Effect of Needling Parameters and Manufacturing Porosities on the Effective Thermal Conductivity of a 3D Carbon–Carbon Composite

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material under Investigation

2.2. X-ray Computed Tomography

2.3. Laser Flash System

2.4. Finite-Element Modelling Details

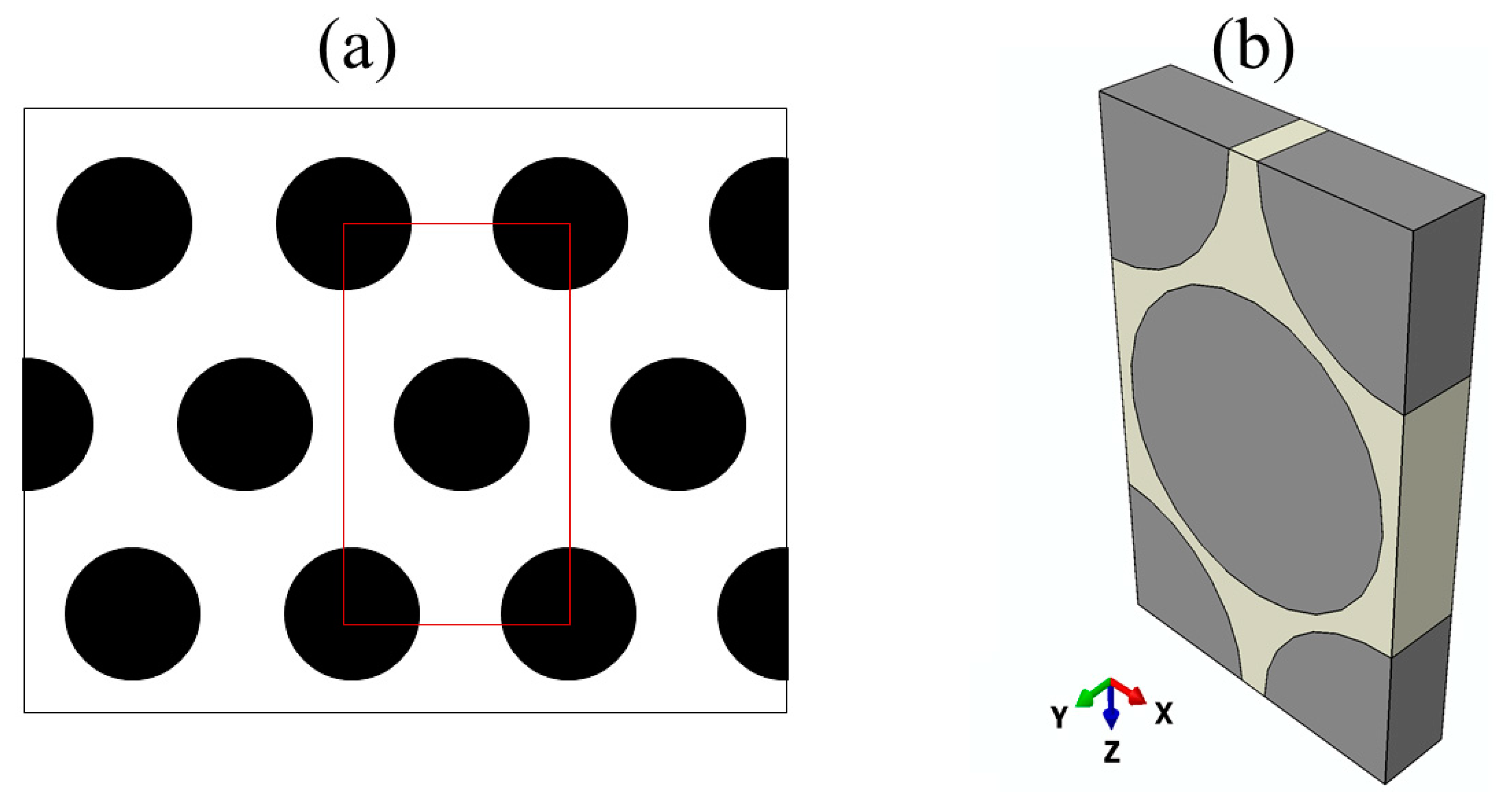

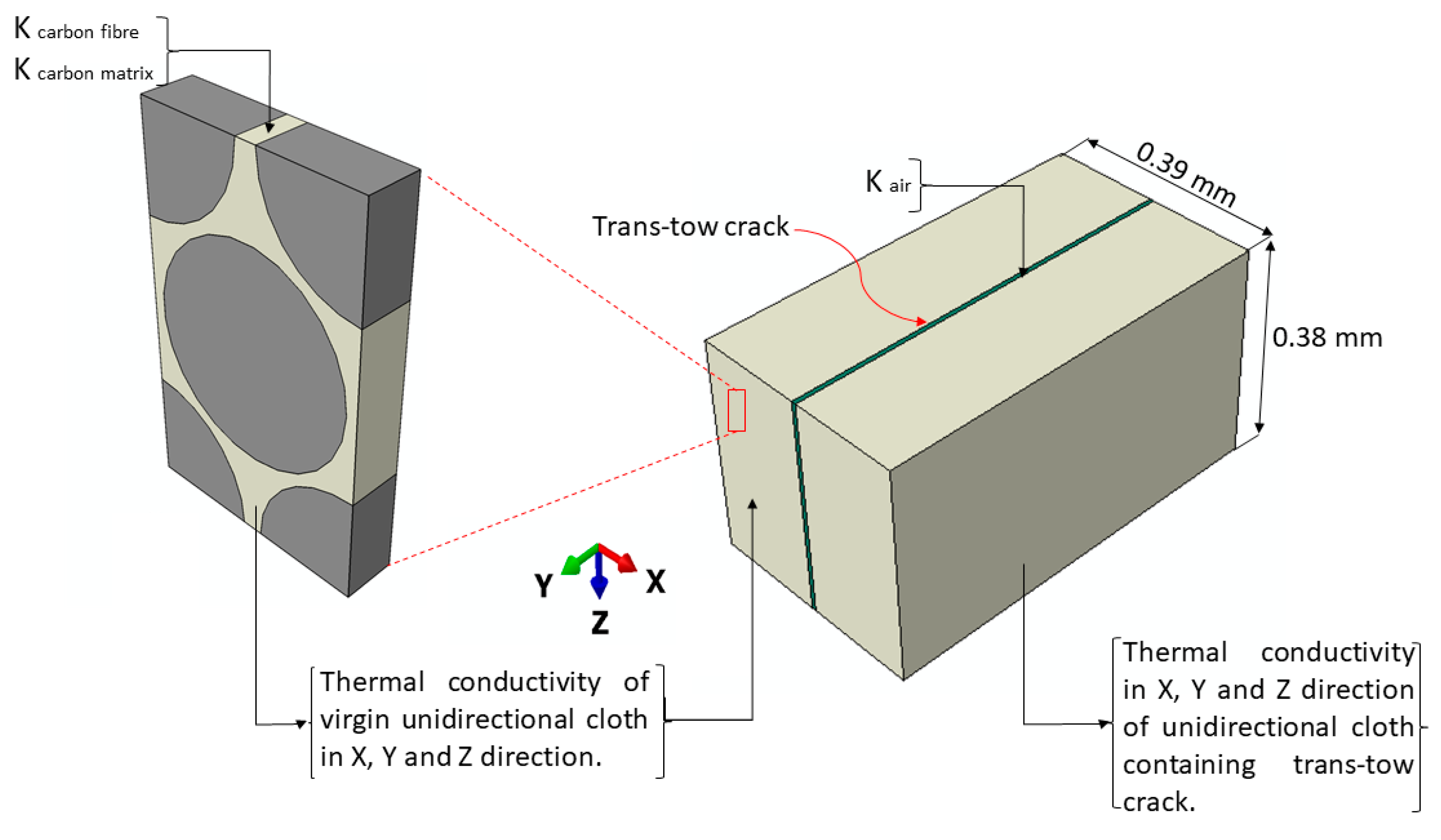

2.4.1. Unidirectional Cloth Model

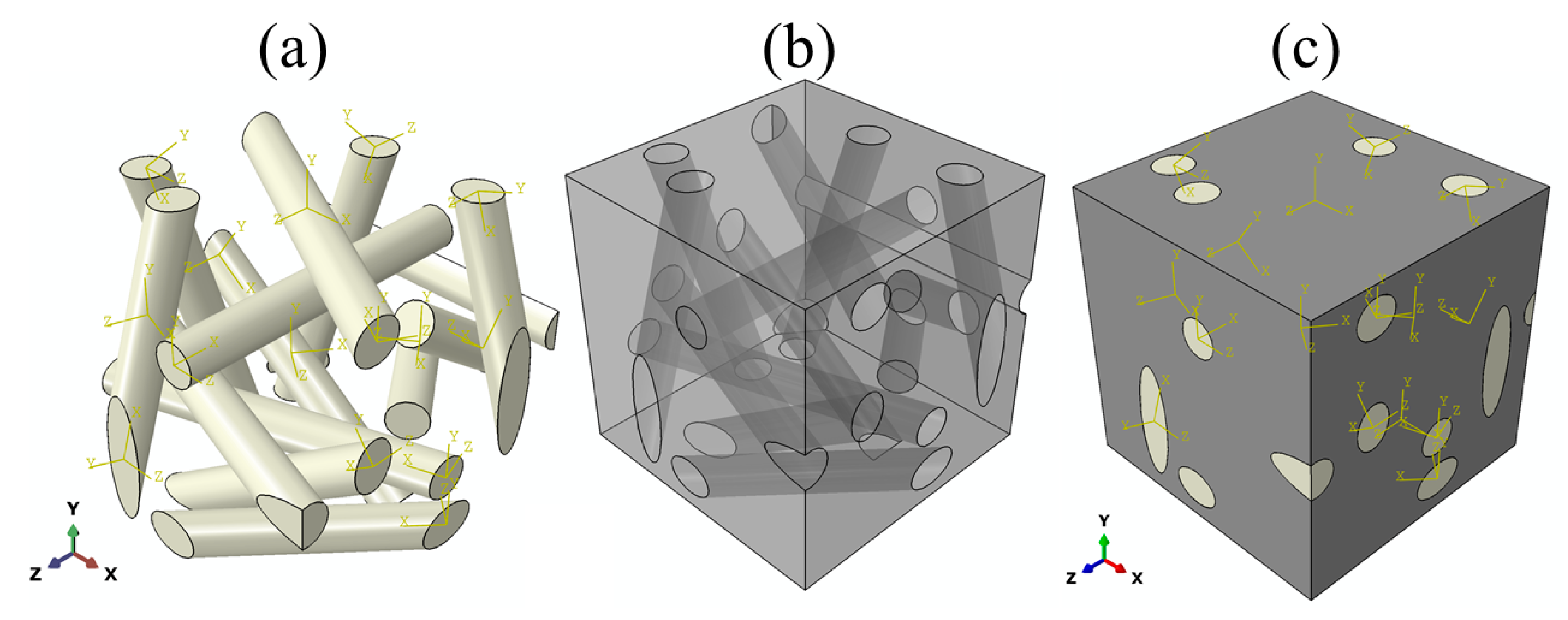

2.4.2. Short-Chopped Fibre Felt Model

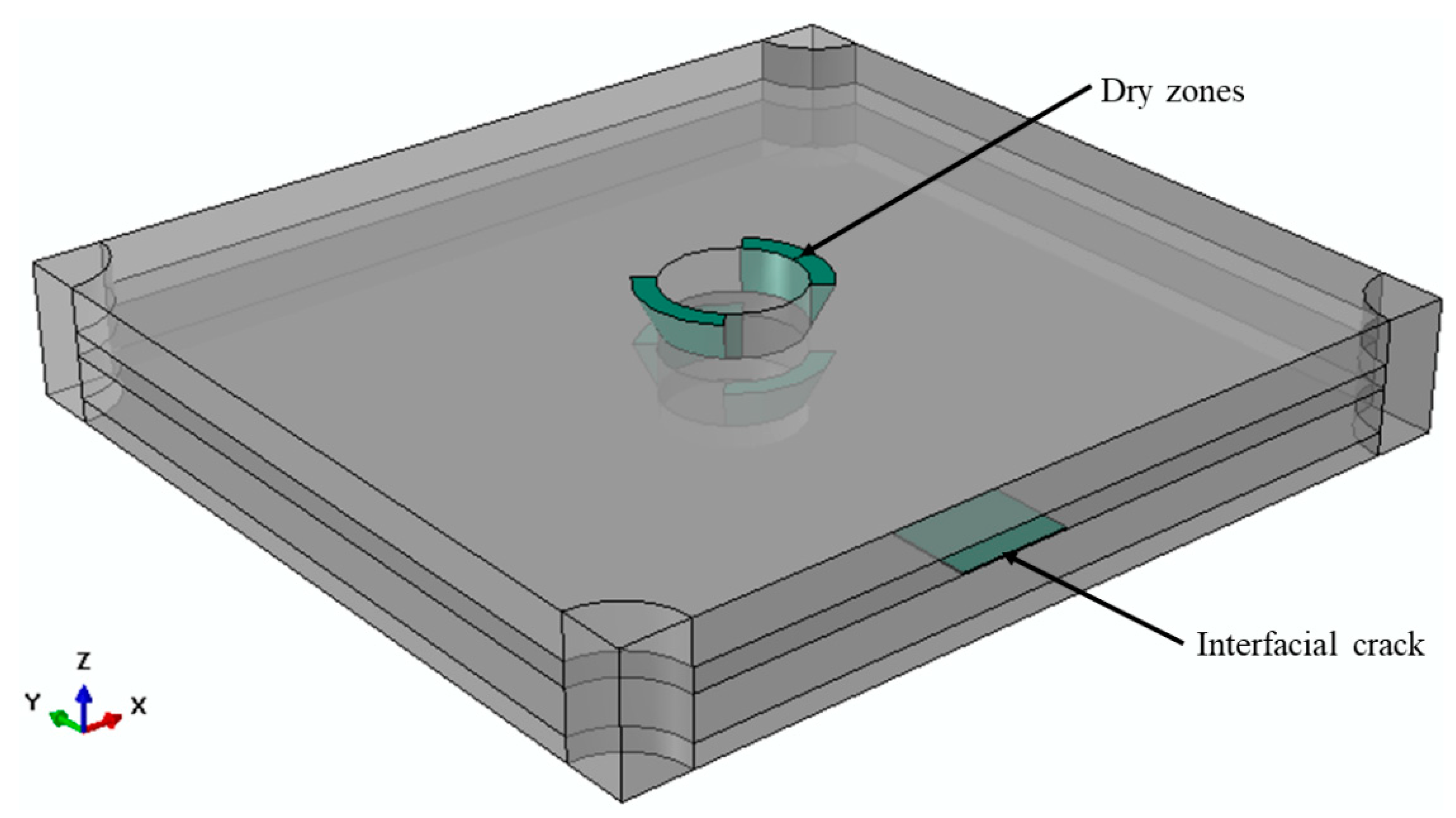

2.4.3. Composite

2.4.4. Boundary Conditions

2.4.5. Material Properties of the Constituents

3. Results

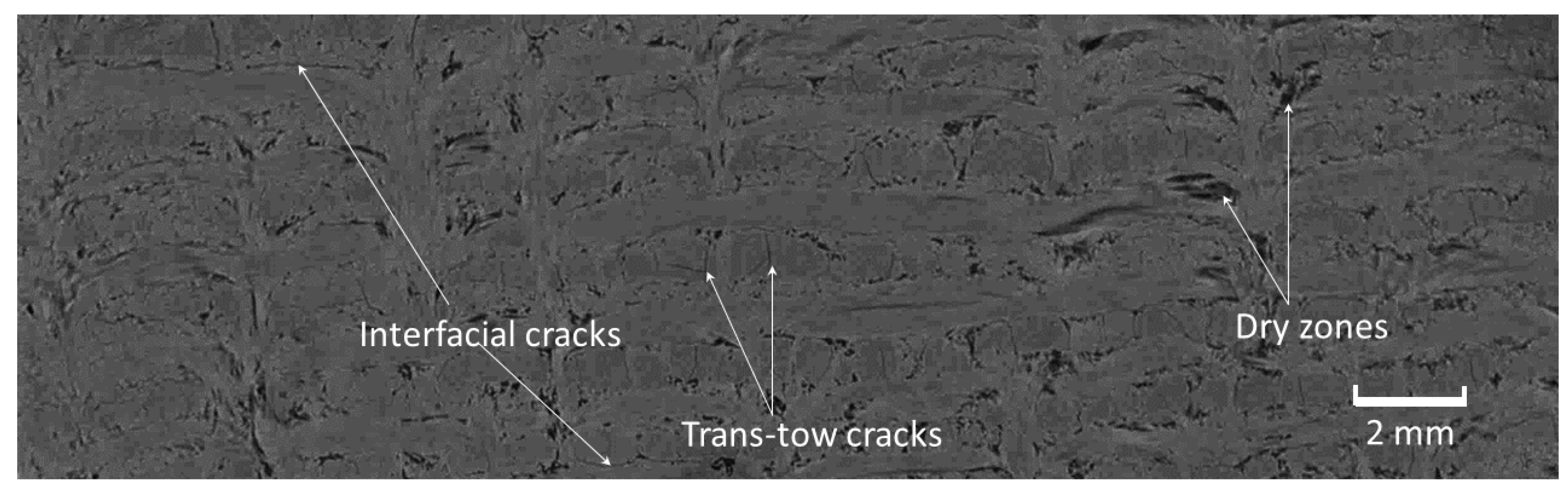

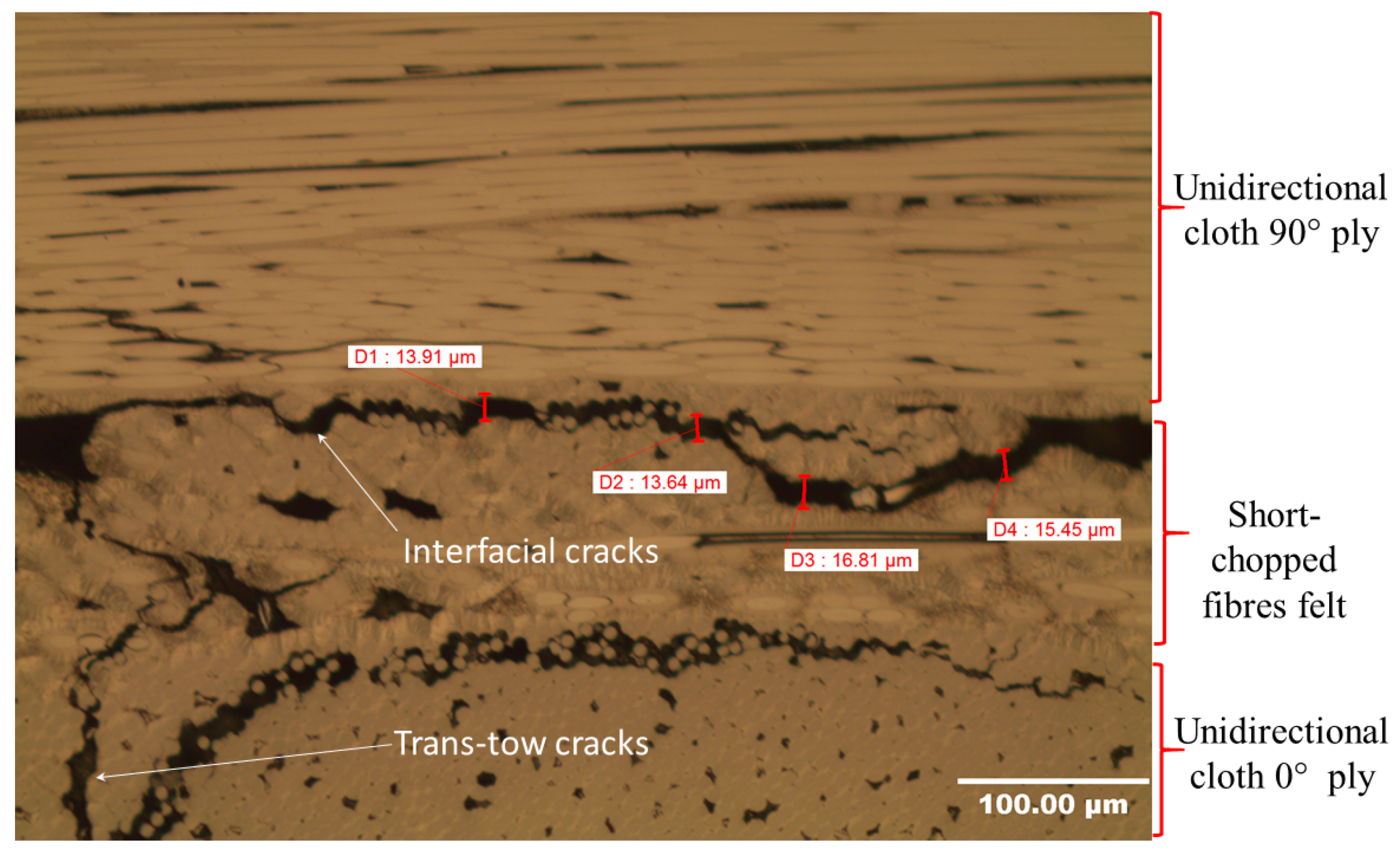

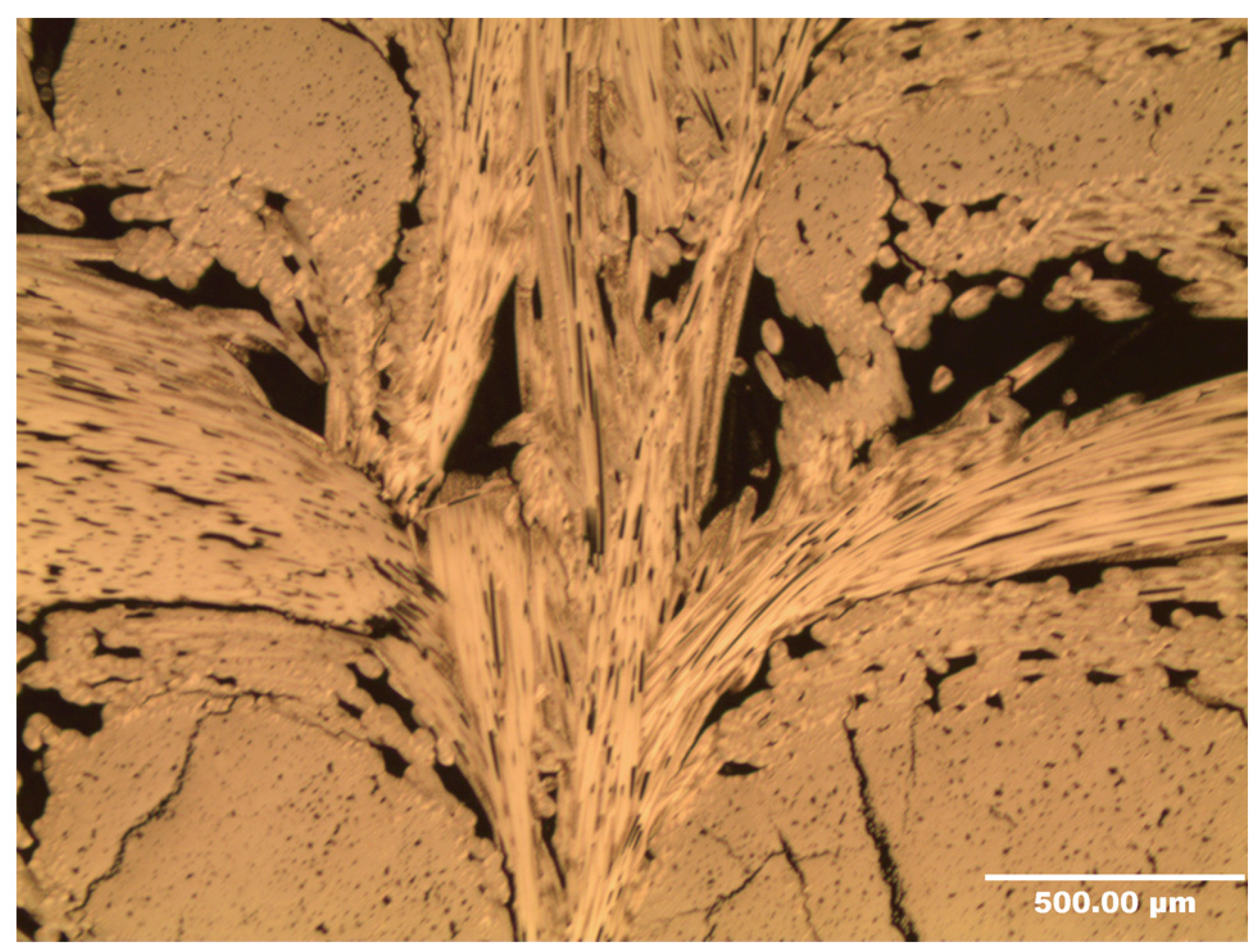

3.1. Manufacturing Porosities

3.2. Thermal Properties

3.3. FE Modelling

3.3.1. Effect of Manufacturing Porosity

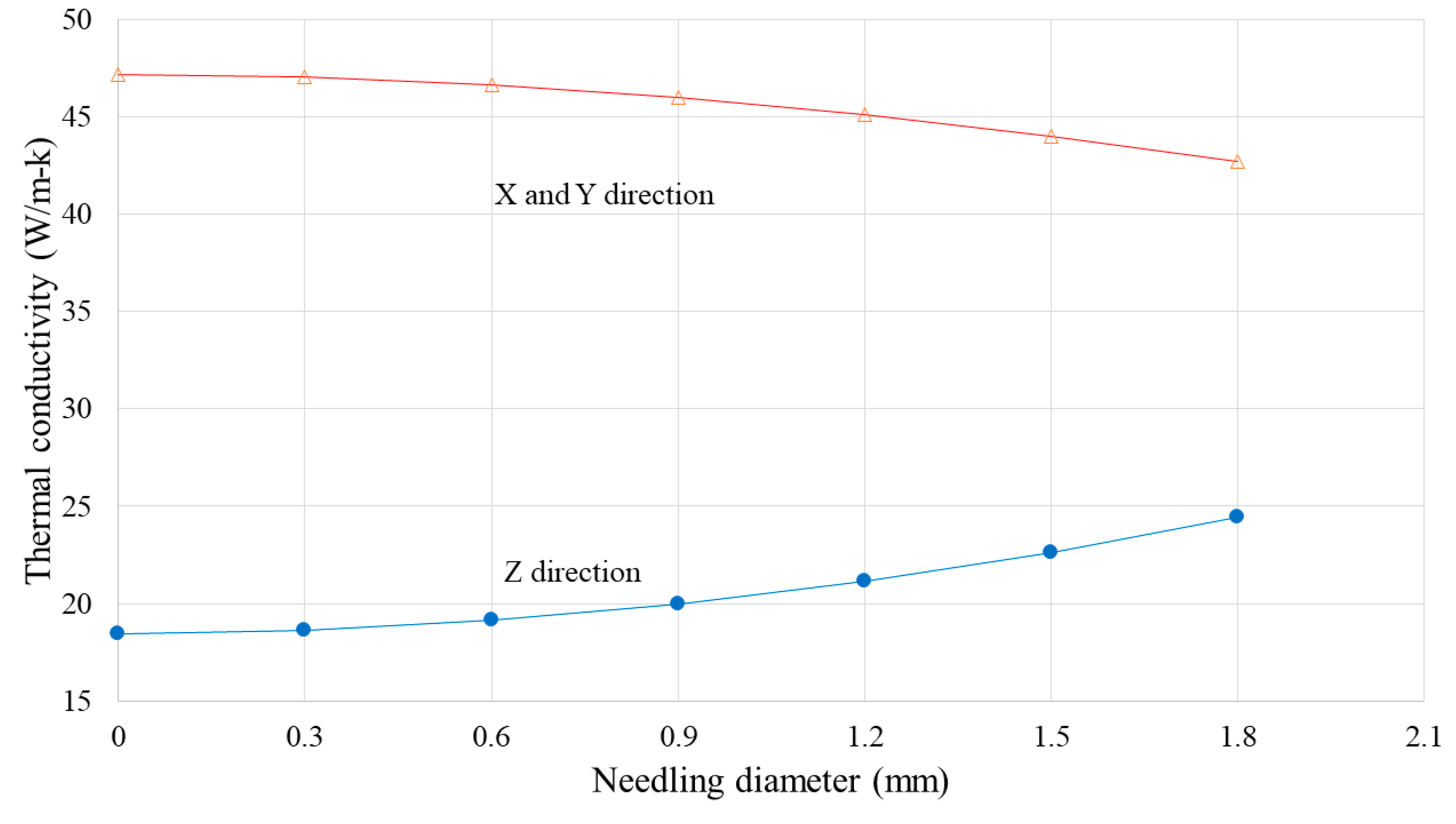

3.3.2. Effect of Needling Diameter

3.3.3. Effect of Needling Density

4. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Symbol | Description | Units |

| α | thermal diffusivity | mm2/s |

| L | thickness of the sample | m |

| t1/2 | half rise time | s |

| k | thermal conductivity | W/(m·K) |

| ρ | density | Kg/m3 |

| cp | specific heat | J/(kg·K) |

| Q | total heat flux | W |

| A | surface area | m2 |

| ∆T | temperature difference | °C |

| Abbreviations | Meaning | |

| C/C | carbon–carbon | |

| RVE | representative volume element |

References

- Luo, R. Friction performance of C/C composites prepared using rapid directional diffused chemical vapor infiltration processes. Carbon 2002, 40, 1279–1285. [Google Scholar] [CrossRef]

- Ai, S.; Fu, H.; He, R.; Pei, Y. Multi-scale modeling of thermal expansion coefficients of C/C composites at high temperature. Mater. Des. 2015, 82, 181–188. [Google Scholar] [CrossRef]

- Feng, Z.; Fan, Z.; Kong, Q.; Xiong, X.; Huang, B. Effect of high temperature treatment on the structure and thermal conductivity of 2d carbon/carbon composites with a high thermal conductivity. N. Carbon Mater. 2014, 29, 357–362. [Google Scholar] [CrossRef]

- Fitzer, E.; Manocha, L.M. Applications of carbon/carbon composites. In Carbon Reinforcements and Carbon/Carbon Composites; Springer: Berlin/Heidelberg, Germany, 1998; pp. 310–336. [Google Scholar]

- Gautronneau, E.; Cros, C.; Pascal, P.; Cutroni, M. Vega Program—The P80 FW SRM Nozzle. In Proceedings of the 40th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibition, Fort Lauderdale, FL, USA, 11–14 July 2004. [Google Scholar]

- Wei, X.; Li, J.; Chen, J.; Jin, W. Experimental investigation on throat insert’s thermal shock resistance using C/C composite in solid rocket motor. Adv. Mat. Res. 2011, 304, 169–174. [Google Scholar] [CrossRef]

- Leong, K.H.; Ramakrishna, S.; Huang, Z.M.; Biboa, G.A. The Potential of knitting for engineering composites—A review. Compos. Part A 2000, 31, 197–220. [Google Scholar] [CrossRef]

- Hou, X.; Cheng, W.; Chen, N.; Zhou, H. Preparation of a high performance carbon/carbon composite throat insert woven with axial carbon rods. New Carbon Mater. 2013, 28, 355–362. [Google Scholar] [CrossRef]

- Jia, Y.; Liao, D.; Cui, H.; Ji, A.; Bai, X.; Yasira, M. Modelling the needling effect on the stress concentrations of laminated C/C composites. Mater. Des. 2016, 104, 19–26. [Google Scholar] [CrossRef]

- Xie, J.; Liang, J.; Fang, G.; Chen, Z. Effect of needling parameters on the effective properties of 3D needled C/C-SiC composites. Compos. Sci. Technol. 2015, 117, 69–77. [Google Scholar] [CrossRef]

- Yu, J.; Zhou, C.; Zhang, H. A micro-image based reconstructed finite element model of needle-punched C/C composite. Compos. Sci. Technol. 2017, 153, 48–61. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, P.; Lu, H.; Zhang, W. Hierarchically modeling the elastic properties of 2D needled carbon/carbon composites. Compos. Struct. 2015, 133, 148–156. [Google Scholar] [CrossRef]

- Del Puglia, P.; Sheikh, M.A.; Hayhurst, D.R. Modelling the degradation of thermal transport in a CMC material due to three different classes of porosity. Model. Simul. Mater. Sci. Eng. 2004, 12, 357. [Google Scholar] [CrossRef]

- Del Puglia, P.; Sheikh, M.A.; Hayhurst, D.R. Thermal transport property prediction of a CMC laminate from base materials properties and manufacturing porosities. Proc. R. Soc. A 2005, 461, 3575–3597. [Google Scholar] [CrossRef]

- Farooqi, J.K.; Sheikh, M.A. Finite element modelling of thermal transport in ceramic matrix composites. Comput. Mater. Sci. 2006, 37, 361–373. [Google Scholar] [CrossRef]

- Alghamdi, A.; Khan, A.; Mummery, P.; Sheikh, M.A. The characterisation and modelling of manufacturing porosity of a 2-D carbon/carbon composite. J. Compos. Mater. 2013, 48, 2815–2829. [Google Scholar] [CrossRef]

- Alghamdi, A.; Mummery, P.; Sheikh, M.A. Multi-scale 3D image-based modelling of a carbon/carbon composite. Model. Simul. Mater. Sci. Eng. 2013, 21, 085014. [Google Scholar] [CrossRef]

- Xu, Y.; Ren, S.; Zhang, W. Thermal conductivities of plain woven C/SiC composite: Micromechanical model considering PyC interphase thermal conductance and manufacture-induced voids. Compos. Struct. 2018, 193, 212–223. [Google Scholar] [CrossRef]

- Parker, W.J.; Jenkins, R.J.; Butler, C.P.; Abbott, G.L. Flash method of determining thermal diffusivity, heat capacity and thermal conductivity. J. Appl. Phys. 1961, 32, 1679–1684. [Google Scholar] [CrossRef]

- Dassault Systèmes Simulia Corp. Abaqus, version 6.14; Dassault Systèmes Simulia Corp.: Johnston, RI, USA, 2014. [Google Scholar]

- Meng, S.; Song, L.; Xu, C.; Wang, W.; Xie, W.; Jin, H. Predicting the effective properties of 3D needled carbon/carbon composites by a hierarchical scheme with a fiber-based representative unit cell. Compos. Struct. 2017, 172, 198–209. [Google Scholar] [CrossRef]

- Tomkova, B.; Sejnoha, M.; Novak, J.; Zeman, J. Evaluation of effective thermal conductivities of porous textile composites. Int. J. Multiscale Comput. Eng. 2008, 6, 153–167. [Google Scholar] [CrossRef]

- Shigang, A.; Rujie, H.; Yongmao, P. A Numerical study on the thermal conductivity of 3d woven C/C composites at high temperature. Appl. Compos. Mater. 2015, 22, 823–835. [Google Scholar] [CrossRef]

- Lemmon, E.W.; Jacobsen, R.T. Viscosity and thermal conductivity equations for nitrogen, oxygen, argon, and air. Int. J. Thermophys. 2004, 25, 21–69. [Google Scholar] [CrossRef]

- Gao, F.; Patrick, J.W.; Walker, A. The characterisation of cracks and voids in two-dimensional carbon-carbon composites. Carbon 1993, 31, 103–108. [Google Scholar] [CrossRef]

- Jortner, J. Microstructure of cloth-reinforced carbon-carbon laminates. Carbon 1992, 30, 153–163. [Google Scholar] [CrossRef]

| Current (mA) | Voltage (kV) | Rotation Path (°) | Pixel Size (µm) | Exposure Time (ms) |

|---|---|---|---|---|

| 100 | 50 | 0.3 | 19.4 | 2001 |

| Phase | Thermal Conductivity W/(m·K) | Specific Heat J/(kg·K) | Density kg/m3 | Source |

|---|---|---|---|---|

| Carbon Fibre | 100(//) 10(┴) | 921 | 1800 | [13,14] |

| Carbon Matrix | 42.2 | 1256 | 1400 | [22,23] |

| Air | 0.026 | 1000 | 1.3 | [24] |

| Test Number | Thermal Diffusivity (mm2/s) | |

|---|---|---|

| Longitudinal | Through Thickness | |

| 1 | 38.16 | 17.677 |

| 2 | 38.026 | 17.536 |

| 3 | 37.817 | 17.492 |

| Mean | 38.001 | 17.569 |

| Standard deviation | 0.173 | 0.097 |

| Direction | Thermal Conductivity (W/(m·K)) |

|---|---|

| x | 40.5 |

| y | 35.6 |

| z | 43.2 |

| Average | 39.76 |

| Direction | Thermal Conductivity (W/(m·K)) | |

|---|---|---|

| Without Porosity | With Porosity | |

| Through-thickness | 21.13 | 20.82 |

| Longitudinal | 45.4 | 43.66 |

| Thermal Conductivity (W/(m·K)) | ||

|---|---|---|

| Direction | Experimental | FE Modelling |

| Through-thickness | 22.48 | 20.82 |

| Longitudinal | 48.62 | 43.66 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alghamdi, A.; Alharthi, H.; Alamoudi, A.; Alharthi, A.; Kensara, A.; Taylor, S. Effect of Needling Parameters and Manufacturing Porosities on the Effective Thermal Conductivity of a 3D Carbon–Carbon Composite. Materials 2019, 12, 3750. https://doi.org/10.3390/ma12223750

Alghamdi A, Alharthi H, Alamoudi A, Alharthi A, Kensara A, Taylor S. Effect of Needling Parameters and Manufacturing Porosities on the Effective Thermal Conductivity of a 3D Carbon–Carbon Composite. Materials. 2019; 12(22):3750. https://doi.org/10.3390/ma12223750

Chicago/Turabian StyleAlghamdi, Abdulrahman, Hamzah Alharthi, Ali Alamoudi, Abdullah Alharthi, Ammar Kensara, and Scott Taylor. 2019. "Effect of Needling Parameters and Manufacturing Porosities on the Effective Thermal Conductivity of a 3D Carbon–Carbon Composite" Materials 12, no. 22: 3750. https://doi.org/10.3390/ma12223750

APA StyleAlghamdi, A., Alharthi, H., Alamoudi, A., Alharthi, A., Kensara, A., & Taylor, S. (2019). Effect of Needling Parameters and Manufacturing Porosities on the Effective Thermal Conductivity of a 3D Carbon–Carbon Composite. Materials, 12(22), 3750. https://doi.org/10.3390/ma12223750