Sensor-Assisted Assessment of the Tribological Behavioral Patterns of Al–SiCp Composites under Various Environmental Temperature Conditions

Abstract

1. Introduction

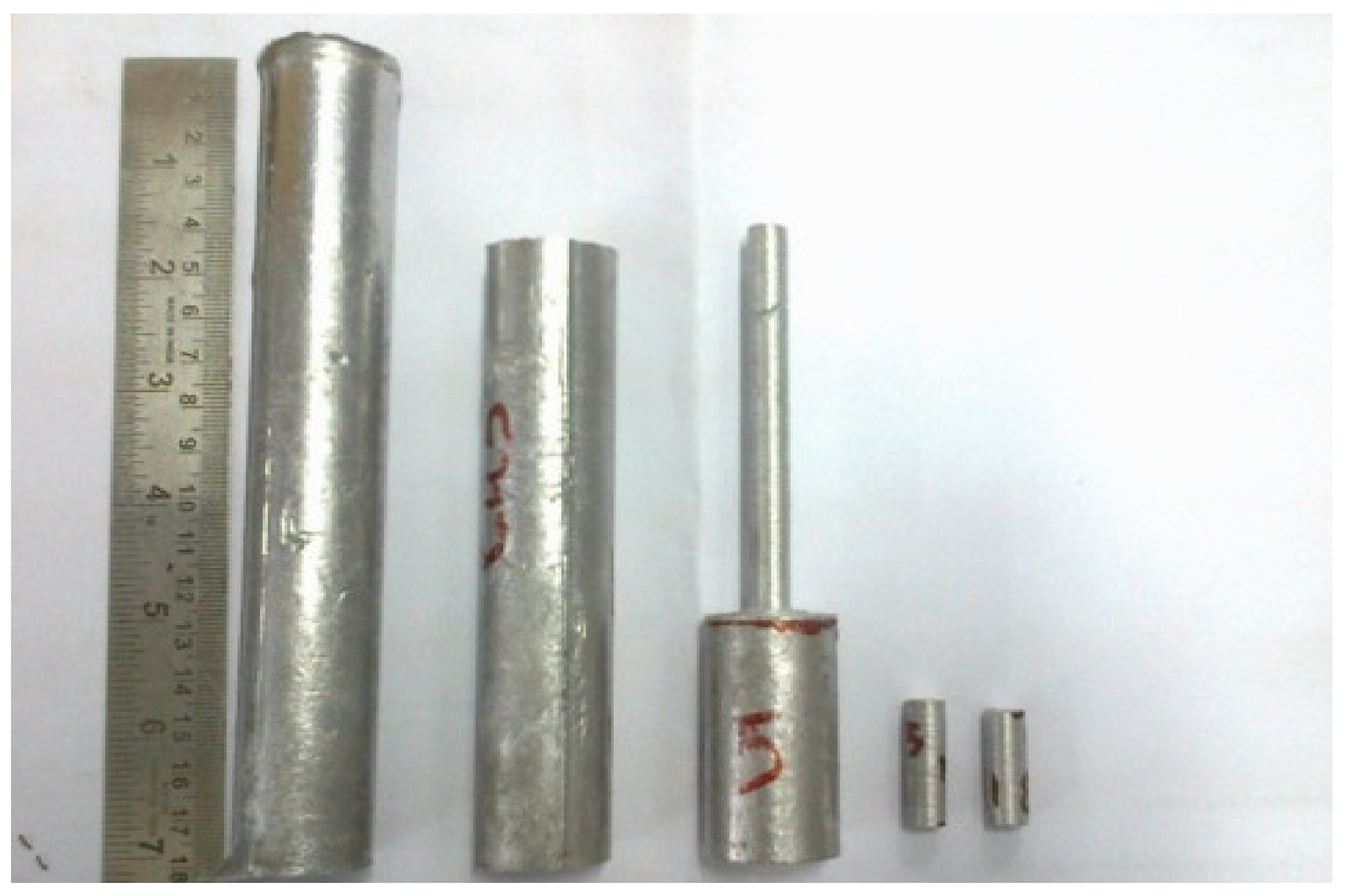

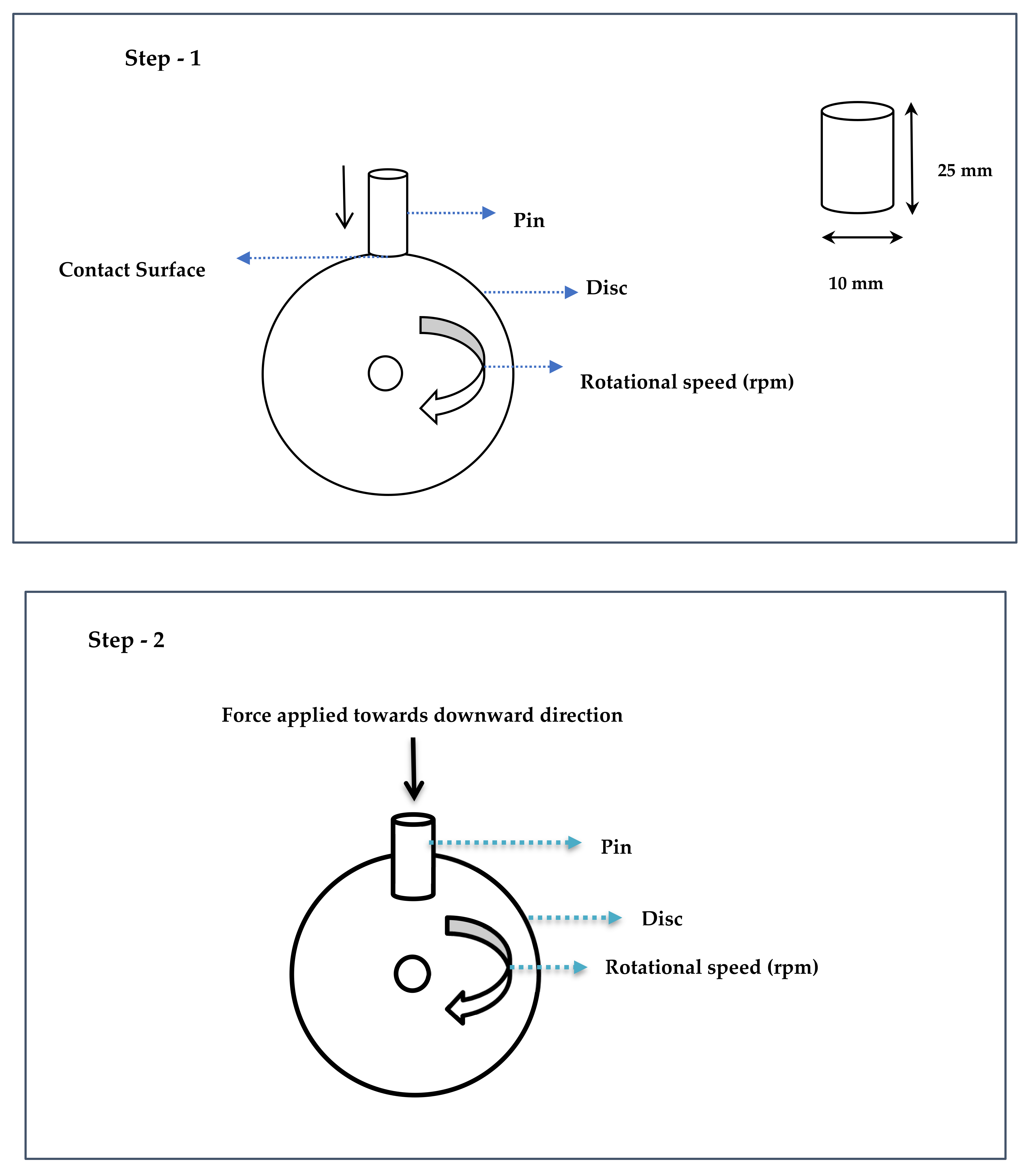

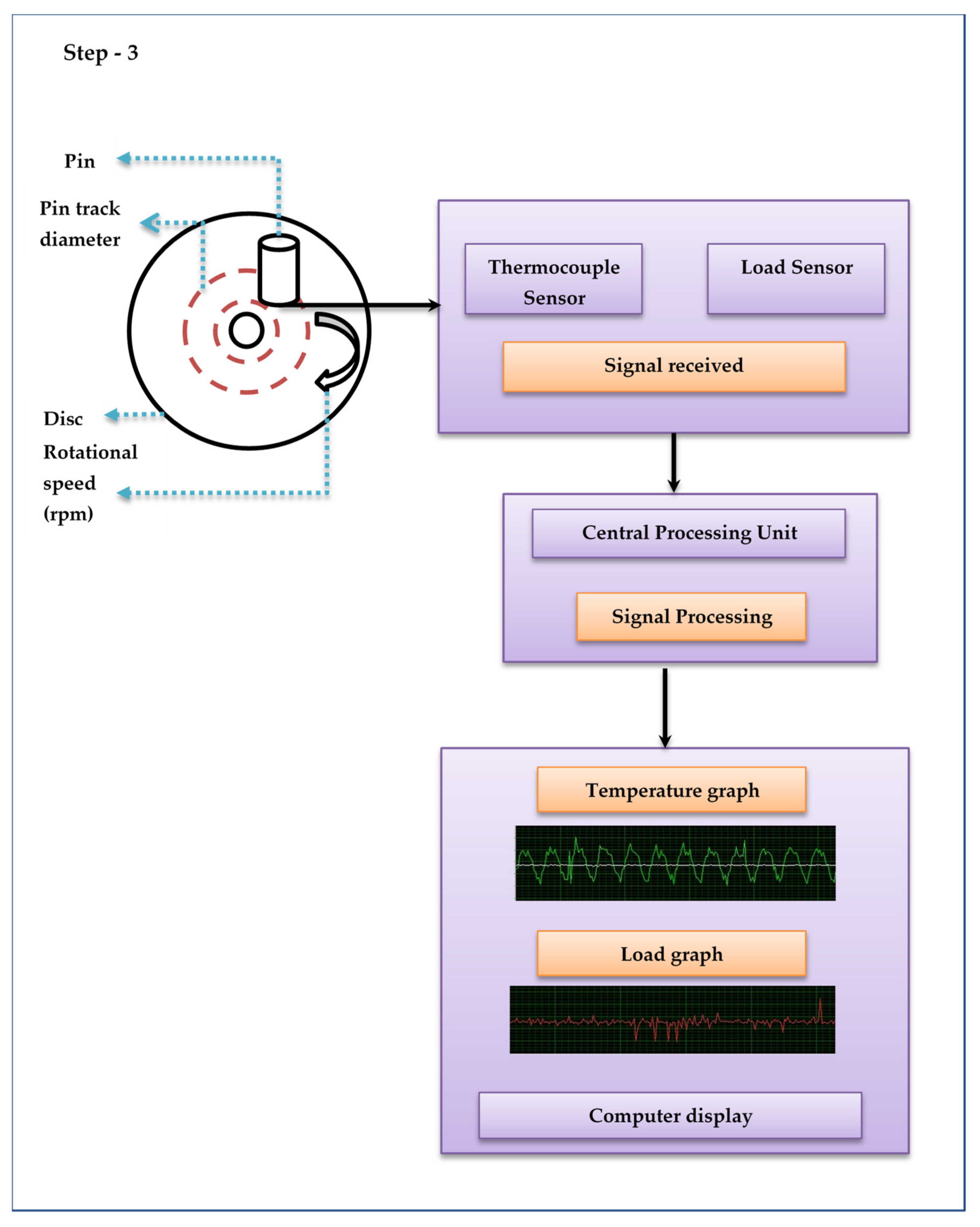

2. Materials and Methods

3. Material Characterization

4. Result and Discussion

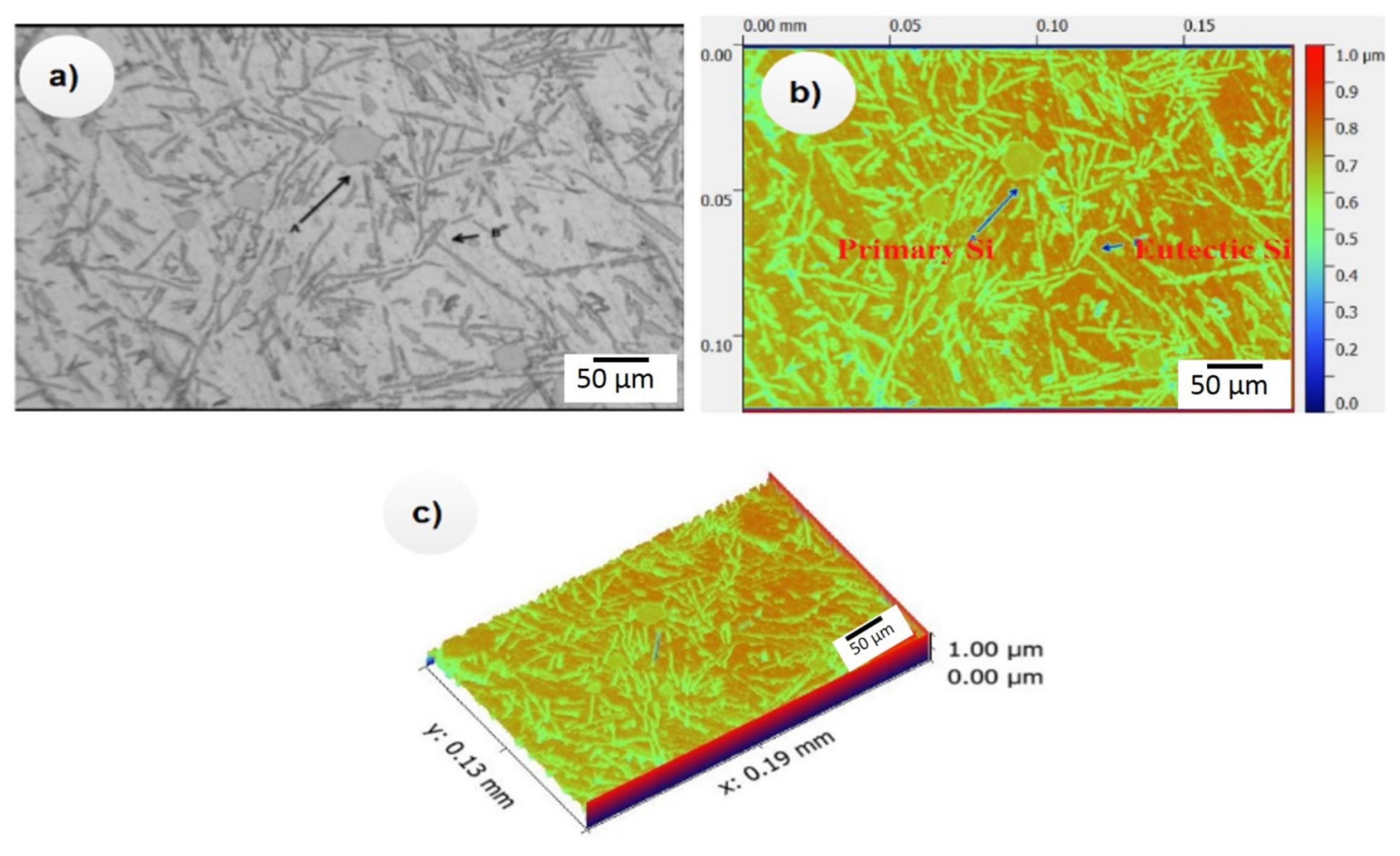

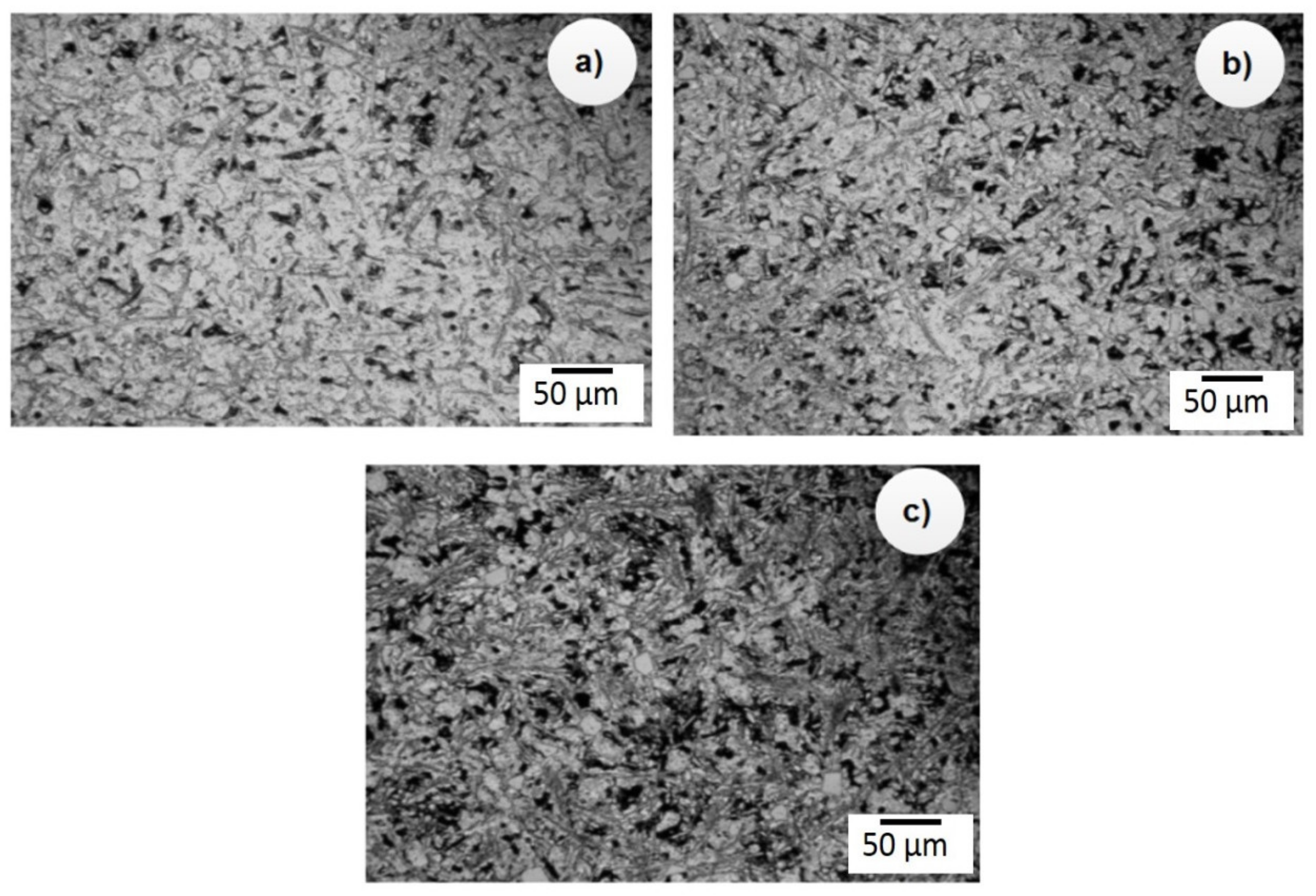

4.1. Microstructural Characterization

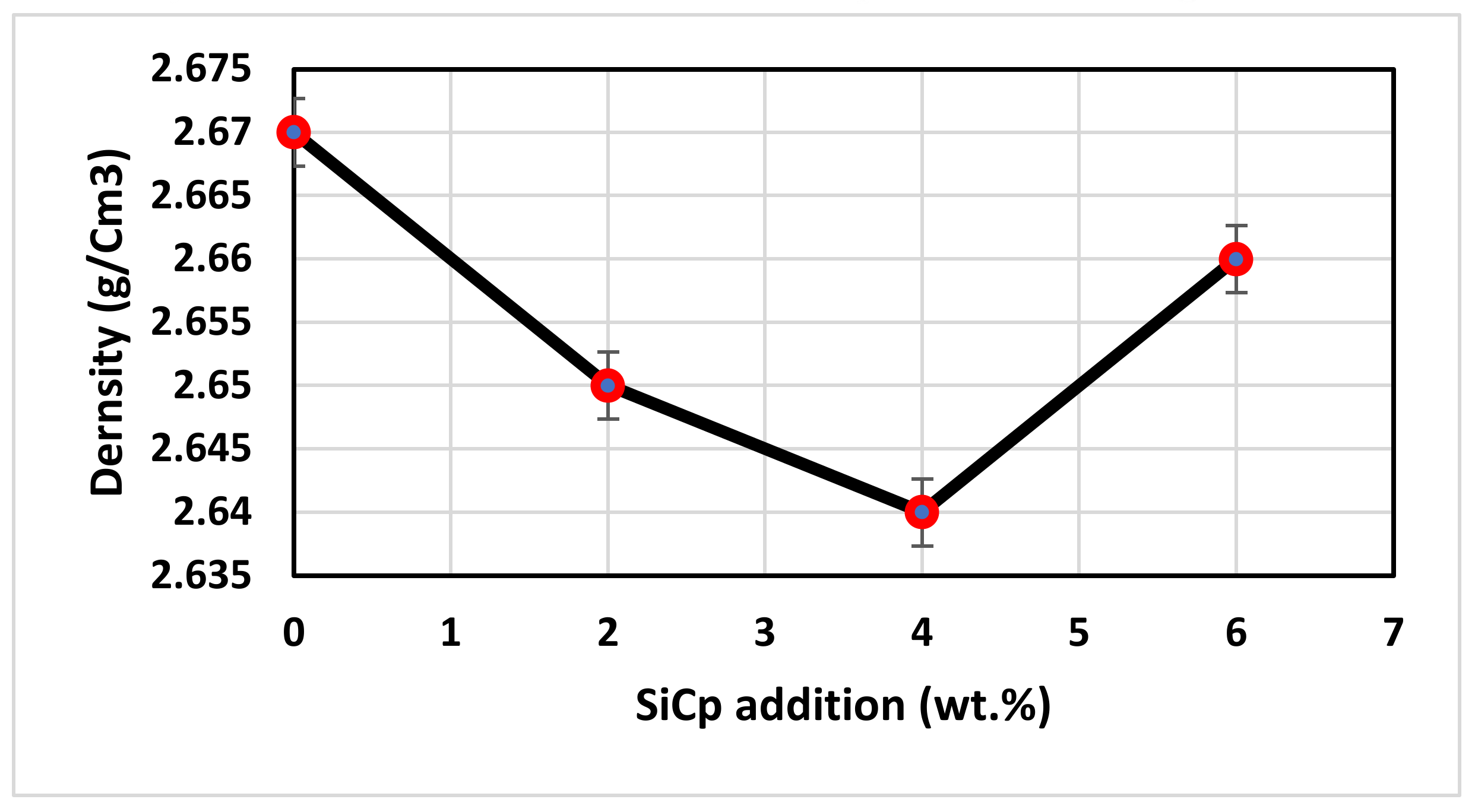

4.2. Density Analysis of the Developed Al MMC

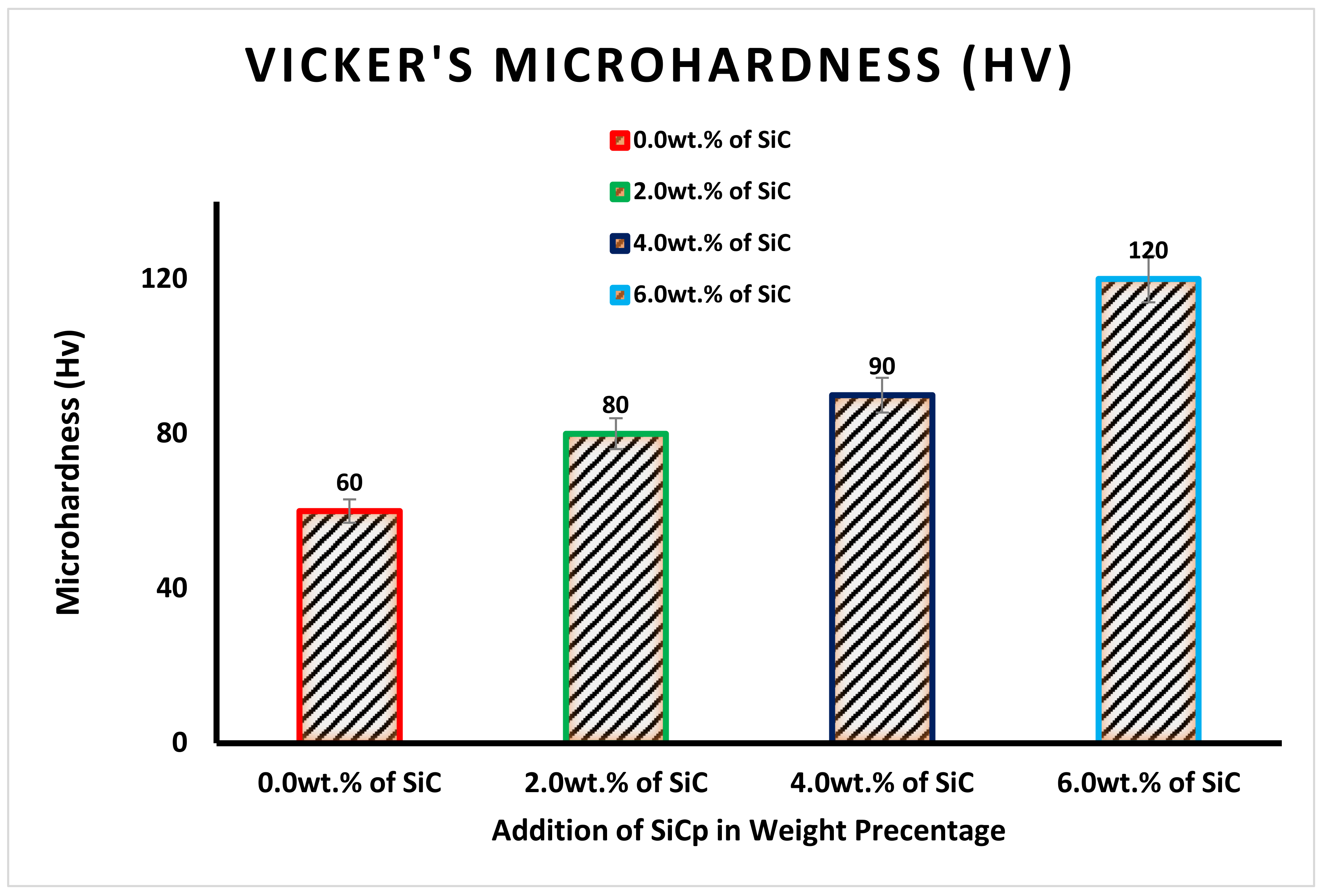

4.3. Hardness Analysis of the Developed Al MMC

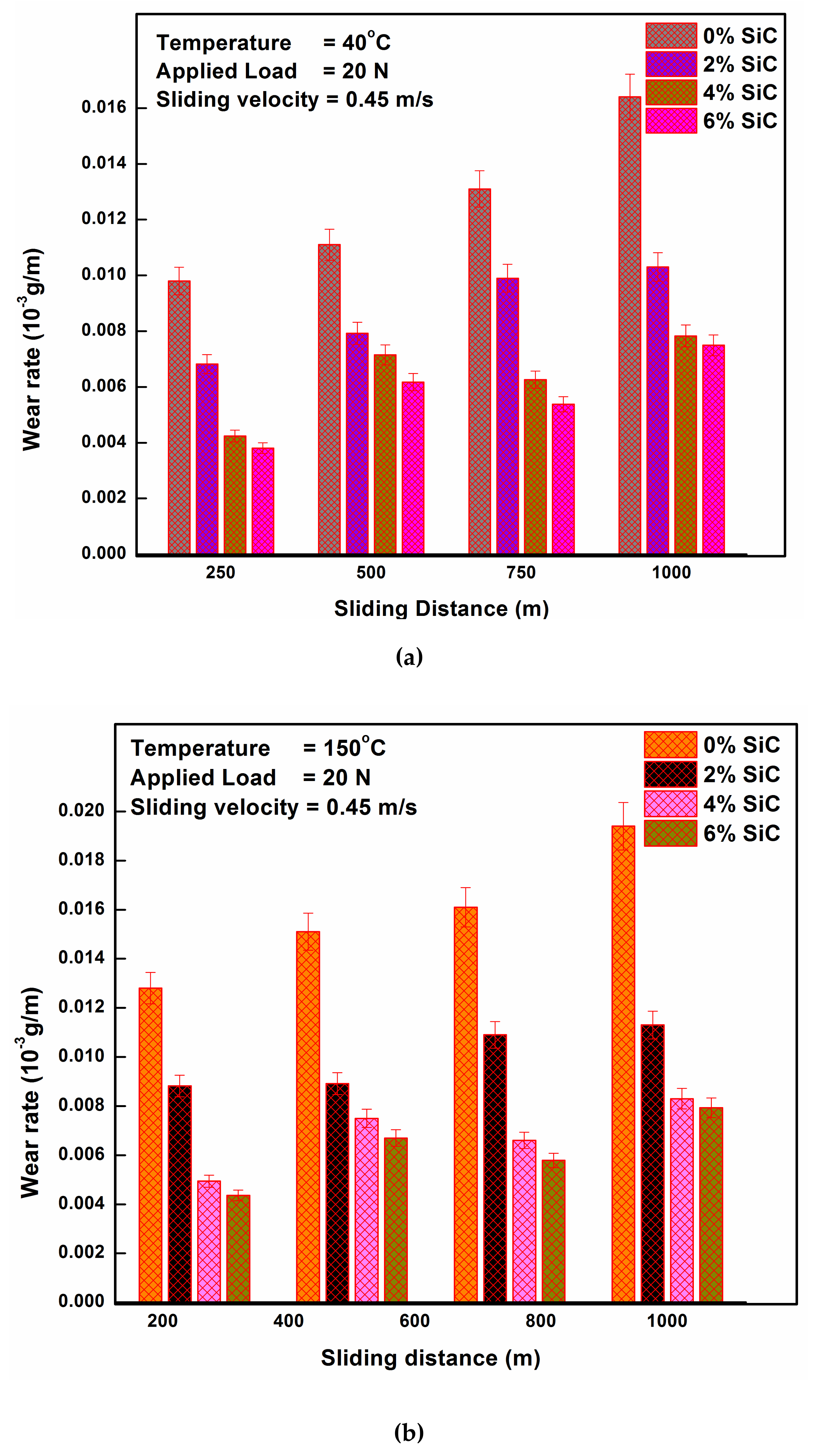

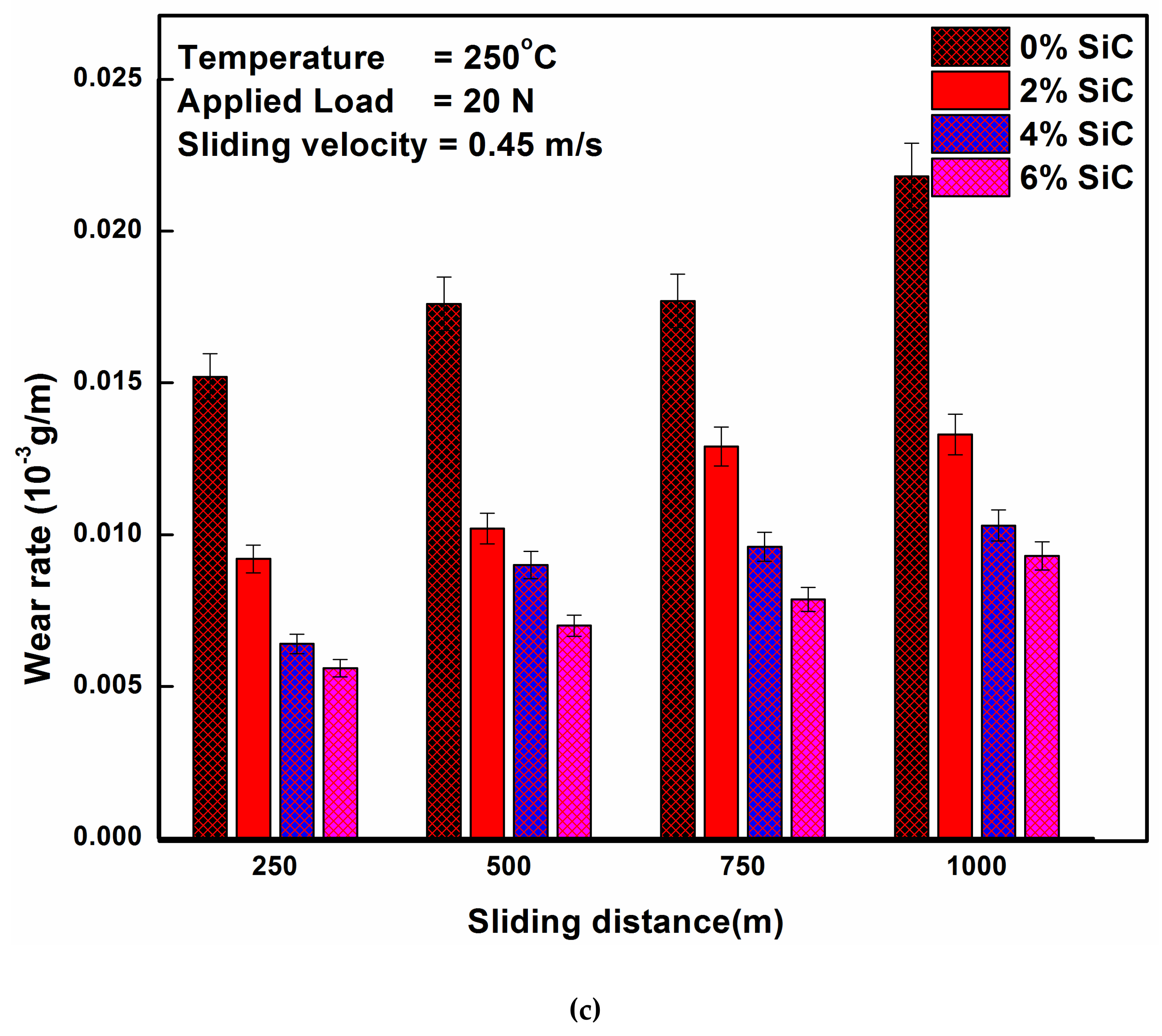

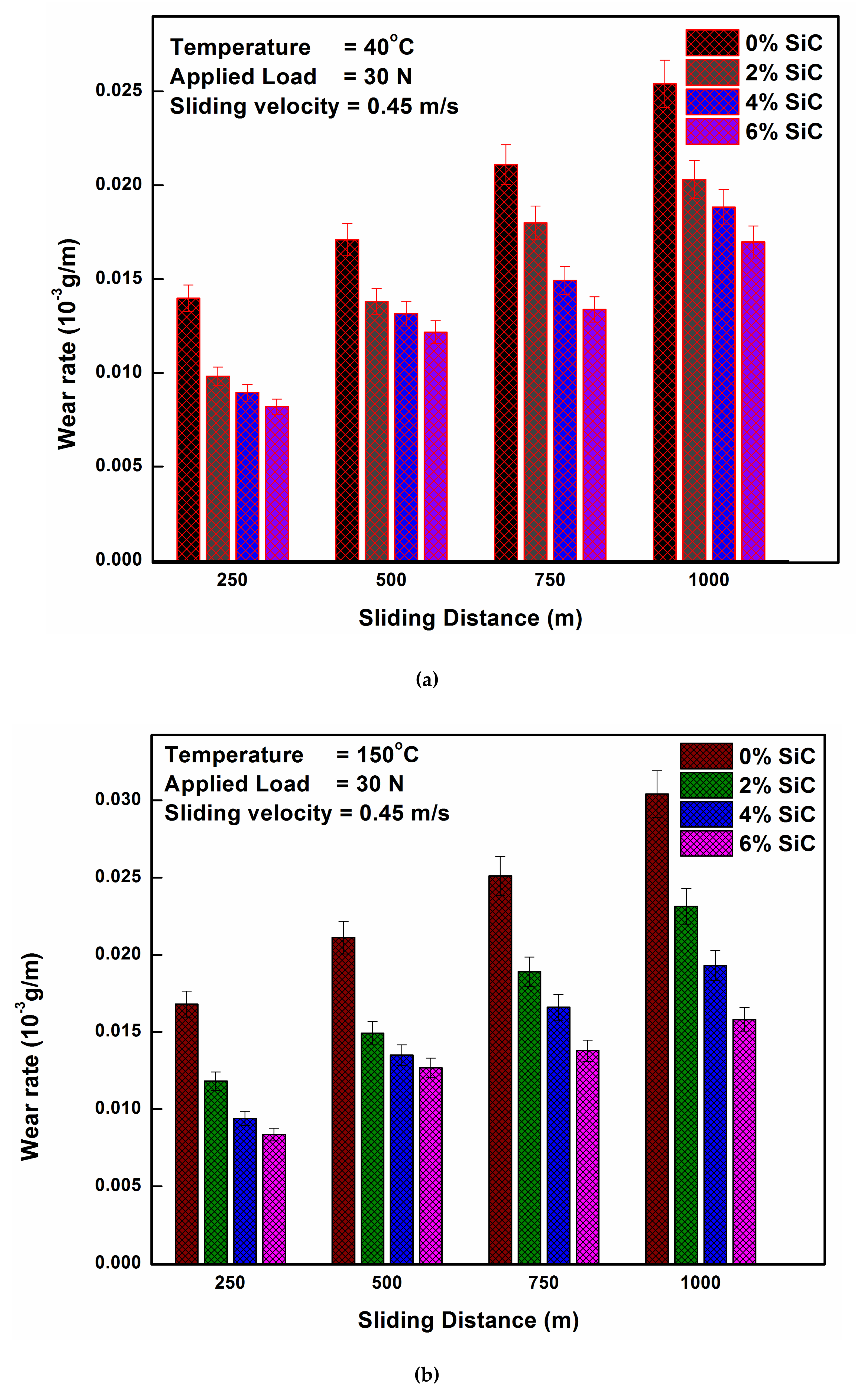

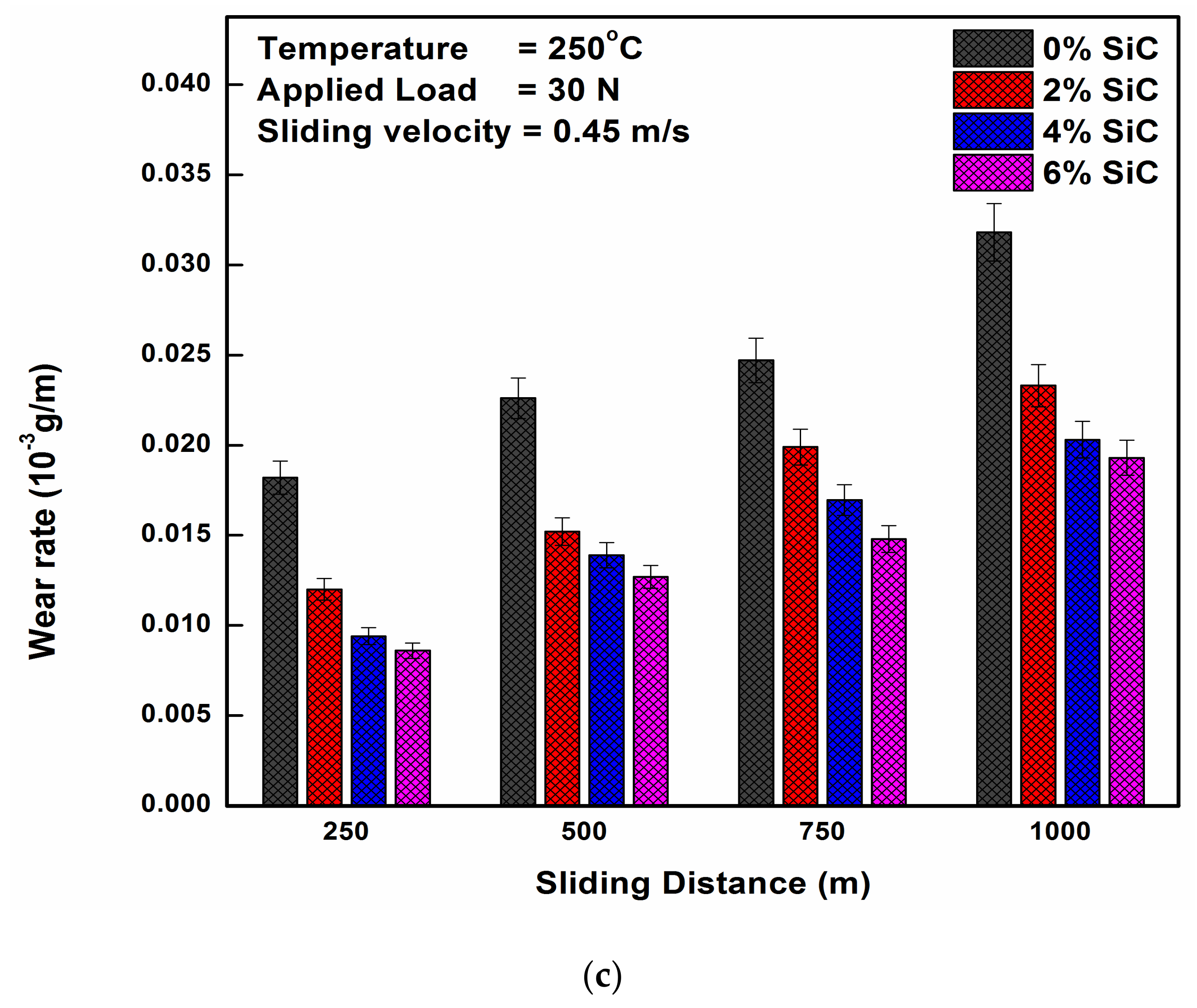

4.4. Wear Behavior of a Developed, Fabricated Composite at Adverse Loading Conditions:

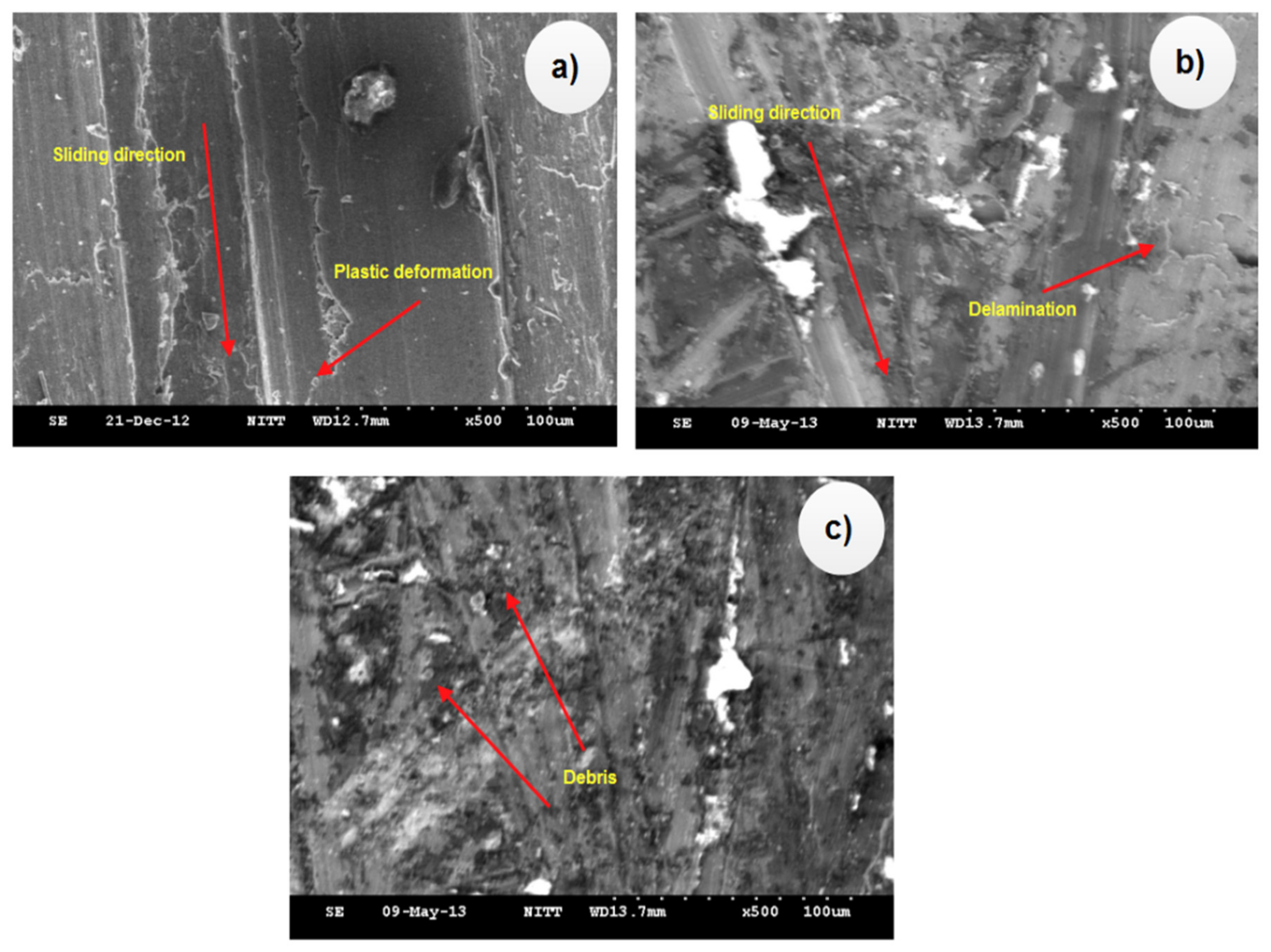

4.5. Worn Out Surface Morphology

5. Conclusions

- The addition of SiCp resulted in a drastic enhancement in hardness (~57%).

- Increments in SiCp wt.% showed increments in wear resistance.

- The occurrence of abrasion and delamination wear was observed on the worn-out surface.

- (a)

- The volumetric wear rate decreases with an increasing wt.% of SiCp, as well as a corresponding decrease in temperature.

- (b)

- The wear resistance decreases at a higher temperature while it drastically increases with an increase in the wt.% of SiCp.

- (c)

- The wear mechanism under the tested conditions was consistently adhesive in nature. The developed composite with a high wt.% of reinforcement agents exhibited abrasive wear mechanisms.

Author Contributions

Funding

Conflicts of Interest

References

- Prakash, K.S.; Moorthy, R.S.; Gopal, P.M.; Kavimani, V. Effect of Reinforcement, Compact Pressure and Hard Ceramic Coating on Aluminium Rock Dust Composite Performance. Int. J. Refract. Met. Hard Mater. 2016, 54, 223–229. [Google Scholar] [CrossRef]

- Kumarasamy, S.P.; Vijayananth, K.; Thankachan, T.; Muthukutti, G.P. Investigations on mechanical and machinability behavior of aluminum/flyash cenosphere/Gr hybrid composites processed through compocasting. J. Appl. Res. Technol. 2017, 15, 430–441. [Google Scholar] [CrossRef]

- Prakash, K.S.; Gopal, P.M.; Kavimani, V. Effect of rock dust, cenosphere and E-waste glass addition on mechanical, wear and machinability behaviour of Al 6061 hybrid composites. Indian J. Eng. Mater. Sci. 2017, 24, 270–282. [Google Scholar]

- Mahmoud, E.R.I.; Takahashi, M.; Shibayanagi, T.; Ikeuchi, K. Wear characteristics of surface-hybrid-MMCs layer fabricated on aluminum plate by friction stir processing. Wear 2010, 268, 1111–1121. [Google Scholar] [CrossRef]

- Afkham, Y.; Khosroshahi, R.A.; Rahimpour, S.; Aavani, C.; Brabazon, D.; Mousavian, R.T. Enhanced mechanical properties of in situ aluminium matrix composites reinforced by alumina nanoparticles. Arch. Civ. Mech. Eng. 2018, 18, 215–226. [Google Scholar] [CrossRef]

- Xu, J.; Qiu, R.; Lian, Z.; Yu, Z.; Yu, P.; Ren, W.; Yu, H. Wear and corrosion resistance of electroforming layer after WEDM for 7075 aluminum alloy. Mater. Res. Express. 2018, 5, 66502. [Google Scholar] [CrossRef]

- Kumar, S.S.; Uthayakumar, M.; Kumaran, S.T.; Varol, T.; Canakci, A. Investigating the surface integrity of aluminium based composites machined by EDM. Def. Technol. 2018, 15, 338–343. [Google Scholar] [CrossRef]

- Prakash, K.S.; Kanagaraj, A.; Gopal, P.M. Dry sliding wear characterization of Al 6061/rock dust composite. Trans. Nonferrous Met. Soc. China 2015, 25, 3893–3903. [Google Scholar] [CrossRef]

- Kavimani, V.; Prakash, K.S.; Pandian, M.A. Influence of r-GO addition on enhancement of corrosion and wear behavior of AZ31 MMC. Appl. Phys. A Mater. Sci. Process. 2017, 123. [Google Scholar] [CrossRef]

- Prakash, K.S.; Gopal, P.M.; Anburose, D.; Kavimani, V. Mechanical, corrosion and wear characteristics of powder metallurgy processed Ti-6Al-4V/B4C metal matrix composites. Ain Shams Eng. J. 2016. [Google Scholar] [CrossRef]

- Kavimani, V.; Prakash, K.S.; Thankachan, T. Investigation of graphene-reinforced magnesium metal matrix composites processed through a solvent-based powder metallurgy route. Bull. Mater. Sci. 2019, 42, 39. [Google Scholar] [CrossRef]

- Kavimani, V.; Prakash, K.S. Tribological behaviour predictions of r-GO reinforced Mg composite using ANN coupled Taguchi approach. J. Phys. Chem. Solids. 2017, 110, 409–419. [Google Scholar] [CrossRef]

- Gopal, P.M.; Prakash, K.S.; Nagaraja, S.; Aravinth, N.K. Effect of weight fraction and particle size of CRT glass on the tribological behaviour of Mg-CRT-BN hybrid composites. Tribol. Int. 2017, 116, 338–350. [Google Scholar] [CrossRef]

- Kavimani, V.; Prakash, K.S.; Rajesh, R.; Rammasamy, D.; Selvaraj, N.B.; Yang, T.; Prabakaran, B.; Jothi, S. Electrodeposition of r-GO/SiCp nano-composites on Magnesium and its Corrosion Behavior in Aqueous Electrolyte. Appl. Surf. Sci. 2016. [Google Scholar] [CrossRef]

- Kavimani, V.; Prakash, K.S.; Gunashri, R.; Sathish, P. Progress in Organic Coatings Corrosion protection behaviour of r-GO/TiO2 hybrid composite coating on Magnesium substrate in 3.5 wt.% NaCl. Prog. Org. Coat. 2018, 125, 358–364. [Google Scholar] [CrossRef]

- Kavimani, V.; Prakash, K.S.; Thankachan, T. Experimental investigations on wear and friction behaviour of SiCp@ r-GO reinforced Mg matrix composites produced through solvent-based powder metallurgy. Compos. Part B Eng. 2019, 162, 508–521. [Google Scholar] [CrossRef]

- Daniel, S.A.A.; Sakthivel, M.; Gopal, P.M.; Sudhagar, S. Study on tribological behaviour of Al/SiCp/MoS 2 hybrid metal matrix composites in high temperature environmental condition. Silicon 2018, 10, 2129–2139. [Google Scholar] [CrossRef]

- Pradhan, S.; Ghosh, S.; Barman, T.K.; Sahoo, P. Tribological behavior of Al-SiCp metal matrix composite under dry, aqueous and alkaline medium. Silicon 2017, 9, 923–931. [Google Scholar] [CrossRef]

- Khan, M.M.; Dixit, G. Evaluation of Microstructure, Mechanical, Thermal and Erosive Wear Behavior of Aluminum-Based Composites. Silicon 2019, 1–12. [Google Scholar] [CrossRef]

- Rouhi, M.; Moazami-Goudarzi, M.; Ardestani, M. Comparison of effect of SiCp and MoS2 on wear behavior of Al matrix composites. Trans. Nonferrous Met. Soc. China 2019, 29, 1169–1183. [Google Scholar] [CrossRef]

- Kumar, N.M.; Kumaran, S.S.; Kumaraswamidhas, L.A. An investigation of mechanical properties and corrosion resistance of Al2618 alloy reinforced with Si3N4, AlN and ZrB2 composites. J. Alloy. Compd. 2015, 652, 244–249. [Google Scholar] [CrossRef]

- Kavimani, V.; Prakash, K.S.; Thankachan, T. Surface characterization and specific wear rate prediction of r-GO/AZ31 composite under dry sliding wear condition. Surf. Interfaces 2017, 6, 143–153. [Google Scholar] [CrossRef]

- Rengasamy, N.V.; Rajkumar, M.; Senthil Kumaran, S. Mining environment applications on Al 4032 - Zrb2 and Tib2 in-situ composites. J. Alloy. Compd. 2016, 658, 757–773. [Google Scholar] [CrossRef]

- Rengasamy, N.V.; Rajkumar, M.; Senthil Kumaran, S. An analysis of mechanical properties and optimization of EDM process parameters of Al 4032 alloy reinforced with Zrb2 and Tib2 in-situ composites. J. Alloy. Compd. 2016, 662, 325–338. [Google Scholar] [CrossRef]

- Paranthaman, P.; Gopal, P.M.; Kumar, N.S. Characterization of Economical Aluminium MMC Reinforced with Weld Slag Particles. In Advances in Manufacturing Technology; Springer: Singapore, 2019; pp. 9–16. [Google Scholar]

- Kavimani, V.; Prakash, K.S.; Starvin, M.S.; Kalidas, B.; Viswamithran, V.; Arun, S.R. Tribo-Surface Characteristics and Wear Behaviour of SiCp@ r-GO/Mg Composite Worn under Varying Control Factor. Silicon 2019, 1–11. [Google Scholar] [CrossRef]

- Kumar, N.M.; Kumaran, S.S.; Kumaraswamidhas, L.A. High temperature investigation on EDM process of Al 2618 alloy reinforced with Si3N4, ALN and ZrB2 in-situ composites. J. Alloy. Compd. 2016, 663, 755–768. [Google Scholar] [CrossRef]

- Kumar, N.M.; Kumaran, S.S.; Kumaraswamidhas, L.A. An investigation of mechanical properties and material removal rate, tool wear rate in EDM machining process of AL2618 alloy reinforced with Si3N4, ALN and ZrB2 in-situ composites. J. Alloy. Compd. 2015, 650, 318–327. [Google Scholar] [CrossRef]

- Kumar, N.M.; Kumaran, S.S.; Kumaraswamidhas, L.A. Wear behaviour of Al 261 8 alloy reinforced with Si3N4, AlN and ZrB2in situ composites at elevated temperatures. Alex. Eng. J. 2016, 55, 19–36. [Google Scholar]

- Kumar, N.M.; Kumaran, S.S.; Kumaraswamidhas, L.A. Aerospace application on Al 2618 with reinforced –Si3N4, ALN and ZrB2 in-situ composites in-situ composites. J. Alloy. Compd. 2016, 672, 238–250. [Google Scholar] [CrossRef]

- Kumar, N.M.; Kumaran, S.S.; Kumaraswamidhas, L.A. An Optimization of Erosive Wear on AA 2618 Reinforced with SI3N4, AlN and ZrB2 In Situ Composites. Appl. Mech. Mater. 2016, 852, 452–458. [Google Scholar] [CrossRef]

- Selvaraj, S.K.; Nagarajan, M.K.; Kumaraswamidhas, L.A. An investigation of abrasive and erosion behaviour of AA 2618 reinforced with Si3N4, ALN and ZrB2 in-situ composites by using optimization techniques. Arch. Civ. Mech. Eng. 2017, 17, 43–54. [Google Scholar] [CrossRef]

- Dolata, A.J. Tribological Properties of AlSi12-Al2O3 Interpenetrating Composite Layers in Comparison with Unreinforced Matrix Alloy. Materials 2017, 10, 1045. [Google Scholar] [CrossRef] [PubMed]

- Toboła, D. Impact of Mechanical Processes as a Pre-Sulphonitriding Treatment on Tribology Properties of Selected P/M Tool Steels. Materials 2019, 12, 3431. [Google Scholar] [CrossRef] [PubMed]

- Lenart, A.; Pawlus, P.; Dzierwa, A. The Effect of Disc Surface Topography on the Dry Gross Fretting Wear of an Equal-Hardness Steel Pair. Materials 2019, 12, 3250. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Wang, X.; Yang, S.; Hou, L.; Wei, Y.; Zhang, Z.; Yang, X. Investigation on Wear Behavior of Cryogenically Treated Ti-6Al-4V Titanium Alloy under Dry and Wet Conditions. Materials 2019, 12, 2850. [Google Scholar] [CrossRef] [PubMed]

| Elements | Si | Fe | Cu | Mn | Ni | Zn | Ti | Pb | Ca | Sn |

|---|---|---|---|---|---|---|---|---|---|---|

| Wt.% | 13.2 | 0.72 | 1.06 | 0.219 | 0.0384 | 0.59 | 0.0419 | 0.079 | 0.0065 | 0.038 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

S, M.; S, S.K.; Narayanan, S.; Srinivasan, K.; Joseph Raj, A.N. Sensor-Assisted Assessment of the Tribological Behavioral Patterns of Al–SiCp Composites under Various Environmental Temperature Conditions. Materials 2019, 12, 4004. https://doi.org/10.3390/ma12234004

S M, S SK, Narayanan S, Srinivasan K, Joseph Raj AN. Sensor-Assisted Assessment of the Tribological Behavioral Patterns of Al–SiCp Composites under Various Environmental Temperature Conditions. Materials. 2019; 12(23):4004. https://doi.org/10.3390/ma12234004

Chicago/Turabian StyleS, Manivannan, Senthil Kumaran S, Srinivasan Narayanan, Kathiravan Srinivasan, and Alex Noel Joseph Raj. 2019. "Sensor-Assisted Assessment of the Tribological Behavioral Patterns of Al–SiCp Composites under Various Environmental Temperature Conditions" Materials 12, no. 23: 4004. https://doi.org/10.3390/ma12234004

APA StyleS, M., S, S. K., Narayanan, S., Srinivasan, K., & Joseph Raj, A. N. (2019). Sensor-Assisted Assessment of the Tribological Behavioral Patterns of Al–SiCp Composites under Various Environmental Temperature Conditions. Materials, 12(23), 4004. https://doi.org/10.3390/ma12234004