The Constitutive Relationship for Corroded Steel Bars: Model and Analysis

Abstract

1. Introduction

2. Assumptions and Model of Steel Bars

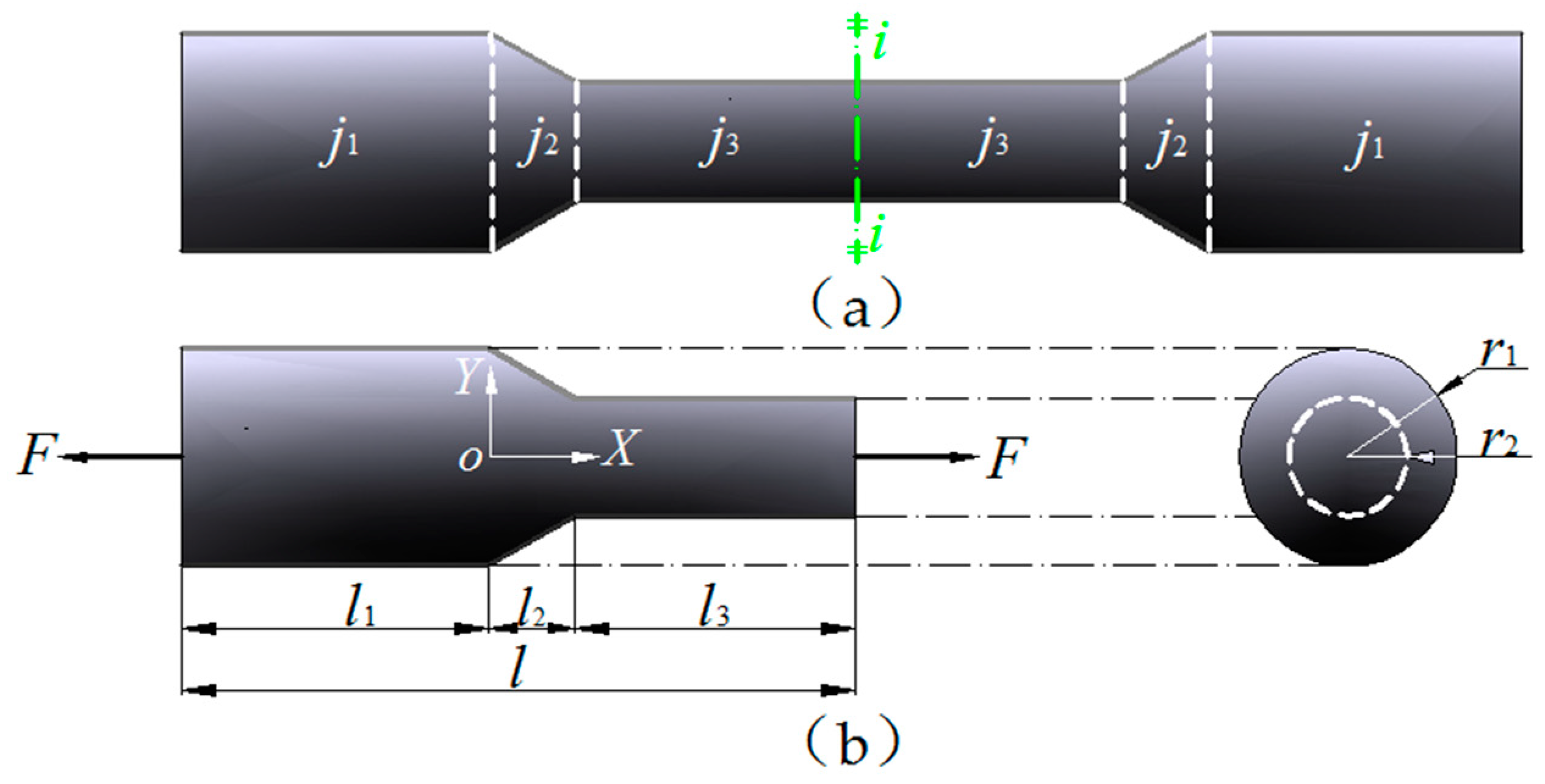

2.1. Basic Model of Steel Bars

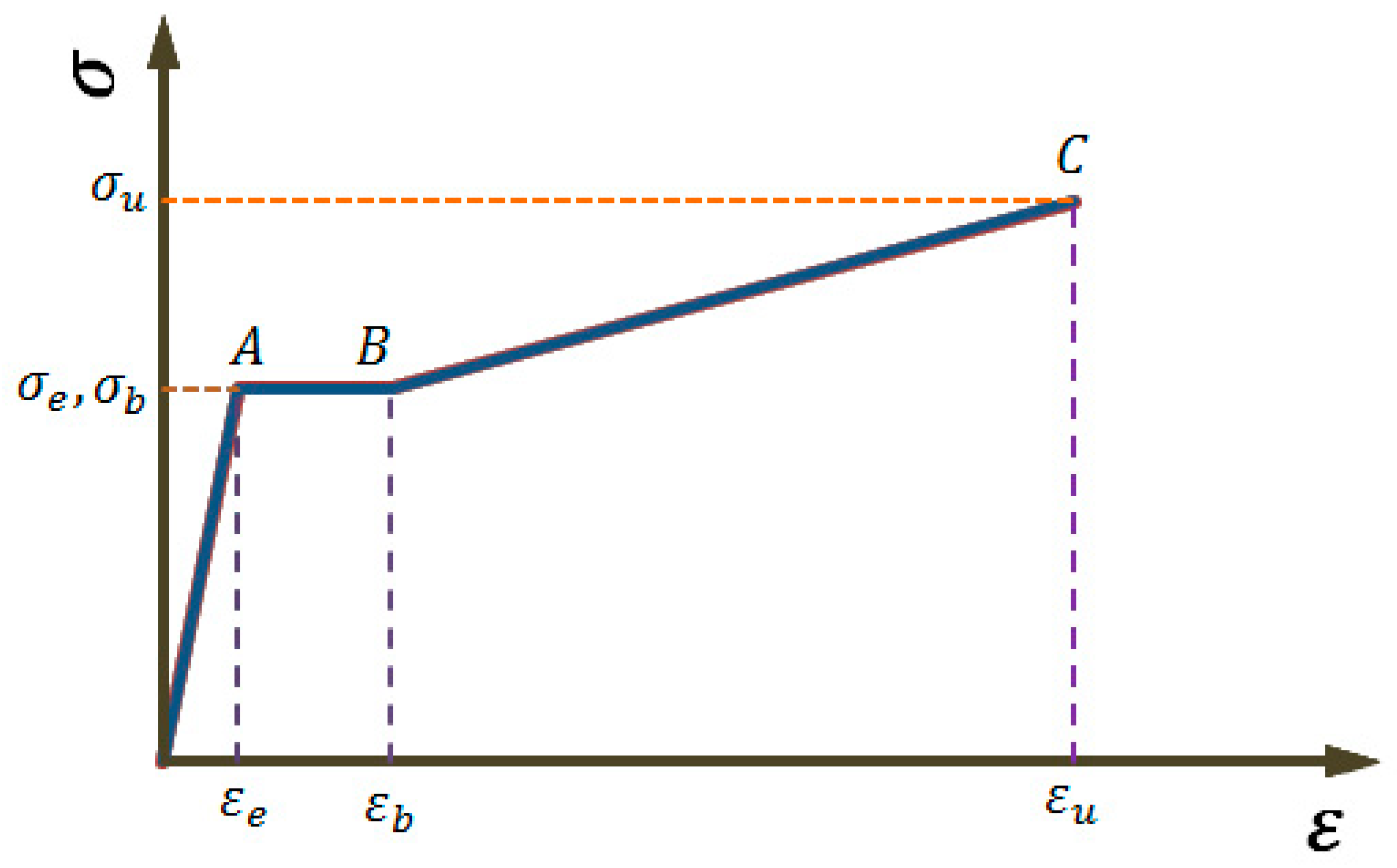

2.2. Simplified Model of the Corroded Steel

3. Analytical Model of Relationship of the Corroded Steel Bar

4. Tensile Experiments of Corroded Steel Bars

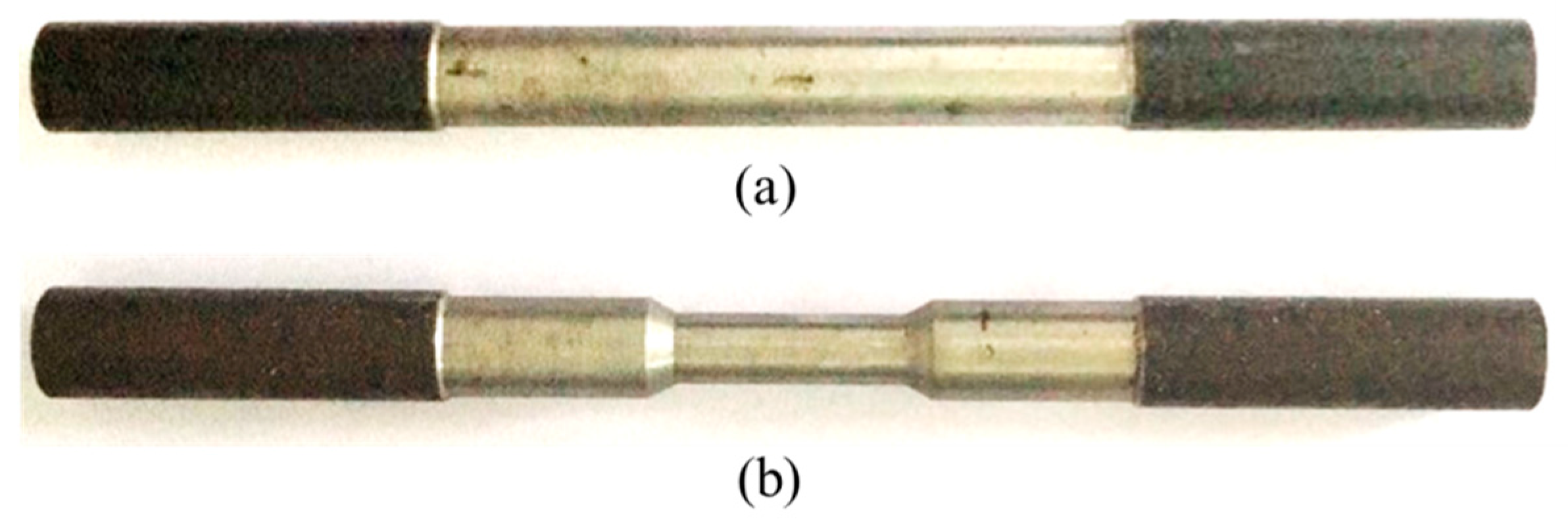

4.1. Specimens

4.2. Experiment

5. Results and Discussion

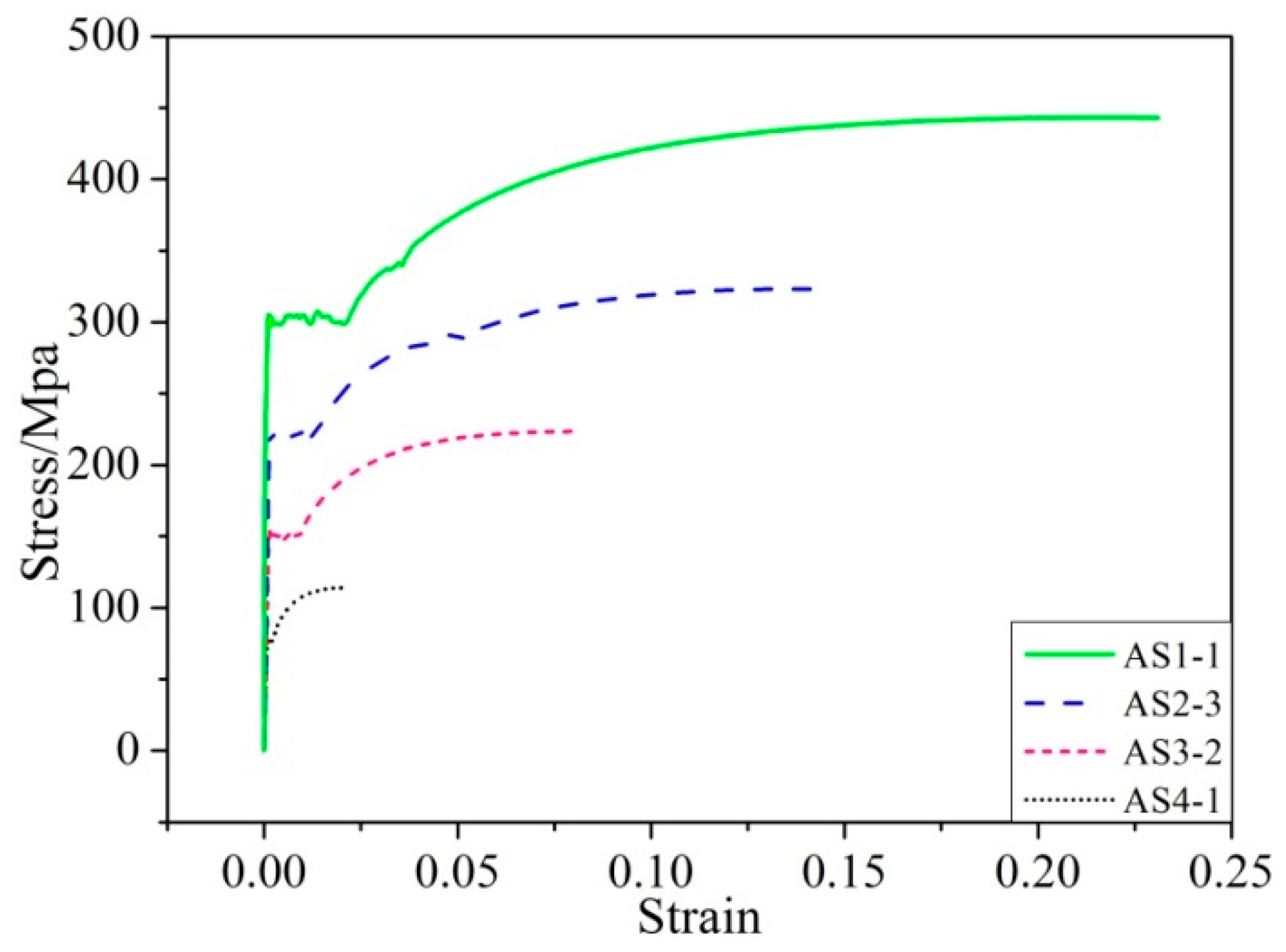

5.1. The Tensile Constitutive Curve of the Steel Bars

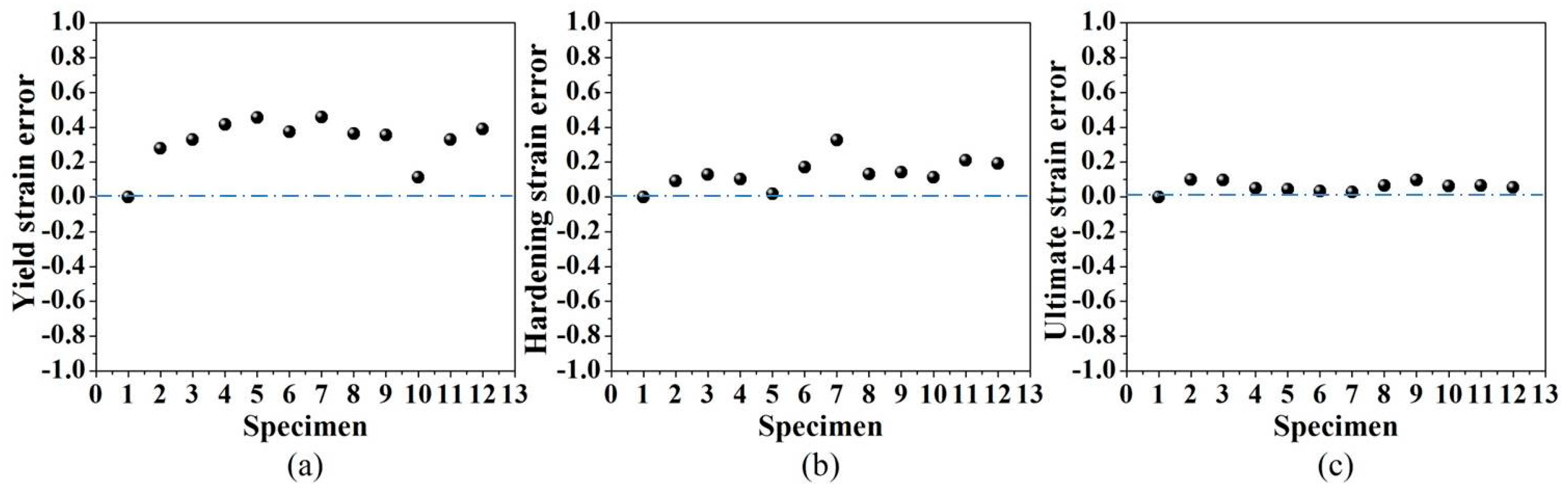

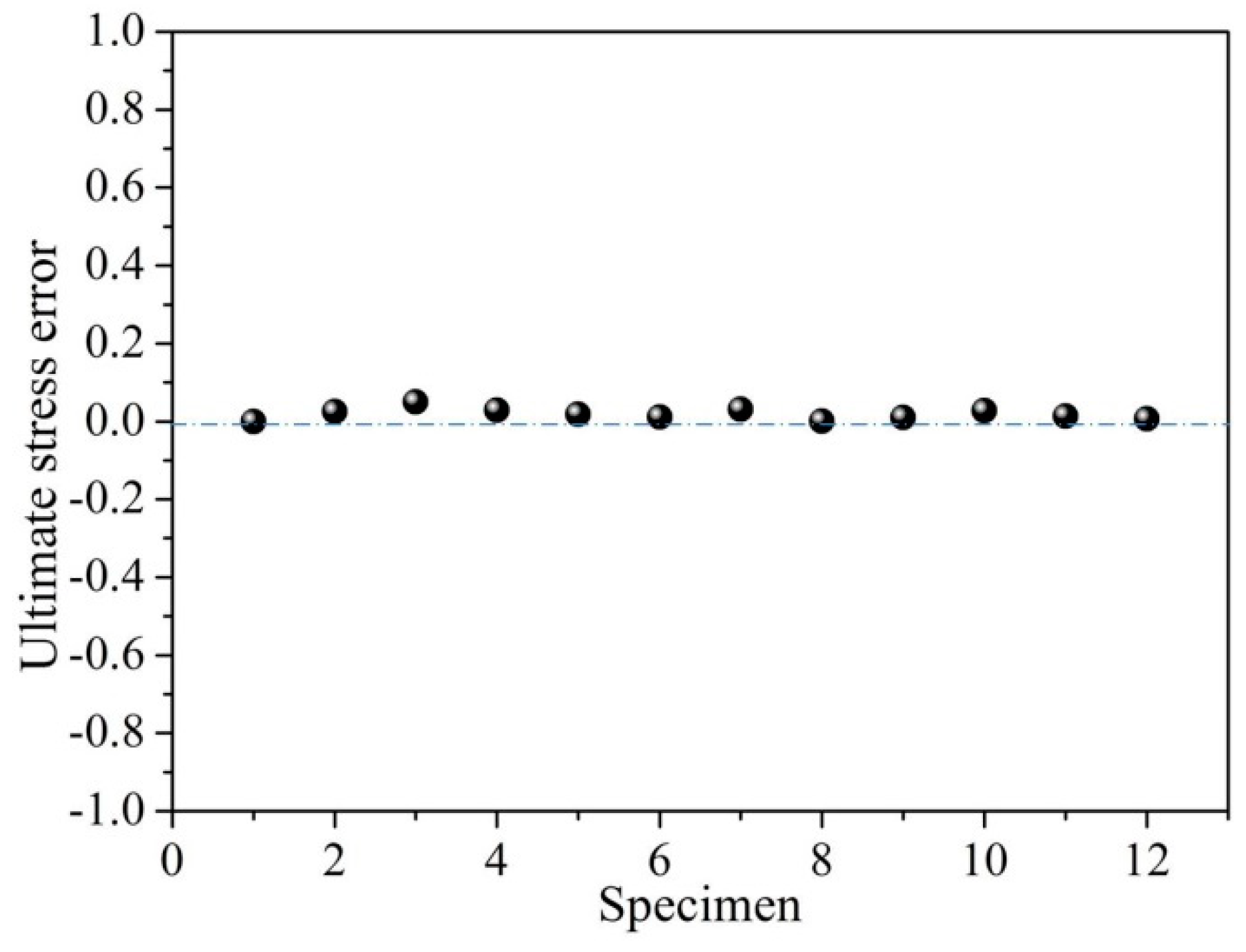

5.2. Comparison of the Theoretical Solution and Experimental Result

5.3. The Attenuation Law of Ultimate Strength

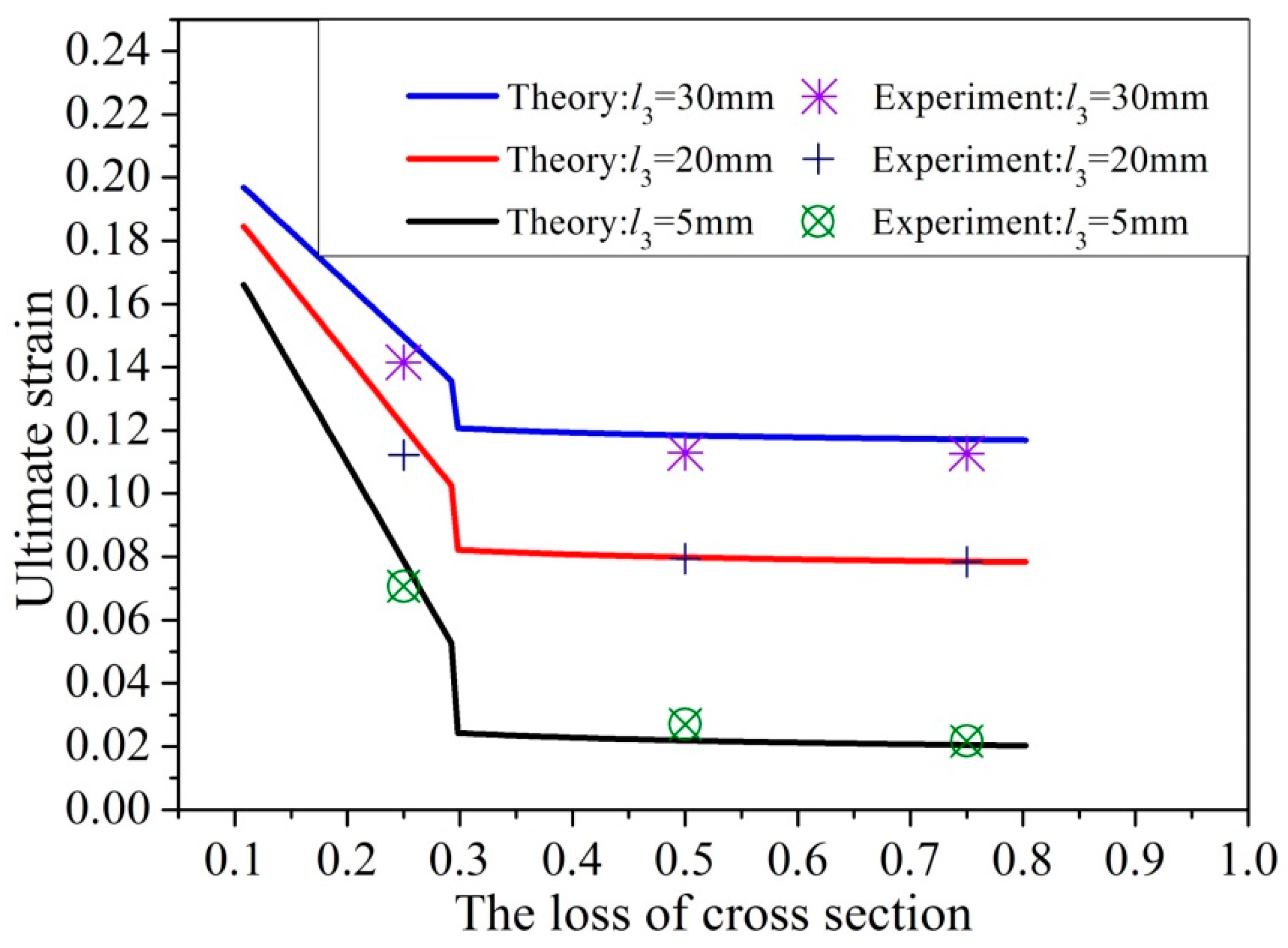

5.4. The Attenuation Law of Ductility

5.5. Influence of Geometric Parameters of Corroded Steel Bars

5.5.1. Effect of Length of the Uniform Corroded Part on Ultimate strain

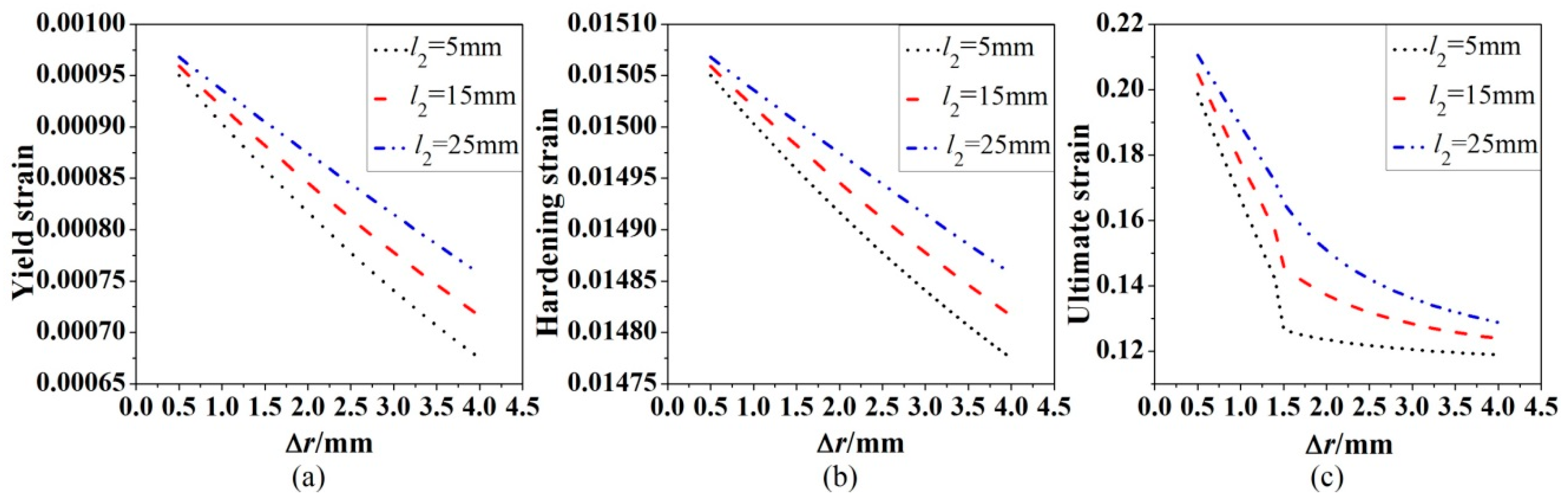

5.5.2. Effect of the Reduction ∆r of the Section Radius

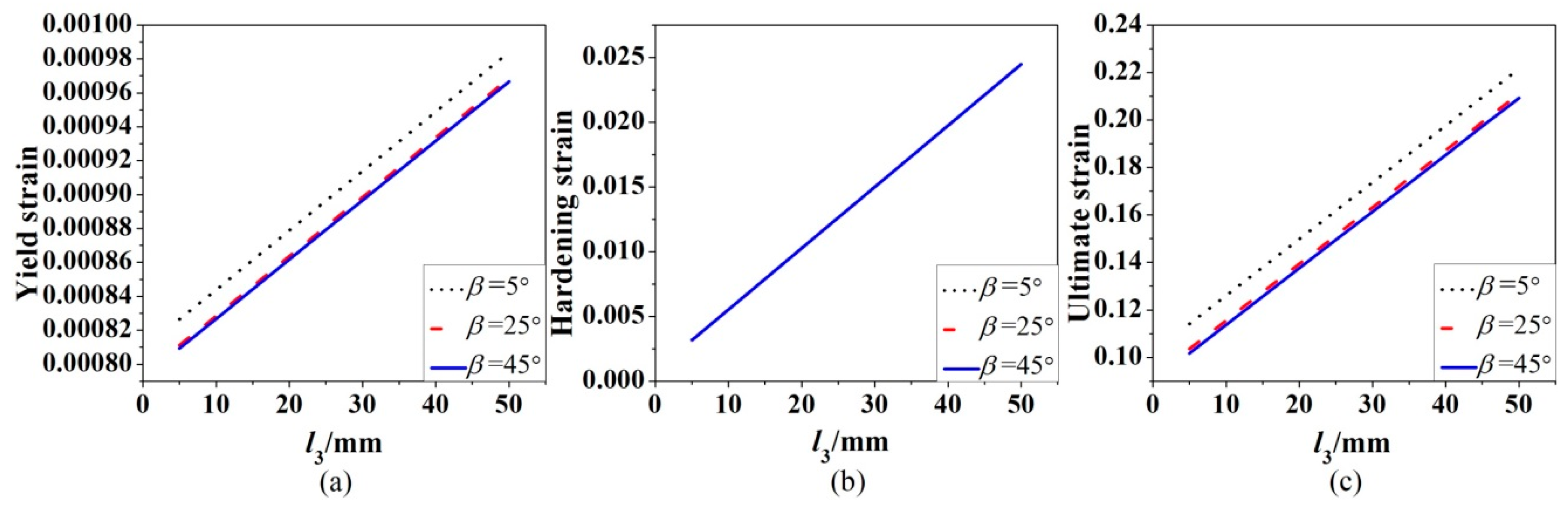

5.5.3. The Effect of Slope Angle β of the Corroded Part

5.6. Discussion

6. Conclusions

- The proposed model can predict the tensile behavior of a corroded steel bar. The prediction for ultimate stress and ultimate strain agree well with the experimental results.

- Compared to bilinear model, the trilinear model can predict the tensile behavior of a corroded steel bar with higher accuracy especially for light corrosions.

- The strength of the corroded steel bar decreases with the increase of the loss rate of the cross-sectional area, regardless of the corrosion length of the steel bar.

- The yield strain, hardening strain and ultimate strain of the corroded steel bar increase with the increase of length of the uniform corrosion of the steel bar.

Author Contributions

Funding

Conflicts of Interest

Notation

| Yield strain; | |

| Hardening strain; | |

| Ultimate strain; | |

| Yield stress; | |

| Hardening stress; | |

| Ultimate stress; | |

| Elastic Modulus; | |

| Slope of hardening stage; | |

| Length of yield platform; | |

| Uncorroded part; | |

| Corroded part with variable cross-section; | |

| Uniform corroded part; | |

| Cross-sectional radius of uncorroded part; | |

| Cross-sectional radius of corroded part with variable cross-section; | |

| Cross-sectional radius of uniform corroded part; | |

| Axial original length of uncorroded part; | |

| Axial original length of corroded part with variable cross-section; | |

| Axial original length of uniform corroded part; | |

| Total length of the half physical model; | |

| Elongation of uncorroded part; | |

| Elongation of corroded part with variable cross-section; | |

| Elongation of uniform corroded part; | |

| Total elongation of three parts; | |

| F | Axial tensile force; |

| Average strain of the corroded steel bar; | |

| Nominal stress of the corroded steel bar; | |

| Original cross-sectional area of the uncorroded steel bar; | |

| Cross-sectional area of uncorroded part; | |

| Cross-sectional area of corroded part with variable cross-section; | |

| Cross-sectional area of uniform corroded part; | |

| Yield load of uncorroded part; | |

| Ultimate load of uncorroded part; | |

| Yield load of uniform corroded part; | |

| Ultimate load of uniform corroded part; | |

| β | Slope angle of corroded part with variable cross-section; |

| Loss rate of the cross-sectional area; | |

| Critical loss rate of the cross-sectional area; | |

| Ultimate load of the corroded steel bar; | |

| Ultimate strength of the corroded steel bar; | |

| ∆r | Reduction of the cross-section radius; |

| [] | Strain interval of the yielding platform of the mild steel; |

References

- Xua, S.H.; Zhang, Z.X.; Qin, G.C. Study on the seismic performance of corroded H-shaped steel columns. Eng. Struct. 2019, 191, 39–61. [Google Scholar] [CrossRef]

- Ou, Y.C.; Tsai, L.L.; Chen, H.H. Cyclic performance of large-scale corroded reinforced concrete beams. Earthq. Eng. Struct. Dyn. 2012, 41, 593–604. [Google Scholar] [CrossRef]

- Li, D.W.; Wei, R.; Xing, F.; Sui, L.L.; Zhou, Y.W.; Wang, W.Y. Influence of Non-uniform corrosion of steel bars on the seismic behavior of reinforced concrete columns. Constr. Build. Mater. 2018, 167, 20–32. [Google Scholar] [CrossRef]

- Du, Y.G.; Clark, L.A.; Chan, A.H.C. Residual capacity of corroded reinforcing bars. Mag. Concr. Res. 2005, 57, 135–147. [Google Scholar] [CrossRef]

- Kashani, M.M.; Crewe, A.J.; Alexander, N.A. Nonlinear stress–strain behaviour of corrosion-damaged reinforcing bars including inelastic buckling. Eng. Struct. 2013, 48, 417–429. [Google Scholar] [CrossRef]

- Li, D.W.; Wei, R.; Du, Y.G.; Guan, X.T.; Zhou, M.Y. Measurement methods of geometrical parameters and amount of corrosion of steel bar. Constr. Build. Mater. 2017, 154, 921–927. [Google Scholar] [CrossRef]

- Du, Y.G.; Clark, L.A.; Chan, A.H.C. Effect of corrosion on ductility of reinforcing bars. Mag. Concr. Res. 2005, 57, 407–419. [Google Scholar] [CrossRef]

- François, R.; Khan, I.; Dang, V.H. Impact of corrosion on mechanical properties of steel embedded in 27-year-old corroded reinforced concrete beams. Mater. Struct. 2013, 46, 899–910. [Google Scholar] [CrossRef]

- Zhu, W.J.; François, R. Corrosion of the reinforcement and its influence on the residual structural performance of a 26-year-old corroded RC beam. Constr. Build. Mater. 2014, 51, 461–472. [Google Scholar] [CrossRef]

- Andisheh, K.; Scott, A.; Palermo, A.; Clucas, D. Influence of chloride corrosion on the effective mechanical properties of steel reinforcement. Struct. Infrastruct. Eng. 2019, 15, 1–13. [Google Scholar] [CrossRef]

- Zhang, W.; Song, X.; Gu, X.; Li, S. Tensile and fatigue behavior of corroded rebars. Constr. Build. Mater. 2012, 34, 409–417. [Google Scholar] [CrossRef]

- Bazán, A.M.; González, M.D.L.N.; Alberti, M.G.; Gálvez, J.C. Influence of the Loading Speed on the Ductility Properties of Corroded Reinforcing Bars in Concrete. Materials 2019, 12, 965. [Google Scholar] [CrossRef] [PubMed]

- Zhu, W.J.; François, R.; Poon, C.S.; Dai, J.G. Influences of corrosion degree and corrosion morphology on the ductility of steel reinforcement. Constr. Build. Mater. 2017, 148, 297–306. [Google Scholar] [CrossRef]

- Dang, V.H.; François, R. Prediction of ductility factor of corroded reinforced concrete beams exposed to long term aging in chloride environment. Cem. Concr. Compos. 2014, 53, 136–147. [Google Scholar] [CrossRef]

- Moreno, E.; Cobo, A.; Palomo, G.; González, M.N. Mathematical models to predict the mechanical behavior of reinforcements depending on their degree of corrosion and the diameter of the rebars. Constr. Build. Mater. 2014, 61, 156–163. [Google Scholar] [CrossRef]

- Tang, F.; Lin, Z.; Chen, G.; Yi, W. Three-dimensional corrosion pit measurement and statistical mechanical degradation analysis of deformed steel bars subjected to accelerated corrosion. Constr. Build. Mater. 2014, 70, 104–117. [Google Scholar] [CrossRef]

- Murer, N.; Buchheit, R.G. Stochastic modeling of pitting corrosion in aluminum alloys. Corros. Sci. 2013, 69, 139–148. [Google Scholar] [CrossRef]

- Valor, A.; Caleyo, F.; Rivas, D.; Hallen, J.M. Stochastic approach to pitting-corrosion-extreme modelling in low-carbon steel. Corros. Sci. 2010, 52, 910–915. [Google Scholar] [CrossRef]

- Gu, X.; Guo, H.; Zhou, B.; Zhang, W.; Jiang, C. Corrosion non-uniformity of steel bars and reliability of corroded RC beams. Eng. Struct. 2018, 167, 188–202. [Google Scholar] [CrossRef]

- Xi, X.; Yang, S.T. Investigating the spatial development of corrosion of corner-located steel bar in concrete by X-ray computed tomography. Constr. Build. Mater. 2019, 221, 177–189. [Google Scholar] [CrossRef]

- Li, D.W.; Xiong, C.; Huang, T.; Wei, R.; Han, N.; Xing, F. A simplified constitutive model for corroded steel bars. Constr. Build. Mater. 2018, 186, 11–19. [Google Scholar] [CrossRef]

- Gao, X.L.; Pan, Y.T.; Ren, X.D. Probabilistic model of the minimum effective cross-section area of non-uniform corroded steel bars. Constr. Build. Mater. 2019, 216, 227–238. [Google Scholar] [CrossRef]

- Fernandez, I.; Bairán, J.M.; Marí, A.R. 3D FEM model development from 3D optical measurement technique applied to corroded steel bars. Constr. Build. Mater. 2016, 124, 519–532. [Google Scholar] [CrossRef]

| Specimen | Label | β | ||||||

|---|---|---|---|---|---|---|---|---|

| 1 | AS1-1 | 60 | 0 | 0 | 9 | 9 | 0 | 0 |

| 2 | AS2-1 | 52.9 | 2.10 | 5 | 9 | 7.79 | 1.21 | 30° |

| 3 | AS2-2 | 37.9 | 2.10 | 20 | 9 | 7.79 | 1.21 | 30° |

| 4 | AS2-3 | 27.9 | 2.10 | 30 | 9 | 7.79 | 1.21 | 30° |

| 5 | AS3-1 | 50.43 | 4.57 | 5 | 9 | 6.36 | 2.64 | 30° |

| 6 | AS3-2 | 35.43 | 4.57 | 20 | 9 | 6.36 | 2.64 | 30° |

| 7 | AS3-3 | 25.43 | 4.57 | 30 | 9 | 6.36 | 2.64 | 30° |

| 8 | AS3-4 | 53.48 | 1.52 | 5 | 9 | 6.36 | 2.64 | 60° |

| 9 | AS3-5 | 55 | 0 | 5 | 9 | 6.36 | 2.64 | 90° |

| 10 | AS4-1 | 47.21 | 7.79 | 5 | 9 | 4.50 | 4.50 | 30° |

| 11 | AS4-2 | 32.21 | 7.79 | 20 | 9 | 4.50 | 4.50 | 30° |

| 12 | AS4-3 | 22.21 | 7.79 | 30 | 9 | 4.50 | 4.50 | 30° |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, C.; Zeng, C.; Li, Y.; Li, L.; Li, P.; Li, D. The Constitutive Relationship for Corroded Steel Bars: Model and Analysis. Materials 2019, 12, 4058. https://doi.org/10.3390/ma12244058

Xiong C, Zeng C, Li Y, Li L, Li P, Li D. The Constitutive Relationship for Corroded Steel Bars: Model and Analysis. Materials. 2019; 12(24):4058. https://doi.org/10.3390/ma12244058

Chicago/Turabian StyleXiong, Cheng, Chaoqun Zeng, Yanru Li, Ly Li, Ping Li, and Dawang Li. 2019. "The Constitutive Relationship for Corroded Steel Bars: Model and Analysis" Materials 12, no. 24: 4058. https://doi.org/10.3390/ma12244058

APA StyleXiong, C., Zeng, C., Li, Y., Li, L., Li, P., & Li, D. (2019). The Constitutive Relationship for Corroded Steel Bars: Model and Analysis. Materials, 12(24), 4058. https://doi.org/10.3390/ma12244058