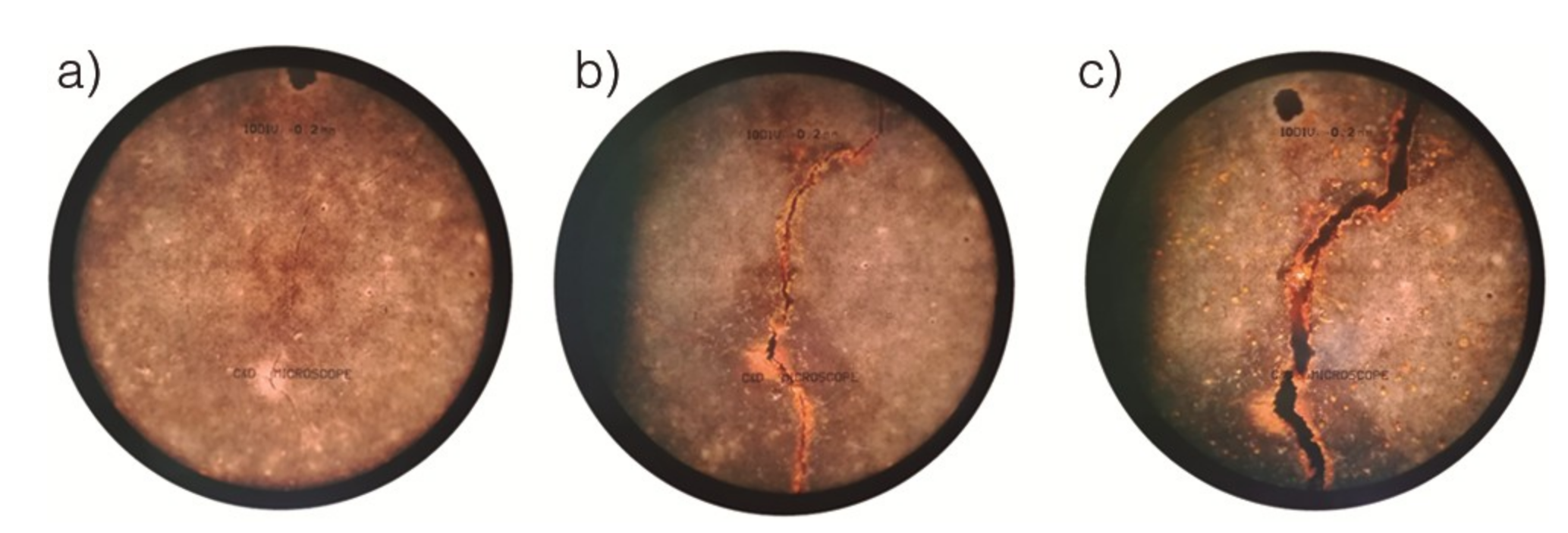

A microscope was used for detecting the appearance of cracks at the mortar surface. This also allowed for the monitoring of the evolution of the crack widths with time.

Figure 7 shows three photos that correspond to the evolution of one of the visible cracks at the surface of one of the tested specimens.

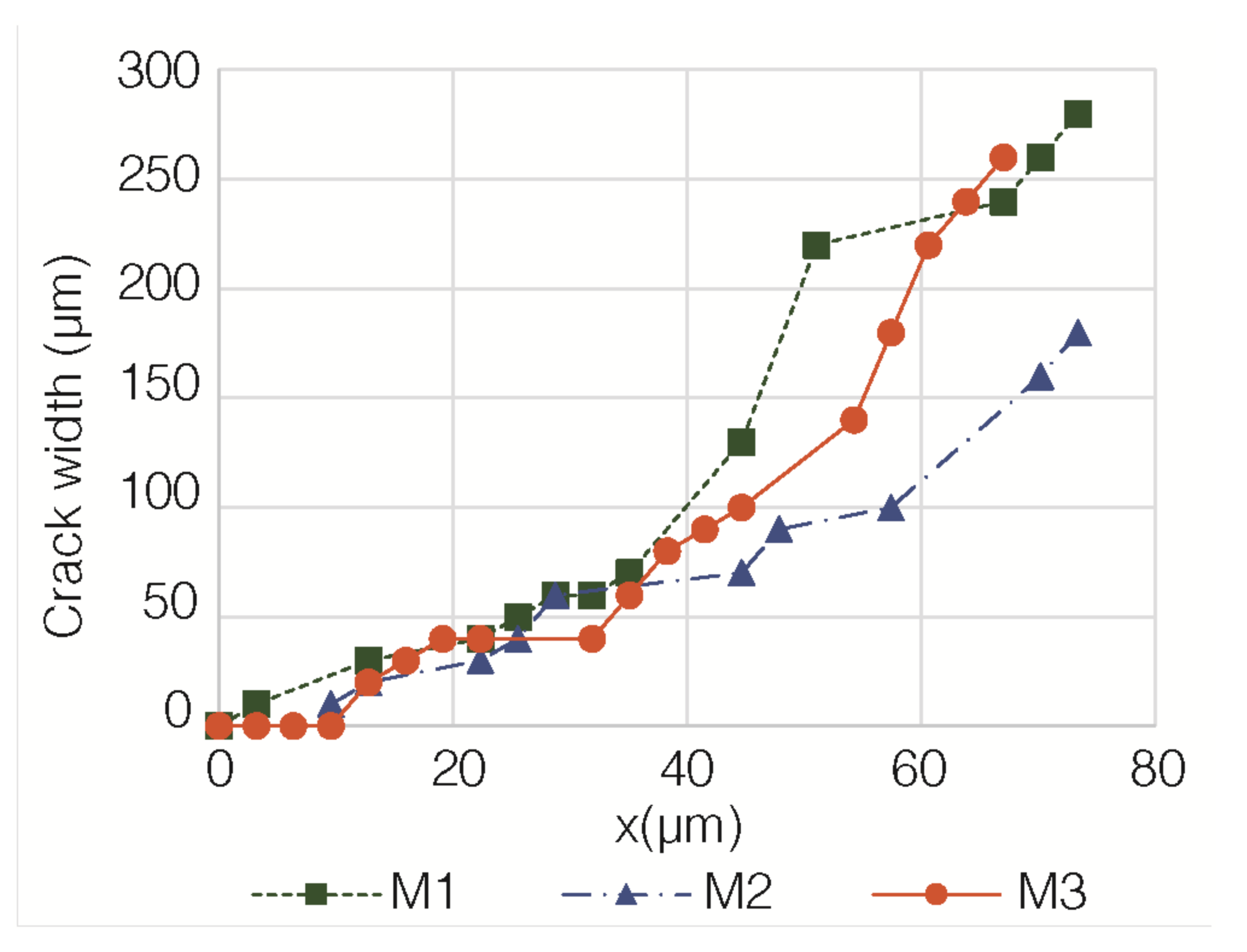

Figure 8 depicts the evolution of the crack widths of the specimens M1, M2, and M3, in function of the progress of the corrosion process, i.e., in function of the losses of effective radius of the steel rebar, calculated through Equation (3). It can be appreciated that the observed evolution is very similar for the three tested specimens. A first stage of the corrosion process seems to exist, up to approximately 10 µm of radius loss (for the cases studied here), during which there is no visible crack. This would be the generation step following Andrade and co-workers [

3,

30,

31,

32]. Afterwards, the crack width shows an approximately linear increase with the radius loss. This would be the generation step [

3,

30,

31,

32].

Table 3 shows the parameters of the least-squares linear fitting of the crack width (w) with x, corresponding to the data of

Figure 8. The fitting was done according to the following equation:

where w is the crack width (µm) and x is the radius loss of the steel bar, due to corrosion (µm). The results that are shown in

Table 3 confirm the approximately linear increase of w with x during the generation step, in agreement with the findings of previous authors [

3].

One of the key points in this research was the detection of the cracking of the mortar specimens due to corrosion of the steel rebar. This has been achieved in this work by the direct microscopic observation of the upper surface of the specimens, see

Figure 7. Besides, NLU measurements were taken periodically during the forced corrosion tests, in order to ascertain the capability of the NLU technique for the early monitoring of the cracking, due to the embedded steel corrosion. The feature event of the NLU measurements, indicating the appearance of micro-cracking, is the generation of higher acoustic harmonics [

14,

19,

20,

21,

22,

23]. The quantitative criterion that is adopted in this work is the variation ratio of the nonlinearity parameters (β or β’), relative to the initial value, which is higher than 10 (see Experimental Procedure).

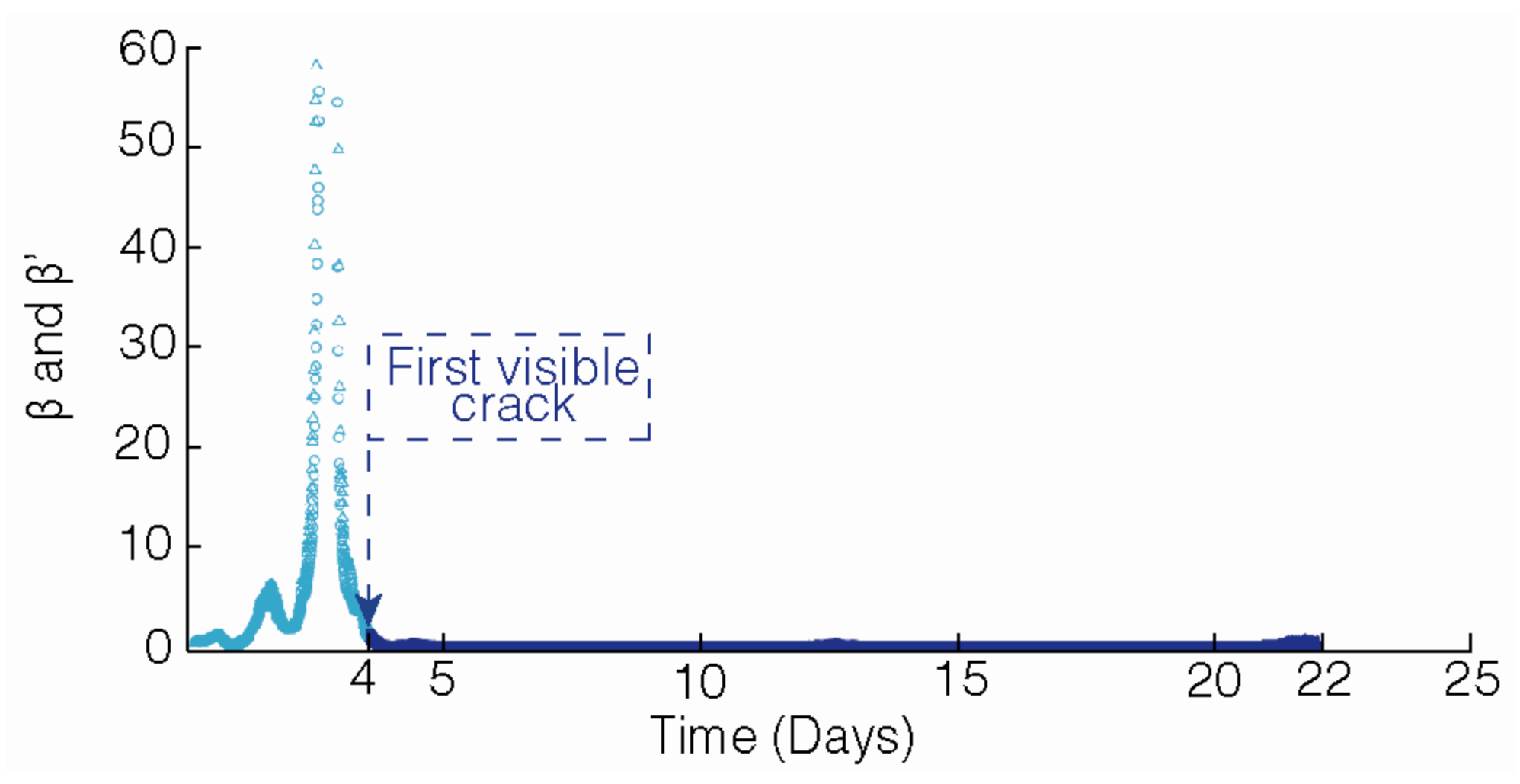

Figure 9 depicts the variation with time of the nonlinearity parameters that were derived from NLU measurements during the forced corrosion test of specimen M3. The abscissa axis of

Figure 9 represents the time elapsed since the starting of passing current. It is appreciable from

Figure 9 that both β and β’ exceeded the established threshold of the 10-fold increase relative to the initial values, approximately two-and-a-half days after the beginning of the forced corrosion test. In this case, the first microscopic observation of cracking at the upper surface of the M3 specimen was at the fourth day after starting the test. Hence, these preliminary results seem to indicate that the microscopic observation of cracking of reinforced mortar due to steel corrosion was accompanied by a clear increase of the nonlinearity parameters. This finding is in agreement with the previous observations of other authors [

23,

34]. For the rest of the tested mortar specimens, the behavior that was found is similar to that which is shown in

Figure 9, although the corresponding figures are not shown here for the sake of brevity of the manuscript.

Table 4 shows the relevant parameters that are related to the detection of cracking of the reinforced mortar specimens, due to steel rebar corrosion. Both for the direct microscopic observation and for the indirect detection, based on the variation of the nonlinearity parameters derived from the NLU measurements,

Table 4 shows the time that is elapsed for when the cracking is detected, and the corresponding losses of the effective radius of the rebar that are calculated through Equation (3). It is appreciable from the table that the detection times are very similar, although it is not possible now to establish whether the NLU measurements can detect the cracking earlier than direct microscopic observations. Nevertheless, it must be considered that using an automated system for the NLU measurements would represent a much lower experimental effort that is needed for detecting the onset of cracking, than that through using direct microscopic observation. Regarding the amount of steel corrosion that is needed for cracking mortar or concrete, a comparison of the values of x

1 (microscopic observation) and x

2 (NLU measurements) in

Table 4 indicate that both detection systems lead to similar values of the penetration of corrosion that is needed for cracking the mortar. These values range between 6 µm and 13 µm (losses of steel bar radius) for the tests of this work. Furthermore, these values are in good agreement with the previous findings of other authors who established that a small penetration of corrosion is enough for generating the first visible crack, due to corrosion in reinforced concrete [

3,

4]. An empirical relationship was proposed for describing the relationship between the minimum amount of corrosion that is needed for cracking (x

0), and the quotient c/Ø [

3]:

where x

0 is expressed in µm, c stands for the concrete cover depth over the steel bar (mm), and Ø stands for the bar diameter (mm). Applying Equation (5) with the relevant geometric parameters of the reinforced mortar specimens tested in this work, a value of x

0 of 15.3 µm is derived, which is in fairly good agreement with the x values that are reported in

Table 4.

The observations in this work seem to indicate that it is possible to use the NLU technique for the detection of the cracking of reinforced concrete, due to the corrosion of the embedded steel. However, this can be considered only as a preliminary result. Further research is necessary to ascertain whether the NLU technique can be extensively used, both for research purposes, and for practice engineering surveys of reinforced concrete structures. In the latter case, differences may be found, regarding, for instance, the steel corrosion rate, which is usually much lower in the case of real-life structures, compared to the values used in this work. Another difficulty which can be found is related to the accessibility of concrete outer surfaces for locating the ultrasonic transducers that need to be close to the corroding steel bars. Particularly, the technique should be tested on bigger and more complex reinforced concrete specimens, and on construction elements such as concrete beams, columns, footings, etc. It is hoped those future studies will provide an optimized protocol indicating where, when to apply the technique, and how many measurements are needed for a proper detection of the cracking of corroding reinforced concrete structures.