1. Introduction

Laser cladding is a surface modification technology that is used to enhance the mechanical properties of a substrate. In this process, a thin layer of metal powder is placed on the surface of the substrate and both the powder and substrate are melted with a laser beam to form a cladding layer [

1,

2]. Due to its modest heat affected zone, small-scale deformation, low dilution rate, and rapid melting and solidification, laser cladding has been widely applied to repair and remanufacture crank shaft and other high value parts in the aerospace, marine, petroleum, and chemical industries [

3,

4,

5].

Recent development in laser cladding powders and surface coatings has been extended beyond traditional materials to include composite materials. For instance, NiCrSiB series alloys are extensively utilized in industry due to their exceptional corrosion, wear and fatigue resistance, and cost efficiency [

6,

7,

8]. Within this series, most of the research has focused on Ni60A powder. However, Ni60A has high brittleness, which could lead to a high possibility of fracture. Ni35A possesses high plasticity but low hardness. However, its hardness could be improved by incorporating add-on materials [

9]. TiC has a high melting point, high hardness, outstanding wear resistance, and a low coefficient of friction. Thus, TiC has been frequently adopted to enhance material properties [

10,

11]. Because of the phenomenal properties, research has been concentrated on combining nickel-based alloys and TiC to form composite cladding materials.

Bakkar et al. investigated the microstructure, micro-hardness, wear resistance, and corrosion resistance of different volume percentages of TiC/Inconel 625 nickel-based composite alloys. They found that the micro-hardness and wear resistance of these type of composites could be improved by adding an appropriate volume fraction of TiC [

12]. Muvvala et al. conducted laser cladding experiments with different weight percentages of TiC/Inconel 718 nickel-based composite alloy powder and investigated the impact of processing parameters on the molten pool and structural properties. Analyzing the result illustrated that optimizing processing parameters could effectively disperse fine TiC particles, which enhanced hardness and wear resistance of the cladding layer [

13]. Liu et al. produced a TiC enhanced nickel-based composite coating. They concluded that the phase and distribution of TiC were affected by convection in the molten pool [

14]. Saroj et al. created a TiC-Inconel 825 composite coating employing a Tungsten Inert Gas (TIG) cladding method and discovered the impact of different TiC percentages (20%, 40%, and 60%) and processing currents on the coating morphology, micro-hardness, and wear resistance. Because of the superior wettability and binding between nickel-based alloys and TiC, the coating hardness reached 1100 HV

0.05, and the wear resistance improved seven times over that of the substrate [

15]. Sahoo et al. also utilized TIG cladding to build TiC-Ni composite coating on an AISI304 steel substrate. The results exhibited outstanding binding between the coating and substrate, the hardness reached 1300 HV

0.05, and the wear resistance increased 70 times with TiC-Ni composite coating when compared to the substrate [

16].

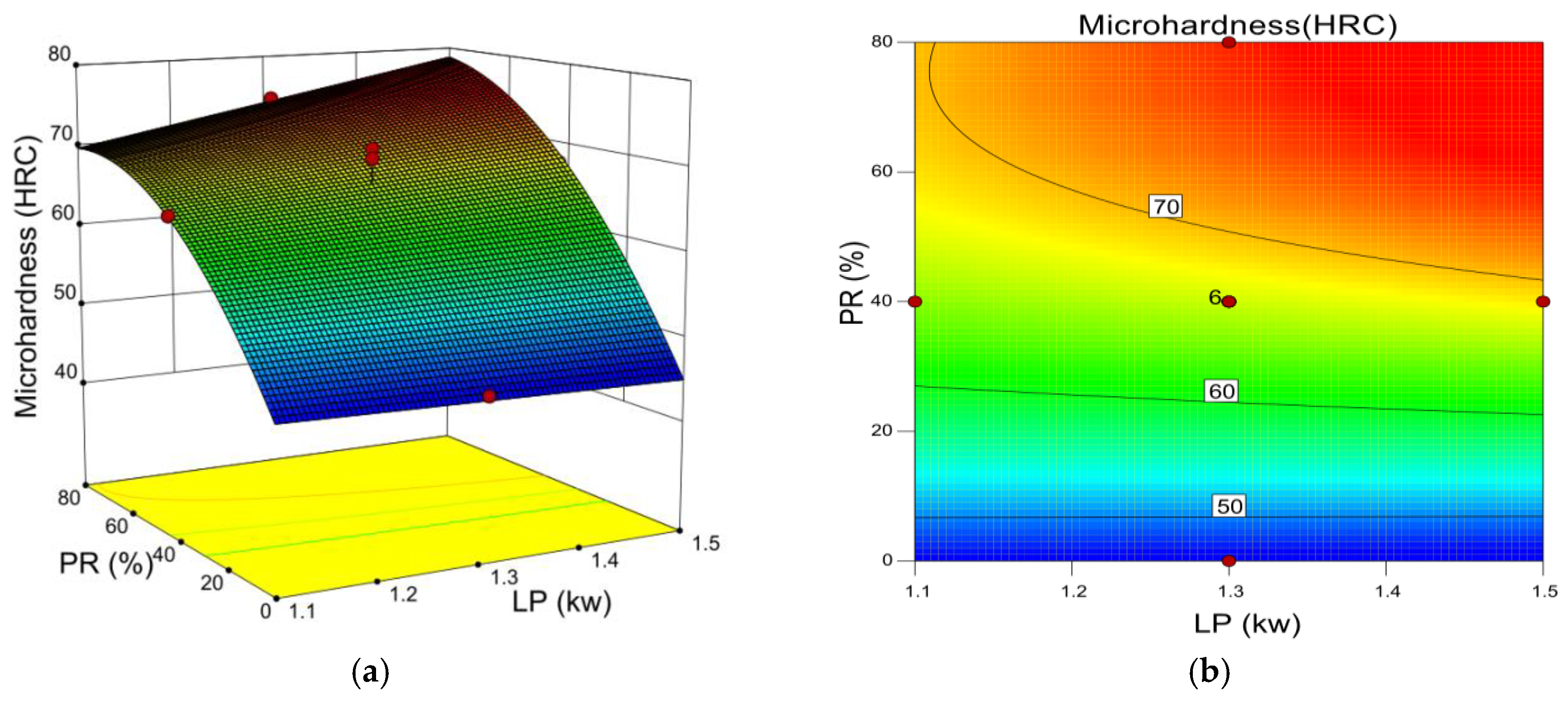

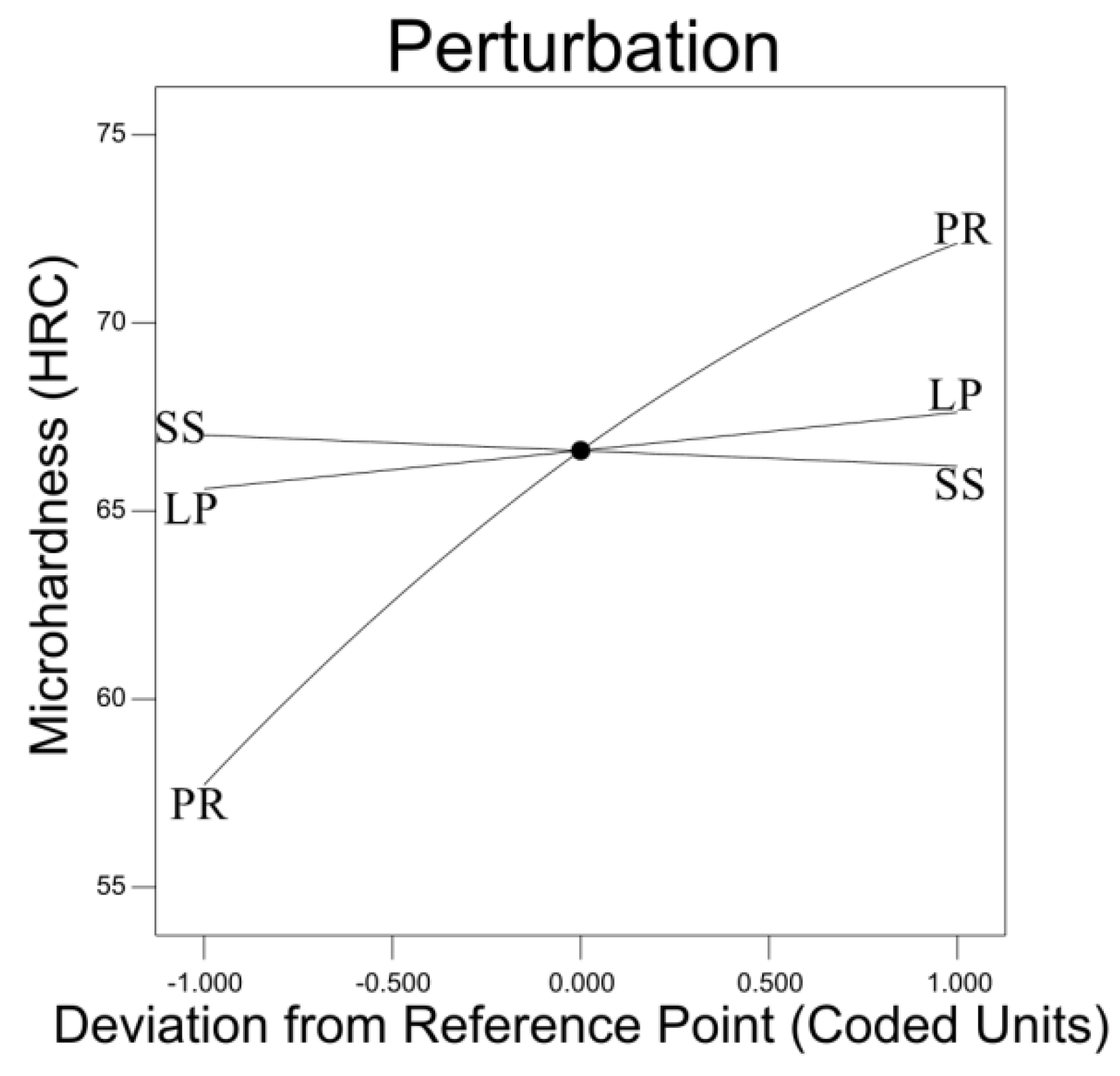

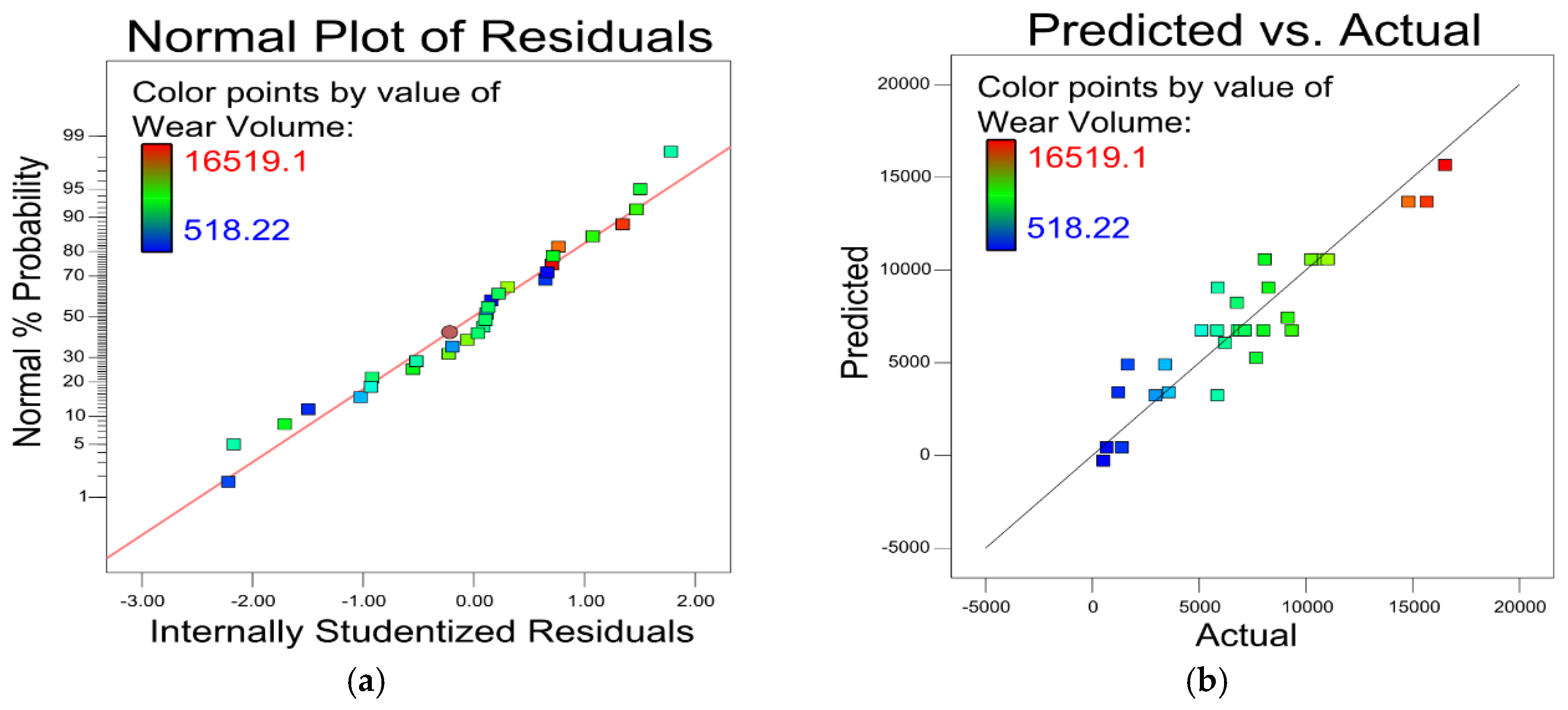

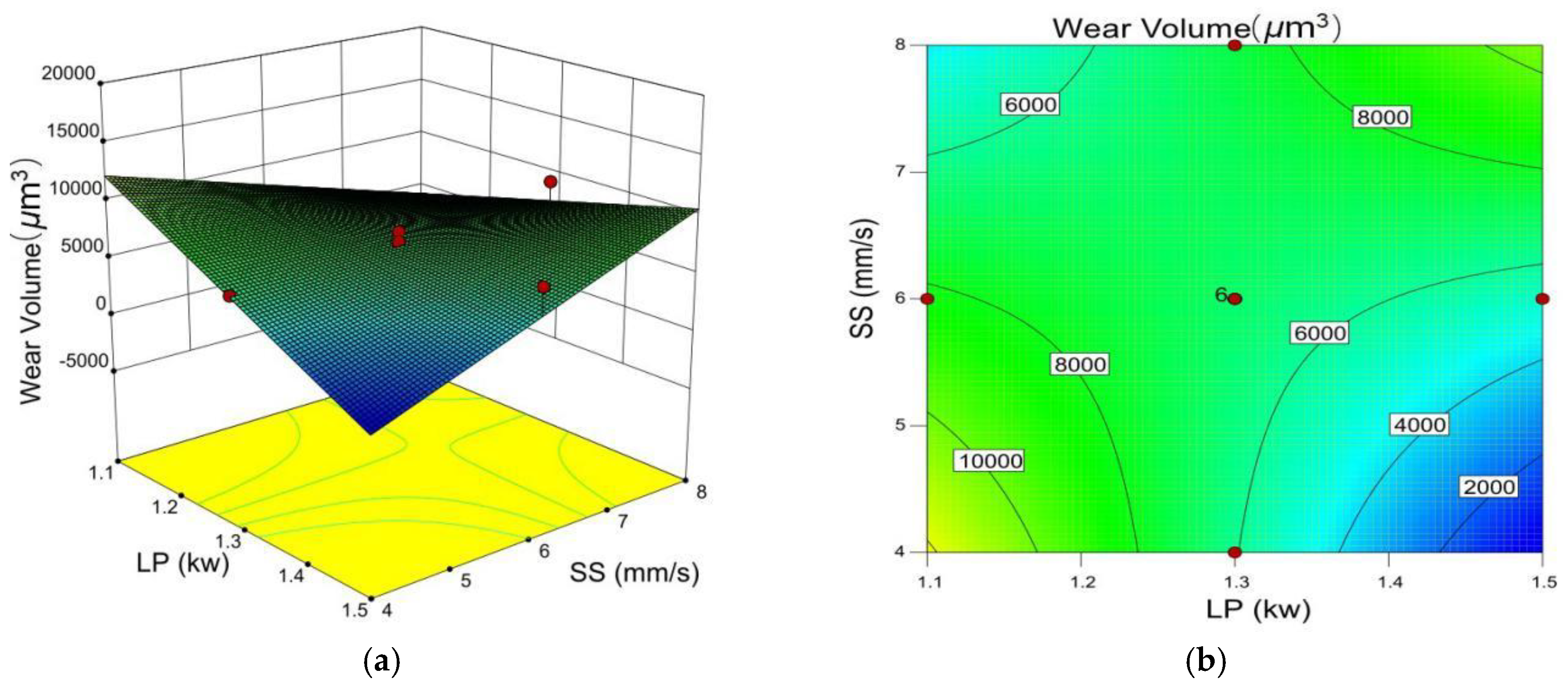

Existing research on a nickel-based alloy and TiC composite material are primarily focused on the influence of different TiC ratios and processing parameters on the structural properties, micro-hardness, and wear resistance of the coating since micro-hardness and wear resistance are two important factors evaluated in industrial applications. However, predicting and controlling the cladding layer micro-hardness and wear resistance by manipulating the laser cladding processing parameters and TiC ratio have rarely been explored. In this paper, mathematical models are developed to predict the micro-hardness and wear resistance of the cladding layer by controlling the laser cladding processing parameters and TiC powder ratio.

2. Materials and Methods

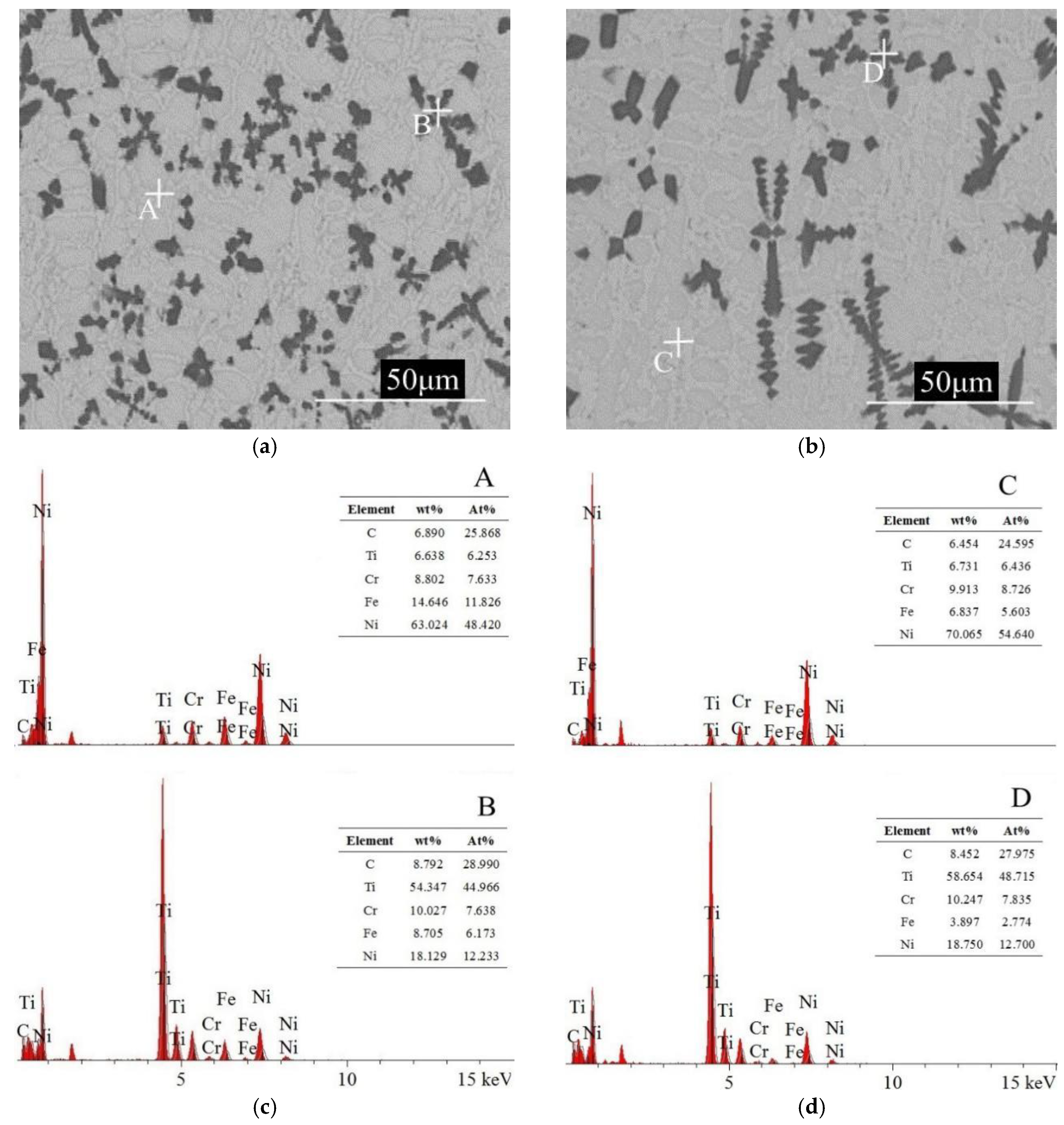

AISI/SAE 1045 steel was selected as the substrate with a size of 40 mm × 20 mm × 5 mm. The laser beam diameter was adjusted to 4 mm. Cladding powder was made from Ni35A and TiC powder with a particle size ranging from 48 μm to 106 μm. The elemental composition and morphology of Ni35A and TiC power are shown in

Table 1 and

Figure 1.

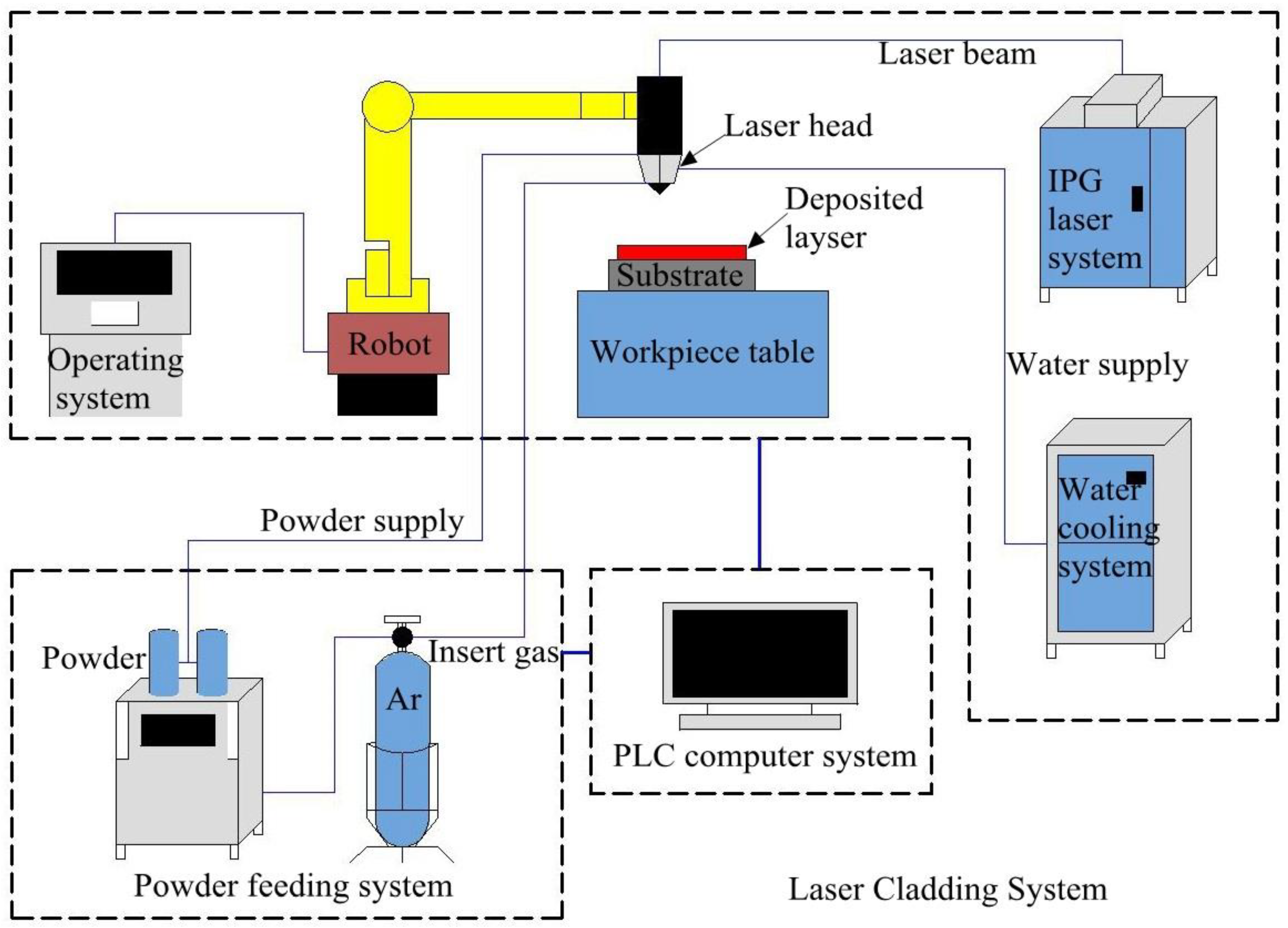

Figure 2 explains the laser cladding system, which includes a laser system (YLS-3000, IPG, Burbach, Germany), laser cladding nozzle with 300 mm focal length (FDH0273, Lasermech, Novi, MI, USA), industrial robot (M-710iC/50, FANUC, Yamanashi, Japan), water cooling system (TFLW-4000WDR-01-3385, Sanhe Tongfei, Sanhe, China), powder feeding system (CR-PGF-D-2, Songxing, Fuzhou, China), control system (PLC, Mitsubishi, Japan), and laser pulse control system (SX14-012PULSE, IPG, Burbach, Germany). Argon gas was used to protect the material during the cladding process.

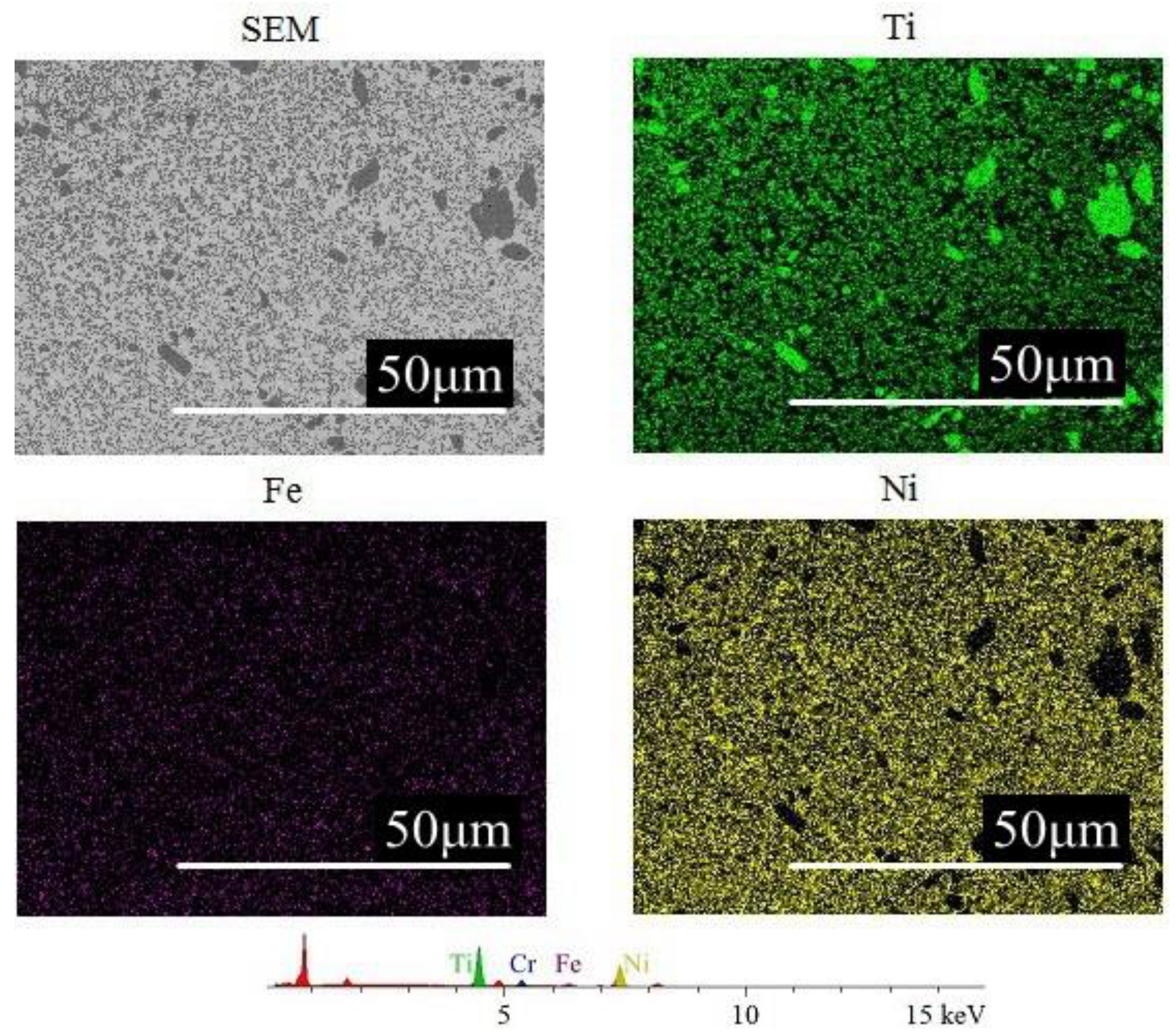

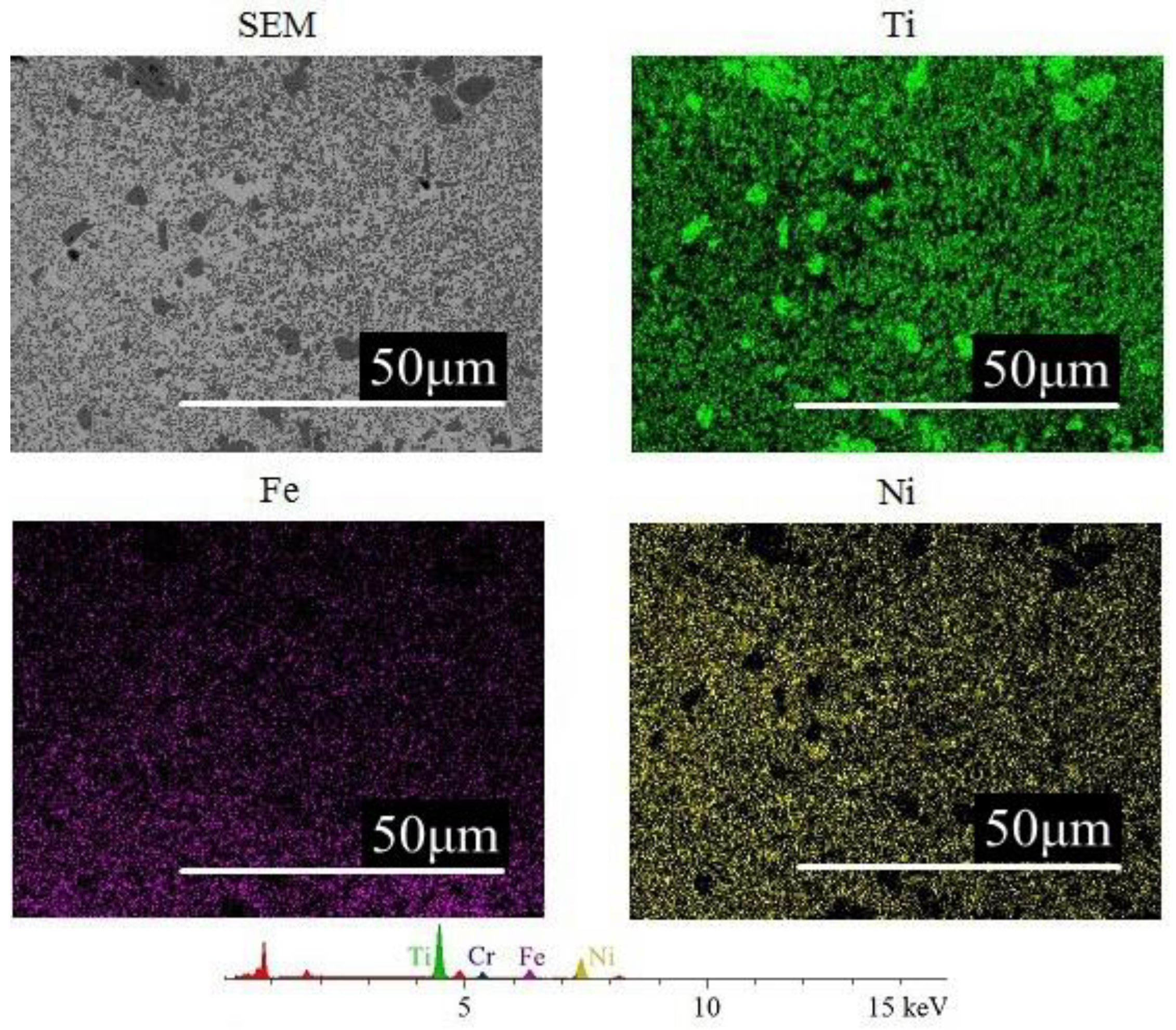

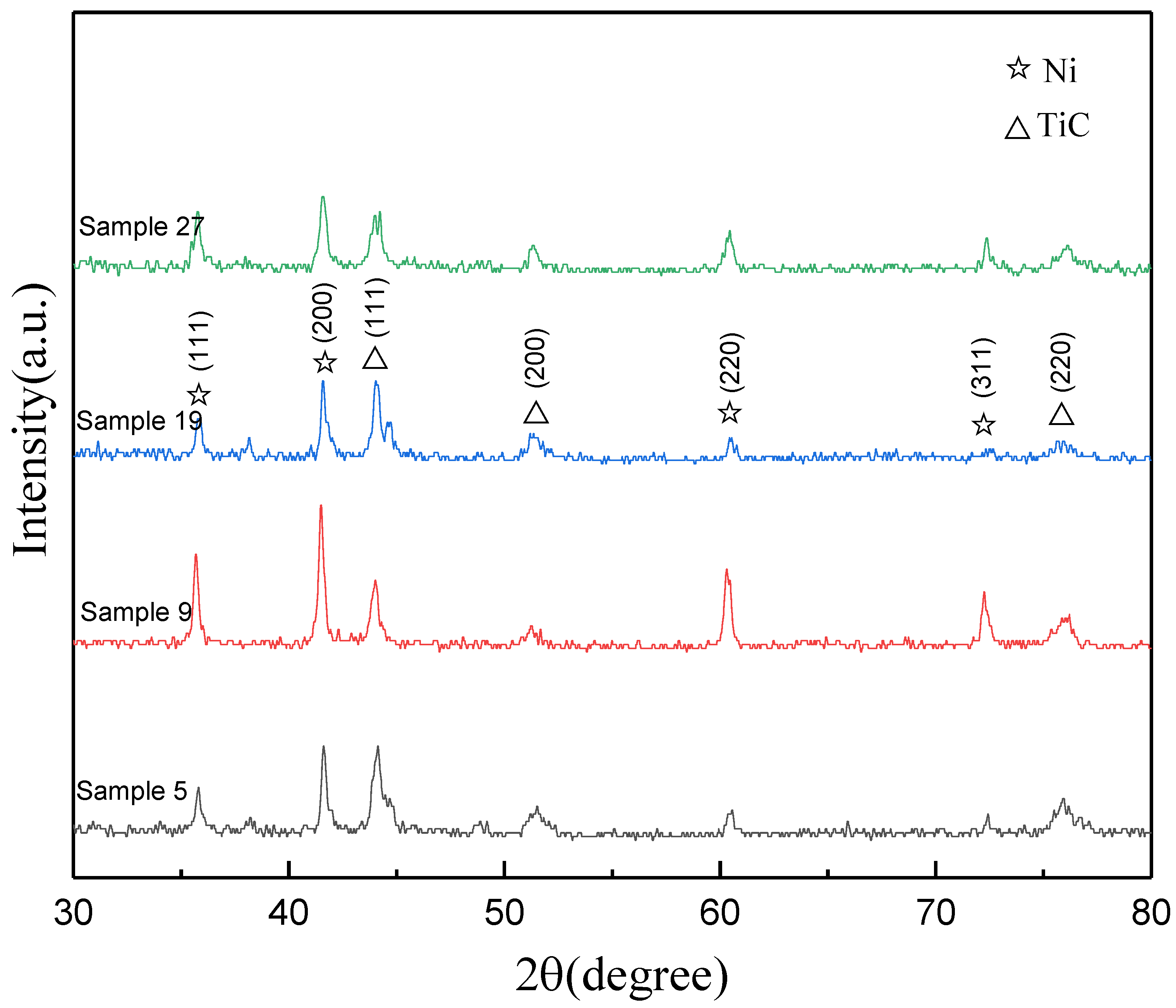

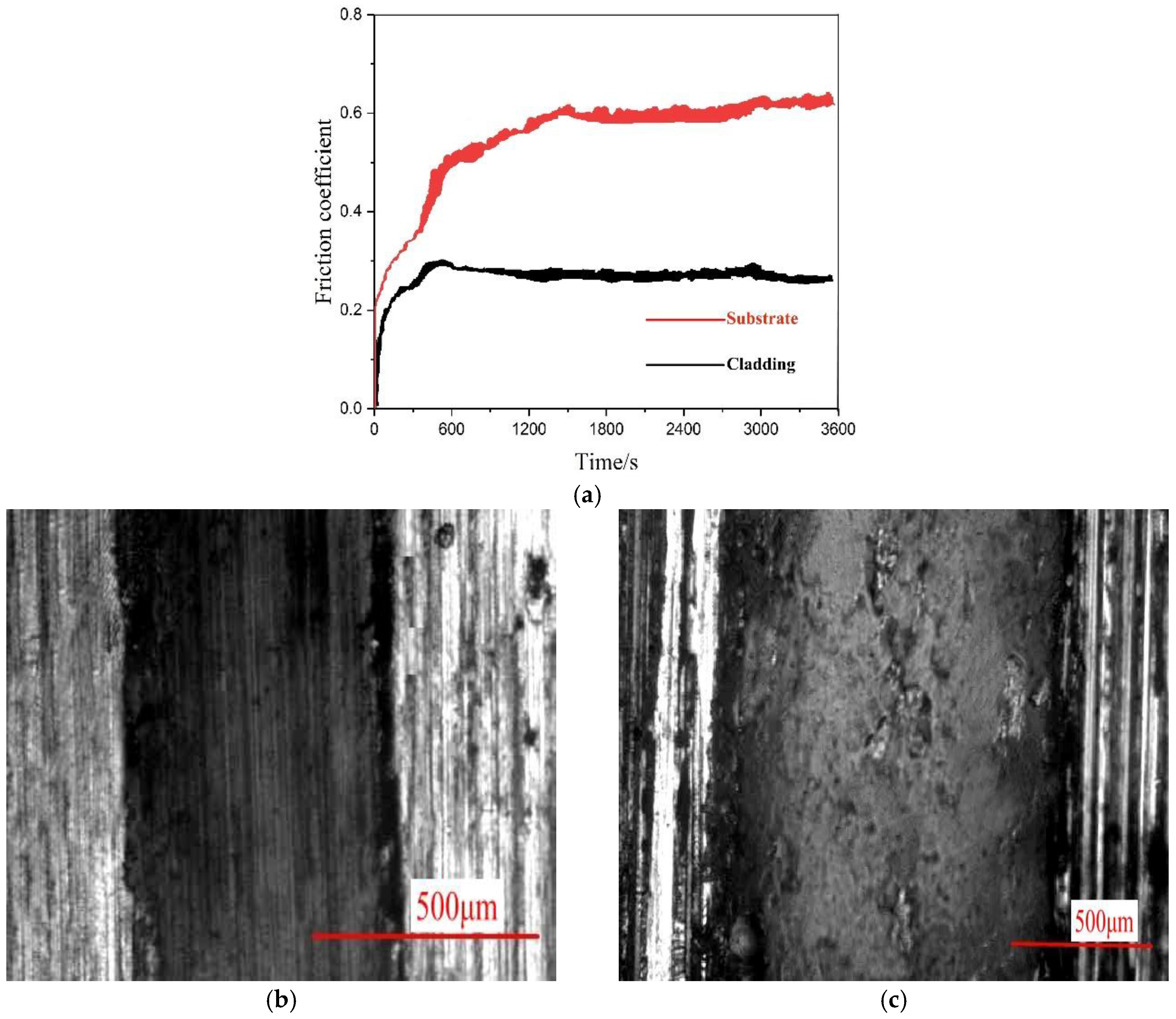

Before cladding, the 1045 steel substrate surface was cleaned with ethanol. The Ni35A and TiC powder was mixed in a MITR--YXQM-2L ball mill machine (MITR, Changsha, China) for 30 min at a speed of 300 rpm and then placed in a vacuum dryer for an additional 30 min at a temperature of 120 °C. After completion of the laser cladding, the sample was processed by cutting, setting, grinding, and polishing. Then the sample was immersed in 4% nitric acid and alcohol mixture for 30 s. An MVA-402TS micro-hardness tester (HDNS, Shanghai, China) was utilized to measure the micro-hardness with a 500 g-force applied for a 30-s duration. The microstructure was observed using a scanning electron microscope (SEM) TM3030Plus (HITACHI 550I, Tokyo, Japan). In addition, element analysis was performed using an energy-dispersive X-ray spectroscopy (EDS) system (A550I, IXRF, Austin, TX, USA). The wear resistance was examined with a UMT-2 high load scratch tester (Bruker, Billerica, MA, USA). The X-ray diffraction (XRD) analysis was conducted with Ultima IV XRD systems (Rigaku Corporation, Tokyo, Japan). 3D morphology of the abrasion surface was obtained using white light interferometry. Afterwards, the width and depth of the worn area was measured. The average wear off area was obtained by repeating the previously mentioned measurement in five different locations. In the end, wear volume was calculated by multiplying the average wear off area by the scratching distance. The wear volume was used to evaluate wear resistance in which lower wear volume indicates greater wear resistance. The friction coefficient was measured every 0.1 s over a duration of 60 min. Conditions for the wear test are shown below in

Table 2.

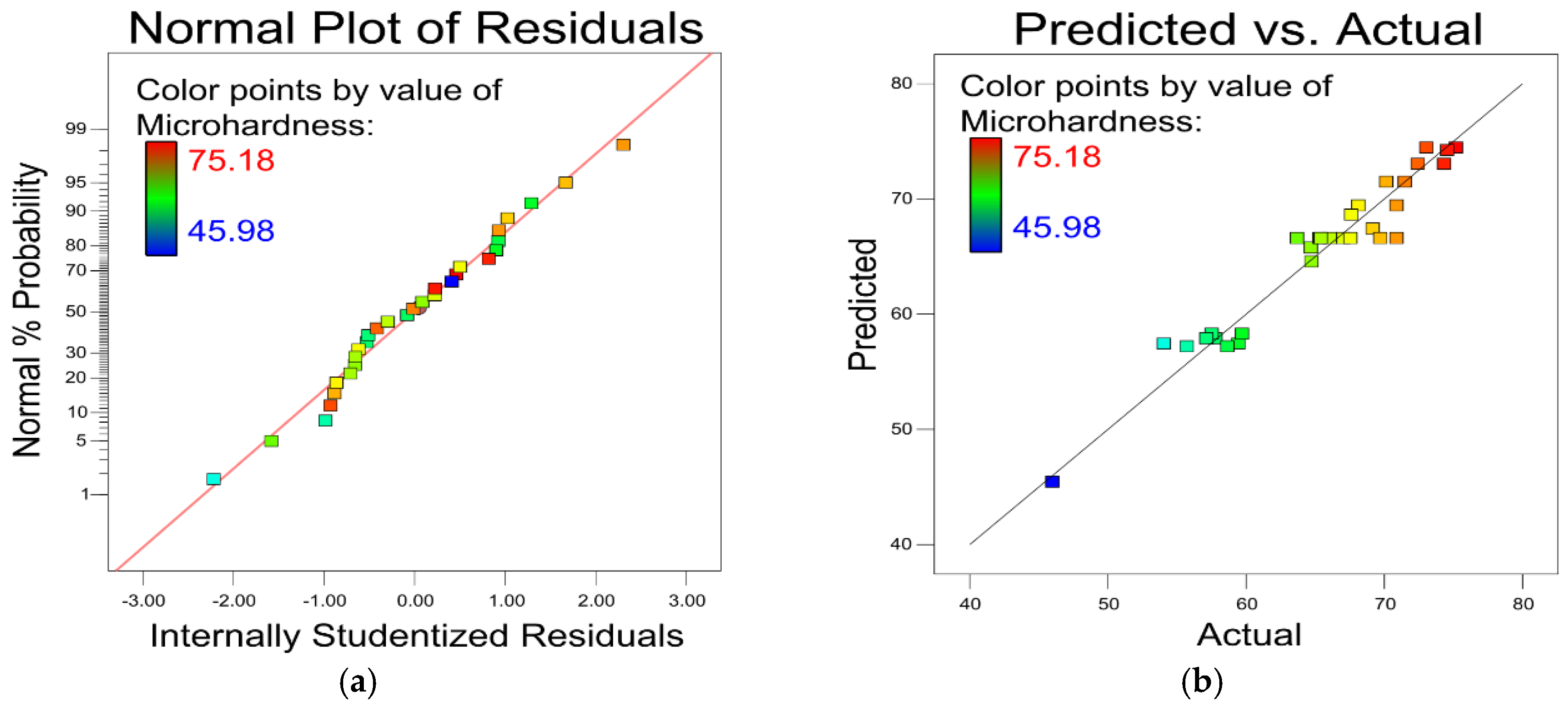

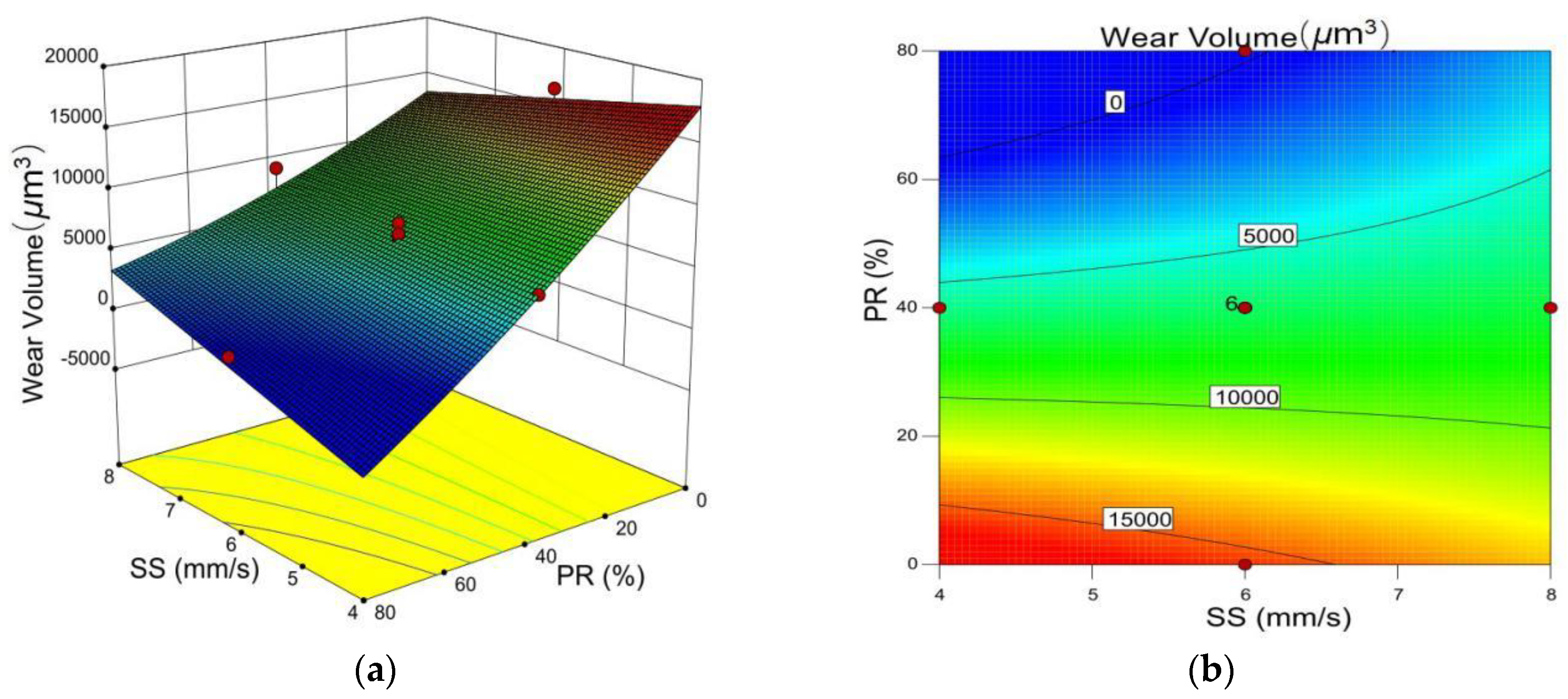

Respond surface methodology (RSM) is an optimization method that can be used to build a mathematic model between output and input variables. In this study, the central composite design (CCD) module in RSM was selected. The experimental design matrix contained four factors and five levels. The four factors were laser power (LP), scanning speed (SS), gas flow (GF), and TiC powder ratio (PR). The variables for the factors were set to 0, ±1, and ±2 in the Design Expert software (Version 10.0). Then the interaction respond value between input and output was obtained with the CCD design. The intent of RSM is to build a statistical prediction model based on experimental results. Afterwards, analysis of variance was utilized to analyze the model [

17]. Multiple regression analysis was employed to build and analyze the model between the input parameters and the output. The polynomial regression function is shown in Equation (1) below [

18], where y is the response value and

β0 is the intercept factor. The coefficients for the linear term, interaction term, and quadratic term are

βj,

βij,

βjj, respectively. Additionally,

xi and

xj represent the processing parameter,

k is the number of factors, and ε is the residual.

The laser cladding processing parameter variables are exhibited in

Table 3. Experimental design and results are shown in

Table 4.