Magnetic Fe3O4@SiO2–Pt and Fe3O4@SiO2–Pt@SiO2 Structures for HDN of Indole

Abstract

1. Introduction

2. Materials and Methods

2.1. Synthesis

2.2. Characterization

2.3. Catalytic Activity

3. Results and Discussion

3.1. Characterization

3.2. Catalytic Activity

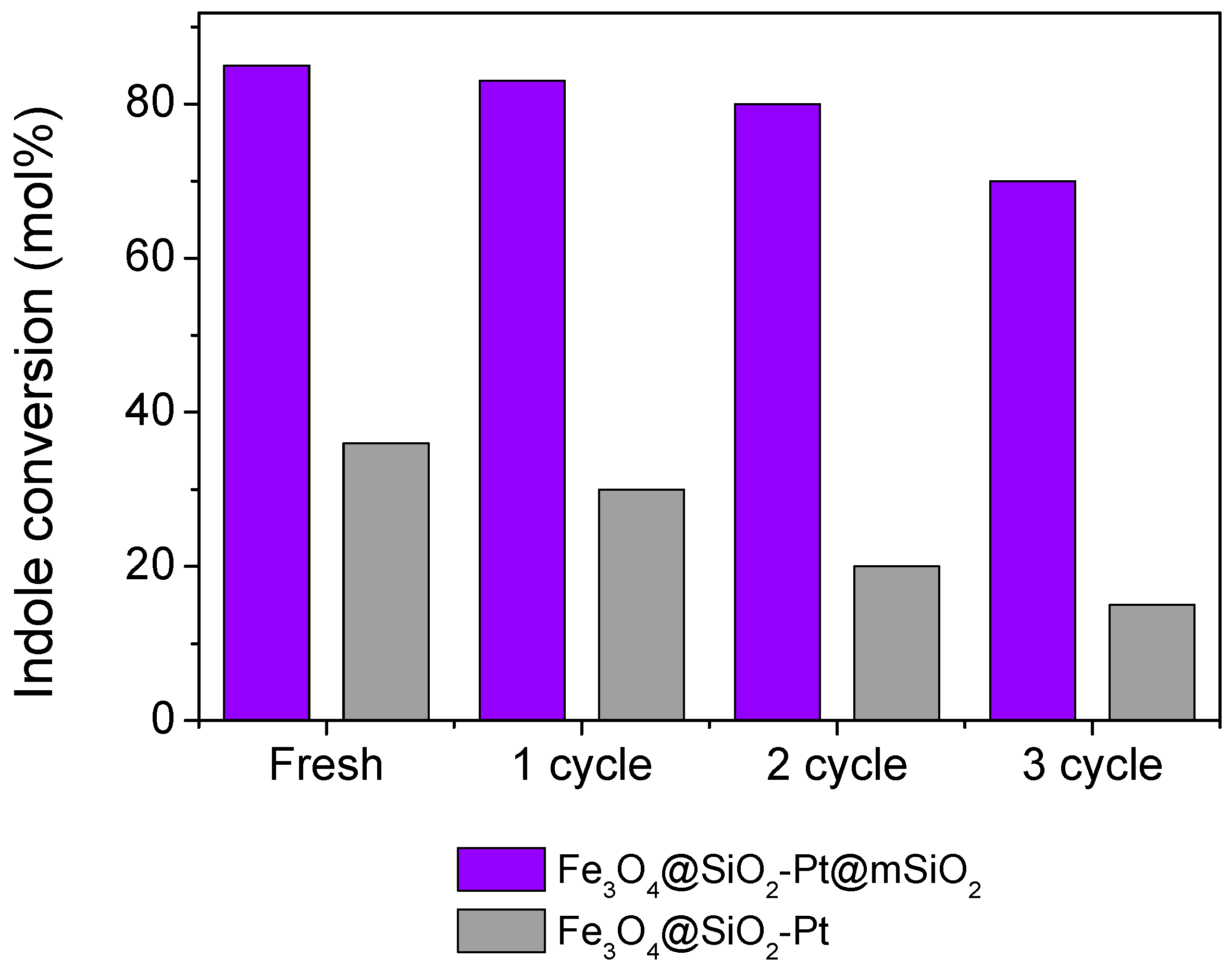

Reutilization Study

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Egorova, M.; Prins, R. Competitive hydrodesulfurization of 4,6-dimethyldibenzothiophene, hydrodenitrogenation of 2-methylpyridine, and hydrogenation of naphthalene over sulfided NiMo/γ-Al2O3. J. Catal. 2004, 224, 2782–2787. [Google Scholar] [CrossRef]

- Egorova, M.; Prins, R. Mutual influence of the HDS of dibenzothiophene and HDN of 2-methylpyridine. J. Catal. 2004, 221, 11–19. [Google Scholar] [CrossRef]

- Nassreddine, S.; Massin, L.; Aouine, M.; Geantet, C.; Piccolo, L. Thiotolerant Ir/SiO2–Al2O3 bifunctional catalysts: Effect of metal—Acid site balance on tetralin hydroconversion. J. Catal. 2011, 278, 253–265. [Google Scholar] [CrossRef]

- Kishore Kumar, S.A.; John, M.; Pai, S.M.; Niwate, Y.; Newalkar, B.L. Low temperatura hydrogenation of aromaticsover Pt–Pd/SiO2–Al2O3 catalyst. Fuel Process. Technol. 2014, 128, 303–309. [Google Scholar] [CrossRef]

- Jongpatiwut, S.; Li, Z.; Resasco, D.E.; Alvarez, W.; Sughrue, E.; Dodwell, G. Competitive hydrogenation of poly-aromatic hydrocarbons on sulfur-resistant bimetallic Pt-Pd catalysts. Appl. Catal. 2004, 262, 241–253. [Google Scholar] [CrossRef]

- Stanislaus, A.; Marafi, A.; Rana, M.S. Recent advances in the science and technology of ultra low sulfur diesel (ULSD) production. Catal. Today 2010, 153, 1–68. [Google Scholar] [CrossRef]

- Lebeau, B.; Bonne, M.; Comparot, J.D.; Rousseau, J.; Michelin, L.; Blin, J.L.; Brunet, S. HDS of 4,6-dimethyldibenzothiophene overCoMoSsupportedmesoporous SiO2-TiO2 materials. Catal. Today 2019. [Google Scholar] [CrossRef]

- Beltramone, A.R.; Resasco, D.E.; Alvarez, W.E.; Choudhary, T.V. Simultaneous Hydrogenation of Multiring Aromatic Compounds over NiMo Catalyst. Ind. Eng. Chem. Res. 2008, 47, 7161–7166. [Google Scholar] [CrossRef]

- Cinibulk, J.; Vit, Z. Preparation of MO/Al2O3 sulfidecatalystsmodifiedby Ir nanoparticles. Stud. Surf. Sci. Catal. 2002, 143, 443–451. [Google Scholar] [CrossRef]

- Ledesma, B.C.; Martínez, M.L.; Beltramone, A.R. Iridium-supported SBA-15 modifiedwith Ga and Al as a highly active catalyst in thehydrodenitrogenation of quinoline. Catal Today 2018. [Google Scholar] [CrossRef]

- Ledesma, B.C.; Anunziata, O.A.; Beltramone, A.R. HDN of indoleover Ir-modified Ti-SBA-15. Appl. Catal. B 2016, 192, 220–233. [Google Scholar] [CrossRef]

- Valles, V.A.; Ledesma, B.C.; Rivoira, L.P.; Cussa, J.; Anunziata, O.A.; Beltramone, A.R. Experimental designoptimization of the tetralin hydrogenationover Ir–Pt-SBA-15. Catal. Today 2016, 271, 140–148. [Google Scholar] [CrossRef]

- Valles, V.A.; Ledesma, B.C.; Juárez, J.; Gómez Costa, M.B.; Anunziata, O.A.; Beltramone, A.R. Noblebimetallicsupported CMK-3 as a novel catalystforhydrogenation of tetralin in thepresence of sulfur and nitrogen. Fuel 2017, 188, 155–165. [Google Scholar] [CrossRef]

- Valles, V.A.; Ledesma, B.C.; Pecchi, G.A.; Anunziata, O.A.; Beltramone, A.R. Hydrogenationof tetralin in presence of nitrogenusing a noble-bimetalliccoupleover a Ti-modifiedSBA-15. Catal. Today 2017, 282, 111–122. [Google Scholar] [CrossRef]

- Ledesma, B.C.; Valles, V.A.; Rivoira, L.P.; Martínez, M.L.; Anunziata, O.A.; Beltramone, A.R. Hydrogenation of tetralin over Ir catalystssupportedontitania-modified SBA-16. Catal. Lett. 2014, 144, 783–795. [Google Scholar] [CrossRef]

- Ledesma, B.C.; Juárez, J.M.; Beltramone, A.R. Short time synthesis of titaniamodified-CMK-3 carbonmesostructure as supportfor Ir-catalystapplied in catalytic hydrotreating. Catal. Today 2018. [Google Scholar] [CrossRef]

- Valles, V.A.; Balangero Bottazzi, G.; Martínez, M.L.; Gómez Costa, M.B.; Anunziata, O.A.; Beltramone, A.R. Hydrogenation of Tetralin over Ir-Containing Mesoporous Catalysts. Ind. Eng. Chem. Res. 2012, 51, 7185–7195. [Google Scholar] [CrossRef]

- Meynen, V.; Cool, P.; Vansant, E.F. Verifiedsyntheses of mesoporousmaterials. Microporous Mesoporous Mater. 2009, 125, 170–223. [Google Scholar] [CrossRef]

- Pachon, L.D.; Rothenberg, G. Transition-metal nanoparticles: Synthesis, stability and the leaching issue. Appl. Organomet. Chem. 2008, 22, 2882–2899. [Google Scholar] [CrossRef]

- Burattin, P.; Che, M.; Louis, C.J. Characterization of the Ni(II) Phase Formed on Silica Upon Deposition−Precipitation. Phys. Chem. B 1997, 101, 7060–7074. [Google Scholar] [CrossRef]

- Zhang, N.; Xu, Y.-J. Aggregation- and Leaching-Resistant, Reusable, and Multifunctional Pd@CeO2 as a Robust Nanocatalyst Achieved by a Hollow Core–Shell Strategy. Chem. Mater. 2013, 25, 1979–1988. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, B.; Wang, Y.; Guo, F.; Li, Z.; Shi, D. Preparation of highly fluorescent magnetic nanoparticles for analytes-enrichment and subsequent biodetection. J. Colloid Interface Sci. 2011, 353, 426–432. [Google Scholar] [CrossRef] [PubMed]

- Fourmond, V.; Stapf, S.; Li, H.; Buesen, D.; Birrell, J.; Ruediger, O.; Lubitz, W.; Schuhmann, W.; Plumere, N.; Leger, C. Mechanism of Protection of Catalysts Supported in Redox Hydrogel Films. J. Am. Chem. Soc. 2015, 137, 5494–5505. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Li, P. Porous Zr-doped SiO2 shell/TiO2 core nanoparticles with expanded channels for photocatalysis. Mater. Des. 2015, 88, 1250–1259. [Google Scholar] [CrossRef]

- Majewski, A.J.; Wood, J.; Bujalski, W. Nickel–silica core@shell catalyst for methane reforming. Int. J. Hydrogen Energy 2013, 38, 14531–14541. [Google Scholar] [CrossRef]

- Gawande, M.B.; Goswami, A.; Asefa, T.; Guo, H.; Biradar, A.V.; Peng, D.-L.; Zboril, R.; Varma, R.S. Core–shell nanoparticles: Synthesis and applications in catalysis and electrocatalysis. Chem. Soc. Rev. 2015, 44, 7540–7590. [Google Scholar] [CrossRef]

- Wang, X.; He, B.; Hu, Z.; Zeng, Z.; Han, S. Current advances in precious metal core–shell catalyst design. Sci. Technol. Adv. Mater. 2014, 15, 043502. [Google Scholar] [CrossRef]

- Biradar, A.V.; Biradar, A.A.; Asefa, T. Silica–Dendrimer Core–Shell Microspheres with Encapsulated Ultrasmall Palladium Nanoparticles: Efficient and Easily Recyclable Heterogeneous Nanocatalysts. Langmuir 2011, 27, 14408–14418. [Google Scholar] [CrossRef]

- Shi, Y.-L.; Asefa, T. Tailored Core−Shell−Shell Nanostructures: Sandwiching Gold Nanoparticles between Silica Cores and Tunable Silica Shells. Langmuir 2007, 23, 9455–9462. [Google Scholar] [CrossRef]

- Polshettiwar, V.; Baruwati, B.; Varma, R.S. Nanoparticle-supported and magnetically recoverable nickel catalyst: A robust and economic hydrogenation and transfer hydrogenation protocol. Green Chem. 2009, 11, 127–131. [Google Scholar] [CrossRef]

- Scahtz, A.; Reiser, O.; Stark, W.J. Nanoparticles as Semi-Heterogeneous Catalyst Supports. Chem. Eur. J. 2010, 16, 8950–8967. [Google Scholar] [CrossRef]

- Long, Y.; Liang, K.; Niu, J.; Yuan, B.; Ma, J. Pt NPs immobilized on core–shell magnetite microparticles: Novel and highly efficient catalysts for the selective aerobic oxidation of ethanol and glycerol in water. Dalton Trans. 2015, 44, 8660–8668. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Shen, D.; Wei, Y.; Li, W.; Zhang, F.; Kong, B.; Zhang, S.; Teng, W.; Fan, J.; Zhang, W.; et al. Monodisperse core-shell structured magnetic mesoporous aluminosilicate nanospheres with large dendritic mesochannels. Nano Res. 2015, 8, 2503–2514. [Google Scholar] [CrossRef]

- Zhang, W.; Shen, F.; Hong, R. Solvothermal synthesis of magnetic Fe3O4 microparticles via self-assembly of Fe3O4 nanoparticles. Particuology 2011, 9, 179–186. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Esmaeili, S.; Zanjanchi, M.; Golmojdeh, H.; Shariati, S. Synthesis, characterization and photocatalytic studies of MCM-41 mesoporous silica core-shells doped with selenium oxide and lanthanum ions. Microporous Mesoporous Mater. 2020, 292, 109714. [Google Scholar] [CrossRef]

- Costa, J.A.; De Jesus, R.; Santos, D.; Mano, J.; Romão, L.; Paranhos, C. Recent progresses in the adsorption of organic, inorganic, and gas compounds by MCM-41-based mesoporous materials. Microporous Mesoporous Mater. 2020, 291, 109698. [Google Scholar] [CrossRef]

- Reich, S.; Svidrytski, A.; Höltzel, A.; Wang, W.; Kübel, C.; Hlushkou, D.; Tallarek, U. Transport under confinement: Hindrance factors for diffusion in core-shell and fully porous particles with different mesopore space morphologies. Microporous Mesoporous Mater. 2019, 282, 188–196. [Google Scholar] [CrossRef]

- Teng, Z.; Su, X.; Chen, G.; Tian, C.; Li, H.; Ai, L.; Lu, G. Superparamagnetic high-magnetization composite microspheres with Fe3O4@SiO2 core and highly crystallized mesoporous TiO2 shell. Colloid Surf. A 2012, 402, 60–65. [Google Scholar] [CrossRef]

- Zhang, L.; Ozkan, U.S. Hydrodenitrogenation of indole over NiMo sulfide catalysts. Stud. Surf. Sci. Catal. 1996, 101, 1223–1232. [Google Scholar] [CrossRef]

- Lanzafame, P.; Barbera, K.; Papanikolaou, G.; Perathoner, S.; Centi, G.; Migliori, M.; Catizzone, E.; Giordano, G. Comparison of H+ and NH4+ forms of zeolites as acid catalysts for HMF etherification. Catal. Today 2018, 304, 97–102. [Google Scholar] [CrossRef]

- Bao, J.; He, J.; Zhang, Y.; Yoneyama, Y.; Tsubaki, N. A Core/Shell Catalyst Produces a Spatially Confined Effect and Shape Selectivity in a Consecutive Reaction. Angew. Chem. Int. Ed. Engl. 2008, 47, 353–356. [Google Scholar] [CrossRef] [PubMed]

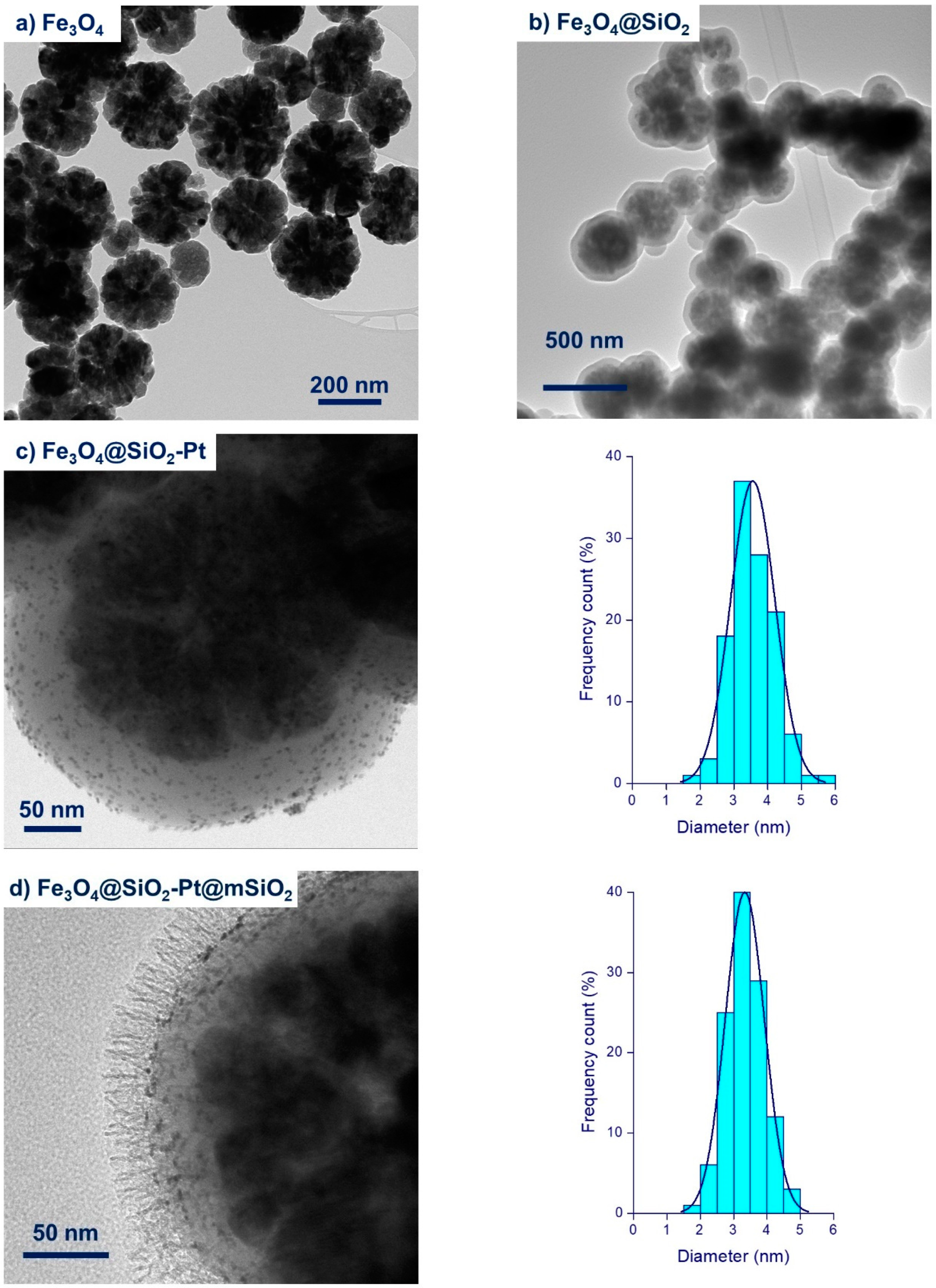

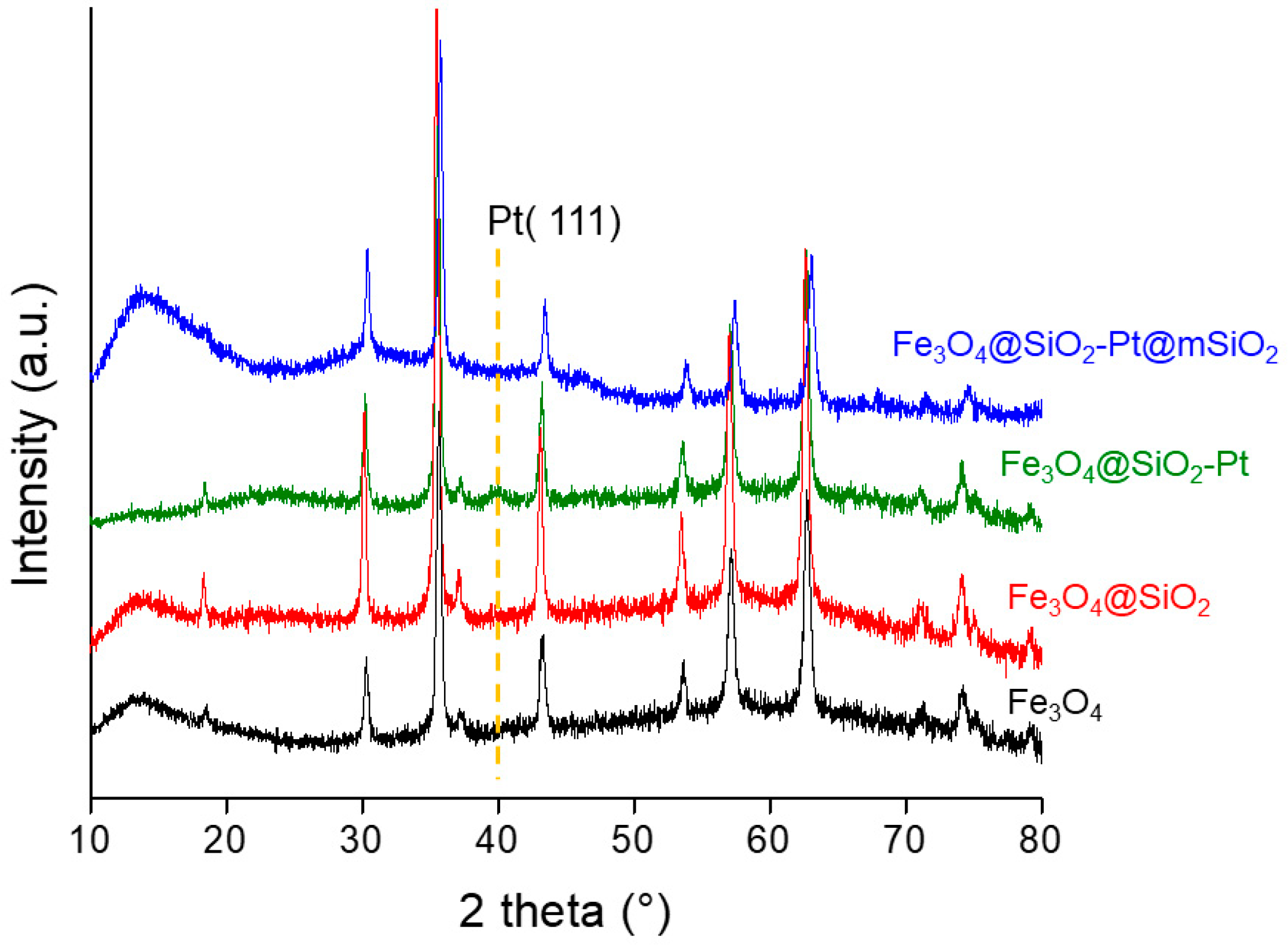

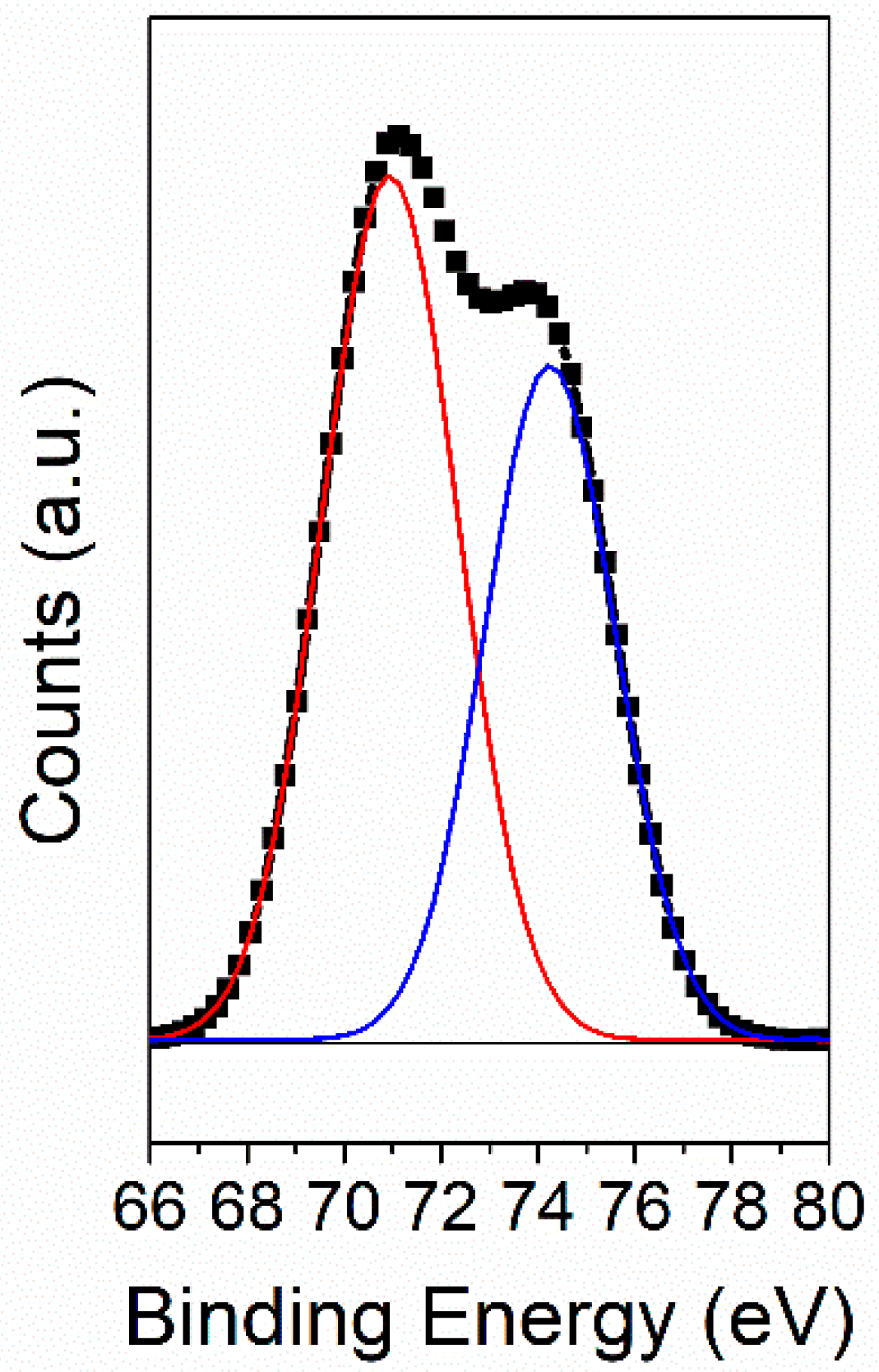

| Catalysts | Core Mean Diameter (nm) | Thickness SiO2 Mean Diameter (nm) | Pt Mean Diameter (nm) | Pt Content (%) | SBET (m2 g−1) | Pt 4f7/2 (eV) |

|---|---|---|---|---|---|---|

| Fe3O4@SiO2–Pt | 229 ± 75 | 45 ± 12 | 3.6 ± 1.0 | 0.7 (1.0) (2) | 11 | 70.9 |

| Fe3O4@SiO2–Pt@mSiO2 | 231 ± 42 | 96 ± 15 (51 ± 14) (1) | 3.4 ± 0.8 | 0.35 (1.0) (2) | 178 | -- |

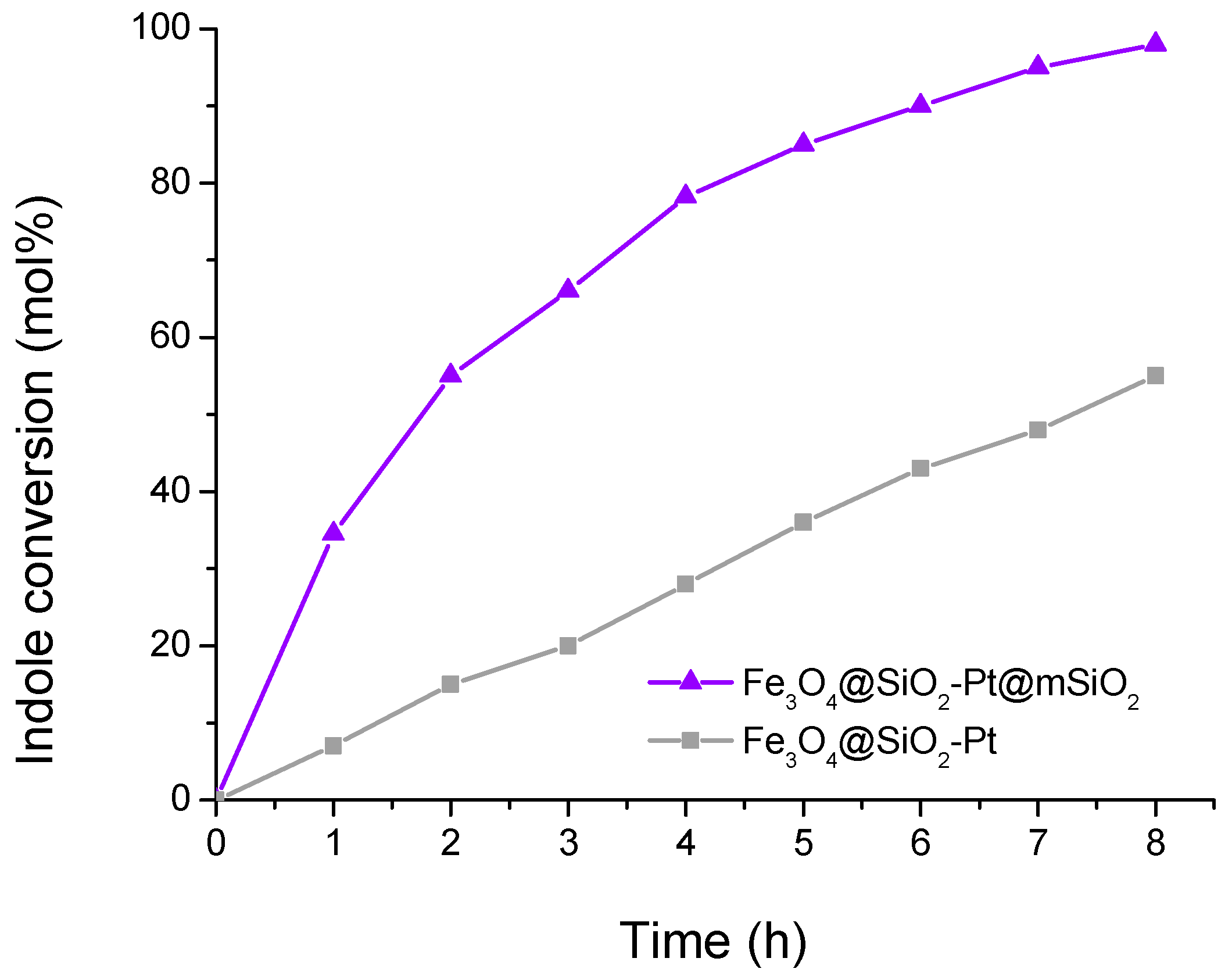

| Catalysts | Indole Conversion | % HDN 1 |

|---|---|---|

| Fe3O4@SiO2–Pt | 55 | 30 |

| Fe3O4@SiO2–Pt@mSiO2 | 98 | 88 |

| NiMo/Al2O3 [11] | 50 | 30 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dinamarca, R.; Valles, V.; Ledesma, B.; Campos, C.H.; Pecchi, G.; Beltramone, A. Magnetic Fe3O4@SiO2–Pt and Fe3O4@SiO2–Pt@SiO2 Structures for HDN of Indole. Materials 2019, 12, 3878. https://doi.org/10.3390/ma12233878

Dinamarca R, Valles V, Ledesma B, Campos CH, Pecchi G, Beltramone A. Magnetic Fe3O4@SiO2–Pt and Fe3O4@SiO2–Pt@SiO2 Structures for HDN of Indole. Materials. 2019; 12(23):3878. https://doi.org/10.3390/ma12233878

Chicago/Turabian StyleDinamarca, Robinson, Verónica Valles, Brenda Ledesma, Cristian H. Campos, Gina Pecchi, and Andrea Beltramone. 2019. "Magnetic Fe3O4@SiO2–Pt and Fe3O4@SiO2–Pt@SiO2 Structures for HDN of Indole" Materials 12, no. 23: 3878. https://doi.org/10.3390/ma12233878

APA StyleDinamarca, R., Valles, V., Ledesma, B., Campos, C. H., Pecchi, G., & Beltramone, A. (2019). Magnetic Fe3O4@SiO2–Pt and Fe3O4@SiO2–Pt@SiO2 Structures for HDN of Indole. Materials, 12(23), 3878. https://doi.org/10.3390/ma12233878