Low Temperature Influence on the Behavior of Viscoelastic Layer of the Pounding Tuned Mass Damper

Abstract

1. Introduction

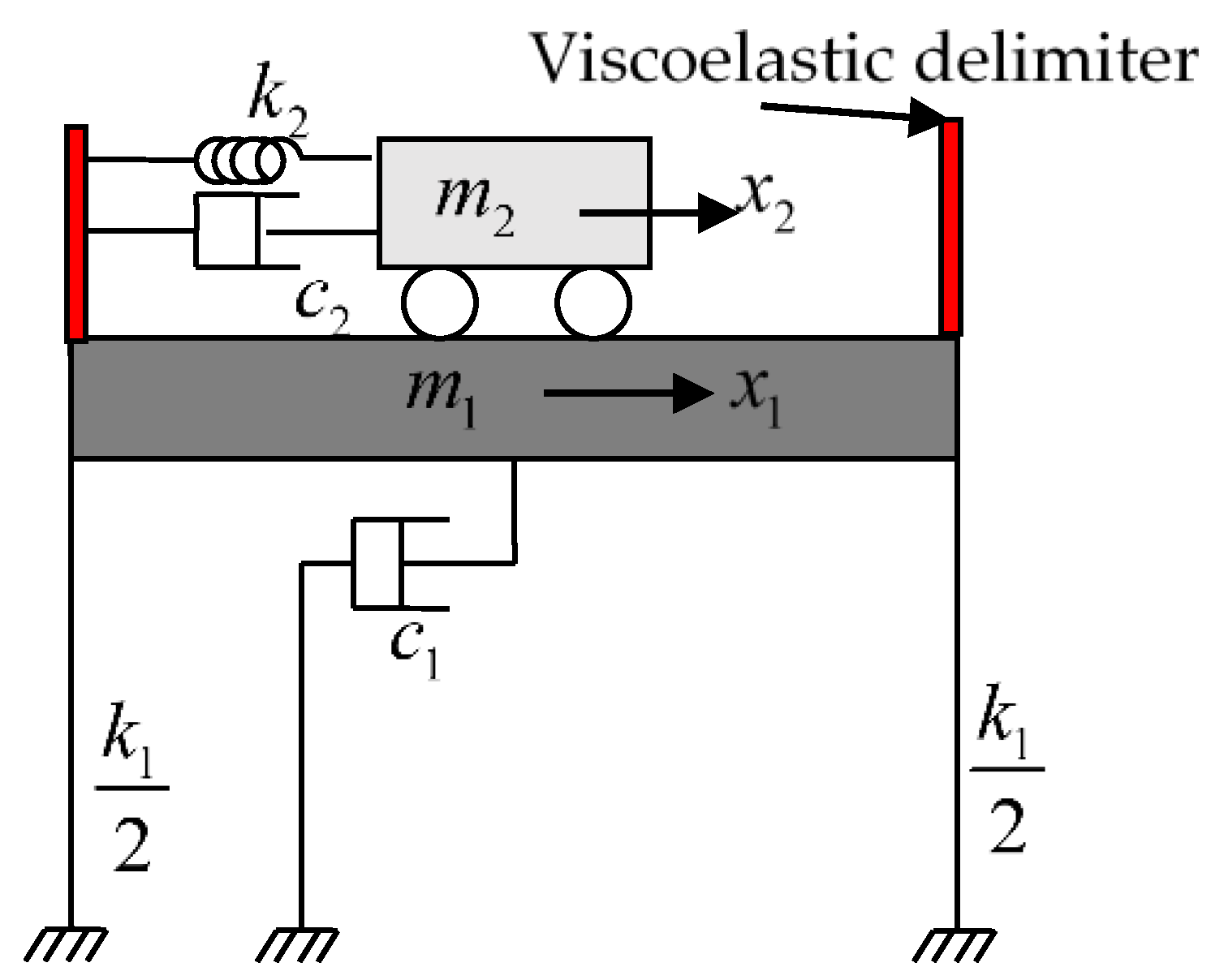

2. Impact Damping Property of the Viscoelastic Material in a PTMD

2.1. Pounding Stiffness

2.2. Energy Dissipated per Impact Cycle

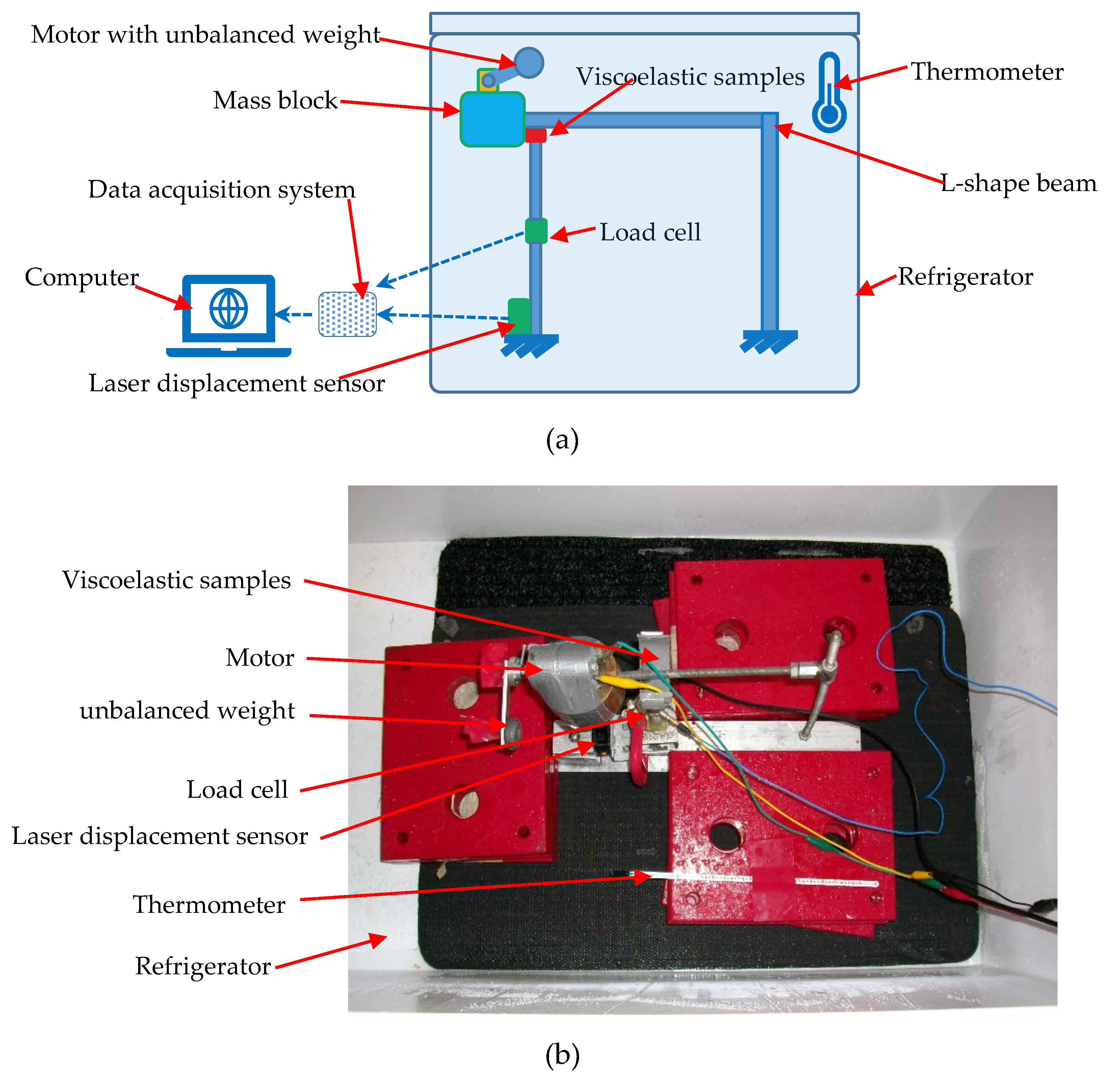

3. Experimental Setup

4. Results and Discussion

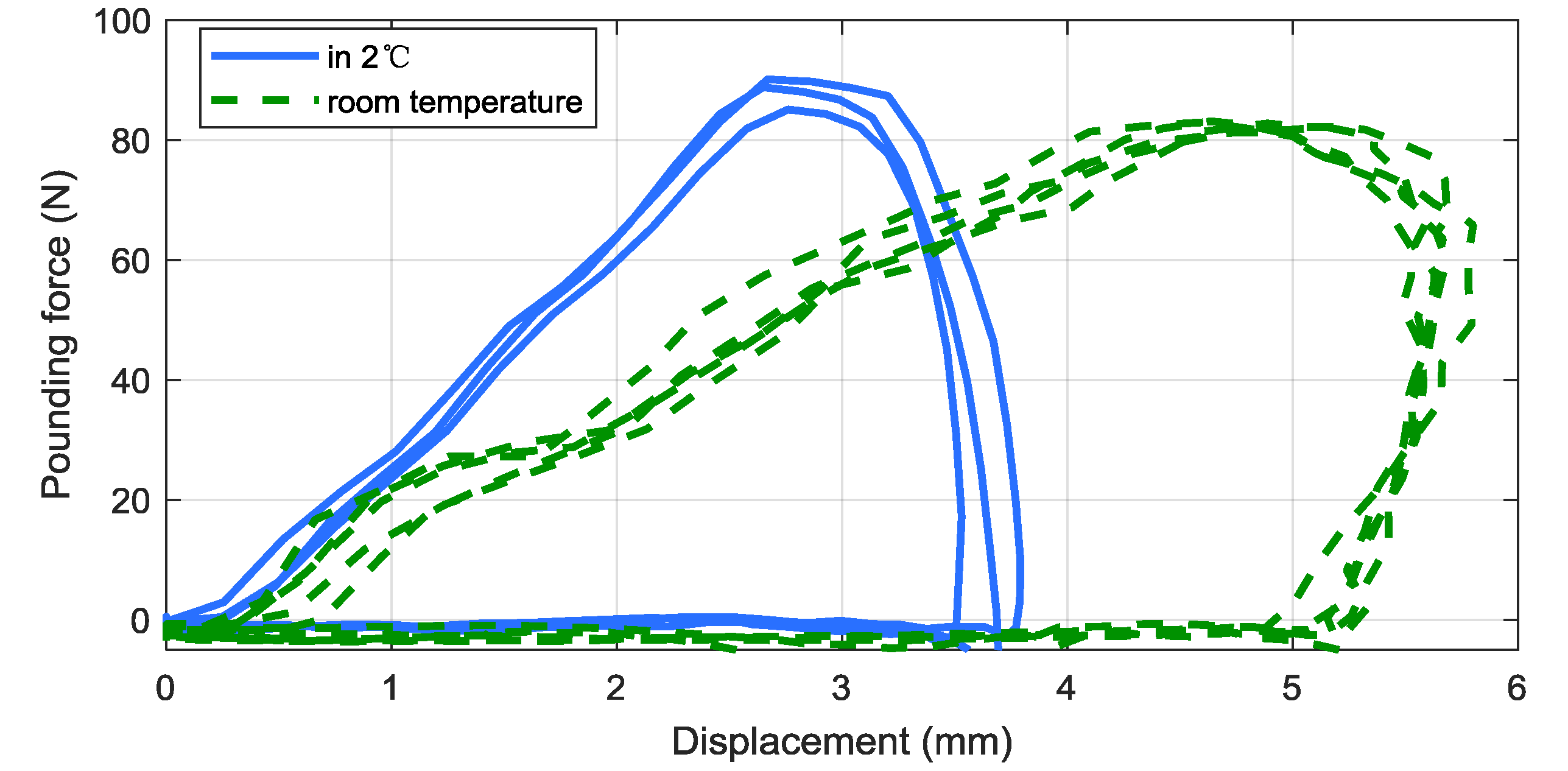

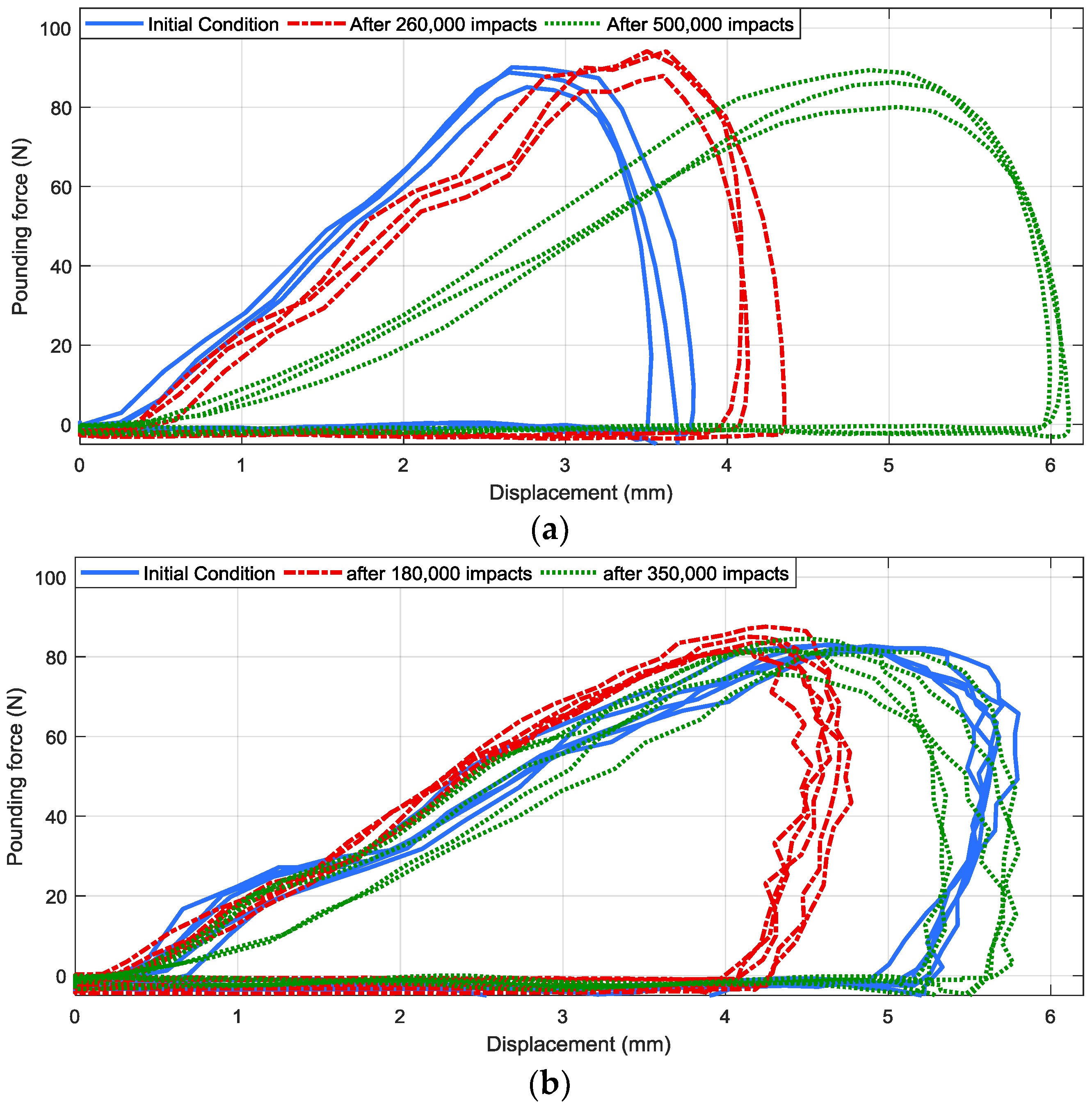

4.1. Impact Damping Behavior in Low Temperature

4.2. Impact Fatigue Test in Low Temperature

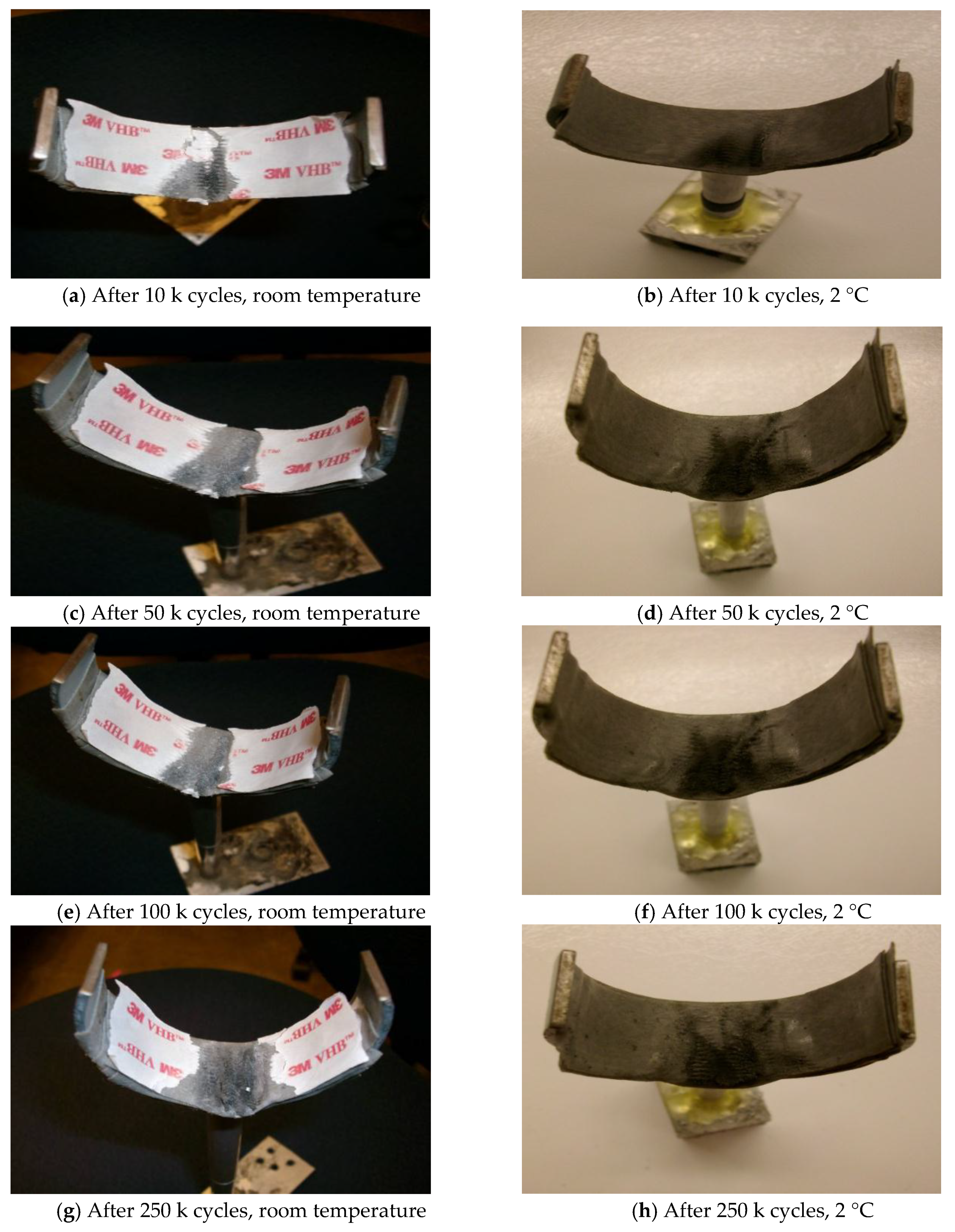

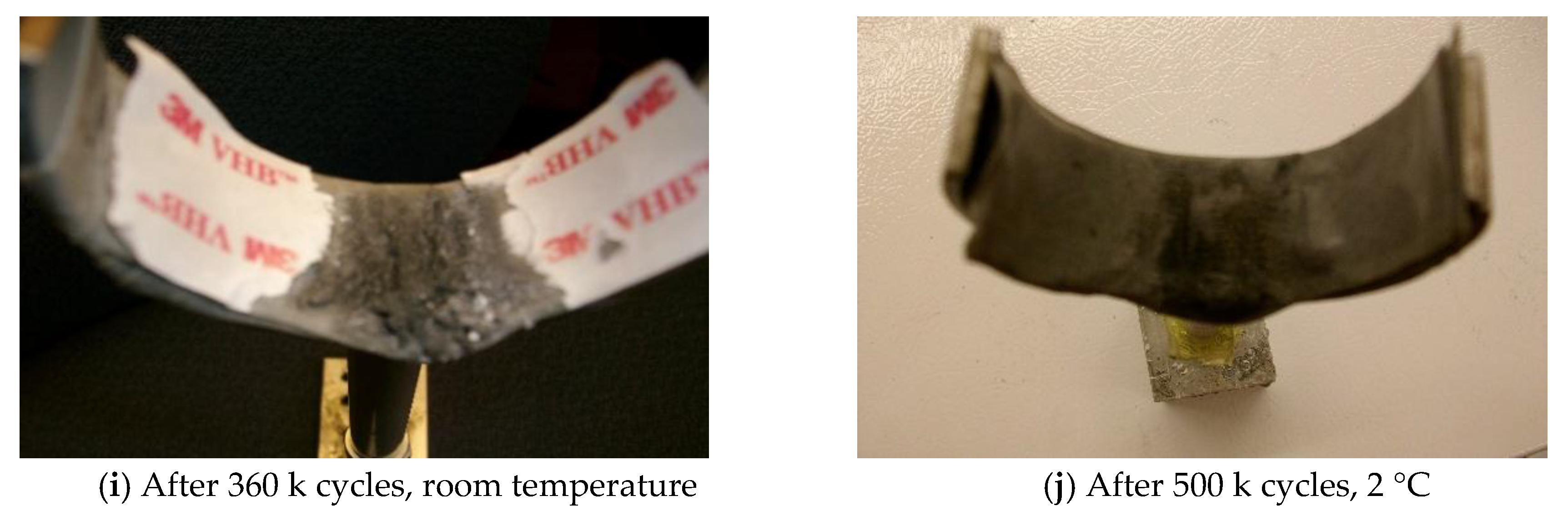

4.2.1. Appearance

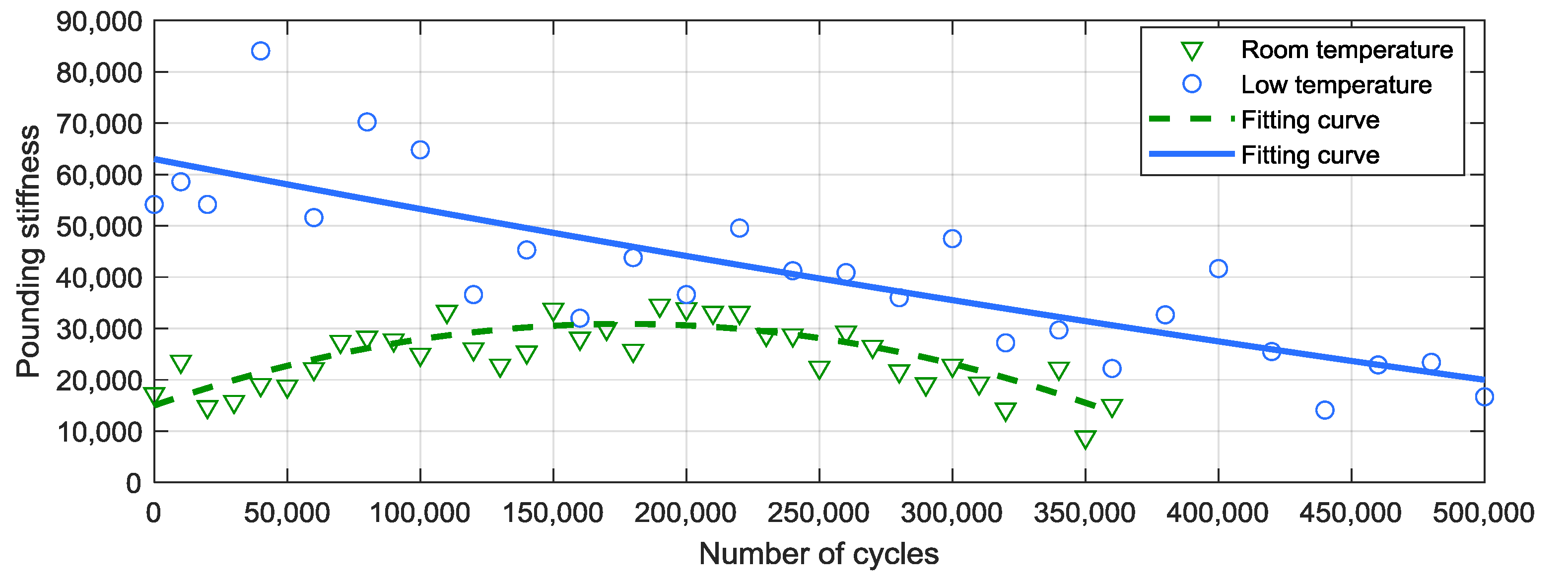

4.2.2. Pounding Stiffness

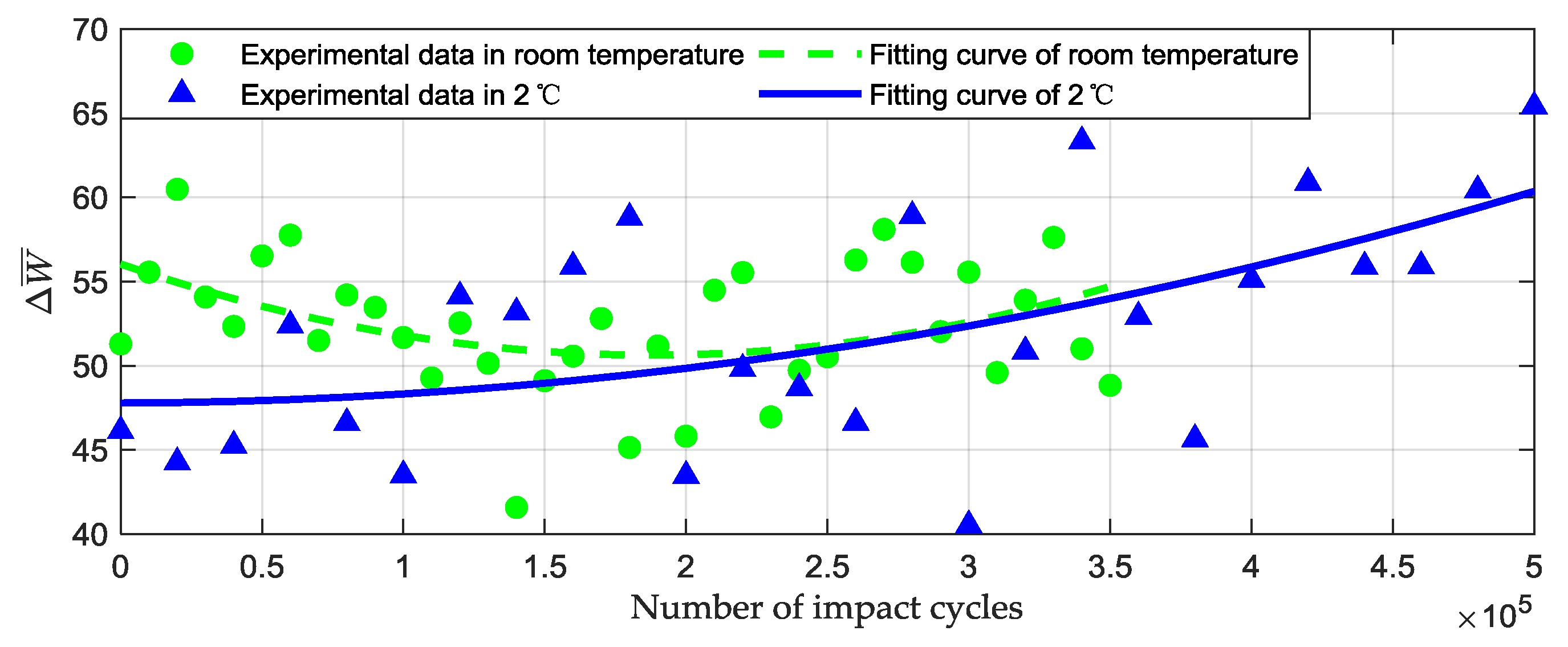

4.2.3. Damping Capacity

5. Conclusions and Future Work

- When ambient temperature drops from room temperature to 2 °C, the pounding stiffness of the viscoelastic material is significantly increased, while its energy dissipation ability is slightly decreased, indicating that the PTMD can be applied for vibration control of structures in the low temperature environment.

- In low temperatures, continuous pounding will cause impact fatigue of the viscoelastic material of the PTMD, with its pounding stiffness gradually reduced and the energy dissipation ability increased. This is different from the room temperature case.

Author Contributions

Funding

Conflicts of Interest

References

- Fu, W.; Zhang, C.; Sun, L.; Askari, M.; Samali, B.; Chung, K.; Sharafi, P. Experimental investigation of a base isolation system incorporating MR dampers with the high-order single step control algorithm. Appl. Sci. 2017, 7, 344. [Google Scholar] [CrossRef]

- Liu, M.; Li, H.; Song, G.; Ou, J. Investigation of vibration mitigation of stay cables incorporated with superelastic shape memory alloy dampers. Smart Mater. Struct. 2007, 16, 2202. [Google Scholar] [CrossRef]

- Mahdisoozani, H.; Mohsenizadeh, M.; Bahiraei, M.; Kasaeian, A.; Daneshvar, A.; Goodarzi, M.; Safaei, M.R. Performance Enhancement of Internal Combustion Engines through Vibration Control: State of the Art and Challenges. Appl. Sci. 2019, 9, 406. [Google Scholar] [CrossRef]

- Zhong, B.; Deng, B.; Zhao, H. Simulation Model and Method for Active Torsional Vibration Control of an HEV. Appl. Sci. 2019, 9, 34. [Google Scholar] [CrossRef]

- Agrawal, B.N.; Mcclelland, R.S.; Song, G. Attitude control of flexible spacecraft using pulse-width pulse-frequency modulated thrusters. Space Technol. 1997, 17, 15–34. [Google Scholar] [CrossRef]

- Huo, L.; Song, G.; Nagarajaiah, S.; Li, H. Semi-active vibration suppression of a space truss structure using a fault tolerant controller. J. Vib. Control 2012, 18, 1436–1453. [Google Scholar] [CrossRef]

- Tang, J.; Cao, D.; Ren, F.; Li, H. Design and Experimental Study of a VCM-Based Whole-Spacecraft Vibration Isolation System. J. Aerosp. Eng. 2018, 31, 4018045. [Google Scholar] [CrossRef]

- Song, G.; Cai, S.; Li, H. Energy dissipation and vibration control: Modeling, algorithm, and devices. Appl. Sci. 2017, 7, 801. [Google Scholar] [CrossRef]

- Ma, G.; Xu, M.; Zhang, S.; Zhang, Y.; Liu, X. Active Vibration Control of an Axially Moving Cantilever Structure Using PZT Actuator. J. Aerosp. Eng. 2018, 31, 4018049. [Google Scholar] [CrossRef]

- Gu, H.; Song, G. Active vibration suppression of a flexible beam with piezoceramic patches using robust model reference control. Smart Mater. Struct. 2007, 16, 1453. [Google Scholar] [CrossRef]

- Xu, X.; Wu, W.; Zhang, W. Sliding mode control for a nonlinear aeroelastic system through backstepping. J. Aerosp. Eng. 2017, 31, 4017080. [Google Scholar] [CrossRef]

- Xu, Z.; Xu, F.; Chen, X. Intelligent vibration isolation and mitigation of a platform by using MR and VE devices. J. Aerosp. Eng. 2016, 29, 4016010. [Google Scholar] [CrossRef]

- Wang, W.; Hua, X.; Wang, X.; Wu, J.; Sun, H.; Song, G. Mechanical behavior of magnetorheological dampers after long-term operation in a cable vibration control system. Struct. Control Health Monit. 2019, 26, e2280. [Google Scholar] [CrossRef]

- Huang, Z.W.; Hua, X.G.; Chen, Z.Q.; Niu, H.W. Modeling, Testing, and Validation of an Eddy Current Damper for Structural Vibration Control. J. Aerosp. Eng. 2018, 31, 4018063. [Google Scholar] [CrossRef]

- Huang, B.; Lao, Y.; Chen, J.; Song, Y. Dynamic Response Analysis of a Frame Structure with Superelastic Nitinol SMA Helical Spring Braces for Vibration Reduction. J. Aerosp. Eng. 2018, 31, 4018096. [Google Scholar] [CrossRef]

- Sun, W.; Wang, Z.; Liu, R.; Yan, X. Inverse identification of the frequency-dependent mechanical parameters of a viscoelastic core layer based on the vibration response. Appl. Sci. 2017, 7, 455. [Google Scholar] [CrossRef]

- Demetriou, D.; Nikitas, N. A novel hybrid semi-active mass damper configuration for structural applications. Appl. Sci. 2016, 6, 397. [Google Scholar] [CrossRef]

- Li, C.; Zhuang, T.; Zhou, S.; Xiao, Y.; Hu, G. Passive Vibration Control of a Semi-Submersible Floating Offshore Wind Turbine. Appl. Sci. 2017, 7, 509. [Google Scholar] [CrossRef]

- Tan, J.; Ho, M.; Chun, S.; Zhang, P.; Jiang, J. Experimental Study on Vibration Control of Suspended Piping System by Single-Sided Pounding Tuned Mass Damper. Appl. Sci. 2019, 9, 285. [Google Scholar] [CrossRef]

- Xu, K.; Bi, K.; Han, Q.; Li, X.; Du, X. Using tuned mass damper inerter to mitigate vortex-induced vibration of long-span bridges: Analytical study. Eng. Struct. 2019, 182, 101–111. [Google Scholar] [CrossRef]

- Wang, D.; Wu, C.; Zhang, Y.; Li, S. Study on vertical vibration control of long-span steel footbridge with tuned mass dampers under pedestrian excitation. J. Constr. Steel Res. 2019, 154, 84–98. [Google Scholar] [CrossRef]

- Tho, N.C.; Ta, N.T.; Thom, D.V. New Numerical Results from Simulations of Beams and Space Frame Systems with a Tuned Mass Damper. Materials 2019, 12, 1329. [Google Scholar] [CrossRef] [PubMed]

- Frahm, H. Device for Damping Vibrations of Bodies. U.S. Patent 0989958, 18 April 1911. [Google Scholar]

- Wu, X.; Wang, J.; Zhou, J. Seismic Performance Analysis of a Connected Multitower Structure with FPS and Viscous Damper. Shock Vib. 2018. [Google Scholar] [CrossRef]

- Kim, S.; Lee, C. Peak response of frictional tuned mass dampers optimally designed to white noise base acceleration. Mech. Syst. Signal Process. 2019, 117, 319–332. [Google Scholar] [CrossRef]

- Jiang, J.; Ho, S.C.M.; Markle, N.J.; Wang, N.; Song, G. Design and control performance of a frictional tuned mass damper with bearing–shaft assemblies. J. Vib. Control 2019, 25, 1812–1822. [Google Scholar] [CrossRef]

- Chen, J.; Lu, G.; Li, Y.; Wang, T.; Wang, W.; Song, G. Experimental study on robustness of an eddy current-tuned mass damper. Appl. Sci. 2017, 7, 895. [Google Scholar] [CrossRef]

- Wang, W.; Dalton, D.; Hua, X.; Wang, X.; Chen, Z.; Song, G. Experimental study on vibration control of a submerged pipeline model by eddy current tuned mass damper. Appl. Sci. 2017, 7, 987. [Google Scholar] [CrossRef]

- Weber, F. Optimal semi-active vibration absorber for harmonic excitation based on controlled semi-active damper. Smart Mater. Struct. 2014, 23, 95033. [Google Scholar] [CrossRef]

- Weber, F.; Maślanka, M. Precise stiffness and damping emulation with MR dampers and its application to semi-active tuned mass dampers of Wolgograd Bridge. Smart Mater. Struct. 2013, 23, 15019. [Google Scholar] [CrossRef]

- Weber, F. Semi-active vibration absorber based on real-time controlled MR damper. Mech. Syst. Signal Process. 2014, 46, 272–288. [Google Scholar] [CrossRef]

- Mishra, S.K.; Gur, S.; Chakraborty, S. An improved tuned mass damper (SMA-TMD) assisted by a shape memory alloy spring. Smart Mater. Struct. 2013, 22, 95016. [Google Scholar] [CrossRef]

- Zhang, P.; Song, G.; Li, H.; Lin, Y. Seismic Control of Power Transmission Tower Using Pounding TMD. J. Eng. Mech. 2013, 139, 1395–1406. [Google Scholar] [CrossRef]

- Wang, W.; Hua, X.; Chen, Z.; Wang, X.; Song, G. Modeling, simulation, and validation of a pendulum-pounding tuned mass damper for vibration control. Struct. Control Health Monit. 2019, 26, e2326. [Google Scholar] [CrossRef]

- Tian, L.; Gai, X. Wind-induced vibration control of power transmission tower using pounding tuned mass damper. J. Vibroeng. 2015, 17, 3693–3701. [Google Scholar]

- Song, G.B.; Zhang, P.; Li, L.Y.; Singla, M.; Patil, D.; Li, H.; Mo, Y.L. Vibration Control of a Pipeline Structure Using Pounding Tuned Mass Damper. J. Eng. Mech. 2016, 142, 4016031. [Google Scholar] [CrossRef]

- Li, H.; Zhang, P.; Song, G.; Patil, D.; Mo, Y. Robustness study of the pounding tuned mass damper for vibration control of subsea jumpers. Smart Mater. Struct. 2015, 24, 095001. [Google Scholar] [CrossRef]

- Zhang, P.; Li, L.; Patil, D.; Singla, M.; Li, H.N.; Mo, Y.L.; Song, G. Parametric study of pounding tuned mass damper for subsea jumpers. Smart Mater. Struct. 2015, 25, 15028. [Google Scholar] [CrossRef]

- Jiang, J.; Zhang, P.; Patil, D.; Li, H.; Song, G. Experimental studies on the effectiveness and robustness of a pounding tuned mass damper for vibration suppression of a submerged cylindrical pipe. Struct. Control Health Monit. 2017, 24, e2027. [Google Scholar] [CrossRef]

- Xue, Q.; Zhang, J.; He, J.; Zhang, C. Control Performance and Robustness of Pounding Tuned Mass Damper for Vibration Reduction in SDOF Structure. Shock Vib. 2016, 2016, 1–15. [Google Scholar] [CrossRef]

- Wu, Q.; Zhao, X.; He, S.; Tang, W.; Zheng, R. A Bufferable Tuned-Mass Damper of an Offshore Platform against Stroke and Response Delay Problems under Earthquake Loads. Shock Vib. 2016, 2016, 1–12. [Google Scholar] [CrossRef]

- Lin, W.; Wang, Q.; Li, J.; Chen, S.; Qi, A. Shaking table test of pounding tuned mass damper (PTMD) on a frame structure under earthquake excitation. Comput. Concr. 2017, 20, 545–553. [Google Scholar]

- Xue, Q.; Zhang, J.; He, J.; Li, Y.; Song, X. Reducing vibration performance of pounding TMD on high-rise steel structures subject to seismic effects. J. Harbin Eng. Univ. 2017, 38, 412–418. [Google Scholar]

- Wang, W.; Hua, X.; Wang, X.; Chen, Z.; Song, G. Optimum design of a novel pounding tuned mass damper under harmonic excitation. Smart Mater. Struct. 2017, 26, 055024. [Google Scholar] [CrossRef]

- Wang, W.; Hua, X.; Wang, X.; Chen, Z.; Song, G. Numerical modeling and experimental study on a novel pounding tuned mass damper. J. Vib. Control 2017, 24, 4023–4036. [Google Scholar] [CrossRef]

- Wang, W.; Wang, X.; Hua, X.; Song, G.; Chen, Z. Vibration control of vortex-induced vibrations of a bridge deck by a single-side pounding tuned mass damper. Eng. Struct. 2018, 173, 61–75. [Google Scholar] [CrossRef]

- Yin, X.; Liu, Y.; Song, G.; Mo, Y.L. Suppression of Bridge Vibration Induced by Moving Vehicles Using Pounding Tuned Mass Dampers. J. Bridge Eng. 2018, 23, 04018047. [Google Scholar] [CrossRef]

- Li, L.; Song, G.; Singla, M.; Mo, Y. Vibration control of a traffic signal pole using a pounding tuned mass damper with viscoelastic materials (II): Experimental verification. J. Vib. Control 2015, 21, 670–675. [Google Scholar] [CrossRef]

- Zhao, N.; Lu, C.; Chen, M.; Luo, N.; Liu, C. Parametric Study of Pounding Tuned Mass Damper Based on Experiment of Vibration Control of a Traffic Signal Structure. J. Aerosp. Eng. 2018, 31, 4018108. [Google Scholar] [CrossRef]

- Chang, K.C.; Soong, T.T.; Oh, S.T.; Lai, M.L. Effect of Ambient Temperature on Viscoelastically damped structure. J. Struct. Eng. 1992, 118, 1955–1973. [Google Scholar] [CrossRef]

- Tsai, C.S. Temperature Effect of Viscoelastic Dampers during Earthquakes. J. Struct. Eng. 1994, 120, 394–409. [Google Scholar] [CrossRef]

- Shen, K.L.; Soong, T.T.; Chang, K.C.; Lai, M.L. Seismic behaviour of reinforced concrete frame with added viscoelastic dampers. Eng. Struct. 1995, 17, 372–380. [Google Scholar] [CrossRef]

- Chronopoulos, D.; Ichchou, M.; Troclet, B.; Bareille, O. Thermal effects on the sound transmission through aerospace composite structures. Aerosp. Sci. Technol. 2013, 30, 192–199. [Google Scholar] [CrossRef]

- Ramrakhyani, D.S.; Lesieutre, G.A.; Smith, E.C. Modeling of elastomeric materials using nonlinear fractional derivative and continuously yielding friction elements. Int. J. Solids Struct. 2004, 41, 3929–3948. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, S.; Xu, C. Experimental and numerical study on long-span reticulate structure with multidimensional high-damping earthquake isolation devices. J. Sound Vib. 2014, 333, 3044–3057. [Google Scholar] [CrossRef]

- Chronopoulos, D.; Antoniadis, I.; Collet, M.; Ichchou, M. Enhancement of wave damping within metamaterials having embedded negative stiffness inclusions. Wave Motion 2015, 58, 165–179. [Google Scholar] [CrossRef]

- Chronopoulos, D.; Antoniadis, I.; Ampatzidis, T. Enhanced acoustic insulation properties of composite metamaterials having embedded negative stiffness inclusions. Extrem. Mech. Lett. 2017, 12, 48–54. [Google Scholar] [CrossRef]

- Liu, C.; Shi, Y. An Improved Analytical Solution for Process-Induced Residual Stresses and Deformations in Flat Composite Laminates Considering Thermo-Viscoelastic Effects. Materials 2018, 11, 2506. [Google Scholar] [CrossRef]

- Chronopoulos, D.; Ampatzidis, T. A wave and finite element approach for computing the optimal damping layer characteristics for composite structures. Noise Control Eng. J. 2018, 66, 251–267. [Google Scholar] [CrossRef]

- Lewandowski, R. Influence of Temperature on the Dynamic Characteristics of Structures with Viscoelastic Dampers. J. Struct. Eng. 2018, 145, 4018245. [Google Scholar] [CrossRef]

- Righetti, M.; Cinelli, P.; Mallegni, N.; Massa, C.; Aliotta, L.; Lazzeri, A. Thermal, Mechanical, Viscoelastic and Morphological Properties of Poly(lactic acid) based Biocomposites with Potato Pulp Powder Treated with Waxes. Materials 2019, 12, 990. [Google Scholar] [CrossRef]

- Olienick Filho, E.G.; Lopes, E.M.O.; Bavastri, C.A. Integrated Dynamic Characterization of Thermorheologically Simple Viscoelastic Materials Accounting for Frequency, Temperature, and Preload Effects. Materials 2019, 12, 1962. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Huo, L.; Song, G. Impact Fatigue of Viscoelastic Materials Subjected to Pounding. Appl. Sci. 2018, 8, 117. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, P.; Jiang, J.; Lu, G. Low Temperature Influence on the Behavior of Viscoelastic Layer of the Pounding Tuned Mass Damper. Materials 2019, 12, 3986. https://doi.org/10.3390/ma12233986

Zhang P, Jiang J, Lu G. Low Temperature Influence on the Behavior of Viscoelastic Layer of the Pounding Tuned Mass Damper. Materials. 2019; 12(23):3986. https://doi.org/10.3390/ma12233986

Chicago/Turabian StyleZhang, Peng, Jinwei Jiang, and Guangtao Lu. 2019. "Low Temperature Influence on the Behavior of Viscoelastic Layer of the Pounding Tuned Mass Damper" Materials 12, no. 23: 3986. https://doi.org/10.3390/ma12233986

APA StyleZhang, P., Jiang, J., & Lu, G. (2019). Low Temperature Influence on the Behavior of Viscoelastic Layer of the Pounding Tuned Mass Damper. Materials, 12(23), 3986. https://doi.org/10.3390/ma12233986