Effect of Vietnamese Fly Ash on Selected Physical Properties, Durability and Probability of Corrosion of Steel in Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mixture Proportions and Specimens

2.3. Compressive Strength Test

2.4. Acid Resistance Test

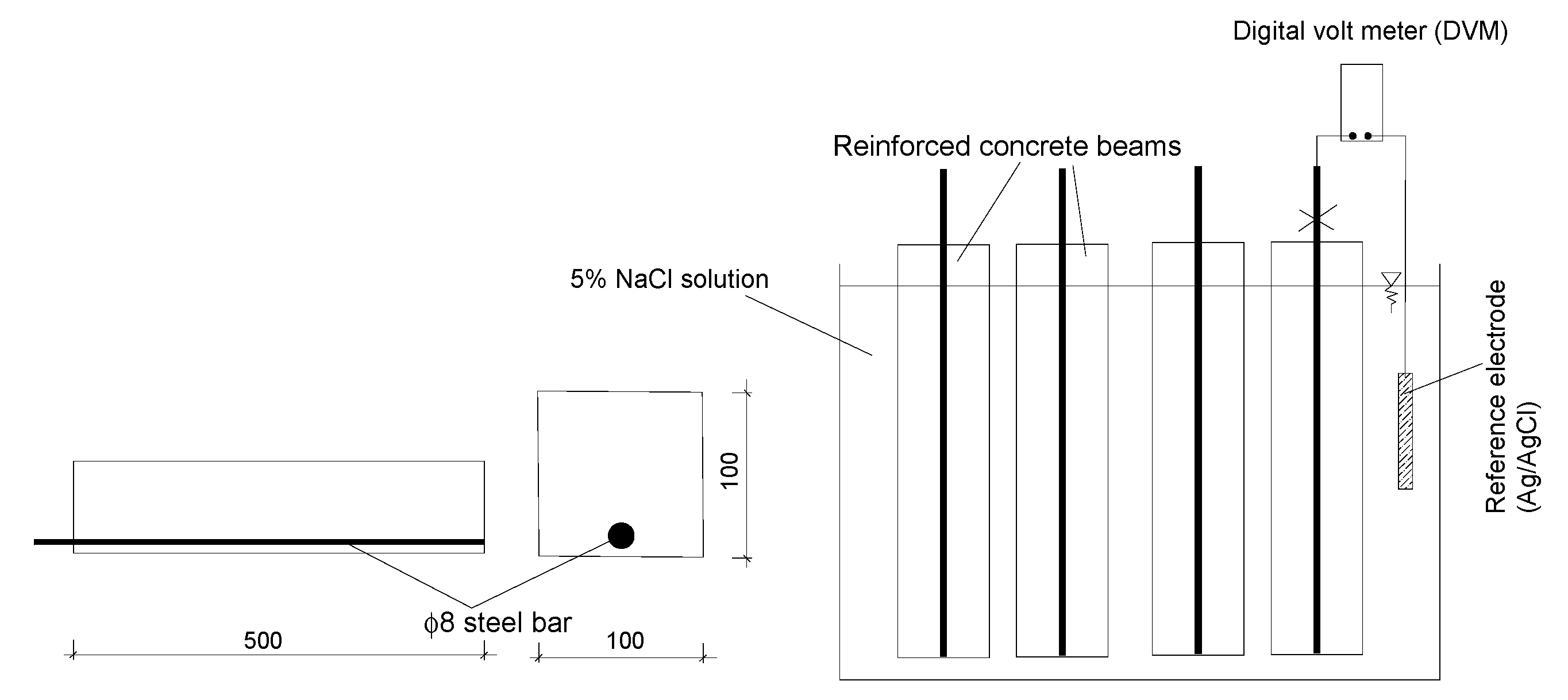

2.5. Probability of Corrosion of Steel in Fly Ash Concrete and Load Capacities of Fly Ash Reinforced Concrete Beams

3. Results and Discussion

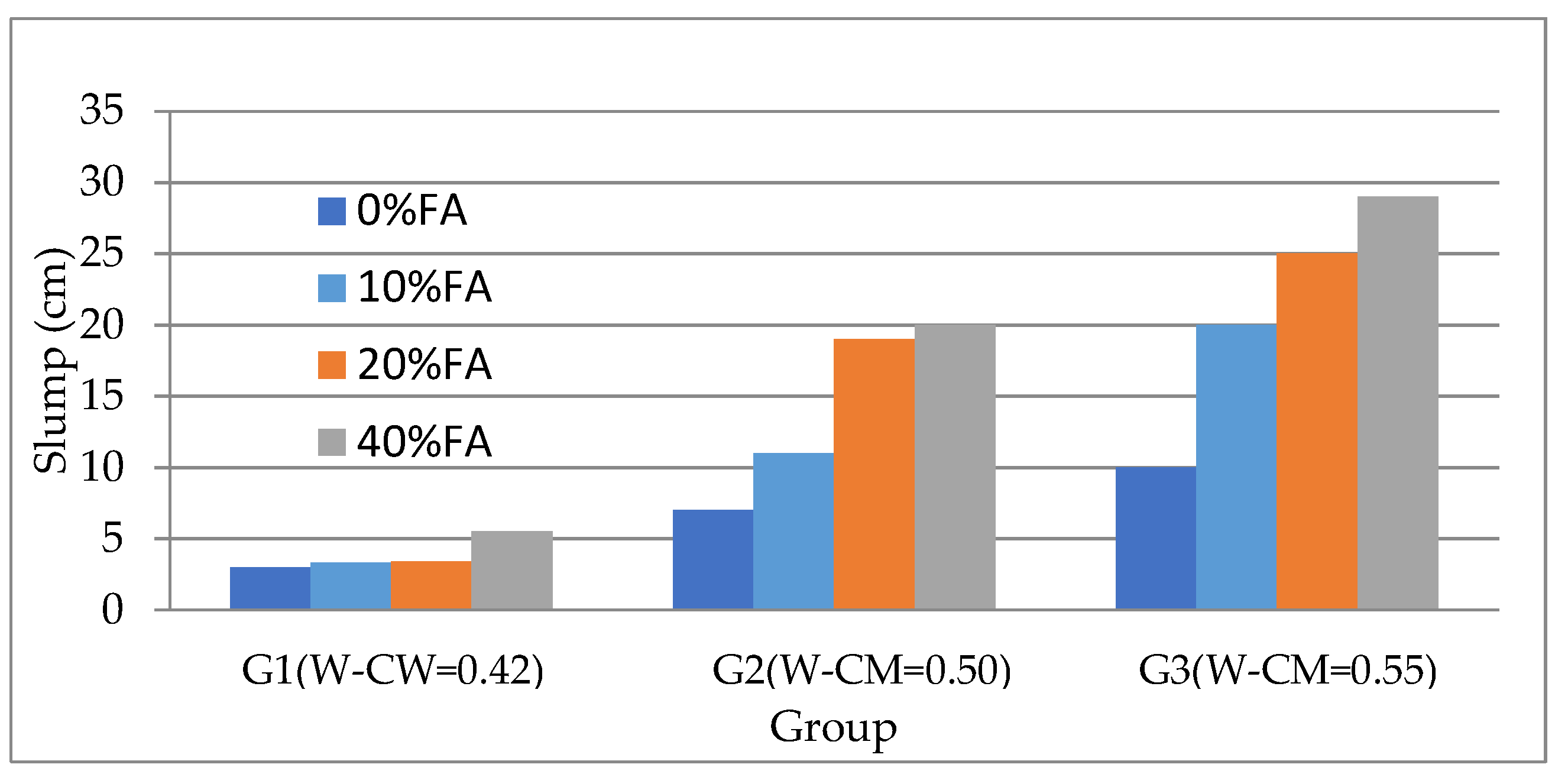

3.1. Workability of Fresh Concrete

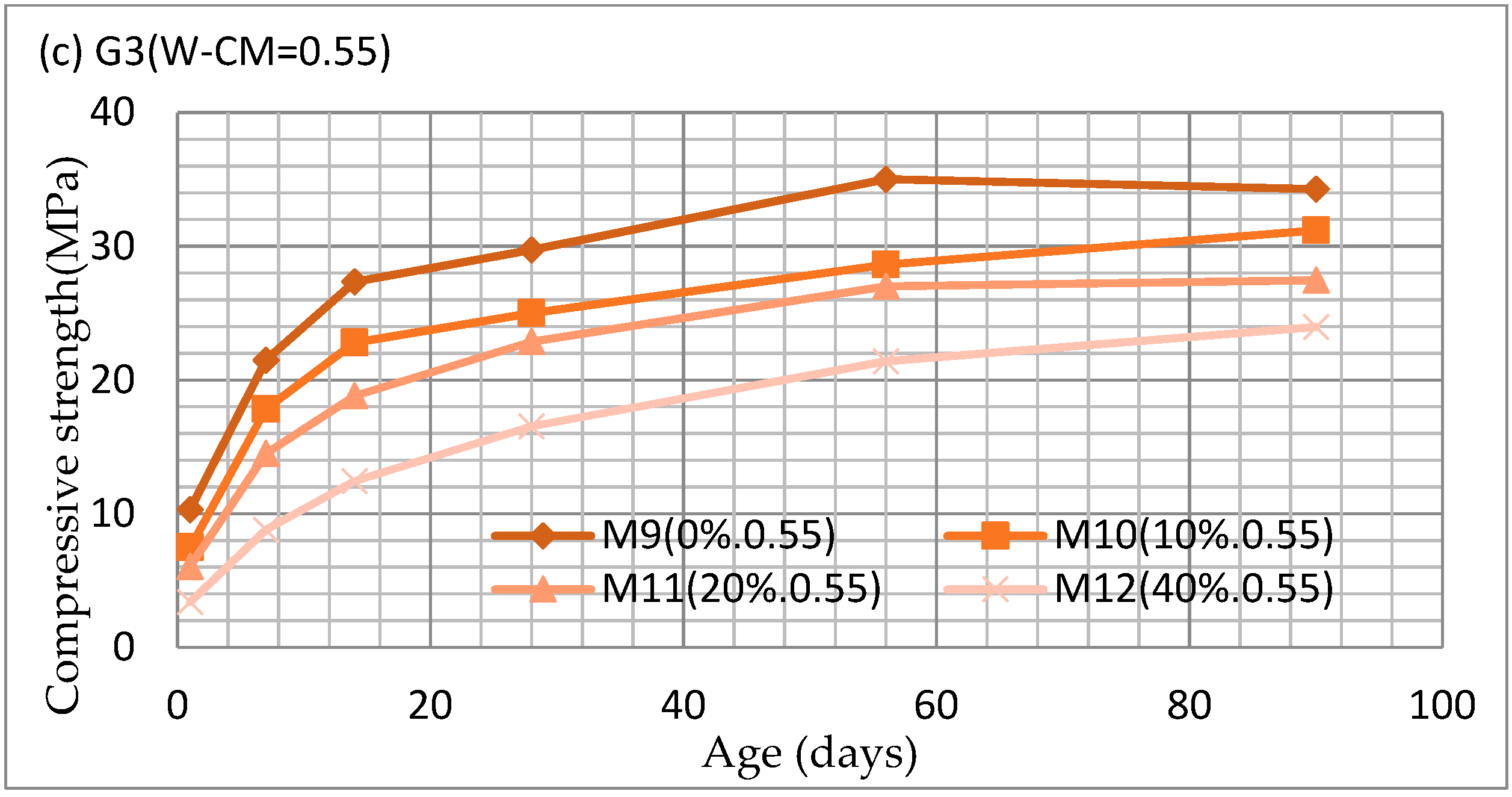

3.2. Compressive Strength Development

3.3. Acid Resistance of Fly Ash Concrete

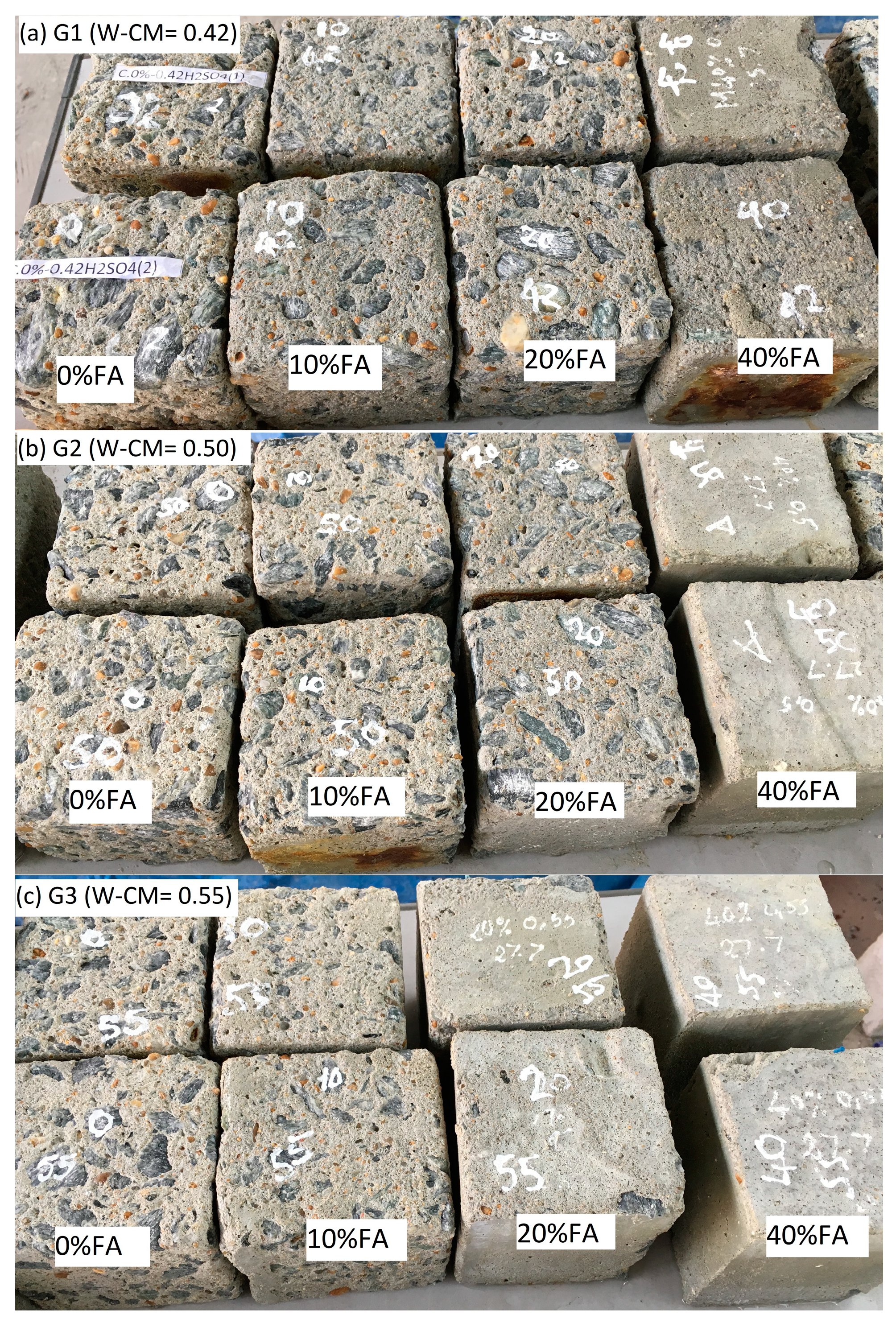

3.3.1. Visual Inspection

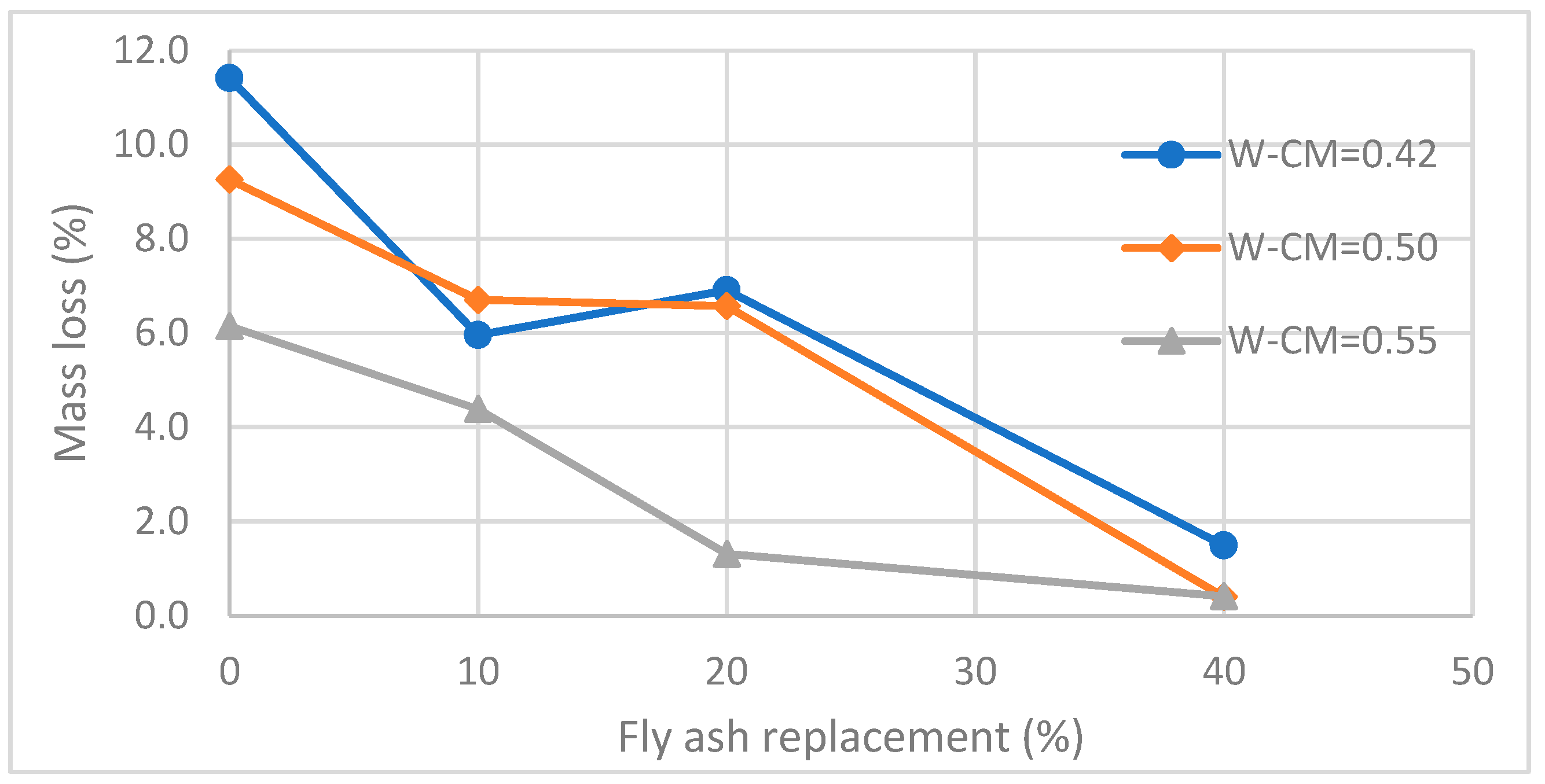

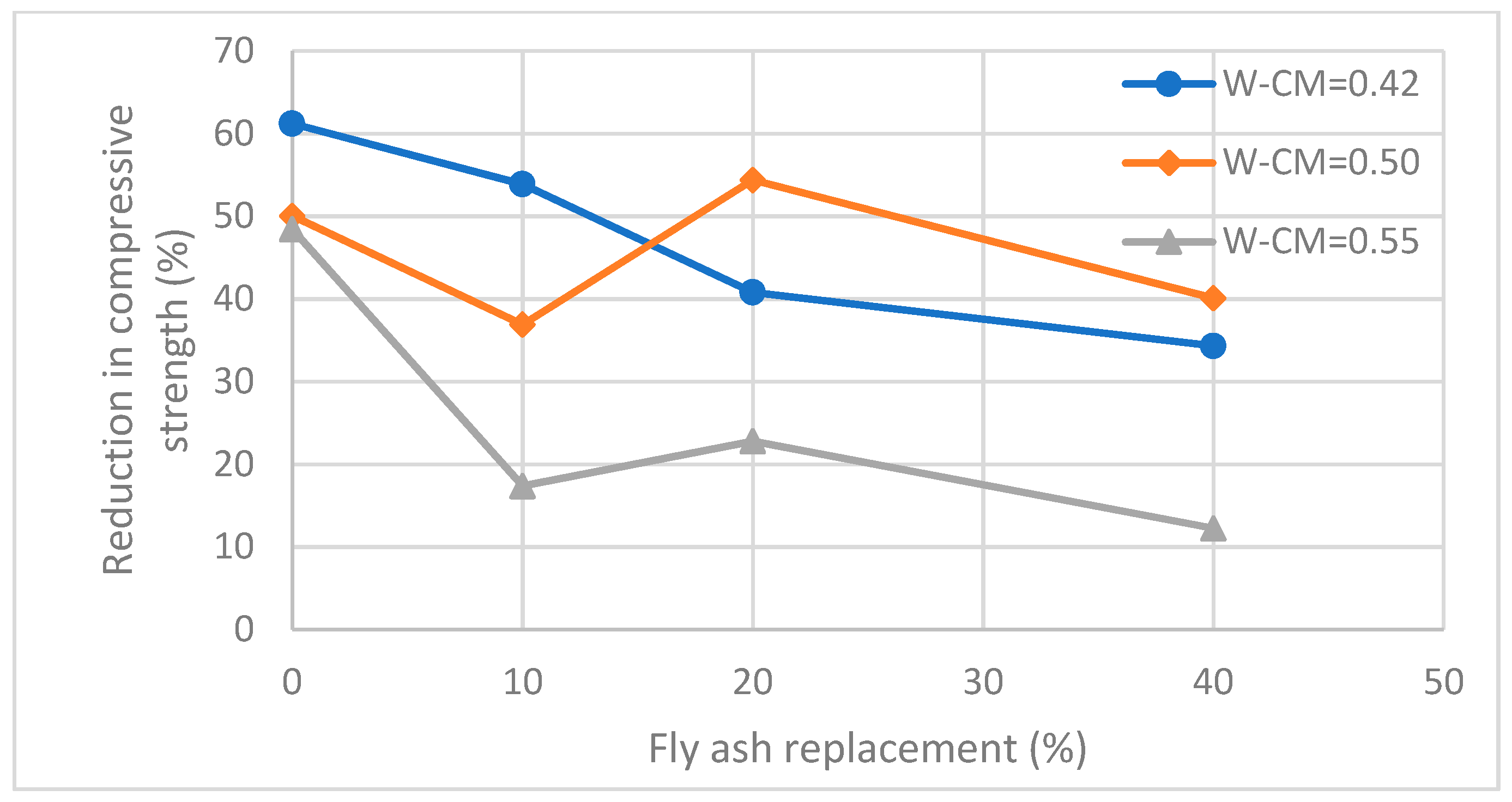

3.3.2. Mass Loss and Compressive Strength Loss

3.4. Probability of Corrosion of Steel in Fly Ash Concrete and Load Capacities of Fly Ash Reinforced Concrete Beams

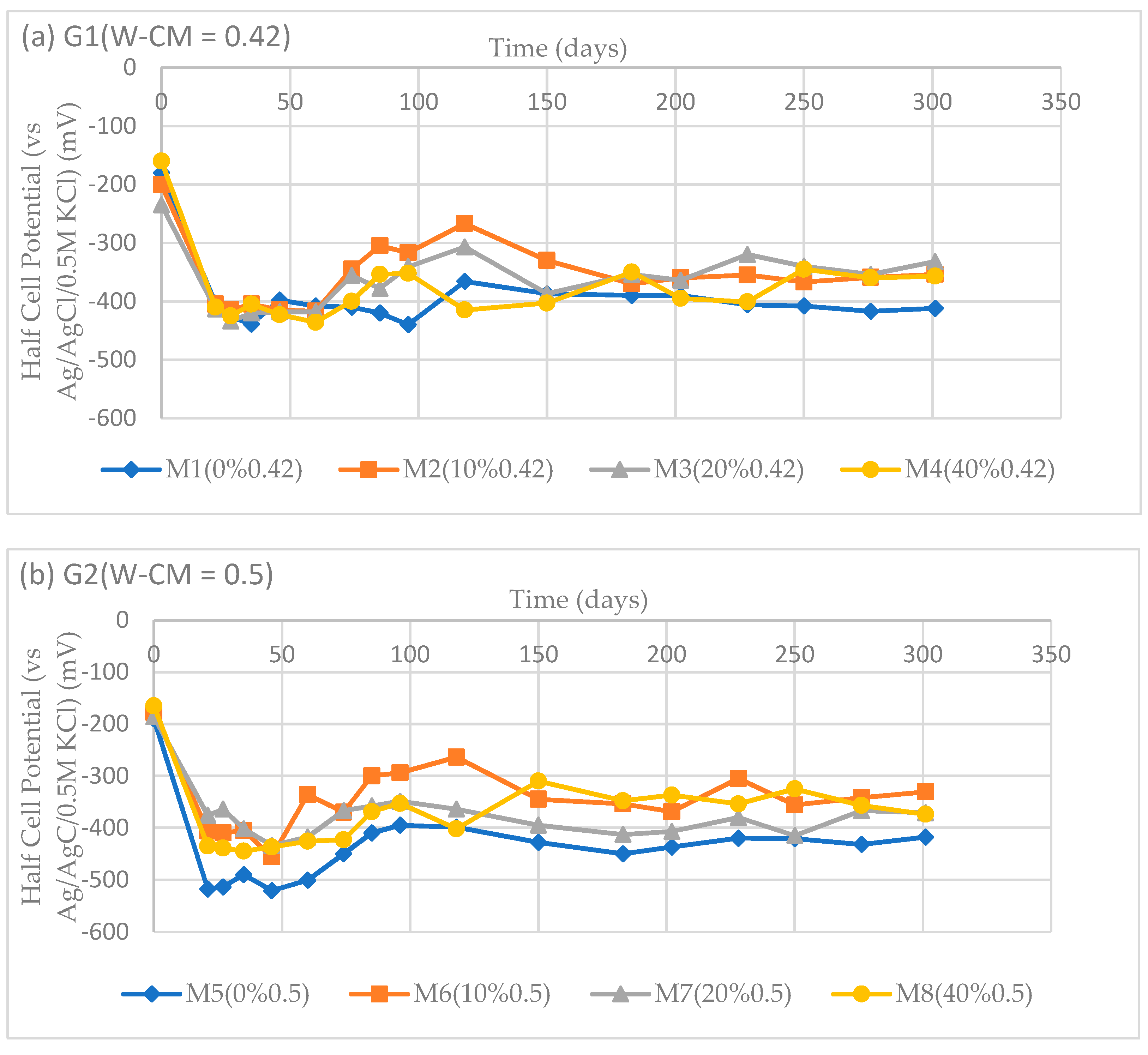

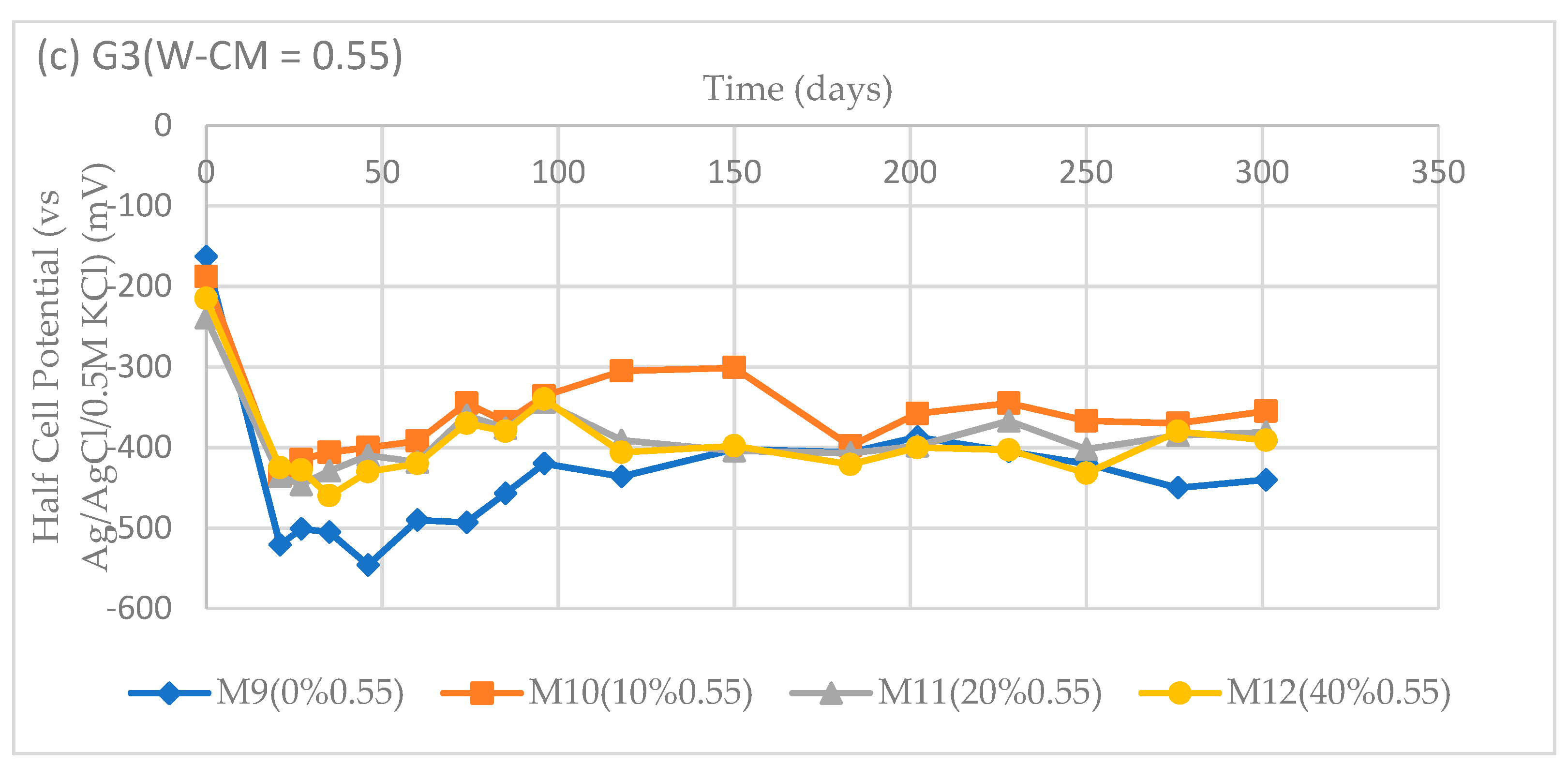

3.4.1. Half-Cell Potential

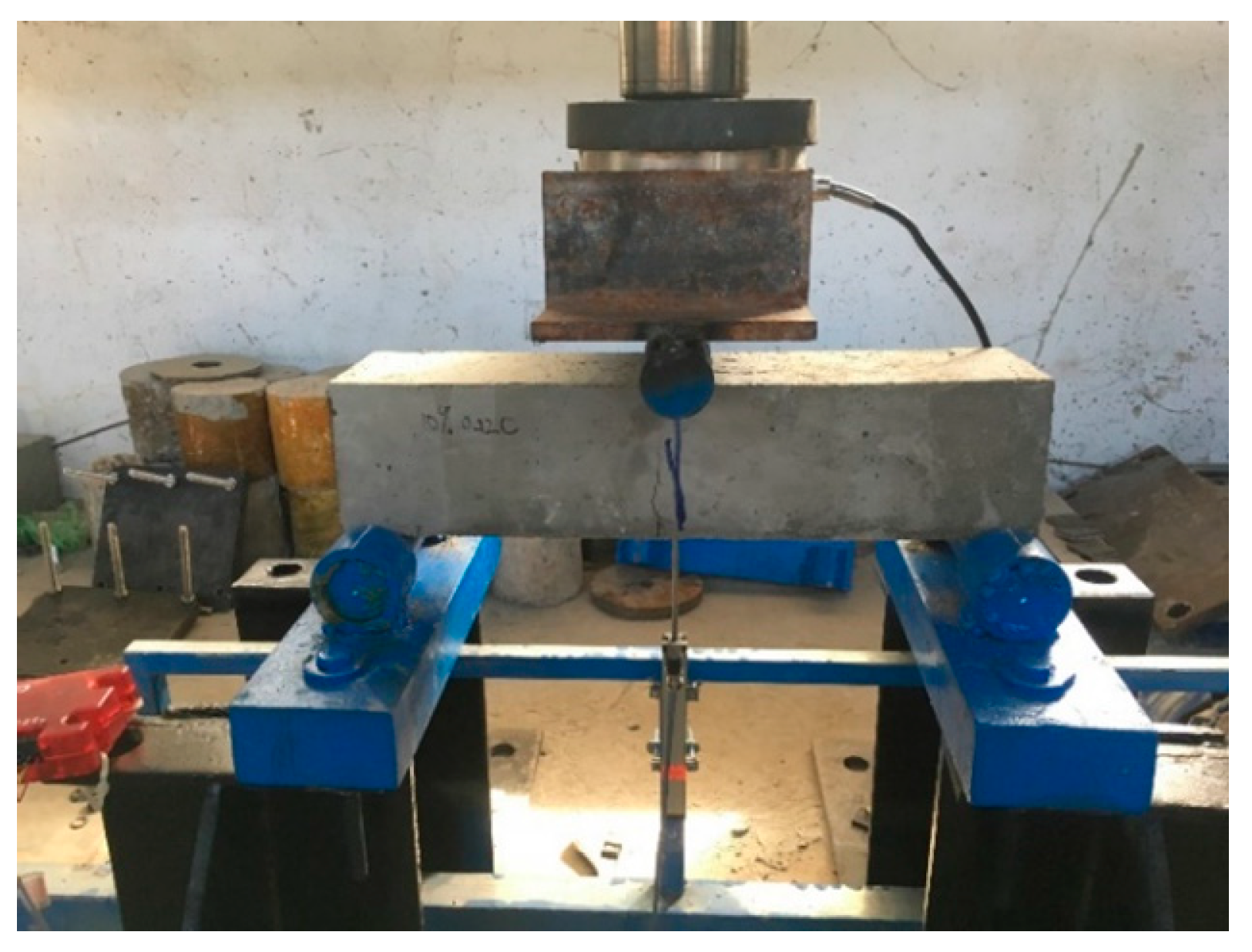

3.4.2. Flexural Resistance of Fly Ash Reinforced Concrete Beams

4. Conclusions

- The Vietnamese sourced fly ash investigated in this study contributes to improvements in the workability of fresh concrete. This is consistent with differences between the spherical shape of fly ash particles and angular shape of the cement particles, as confirmed by previous research.

- Within the range of investigation (10% to 40% replacement), fly ash reduced the compressive strength of the concrete at early age, either before 28 days or 56 days depending on the W–CM ratios. After this time, the compressive strength of the fly ash specimens continues to develop, albeit slowly, and gains higher strengths than that of the control specimens, while the compressive strengths of the control specimens (0% fly ash) is no longer developed.

- Within the range of investigation, (10% to 40% replacement), the optimum fly ash replacement proportion was found to be 20% by weight of Portland cement.

- Fly ash increases the sulfuric acid resistance of the concrete. This results in a reduction in surface degradation, mass loss and compressive strength loss resulting from exposure to sulfuric acid solution. The greater the level of fly ash replacement, the less surface degradation, mass loss and compressive strength loss was observed. Within the scope of this investigation, water to cementitious ratio of 0.55 shows the highest acid resistance compared with values of 0.42 and 0.5.

- Within the scope of this investigation, fly ash has had little effect on reducing the probability of corrosion of steel bars embedded in concrete specimens, but a 10% fly ash replacement showed greatest benefit.

- In general, 10% and 20% fly ash reinforced concrete beams show better flexural resistance than that of the control beams without fly ash after 300 days exposure in a 5% NaCl solution.

- Further research should be conducted at different levels of replacements (e.g., 5%, 15%, 25%, 30%, 35%) to identify optimum replacement levels for the enhancement of the various performance criteria investigated.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Anonymous. An investigation of the pozzolanic nature of coal ashes. Eng. News 1914, 71, 1334–1335. [Google Scholar]

- Balakrishnan, B.; Abdul Awal, A.S.M. Durability properties of concrete containing high volume Malaysian fly ash. Int. J. Res. Eng. Technol. 2014, 4, 529–533. [Google Scholar]

- ASTM C618-17a Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM: West Conshohocken, PA, USA, 2017.

- Ahmaruzzaman, M. A review on use of fly ash. Prog. Energy Combust. Sci. 2010, 36, 327–363. [Google Scholar] [CrossRef]

- CAN/CSA A3001-03 Cementitious Materials for Use in Concrete; Canadian Standards Association: Mississauga, ON, Canada, 2003.

- Thomas, M.; Shehata, M.; Shashiprakash, S. The use of fly ash in concrete: classification by composition. Cem. Concr. Aggreg. 1999, 12, 105–110. [Google Scholar]

- Fly Ash for Cement Concrete—Resource for High Strength and Durability of Structures at Lower Cost; NTPC limited: New Delhi, India, 2013.

- Use of Fly Ash to Achieve Enhanced Sustainability in Construction. Available online: http://www.adaa.asn.au/uploads/default/files/adaa_technical_note_11.pdf (accessed on 10 January 2019).

- Mohamad, R. Study on Ultilization of Fly Ash as a Replacement of Cement and Fine Aggregates in Concrete. Bachelor Thesis, Charles Dawin University, Casuarina, NT, Australia, July 2015. [Google Scholar]

- Thomas, M.D.A. Optimizing the Use of Fly Ash in Concrete. Available online: https://www.cement.org/docs/default-source/fc_concrete_technology/is548-optimizing-the-use-of-fly-ash-concrete.pdf (accessed on 10 January 2019).

- Yazici, S.; Arel, H.S. Effects of fly ash fineness on the mechanical properties of concrete. Sadhana 2012, 37, 389–403. [Google Scholar] [CrossRef]

- Feng, X.; Clark, B. Evaluation of the physical and chemical properties of fly ash products for use in Portland cement concrete. In Proceedings of the World of Coal Ash Conference, Denver, CO, USA, 9–12 May 2011. [Google Scholar]

- Malhotra, V.M.; Mehta, P.K. High-performance, High-volume Fly Ash Concrete: Materials, Mixture Proportioning, Properties, Construction Practice, and Case Histories; Supplementary Cementing Materials for Sustainable Development, Inc.: Ottawa, ON, Canada, 2002. [Google Scholar]

- Atiş, C.D. High volume fly ash abrasion resistant concrete. J. Mater. Civ. Eng. 2002, 14, 274–277. [Google Scholar] [CrossRef]

- BS EN 12390-3:2009 Testing Hardened Concrete. Part 3: Compressive Strength of Test Specimens; British Standard Institution: London, UK, 2009. [Google Scholar]

- ASTM C267-01 Standard Test Methods for Chemical Resistance of Mortars, Grouts, and Monolithic Surfacings and Polymer Concretes; ASTM International: West Conshohocken, PA, USA, 2012.

- Redner, J.A.; His, R.P.; Esfandi, E.J.; Sydney, R.; Jones, R.M.; Won, D.; Andraska, J. Evaluation of Protective Coatings for Concrete. Available online: https://www.powercoatings.co.uk/wp-content/uploads/2017/07/Evaluations-of-Protective-Coatings-for-Concrete-Redner-2004.pdf (accessed on 10 January 2019).

- Pei, X.; Noël, M.; Green, M.; Fam, A.; Shier, G. Cementitious coatings for improved corrosion resistance of steel reinforcement. Surf. Coat. Technol. 2007, 315, 188–195. [Google Scholar] [CrossRef]

- ASTM C876-15 Standard Test Method for Corrosion Potentials of Uncoated Reinforcing Steel in Concrete; ASTM International: West Conshohocken, PA, USA, 2015.

- Arezoumandi, M.; Volz, J.S. Effect of fly ash replacement level on the shear strength of high volume fly ash concrete beams. J. Clean. Prod. 2013, 59, 120–130. [Google Scholar] [CrossRef]

| Properties | Fly Ash |

|---|---|

| Fineness (%) | 21.5 (>45 μm) |

| Loss on ignition (LOI) (%) | 5.83 |

| Moisture (%) | 0.04 |

| SiO2 (%) | 58.9 |

| Fe2O3 (%) | 5.75 |

| Al2O3 (%) | 23.9 |

| SO3 (%) | 0.03 |

| Group | Identification | W–CM | W–C | OPC | Fly Ash | OPC + Fly Ash | Aggregate | Sand | Slump (cm) |

|---|---|---|---|---|---|---|---|---|---|

| G1 | M1 (0% 0.42) | 0.42 | 0.42 | 1 | 0 | 1 | 3 | 2 | 3 |

| M2 (10% 0.42) | 0.42 | 0.47 | 0.9 | 0.1 | 1 | 3 | 2 | 3.3 | |

| M3 (20% 0.42) | 0.42 | 0.53 | 0.8 | 0.2 | 1 | 3 | 2 | 3.4 | |

| M4 (40% 0.42) | 0.42 | 0.7 | 0.6 | 0.4 | 1 | 3 | 2 | 5.5 | |

| G2 | M5 (0% 0.50) | 0.5 | 0.5 | 1 | 0 | 1 | 3 | 2 | 7 |

| M6 (10% 0.50) | 0.5 | 0.56 | 0.9 | 0.1 | 1 | 3 | 2 | 11 | |

| M7 (20% 0.50) | 0.5 | 0.63 | 0.8 | 0.2 | 1 | 3 | 2 | 19 | |

| M8 (40% 0.50) | 0.5 | 0.83 | 0.6 | 0.4 | 1 | 3 | 2 | 20 | |

| G3 | M9 (0% 0.55) | 0.55 | 0.55 | 1 | 0 | 1 | 3 | 2 | 10 |

| M10 (10% 0.55) | 0.55 | 0.61 | 0.9 | 0.1 | 1 | 3 | 2 | 20 | |

| M11 (20% 0.55) | 0.55 | 0.69 | 0.8 | 0.2 | 1 | 3 | 2 | 25 | |

| M12 (40% 0.55) | 0.55 | 0.92 | 0.6 | 0.4 | 1 | 3 | 2 | 29 |

| Group | Specimen ID | Mass before Immersion in H2SO4 (g) | Mass after Immersion in H2SO4 (g) | Mass Loss (%) | Crushing Load Cured in Water (kN) | Crushing Load Cured in H2SO4 (kN) | Compressive Strength Loss (%) |

|---|---|---|---|---|---|---|---|

| 1 | M1 (0% 0.42) | 2537.5 | 2248 | −11.4 | 467.43 | 181.185 | −61.2 |

| M2 (10% 0.42) | 2469 | 2322 | −6.0 | 364.815 | 168.195 | −53.9 | |

| M3 (20% 0.42) | 2504 | 2331 | −6.9 | 370.795 | 219.51 | −40.8 | |

| M4 (40% 0.42) | 2524.5 | 2487 | −1.5 | 336.465 | 220.97 | −34.3 | |

| 2 | M5 (0% 0.50) | 2522.5 | 2289 | −9.3 | 410.255 | 204.885 | −50.1 |

| M6 (10% 0.50) | 2483 | 2316.5 | −6.7 | 338.1 | 213.305 | −36.9 | |

| M7 (20% 0.50) | 2548.5 | 2381 | −6.6 | 334.235 | 152.385 | −54.4 | |

| M8 (40% 0.50) | 2526.5 | 2516.5 | −0.4 | 312.055 | 186.865 | −40.1 | |

| 3 | M9 (0% 0.55) | 2530 | 2374.5 | −6.1 | 359.9 | 185.51 | −48.5 |

| M10 (10% 0.55) | 2531 | 2420 | −4.4 | 242.795 | 200.64 | −17.4 | |

| M11 (20% 0.55) | 2517 | 2484 | −1.3 | 298.23 | 230.23 | −22.8 | |

| M12 (40% 0.55) | 2445 | 2435 | −0.4 | 247.515 | 217.2 | −12.2 |

| Group | Beam ID | Dimensions (mm3) | Yield Load (kN) | Ultimate Load (kN) |

|---|---|---|---|---|

| 1 | M1 (0% FA, 0.42) | 100 × 100 × 500 | 21 | 21.55 |

| M2 (10% FA, 0.42) | 100 × 100 × 500 | 15.5 | 16.23 | |

| M3 (20% FA, 0.42) | 100 × 100 × 500 | 16.6 | 18.9 | |

| M4 (40% FA, 0.42) | 100 × 100 × 500 | 16.3 | 17.08 | |

| 2 | M5 (0% FA, 0.50) | 100 × 100 × 500 | 16 | 17.32 |

| M6 (10% FA, 0.50) | 100 × 100 × 500 | 17 | 18.45 | |

| M7 (20% FA, 0.50) | 100 × 100 × 500 | 16.2 | 17.97 | |

| M8 (40% FA, 0.50) | 100 × 100 × 500 | 15.8 | 16.95 | |

| 3 | M9 (0% FA, 0.55) | 100 × 100 × 500 | 14 | 16.71 |

| M10 (10% FA, 0.55) | 100 × 100 × 500 | 18 | 19.02 | |

| M11 (20% FA, 0.55) | 100 × 100 × 500 | 14.5 | 17.66 | |

| M12 (40% FA, 0.55) | 100 × 100 × 500 | 15.5 | 18.73 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Van Nguyen, C.; Lambert, P.; Hung Tran, Q. Effect of Vietnamese Fly Ash on Selected Physical Properties, Durability and Probability of Corrosion of Steel in Concrete. Materials 2019, 12, 593. https://doi.org/10.3390/ma12040593

Van Nguyen C, Lambert P, Hung Tran Q. Effect of Vietnamese Fly Ash on Selected Physical Properties, Durability and Probability of Corrosion of Steel in Concrete. Materials. 2019; 12(4):593. https://doi.org/10.3390/ma12040593

Chicago/Turabian StyleVan Nguyen, Chinh, Paul Lambert, and Quang Hung Tran. 2019. "Effect of Vietnamese Fly Ash on Selected Physical Properties, Durability and Probability of Corrosion of Steel in Concrete" Materials 12, no. 4: 593. https://doi.org/10.3390/ma12040593

APA StyleVan Nguyen, C., Lambert, P., & Hung Tran, Q. (2019). Effect of Vietnamese Fly Ash on Selected Physical Properties, Durability and Probability of Corrosion of Steel in Concrete. Materials, 12(4), 593. https://doi.org/10.3390/ma12040593