1. Introduction

The application of porous media in sound fields is a widely applied measure for noise mitigation. Thereby, two main applications are common. The first application is the use of porous absorbers and resonators to introduce acoustic damping into sound fields. This is widely applied in room acoustics in order to adjust the reverberation time of the room. In this field, resonators are mainly applied in the low frequency regime and for specific, narrow frequency bands. On the other side, porous absorbers are applied in the mid and high frequency regime, as the absorption performance of these materials basically increases with the frequency. The use of both, resonators and porous absorbers, is widely investigated and well understood, from the vast field of publications on this topic see, e.g., [

1,

2,

3,

4]. Another application of porous media is the reduction of noise generation in flows, i.e., in the field of aeroacoustics. Whereas porous liners oftentimes are applied to gas turbine aircraft engines with the goal of absorption (e.g., [

5,

6,

7]), a relatively new field is the application of porous liners for reducing the flow noise generation. For the acoustics of aircraft, one of the major airframe noise sources is the noise generation at the aircraft wing’s trailing edge. The work presented in [

8,

9,

10,

11] shows the effect and investigates the application of porous media to mitigate the noise generation. Within the Collaborative Research Center (CRC) 880 at TU Braunschweig, several investigations have been conducted to reduce the aeroacoustic noise at the trailing edge by manufacturing the trailing edge of porous material. Basic design recommendations for this application are given in [

12] and a manufacturing process for trailing edges with spatially varying material parameters is presented in [

13]. In [

14,

15], numerical investigations are carried out that investigate the influence of porous liners that are placed on the outer skin of an aircraft on the structure borne sound energy flow into the airframe under an aeroacoustic load. It can be shown that the application of porous material reduces the sound energy that is transmitted into the structure and, hence, the vibration of the airframe is reduced. An investigation regarding the long-term application of porous media is done in [

16]. This work covers the effect of degradation of the porous material due to fouling and staining and identifies the change of the material parameters during the degradation process.

The investigations mentioned above are just a small and far from exhaustive overview of applications for porous materials in acoustics. To achieve a sufficient performance, absorbers have to be designed and produced according to the design requirements. Nevertheless, the design and manufacturing of porous materials is a challenging task. The absorption characteristics highly depend on the microstructure of the materials such as pore geometry and pore size, as these properties influence macroscopic properties such as flow resistivity and surface impedance. For noise mitigation and reverberation time adjustment in interior applications, fibrous porous media such as mineral wool or melamine foams are widely applied. These materials incorporate good absorption characteristics combined with low interaction with the surrounding environment. On the other side, their microstructure is basically unknown. Hence, the characterization of the material refers to macroscopic parameters, such as the flow resistivity and the porosity and to homogenized quantities such as the tortuosity.

A promising approach to manufacture sound absorbers is the application of 3D-printing technologies. 3D-printing allows for the manufacturing of complex shapes directly from Computer-Aided Design (CAD) data. Thereby, the geometries can be designed very freely, since the limitations of conventional manufacturing technologies, e.g., grinding or casting, do not apply. For porous materials, this results in specimen whose microstructure is known and hence can be related to the macroscopic homogenized quantities. In the literature, some examples can be found where 3D-printing technology has been applied to produce sound absorbers. For example, in [

17], absorbers are manufactured that apply the principle of destructive interference. Thereby, two connected ducts of different length are produced. The sound waves enter and travel through both ducts separately. The length difference between the ducts produces a phase shift of both traveling waves of 180

at the connection point of the ducts. This leads to a destructive interference effect. However, as the phase shift occurs only for one specific wavelength, the absorption characteristic is rather narrow-banded. This effect is reduced be using several absorbers with different target frequencies together within one sample. Another approach for sound attenuation is shown in [

18]. The authors present a structure that reduces sound transmission in ducts while being permeable and thus can be applied within fluid flows. The working principle also employs destructive interference, hence the ability for a high sound transmission loss is available only in a narrow frequency band. An approach that aims for sound absorption in a broader frequency range is presented in [

19]. The authors present a multilayered perforated panel absorber and manufacture parts of the structure using 3D-printing technology.

The acoustic properties of porous media can be estimated using several material models of different complexity, among which the

Biot-model is the most complex one and seen as the reference [

20]. The models estimate the acoustic behavior based on homogenized quantities, such as airflow resistivity, tortuosity, porosity and others. In the following, these are referred to as the

Biot-parameters. Using these models, the tailoring of porous media to specific applications becomes possible. For this tailoring process, two prerequisites are necessary. First, the microgeometry of the porous absorber has to be known and can be manufactured with high accuracy. Second, the relation of the microstructure and the

Biot-parameters has to be known. This second prerequisite is crucial as it allows the prediction of the acoustic behavior based on the specimen geometry. Nevertheless, this relation is rarely investigated. Within this contribution, the manufacturing and optimization of porous absorbers based on the

Biot-model is shown. Thereby, measures are identified that allow for a tailoring of the porous material by adjusting geometric quantities of the investigated specimen. To achieve the first prerequisite, the porous specimen are manufactured using 3D-printing technology. To relate the

Biot-parameters to the microstructure, the parameters are inversely estimated from measurements and related to the manufactured geometry. These results are backed up with a sensitivity analysis and an uncertainty quantification in order to obtain the most promising measures for tailoring 3D-printed porous absorbers to specific applications.

2. Specimen Description

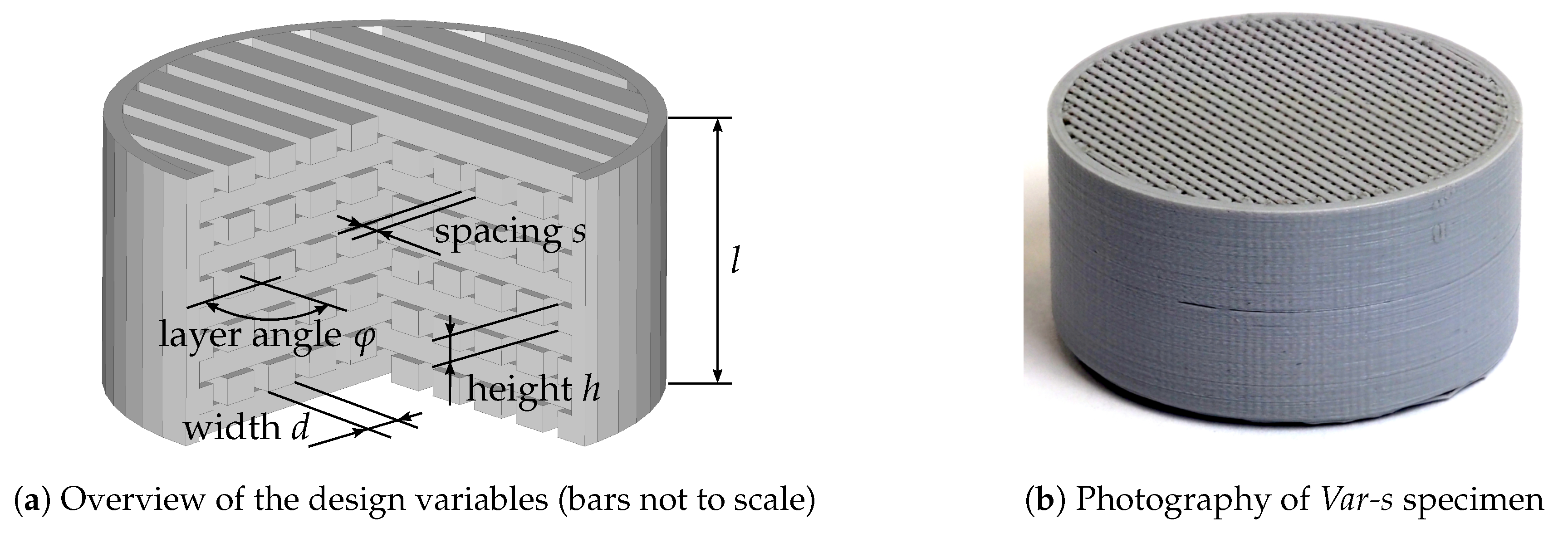

The specimens investigated within this contribution are shown in

Figure 1. In

Figure 1a, a schematic overview of the construction of the specimen and the investigated design variables is given. The specimens consist of layers with a layer height

h. Each layer consists of parallel bars with a width

d and the bars are set apart with a spacing

s. From one layer to the next, the layers are rotated with an angle

in clockwise direction. The overall specimen height is denoted with

l. The specimens are surrounded with a solid ring with a thickness of 1 mm for an increase of the mechanical stability of the specimen and reduction of the leakage in the experimental setups. The top and bottom side of the specimens are left open to allow for the measurement of flow resistivity (see

Section 3.1) and absorption coefficient (see

Section 3.2) in two directions. In

Figure 1b, an image of the specimen with varied bar spacing (

Var-s) is shown. What can be seen is the last layer of parallel bars and the solid, outer ring. Further, the layered structure that results from the 3D-printing process, can be recognized on the outer surface.

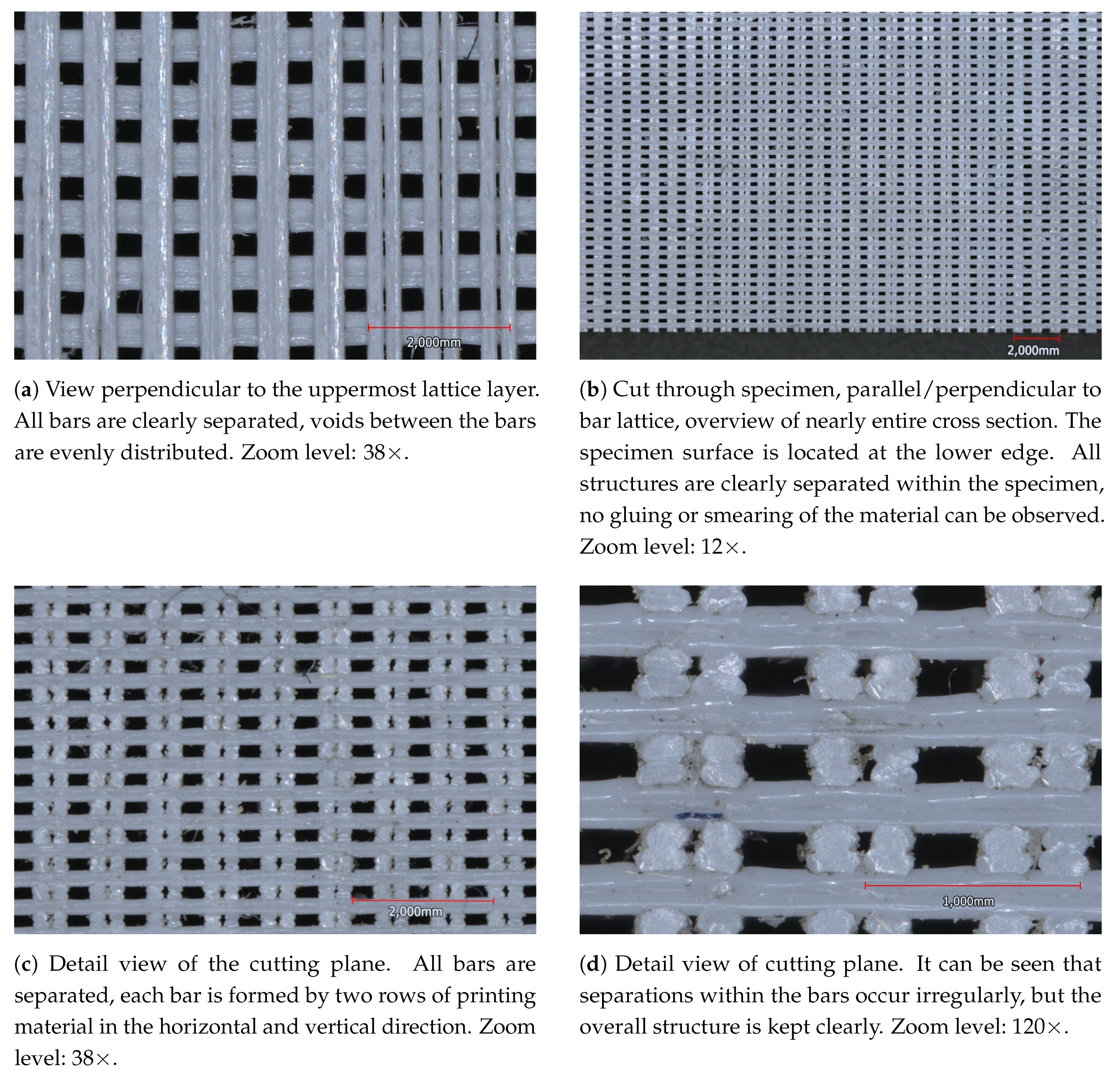

To ensure that the bar structures are separated and no unexpected connections due to manufacturing imperfections occur, following the acoustical tests, the

Ref 2 specimen was cut to provide insight into the specimen cross-section.

Figure A3 in the

Appendix C presents cross-sectional views of the specimen inner structure. It can be seen that the parallel bars within one layer, as well as the different layers, are separated and no gluing-together of the structures is observed. From these investigations, it is expected that the bar lattice geometry is manufactured according to the specimen design and, hence, the conclusions regarding the influence of the geometry on the

Biot-parameters are reasonable.

2.1. Geometric Design

Within this contribution, five different configurations were tested: one reference configuration (referred to as

Ref 1/2) and one variation of each design variable. The geometric dimensions of all variations are given in

Table 1. The overall height

l is 15

and the diameter is 30

for all specimens. The height was chosen: (a) to reduce the manufacturing time and cost; and (b) to achieve a sufficient thickness so a relevant absorption can be expected in the desired frequency range of 900–6600 Hz. The specimen diameter was chosen according to existing impedance tubes with a diameter of 30

that prescribe the investigated frequency range. As shown in the table, two samples of the

Ref 1 configuration were manufactured (

Ref 1/2) with the same geometric dimensions in order to account for manufacturing uncertainties.

Further, two geometrically equal specimens (

Ref 3/4) were printed with an overall specimen height

l of 30

. All other geometric dimension are equal to those of specimens

Ref 1/2. The specimens

Ref 3/4 allow for a verification of the parameter identification process described in

Section 4.2.

2.2. 3D-Printing Process

The printing of the specimen was done using a standard commercial Ultimaker 3 3D-printer with a fine nozzle. The nozzle diameter is 0.25 mm. The 3D-printer built the entire structure layer by layer, with a layer resolution of 0.15

and an xyz-resolution of 12.5, 12.5, 2.5

(all technical data according to Ultimaker B.V. [

21]). The material used for printing the specimen is Ingeo™Biopolymer 4043D, which is a Polylactic Acid (PLA) Biopolymer [

22]. No special treatment was conducted prior to the printing process. The specimen were built up from layers supported on a building platform; the build direction is the vertical direction in

Figure 1. Further, no supporting structures were used and, hence, no cleaning or removing of such structures was conducted after the printing process.

4. Numerical Characterization

Besides the experimental characterization, the specimens were modeled mathematically using the

Biot-model [

34,

35] and solved numerically using the finite element method (FEM). The goal of this procedure is to inversely extract the

Biot-parameters and to relate these to the geometric variations of the specimen described in

Section 2.1. The

Biot-model assumes the solid phase to be elastic and thus incorporates three wave types traveling within the porous medium, i.e., one shear wave within the solid phase and two compressional waves in both the fluid phase and the solid phase [

1]. The consideration of the elasticity of the solid phase distinguishes the

Biot-model from the class of models with a rigid solid phase, the so-called complex fluids. This class of models is applicable when the motion of the solid phase can be neglected, i.e., when its stiffness is very high or when the material is mechanically coupled to other components of high stiffness. Well-known material models of this class are, among others, the

Champoux–Allard model, the

Lafarge et al. model and the

Johnson et al. model [

36,

37]. For the investigations presented in this contribution, the

Biot-model seems the most promising one as the material used in the 3D-printer is a thermoplastic with a rather low stiffness. Thus, it is assumed that motions of the solid phase cannot be neglected.

4.1. Finite Element Model

The numerical characterization was done using a numerical model of an impedance tube, as shown in

Figure A1 in the

Appendix A. The model represents a generic impedance tube, as shown in

Figure 3. The dimensions of the modeled impedance tube were 1

in length with a square cross section and an edge length of 30

. Hence, the cut-on frequency was nearly (difference approximately 15%) identical with the circular impedance tube used for the experiments. The square cross section was used to ease the discretization using hexaeder volume elements. The air within the tube was modeled as an undamped fluid, while the porous material was modeled using the

Biot-model. The speaker shown in

Figure 3 was modeled using a harmonic sound flow. For both, the air and the porous material, 27-node elements with quadratic ansatz functions were used. The FEM-implementation of the

Biot-model uses the four-degree-of-freedom (DOF) u-p-formulation presented in [

38,

39], i.e., the pore pressure (p) is formulated using the displacements (u) of the solid phase. It should be noted here that the motivation for applying the

Biot-model instead of modeling the microstructure of the material directly is to allow for an application of the obtained parameters in a realistic scenario, where the modeling of the microstructure is prohibitively expensive and homogenized material models are necessary.

The element edge length of all elements was 10

and thus allowed the application of the discretization up to a frequency of 7555 Hz with a resolution of ten nodes per wavelength. Hence, a high accuracy of the computed sound pressure distribution within the tube can be expected. The resulting finite element model consisted of 412 elements and resulted in a system of equations with a total of 5500 DOF. The system of equations was solved in the frequency domain using the in-house code

ePaSo (in-house code of the Institute for Acoustics, TU Braunschweig; see

https://www.tu-braunschweig.de/ina/tech/elpaso/index.html) [

40]. The rather small dimension of the computational problem allowed for a fast computation of the sound pressure distribution and thus enabled the inverse parameter identification using an optimization strategy, as described in

Section 4.2.

The absorption coefficient is computed from the sound pressure distribution along the central axis of the impedance tube using the so called mini-max procedure, described for example in [

41]. The principle computes the absorption coefficient from the sound pressure distribution

, where the coordinate

x denotes the direction along the impedance tube axis.

4.2. Inverse Parameter Identification

The inverse parameter identification is based upon the minimization of the mean squared difference between the measured absorption coefficient

and the computed value

. Thereby, the solution

was computed in the frequency domain for 218 frequency steps in the range of 900–6600 Hz with a frequency step size of 30

. The much higher resolved measured absorption coefficient

was interpolated to the frequency steps used in the computation. The target function

to be minimized is given as follows:

The computed absorption coefficient and thus the target function depends on the material parameters of the

Biot-model, as given in

Table 2. The mechanical properties for the solid phase were taken from the 3D-printing material data sheet [

22], while the values for the Poisson’s ratio and the damping were based on empirical values. The air density was computed based on the room temperature using the ideal gas law. The flow resistivity was measured for all specimens using the procedure described in

Section 3.1. Hence, the remaining parameters for the optimization procedure are the

tortuosity , the

porosity , the

viscous characteristic length and the

thermal characteristic length . The minimization procedure was implemented using the

Nelder–Mead simplex algorithm [

42] taken from the Python library

scipy [

43]. The optimization was, due to the used algorithm, set up as an unconstrained optimization problem. Nevertheless, as negative values are not meaningful for the modeled physical quantities, only positively valued results were accepted as a sufficient result. It should be noted that using the initial parameter set given in

Table 2, all inversely identified parameters were positive for every run of the optimization.

The presented inverse parameter identification procedure is similar to the one described in [

44]. Nevertheless, in this contribution, the applied material model is the full

Biot-model, whereas in [

44] a formulation based on the

Johnson et al. and the

Champoux-Allard model is applied. Further, within the procedure presented here, the porosity was evaluated using the optimization technique as well, whereas in [

44], the porosity is measured directly.

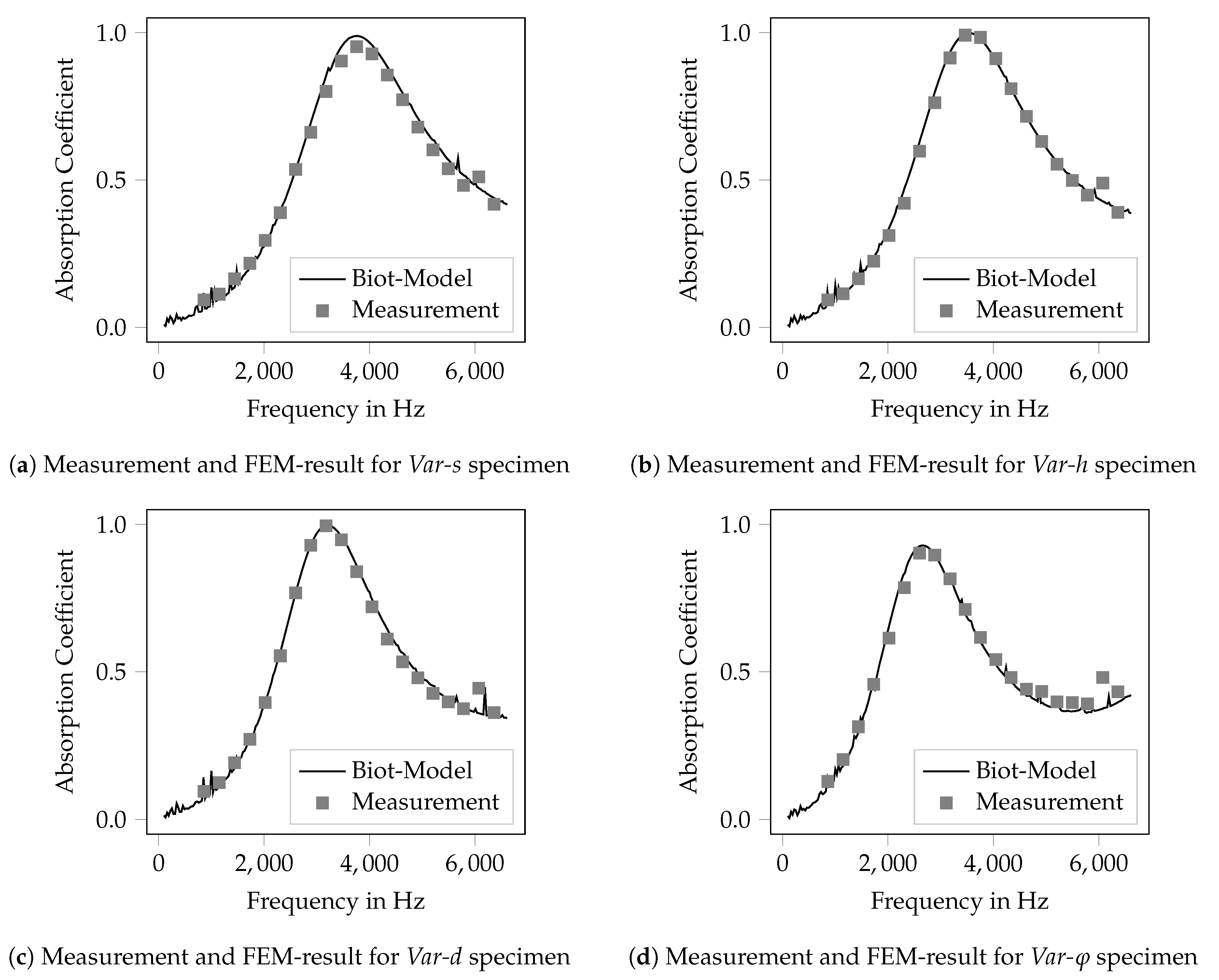

The inverse parameter identification was run for each specimen given in

Table 1, the identified

Biot-parameters are given in

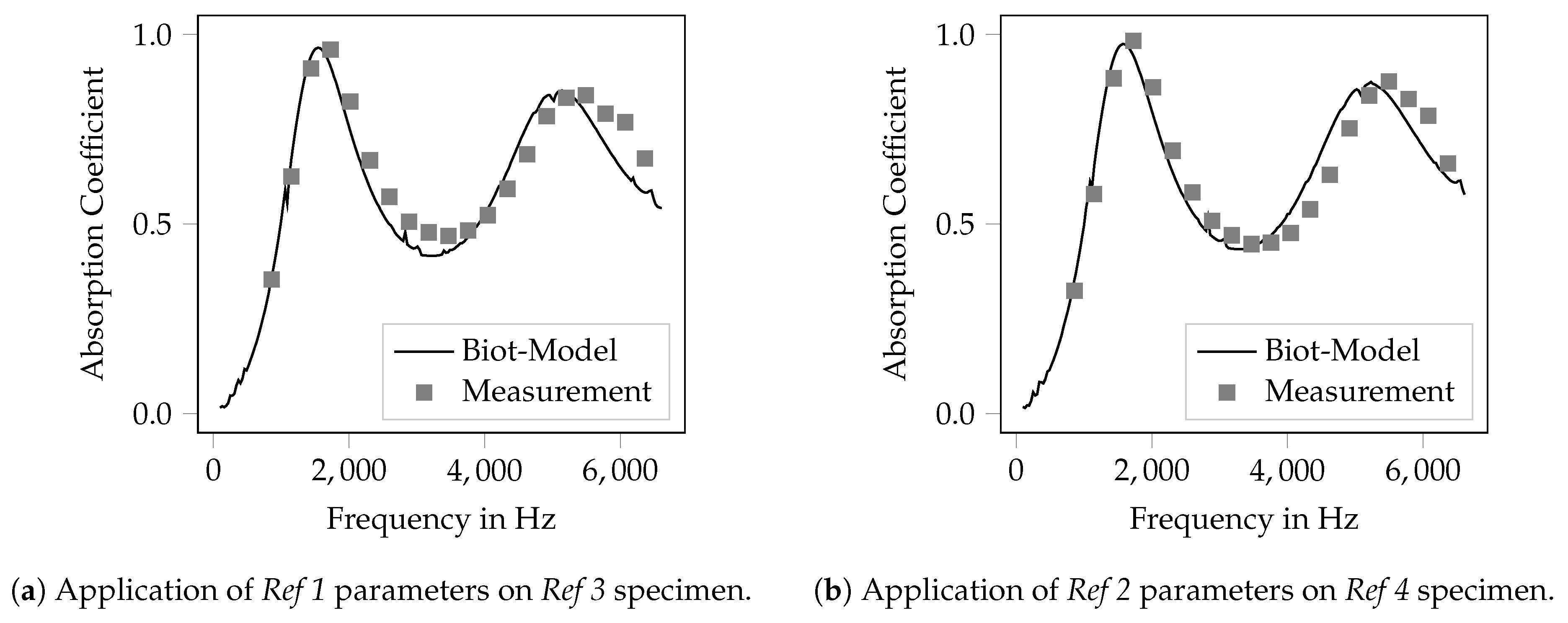

Table 3. In

Figure 4, the results are shown for the specimen

Ref 1 (

Figure 4a) and

Ref 2 (

Figure 4b). It can be seen that the computed absorption coefficient fits the measured data fairly well. This holds as well for all other investigated specimens. The results of the other specimens are shown graphically in

Appendix B. Previous studies of the authors on well-known melamine foams and the works in [

44] have shown the ability of the presented method to obtain physically reasonable results and based on the good agreement of the measured and the computed absorption coefficient, it can be expected that the identified material parameters represent a good estimation of the physically correct values. Nonetheless, the optimization problem might not be unique, thus the presented optimal result might not be the global optimum.

In

Table 3, the inversely identified parameters for the

Biot-model are shown for all investigated specimens. Further, for each quantity, the relative deviation from the

Ref 1 configuration is given. It can be observed that for all specimens the viscous and thermal characteristic lengths are nearly equal, whereas the thermal characteristic length is slightly smaller than the viscous characteristic length. This is contradictory to the findings in [

44] after that the viscous length typically is smaller than the thermal length. Nevertheless, the difference between both is small, therefore it is assumed that no general error occurred during the parameter identification. Further, the estimated porosity is near [round-precision=1].4. As the manufactured specimen are regular and periodic structures, the porosity can be estimated analytically using the bar spacing and width. Assuming an infinitely extended lattice in the layer plane and using the dimension given in

Table 1, the theoretical porosity is .375. Thus, the inversely identified parameters seem reasonable and were used in the following investigations.

The specimen Ref 1 and Ref 2 were printed using the same CAD-file and hence should show equal Biot-parameters. Nevertheless, a difference of up to % can be observed for flow resistivity. The other, numerically identified parameters differ less, with up to %. The variation of the design variables also led to altered Biot-parameters. It can be seen that the variation of the layer angle thereby results in the largest variations of the inversely identified parameters.

4.3. Verification of the Inversely Identified Parameters

To allow for a verification of the inversely identified parameter sets, the following procedure was chosen: it is expected that the set of Biot-parameters gives a description of the porous material. Hence, a variation of the macroscopic geometric dimensions of the specimen (length and diameter) does not affect the material parameters. Accordingly, specimens with other lengths than the ones used for the parameter identification can be described using the same Biot-parameters. For this investigation, two specimens (Ref 3/4) with an overall length of were printed and their absorption coefficient was measured. The microscopic dimensions of the bar lattice of both specimen are equal to specimens Ref 1/2.

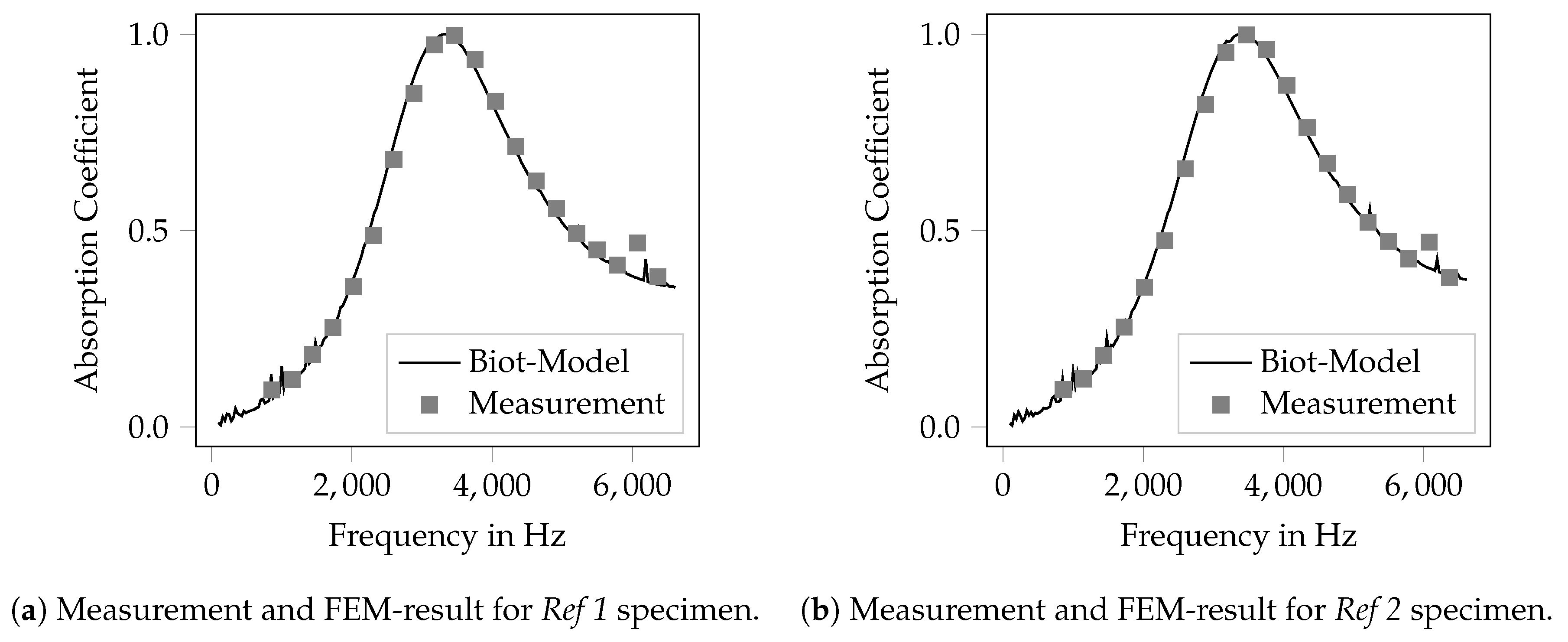

In

Figure 5, the measured absorption coefficient for the verification samples with a specimen length of 30

is shown. Moreover, the computed absorption coefficient is given. The computational result was produced using the FEM-model of the same impedance tube as was used for the parameter identification, but the porous sample was geometrically modeled with the varied overall length of 30

. The material model used for the shown computations was parameterized using the parameter values from the

Ref 1/2 configuration given in

Table 3. It can be seen that the difference of the computed and measured results is rather low. Within the frequency domain, two absorption maxima are present. Both are met fairly well regarding the frequency and the maximum absorption. As expected, the frequency of the absorption maximum drops from 3370 Hz (15

) to 1600 Hz for the 30

long specimen. For the second absorption maximum, the frequency of the peak was computed at a slightly lower value than it appears in the measurement. Nevertheless, the value of the maximum absorption is met quite well, whereas the parameters of the

Ref 2 configuration fit the measured data slightly better.

In total, this investigation shows that the inversely identified

Biot-parameters are valid for a given set of microscopic dimensions of the bar lattice and remain valid if the macroscopic specimen dimensions are altered. Hence, the rather narrow absorption maximum that can be seen in

Figure 4 cannot be attributed to a resonance effect but is the effect of a porous material.

4.4. Uncertainty Quantification

The investigations on specimens

Ref 1/2 show a rather good reproducibility of the manufacturing process. Nevertheless, there are uncertainties associated with the produced specimen geometry and, hence, the

Biot-parameters become uncertain as well. To account for these uncertainties, an uncertainty quantification was conducted to get an impression of the influence of parameter variations due to manufacturing uncertainties. The uncertainty quantification was conducted as a one-at-a-time parameter variation based on the analytic procedure of the

Guide to the expression of uncertainty in measurement (GUM), described in [

45,

46]. The procedure computes the combined uncertainty

of the quantity of interest (here, the absorption coefficient) as the sum of the squared product of the sensitivity coefficient

and the uncertainty of the input parameter

, as shown in Equation (

5). The sensitivity

is the partial derivative of the absorption coefficient after all input parameters, i.e., the

Biot-parameters.

For the uncertainty quantification, an uncertainty of 10% of the mean value given in

Table 3 for all input parameters was assumed. The uncertainty quantification was done exemplarily for the

Ref 3 configuration. The derivative in the sensitivity coefficient given in Equation (

5) was computed numerically using the central differential quotient:

Thus, for each parameter, a parameter variation was done, the sensitivity was computed and all uncertainty contributions were combined to the combined uncertainty. The sensitivity coefficients are further used in the investigation presented in

Section 5 for determining possible design variables for an optimization of the material. It should be noted that this procedure is only valid for small perturbations around the mean value and the resulting sensitivities are only valid at the evaluation point because the underlying function can not be assumed to be linear. These drawbacks can be overcome using a global sensitivity analysis, for example using the

Saltelli-method as described in [

47]. In [

48], a global sensitivity analysis is presented for the

Johnson–Champoux–Allard-model using a transfer-matrix-method implementation modeling a three-layer NFRP (natural fiber reinforced plastic) component. Further, global sensitivity analysis on different material models for porous media is carried out in [

49]. Nevertheless, the global sensitivity analysis is based on a Monte-Carlo method and thus is computationally very costly. This especially holds for the FEM-model used in this contribution, therefore the one-at-a-time parameter variation was used as described before.

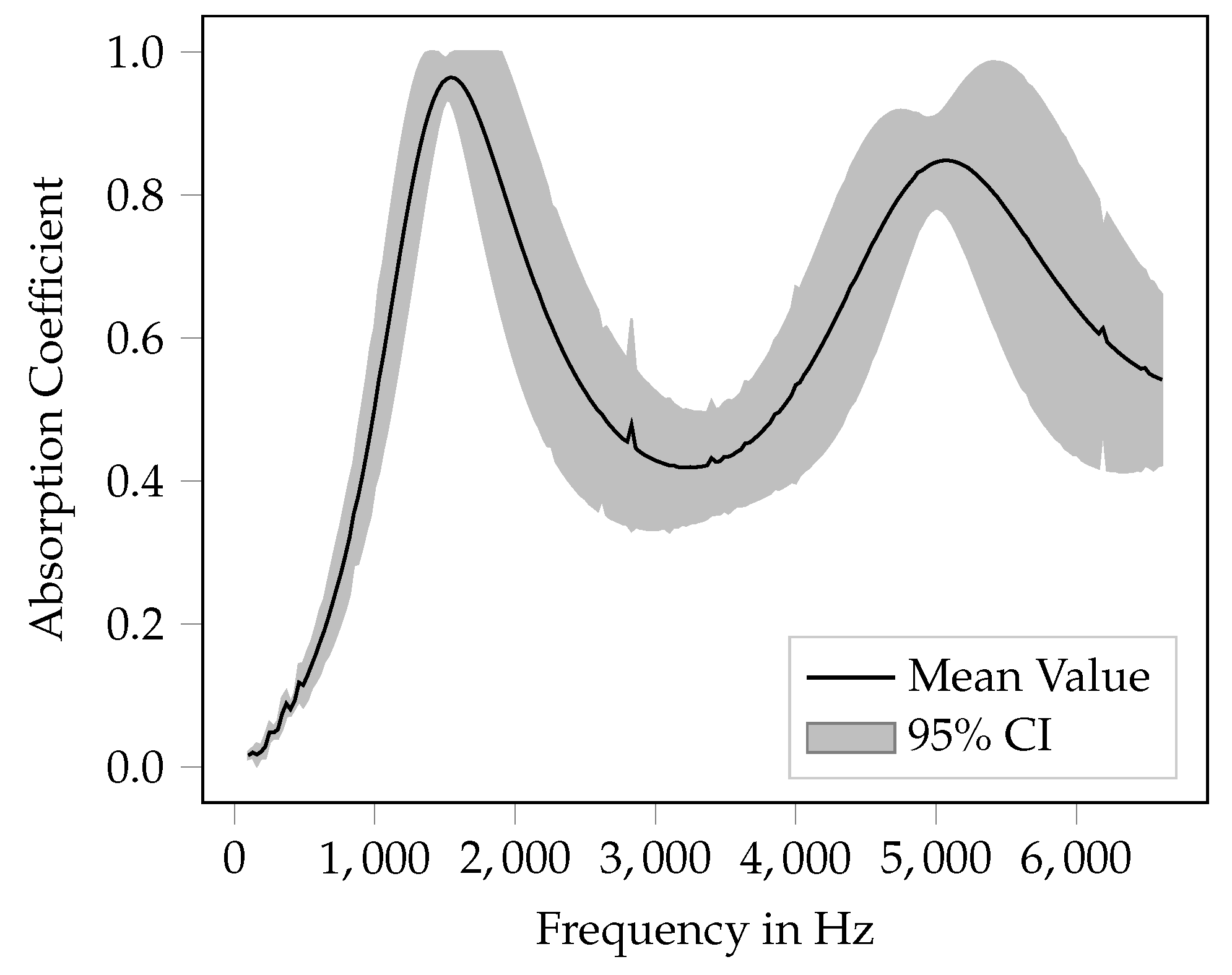

The result of the uncertainty quantification is shown in

Figure 6. In the figure, the mean absorption coefficient of the

Ref 3-specimen is plotted as a solid line. Further, the 95% confidence interval is shown. The confidence interval (1.96 times the standard deviation) is computed from the combined uncertainty

, which represents one standard deviation. It can be seen that, for uncertain input parameters, the absorption coefficient is mainly affected in the frequency domain above the first absorption maximum, whereas the effect is rather low in the lower frequency domain. In general, the effect of uncertain parameters grows with the frequency, except from the point where the highest absorption occurs. Here, the effect of uncertainty is very low.

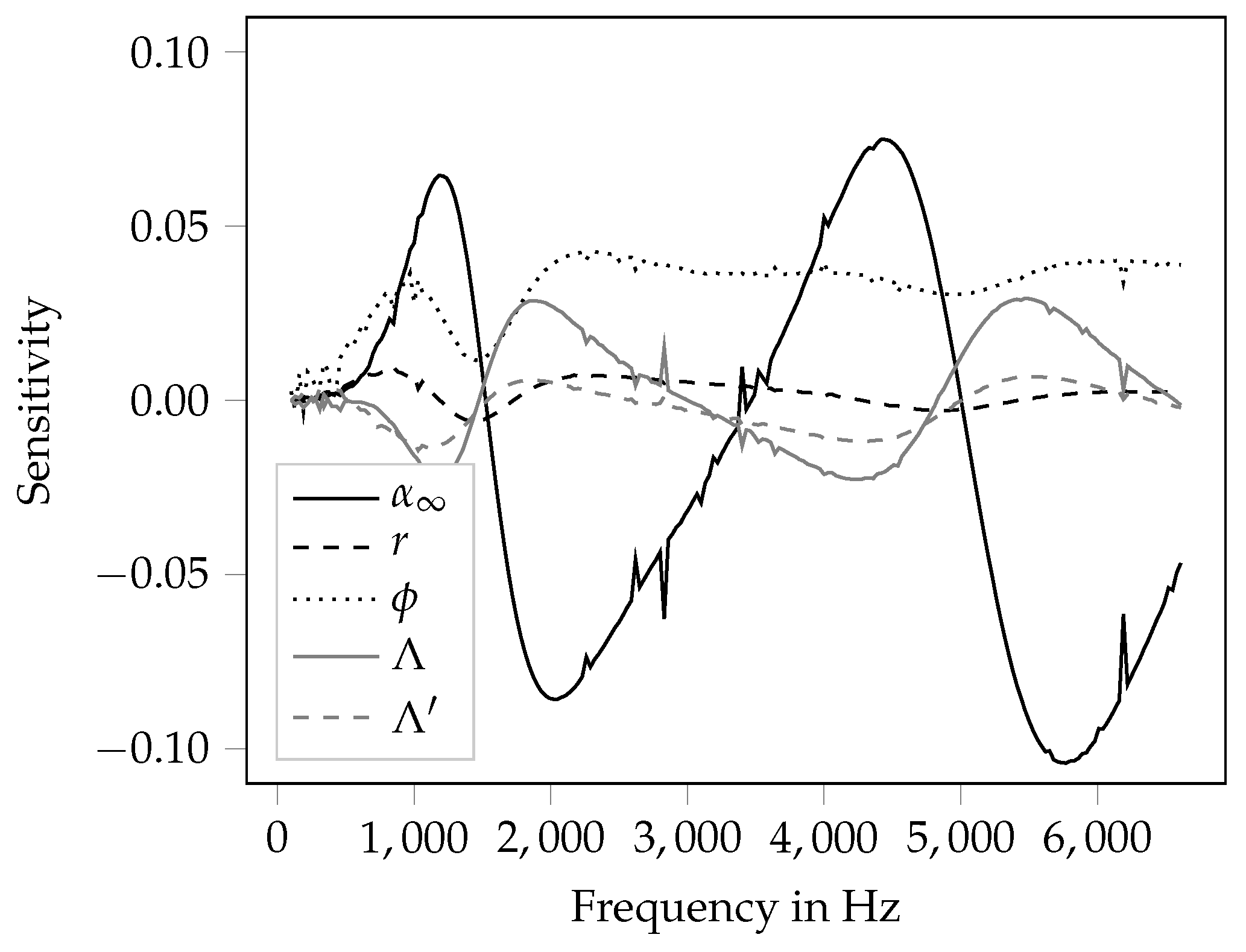

5. Optimization of the Porous Material

The overall aim of the presented work is to investigate the possibility of optimizing the printed porous material for a good sound absorption characteristic. It is assumed that a good absorption characteristic incorporates high absorption coefficients in a broad frequency band. In

Table 3, it can be seen that the variation of the rotation angle of the layers results in a high variation of the

Biot-parameters. Thereby, the flow resistivity, the tortuosity and the thermal characteristic length are the parameters that are affected most by rotating the bar layers. On the other side, a sensitivity analysis on the

Biot-parameters can give insight in how the direct variation of theses values influences the absorption coefficient. In

Figure 7, the term

from Equation (

5) is plotted for all inversely identified parameters over the frequency. The reason for plotting the product of sensitivity coefficient

and the related uncertainty

is that the term becomes dimensionless and thus the different values can be compared directly. For all input parameters with values of the sensitivity term greater than zero, an increase of the parameter leads to a higher absorption coefficient, whereas a negative sensitivity value indicates a decrease of the absorption coefficient with an increase of the parameter.

What can be observed in

Figure 7 is that most quantities have a frequency dependent influence on the absorption coefficient. Generally, the tortuosity has the highest influence on the absorption coefficient. This is somewhat contradictory to the findings in [

49], where the flow resistivity is identified as the most influential parameter. Thereby, the negative values in the frequency ranges 1540–3490 Hz and 5020–6610 Hz indicate that an increase of the tortuosity leads to a reduction of the absorption coefficient. In the other frequency ranges, increasing the tortuosity increases the absorption coefficient as well. This behavior is generally apparent for all

Biot-parameters except from the porosity, which shows positive sensitivities in the entire frequency range. Hence, the increase of the porosity is beneficial in the entire frequency range. In general, for an optimization of the material with the goal of a broadband increase of the absorption coefficient, design variables that exhibit the same direction of the sensitivity in the entire frequency range are most handy. For the investigated material in this contribution, only the porosity fulfills this requirement. The flow resistivity generally has a rather low sensitivity, but the sensitivity is positive in nearly the entire frequency range. Only at the absorption maxima at 1600 Hz and 5200 Hz weak negative sensitivities can be observed. Summarizing, for increasing the absorption coefficient in a broadband sense, an increase of the porosity and of the flow resistivity is beneficial.

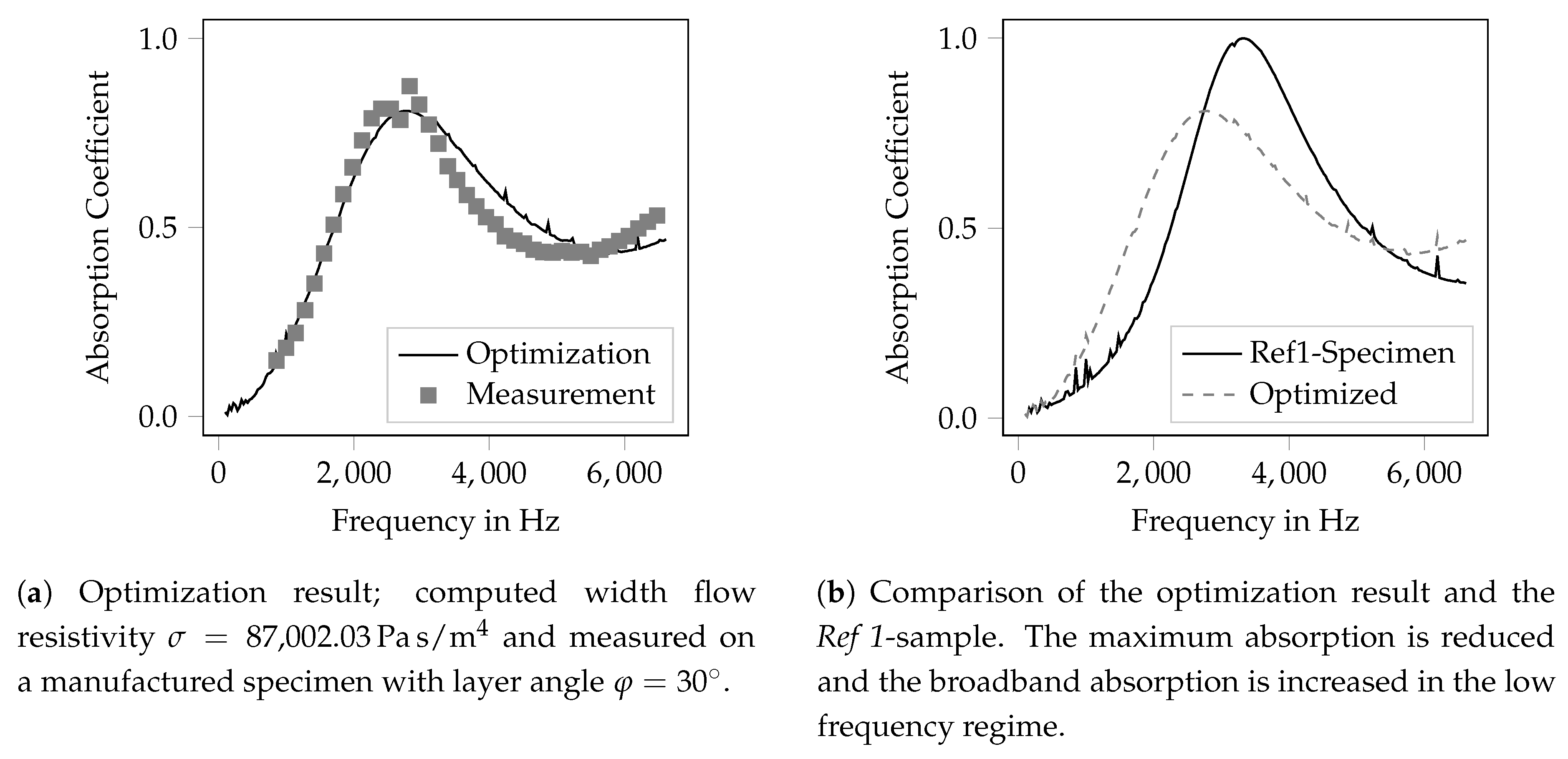

Based on the observation that both the porosity and (except from very narrow frequency bands) the flow resistivity show a sensitivity that has no change of sign in the entire frequency range, these parameters can be used for an optimization of the porous material. Nevertheless, as shown in

Table 3, the porosity is not affected strongly by a variation of the geometric parameters of the material. On the other side, the flow resistivity can easily be adjusted using the layer angle of the material. Hence, this parameter can be optimized in order to obtain a high absorption coefficient in a broad frequency range. Therefore, an optimization strategy was set up to maximize the absorption coefficient by adjusting the flow resistivity of the specimen. Nevertheless, the variation of the rotation angle of the layers results in changes of the other

Biot-parameters as well, especially the tortuosity. Thus, this approach is a somewhat pragmatic procedure and might not be able to produce optimal results. As the target function to be minimized, the inverse of the sum of the squared frequency dependent absorption coefficients was used:

For the optimization procedure, the

Biot-parameters of the

Var-φ specimen were used and the flow resistivity was optimized. Based on the target function (Equation (

7)), the optimal value of the flow resistivity is

. As there is no direct link between the flow resistivity and the layer angle, this information cannot be translated directly into the necessary layer angle. Instead, two further specimen were manufactured with layer angles of 60

and 30

, respectively. All other geometric parameters were kept identical to those of the angle variation specimen. For both samples, the flow resistivity was measured. The material with a layer angle of 60

shows a flow resistivity of

, the specimen with an angle of 30

has a flow resistivity of

. However, neither specimen shows the desired flow resistivity that is obtained using the optimization procedure, but they get quite close. The optimization result is summarized in

Figure 8 by a comparison to the measured absorption coefficient and to the

Ref 1 sample, respectively.

In

Figure 8a, the measured absorption coefficient of the specimen with the layer angle of 30

and the resulting absorption coefficient from the optimization procedure is shown. It can be seen that in the frequency range below the peak the computed result meets the measurement quite well. Nevertheless, in the frequency range above the highest absorption coefficient, some differences can be observed. These can be attributed to changes of the other

Biot-parameters that are affected from the variation of the layer angle as well. Further, as the flow resistivity is changed quite dramatically compared to the small perturbations used for the sensitivity analysis, it must be expected that the linearity-requirement is not fulfilled.

The comparison to the specimen

Ref 1 is shown in

Figure 8b. It can be seen that the maximum of the absorption coefficient drops from 0.99 (

Ref 1) to 0.81 (optimized geometry). Meanwhile, the overall magnitude of the absorption coefficient is increased, especially below 3000 Hz and above 5800 Hz. It should be noted that the mean absorption coefficient of both specimen are nearly equal with

and

. Hence, the optimization does not result in a significant increase of the absorption coefficient, but the areas of high absorption are more evenly distributed along the frequency axis. This may be the result of the chosen target function (Equation (

7)). Nevertheless, a more homogeneous distribution of the absorption characteristics can be of more practical use than the narrow banded absorption characteristics of the

Ref 1 sample; hence, the optimization outcome is assumed to be suitable for practical needs. It can be summarized that the adjustment of the flow resistivity indeed leads to an improved acoustical behavior but that it is not the only quantity of interest for a suitable tailoring of porous media.

6. Conclusions and Outlook

The application of porous material is a common and widely applied noise mitigation measure. The most common application is the adjustment of room acoustics using porous absorbers; another application is the reduction of aeroacoustic sources. Porous materials typically exhibit a broadband absorption characteristic with an absorption coefficient that generally increases with frequency. The characterization of porous materials oftentimes relies on the measurement of macroscopic quantities, such as the flow resistivity. Further, homogenized values, i.e., the Biot-parameters porosity, tortuosity and characteristic lengths, are needed to use material models such as the Biot-model and models from the class of complex fluids. As the geometric structure on the microscale of the porous materials is generally unknown, the Biot-parameters cannot be related directly to the geometric structure. Hence, tailoring the material to a desired acoustic behavior by adjusting the material geometry on the microscale is not possible yet.

In this contribution, generic porous materials were manufactured based on lattices of bars. The dimensions of these bars served as design variables for the design of the porous material. Each bar lattice formed one layer of the porous material, several layers were stacked above each other to build the entire specimen. Thereby, the layers were rotated around a specified angle from one layer to the next. The material was manufactured using 3D-printing technology. Thereby, parameter variations of all geometric design variables were investigated. Using inverse parameter identification based on the Biot-model and a finite-element formulation, the Biot-parameters were identified from measurements of the absorption coefficient. It can be shown that most design variables have a rather small influence on the Biot-parameters, whereas the layer angle strongly influences the flow resistivity. Further, it can be shown numerically that the porosity and the flow resistivity both have a positive sensitivity regarding the absorption coefficient in the entire frequency range. Hence, these parameters can be used for an optimization of the material. Together with the observation that the flow resistivity is strongly affected by the layer angle, the material is optimized based on a given set of Biot-parameters and an optimization of the flow resistivity. It can be shown that this optimal flow resistivity can be accomplished effectively by an adjustment of the layer angle of the specimen.

Summarizing, the presented procedure introduces a possible methodology to generate tailored porous materials based on an optimized set of Biot-parameters. It can be shown that for generic specimen the Biot-parameters can be connected to the geometric design of the specimen and, thus, an optimization of the material on the microscale becomes possible. Moreover, it can be shown that 3D-printing technology is a promising approach for manufacturing porous materials, as the degrees of freedom during the printing process allow for the manufacturing of complex structures that are needed for porous material design.

During the presented procedure, it is necessary to optimize the material with respect to the flow resistivity. To connect the flow resistivity with the design variables, specimen with an estimated set of design variables are manufactured and the flow resistivity is measured. This procedure can be done using numerical methods as well by applying computational fluid dynamics (CFD) methods for estimating the flow resistivity. This procedure is shown for 3D-printed specimen by the authors in [

50].

Future work is planned on increasing the porosity of the printed specimen, as this parameter shows an even higher sensitivity as the flow resistivity and thus is a promising approach to further increase the absorption characteristic of the presented specimen. Another part of the work aims for an estimation of the remaining Biot-parameters from the geometry.