Laser-Assisted Synthesis of Cu-Al-Ni Shape Memory Alloys: Effect of Inert Gas Pressure and Ni Content

Abstract

1. Introduction

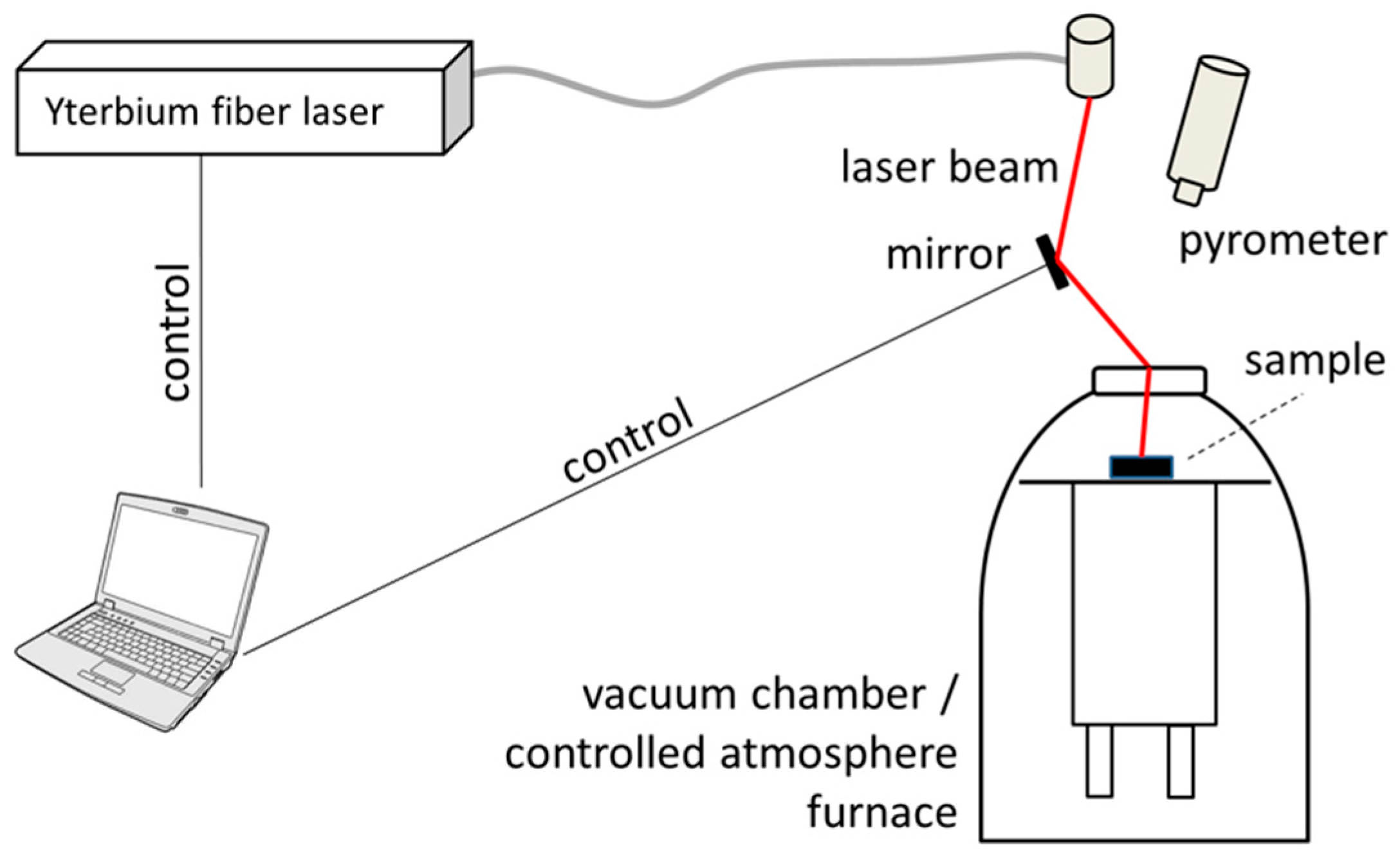

2. Materials and Methods

2.1. Fabrication Procedure

2.2. Characterization

3. Results

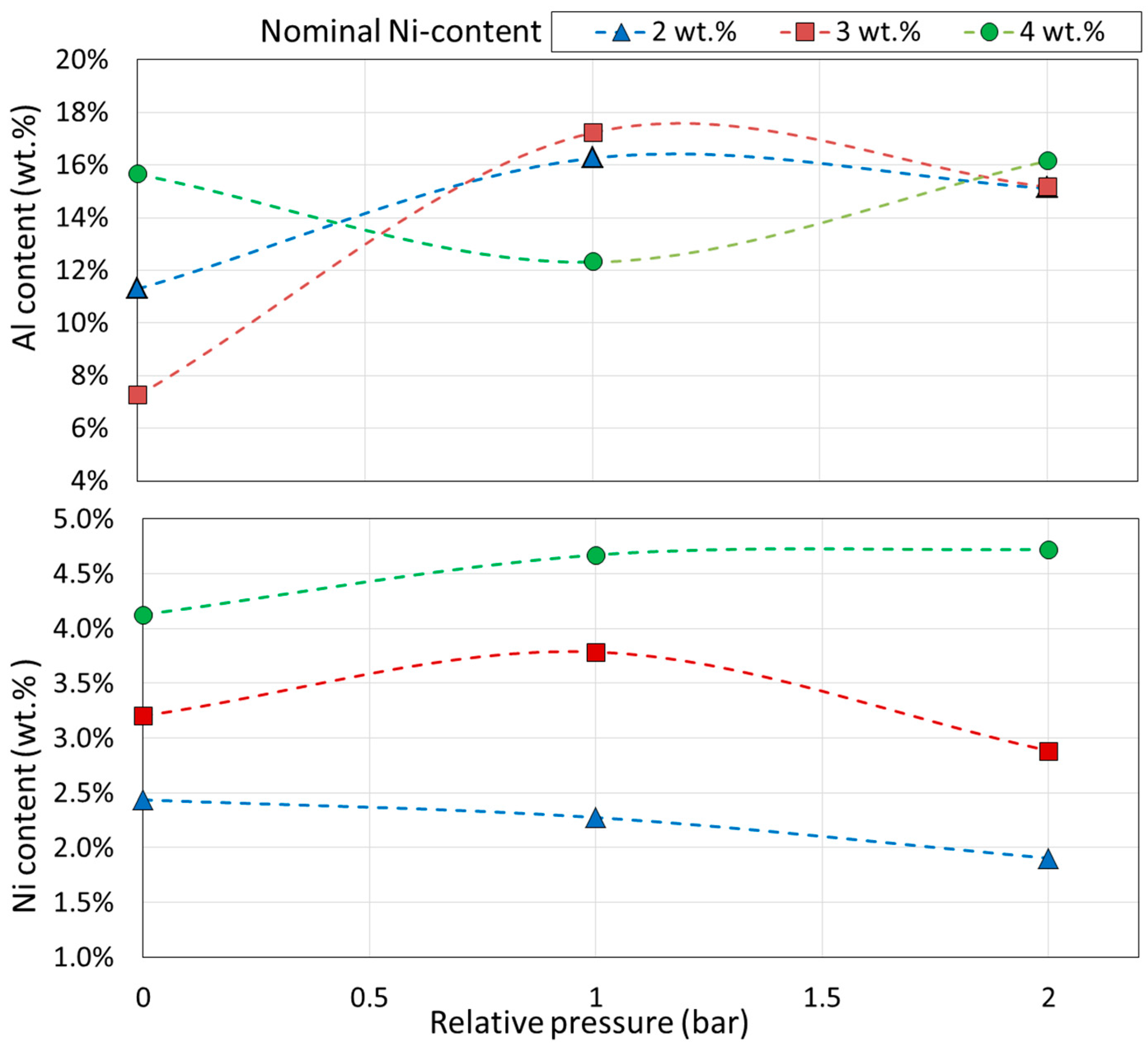

3.1. Chemical Composition

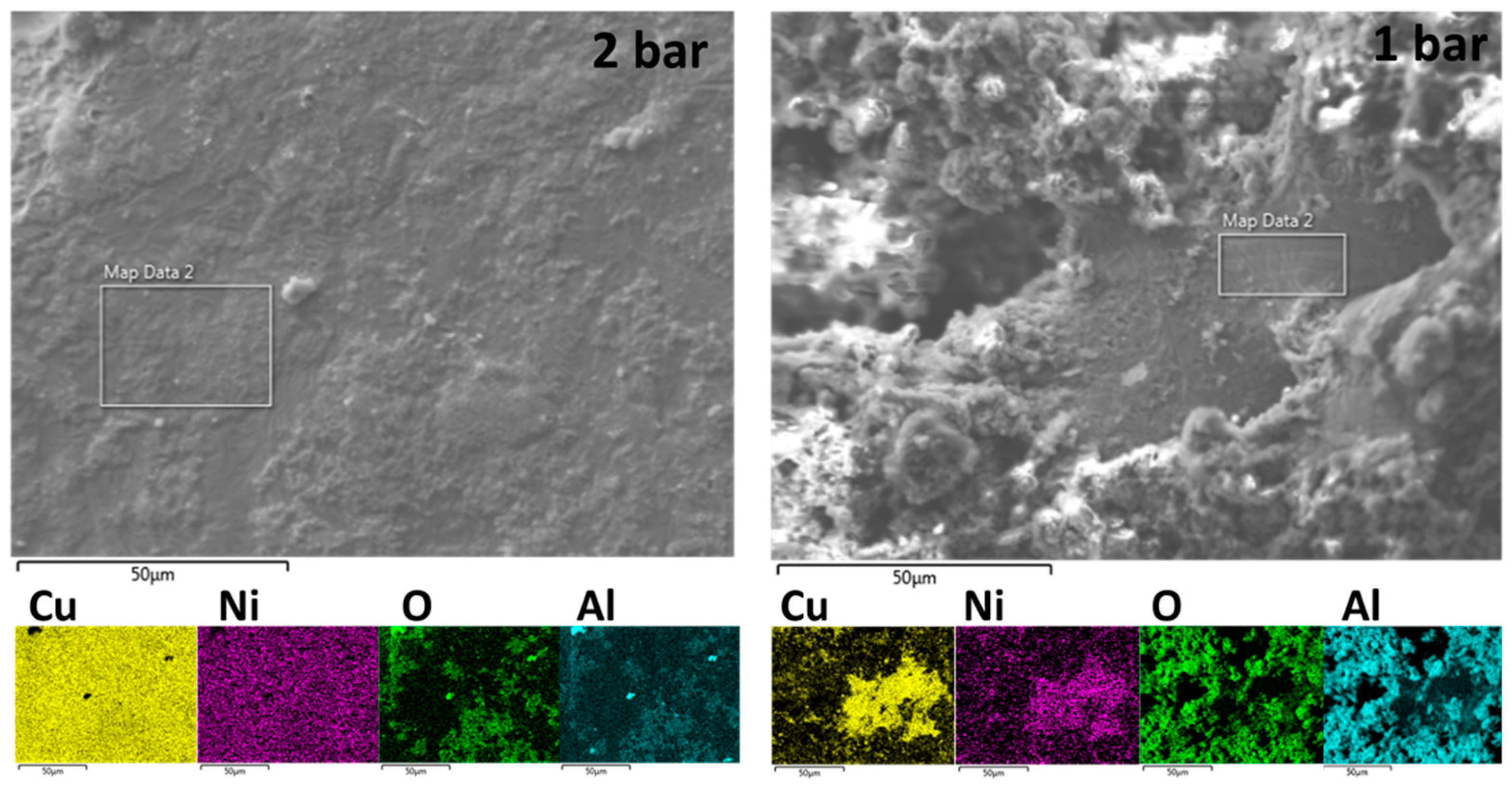

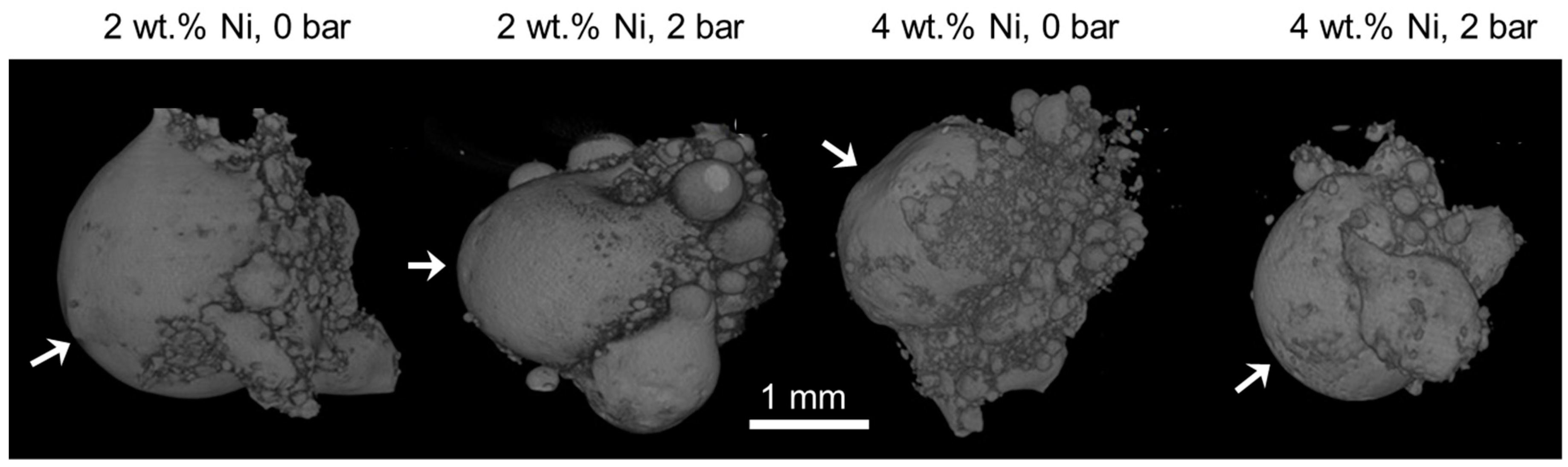

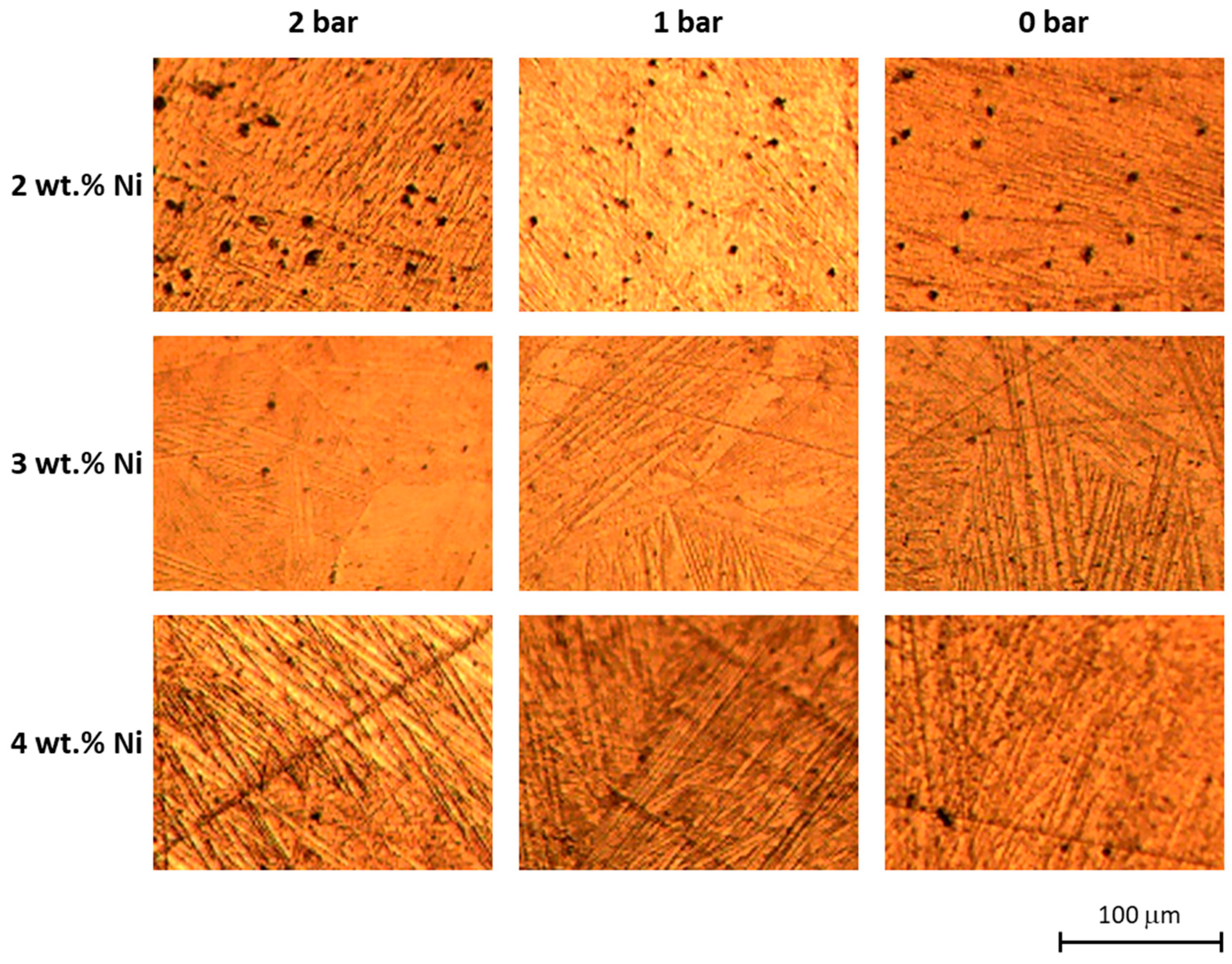

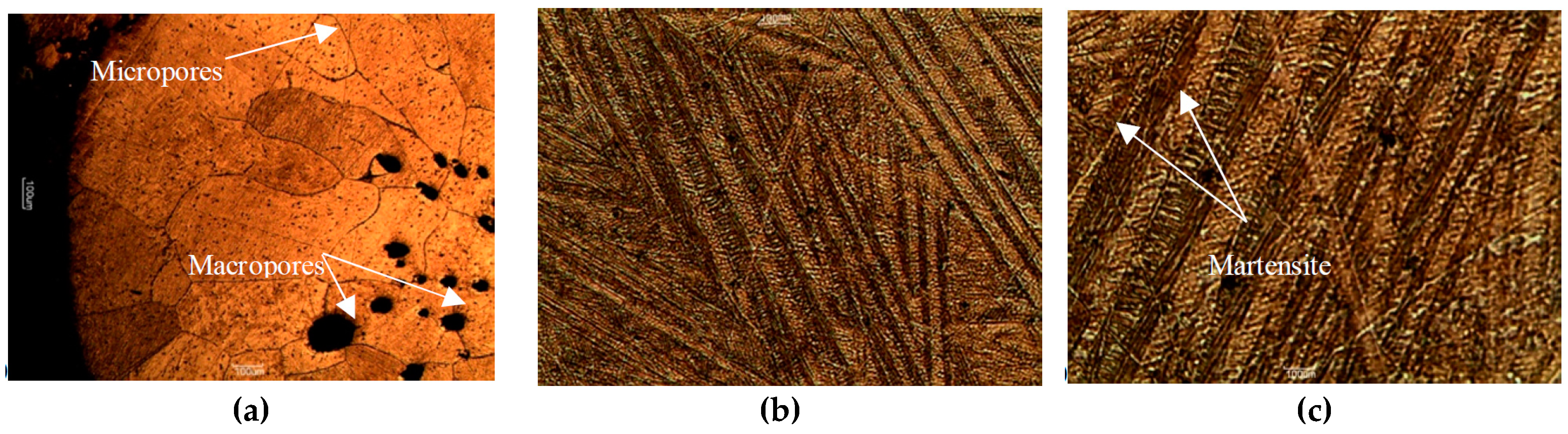

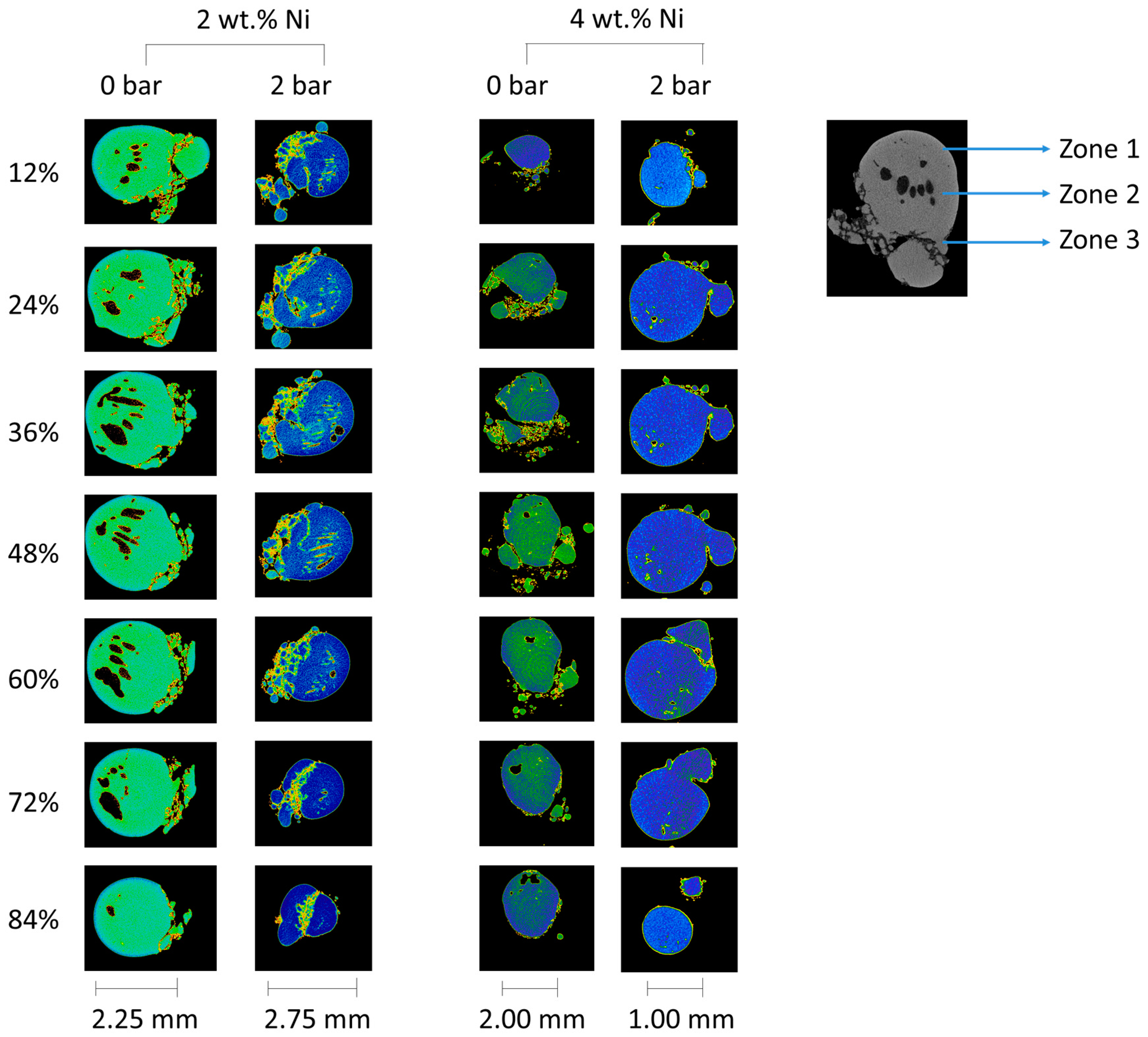

3.2. Microstructure

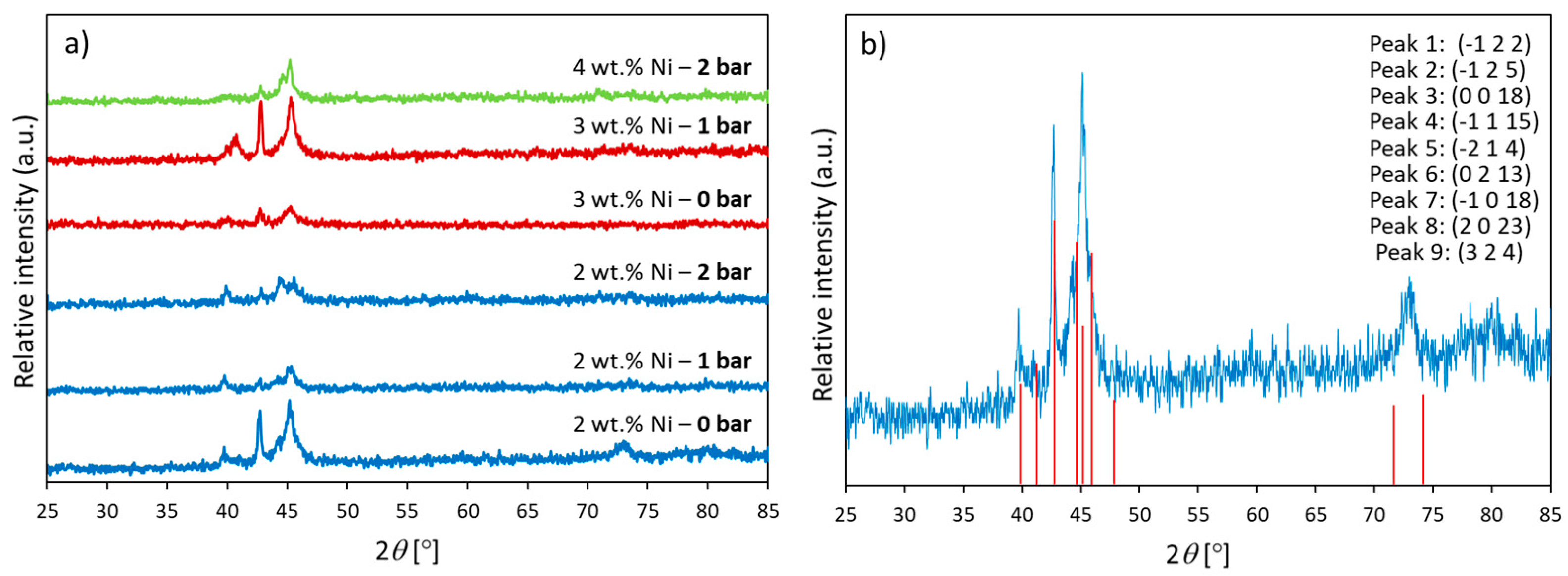

3.3. XRD Analysis

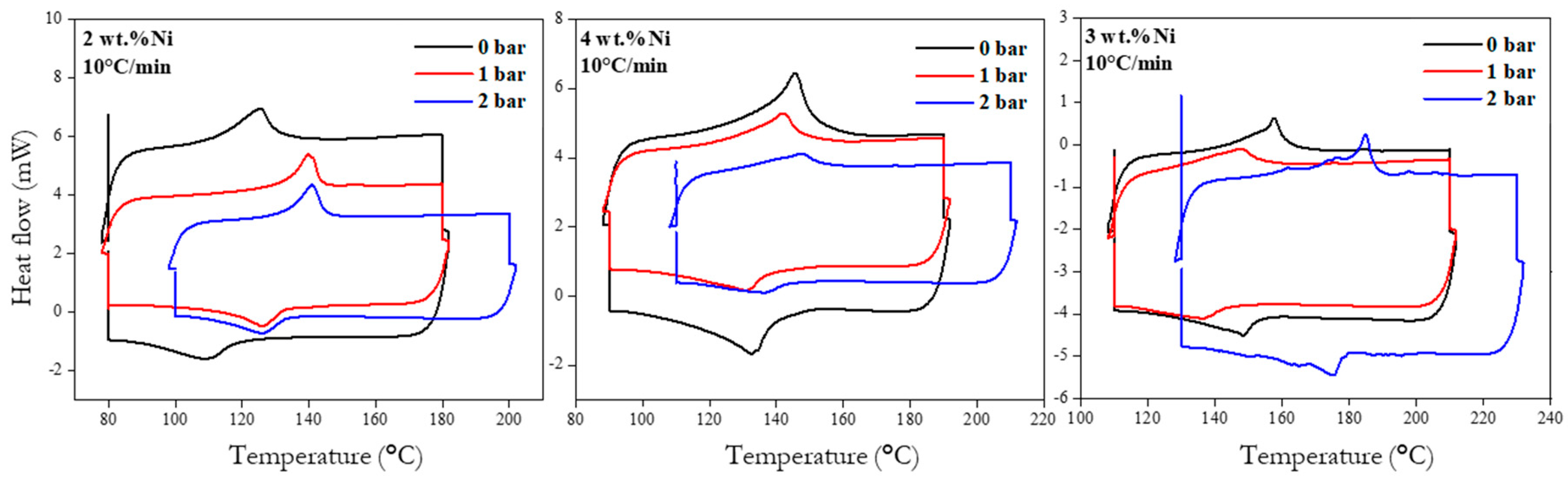

3.4. DSC Analysis

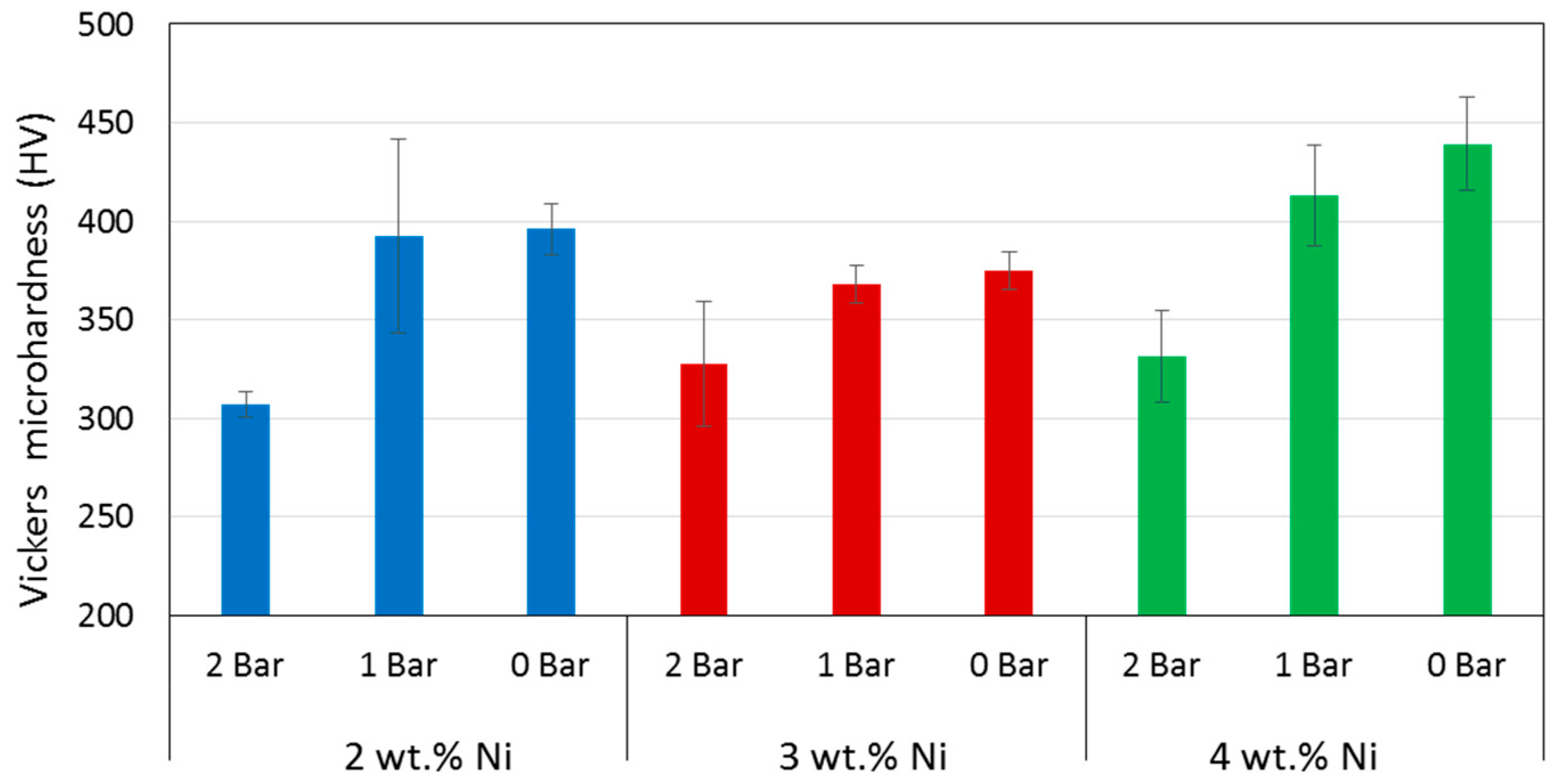

3.5. Microhardness

4. Discussion

5. Conclusions

- (1)

- Higher gas pressure in the processing chamber resulted in decreased transformation enthalpies (in both directions), as well as in lower microhardness. This suggest that the principal effect for microhardness reduction is the hindering of martensite volumetric transformation as the transformation enthalpy is lowered by increasing pressure.

- (2)

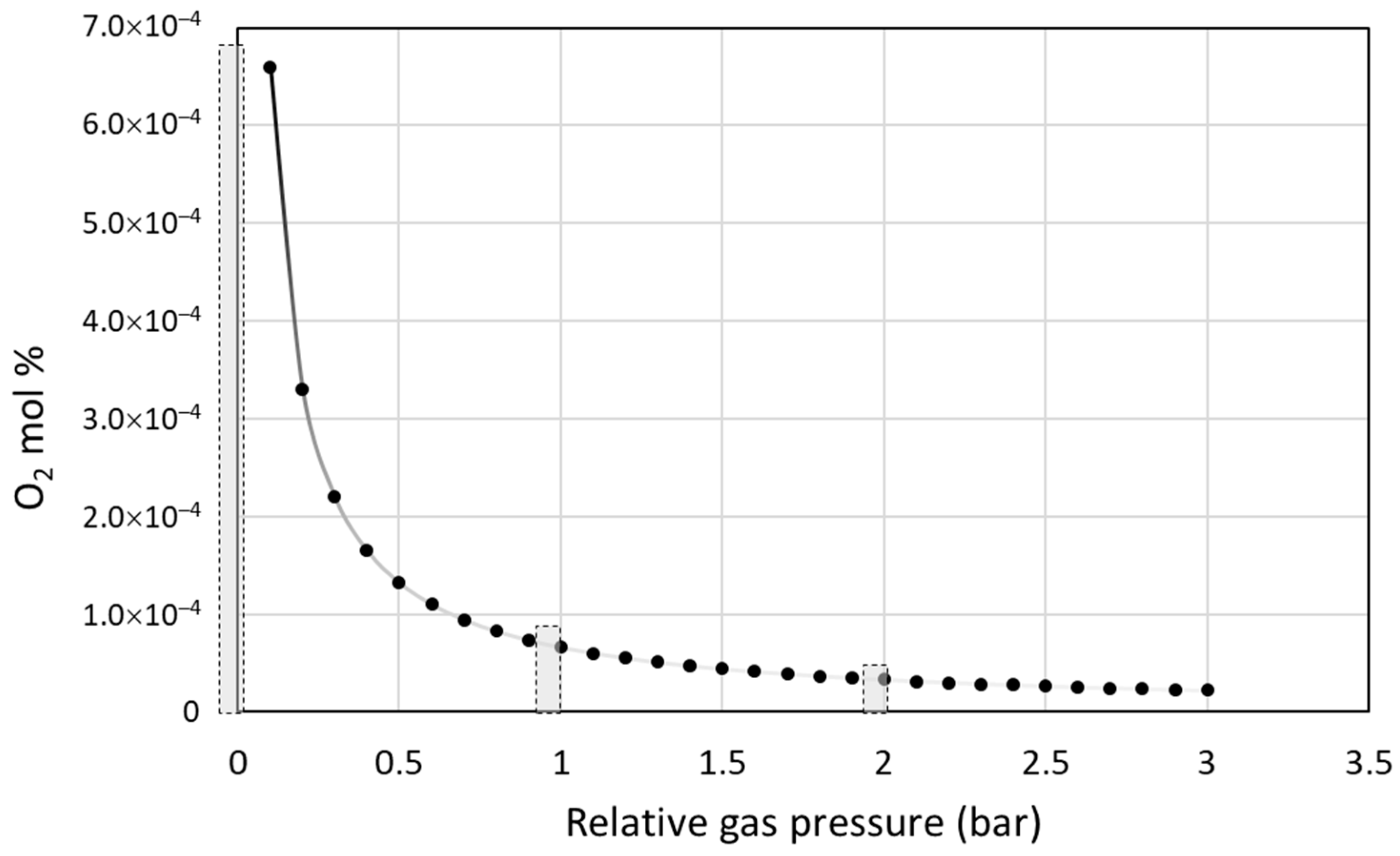

- Lower gas pressures were associated with higher molar fraction of residual oxygen, which increased the probability of oxidation, especially at short laser interaction times.

- (3)

- Higher gas pressures were associated with shorter solidification times, diminishing the probability of oxidation and resulting in purer alloy of lower hardness.

- (4)

- The effect of gas pressure on transformation temperatures was indirect, through microstructure, rather than direct, through enthalpy of the volume. However, the effect of gas pressure on transformation enthalpy was direct and associated with the hindering of the volumetric transformation of austenite into martensite upon cooling.

- (5)

- Porosity of the specimens was associated with release of adsorbed gases rather than residual voids known from sintering and incomplete melting of powders.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Otsuka, K.; Wayman, C.M. Shape Memory Materials; Cambridge University Press: Cambridge, UK, 1999; ISBN 9780521663847. [Google Scholar]

- Mohd Jani, J.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Van Humbeeck, J. Shape Memory Alloys: A Material and a Technology. Adv. Eng. Mater. 2001, 3, 837–850. [Google Scholar] [CrossRef]

- Khoo, Z.X.; Liu, Y.; An, J.; Chua, C.K.; Shen, Y.F.; Kuo, C.N. A review of selective laser melted NiTi shape memory alloy. Materials 2018, 11, 519. [Google Scholar] [CrossRef] [PubMed]

- Mehrpouya, M.; Gisario, A.; Elahinia, M. Laser welding of NiTi shape memory alloy: A review. J. Manuf. Process. 2018, 31, 162–186. [Google Scholar] [CrossRef]

- Elahinia, M.; Shayesteh Moghaddam, N.; Taheri Andani, M.; Amerinatanzi, A.; Bimber, B.A.; Hamilton, R.F. Fabrication of NiTi through additive manufacturing: A review. Prog. Mater. Sci. 2016, 83, 630–663. [Google Scholar] [CrossRef]

- Wang, X.; Kustov, S.; Van Humbeeck, J. A short review on the microstructure, transformation behavior and functional properties of NiTi shape memory alloys fabricated by selective laser melting. Materials 2018, 11, 1683. [Google Scholar] [CrossRef] [PubMed]

- Dasgupta, R. A look into Cu-based shape memory alloys: Present scenario and future prospects. J. Mater. Res. 2014, 29, 1681–1698. [Google Scholar] [CrossRef]

- Lojen, G.; Anzel, I.; Kneissl, A.; Krizman, A.; Unterweger, E.; Kosec, B.; Bizjak, M. Microstructure of rapidly solidified Cu-Al-Ni shape memory alloy ribbons. J. Mater. Process. Technol. 2005, 162–163, 220–229. [Google Scholar] [CrossRef]

- Mazzer, E.M.; Kiminami, C.S.; Bolfarini, C.; Cava, R.D.; Botta, W.J.; Gargarella, P. Thermodynamic analysis of the effect of annealing on the thermal stability of a Cu-Al-Ni-Mn shape memory alloy. Thermochim. Acta 2015, 608, 1–6. [Google Scholar] [CrossRef]

- Balo, S.N.; Sel, N. Effects of thermal aging on transformation temperatures and some physical parameters of Cu-13.5 wt. %Al–4 wt. %Ni shape memory alloy. Thermochim. Acta 2012, 536, 1–5. [Google Scholar] [CrossRef]

- Pereira, E.C.; Matlakhova, L.A.; Matlakhov, A.N.; de Araújo, C.J.; Shigue, C.Y.; Monteiro, S.N. Reversible martensite transformations in thermal cycled polycrystalline Cu-13.7%Al–4.0%Ni alloy. J. Alloys Compd. 2016, 688, 436–446. [Google Scholar] [CrossRef]

- Sari, U.; Kirindi, T. Effects of deformation on microstructure and mechanical properties of a Cu-Al-Ni shape memory alloy. Mater. Charact. 2008, 59, 920–929. [Google Scholar] [CrossRef]

- Qiu, C.X.; Zhu, S. Characterization of cyclic properties of superelastic monocrystalline Cu-Al-Be SMA wires for seismic applications. Constr. Build. Mater. 2014, 72, 219–230. [Google Scholar] [CrossRef]

- Liu, J.-L.; Huang, H.-Y.; Xie, J.-X. Superelastic anisotropy characteristics of columnar-grained Cu-Al-Mn shape memory alloys and its potential applications. Mater. Des. 2015, 85, 211–220. [Google Scholar] [CrossRef]

- Jiao, Y.Q.; Wen, Y.H.; Li, N.; He, J.Q.; Teng, J. Effect of solution treatment on damping capacity and shape memory effect of a CuAlMn alloy. J. Alloys Compd. 2010, 491, 627–630. [Google Scholar] [CrossRef]

- Chang, W.-S.; Araki, Y. Use of shape-memory alloys in construction: A critical review. Proc. Inst. Civ. Eng. Civ. Eng. 2016, 169, 87–95. [Google Scholar] [CrossRef]

- Ozbulut, O.E.; Hurlebaus, S.; Desroches, R. Seismic Response Control Using Shape Memory Alloys: A Review. J. Intell. Mater. Syst. Struct. 2011, 22, 1531–1549. [Google Scholar] [CrossRef]

- Miyazaki, S.; Otsuka, K. Development of Shape Memory Alloys. ISIJ Int. 1989, 29, 353–377. [Google Scholar] [CrossRef]

- Edmunds, W.M. Encyclopedia of Environmental Health; Elsevier: New York, NY, USA, 2011; ISBN 9780444522726. [Google Scholar]

- Picornell, C.; L’vov, V.A.; Pons, J.; Cesari, E. Experimental and theoretical study of mechanical stabilization of martensite in Cu-Al-Ni single crystals. Mater. Sci. Eng. A 2006, 438–440, 730–733. [Google Scholar] [CrossRef]

- Xiangyang, Z.; Qingping, S.; Shouwen, Y. Non-invariant plane model for the interface in CuAlNi single crystal shape memory alloys. J. Mech. Phys. Solids 2000, 48, 2163–2182. [Google Scholar] [CrossRef]

- Sakamoto, H.; Shimizu, K.; Otsuka, K. A detailed observation on successive stress-induced martensitic transformations in Cu-Al-Ni alloy single crystals above Af. Trans. Jpn. Inst. Met. 1985, 26, 638–645. [Google Scholar] [CrossRef]

- Otsuka, K.; Saxena, A.; Deng, J.; Ren, X. Mechanism of the shape memory effect in martensitic alloys: An assessment. Philos. Mag. 2011, 91, 4514–4535. [Google Scholar] [CrossRef]

- Recarte, V.; Pérez-Sáez, R.B.; Bocanegra, E.H.; Nó, M.L.; San Juan, J. Influence of Al and Ni concentration on the martensitic transformation in Cu-Al-Ni shape-memory alloys. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2002, 33, 2581–2591. [Google Scholar] [CrossRef]

- Sarı, U.; Aksoy, İ. Micro-structural analysis of self-accommodating martensites in Cu–11.92wt%Al–3.78wt%Ni shape memory alloy. J. Mater. Process. Technol. 2008, 195, 72–76. [Google Scholar] [CrossRef]

- Suresh, N.; Ramamurty, U. Aging response and its effect on the functional properties of Cu-Al-Ni shape memory alloys. J. Alloys Compd. 2008, 449, 113–118. [Google Scholar] [CrossRef]

- Portier, R.A.; Ochin, P.; Pasko, A.; Monastyrsky, G.E.; Gilchuk, A.V.; Kolomytsev, V.I.; Koval, Y.N. Spark plasma sintering of Cu-Al-Ni shape memory alloy. J. Alloys Compd. 2013, 577, 472–477. [Google Scholar] [CrossRef]

- Yuan, B.; Zheng, P.; Gao, Y.; Zhu, M.; Dunand, D.C. Effect of directional solidification and porosity upon the superelasticity of Cu-Al-Ni shape-memory alloys. Mater. Des. 2015, 80, 28–35. [Google Scholar] [CrossRef]

- Vajpai, S.K.; Dube, R.K.; Sangal, S. Application of rapid solidification powder metallurgy processing to prepare Cu-Al-Ni high temperature shape memory alloy strips with high strength and high ductility. Mater. Sci. Eng. A 2013, 570, 32–42. [Google Scholar] [CrossRef]

- Morán, M.J.; Condó, A.M.; Soldera, F.; Sirena, M.; Haberkorn, N. Martensitic transformation in freestanding and supported Cu-Al-Ni thin films obtained at low deposition temperatures. Mater. Lett. 2016, 184, 177–180. [Google Scholar] [CrossRef]

- Liu, Y.H.; Guo, Z.X.; Shen, P.; Wang, H.Y.; Hu, J.D. Study on densification of laser ignited reaction sintering of Ni-Al-Cu powder. Sci. Sin. 2007, 39, 31–37. [Google Scholar] [CrossRef]

- Yue, T.M.; Li, T.; Lin, X. Microstructure and phase evolution in laser cladding of Ni/Cu/Al multilayer on magnesium substrates. Metall. Mater. Trans. A 2010, 41, 212–223. [Google Scholar] [CrossRef]

- Shishkovsky, I.; Yadroitsev, I.; Morozov, Y. Laser-assisted synthesis in Cu-Al-Ni system and some of its properties. J. Alloys Compd. 2016, 658, 875–879. [Google Scholar] [CrossRef]

- Volyanski, I.; Shishkovsky, I.V.; Yadroitsev, I.; Shcherbakov, V.I.; Morozov, Y.G. Layer-by-layer laser synthesis of Cu-Al-Ni intermetallic compounds and shape memory effect. Inorg. Mater. 2016, 52, 566–572. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Spears, T.G.; Gold, S.A. In-process sensing in selective laser melting (SLM) additive manufacturing. Integr. Mater. Manuf. Innov. 2016, 5, 1–25. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Gusarov, A.; Yadroitsava, I.; Smurov, I. Single track formation in selective laser melting of metal powders. J. Mater. Process. Technol. 2010, 210, 1624–1631. [Google Scholar] [CrossRef]

- Zhu, H.H.; Lu, L.; Fuh, J.Y.H. Development and characterisation of direct laser sintering Cu-based metal powder. J. Mater. Process. Technol. 2003, 140, 314–317. [Google Scholar] [CrossRef]

- Gu, D.; Shen, Y. Development and characterisation of direct laser sintering Cu-based metal powder. Powder Metall. 2006, 49, 258–264. [Google Scholar] [CrossRef]

- Cava, R.D.; Bolfarini, C.; Kiminami, C.S.; Mazzer, E.M.; Botta Filho, W.J.; Gargarella, P.; Eckert, J. Spray forming of Cu-11.85Al-3.2Ni-3Mn (wt%) shape memory alloy. J. Alloys Compd. 2015, 615, S602–S606. [Google Scholar] [CrossRef]

- Zhang, X.; Sui, J.; Liu, Q.; Cai, W. Effects of Gd addition on the microstructure, mechanical properties and shape memory effect of polycrystalline Cu-Al-Ni shape memory alloy. Mater. Lett. 2016, 180, 223–227. [Google Scholar] [CrossRef]

- Ladewig, A.; Schlick, G.; Fisser, M.; Schulze, V.; Glatzel, U. Influence of the shielding gas flow on the removal of process by-products in the selective laser melting process. Addit. Manuf. 2016, 10, 1–9. [Google Scholar] [CrossRef]

- Reyes-Donoso, G.; Walczak, M.; Ramos-Moore, E.; Ramos-Grez, J. Towards direct metal laser fabrication of Cu–based shape memory alloys. Rapid. Prototyp. J. 2017, 23, 329–336. [Google Scholar] [CrossRef]

- Abràmoff, M.D.; Magalhães, P.J.; Ram, S.J. Image processing with imageJ. Biophotonics Int. 2004, 11, 36–41. [Google Scholar]

- Wang, Z.; Liu, X.F.; Xie, J.X. Effects of solidification parameters on microstructure and mechanical properties of continuous columnar-grained Cu-Al-Ni alloy. Prog. Nat. Sci. Mater. Int. 2011, 21, 368–374. [Google Scholar] [CrossRef]

- Lojen, G.; Gojić, M.; Anžel, I. Continuously cast Cu-Al-Ni shape memory alloy—Properties in as-cast condition. J. Alloys Compd. 2013, 580, 497–505. [Google Scholar] [CrossRef]

- Dagdelen, F.; Gokhan, T.; Aydogdu, A.; Aydogdu, Y.; Adigu, O. Effects of thermal treatments on transformation behaviour in shape memory Cu-Al-Ni alloys. Mater. Lett. 2003, 57, 1079–1085. [Google Scholar] [CrossRef]

- Vives, E.; Ortín, J.; Mañosa, L.; Ráfols, I.; Pérez-Magrané, R.; Planes, A. Distributions of Avalanches in Martensitic Transformations. Phys. Rev. Lett. 1987, 58, 1799–1802. [Google Scholar] [CrossRef] [PubMed]

- Faran, E.; Seiner, H.; Landa, M.; Shilo, D. The effects of microstructure on crackling noise during martensitic transformation in Cu-Al-Ni. Appl. Phys. Lett. 2015, 107, 171601. [Google Scholar] [CrossRef]

- Vives, E.; Baró, J.; Gallardo, M.C.; Martín-Olalla, J.M.; Romero, F.J.; Driver, S.L.; Carpenter, M.A.; Salje, E.K.H.; Stipcich, M.; Romero, R.; et al. Avalanche criticalities and elastic and calorimetric anomalies of the transition from cubic Cu-Al-Ni to a mixture of 18R and 2H structures. Phys. Rev. B Condens. Matter Mater. Phys. 2016, 94, 1–8. [Google Scholar] [CrossRef]

- Das, S. Physical Aspects of Process Control in Selective Laser Sintering of Metals. Adv. Eng. Mater. 2003, 5, 701–711. [Google Scholar] [CrossRef]

- Verhaeghe, F.; Craeghs, T.; Heulens, J.; Pandelaers, L. A pragmatic model for selective laser melting with evaporation. Acta Mater. 2009, 57, 6006–6012. [Google Scholar] [CrossRef]

- Prince, A.; Kumar, K.C.H. Al-Cu-Ni (Aluminium-Copper-Nickel). In Landolt-Börnstein Series IV/11A2; Springer: Stuttgart, Germany, 1991; pp. 104–126. [Google Scholar]

- Straumal, B.B.; Kilmametov, A.R.; López, G.A.; López-Ferreño, I.; Nó, M.L.; San Juan, J.; Hahn, H.; Baretzky, B. High-pressure torsion driven phase transformations in Cu-Al-Ni shape memory alloys. Acta Mater. 2017, 125, 274–285. [Google Scholar] [CrossRef]

- Kunze, K.; Etter, T.; Grässlin, J.; Shklover, V. Texture, anisotropy in microstructure and mechanical properties of IN738LC alloy processed by selective laser melting (SLM). Mater. Sci. Eng. A 2014, 620, 213–222. [Google Scholar] [CrossRef]

- Thijs, L.; Kempen, K.; Kruth, J.P.; Van Humbeeck, J. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef]

- Zhou, X.; Li, K.; Zhang, D.; Liu, X.; Ma, J.; Liu, W.; Shen, Z. Textures formed in a CoCrMo alloy by selective laser melting. J. Alloys Compd. 2015, 631, 153–164. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I.; Johansson, S.; Smurov, I. Energy input effect on morphology and microstructure of selective laser melting single track from metallic powder. J. Mater. Process. Technol. 2013, 213, 606–613. [Google Scholar] [CrossRef]

- Weafer, F.M.; Bruzzi, M.S. Micromechanical investigation into the effect of texture on the fatigue behaviour of superelastic nitinol. Int. J. Fatigue 2016, 93, 148–155. [Google Scholar] [CrossRef]

- La Roca, P.; Isola, L.; Vermaut, P.; Malarría, J. β-grain size Effects on the 18R-martensite Microstructure in Cu-based SMA. Procedia Mater. Sci. 2015, 8, 1133–1139. [Google Scholar] [CrossRef]

- De Damborenea, J.J.; Arenas, M.A.; Larosa, M.A.; Jardini, A.L.; de Carvalho Zavaglia, C.A.; Conde, A. Corrosion of Ti6Al4V pins produced by direct metal laser sintering. Appl. Surf. Sci. 2017, 393, 340–347. [Google Scholar] [CrossRef]

- Kasperovich, G.; Haubrich, J.; Gussone, J.; Requena, G. Correlation between porosity and processing parameters in TiAl6V4 produced by selective laser melting. Mater. Des. 2016, 105, 160–170. [Google Scholar] [CrossRef]

- Recarte, V.; Pérez-Sáez, R.B.; Bocanegra, E.H.; Nó, M.L.L.; San Juan, J. Dependence of the martensitic transformation characteristics on concentration in Cu-Al-Ni shape memory alloys. Mater. Sci. Eng. A 1999, 275, 380–384. [Google Scholar] [CrossRef]

- Karagoz, Z.; Canbay, C.A. Relationship between transformation temperatures and alloying elements in Cu-Al-Ni shape memory alloys. J. Therm. Anal. Calorim. 2013, 114, 1069–1074. [Google Scholar] [CrossRef]

- da Silva, M.R.; Gargarella, P.; Gustmann, T.; Botta Filho, W.J.; Kiminami, C.S.; Eckert, J.; Pauly, S.; Bolfarini, C. Laser surface remelting of a Cu-Al-Ni-Mn shape memory alloy. Mater. Sci. Eng. A 2016, 661, 61–67. [Google Scholar] [CrossRef]

- Saud, S.N.; Hamzah, E.; Abubakar, T.; Farahany, S. Structure-property relationship of Cu-Al-Ni-Fe shape memory alloys in different quenching media. J. Mater. Eng. Perform. 2014, 23, 255–261. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Q.-S. Influence of Alloying Element Addition on Cu-Al-Ni High-Temperature Shape Memory Alloy without Second Phase Formation. Acta Metall. Sin. (Engl. Lett.) 2016, 29, 884–888. [Google Scholar] [CrossRef]

- Saud, S.N.; Hamzah, E.; Abubakar, T.; Bakhsheshi-Rad, H.R.; Mohammed, M.N. Influence of Tin Additions on the Phase-Transformation Characteristics of Mechanical Alloyed Cu-Al-Ni Shape-Memory Alloy. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2016, 47, 5242–5255. [Google Scholar] [CrossRef]

- Izadinia, M.; Dehghani, K. Microstructural evolution and mechanical properties of nanostructured Cu-Al-Ni shape memory alloys. Int. J. Miner. Metall. Mater. 2012, 19, 333–338. [Google Scholar] [CrossRef]

| Element | Cu | Al | Ni | Total | |

|---|---|---|---|---|---|

| Elemental powders | Average particle size (µm) | 45 | 149 | 5 | - |

| Powder purity (wt.%) | 99.7 | 93 | 99.99 | - | |

| Alloy Cu-14.2%Al-3%Ni | Alloy composition (wt.%) | 82.8 | 14.2 | 3 | 100 |

| Equivalent mass (g) | 8.28 | 1.42 | 0.3 | 10 | |

| Real mass (g) | 8.3049 | 1.5269 | 0.3000 | 10.1318 |

| Nominal Content of Ni | Relative Pressure (p − patm) | Oxygen Content | Porosity |

|---|---|---|---|

| 2 wt.% | 0 bar | 0.04020 wt.% | 9.33% |

| 1 bar | 0.03704 wt.% | 3.18% | |

| 2 bar | 0.03336 wt.% | 4.23% | |

| 3 wt.% | 0 bar | 0.52080 wt.% | 4.48% |

| 1 bar | 0.02026 wt.% | 1.40% | |

| 2 bar | 0.00522 wt.% | 2.60% | |

| 4 wt.% | 0 bar | 0.00690 wt.% | 2.33% |

| 1 bar | 0.12320 wt.% | 2.73% | |

| 2 bar | 0.03244 wt.% | 0.76% |

| Sample | p − patm | Austenitic Transition | Martensitic Transition | Hysteresis | ||||

|---|---|---|---|---|---|---|---|---|

| As (°C) | Af (°C) | ΔHa (J/g) | Ms (°C) | Mf (°C) | ΔHm (J/g) | ΔTH (°C) | ||

| 2 wt.% Ni | 0 bar | 98.30 | 149.63 | 6.84 | 125.37 | 85.38 | 4.46 | 18.59 |

| 1 bar | 118.49 | 150.32 | 5.98 | 136.34 | 98.67 | 6.19 | 16.91 | |

| 2 bar | 128.69 | 159.36 | 4.41 | 147.16 | 85.66 | 4.20 | 27.62 | |

| 3 wt.% Ni | 0 bar | 145.98 | 166.98 | 8.29 | 158.02 | 130.70 | 6.89 | 12.12 |

| 1 bar | 123.83 | 165.67 | 4.57 | 158.50 | 112.37 | 3.70 | 9.32 | |

| 2 bar | 166.26 | 192.23 | 3.89 | 182.36 | 152.36 | 3.35 | 11.89 | |

| 4 wt.% Ni | 0 bar | 115.65 | 161.66 | 6.32 | 151.02 | 96.07 | 6.19 | 15.11 |

| 1 bar | 114.85 | 161.34 | 5.52 | 153.83 | 93.00 | 5.49 | 14.68 | |

| 2 bar | 124.34 | 167.50 | 4.57 | 158.17 | 112.37 | 3.53 | 10.65 | |

| 4 wt.% Ni | HT | 98.62 | 161.65 | 8.73 | 148.33 | 92.36 | 5.04 | 9.79 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niedbalski, S.; Durán, A.; Walczak, M.; Ramos-Grez, J.A. Laser-Assisted Synthesis of Cu-Al-Ni Shape Memory Alloys: Effect of Inert Gas Pressure and Ni Content. Materials 2019, 12, 794. https://doi.org/10.3390/ma12050794

Niedbalski S, Durán A, Walczak M, Ramos-Grez JA. Laser-Assisted Synthesis of Cu-Al-Ni Shape Memory Alloys: Effect of Inert Gas Pressure and Ni Content. Materials. 2019; 12(5):794. https://doi.org/10.3390/ma12050794

Chicago/Turabian StyleNiedbalski, Stefan, Alicia Durán, Magdalena Walczak, and Jorge A. Ramos-Grez. 2019. "Laser-Assisted Synthesis of Cu-Al-Ni Shape Memory Alloys: Effect of Inert Gas Pressure and Ni Content" Materials 12, no. 5: 794. https://doi.org/10.3390/ma12050794

APA StyleNiedbalski, S., Durán, A., Walczak, M., & Ramos-Grez, J. A. (2019). Laser-Assisted Synthesis of Cu-Al-Ni Shape Memory Alloys: Effect of Inert Gas Pressure and Ni Content. Materials, 12(5), 794. https://doi.org/10.3390/ma12050794