Superior Wear Resistance in EBM-Processed TC4 Alloy Compared with SLM and Forged Samples

Abstract

1. Introduction

2. Experimental Details

3. Results

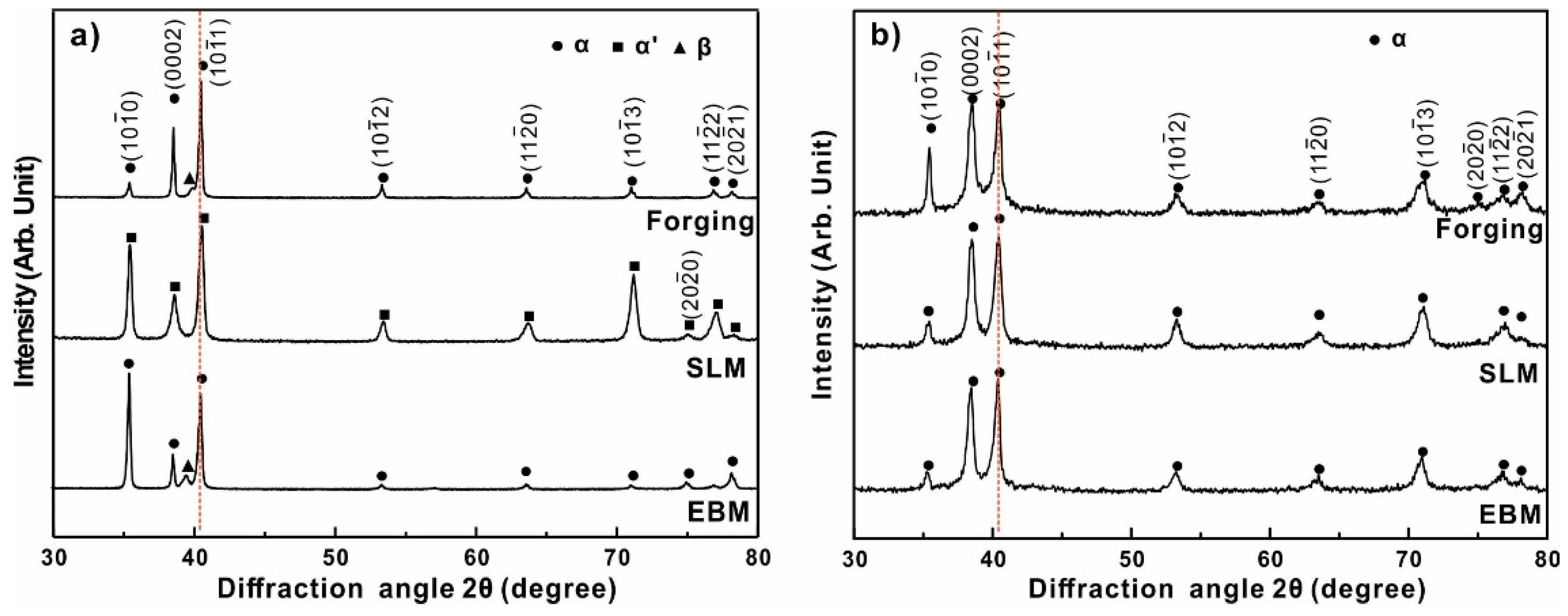

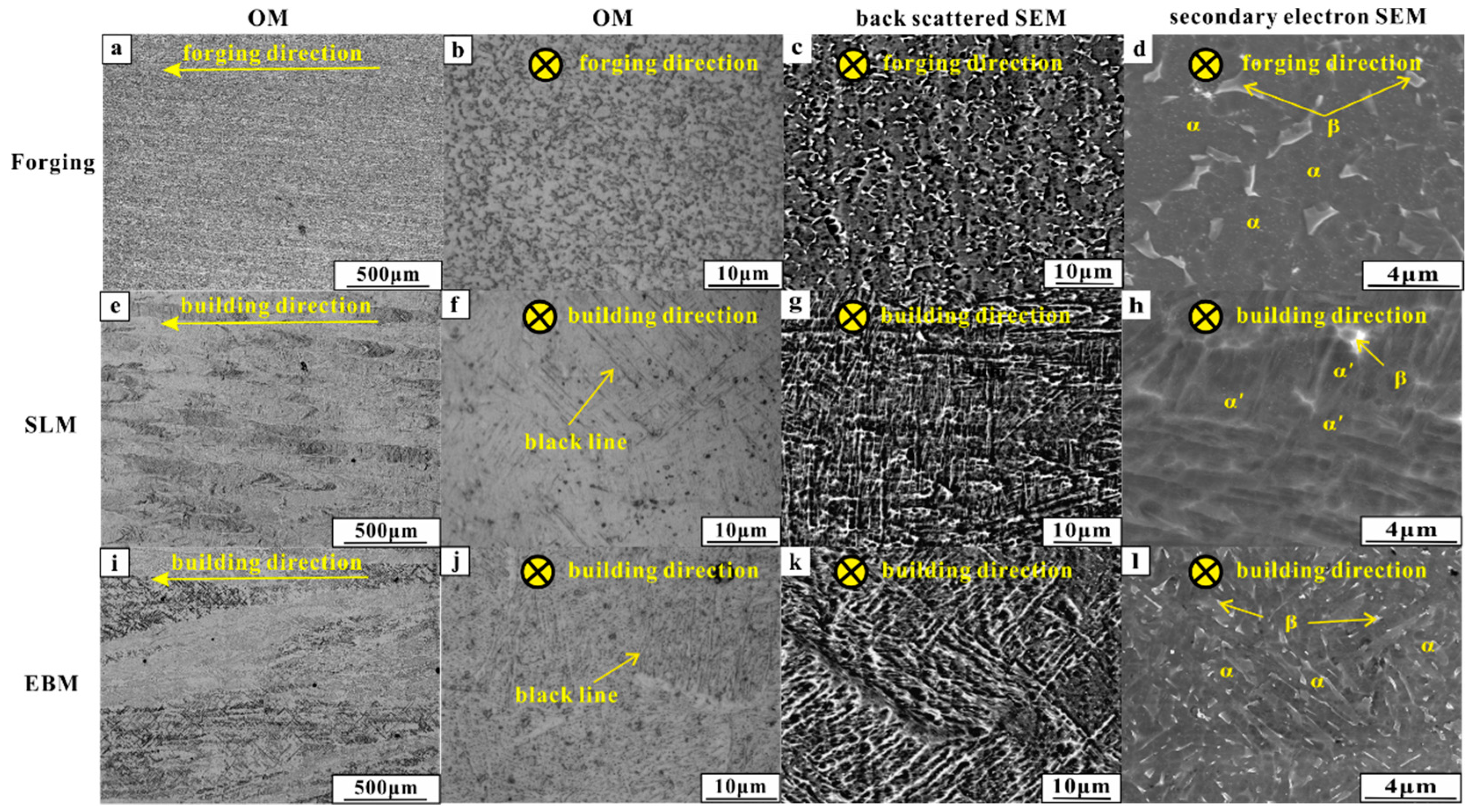

3.1. Microstructural Observation

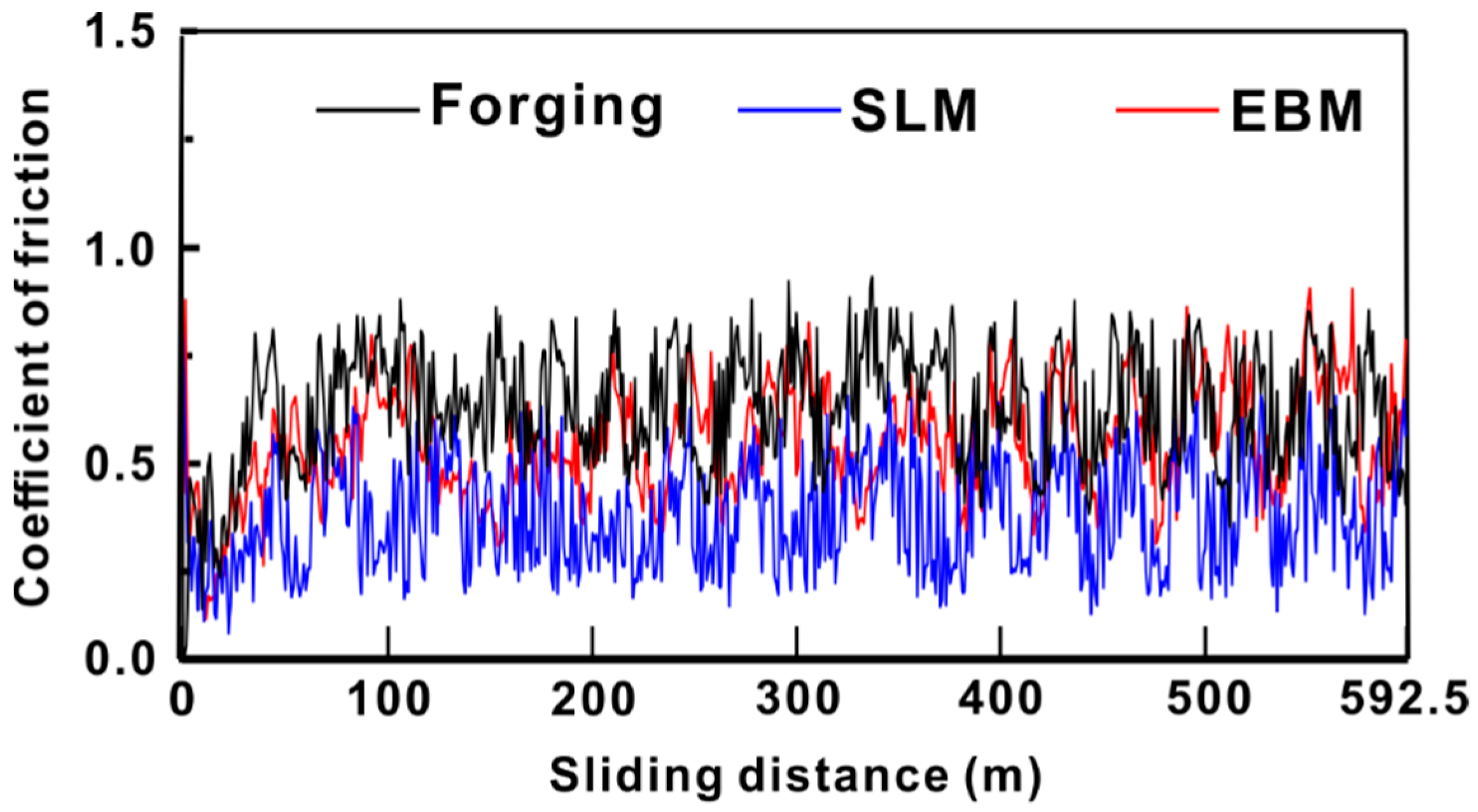

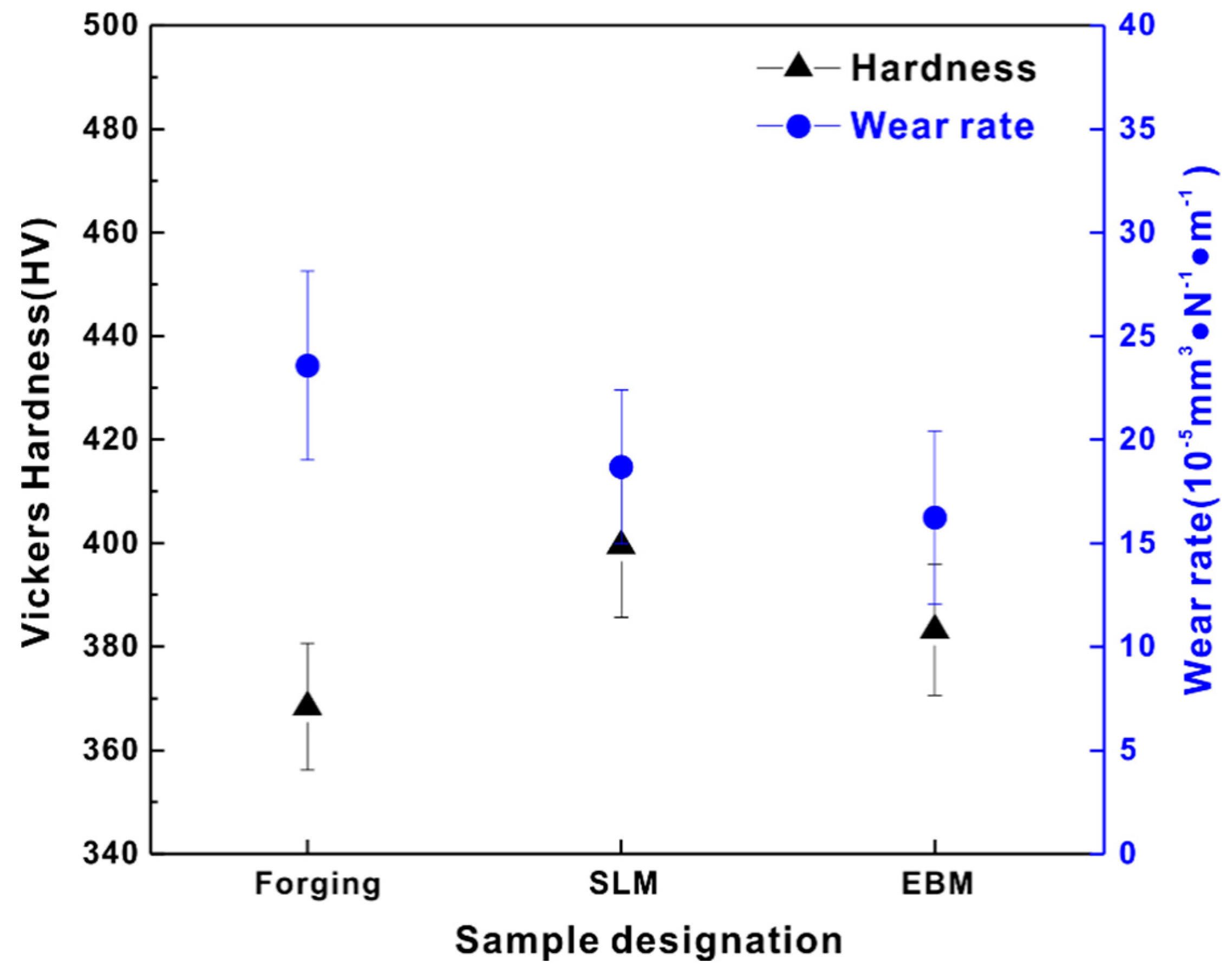

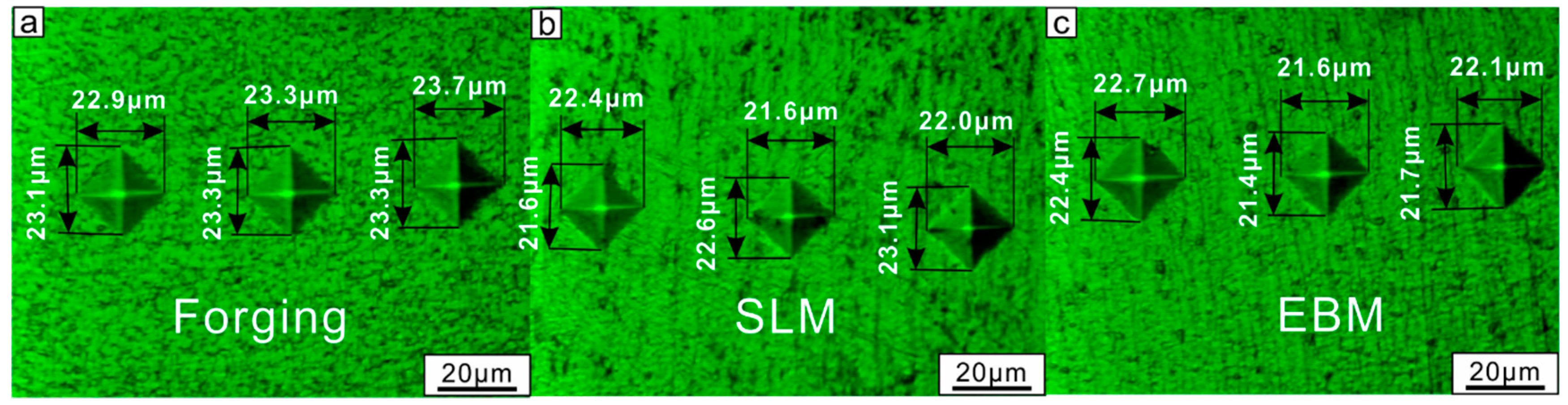

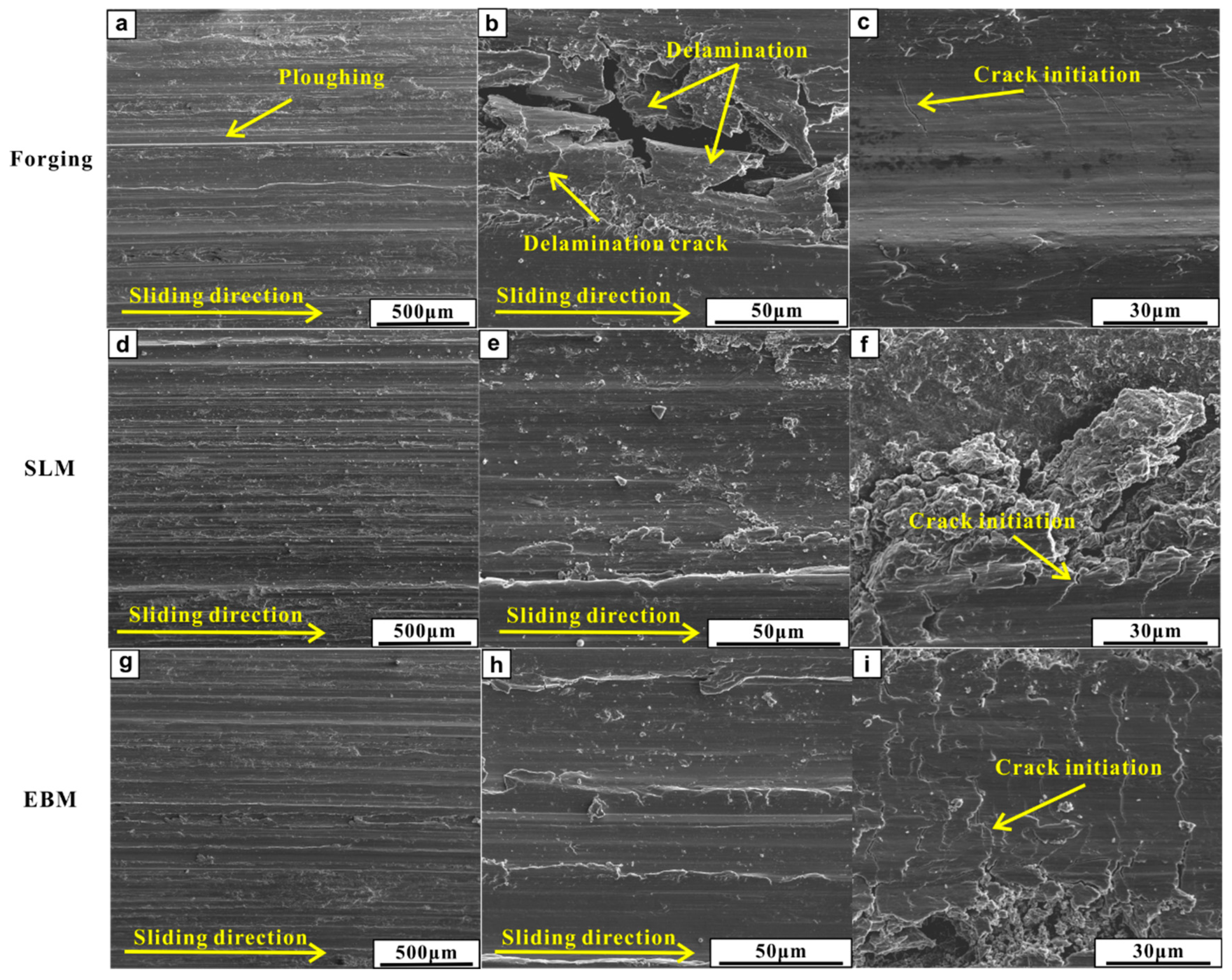

3.2. Friction and Wear Properties

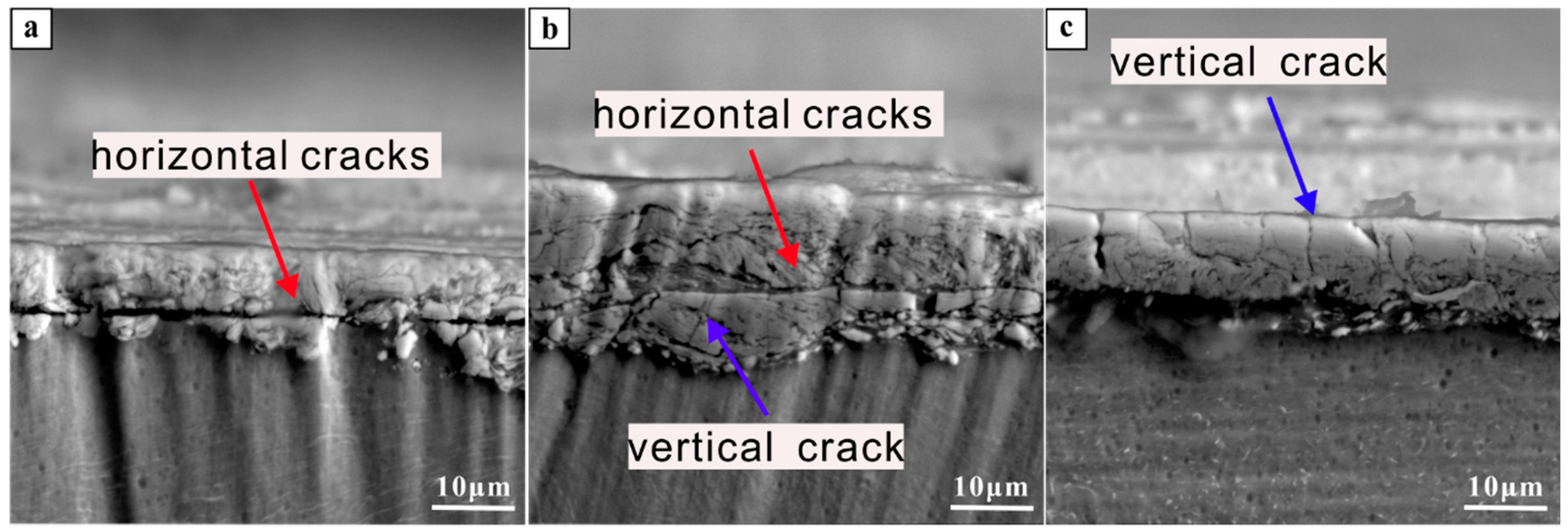

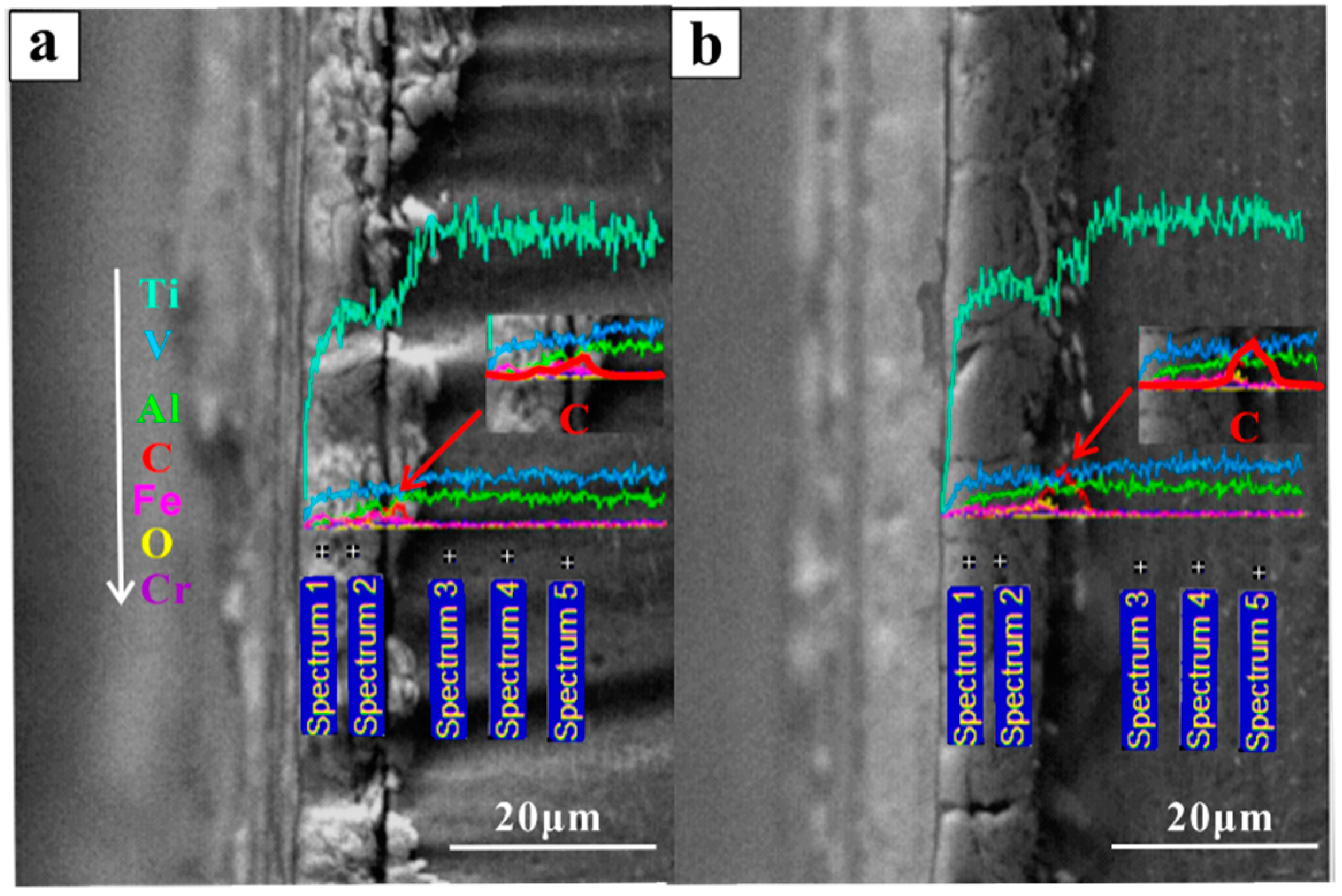

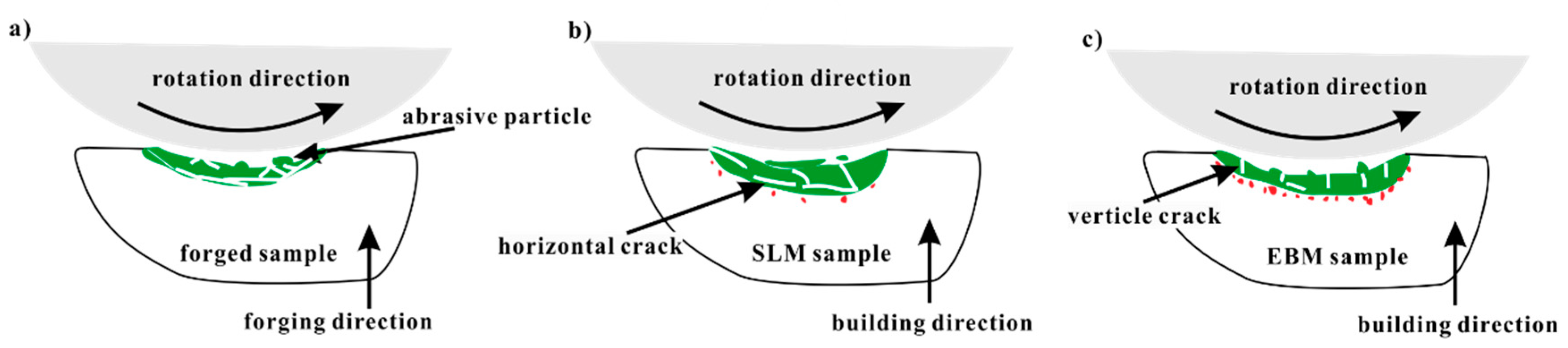

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Harun, W.S.W.; Kamariah, M.S.I.N.; Muhamad, N.; Ghani, S.A.C.; Ahmad, F.; Mohamed, Z. A review of powder additive manufacturing processes for metallic biomaterials. Powder Technol. 2018, 327, 128–151. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Klauss, H.J.; Surreddi, K.B.; Löber, L.; Wang, Z.; Chaubey, A.K.; Kühn, U.; Eckert, J. Microstructure and mechanical properties of Al–12Si produced by selective laser melting: Effect of heat treatment. Mater. Sci. Eng. A 2014, 590, 153–160. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Damodaram, R.; Maity, T.; Wang, P.; Eckert, J. Friction welding of selective laser melted Ti6Al4V parts. Mater. Sci. Eng. A 2017, 704, 66–71. [Google Scholar] [CrossRef]

- Gokuldoss, P.K.; Kolla, S.; Eckert, J. Additive manufacturing processes: Selective laser melting, electron beam melting and binder jetting-selection guidelines. Materials 2017, 10, 672. [Google Scholar] [CrossRef] [PubMed]

- Van Hooreweder, B.; Moens, D.; Boonen, R.; Kruth, J.P.; Sas, P. Analysis of fracture toughness and crack propagation of Ti6Al4V produced by selective laser melting. Adv. Eng. Mater. 2012, 14, 92–97. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Sing, S.L.; An, J.; Yeong, W.Y.; Wiria, F.E. Laser and electron-beam powder-bed additive manufacturing of metallic implants: A review on processes, materials and designs. J. Orthop. Res. 2016, 34, 369–385. [Google Scholar] [CrossRef] [PubMed]

- Scudino, S.; Unterdörfer, C.; Prashanth, K.G.; Attar, H.; Ellendt, N.; Uhlenwinkel, V.; Eckert, J. Additive manufacturing of Cu–10Sn bronze. Mater. Lett. 2015, 156, 202–204. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Eckert, J. Defining the tensile properties of Al-12Si parts produced by selective laser melting. Acta Mater. 2017, 126, 25–35. [Google Scholar] [CrossRef]

- Ataee, A.; Li, Y.; Brandt, M.; Wen, C. Ultrahigh-strength titanium gyroid scaffolds manufactured by selective laser melting (SLM) for bone implant applications. Acta Mater. 2018, 158, 354–368. [Google Scholar] [CrossRef]

- Prashanth, K.; Löber, L.; Klauss, H.-J.; Kühn, U.; Eckert, J. Characterization of 316L Steel Cellular Dodecahedron Structures Produced by Selective Laser Melting. Technologies 2016, 4, 34. [Google Scholar] [CrossRef]

- Attar, H.; Löber, L.; Funk, A.; Calin, M.; Zhang, L.C.; Prashanth, K.G.; Scudino, S.; Zhang, Y.S.; Eckert, J. Mechanical behavior of porous commercially pure Ti and Ti–TiB composite materials manufactured by selective laser melting. Mater. Sci. Eng. A 2015, 625, 350–356. [Google Scholar] [CrossRef]

- Banerjee, D.; Williams, J.C. Perspectives on titanium science and technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Williams, J.C. Titanium alloys: Production, behavior and application. In High Performance Materials in Aerospace; Flower, H.M., Ed.; Springer: Dordrecht, The Netherlands, 1995; pp. 85–134. ISBN 978-94-011-0685-6. [Google Scholar]

- Bruschi, S.; Bertolini, R.; Bordin, A.; Medea, F.; Ghiotti, A. Influence of the machining parameters and cooling strategies on the wear behavior of wrought and additive manufactured Ti6Al4V for biomedical applications. Tribol. Int. 2016, 102, 133–142. [Google Scholar] [CrossRef]

- Koike, M.; Greer, P.; Owen, K.; Lilly, G.; Murr, L.E.; Gaytan, S.M.; Martinez, E.; Okabe, T. Evaluation of titanium alloys fabricated using rapid prototyping technologies-electron beam melting and laser beam melting. Materials 2011, 4, 1776–1792. [Google Scholar] [CrossRef] [PubMed]

- Attar, H.; Bönisch, M.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Selective laser melting of in situ titanium-titanium boride composites: Processing, microstructure and mechanical properties. Acta Mater. 2014, 76, 13–22. [Google Scholar] [CrossRef]

- Weißmann, V.; Drescher, P.; Bader, R.; Seitz, H.; Hansmann, H.; Laufer, N. Comparison of Single Ti6Al4V Struts Made Using Selective Laser Melting and Electron Beam Melting Subject to Part Orientation. Metals 2017, 7, 91. [Google Scholar] [CrossRef]

- Zhao, X.; Li, S.; Zhang, M.; Liu, Y.; Sercombe, T.B.; Wang, S.; Hao, Y.; Yang, R.; Murr, L.E. Comparison of the microstructures and mechanical properties of Ti-6Al-4V fabricated by selective laser melting and electron beam melting. Mater. Des. 2016, 95, 21–31. [Google Scholar] [CrossRef]

- Vastola, G.; Zhang, G.; Pei, Q.X.; Zhang, Y.W. Active Control of Microstructure in Powder-Bed Fusion Additive Manufacturing of Ti6Al4V. Adv. Eng. Mater. 2017, 19, 1–6. [Google Scholar] [CrossRef]

- Attar, H.; Prashanth, K.G.; Chaubey, A.K.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Comparison of wear properties of commercially pure titanium prepared by selective laser melting and casting processes. Mater. Lett. 2015, 142, 38–41. [Google Scholar] [CrossRef]

- Saravanan, I.; Perumal, A.E. Wear behavior of γ-irradiated Ti6Al4V alloy sliding on TiN deposited steel surface. Tribol. Int. 2016, 93, 451–463. [Google Scholar] [CrossRef]

- Wang, Y.; Li, J.; Dang, C.; Wang, Y.; Zhu, Y. Influence of carbon contents on the structure and tribocorrosion properties of TiSiCN coatings on Ti6Al4V. Tribol. Int. 2017, 109, 285–296. [Google Scholar] [CrossRef]

- Balla, V.K.; Soderlind, J.; Bose, S.; Bandyopadhyay, A. Microstructure, mechanical and wear properties of laser surface melted Ti6Al4V alloy. J. Mech. Behav. Biomed. Mater. 2014, 32, 335–344. [Google Scholar] [CrossRef] [PubMed]

- Bartolomeu, F.; Buciumeanu, M.; Pinto, E.; Alves, N.; Silva, F.S.; Carvalho, O.; Miranda, G. Wear behavior of Ti6Al4V biomedical alloys processed by selective laser melting, hot pressing and conventional casting. Trans. Nonferr. Met. Soc. China 2017, 27, 829–838. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Debalina, B.; Wang, Z.; Gostin, P.F.; Gebert, A.; Calin, M.; Kühn, U.; Kamaraj, M.; Scudino, S.; Eckert, J. Tribological and corrosion properties of Al-12Si produced by selective laser melting. J. Mater. Res. 2014, 29, 2044–2054. [Google Scholar] [CrossRef]

- Wang, Z.; Tan, J.; Sun, B.A.; Scudino, S.; Prashanth, K.G.; Zhang, W.W.; Li, Y.Y.; Eckert, J. Fabrication and mechanical properties of Al-based metal matrix composites reinforced with Mg65Cu20Zn5Y10 metallic glass particles. Mater. Sci. Eng. A 2014, 600, 53–58. [Google Scholar] [CrossRef]

- Welsch, G.; Boyer, R.; Collings, E.W. Materilas Properties Handbook: Titanium Alloy; ASM International: Metals Park, OH, USA, 1994. [Google Scholar]

- Tang, B.; Wu, P.Q.; Fan, A.L.; Qin, L.; Hu, H.J.; Celis, J.P. Improvement of corrosion-wear resistance of Ti-6Al-4V alloy by plasma Mo-N surface modification. Adv. Eng. Mater. 2005, 7, 232–238. [Google Scholar] [CrossRef]

- Gu, D.; Hagedorn, Y.; Meiners, W.; Meng, G. Densification behavior, microstructure evolution, and wear performance of selective laser melting processed commercially pure titanium. Acta Mater. 2012, 60, 3849–3860. [Google Scholar] [CrossRef]

- Jung, H.Y.; Choi, S.J.; Prashanth, K.G.; Stoica, M.; Scudino, S.; Yi, S.; Kühn, U.; Kim, D.H.; Kim, K.B.; Eckert, J. Fabrication of Fe-based bulk metallic glass by selective laser melting: A parameter study. Mater. Des. 2015, 86, 703–708. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Eckert, J. Formation of metastable cellular microstructures in selective laser melted alloys. J. Alloy. Compd. 2017, 707, 27–34. [Google Scholar] [CrossRef]

- Hooper, P.A. Melt pool temperature and cooling rates in laser powder bed fusion. Addit. Manuf. 2018, 22, 548–559. [Google Scholar] [CrossRef]

- Xu, W.; Brandt, M.; Sun, S.; Elambasseril, J.; Liu, Q.; Latham, K.; Xia, K.; Qian, M. Additive manufacturing of strong and ductile Ti-6Al-4V by selective laser melting via in situ martensite decomposition. Acta Mater. 2015, 85, 74–84. [Google Scholar] [CrossRef]

- Xu, W.; Lui, E.W.; Pateras, A.; Qian, M.; Brandt, M. In situ tailoring microstructure in additively manufactured Ti-6Al-4V for superior mechanical performance. Acta Mater. 2017, 125, 390–400. [Google Scholar] [CrossRef]

- Zhang, L.-C.; Liu, Y.; Li, S.; Hao, Y. Additive Manufacturing of Titanium Alloys by Electron Beam Melting: A Review. Adv. Eng. Mater. 2017, 20, 1700842. [Google Scholar] [CrossRef]

- Chapala, P.; Sunil Kumar, P.; Joardar, J.; Bhandari, V.; Ghosh Acharyya, S. Effect of alloying elements on the microstructure, coefficient of friction, in-vitro corrosion and antibacterial nature of selected Ti-Nb alloys. Appl. Surf. Sci. 2019, 469, 617–623. [Google Scholar] [CrossRef]

- Rodgers, G.W.; Herve, R.; MacRae, G.A.; Chanchi Golondrino, J.; Chase, J.G. Dynamic Friction Coefficient and Performance of Asymmetric Friction Connections. Structures 2018, 14, 416–423. [Google Scholar] [CrossRef]

- Li, Y.; Kang, G.; Wang, C.; Dou, P.; Wang, J. Vertical short-crack behavior and its application in rolling contact fatigue. Int. J. Fatigue 2006, 28, 804–811. [Google Scholar] [CrossRef]

- Under, S.; Tractive, M.; Contact, R. Vertical Short Crack Initiation in Medium Carbon Bainitic Steel Under Mild Tractive Rolling Contact. J. Iron Steel Res. Int. 2008, 15, 37–41. [Google Scholar]

- Dou, P.; Suo, S.; Yang, Z.; Li, Y.; Chen, D. Ratcheting short crack behavior in medium carbon bainitic back-up roll steel under mild tractive rolling contact. Wear 2010, 268, 302–308. [Google Scholar] [CrossRef]

- Rapoport, L.; Salganik, R.L.; Gotlib, V.A. A model of brittle-dominated wear due to delayed fracture (vertical crack growth). Wear 1995, 188, 166–174. [Google Scholar] [CrossRef]

| Process | Position | C (%) | O (%) | Al (%) | Ti (%) | V (%) | Fe (%) |

|---|---|---|---|---|---|---|---|

| Forging | tribo-layer | 6.10 ± 3.85 | 5.73 ± 4.90 | 2.24 ± 0.85 | 77.39 ± 7.00 | 3.45 ± 0.28 | 4.86 ± 1.92 |

| matrix | 1.30 ± 0.40 | −2.26 ± 1.17 | 5.96 ± 0.19 | 91.14 ± 1.24 | 3.72 ± 0.27 | 0.19 ± 0.10 | |

| SLM | tribo-layer | 5.91 ± 1.49 | 10.43 ± 0.99 | 3.40 ± 0.69 | 72.37 ± 2.62 | 2.97 ± 0.40 | 4.93 ± 0.11 |

| matrix | 0.90 ± 0.31 | −1.63 ± 0.40 | 5.25 ± 0.36 | 91.90 ± 0.75 | 3.49 ± 0.13 | 0.06 ± 0.09 | |

| EBM | tribo-layer | 2.47 ± 2.14 | 12.37 ± 5.10 | 3.29 ± 0.34 | 75.08 ± 6.80 | 3.02 ± 0.37 | 3.77 ± 0.46 |

| matrix | 1.27 ± 0.35 | −1.68 ± 1.27 | 5.60 ± 0.24 | 91.51 ± 0.96 | 3.18 ± 0.43 | 0.07 ± 0.01 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Qin, P.; Wang, Z.; Yang, C.; Kollo, L.; Grzesiak, D.; Prashanth, K.G. Superior Wear Resistance in EBM-Processed TC4 Alloy Compared with SLM and Forged Samples. Materials 2019, 12, 782. https://doi.org/10.3390/ma12050782

Zhang W, Qin P, Wang Z, Yang C, Kollo L, Grzesiak D, Prashanth KG. Superior Wear Resistance in EBM-Processed TC4 Alloy Compared with SLM and Forged Samples. Materials. 2019; 12(5):782. https://doi.org/10.3390/ma12050782

Chicago/Turabian StyleZhang, Weiwen, Peiting Qin, Zhi Wang, Chao Yang, Lauri Kollo, Dariusz Grzesiak, and Konda Gokuldoss Prashanth. 2019. "Superior Wear Resistance in EBM-Processed TC4 Alloy Compared with SLM and Forged Samples" Materials 12, no. 5: 782. https://doi.org/10.3390/ma12050782

APA StyleZhang, W., Qin, P., Wang, Z., Yang, C., Kollo, L., Grzesiak, D., & Prashanth, K. G. (2019). Superior Wear Resistance in EBM-Processed TC4 Alloy Compared with SLM and Forged Samples. Materials, 12(5), 782. https://doi.org/10.3390/ma12050782