Influence of Preparation Technology on Microstructural and Magnetic Properties of Fe2MnSi and Fe2MnAl Heusler Alloys

Abstract

1. Introduction

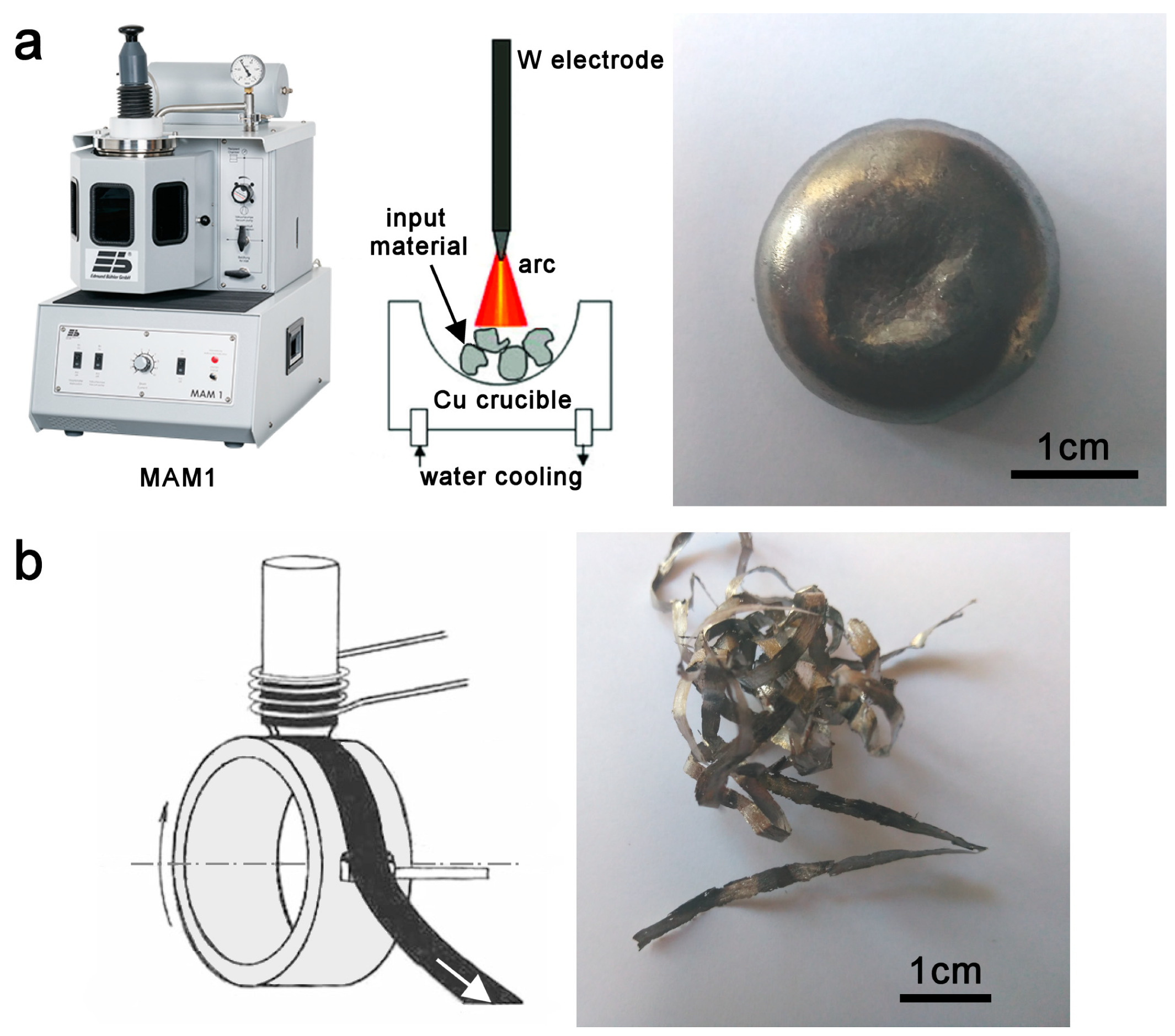

2. Materials and Methods

3. Results and Discussion

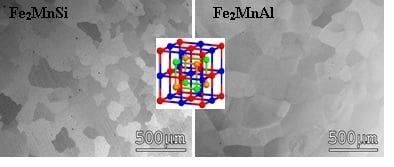

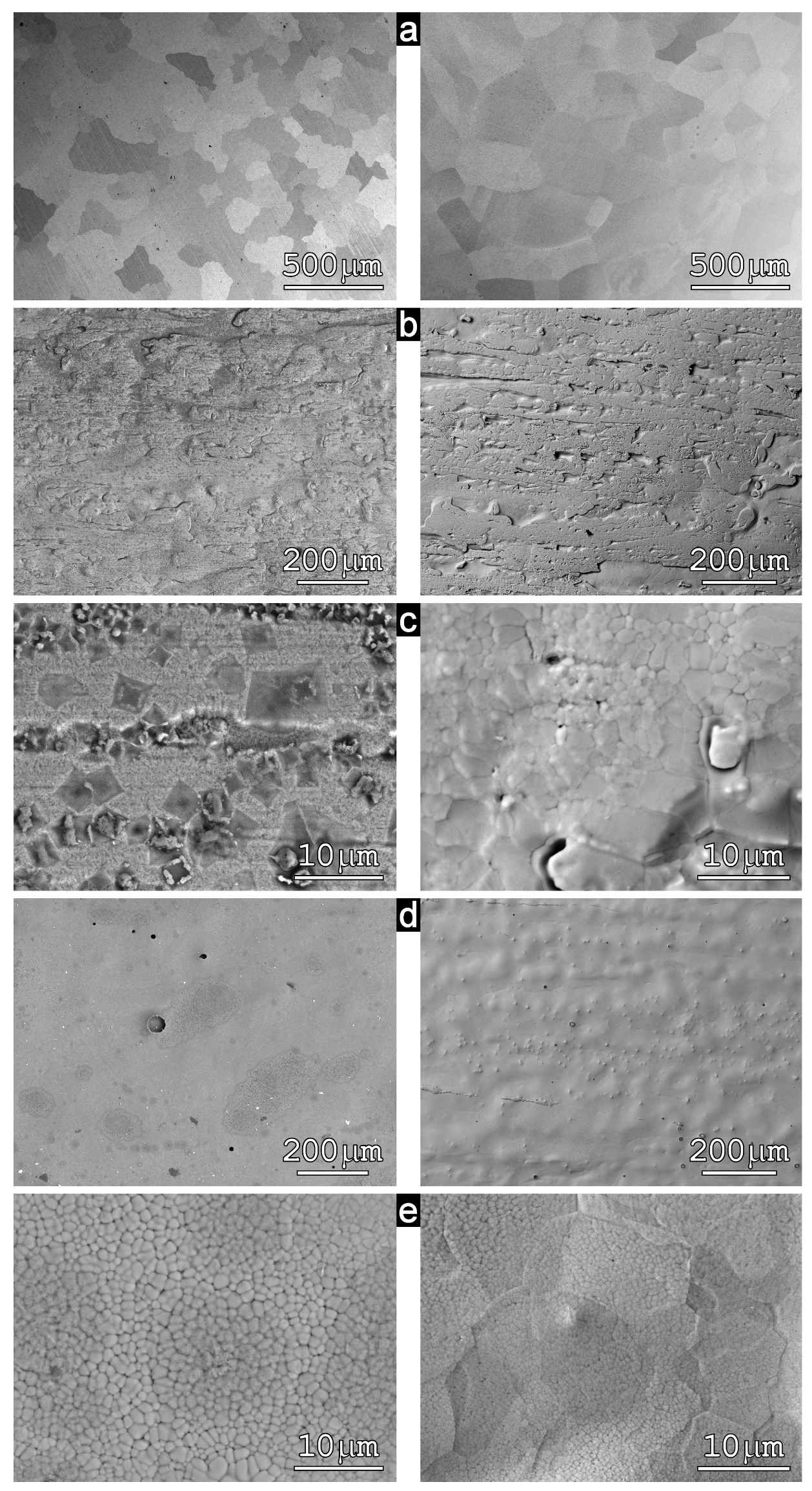

3.1. SEM—Morphology and Chemical Composition

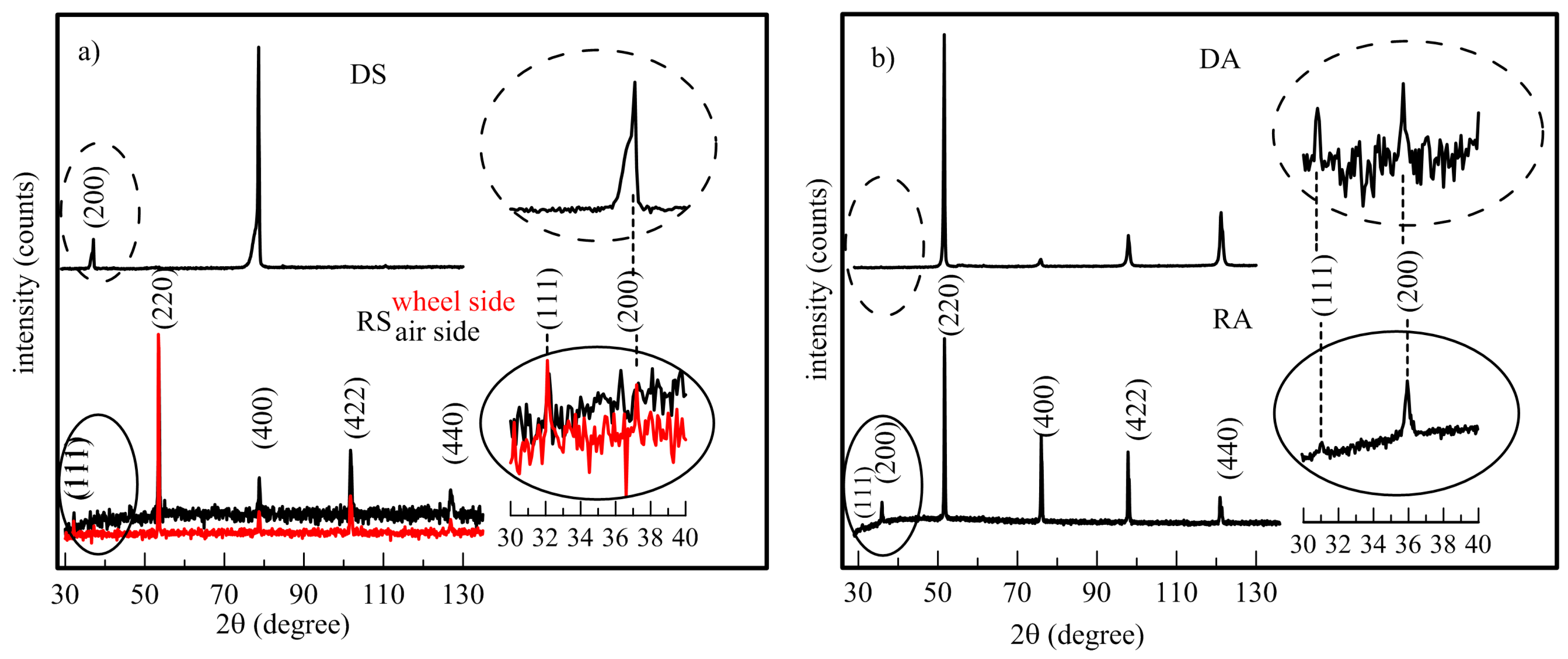

3.2. XRD—Chemical and Phase Structure

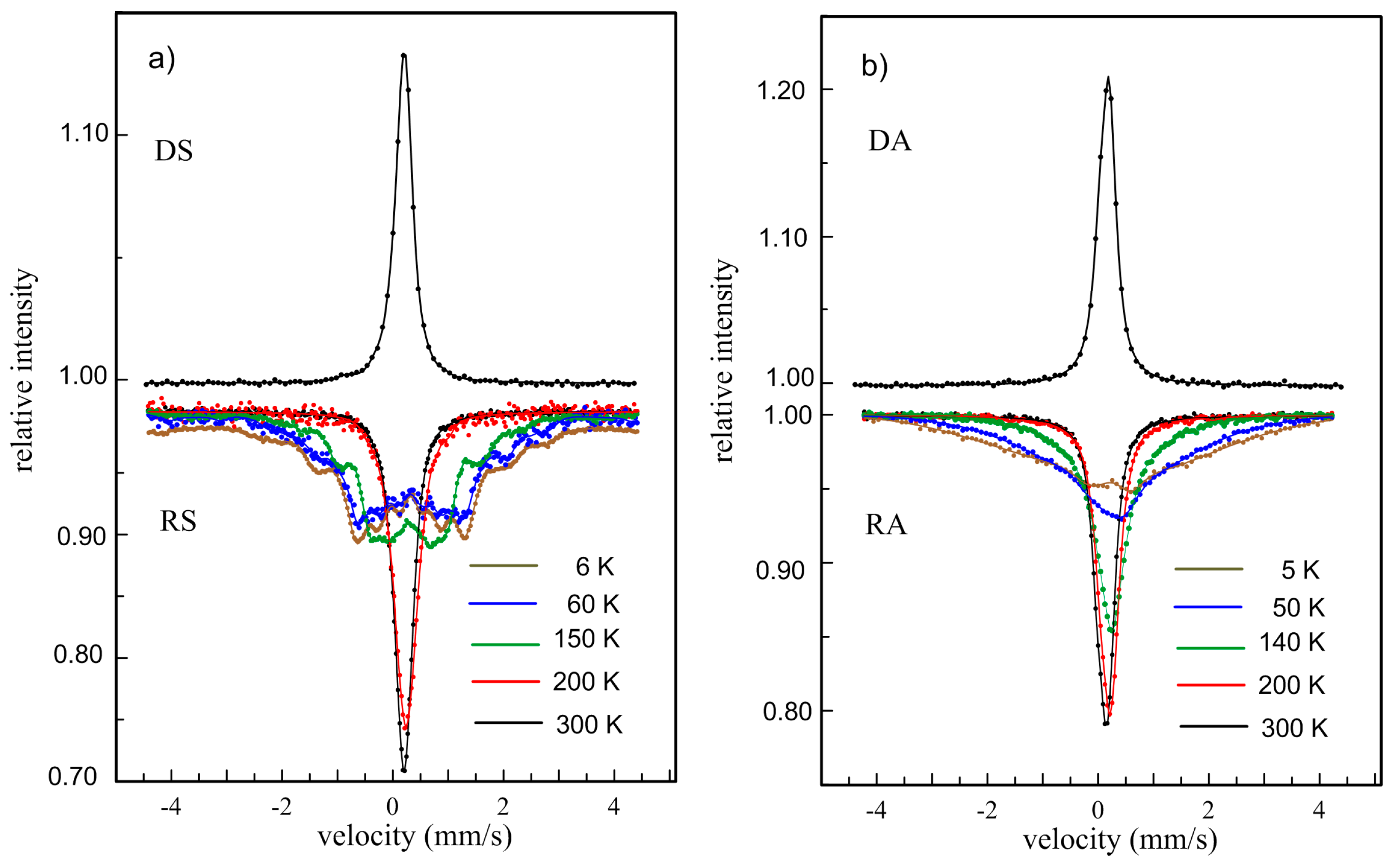

3.3. MS—Mössbauer Spectroscopy

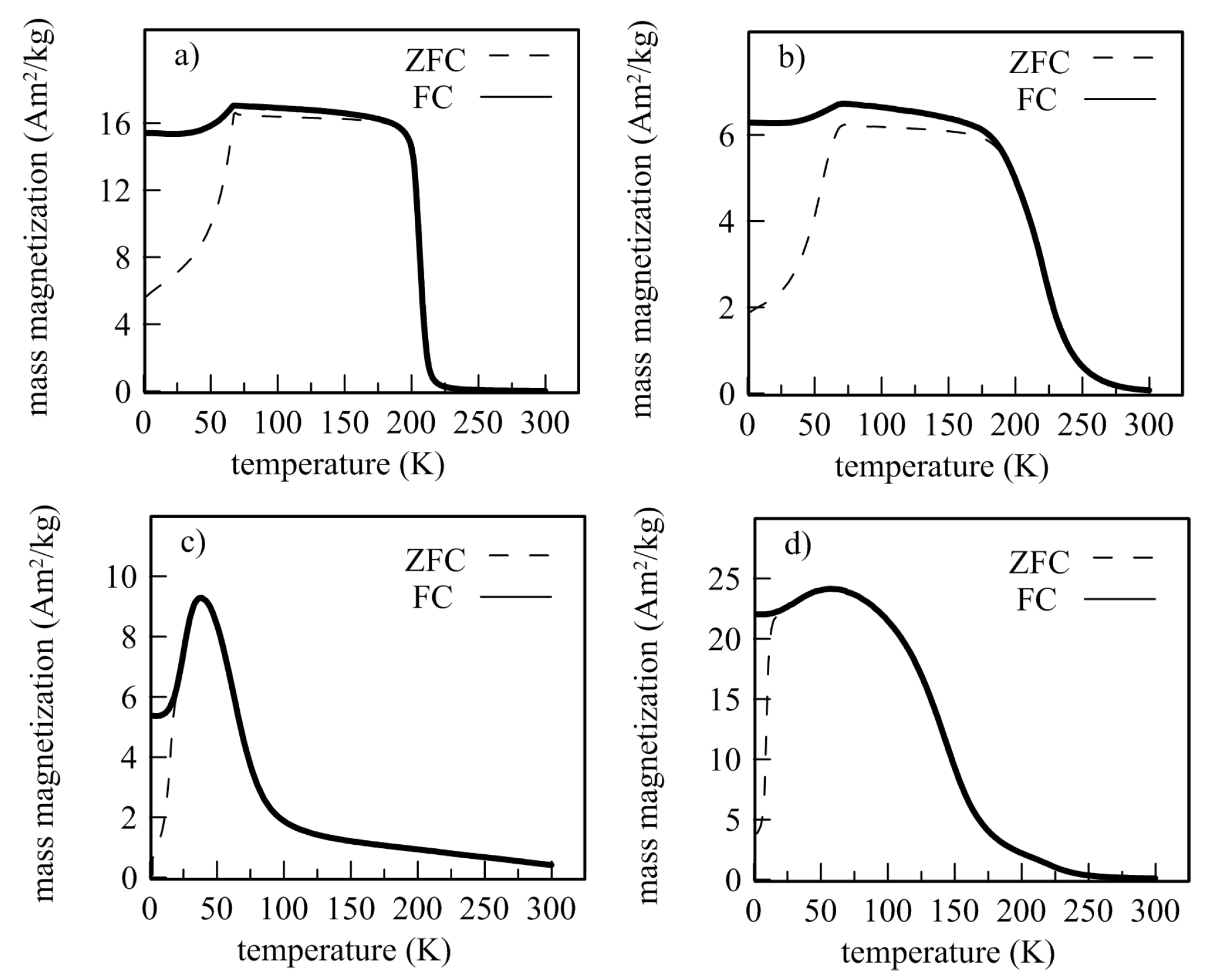

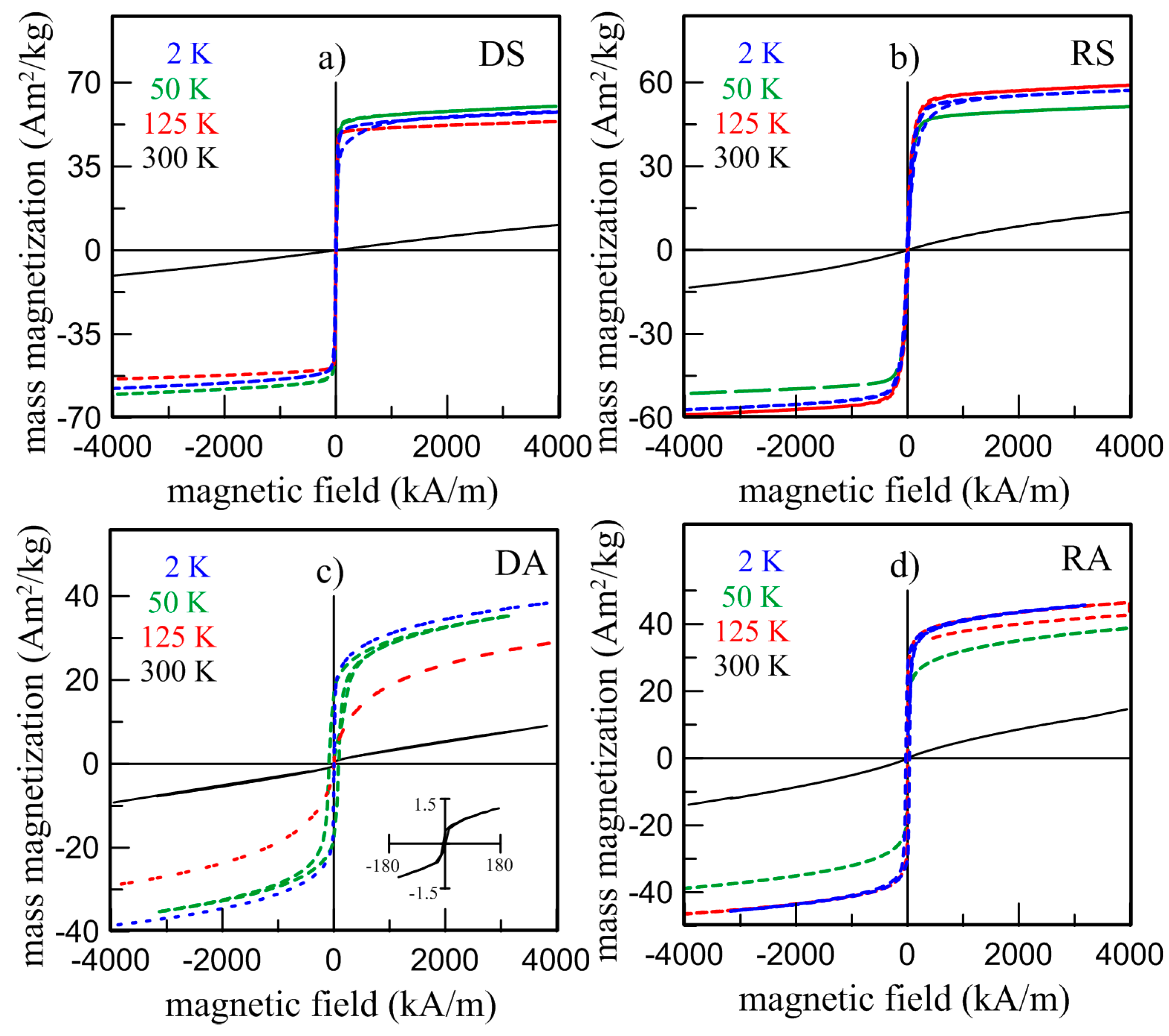

3.4. Magnetic Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Khan, R.A.A.; Ghomashi, R.; Xie, Z.; Chen, L. Ferromagnetic Shape Memory Heusler Materials: Synthesis, Microstructure Characterization and Magnetostructural Properties. Materials 2018, 11, 988. [Google Scholar] [CrossRef] [PubMed]

- Brown, P.J.; Neumann, K.U.; Webster, P.J.; Ziebeck, K.R.A. The magnetization distributions in some Heusler alloys proposed as half-metallic ferromagnets. J. Phys. Condens. Matter 2000, 12, 1827–1835. [Google Scholar] [CrossRef]

- Block, T.; Wurmehl, S.; Felser, C.; Windeln, J. Powder magnetoresistance of Co2Cr0.6Fe0.4Al/Al2O3 powder compacts. Appl. Phys. Lett. 2006, 88, 202504. [Google Scholar] [CrossRef]

- Bainsla, L.; Raja, M.M.; Nigam, A.K.; Suresh, K.G. CoRuFeX (X = Si and Ge) Heusler alloys: High TC materials for spintronic applications. J. Alloys Comp. 2015, 651, 631–635. [Google Scholar] [CrossRef]

- Mizukami, S.; Serga, A.A. Advancement in Heusler compouynds and otrher spintronics material designs and applications. J. Phys. D Appl. Phys. 2015, 48, 160301. [Google Scholar] [CrossRef]

- Hamad, B.A. The effect of defects on the electronic structure and magnetic map of the Fe2CrSi Heusler alloy: Ab-initio calculations. Eur. Phys. J. B 2011, 80, 11–18. [Google Scholar] [CrossRef]

- Fujii, S.; Ishida, S.; Asano, S. Electroinic and Magnetic-Properties of X2Mn1−xVxSi(X = Fe and Co). J. Phys. Soc. Jpn. 1994, 63, 1881–1888. [Google Scholar] [CrossRef]

- Veis, M.; Beran, L.; Antos, R.; Legut, D.; Hamrle, J.; Pistora, J.; Sterverf, C.; Meinert, M.; Schmalhorst, J.M.; Kuschel, T.; et al. Magneto-optical spectroscopy of Co2FeSi Heusler compound. J. Appl. Phys. 2014, 115, 17A927. [Google Scholar] [CrossRef]

- Wolf, G.; Hamrle, J.; Trudel, S.; Kubota, T.; Ando, Y.; Hillebrands, B. Quadratic magneto-optical Kerr effect in Co2MnSi. J. Appl. Phys. 2011, 110, 043904. [Google Scholar] [CrossRef]

- Belkhouane, M.; Amari, S.; Yakobi, A.; Tadjer, A.; Méçabih, S.; Murtaza, G.; Bin Omran, S.; Khenata, R. First-principles study of the electronic and magnetic properties of Fe2MnAl, Fe2MnSi and Fe2MnSi0.5Al0.5. J. Magn. Magn. Mater. 2015, 377, 211–214. [Google Scholar] [CrossRef]

- Fecher, G.H.; Kandpal, H.C.; Wurmehl, S.; Morais, J.; Lin, H.-J.; Elme, H.-J.; Schönhense, G.; Felser, C. Design of magnetic materials: The electronic structure of the ordered, doped Heusler compound Co2Cr1−xFexAl. J. Phys. Condens. Matter 2005, 17, 7237–7252. [Google Scholar] [CrossRef]

- Tanaka, M.A.; Maezaki, D.; Ishii, T.; Okubo, A.; Hiramatsu, R.; Ono, T.; Mibu, K. Interface magnetism of Co2FeGe Heusler alloy layers and magnetoresistance of Co2FeGe/MgO/Fe magnetic tunnel junctions. J. Appl. Phys. 2014, 116, 163902. [Google Scholar] [CrossRef]

- Bremers, H.; Hesse, J.; Ahlers, H.; Sievert, J.; Zachmann, D. Order and magnetic properties of Fe89−xMn11Alx Alloys. J. Alloys Comp. 2004, 366, 67–75. [Google Scholar] [CrossRef]

- Životský, O.; Buršík, J.; Janičkovič, D.; Titov, A.; Jirásková, Y. Low-temperature magnetic transitions in Fe2MnSi Heusler alloys prepared in bulk and ribbon form. J. Magn. Magn. Mater. 2019, 475, 5–9. [Google Scholar] [CrossRef]

- Webster, P.J.; Ziebeck, K.R.A. The paramagnetic properties of heusler alloys containing iron. Phys. Lett. 1983, 98, 51–53. [Google Scholar] [CrossRef]

- Hakimi, M.; Kameli, P.; Salamati, H.; Mazaheri, Y. Evolution of microstructural and mechanical properties of nanocrystalline Co2FeAl Heusler alloy prepared by mechanical alloying. Powder Metall. 2013, 56, 111–116. [Google Scholar] [CrossRef]

- Young, R.A. (Ed.) The Rietveld Method. International Union of Crystallography; Book Series; Oxford University Press: New York, NY, USA, 1993; ISBN 0-19-855912-7. [Google Scholar]

- ICSD Database; Version 1.9.4.; NIST/FIZ; FIZ Karlsruhe: Karlsruhe, Germany, 2014; Volume 1.

- Žák, T.; Jirásková, Y. CONFIT: Mössbauer spectra fitting program. Surf. Interface Anal. 2006, 38, 710–714. [Google Scholar] [CrossRef]

- Webster, P.J. Heusler Alloys. Contemp. Phys. 1969, 10, 559–577. [Google Scholar] [CrossRef]

- Azar, S.M.; Hamad, B.A.; Khalifeh, J.M. Structural, electronic and magnetic properties of Fe(3−x)Mn(x)Z (Z=Al, Ge, Sb) Heusler alloys. J. Magn. Magn. Mater. 2012, 324, 1776–1785. [Google Scholar] [CrossRef]

- Mori, H.; Odahara, Y.; Shigyo, D.; Yoshitake, T.; Miyoshi, E. Electronic band structure calculations on thin films of the L2(1) full Heusler alloys X2YSi (X, Y = Mn, Fe, and Co): Toward spintronic materials. Thin Solid Films 2012, 520, 4979–4983. [Google Scholar] [CrossRef]

- Pugaczowa-Michalska, M.; Go, A.; Dobrzynski, L. Electronic structure and magnetism of Fe3−xMnxAl alloys. Phys. Stat. Sol. B 2005, 242, 463–467. [Google Scholar] [CrossRef]

- Plogmann, S.; Schlatholter, T.; Braun, J.; Neumann, M.; Yarmoshenko, Y.M.; Yablonskikh, M.V.; Shreder, E.I.; Kurmaev, E.Z.; Wrona, A.; Slebarski, A. Local moments in Mn-based Heusler alloys and their electronic structures. Phys. Rev. B 1999, 60, 6428–6438. [Google Scholar] [CrossRef]

- Buschow, K.H.J.; Hvan Engen, P.G. Magnetic and Magneto-Optical Properties of Heusler Alloys Based on Aluminum and Galium. J. Magn. Magn. Mater. 1981, 25, 90–96. [Google Scholar] [CrossRef]

- Kourov, N.I.; Marchenkov, V.V.; Korolev, A.V.; Stashkova, L.A.; Emel’yanov, S.M.; Weber, H.W. Specific Features of the Properties of Half-Metallic Ferromagnetic Heusler Alloys Fe2MnAl, Fe2MnSi, and Co2MnAl. Phys. Sol. State 2015, 57, 700–708. [Google Scholar] [CrossRef]

- Ziebeck, K.R.A.; Webster, P.J. The antiferromagnetic and ferromagnetic properties of Fe2MnSi. Philos. Mag. 1976, 34, 973–982. [Google Scholar] [CrossRef]

- Goto, T.; Kashiwakura, A.; Ido, H. Effect of atomic environment on the 57Fe hyperfine field in Fe2MnSi. J. Appl. Phys. 1991, 69, 4636–4638. [Google Scholar] [CrossRef]

- Liu, Z.; Ma, X.; Meng, F.; Wu, G. Magnetic and anomalous transport properties in Fe2MnAl. J. Alloys Comp. 2011, 509, 3219–3222. [Google Scholar] [CrossRef]

- Paduani, C.; Mighavacca, A.; Pöttker, W.E.; Schaf, J.; Krause, J.C.; Ardisson, J.D.; Perez, C.A.S.; Takeuchi, A.Y.; Yoshida, M.I. A study of Fe2+xMn1−xAl alloys: Structural and magnetic properties. Phys. B Condens. Matter 2007, 398, 60–64. [Google Scholar] [CrossRef]

- Vinesh, A.; Bhargava, H.; Lakshmi, N.; Venugopalan, K. Magnetic anisotropy induced by high energy ball milling of Fe2MnAl. J. Appl. Phys. 2009, 105, 07A309. [Google Scholar] [CrossRef]

- Petrovský, E.; Kapička, A. On determination of the Curie point from thermomagnetic curves. J. Geophys. Res. 2006, 111, B12S27. [Google Scholar] [CrossRef]

- Pedro, S.S.; Vivas, R.J.C.; Andrade, V.M.; Cruz, C.; Paixao, L.S.; Contreras, C.; Costa-Soares, T.; Caldeira, L.; Coelho, A.A.; Carvalho, A.M.G.; et al. Effects of Ga substitution on the structural and magnetic properties of half metallic Fe2MnSi Heusler compound. J. Appl. Phys. 2015, 117, 013902. [Google Scholar] [CrossRef]

- Niculescu, V.; Raj, K.; Burch, T.J.; Budnick, J.I. Correlation of the internal fields, magnetic moments, and site preferences in Fe3−xMnxSi alloys. Phys. Rev. B 1976, 13, 3167–3174. [Google Scholar] [CrossRef]

- Sakon, T.; Koyama, K.; Kamia, O.; Awaji, S.; Nakamura, S.; Nojiri, T.; Watanabe, K.; Hiroi, M.J. High-Field Magnetization Measurements of Fe2MnSi. Phy. Soc. Jpn. 2013, 82, 044802. [Google Scholar] [CrossRef]

- Kandpal, H.C.; Fecher, G.H.; Felser, C. Calculated electronic and magnetic properties of the half-metallic, transition metal based Heusler compounds. J. Phys. D Appl. Phys. 2007, 40, 1507–1523. [Google Scholar] [CrossRef]

| Sample | Fe (at.%) | Mn (at.%) | Si/Al (at.%) | |

|---|---|---|---|---|

| DS | 48.30 ± 0.14 | 24.69 ± 0.09 | 27.01 ± 0.05 | |

| DA | 49.95 ± 0.31 | 22.98 ± 0.12 | 27.07 ± 0.25 | |

| RS | air side | 47.10 ± 0.19 | 27.62 ± 0.52 | 25.28 ± 0.36 |

| wheel side | 43.36 ± 0.67 | 30.54 ± 0.19 | 26.10 ± 0.84 | |

| RA | air side | 49.27 ± 0.16 | 24.51 ± 0.30 | 26.22 ± 0.45 |

| wheel side | 48.36 ± 0.54 | 24.24 ± 0.17 | 27.40 ± 0.70 | |

| Compound | Fe2MnSi | Fe2MnAl | |||

|---|---|---|---|---|---|

| DS | RS | DA | RA | ||

| Air Side | Wheel Side | ||||

| present exp. | 0.5685 (40) | 0.5669 (1) | 0.5667 (1) | 0.5847 (3) | 0.5668 (1) |

| [21] theor. | - | 0.5683 | |||

| [10] theor. | 0.5599 | 0.5680 | |||

| [24,25] exp. | 0.5671 [24] | 0.5816 [25] | |||

| [26] exp. | 0. 5671 | 0.5836 | |||

| [22] theor. | 0.5601 | - | |||

| [23] theor. | - | 0.5590 | |||

| T (K) | B1m (T) | A1 (%) | B2m (T) | A2 (%) | B3m (T) | A3 (%) | Ap |

|---|---|---|---|---|---|---|---|

| 150 | 8.015 | 34.8 | 12.991 | 5.0 | 22.411 | 10.0 | 50.2 |

| 60 | 6.977 | 71.3 | 11.268 | 14.0 | 24.465 | 14.7 | 0 |

| 6 | 6.561 | 65.3 | 11.865 | 20.0 | 24.302 | 14.7 | 0 |

| Sample | T (K) | M5 (Am2/kg) | Mr (Am2/kg) | Hc (kA/m) | C (m3·K/kg) | TC (K) | TR (K) |

|---|---|---|---|---|---|---|---|

| DS | 300 | 10.55 | 0.02 | 2.22 | 2.37 × 10−4 | 216 | 68.58 |

| 125 | 53.77 | 2.45 | 1.64 | ||||

| 50 | 60.15 | 3.54 | 1.70 | ||||

| 2 | 57.83 | 11.22 | 8.61 | ||||

| RS | 300 | 13.55 | 0.01 | 1.13 | 1.64 × 10−4 | 272 | 69.02 |

| 125 | 51.33 | 3.51 | 4.10 | ||||

| 50 | 59.03 | 4.15 | 6.30 | ||||

| 2 | 57.05 | 10.11 | 16.02 | ||||

| DA | 300 | 10.36 | 0.29 | 3.52 | 2.82 × 10−4 | 137 | 42.02 |

| 125 | 29.02 | 0.64 | 3.32 | ||||

| 50 | 38.57 | 1.54 | 1.04 | ||||

| 2 | 39.53 | 19.12 | 73.13 | ||||

| RA | 300 | 14.39 | 0.02 | 1.63 | 1.60 × 10−4 | 263 | 65.25 |

| 125 | 39.76 | 4.39 | 2.41 | ||||

| 50 | 47.95 | 8.06 | 3.74 | ||||

| 2 | 48.66 | 32.15 | 32.12 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jirásková, Y.; Buršík, J.; Janičkovič, D.; Životský, O. Influence of Preparation Technology on Microstructural and Magnetic Properties of Fe2MnSi and Fe2MnAl Heusler Alloys. Materials 2019, 12, 710. https://doi.org/10.3390/ma12050710

Jirásková Y, Buršík J, Janičkovič D, Životský O. Influence of Preparation Technology on Microstructural and Magnetic Properties of Fe2MnSi and Fe2MnAl Heusler Alloys. Materials. 2019; 12(5):710. https://doi.org/10.3390/ma12050710

Chicago/Turabian StyleJirásková, Yvonna, Jiří Buršík, Dušan Janičkovič, and Ondřej Životský. 2019. "Influence of Preparation Technology on Microstructural and Magnetic Properties of Fe2MnSi and Fe2MnAl Heusler Alloys" Materials 12, no. 5: 710. https://doi.org/10.3390/ma12050710

APA StyleJirásková, Y., Buršík, J., Janičkovič, D., & Životský, O. (2019). Influence of Preparation Technology on Microstructural and Magnetic Properties of Fe2MnSi and Fe2MnAl Heusler Alloys. Materials, 12(5), 710. https://doi.org/10.3390/ma12050710