Multi-Segmented Nanowires: A High Tech Bright Future

Abstract

1. Introduction

2. Advanced Fabrication of Nanowires

2.1. Template Based Synthesis

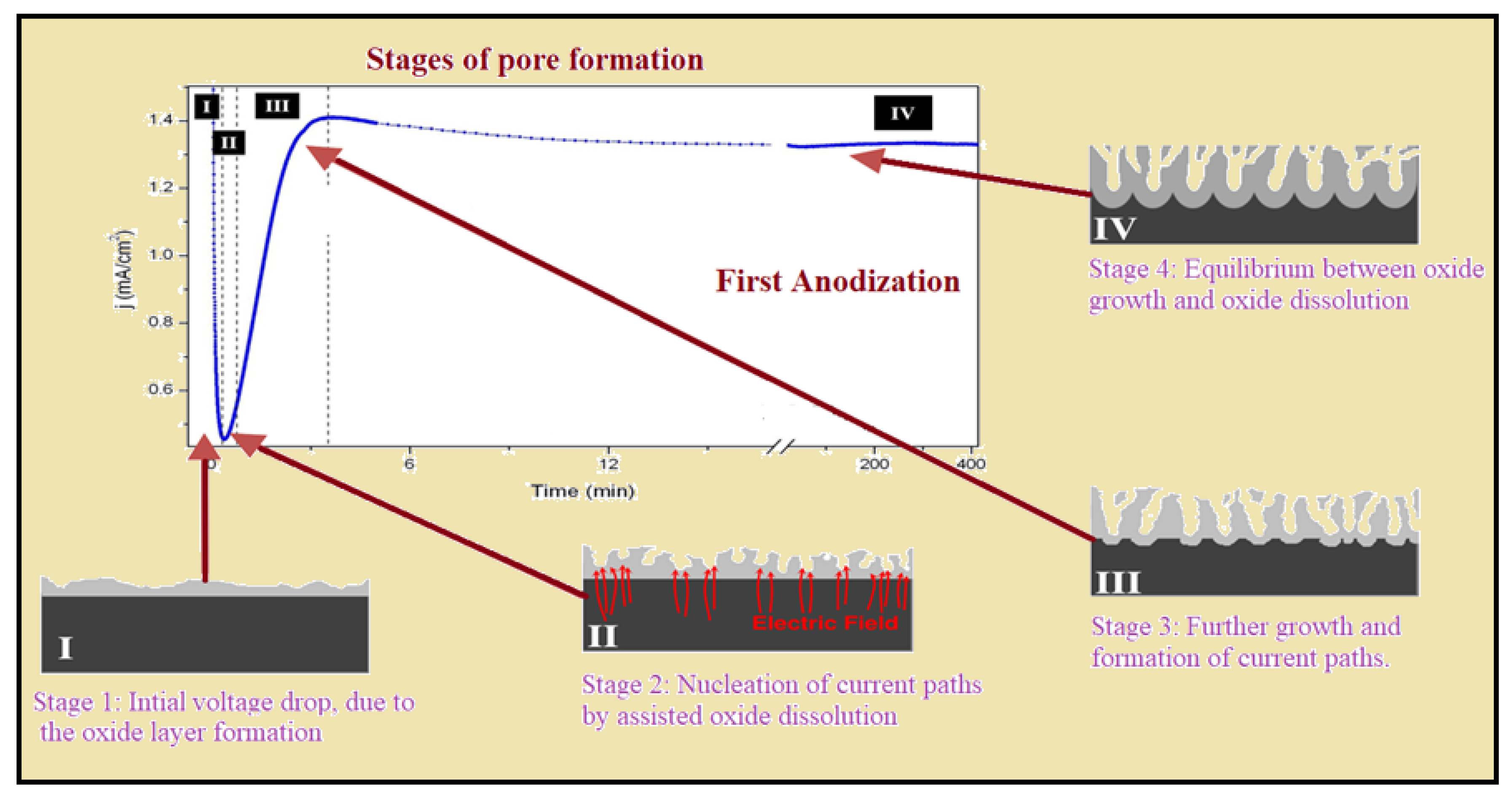

2.1.1. Anodic Aluminum Oxide (AAO)

2.1.2. Hard and Mild Anodization in AAO

2.1.3. Track Poly Carbonate Membrane

2.1.4. Step Edge Decoration

2.2. Electro-Spinning

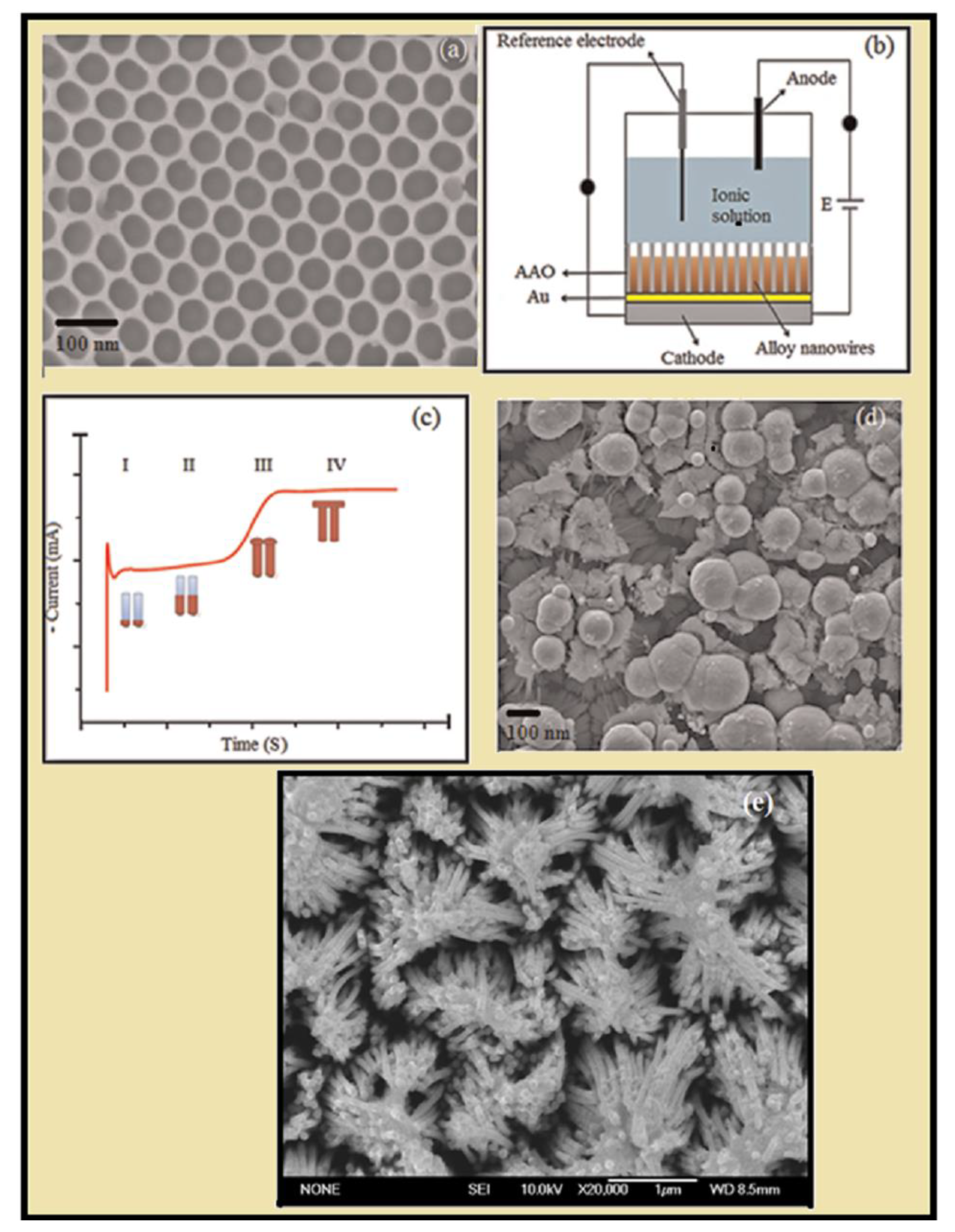

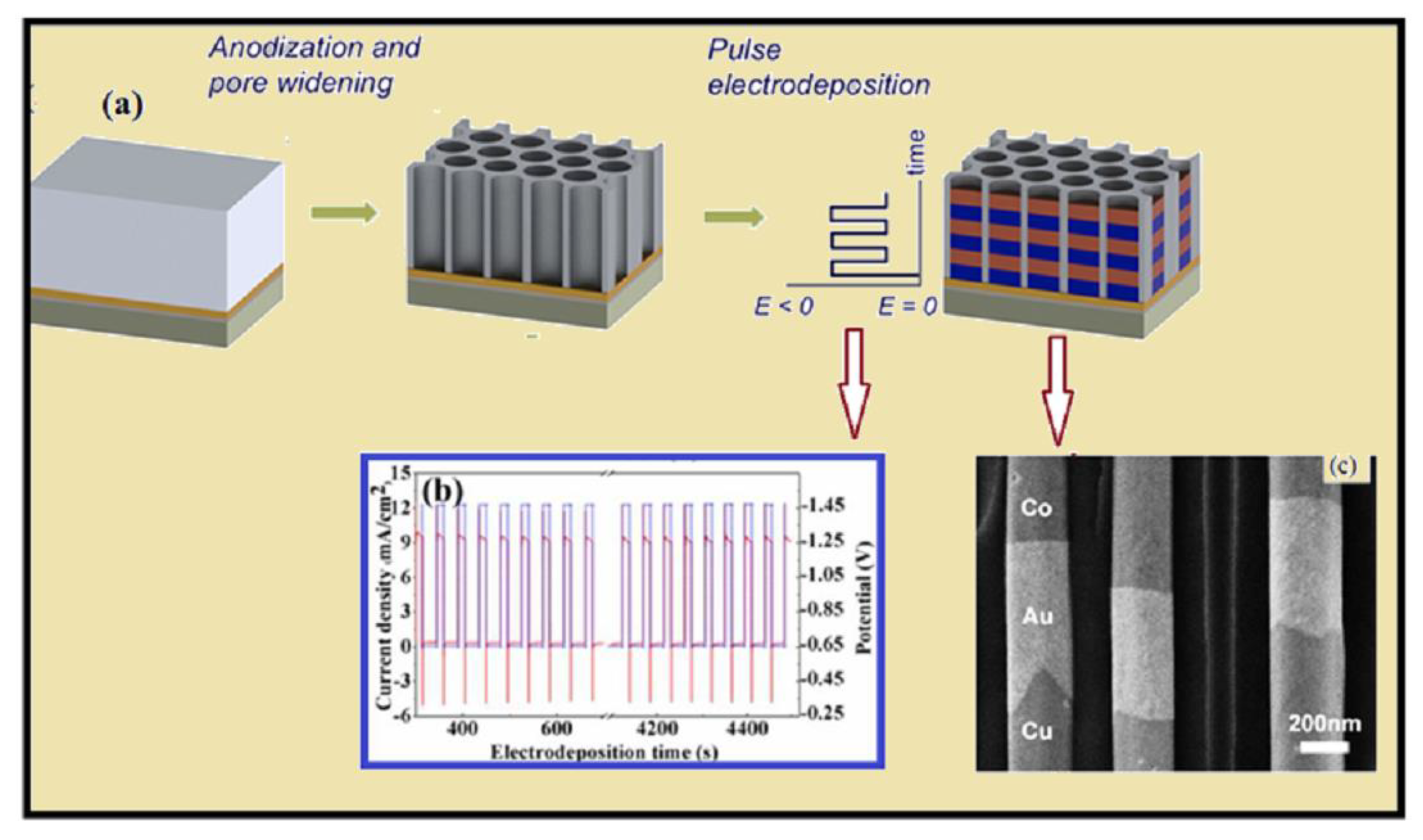

3. Electrodeposition and Structure of Multi-Segmented NWs in AAO Template

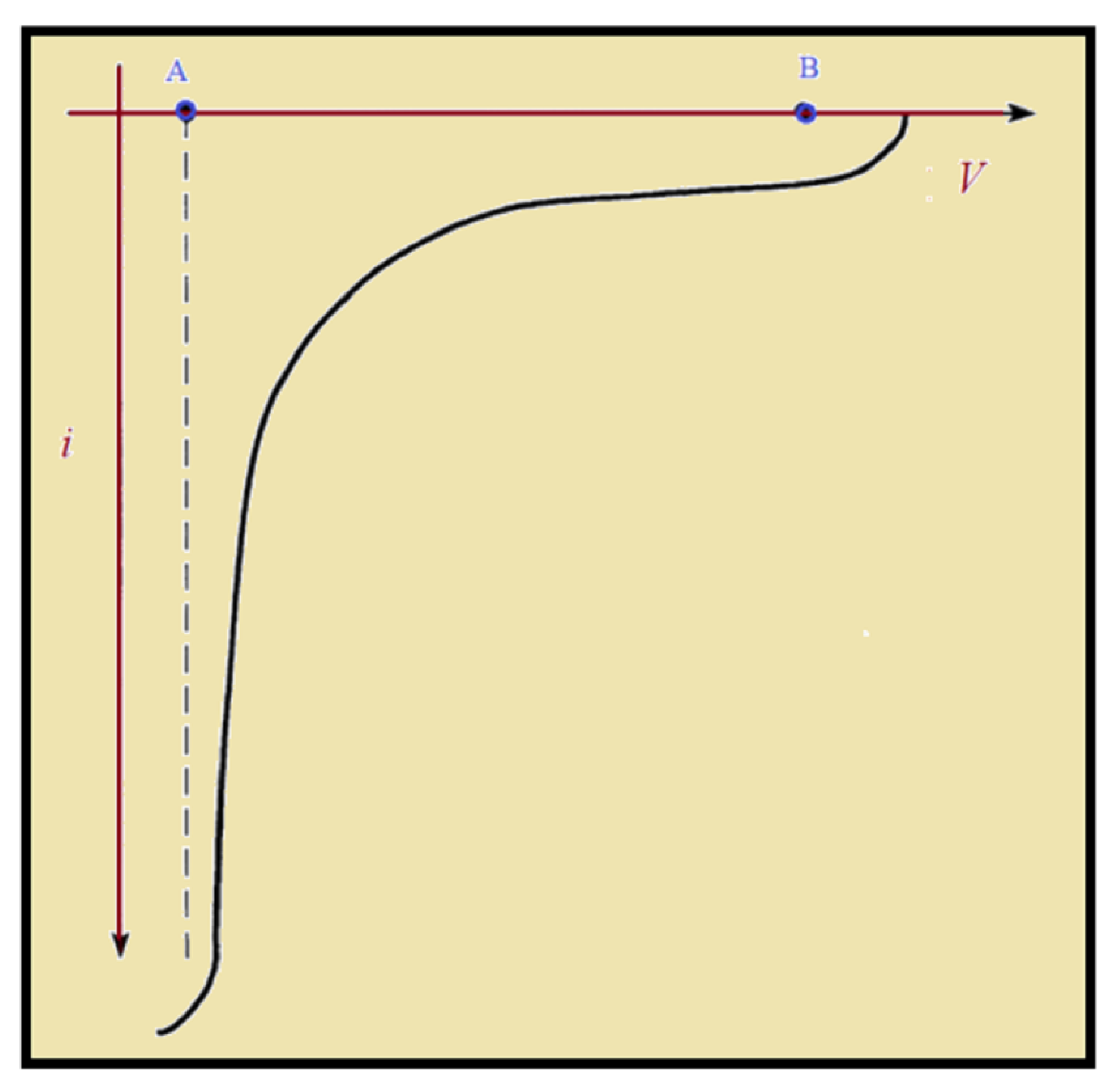

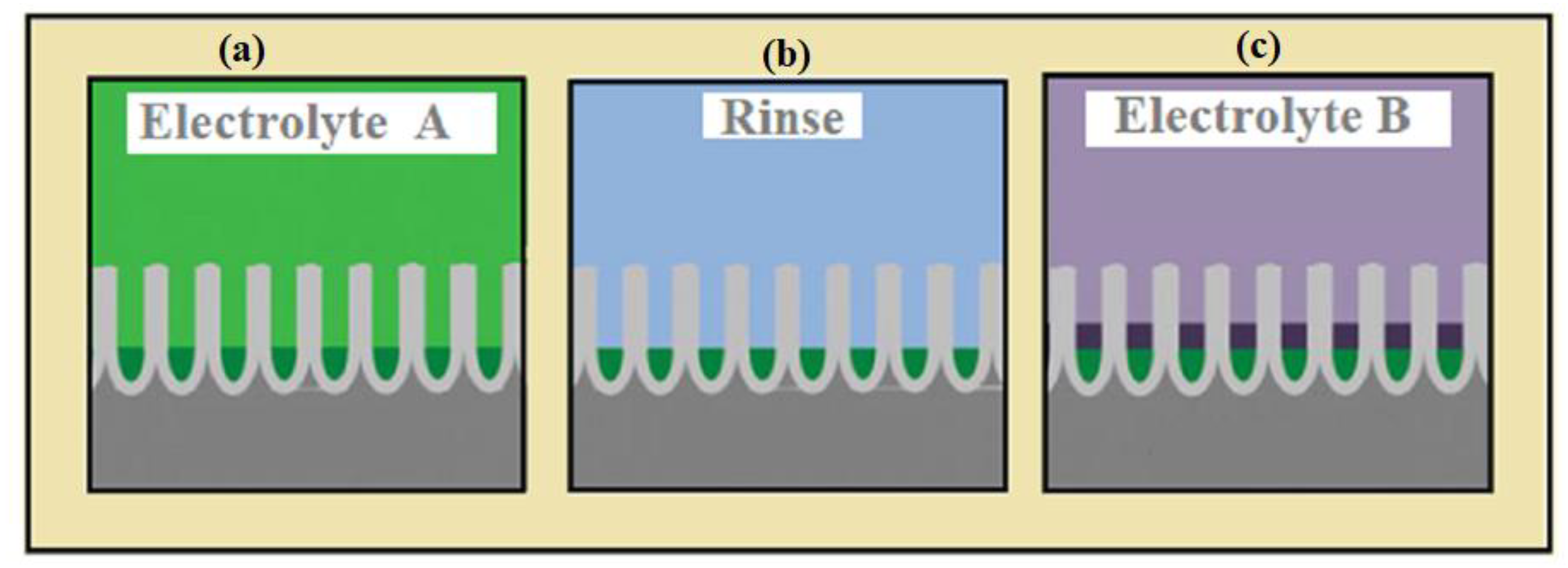

3.1. Dual Bath Deposition

3.2. Single Bath Deposition

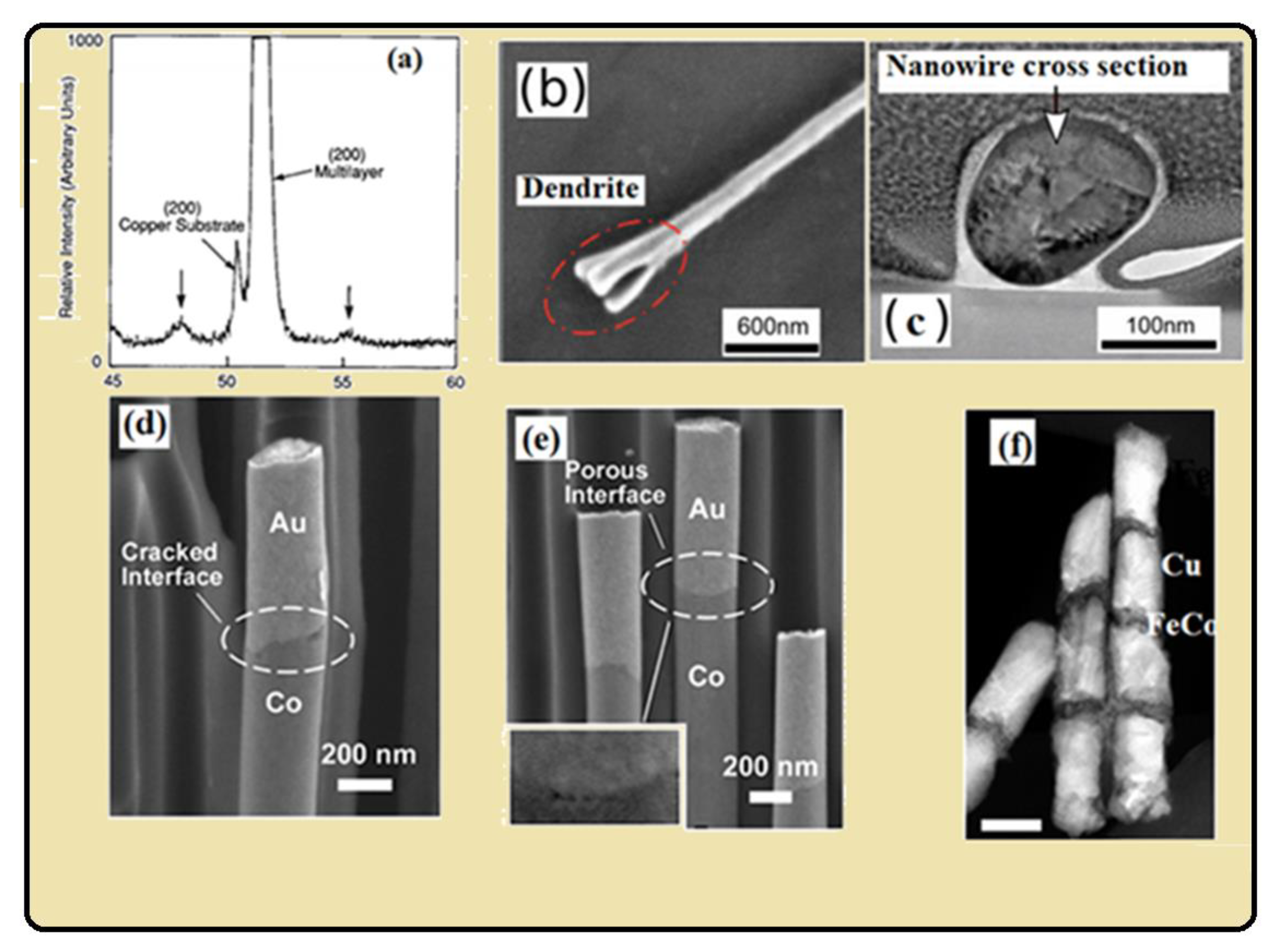

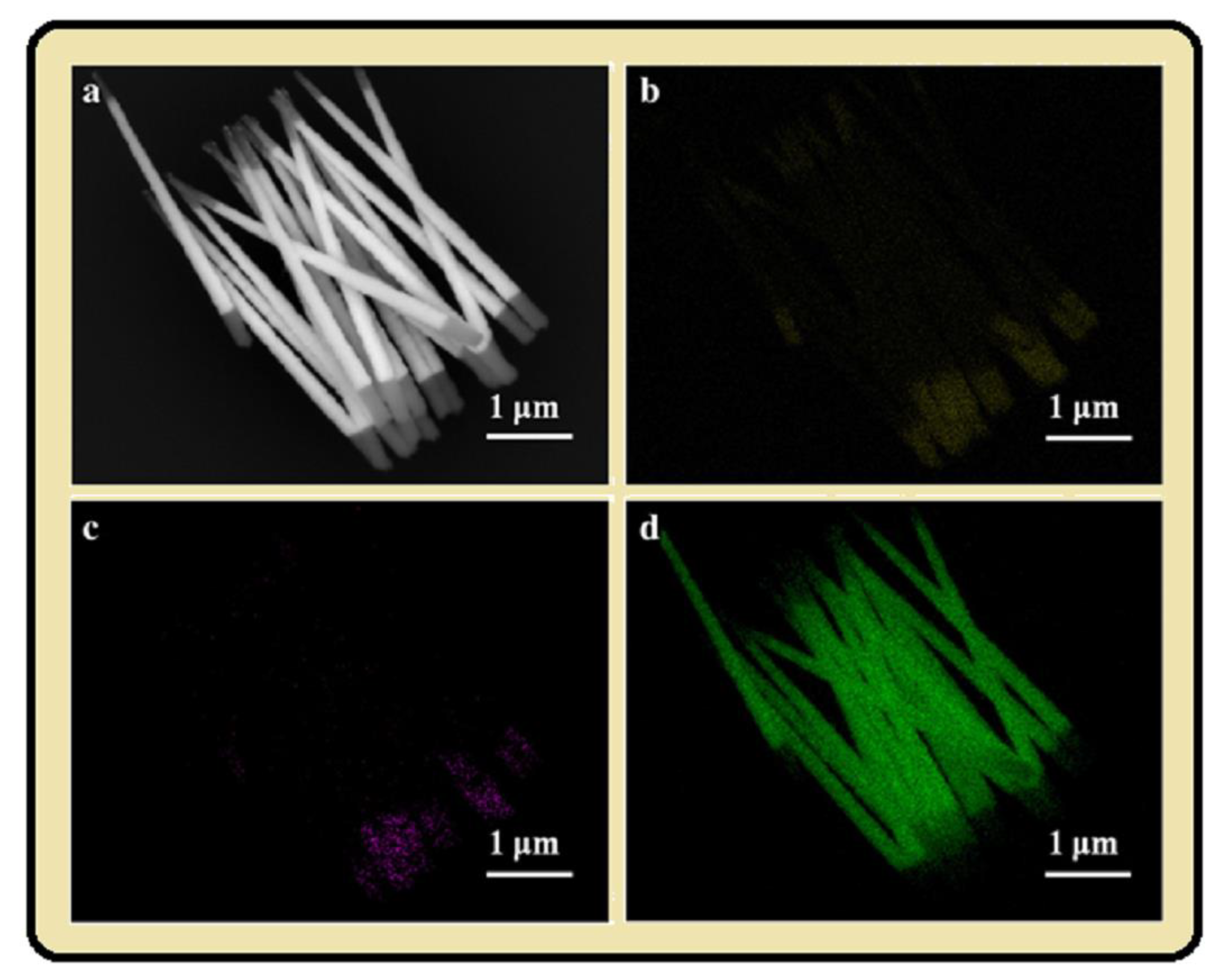

3.3. Structure of Electrodeposited Multilayer NWs

4. Properties and Application of Multi-Segmented NWs

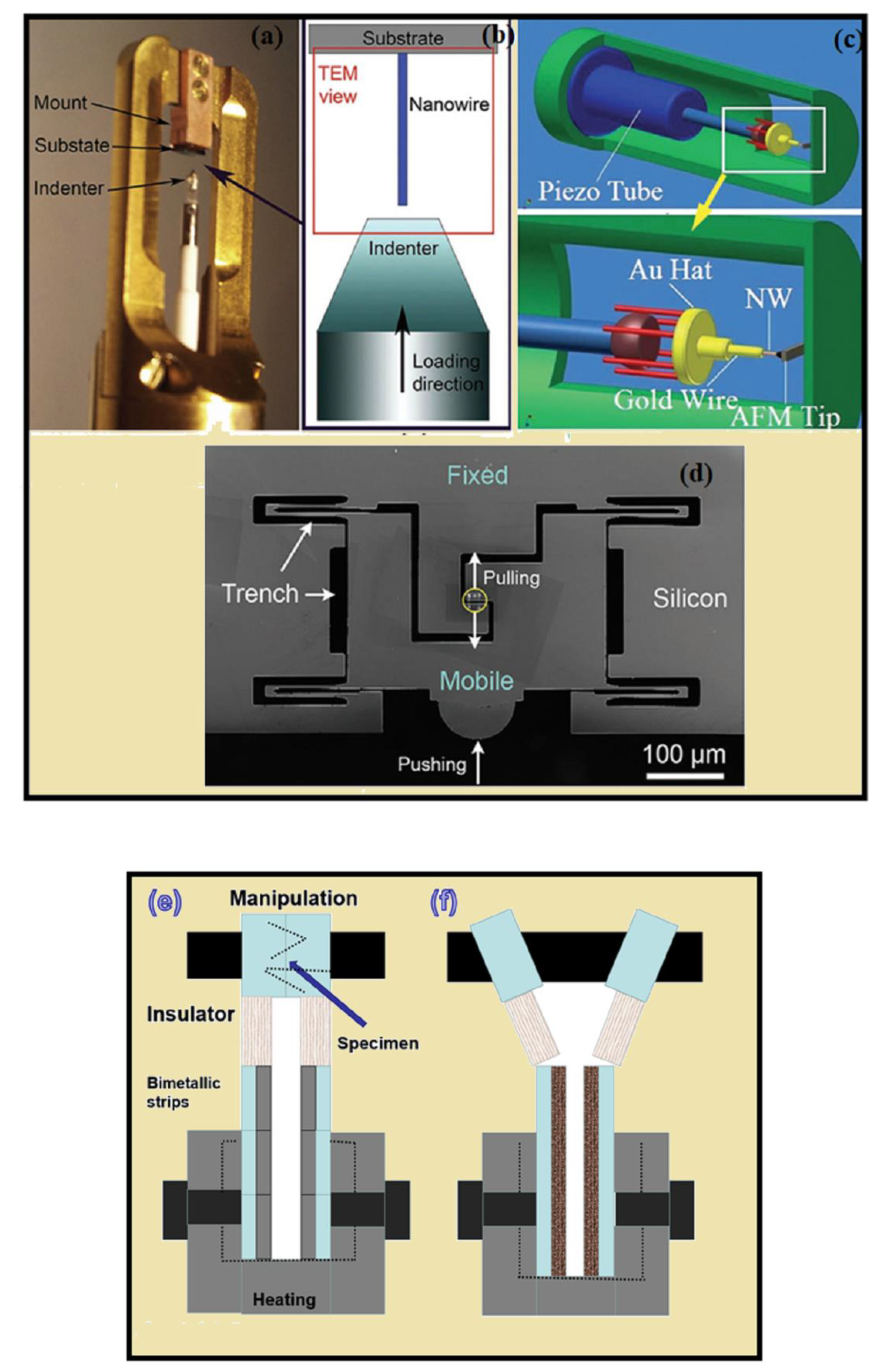

4.1. Mechanical Properties

4.2. Magnetic Properties

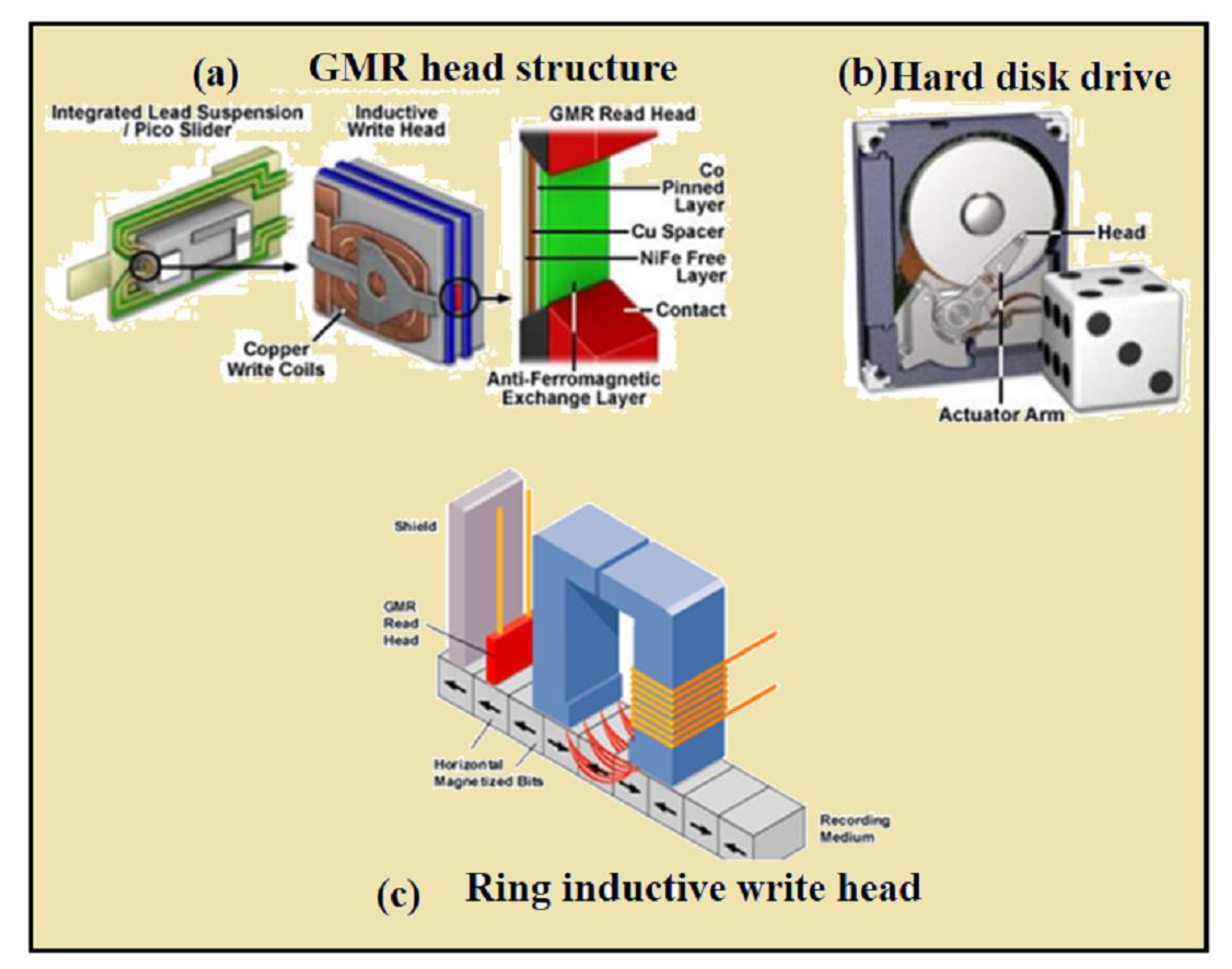

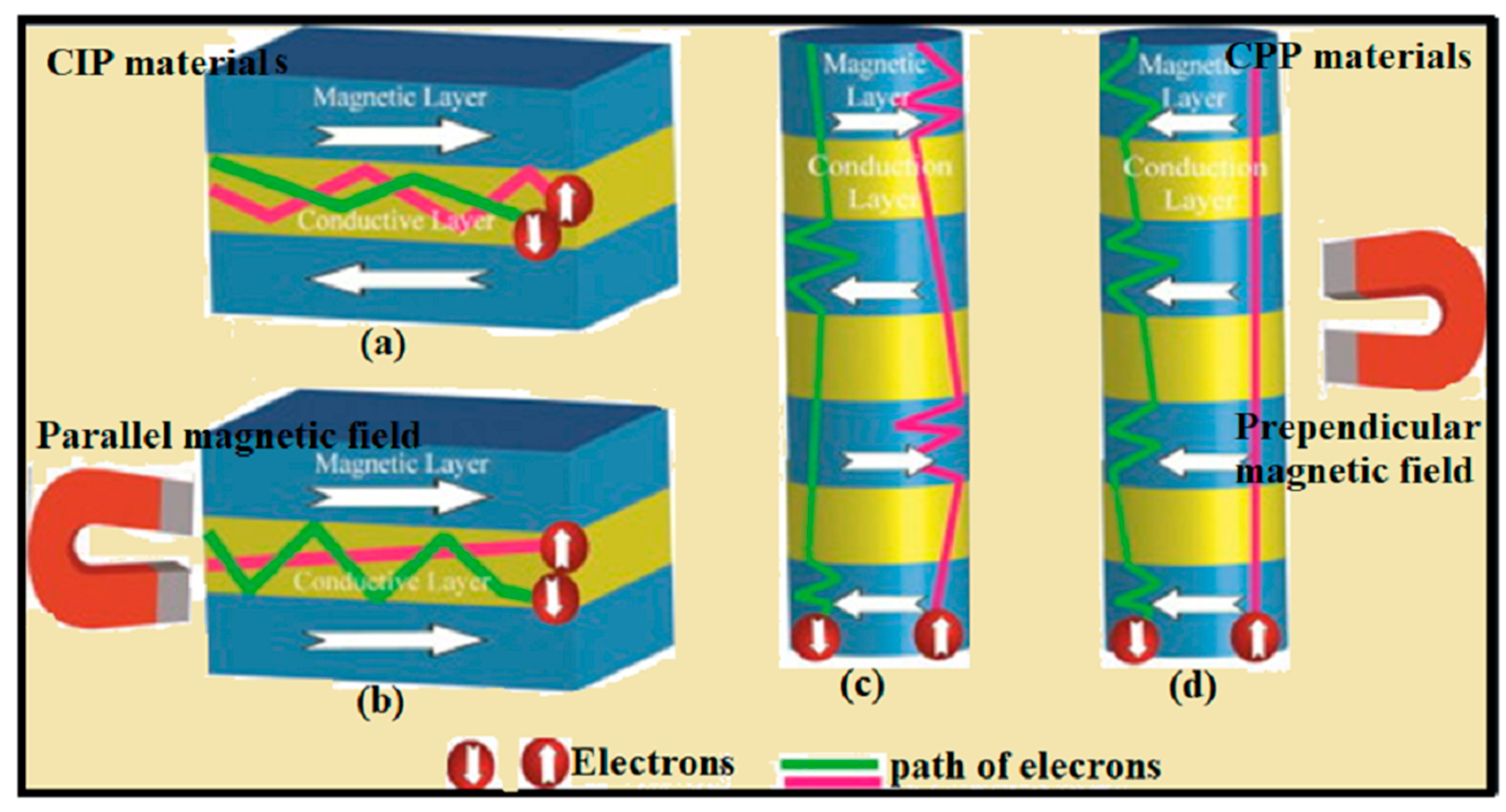

GMR in Nanowires

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Murphy, C.J.; Jana, N.R. Controlling the Aspect Ratio of Inorganic Nanorods and Nanowires. Adv. Mater. 2002, 14, 80–82. [Google Scholar] [CrossRef]

- Bakkers, E.P.A.M.; Feiner, L.F.; Balkenende, A.R. Fabricating a Set of Semiconducting Nanowires, and Electric Device Comprising a Set of Nanowires. U.S. Patent No. 7,825,032, 2 November 2010. [Google Scholar]

- Heidarshenas, B.; Wei, H.; Moghimi, Z. Nanowires in magnetic drug targeting. Material Sci. Eng. 2019, 3, 3–9. [Google Scholar]

- Reppert, J.; He, J.; Skove, M.; Edwards, B.; Tritt, T.; Rao, A. Bismuth Nanowires: Synthesis, Microscopy and Transport Properties. In Proceedings of the APS Meeting Abstracts, San Diego, CA, USA, 28 July–1 August 2007. [Google Scholar]

- Kelly, A. Composite materials after seventy years. J. Mater. Sci. 2006, 41, 905–912. [Google Scholar] [CrossRef]

- Thostenson, E.; Li, C.; Chou, T. Nanocomposites in context. Compos. Sci. Technol. 2005, 65, 491–516. [Google Scholar] [CrossRef]

- Bran, C.; Berganza, E.; Palmero, E.M.; Fernandez-Roldan, J.A.; Del Real, R.P.; Aballe, L.; Foerster, M.; Asenjo, A.; Rodríguez, A.F.; Vazquez, M. Spin configuration of cylindrical bamboo-like magnetic nanowires. J. Mater. Chem. C 2016, 4, 978–984. [Google Scholar] [CrossRef]

- Bicelli, L.P.; Bozzini, B.; Mele, C.; D’Urzo, L. A review of nanostructural aspects of metal electrodeposition. Int. J. Electrochem. Sci. 2008, 3, 356–408. [Google Scholar]

- Hyun, J.K.; Zhang, S.; Lauhon, L.J. Nanowire heterostructures. Annu. Rev. Mater. Res. 2013, 43, 451–479. [Google Scholar] [CrossRef]

- Li, Y.; Qian, F.; Xiang, J.; Lieber, C.M. Nanowire electronic and optoelectronic devices. Mater. Today 2006, 9, 18–27. [Google Scholar] [CrossRef]

- Yan, R.; Gargas, D.; Yang, P. Nanowire photonics. Nat. Photonics 2009, 3, 569. [Google Scholar] [CrossRef]

- Lu, W.; Lieber, C.M. Semiconductor nanowires. J. Phys. D Appl. Phys. 2006, 39, R387. [Google Scholar] [CrossRef]

- Yuan, J.; Xu, Y.; Mueller, A.H. One-dimensional magnetic inorganic–organic hybrid nanomaterials. Chem. Soc. Rev. 2011, 40, 640–655. [Google Scholar] [CrossRef] [PubMed]

- Nicewarner-Pena, S.R.; Freeman, R.G.; Reiss, B.D.; He, L.; Peña, D.J.; Walton, I.D.; Cromer, R.; Keating, C.D.; Natan, M.J. Submicrometer metallic barcodes. Science 2001, 294, 137–141. [Google Scholar] [CrossRef] [PubMed]

- Rojo, M.M.; Calero, O.C.; Lopeandia, A.F.; Rodriguez-Viejo, J.; Martín-Gonzalez, M. Review on measurement techniques of transport properties of nanowires. Nanoscale 2013, 5, 11526–11544. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Li, T.; Xu, T.; Kiristi, M.; Liu, W.; Wu, Z.; Wang, J. Magneto–acoustic hybrid nanomotor. Nano Lett. 2015, 15, 4814–4821. [Google Scholar] [CrossRef] [PubMed]

- Kawamura, G.; Muto, H.; Matsuda, A. Hard template synthesis of metal nanowires. Front. Chem. 2014, 2, 104. [Google Scholar] [CrossRef]

- Hu, L.; Wu, H.; Cui, Y. Metal nanogrids, nanowires, and nanofibers for transparent electrodes. MRS Bull. 2011, 36, 760–765. [Google Scholar] [CrossRef]

- Shin, S.-H.; Kim, G.-Y.; Shim, J.; Kim, J.; Hur, H.-G.; Lee, D.-J.; Song, L.-I.; Moon, S.-H. Use of biologically designed gold nanowire for biosensor application. Korean J. Chem. Eng. 2012, 29, 1666–1669. [Google Scholar] [CrossRef]

- Proenca, M.; Sousa, C.; Escrig, J.; Ventura, J.; Vazquez, M.; Araujo, J. Magnetic interactions and reversal mechanisms in Co nanowire and nanotube arrays. J. Appl. Phys. 2013, 113, 093907. [Google Scholar] [CrossRef]

- Wang, Q.; Min, F.; Zhu, J. Preparation of gold nanowires and its application in glucose biosensing. Mater. Lett. 2013, 91, 9–11. [Google Scholar] [CrossRef]

- Routkevitch, D.; Tager, A.A.; Haruyama, J.; Almawlawi, D.; Moskovits, M.; Xu, J.M. Nonlithographic nano-wire arrays: Fabrication, physics, and device applications. IEEE Trans. Electron Devices 1996, 43, 1646–1658. [Google Scholar] [CrossRef]

- Sattayasamitsathit, S.; Burdick, J.; Bash, R.; Kanatharana, P.; Thavarungkul, P.; Wang, J. Alloy nanowires bar codes based on nondestructive X-ray fluorescence readout. Anal. Chem. 2007, 79, 7571–7575. [Google Scholar] [CrossRef] [PubMed]

- Walton, I.D.; Norton, S.M.; Arjuna, B.; Lin, H.; Oviso, D.F.; Dimpy, G.; Raju, P.-A.; Natan, M.; Freeman, R.-G. Particles for multiplexed analysis in solution: Detection and identification of striped metallic particles using optical microscopy. Anal. Chem. 2002, 74, 2240–2247. [Google Scholar] [CrossRef] [PubMed]

- Simovski, C.R.; Belov, P.A.; Atrashchenko, A.V.; Kivshar, Y.S. Wire metamaterials: Physics and applications. Adv. Mater. 2012, 24, 4229–4248. [Google Scholar] [CrossRef] [PubMed]

- Gudiksen, M.S.; Lauhon, L.J.; Jianfang, W.; Smith, D.C.; Lieber, C.M. Growth of nanowire superlattice structures for nanoscale photonics and electronics. Nature 2002, 415, 617–620. [Google Scholar] [CrossRef] [PubMed]

- Wang, J. Barcoded metal nanowires. J. Mater. Chem. 2008, 18, 4017–4020. [Google Scholar] [CrossRef]

- Lai, J.; Ling, Z.; Qi, W.; Zhao, J.; Min, X.; Gao, W.; Xu, G. Facile Synthesis of Porous PtM (M = Cu, Ni) Nanowires and Their Application as Efficient Electrocatalysts for Methanol Electrooxidation. Chemcatchem 2014, 6, 2253–2257. [Google Scholar] [CrossRef]

- Possin, G.E. A method for forming very small diameter wires. Rev. Sci. Instrum. 1970, 41, 772–774. [Google Scholar] [CrossRef]

- Masuda, H.; Mizuno, T.; Baba, N.; Ohmori, T. Fabrication of Pt microporous electrodes from anodic porous alumina and immobilization of GOD into their micropores. J. Electroanal. Chem. 1994, 368, 333–336. [Google Scholar] [CrossRef]

- Choi, J.; Sauer, G.; Nielsch, K.; Wehrspohn, R.B.; Gösele, U. Hexagonally Arranged Monodisperse Silver Nanowires with Adjustable Diameter and High Aspect Ratio. Chem. Mater. 2003, 15, 776. [Google Scholar] [CrossRef]

- Nielsch, K.; Muller, F.; Li, A.P.; Gosele, U. Uniform Nickel Deposition into Ordered Alumina Pores by Pulsed Electrodeposition. Cheminform 2010, 31, 582–586. [Google Scholar] [CrossRef]

- Asoh, H.; Nishio, K.; Nakao, M.; Tamamura, T.; Masuda, H. Conditions for fabrication of ideally ordered anodic porous alumina using pretextured Al. J. Electrochem. Soc. 2001, 148, B152–B156. [Google Scholar] [CrossRef]

- Masuda, H.; Fukuda, K. Ordered metal nanohole arrays made by a two-step replication of honeycomb structures of anodic alumina. Science 1995, 268, 1466–1468. [Google Scholar] [CrossRef] [PubMed]

- Masuda, H.; Asoh, H.; Watanabe, M.; Nishio, K.; Nakao, M.; Tamamura, T. Square and Triangular Nanohole Array Architectures in Anodic Alumina. Adv. Mater. 2001, 13, 189–192. [Google Scholar] [CrossRef]

- Lee, W.; Park, S.J. Porous anodic aluminum oxide: Anodization and templated synthesis of functional nanostructures. Chem. Rev. 2014, 114, 7487–7556. [Google Scholar] [CrossRef] [PubMed]

- Alkire, R.C.; Gogotsi, Y.; Simon, P. Nanostructured Materials in Electrochemistry; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Manzano, C.; Best, J.; Schwiedrzik, J.; Cantarero, A.; Michler, J.; Philippe, L. The influence of thickness, interpore distance and compositional structure on the optical properties of self-ordered anodic aluminum oxide films. J. Mater. Chem. C 2016, 4, 7658–7666. [Google Scholar] [CrossRef]

- Han, X.; Shen, W. Improved two-step anodization technique for ordered porous anodic aluminum membranes. J. Electroanal. Chem. 2011, 655, 56–64. [Google Scholar] [CrossRef]

- Lee, W.; Ji, R.; Gösele, U.; Nielsch, K. Fast fabrication of long-range ordered porous alumina membranes by hard anodization. Nat. Mater. 2006, 5, 741. [Google Scholar] [CrossRef]

- Chu, S.Z.; Wada, K.; Inoue, S.; Isogai, M.; Katsuta, Y.; Yasumori, A. Large-Scale Fabrication of Ordered Nanoporous Alumina Films with Arbitrary Pore Intervals by Critical-Potential Anodization. J. Electrochem. Soc. 2006, 153, B384–B391. [Google Scholar] [CrossRef]

- Chu, S.-Z.; Wada, K.; Inoue, S.; Isogai, M.; Yasumori, A. Fabrication of Ideally Ordered Nanoporous Alumina Films and Integrated Alumina Nanotubule Arrays by High-Field Anodization. Adv. Mater. 2005, 17, 2115–2119. [Google Scholar] [CrossRef]

- Ono, S.; Saito, M.; Ishiguro, M.; Asoh, H. Controlling Factor of Self-Ordering of Anodic Porous Alumina. J. Electrochem. Soc. 2004, 151, B473–B478. [Google Scholar] [CrossRef]

- Li, A.P.; Müller, F.; Birner, A.; Nielsch, K.; Gösele, U. Polycrystalline nanopore arrays with hexagonal ordering on aluminum. J. Vac. Sci. Technol. A 1999, 17, 1428–1431. [Google Scholar] [CrossRef]

- Li, A.P.; Müller, F.; Gösele, U. Polycrystalline and Monocrystalline Pore Arrays with Large Interpore Distance in Anodic Alumina. Electrochem. Solid State Lett. 2000, 3, 131–134. [Google Scholar] [CrossRef]

- Li, A.P.; Müller, F.; Birner, A.; Nielsch, K.; Gösele, U. Hexagonal pore arrays with a 50–420 nm interpore distance formed by self-organization in anodic alumina. J. Appl. Phys. 1998, 84, 6023–6026. [Google Scholar] [CrossRef]

- Jessensky, O.; Müller, F.; Gösele, U. Self-Organized Formation of Hexagonal Pore Structures in Anodic Alumina. J. Electrochem. Soc. 1998, 145, 3735–3740. [Google Scholar] [CrossRef]

- Rajendra, A.; Parmar, B.J.; Sharma, A.; Bhojraj, H.; Nayak, M.; Rajanna, K. Hard anodisation of aluminium and its application to sensorics. Surf. Eng. 2005, 21, 193–197. [Google Scholar] [CrossRef]

- Balasubramanian, S.; Shenoi, B. Hard anodizing aluminum and its alloys-ac in sulfuric-acid sodium-sulfate BATH. Metal Finish. 1984, 82, 33–39. [Google Scholar]

- Hecker, J. Aluminum hard coats. Prod. Finish. 1988, 53, 88–92. [Google Scholar]

- Schwirn, K.; Lee, W.; Hillebrand, R.; Steinhart, M.; Nielsch, K.; Gösele, U. Self-ordered anodic aluminum oxide formed by H2SO4 hard anodization. ACS Nano. 2008, 2, 302–310. [Google Scholar] [CrossRef]

- Mohammed, H.; Moreno, J.A.; Kosel, J. Advanced Fabrication and Characterization of Magnetic Nanowires. In Magnetism and Magnetic Materials; IntechOpen: London, UK, 2017. [Google Scholar]

- El Mendili, Y.; Bardeau, J.-F.; Randrianantoandro, N.; Greneche, J.-M.; Grasset, F. Structural behavior of laser-irradiated γ-Fe2O3 nanocrystals dispersed in porous silica matrix: γ-Fe2O3 to α-Fe2O3 phase transition and formation of ε-Fe2O3. Sci. Technol. Adv. Mater. 2016, 17, 597–609. [Google Scholar] [CrossRef]

- Apel, P.Y.; Dmitriev, S. Micro-and nanoporous materials produced using accelerated heavy ion beams. Adv. Nat. Sci. Nanosci. Nanotechnol. 2011, 2, 013002. [Google Scholar] [CrossRef]

- Stano, M.; Fruchart, O. Magnetic nanowires and nanotubes. Handb. Magn. Mater. 2018, 27, 155. [Google Scholar]

- Serrà, A.; Vázquez-Mariño, G.; García-Torres, J.; Bosch, M.; Vallés, E. Magnetic actuation of multifunctional nanorobotic platforms to induce cancer cell death. Adv. Biosyst. 2018, 2, 1700220. [Google Scholar] [CrossRef]

- Duan, C.; Wang, W.; Xie, Q. Fabrication of nanofluidic devices. Biomicrofluidics 2013, 7, 026501. [Google Scholar] [CrossRef] [PubMed]

- Taheri, A.; Saramad, S.; Setayeshi, S. ZnO nanowires in polycarbonate membrane as a high resolution X-ray detector (a Geant4 simulation). Nucl. Instrum. Methods Phys. Res. Sect. A 2013, 716, 15–22. [Google Scholar] [CrossRef]

- Bae, S.Y.; Cho, D.H.; Kim, H.T.; Kumazawa, H. Transport of oxygen and carbon dioxide through polycarbonate membrane. Korean J. Chem. Eng. 1994, 11, 127–130. [Google Scholar] [CrossRef]

- Min, K.-J.; Shul, Y.-G.; Kim, H.; Chun, M.-S. Change of surface property and flux of polycarbonate membrane by surface modification with fluorine. Front. Sep. Sci. Technol. 2004, 555–560. [Google Scholar]

- Stanňo, M. Magnetic Microscopy of Domains and Domain Walls in Ferromagnetic Nanotubes; Université Grenoble Alpes: Grenoble, France, 2017. [Google Scholar]

- Zach, M.P.; Ng, K.H.; Penner, R.M. Molybdenum Nanowires by Electrodeposition. Science 2000, 290, 2120–2123. [Google Scholar] [CrossRef]

- Li, Q.; Brown, M.A.; Hemminger, J.C.; Penner, R.M. Luminescent Polycrystalline Cadmium Selenide Nanowires Synthesized by Cyclic Electrodeposition/Stripping Coupled with Step Edge Decoration. Chem. Mater. 2006, 18, 3432–3441. [Google Scholar] [CrossRef]

- Bowling, R.J.; Packard, R.T.; McCreery, R.L. Activation of highly ordered pyrolytic graphite for heterogeneous electron transfer: Relationship between electrochemical performance and carbon microstructure. J. Am. Chem. Soc. 1989, 111, 1217–1223. [Google Scholar] [CrossRef]

- Rice, R.J.; McCreery, R.L. Quantitative relationship between electron transfer rate and surface microstructure of laser-modified graphite electrodes. Anal. Chem. 1989, 61, 1637–1641. [Google Scholar] [CrossRef]

- Menke, E.; Brown, M.; Li, Q.; Hemminger, J.; Penner, R. Bismuth telluride (Bi2Te3) nanowires: Synthesis by cyclic electrodeposition/stripping, thinning by electrooxidation, and electrical power generation. Langmuir 2006, 22, 10564–10574. [Google Scholar] [CrossRef] [PubMed]

- Menke, E.; Li, Q.; Penner, R. Bismuth telluride (Bi2Te3) nanowires synthesized by cyclic electrodeposition/stripping coupled with step edge decoration. Nano Lett. 2004, 4, 2009–2014. [Google Scholar] [CrossRef]

- Li, Q.; Walter, E.C.; Van der Veer, W.E.; Murray, B.J.; Newberg, J.T.; Bohannan, E.W.; Switzer, J.A.; Hemminger, J.C.; Penner, R.M. Molybdenum Disulfide Nanowires and Nanoribbons by Electrochemical/Chemical Synthesis. J. Phys. Chem. B 2005, 109, 3169–3182. [Google Scholar] [CrossRef]

- Cao, X.; Zhang, X.; Shao, H.; Feng, Y. Fabrication of Magnetic Fe3O4 Nanotubes by Electrospinning. Rare Metal Mater. Eng. 2014, 43, 2330–2334. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, R.; Liu, X.; Lin, D.; Pan, W. Electrospinning of Fe, Co, and Ni Nanofibers: Synthesis, Assembly, and Magnetic Properties. Chem. Mater. 2007, 19, 3506–3511. [Google Scholar] [CrossRef]

- Sakar, M.; Balakumar, S.; Saravanan, P.; Jaisankar, S.N. Electric field induced formation of one-dimensional bismuth ferrite (BiFeO3) nanostructures in electrospinning process. Mater. Des. 2016, 94, 487–495. [Google Scholar] [CrossRef]

- Barakat, N.A.; Khalil, K.A.; Mahmoud, I.H.; Kanjwal, M.A.; Sheikh, F.A.; Kim, H.Y. CoNi bimetallic nanofibers by electrospinning: Nickel-based soft magnetic material with improved magnetic properties. J. Phys. Chem. C 2010, 114, 15589–15593. [Google Scholar] [CrossRef]

- Zhang, X.; Pan, W.; Dong, J.; Liu, Q.; Wang, J. Fabrication and characterization of FePt magnetic nanofibers via electrospinning technique. J. Mater. Sci. 2015, 50, 7218–7226. [Google Scholar] [CrossRef]

- Chen, H.; Wang, N.; Di, J.; Zhao, Y.; Song, Y.; Jiang, L. Nanowire-in-microtube structured core/shell fibers via multifluidic coaxial electrospinning. Langmuir 2010, 26, 11291–11296. [Google Scholar] [CrossRef]

- Liu, W.; Ni, C.; Chase, D.B.; Rabolt, J.F. Preparation of multilayer biodegradable nanofibers by triaxial electrospinning. ACS Macro Lett. 2013, 2, 466–468. [Google Scholar] [CrossRef]

- Motoyama, M.; Fukunaka, Y.; Sakka, T.; Ogata, Y. Initial stages of electrodeposition of metal nanowires in nanoporous templates. Electrochim. Acta 2007, 53, 205–212. [Google Scholar] [CrossRef]

- Petrii, O.A. Electrosynthesis of nanostructures and nanomaterials. Russ. Chem. Rev. 2015, 84, 159. [Google Scholar] [CrossRef]

- Mehmood, T.; Wu, K.; Mukhtar, A.; Khan, B.S.; Saeed, A.; Latif, H.; Parveen, Z.; Kazmi, S.-R. Electrochemically fabricated Fe–Ni alloy nanowires and their structural characterization. Int. J. Mater. Res. 2017, 108, 688–692. [Google Scholar] [CrossRef]

- Tench, D.; White, J. Enhanced tensile strength for electrodeposited nickel-copper multilayer composites. Metall. Trans. A 1984, 15, 2039–2040. [Google Scholar] [CrossRef]

- Yahalom, J.; Zadok, O. Formation of composition-modulated alloys by electrodeposition. J. Mater. Sci. 1987, 22, 499–503. [Google Scholar] [CrossRef]

- Ueda, Y.; Houga, T.; Zaman, H.; Yamada, A. Magnetoresistance Effect of Co–Cu Nanostructure Prepared by Electrodeposition Method. J. Solid State Chem. 1999, 147, 274–280. [Google Scholar] [CrossRef]

- Tóth-Kádár, E.; Péter, L.; Becsei, T.; Tóth, J.; Pogány, L.; Tarnóczi, T.; Kamasa, P.; Lang, G.; Cziraki, A.; Schwarzacher, W. Preparation and Magnetoresistance Characteristics of Electrodeposited Ni-Cu Alloys and Ni-Cu/Cu Multilayers. J. Electrochem. Soc. 2000, 147, 3311–3318. [Google Scholar]

- Pasa, A.A.; Schwarzacher, W. Electrodeposition of Thin Films and Multilayers on Silicon. Phys. Status Solidi (a) 1999, 173, 73–84. [Google Scholar] [CrossRef]

- Mosca, D.H.; Petroff, F.; Fert, A.; Schroeder, P.A.; Pratt, W.P.; Laloee, R. Oscillatory interlayer coupling and giant magnetoresistance in Co/Cu multilayers. J. Magn. Magn. Mater. 1991, 94, L1–L5. [Google Scholar] [CrossRef]

- Tsunoda, M.; Arai, H.; Takahashi, D.; Miura, S.; Takahashi, M. Interactive effect of impurities on giant magnetoresistance of Co–Fe/Cu multilayers. J. Magn. Magn. Mater. 2002, 240, 189–191. [Google Scholar] [CrossRef]

- Chen, M.; Chien, C.-L.; Searson, P.C. Potential Modulated Multilayer Deposition of Multisegment Cu/Ni Nanowires with Tunable Magnetic Properties. Chem. Mater. 2006, 18, 1595–1601. [Google Scholar] [CrossRef]

- Berganza, E.; Jaafar, M.; Bran, C.; Fernández-Roldán, J.; Chubykalo-Fesenko, O.; Vázquez, M.; Asenjo, A. Multisegmented Nanowires: A Step towards the Control of the Domain Wall Configuration. Sci. Rep. 2017, 7, 11576. [Google Scholar] [CrossRef] [PubMed]

- Zheng, W. Fundamentals of Electrochemical Deposition. Corrosion 2003, 59, 88. [Google Scholar]

- Mohammed, H.; Vidal, E.V.; Ivanov, Y.P.; Kosel, J. Magnetotransport measurements of domain wall propagation in individual multisegmented cylindrical nanowires. IEEE Trans. Magn. 2016, 52, 1–5. [Google Scholar] [CrossRef]

- Geng, X.; Podlaha, E.J. Coupled, Simultaneous Displacement and Dealloying Reactions into Fe–Ni–Co Nanowires for Thinning Nanowire Segments. Nano Lett. 2016, 16, 7439–7445. [Google Scholar] [CrossRef]

- Rieger, P. Electrochemistry; Prentice-Hall Inc.: Englewood Cliffs, NJ, USA, 1987. [Google Scholar]

- Péter, L.; Liu, Q.; Kerner, Z.; Bakonyi, I. Relevance of the potentiodynamic method in parameter selection for pulse-plating of Co–Cu/Cu multilayers. Electrochim. Acta 2004, 49, 1513–1526. [Google Scholar] [CrossRef]

- Weihnacht, V.; Péter, L.; Tóth, J.; Pádár, J.; Kerner, Z.; Schneider, C.M.; Bakonyi, I. Giant Magnetoresistance in Co-Cu/Cu Multilayers Prepared by Various Electrodeposition Control Modes. J. Electrochem. Soc. 2003, 150, C507–C515. [Google Scholar] [CrossRef]

- Cziráki, Á.; Péter, L.; Weihnacht, V.; Tóth, J.; Simon, E.; Pádár, J.; Pogány, L.; Schneider, C.M.; Gemming, T.; Wetzig, K.; et al. Structure and Giant Magnetoresistance Behaviour of Co–Cu/Cu Multilayers Electrodeposited Under Various Deposition Conditions. J. Nanosci. Nanotechnol. 2006, 6, 2000–2012. [Google Scholar] [CrossRef]

- Zhang, J.; Ma, H.; Zhang, S.; Zhang, H.; Deng, X.; Lan, Q.; Xue, D.; Bai, F.; Mellors, N.-J.; Peng, Y. Nanoscale characterisation and magnetic properties of Co 81 Cu 19/Cu multilayer nanowires. J. Mater. Chem. C 2015, 3, 85–93. [Google Scholar] [CrossRef]

- Jang, B.; Pellicer, E.; Guerrero, M.; Chen, X.; Choi, H.; Nelson, B.J.; Sort, J.; Pane, S. Fabrication of segmented Au/Co/Au nanowires: Insights in the quality of Co/Au Junctions. ACS Appl. Mater. Interfaces 2014, 6, 14583–14589. [Google Scholar] [CrossRef]

- Valizadeh, S.; George, J.; Leisner, P.; Hultman, L. Electrochemical synthesis of Ag/Co multilayered nanowires in porous polycarbonate membranes. Thin Solid Films 2002, 402, 262–271. [Google Scholar] [CrossRef]

- Tóth, B.G.; Péter, L.; Dégi, J.; Révész, Á.; Oszetzky, D.; Molnár, G.; Bakonyi, I. Influence of Cu deposition potential on the giant magnetoresistance and surface roughness of electrodeposited Ni–Co/Cu multilayers. Electrochim. Acta 2013, 91, 122–129. [Google Scholar]

- Kazeminezhad, I.; Blythe, H.; Schwarzacher, W. Alloys by precision electrodeposition. Appl. Phys. Lett. 2001, 78, 1014–1016. [Google Scholar] [CrossRef]

- Ramazani, A.; Ghaffari, M.; Kashi, M.A.; Kheiry, F.; Eghbal, F. A new approach to fabricating magnetic multilayer nanowires by modifying the ac pulse electrodeposition in a single bath. J. Phys. D Appl. Phys. 2014, 47, 355003. [Google Scholar] [CrossRef]

- Neetzel, C.; Ohgai, T.; Yanai, T.; Nakano, M.; Fukunaga, H. Uniaxial Magnetization Performance of Textured Fe Nanowire Arrays Electrodeposited by a Pulsed Potential Deposition Technique. Nanoscale Res. Lett. 2017, 12, 598. [Google Scholar] [CrossRef] [PubMed]

- Özkale, B.; Shamsudhin, N.; Chatzipirpiridis, G.; Hoop, M.; Gramm, F.; Chen, X.; Marti, X.; Sort, J.; Pellicer, E.; Pane, S. Multisegmented FeCo/Cu nanowires: Electrosynthesis, characterization, and magnetic control of biomolecule desorption. ACS Appl. Mater. Interfaces 2015, 7, 7389–7396. [Google Scholar]

- Bochmann, S.; Fernandez-Pacheco, A.; Mačković, M.; Neff, A.; Siefermann, K.; Spiecker, E.; Cowburn, R.-P.; Bachmann, J. Systematic tuning of segmented magnetic nanowires into three-dimensional arrays of ‘bits’. RSC Adv. 2017, 7, 37627–37635. [Google Scholar] [CrossRef]

- Tekgül, A.; Kockar, H.; Kuru, H.; Alper, M. Electrochemical Deposition of CoCu/Cu Multilayers: Structural and Magnetic Properties as a Function of Non-magnetic Layer Thickness. Z. Naturforschung A 2018, 73, 127–133. [Google Scholar] [CrossRef]

- Dariel, M.; Bennett, L.; Lashmore, D.; Lubitz, P.; Rubinstein, M.; Lechter, W.; Harford, M.-Z. Properties of electrodeposited Co-Cu multilayer structures. J. Appl. Phys. 1987, 61, 4067–4069. [Google Scholar] [CrossRef]

- Peng, C.-H.; Wu, T.-Y.; Hwang, C.-C. A preliminary study on the synthesis and characterization of multilayered Ag/Co magnetic nanowires fabricated via the electrodeposition method. Sci. World J. 2013. [Google Scholar] [CrossRef]

- Lucatero, S.; Podlaha, E. Electrodeposited Au/FeAu Nanowires with Controlled Porosity of the FeAu Layer. In Meeting Abstracts; The Electrochemical Society: Pennington, NJ, USA, 2009; p. 57. [Google Scholar]

- Saidin, N.; Kok, K.; Ng, I.; Ilias, S. Fabrication of Au/Ni Multilayered Nanowires by Electrochemical Deposition. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2013; p. 012006. [Google Scholar]

- Choi, J.-R.; Oh, S.J.; Ju, H.; Cheon, J. Massive fabrication of free-standing one-dimensional Co/Pt nanostructures and modulation of ferromagnetism via a programmable barcode layer effect. Nano Lett. 2005, 5, 2179–2183. [Google Scholar] [CrossRef] [PubMed]

- Su, Y.-K.; Qin, D.-H.; Zhang, H.-L.; Li, H.; Li, H.-L. Microstructure and magnetic properties of bamboo-like CoPt/Pt multilayered nanowire arrays. Chem. Phys. Lett. 2004, 388, 406–410. [Google Scholar] [CrossRef]

- Reddy, S.M.; Park, J.J.; Na, S.M.; Maqableh, M.M.; Flatau, A.B.; Stadler, B.J. Electrochemical synthesis of magnetostrictive Fe–Ga/Cu multilayered nanowire arrays with tailored magnetic response. Adv. Funct. Mater. 2011, 21, 4677–4683. [Google Scholar] [CrossRef]

- Tian, M.; Wang, J.; Kurtz, J.; Mallouk, T.E.; Chan, M.H.-W. Electrochemical growth of single-crystal metal nanowires via a two-dimensional nucleation and growth mechanism. Nano Lett. 2003, 3, 919–923. [Google Scholar] [CrossRef] [PubMed]

- Pan, H.; Sun, H.; Poh, C.; Feng, Y.; Lin, J. Single-crystal growth of metallic nanowires with preferred orientation. Nanotechnology 2005, 16, 1559. [Google Scholar] [CrossRef]

- Rahman, I.; Razeeb, K.; Rahman, M.; Kamruzzaman, M. Fabrication and characterization of nickel nanowires deposited on metal substrate. J. Magn. Magn. Mater. 2003, 262, 166–169. [Google Scholar] [CrossRef]

- Pan, H.; Liu, B.; Yi, J.; Poh, C.; Lim, S.; Ding, J.; Feng, Y.; Huan, C.H.A.; Lin, J. Growth of single-crystalline Ni and Co nanowires via electrochemical deposition and their magnetic properties. J. Phys. Chem. B 2005, 109, 3094–3098. [Google Scholar] [CrossRef]

- Wang, X.W.; Fei, G.T.; Xu, X.J.; Jin, Z.; Zhang, L.D. Size-dependent orientation growth of large-area ordered Ni nanowire arrays. J. Phys. Chem. B 2005, 109, 24326–24330. [Google Scholar] [CrossRef]

- Wang, X.W.; Fei, G.T.; Chen, L.; Xu, X.J.; De Zhang, L. Orientation-controllable growth of Ni nanowire arrays with different diameters. Electrochem. Solid State Lett. 2007, 10, E1–E3. [Google Scholar] [CrossRef]

- Xu, X.J.; Fei, G.T.; Yu, W.H.; Chen, L.; De Zhang, L.; Ju, X.; Hao, X.-P.; Wang, B.-Y. In situ X-ray diffraction study of the thermal expansion of the ordered arrays of silver nanowires embedded in anodic alumina membranes. Appl. Phys. Lett. 2006, 88, 211902. [Google Scholar] [CrossRef]

- Tan, M.; Chen, X. Growth mechanism of single crystal nanowires of fcc metals (Ag, Cu, Ni) and hcp metal (Co) electrodeposited. J. Electrochem. Soc. 2011, 159, K15–K20. [Google Scholar] [CrossRef]

- Pirota, K.R.; Vazquez, M. Arrays of Electroplated Multilayered Co/Cu Nanowires with Controlled Magnetic Anisotropy. Adv. Eng. Mater. 2005, 7, 1111–1113. [Google Scholar] [CrossRef]

- Irshad, M.I.; Mohamed, N.M.; Abdullah, M.Z.; Saheed, M.S.M.; Mumtaz, A.; Yasar, M.; Yar, A.; Zeeshan, M.A.; Sort, J. Influence of the electrodeposition potential on the crystallographic structure and effective magnetic easy axis of cobalt nanowires. RSC Adv. 2016, 6, 14266–14272. [Google Scholar] [CrossRef]

- Kaur, D.; Chaudhary, S.; Pandya, D.K. Manifestations in the magnetization of the hcp-Co nanowires due to interdependence of aspect ratio and c-axis orientation. J. Appl. Phys. 2013, 114, 043909. [Google Scholar] [CrossRef]

- Mukhtar, A.; Mehmood, T.; Khan, B.S.; Tan, M. Effect of Co2+ concentration on the crystal structure of electrodeposited Co nanowires. J. Cryst. Growth 2016, 441, 26–32. [Google Scholar] [CrossRef]

- Mehmood, T.; Khan, B.S.; Mukhtar, A.; Chen, X.; Yi, P.; Tan, M. Mechanism for formation of fcc-cobalt nanowires in electrodeposition at ambient temperature. Mater. Lett. 2014, 130, 256–258. [Google Scholar] [CrossRef]

- Mehmood, T.; Khan, B.S.; Mukhtar, A.; Tan, M. Influence of bath temperature and pH on the structure of electrodeposited cobalt nanowires. Int. J. Mater. Res. 2015, 106, 957–961. [Google Scholar] [CrossRef]

- Mukhtar, A.; Mehmood, T.; Wu, K.; Khan, B.S.; Latif, H.; Parveen, Z.; Kazmi, S.-R. Study of phase transformation and crystal structure of Co nanowires. Int. J. Mater. Res. 2017, 108, 710–714. [Google Scholar] [CrossRef]

- Mukhtar, A.; Cao, X.-M.; Mehmood, T.; Wang, D.-S.; Wu, K.-M. Structural characterization of self-assembled chain like Fe-FeOx Core shell nanostructure. Nanoscale Res. Lett. 2019, 14, 308. [Google Scholar] [CrossRef]

- Pirota, K.; Béron, F.; Zanchet, D.; Rocha, T.; Navas, D.; Torrejón, J.; Vazquez, M.; Knobel, M. Magnetic and structural properties of fcc/hcp bi-crystalline multilayer Co nanowire arrays prepared by controlled electroplating. J. Appl. Phys. 2011, 109, 083919. [Google Scholar] [CrossRef]

- Wang, X.W.; Yuan, Z.H.; Sun, S.Q.; Duan, Y.Q.; Bie, L.J. Thermal expansion behaviors of hcp and fcc Co nanowire arrays. Phys. Lett. A 2009, 373, 2887–2889. [Google Scholar] [CrossRef]

- Bird, K.D.; Schlesinger, M. Giant magnetoresistance in electrodeposited Ni/Cu and Co/Cu multilayers. J. Electrochem. Soc. 1995, 142, L65–L66. [Google Scholar] [CrossRef]

- Vilanova Vidal, E.; Ivanov, Y.P.; Mohammed, H.; Kosel, J. A detailed study of magnetization reversal in individual Ni nanowires. Appl. Phys. Lett. 2015, 106, 032403. [Google Scholar] [CrossRef]

- Kim, B.G.; Yoon, S.J.; Jeon, I.T.; Kim, K.H.; Wu, J.H.; Kim, Y.K. Dimensional dependence of magnetic properties in arrays of CoFe/Au barcode nanowire. IEEE Trans. Magn. 2012, 48, 3929–3932. [Google Scholar] [CrossRef]

- Lee, J.H.; Wu, J.H.; Liu, H.L.; Cho, J.U.; Cho, M.K.; An, B.H.; Min, J.H.; Noh, S.J.; Kim, Y.K. Iron–gold barcode nanowires. Angew. Chem. Int. Ed. 2007, 46, 3663–3667. [Google Scholar] [CrossRef]

- Park, B.C.; Kim, B.G.; Seo, H.W.; Kim, Y.K. Magnetic anisotropy evolution in CoFe/Au barcode nanowire arrays. IEEE Trans. Magn. 2013, 50, 1–4. [Google Scholar] [CrossRef]

- Yoon, S.J.; Kim, B.G.; Jeon, I.T.; Wu, J.H.; Kim, Y.K. Compositional dependence of magnetic properties in CoFe/Au nanobarcodes. Appl. Phys. Express 2012, 5, 103003. [Google Scholar] [CrossRef]

- Egerton, R.F. Electron Energy-Loss Spectroscopy in the Electron Microscope; Springer Science & Business Media: Berlin, Germany, 2011. [Google Scholar]

- Bran, C.; Ivanov, Y.P.; Kosel, J.; Chubykalo-Fesenko, O.; Vazquez, M. Co/Au multisegmented nanowires: A 3D array of magnetostatically coupled nanopillars. Nanotechnology 2017, 28, 095709. [Google Scholar] [CrossRef]

- Jeon, I.T.; Yoon, S.J.; Kim, B.G.; Lee, J.S.; An, B.H.; Ju, J.-S.; Wu, J.H.; Kim, Y.K. Magnetic NiFe/Au barcode nanowires with self-powered motion. J. Appl. Phys. 2012, 111, 07B513. [Google Scholar] [CrossRef]

- Mehr, S.S.; Ramazani, A.; Kashi, M.A. Study on magnetic properties of NiFe/Cu multisegmented nanowire arrays with different Cu thicknesses via FORC analysis: Coercivity, interaction, magnetic reversibility. J. Mater. Sci. Mater. Electron. 2018, 29, 18771–18780. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, J.; Li, Y.; Xu, S.; Zhu, Z.; Chen, J.; Wu, G. The pH rule for fabricating composite CoCu nanowire arrays. Chem. Lett. 2006, 36, 166–167. [Google Scholar] [CrossRef]

- Ren, Y.; Wang, J.-B.; Liu, Q.-F.; Han, X.-H.; Xue, D.-S. The effect of substrate on magnetic properties of Co/Cu multilayer nanowire arrays. Chin. Phys. B 2009, 18, 3573–3576. [Google Scholar]

- Reyes, D.; Biziere, N.; Warot-Fonrose, B.; Wade, T.; Gatel, C. Magnetic Configurations in Co/Cu Multilayered Nanowires: Evidence of Structural and Magnetic Interplay. Nano Lett. 2016, 16, 1230–1236. [Google Scholar] [CrossRef] [PubMed]

- Ramulu, T.; Venu, R.; Sinha, B.; Lim, B.; Yoon, S.; Kim, C. Synthesis and cysteamine functionalization of CoFe/Au/CoFe nanowires. Thin Solid Films 2013, 546, 255–258. [Google Scholar] [CrossRef]

- Chen, B.; Wang, J.; Gao, Q.; Chen, Y.; Liao, X.; Lu, C.; Tan, H.H.; Mai, Y.-M.; Zou, J.; Ringer, S.P.; et al. Anelastic behavior in GaAs semiconductor nanowires. Nano Lett. 2013, 13, 3169–3172. [Google Scholar] [CrossRef]

- Chen, B.; Wang, J.; Gao, Q.; Chen, Y.; Liao, X.; Lu, C.; Tan, H.H.; Mai, Y.-W.; Zou, J.; Ringer, S.R.; et al. Strengthening brittle semiconductor nanowires through stacking faults: Insights from in situ mechanical testing. Nano Lett. 2013, 13, 4369–4373. [Google Scholar] [CrossRef]

- Dai, S.; Zhao, J.; He, M.-R.; Wang, X.; Wan, J.; Shan, Z.; Zhu, J. Elastic properties of GaN nanowires: Revealing the influence of planar defects on Young′s modulus at nanoscale. Nano Lett. 2014, 15, 8–15. [Google Scholar] [CrossRef]

- Guo, H.; Chen, K.; Oh, Y.; Wang, K.; Dejoie, C.; Syed Asif, S.; Warren, O.L.; Shan, Z.W.; Wu, J.; Minor, A.M. Mechanics and dynamics of the strain-induced M1–M2 structural phase transition in individual VO2 nanowires. Nano Lett. 2011, 11, 3207–3213. [Google Scholar] [CrossRef]

- Davami, K.; Mortazavi, B.; Ghassemi, H.M.; Yassar, R.S.; Lee, J.-S.; Rémond, Y.; Meyyappan, M. A computational and experimental investigation of the mechanical properties of single ZnTe nanowires. Nanoscale 2012, 4, 897–903. [Google Scholar] [CrossRef]

- Wang, Y.; Lee, C.; Yi, J.; An, X.; Pan, M.; Xie, K.; Liao, X.Z.; Cairney, J.M.; Ringer, S.P.; Wamg, W.H. Ultrahigh-strength submicron-sized metallic glass wires. Scr. Mater. 2014, 84, 27–30. [Google Scholar] [CrossRef]

- Wang, S.; Shan, Z.; Huang, H. The Mechanical Properties of Nanowires. Adv. Sci. 2017, 4, 1600332. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Liao, X. Mechanical Behaviors of Semiconductor Nanowires. In Semiconductors and Semimetals; Elsevier: Amsterdam, The Netherlands, 2016; pp. 109–158. [Google Scholar]

- Zhang, Y.; Han, X.; Zheng, K.; Zhang, Z.; Zhang, X.; Fu, J.; Hao, Y.; Guo, X.; Wang, Z.L. Direct Observation of Super-Plasticity of Beta-SiC Nanowires at Low Temperature. Adv. Funct. Mater. 2007, 17, 3435–3440. [Google Scholar] [CrossRef]

- Yue, Y.; Liu, P.; Zhang, Z.; Han, X.; Ma, E. Approaching the Theoretical Elastic Strain Limit in Copper Nanowires. Nano Lett. 2011, 11, 3151–3155. [Google Scholar] [CrossRef] [PubMed]

- Yue, Y.; Liu, P.; Deng, Q.; Ma, E.; Zhang, Z.; Han, X. Quantitative Evidence of Crossover toward Partial Dislocation Mediated Plasticity in Copper Single Crystalline Nanowires. Nano Lett. 2012, 12, 4045–4049. [Google Scholar] [CrossRef]

- Paunovic, M.; Schlesinger, M. Fundamentals of Electrochemical Deposition; Wiley & Sons, Inc.: New York, NY, USA, 1998. [Google Scholar]

- Zhu, T.; Li, J. Ultra-strength materials. Prog. Mater. Sci. 2010, 55, 710–757. [Google Scholar] [CrossRef]

- Greer, J.R.; Nix, W.D. Size dependence of mechanical properties of gold at the sub-micron scale. Appl. Phys. A 2005, 80, 1625–1629. [Google Scholar] [CrossRef]

- Volkert, C.; Donohue, A.; Spaepen, F. Effect of sample size on deformation in amorphous metals. J. Appl. Phys. 2008, 103, 083539. [Google Scholar] [CrossRef]

- Rinaldi, A.; Peralta, P.; Friesen, C.; Sieradzki, K. Sample-size effects in the yield behavior of nanocrystalline nickel. Acta Mater. 2008, 56, 511–517. [Google Scholar] [CrossRef]

- Seo, J.-H.; Park, H.S.; Yoo, Y.; Seong, T.-Y.; Li, J.; Ahn, J.-P.; Kim, B. Origin of size dependency in coherent-twin-propagation-mediated tensile deformation of noble metal nanowires. Nano Lett. 2013, 13, 5112–5116. [Google Scholar] [CrossRef]

- Greer, J.R.; De Hosson, J.T.M. Plasticity in small-sized metallic systems: Intrinsic versus extrinsic size effect. Prog. Mater. Sci. 2011, 56, 654–724. [Google Scholar] [CrossRef]

- Lee, S.; Im, J.; Yoo, Y.; Bitzek, E.; Kiener, D.; Richter, G.; Kim, B.; Oh, S.H. Reversible cyclic deformation mechanism of gold nanowires by twinning–detwinning transition evidenced from in situ TEM. Nat. Commun. 2014, 5, 3033. [Google Scholar] [CrossRef] [PubMed]

- Jang, D.; Li, X.; Gao, H.; Greer, J.R. Deformation mechanisms in nanotwinned metal nanopillars. Nat. Nanotechnol. 2012, 7, 594. [Google Scholar] [CrossRef] [PubMed]

- Sansoz, F.; Dupont, V. Nanoindentation and plasticity in nanocrystalline Ni nanowires: A case study in size effect mitigation. Scr. Mater. 2010, 63, 1136–1139. [Google Scholar] [CrossRef]

- Chokshi, A.; Rosen, A.; Karch, J.; Gleiter, H. On the validity of the Hall-Petch relationship in nanocrystalline materials. Scr. Metall. 1989, 23, 1679–1683. [Google Scholar] [CrossRef]

- Greer, J.R.; Jang, D.; Gu, X.W. Exploring deformation mechanisms in nanostructured materials. JOM 2012, 64, 1241–1252. [Google Scholar] [CrossRef]

- Carlton, C.; Ferreira, P.J. What is behind the inverse Hall–Petch effect in nanocrystalline materials? Acta Mater. 2007, 55, 3749–3756. [Google Scholar] [CrossRef]

- An, B.H.; Jeon, I.T.; Seo, J.-H.; Ahn, J.-P.; Kraft, O.; Choi, I.-S.; Kim, Y.K. Ultrahigh tensile strength nanowires with a Ni/Ni–Au multilayer nanocrystalline structure. Nano Lett. 2016, 16, 3500–3506. [Google Scholar] [CrossRef]

- Kim, J.-Y.; Jang, D.; Greer, J.R. Insight into the deformation behavior of niobium single crystals under uniaxial compression and tension at the nanoscale. Scr. Mater. 2009, 61, 300–303. [Google Scholar] [CrossRef]

- Kim, J.-Y.; Greer, J.R. Tensile and compressive behavior of gold and molybdenum single crystals at the nano-scale. Acta Mater. 2009, 57, 5245–5253. [Google Scholar] [CrossRef]

- Kim, J.-Y.; Jang, D.; Greer, J.R. Tensile and compressive behavior of tungsten, molybdenum, tantalum and niobium at the nanoscale. Acta Mater. 2010, 58, 2355–2363. [Google Scholar] [CrossRef]

- Richter, G.; Hillerich, K.; Gianola, D.S.; Monig, R.; Kraft, O.; Volkert, C.A. Ultrahigh strength single crystalline nanowhiskers grown by physical vapor deposition. Nano Lett. 2009, 9, 3048–3052. [Google Scholar] [CrossRef] [PubMed]

- Jennings, A.T.; Greer, J.R. Tensile deformation of electroplated copper nanopillars. Philos. Mag. 2011, 91, 1108–1120. [Google Scholar] [CrossRef]

- Ferré, R.; Ounadjela, K.; George, J.M.; Piraux, L.; Dubois, S. Magnetization processes in nickel and cobalt electrodeposited nanowires. Phys. Rev. B 1997, 56, 14066–14075. [Google Scholar] [CrossRef]

- Ji, U.C.; Wu, J.H.; Min, J.H.; Ju, H.L.; Liu, H.L.; Kim, Y.K. Effect of field deposition and pore size on Co/Cu barcode nanowires by electrodeposition. J. Magn. Magn. Mater. 2007, 310, 2420–2422. [Google Scholar]

- Chen, M.; Sun, L.; Bonevich, J.E.; Reich, D.H.; Chien, C.; Searson, P. Tuning the response of magnetic suspensions. Appl. Phys. Lett. 2003, 82, 3310–3312. [Google Scholar] [CrossRef]

- Yao, H.; Xie, L.; Cheng, Y.; Duan, J.; Chen, Y.; Lyu, S.; Sun, Y.; Liu, J. Tuning the coercivity of Cu/Ni multilayer nanowire arrays by tailoring multiple parameters. Mater. Des. 2017, 123, 165–173. [Google Scholar] [CrossRef]

- Song, J.; Li, J.; Xu, J.; Zeng, H. Superstable transparent conductive Cu@Cu4Ni nanowire elastomer composites against oxidation, bending, stretching, and twisting for flexible and stretchable optoelectronics. Nano Lett. 2014, 14, 6298. [Google Scholar] [CrossRef]

- Guo, Y.G.; Wan, L.J.; Zhu, C.F.; Yang, D.L.; Chen, D.M.; Bai, C.L. Ordered Ni—Cu Nanowire Array with Enhanced Coercivity. Cheminform 2003, 34, 664–667. [Google Scholar] [CrossRef]

- Motoyama, M.; Fukunaka, Y.; Sakka, T.; Ogata, Y.H.; Kikuchi, S. Electrochemical processing of Cu and Ni nanowire arrays. J. Electroanal. Chem. 2005, 584, 84–91. [Google Scholar] [CrossRef]

- Carignan, L.P.; Lacroix, C.; Ouimet, A.; Ciureanu, M.; Yelon, A.; Ménard, D. Magnetic anisotropy in arrays of Ni, CoFeB, and Ni/Cu nanowires. J. Appl. Phys. 2007, 102, 200. [Google Scholar] [CrossRef]

- Grobis, M.K.; Hellwig, O.; Hauet, T.; Dobisz, E.; Albrecht, T.R. High-density bit patterned media: Magnetic design and recording performance. IEEE Trans. Magn. 2010, 47, 6–10. [Google Scholar] [CrossRef]

- Stipe, B.C.; Strand, T.C.; Poon, C.C.; Balamane, H.; Boone, T.D.; Katine, J.A.; Li, J.-L.; Rawat, V.; Nemoto, H.; Hirostune, A.; et al. Magnetic recording at 1.5 Pb m−2 using an integrated plasmonic antenna. Nat. Photonics 2010, 4, 484. [Google Scholar] [CrossRef]

- Yan, M.; Kákay, A.; Gliga, S.; Hertel, R. Beating the Walker limit with massless domain walls in cylindrical nanowires. Phys. Rev. Lett. 2010, 104, 057201. [Google Scholar] [CrossRef]

- Piao, H.-G.; Shim, J.-H.; Djuhana, D.; Kim, D.-H. Intrinsic pinning behavior and propagation onset of three-dimensional Bloch-point domain wall in a cylindrical ferromagnetic nanowire. Appl. Phys. Lett. 2013, 102, 112405. [Google Scholar] [CrossRef]

- Ivanov, Y.P.; Chuvilin, A.; Lopatin, S.; Kosel, J. Modulated magnetic nanowires for controlling domain wall motion: Toward 3D magnetic memories. ACS Nano 2016, 10, 5326–5332. [Google Scholar] [CrossRef]

- Mohammed, H.; Corte-León, H.; Ivanov, Y.P.; Lopatin, S.; Moreno, J.A.; Chuvilin, A.; Salimath, A.; Manchon, A.; Kazakova, O.; Kosel, J. Current Controlled Magnetization Switching in Cylindrical Nanowires for High-Density 3D Memory Applications. arXiv 2018, arXiv:180406616. [Google Scholar]

- Parkin, S. R, Bhadra and KP Roche. Phys. Rev. Lett. 1991, 66, 2152. [Google Scholar] [CrossRef]

- De Miguel, J.; Cebollada, A.; Gallego, J.; Miranda, R.; Schneider, C.; Schuster, P.; Kirschner, J. Influence of the growth conditions on the magnetic properties of fcc cobalt films: From monolayers to superlattices. J. Magn. Magn. Mater. 1991, 93, 1–9. [Google Scholar] [CrossRef]

- Grünberg, P.; Schreiber, R.; Pang, Y.; Brodsky, M.; Sowers, H. Layered magnetic structures: Evidence for antiferromagnetic coupling of Fe layers across Cr interlayers. Phys. Rev. Lett. 1986, 57, 2442. [Google Scholar] [CrossRef]

- Parkin, S.; More, N.; Roche, K. Oscillations in exchange coupling and magnetoresistance in metallic superlattice structures: Co/Ru, Co/Cr, and Fe/Cr. Phys. Rev. Lett. 1990, 64, 2304. [Google Scholar] [CrossRef]

- Purcell, S.; Johnson, M.; McGee, N.; Coehoorn, R.; Hoving, W. Two-monolayer oscillations in the antiferromagnetic exchange coupling through Mn in Fe/Mn/Fe sandwich structures. Phys. Rev. B 1992, 45, 13064. [Google Scholar] [CrossRef]

- Holstein, T.; Norton, R.; Pincus, P. de Haas-van Alphen effect and the specific heat of an electron gas. Phys. Rev. B 1973, 8, 2649. [Google Scholar] [CrossRef]

- Fert, A.; Grünberg, P.; Barthélémy, A.; Petroff, F.; Zinn, W. Layered magnetic structures: Interlayer exchange coupling and giant magnetoresistance. J. Magn. Magn. Mater. 1995, 140, 1–8. [Google Scholar] [CrossRef]

- Baibich, M.N.; Broto, J.M.; Fert, A.; Van Dau, F.N.; Petroff, F.; Etienne, P.; Creuzet, G.; Friederich, A.; Chazelas, J. Giant Magnetoresistance of (001)Fe/(001)Cr Magnetic Superlattices. Phys. Rev. Lett. 1988, 61, 2472–2475. [Google Scholar] [CrossRef]

- Vedyayev, A.; Chshiev, M.; Ryzhanova, N.; Dieny, B.; Cowache, C.; Brouers, F. A unified theory of CIP and CPP giant magnetoresistance in magnetic sandwiches. J. Magn. Magn. Mater. 1997, 172, 53–60. [Google Scholar] [CrossRef]

- Tang, X.T.; Wang, G.C.; Shima, M. Layer thickness dependence of CPP giant magnetoresistance in individual CoNi/Cu multilayer nanowires grown by electrodeposition. Phys. Rev. B 2007, 75, 134404. [Google Scholar] [CrossRef]

- Bryan, C.; Don, L.; Chester, W.; Despina, D. GMR Sensors: Technologies and Medical Applications. Recent Pat. Nanomed. Discontin. 2011, 1, 130–137. [Google Scholar]

- Nagasaka, K. CPP-GMR technology for magnetic read heads of future high-density recording systems. J. Magn. Magn. Mater. 2009, 321, 508–511. [Google Scholar] [CrossRef]

- Takagishi, M.; Koi, K.; Yoshikawa, M.; Funayama, T.; Iwasaki, H.; Sahashi, M. The applicability of CPP-GMR heads for magnetic recording. IEEE Trans. Magn. 2002, 38, 2277–2282. [Google Scholar] [CrossRef]

- Velev, J.; Chang, Y.-C. Perpendicular giant magnetoresistance in Fe/Cr nanowires. J. Magn. Magn Mater. 2002, 250, 219–224. [Google Scholar] [CrossRef]

- Piraux, L.; Dubois, S.; Duvail, J.L.; Ounadjela, K.; Fert, A. Arrays of nanowires of magnetic metals and multilayers: Perpendicular GMR and magnetic properties. J. Magn. Magn. Mater. 1997, 175, 127–136. [Google Scholar] [CrossRef]

- Gravier, L.; Wegrowe, J.; Ansermet, J. Thermopower and GMR of a single Co/Cu multilayer nanowire. In 2002 IEEE International Magnetics Conference (INTERMAG); IEEE: Piscataway, NJ, USA, 2002; pp. 2700–2702. [Google Scholar]

- Liu, K.; Nagodawithana, K.; Searson, P.; Chien, C. Perpendicular giant magnetoresistance of multilayered Co/Cu nanowires. Phys. Rev. B 1995, 51, 7381. [Google Scholar] [CrossRef] [PubMed]

- Shakya, P.; Cox, B.; Davis, D. Giant magnetoresistance and coercivity of electrodeposited multilayered FeCoNi/Cu and CrFeCoNi/Cu. J. Magn. Magn. Mater. 2012, 324, 453–459. [Google Scholar] [CrossRef]

- Bussmann, K.; Cheng, S.; Prinz, G.; Hu, Y.; Gutmann, R.; Wang, D.; Beech, R.; Zhu, J. CPP giant magnetoresistance of NiFeCo/Cu/CoFe/Cu multilayers. CPP giant magnetoresistance of NiFeCo/Cu/CoFe/Cu multilayers. IEEE Trans. Magn. 1998, 34, 924–926. [Google Scholar] [CrossRef]

- Chassaing, E.; Morrone, A.; Schmidt, J.E. Nanometric Cu-Co Multilayers Electrodeposited on Indium-Tin Oxide Glass. J. Electrochem. Soc. 1999, 146, 1794–1797. [Google Scholar] [CrossRef]

- Chang, L.; Wang, M.; Liu, L.; Luo, S.; Xiao, P. A brief introduction to giant magnetoresistance. arXiv 2014, arXiv:14127691. [Google Scholar]

- Cox, B.; Davis, D.; Crews, N. Creating magnetic field sensors from GMR nanowire networks. Sens. Actuators A Phys. 2013, 203, 335–340. [Google Scholar] [CrossRef]

- Reich, D.; Tanase, M.; Hultgren, A.; Bauer, L.; Chen, C.; Meyer, G. Biological applications of multifunctional magnetic nanowires. J. Appl. Phys. 2003, 93, 7275–7280. [Google Scholar] [CrossRef]

- Qian, Z.; Daughton, J.M.; Wang, D.; Tondra, M. Magnetic design and fabrication of linear spin-valve sensors. IEEE Trans. Magn. 2003, 39, 3322–3324. [Google Scholar] [CrossRef]

- Park, J.J.; Reddy, S.M.; Stadler, B.; Flatau, A. Magnetostrictive Fe-Ga/Cu Nanowires Array with GMR Sensor for Sensing Applied Pressure. IEEE Sens. J. 2017, 7, 2015–2020. [Google Scholar] [CrossRef]

| Hard Anodization | Mild Anodization | ||||||

|---|---|---|---|---|---|---|---|

| Electrolyte | Anodization Potential | Self-Ordering Regime | Ref | Electrolyte | Anodization Potential | Self-Ordering Regime | Ref. |

| H2SO4 | 40–70 | 70 | [41,42] | H2SO4 | 10–25 | 25 | [42,43,44] |

| H3PO4 | 195–235 | 235 | [41] | H3PO4 | 160–195 | 195 | [43] |

| H2C2O4 | 100–160 | 120–160 | [40,41] | H2C2O4 | 30–100 | 40 | [44,45,46,47] |

| Multilayer Nanostructure | Composition of Electrolyte (g/L) | Current Density (mA/cm2) | Potential (mV) | Technique | Reference |

|---|---|---|---|---|---|

| NiCo/Cu | NiSO4, CuSO4, CuCl2, H3BO3, saachrin (C7H5O3NS) | N/A | VCu = −400 VNiCo = 1100 | Potentiostaic deposition | [103] |

| CoCu/Cu | 116.25CoSO4, 8CuSO4, 15.5H3BO3, 0.97H3NSO3 | ico = 60 icu = 40 | Vco = −1.5 Vcu = −1.3 | Potentiostaic deposition | [104] |

| Co-Cu | 90Co, 1.1Cu. In the form of Cu sulfate, 40H3BO3, and 0.2 of triton X-Loo | ico = 24 icu = 0.7 | N/A | Galvanostatic desposition | [105] |

| CoNi/Ni NWs | 116.25NiSO4, 38.7NiCl2, 18.6H3BO3, 19.375CoSO4 | N/A | VCoNi = 1200 V VNi = 1200 V | Direct current (Dual bath deposition) | [87] |

| Ag/Co | 23.25CoSO4, 118.8K4P2O7, 0.0804AgCN | N/A | Vco = −1100 VAg = −600 | Potentiostaic deposition | [97] |

| Ag/Co | 42.15CoSO4, 7H2O, 0.85AgNO3, 30.8CH3COON4 | N/A | Vco = 1000 VAg = 650 | Potentiostaic deposition | [106] |

| Au/Fe Au | 94.08C6H8OH, 44.08FeSO4, 16.24KOH, 210.79 and 0.4925Au | iAu = 0.9 to 10 iFeAu = −15 to −20 | VAu = −200, −1100 VFe = −1250 | Galvanostatic Desposition | [107] |

| Au/Ni | 155NiSO4, 31H3BO3, 98.5Au | iAu = −0.34 iNi = 3.4 | N/A | Galvanostatic desposition | [108] |

| CoPt | 46.5CoSO4, 14.49K2PtCl6, 30.07H3BO3 | N/A | Vco = −1000 Vpt = −350 | Potentiostaic deposition | [109] |

| CoPt/Pt NWs | 310CoSO4, 20.5[H2PtCl6]1/4, 20–40H3BO3 | N/A | Vcopt = 1000 Vpt = −400 | Potentiostaic deposition | [110] |

| FeGa/Cu NWs | 2.28FesO4, 7.49 Ga2(SO4)3, 10.29Na3C6H5OH, 2H2O(Na3-citrate) | N/A | VFeGa = −110 VCu = −800 | Potentiostaic deposition | [111] |

| Co0.96Cu0.04/Co0.32Cu0.68 | 116CoSO4·7H2O, 6CuSO4·5H2O and 45 | N/A | 15/15 V | Ac Pulse potential | [100] |

| Ni-Co/Cu | 2.5CuSO4, 15.45H3BO3, 112.96NiSO4 and 5.73CoSO4 | iNiCo = −35.0 | Vcu = 0.585 | G/P mode | [98] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.-S.; Mukhtar, A.; Wu, K.-M.; Gu, L.; Cao, X. Multi-Segmented Nanowires: A High Tech Bright Future. Materials 2019, 12, 3908. https://doi.org/10.3390/ma12233908

Wang D-S, Mukhtar A, Wu K-M, Gu L, Cao X. Multi-Segmented Nanowires: A High Tech Bright Future. Materials. 2019; 12(23):3908. https://doi.org/10.3390/ma12233908

Chicago/Turabian StyleWang, Da-Shuang, Aiman Mukhtar, Kai-Ming Wu, Liyuan Gu, and Xiaoming Cao. 2019. "Multi-Segmented Nanowires: A High Tech Bright Future" Materials 12, no. 23: 3908. https://doi.org/10.3390/ma12233908

APA StyleWang, D.-S., Mukhtar, A., Wu, K.-M., Gu, L., & Cao, X. (2019). Multi-Segmented Nanowires: A High Tech Bright Future. Materials, 12(23), 3908. https://doi.org/10.3390/ma12233908