Effect of TiB Orientation on Near-Threshold Fatigue Crack Propagation in TiB-Reinforced Ti-3Al-2.5V Matrix Composites Treated with Heat Extrusion

Abstract

1. Introduction

2. Experimental Procedures

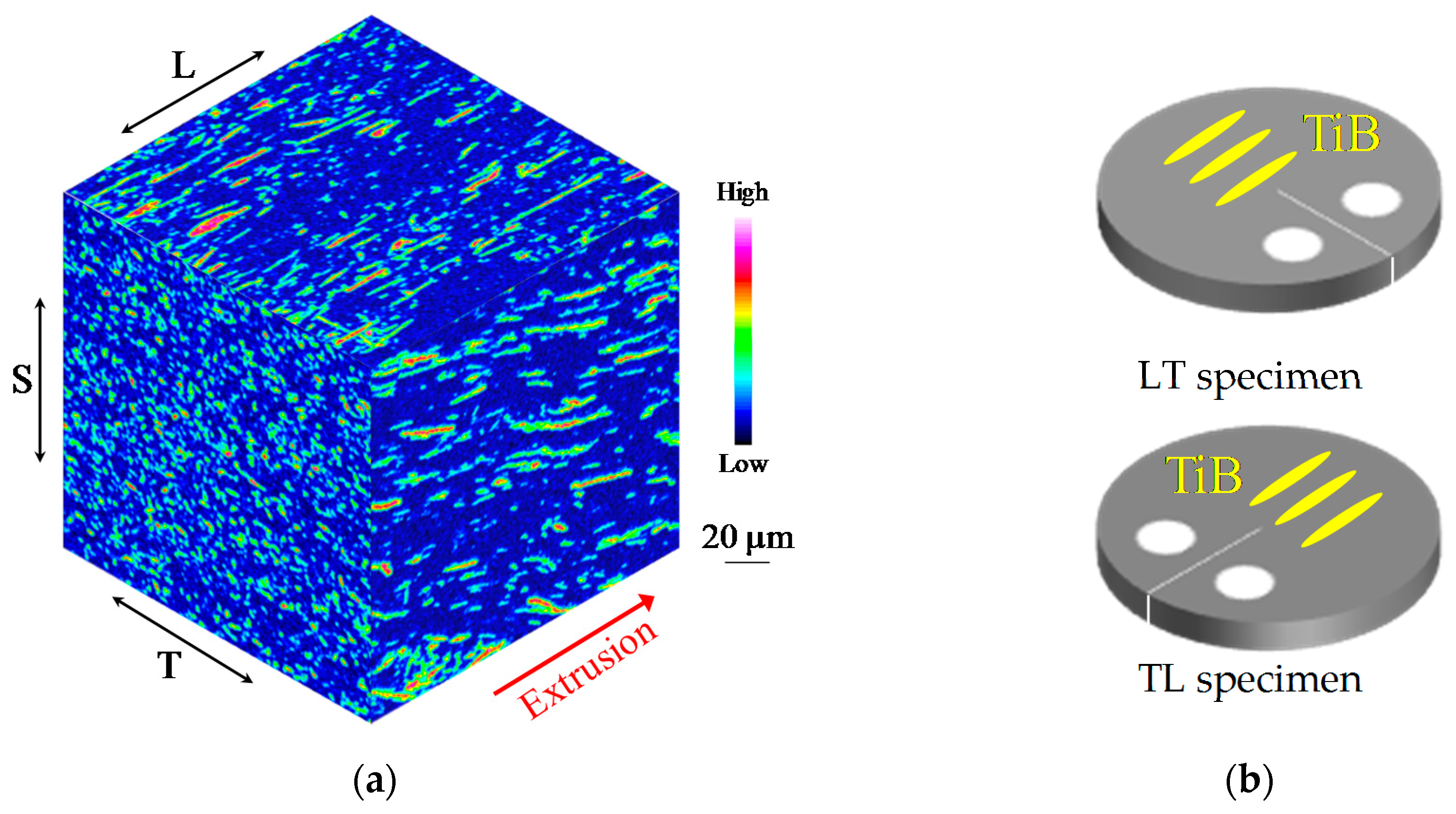

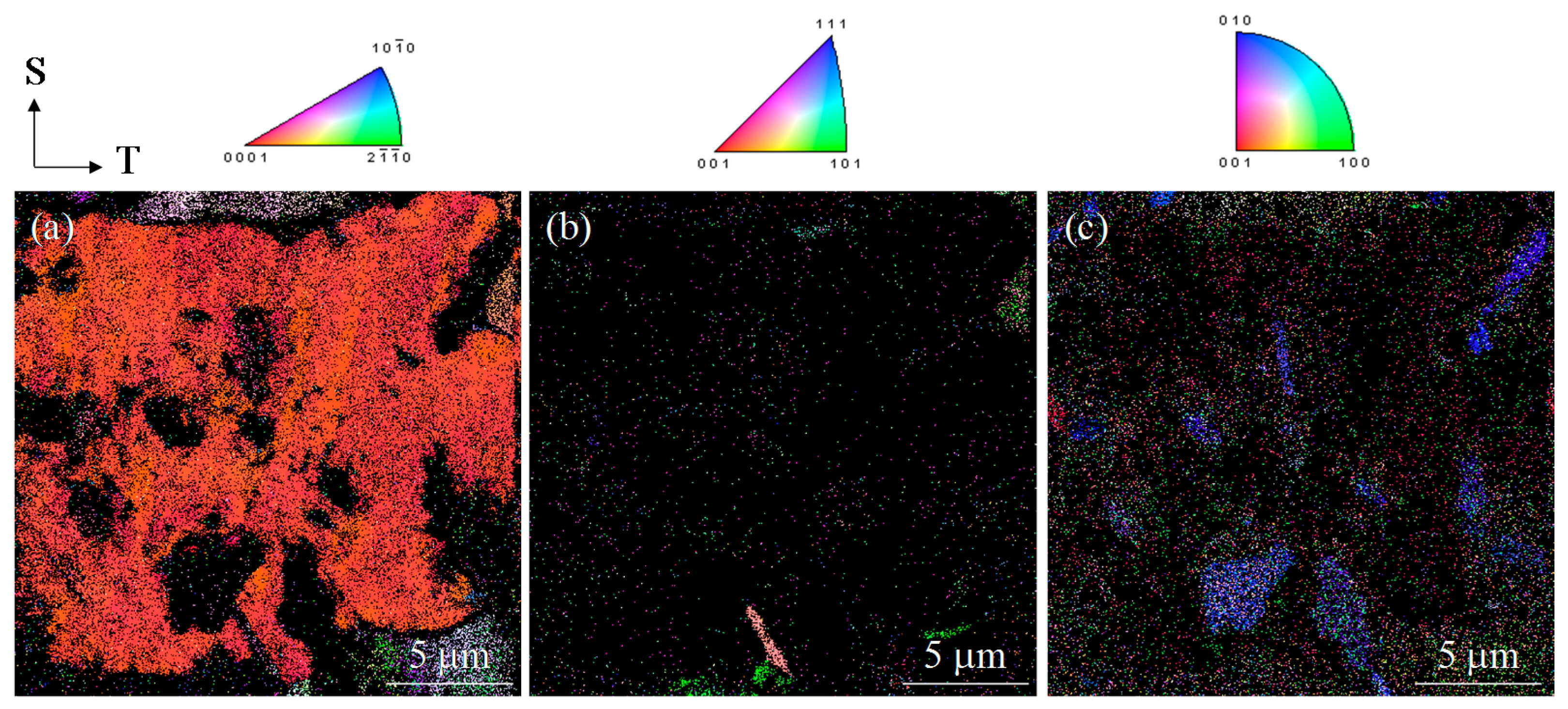

2.1. Materials

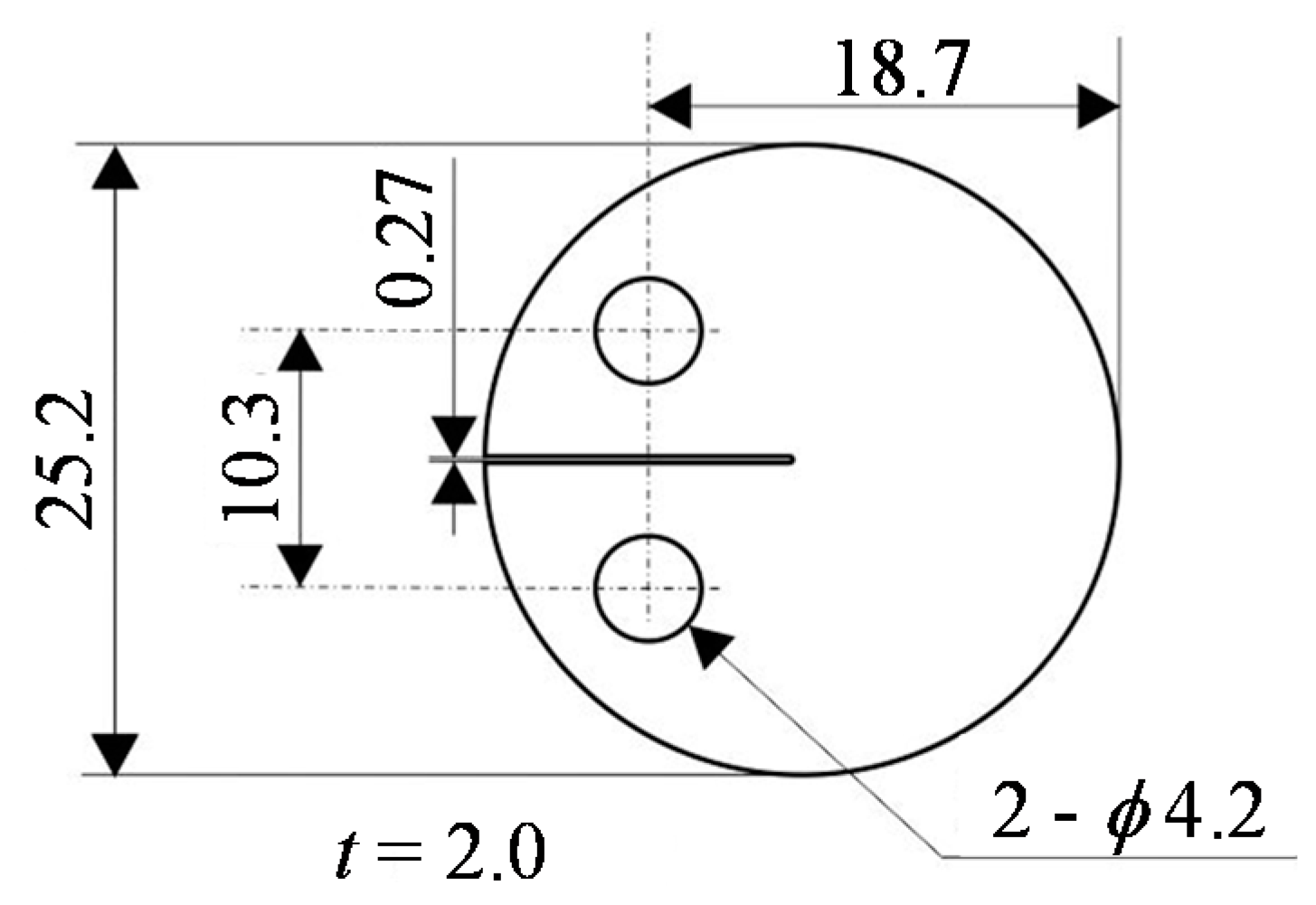

2.2. Experimental Tests

3. Results and Discussion

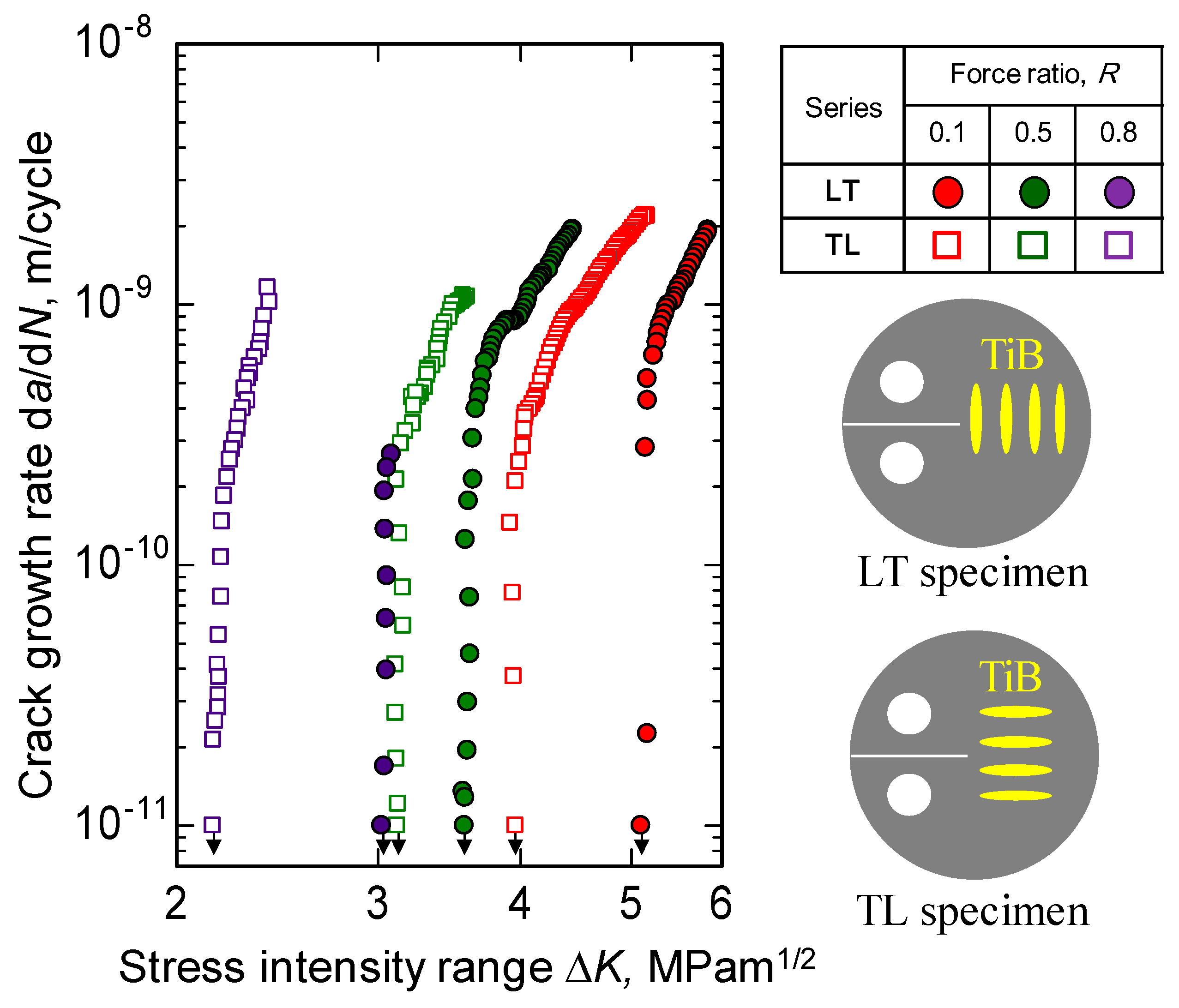

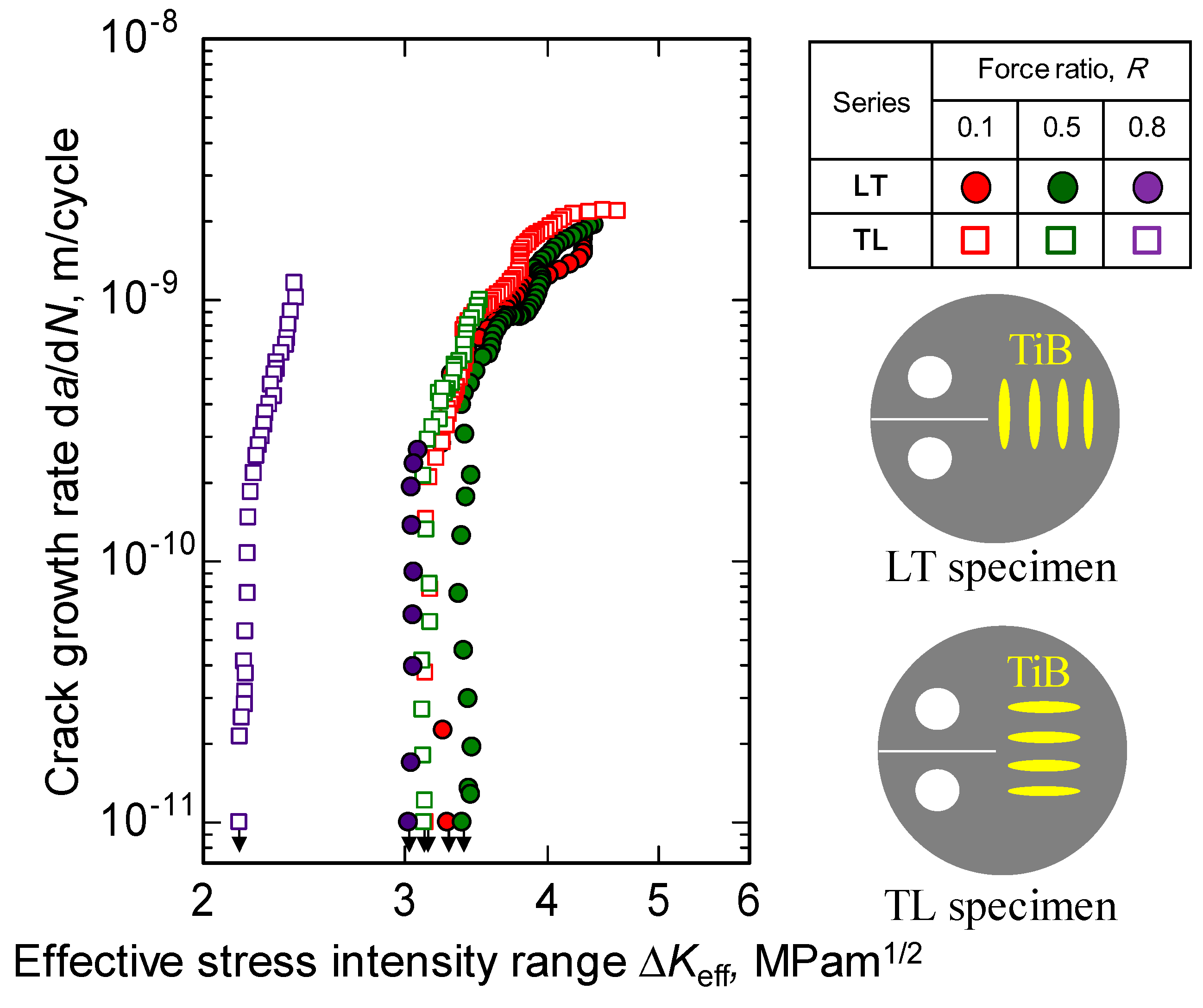

3.1. Effects of Force Ratio and TiB Orientation on Fatigue Crack Propagation

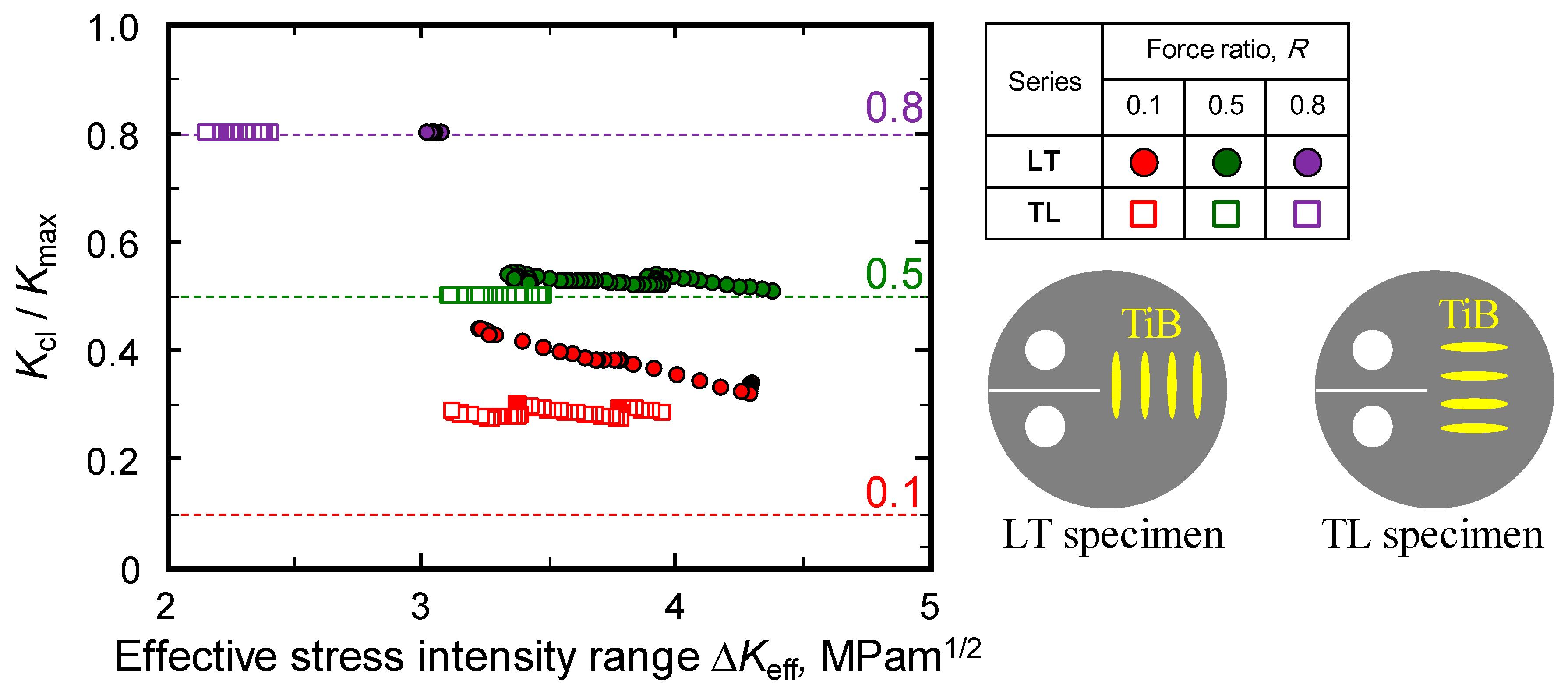

3.2. Crack Closure

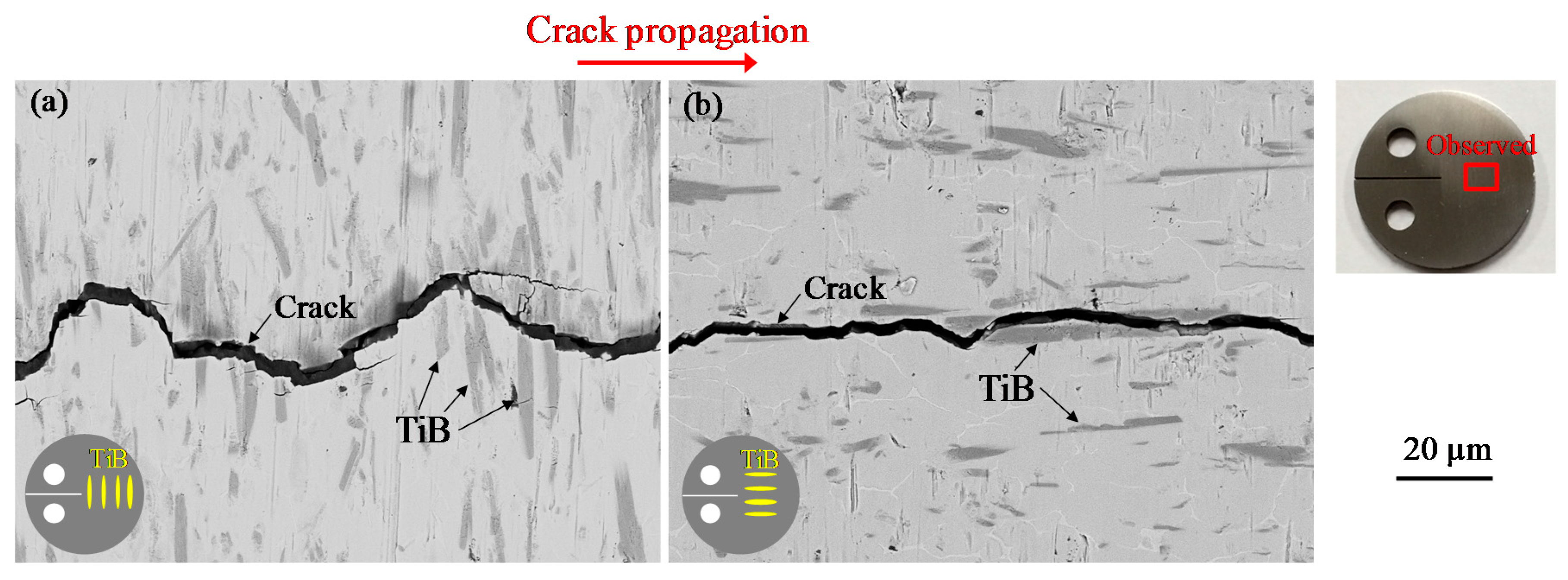

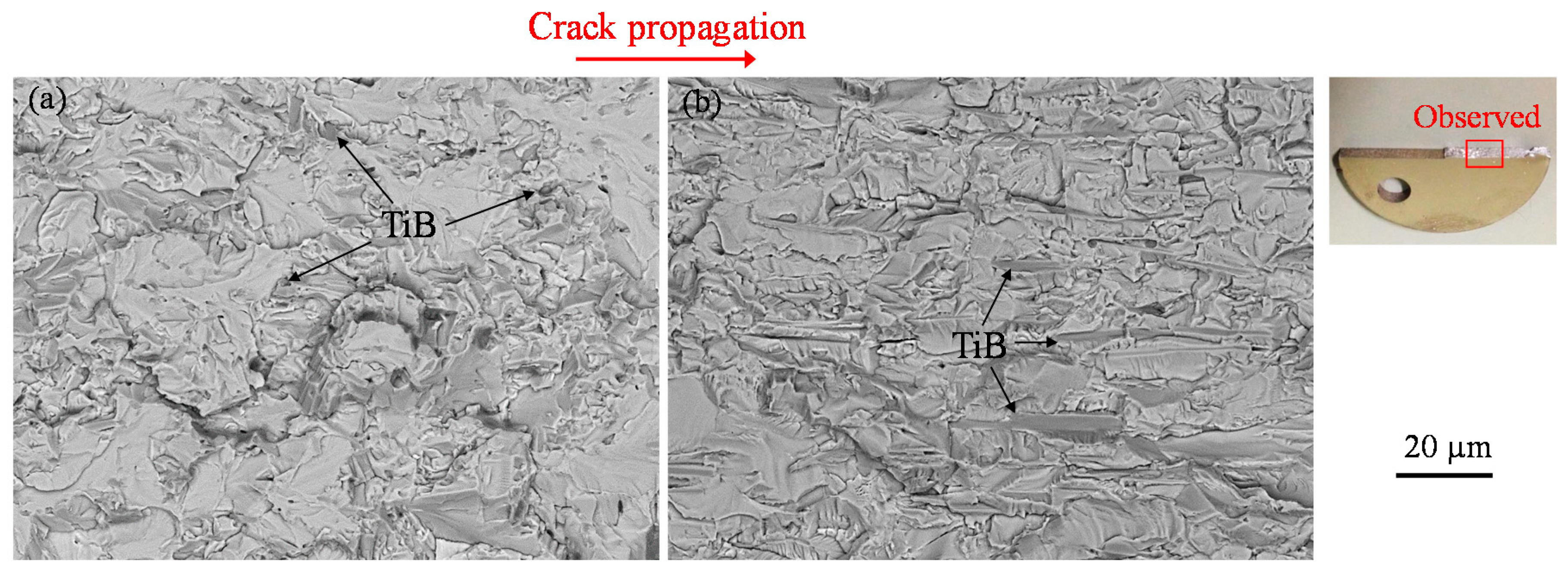

3.3. Analyses of Crack Profiles and Fracture Surfaces

4. Conclusions

- The orientation of TiB whiskers in a TiB-reinforced Ti-3Al-2.5V alloy determines the crack path;

- The threshold stress intensity range values, ΔKth, for a Ti-3Al-2.5V alloy incorporating TiB whiskers oriented perpendicular to the direction of crack growth are greater than that obtained in the case that the orientation is parallel. This effect can be explained by the increase in the degree of the roughness-induced crack closure resulting from the perpendicular TiB, because the deflected and tortuous cracks appear in a Ti-3Al-2.5V alloy reinforced with TiB;

- The effective threshold stress intensity range values, ΔKeff,th, determined for the Ti-3Al-2.5V alloy are unaffected by the TiB orientation when the force ratio value is less than 0.5.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kurashina, Y.; Edura, A.; Murakami, R.; Mizutani, M.; Komotori, J. Effect of hydroxy groups and microtopography generated by a nanosecond-pulsed laser on pure Ti surfaces. J. Mater. Sci. Mater. Med. 2019, 30, 57–65. [Google Scholar] [CrossRef] [PubMed]

- Ijiri, M.; Takemoto, Y. Phase transformation behavior of Ti-10Mo-7Al alloy with heat treatment. J. Jpn. Inst. Met. Mater. 2015, 79, 468–473. [Google Scholar] [CrossRef]

- Ijiri, M.; Tomita, Y.; Ishikawa, T.; Takemoto, Y. Phase transformation behavior of Ti-35Nb-7Al alloy with tempering. J. Jpn. Inst. Met. Mater. 2016, 80, 547–552. [Google Scholar] [CrossRef]

- Ijiri, M.; Okumura, A.; Ishikawa, T.; Kadowaki, K.; Takemoto, Y. Microstructure of Ti-4Fe-7Al alloy quenched in a salt bath after solution treatment. J. Jpn. Inst. Met. Mater. 2016, 80, 691–696. [Google Scholar] [CrossRef]

- Ijiri, M.; Tomita, Y.; Ishikawa, T.; Kadowaki, K.; Takemoto, Y. Influence of Nb content of Ti-xNb-7Al alloys on β→α” transformation with tempering. J. Jpn. Inst. Met. Mater. 2017, 81, 345–351. [Google Scholar] [CrossRef]

- Fujii, T.; Tohgo, K.; Isono, H.; Shimamura, Y. Fabrication of a PSZ-Ti functionally graded material by spark plasma sintering and its fracture toughness. Mater. Sci. Eng. A 2017, 682, 656–663. [Google Scholar] [CrossRef]

- Kikuchi, S.; Katahira, K.; Komotori, J. Formation of titanium/zirconia based biomaterials fabricated by spark plasma sintering. J. Jpn. Inst. Met. Mater. 2018, 82, 341–348. [Google Scholar] [CrossRef]

- Kikuchi, S.; Akebono, H.; Ueno, A.; Ameyama, K. Formation of commercially pure titanium with a bimodal nitrogen diffusion phase using plasma nitriding and spark plasma sintering. Powder Technol. 2018, 330, 349–356. [Google Scholar] [CrossRef]

- Takesue, S.; Kikuchi, S.; Akebono, H.; Misaka, Y.; Komotori, J. Effect of pre-treatment with fine particle peening on surface properties and wear resistance of gas blow induction heating nitrided titanium alloy. Surf. Coat. Technol. 2019, 359, 476–484. [Google Scholar] [CrossRef]

- Takesuke, S.; Kikuchi, S.; Akebono, H.; Komotori, J.; Fukazawa, K.; Misaka, Y. Effects of gas blow velocity on the surface properties of Ti-6Al-4V alloy treated by gas blow IH nitriding. Mater. Trans. 2017, 58, 1155–1160. [Google Scholar] [CrossRef]

- Kikuchi, S.; Yoshida, S.; Ueno, A. Improvement of fatigue properties of Ti-6Al-4V alloy under four-point bending by low temperature nitriding. Int. J. Fatigue 2019, 120, 134–140. [Google Scholar] [CrossRef]

- Terada, D.; Inoue, S.; Tsuji, N. Microstructure and mechanical properties of commercial purity titanium severely deformed by ARB process. J. Mater. Sci. 2007, 42, 1673–1681. [Google Scholar] [CrossRef]

- Kikuchi, S.; Hayami, Y.; Ishiguri, T.; Guennec, B.; Ueno, A.; Ota, M.; Ameyama, K. Effect of bimodal grain size distribution on fatigue properties of Ti-6Al-4V alloy with harmonic structure under four-point bending. Mater. Sci. Eng. A 2017, 687, 269–275. [Google Scholar] [CrossRef]

- Nukui, Y.; Kubozono, H.; Kikuchi, S.; Nakai, Y.; Ueno, A.; Kawabata, M.O.; Ameyama, K. Fractographic analysis of fatigue crack initiation and propagation in CP titanium with a bimodal harmonic structure. Mater. Sci. Eng. A 2018, 716, 228–234. [Google Scholar] [CrossRef]

- Koga, G.Y.; Otani, L.B.; Silva, A.M.B.; Roche, V.; Nogueira, R.P.; Jorge, A.M., Jr.; Bolfarini, C.; Kiminami, C.S.; Botta, W.J. Characterization and corrosion resistance of boron-containing-austenitic stainless steels produced by rapid solidification techniques. Materials 2018, 11, 2189. [Google Scholar] [CrossRef]

- Zhang, S.; Song, J.; Liao, H.; Liu, Y.; Zhang, G.; Ma, S.; Tang, A.; Atrens, A.; Pan, F. Effect of boron on the grain refinement and mechanical properties of as-cast Mg alloy AM50. Materials 2019, 12, 1100. [Google Scholar] [CrossRef]

- Hernandez-Rodriguez, M.A.L.; Mercado-Solis, R.D.; Presbítero, G.; Lozano, D.E.; Martinez-Cazares, G.M.; Bedolla-Gil, Y. Influence of boron additions and heat treatments on the fatigue resistance of CoCrMo alloys. Materials 2019, 12, 1076. [Google Scholar] [CrossRef]

- Bazhin, P.M.; Stolin, A.M.; Konstantinov, A.S.; Kostitsyna, E.V.; Ignatov, A.S. Ceramic Ti-B composites synthesized by combustion followed by high-temperature deformation. Materials 2016, 9, 1027. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, J.; Luo, G.; Shen, Q.; Zhang, L. Microstructure and mechanical behaviors of titanium matrix composites containing in situ whiskers synthesized via plasma activated sintering. Materials 2018, 11, 544. [Google Scholar] [CrossRef]

- Kurita, H.; Suzuki, S.; Kikuchi, S.; Yodoshi, N.; Gourdet, S.; Narita, F. Strengthening mechanism of two-dimensional randomly oriented titanium boride whisker-reinforced Ti-6Al-4V alloy matrix composites. Materials 2019, 12, 2401. [Google Scholar] [CrossRef]

- Kurita, H.; Sakayanagi, K.; Kikuchi, S.; Yodoshi, N.; Gourdet, S.; Narita, F. Crack initiation behavior of titanium boride whisker reinforced titanium matrix composites during small punch test. Mater. Des. Process. Commun. 2019, 1, e80. [Google Scholar]

- Wang, S.; Huang, L.; Zhang, R.; Liu, B.; Cui, X.; Geng, L.; Peng, H.X. Enhancing ductility of titanium matrix composites by multimodal α-grains. Scr. Mater. 2019, 170, 161–165. [Google Scholar] [CrossRef]

- Chen, W.; Boehlert, C.J.; Payzant, E.A.; Howe, J.Y. The effect of processing on the 455oC tensile and fatigue behavior of boron-modified Ti-6Al-4V. Int. J. Fatigue 2010, 32, 627–638. [Google Scholar] [CrossRef]

- Chen, W.; Boehlert. The elevated-temperature fatigue behavior of boron-modified Ti-6Al-4V(wt.%) castings. Mater. Sci. Eng A 2008, 494, 132–138. [Google Scholar] [CrossRef]

- Chandran, K.S.R.; Panda, K.B.; Sahay, S.S. TiBw-reinforced Ti composites: Processing, properties, application prospects, and research needs. JOM 2004, 56, 42–48. [Google Scholar] [CrossRef]

- Morsi, K.; Patel, V.V. Processing and properties of titanium-titanium boride (TiBw) matrix composites (a review). J. Mater. Sci. 2007, 42, 2037–2047. [Google Scholar] [CrossRef]

- Sen, I.; Tamirisakanadala, S.; Miracle, D.B.; Ramanmurty, U. Microstructural effects on the mechanical behavior of B-modified Ti–6Al–4V alloys. Acta Mater. 2007, 55, 4983–4993. [Google Scholar] [CrossRef]

- Gorsse, S.; Miracle, D.B. Mechanical properties of Ti-6Al-4VTiB composites with randomly oriented and aligned TiB reinforcements. Acta Mater. 2013, 51, 2427–2442. [Google Scholar] [CrossRef]

- Arévalo, C.; Montealegre-Melendez, I.; Pérez-Soriano, E.M.; Ariza, E.; Kitzmantel, M.; Neubauer, E. Study of the influence of TiB content and temperature in the properties of in situ titanium matrix composites. Metals 2017, 7, 457. [Google Scholar] [CrossRef]

- Wang, B.; Huang, L.J.; Hu, H.T.; Liu, B.X.; Geng, L. Superior tensile strength and microstructure evolution of TiB whisker reinforced Ti60 composites with network architecture after β extrusion. Mater. Charact. 2015, 103, 140–149. [Google Scholar] [CrossRef]

- Hyman, M.E.; McCullough, C.; Valencia, J.J.; Levi, C.G.; Mehrabian, R. Microstructure evolution in TiAl alloys with B additions: Conventional solidification. Metall. Trans. A 1989, 20, 1847–1859. [Google Scholar] [CrossRef]

- Li, D.X.; Ping, D.H.; Lu, Y.X.; Ye, H.Q. Characterization of the microstructure in TiB-whisker reinforced Ti alloy matrix composite. Mater. Lett. 1993, 16, 322–326. [Google Scholar] [CrossRef]

- Feng, H.; Zhou, Y.; Jia, D.; Meng, Q.; Rao, J. Growth mechanism of in situ TiB whiskers in spark plasma sintered TiB-Ti metal matrix composites. Cryst. Growth Des. 2006, 6, 1626–1630. [Google Scholar] [CrossRef]

- Feng, H.; Zhou, Y.; Jia, D.; Meng, Q. Microstructural Characterization of spark plasma sintered in situ TiB reinforced Ti matrix composite by EBSD and TEM. Mater. Trans. 2005, 46, 575–580. [Google Scholar] [CrossRef][Green Version]

- Schun, C.; Dunand, D.C. Whisker alignment of Ti-6Al-4V/TiB composites during deformation by transformation superplasticity. Int. J. Plast. 2001, 17, 317–340. [Google Scholar]

- Ropars, L.; Dehmas, M.; Gautier, E.; Tricker, D.; Schuster, D.; Gourdet, S. Effect of processing route on microstructure and mechanical properties of a Ti-3Al-2.5V/TiB composite. In Proceedings of the THERMEC’2018, Paris, France, 9–13 July 2018. [Google Scholar]

- Ropars, L.; Dehmas, M.; Gourdet, S.; Tricker, D.; Aeby-Gautier, E. Kinetics of phase transformations in Ti-TiB composites characterized using high energy X-ray diffraction. In Proceedings of the 19th International Conference on Composite Materials, Montreal, QC, Canada, 28 July–2 August 2013. [Google Scholar]

- Ropars, L.; Jonathan, S.; Tnaguy, B.; Gourdet, S. Characterisation of a ductile Ti-3Al-2.5V/TiBp composite produced via mechanical alloying. In Proceedings of the 12th World Conference on Titanium, Beijing, China, 19–24 June 2011; Volume 2, pp. 1402–1406. [Google Scholar]

- Kikuchi, S.; Imai, T.; Kubozono, H.; Nakai, Y.; Ueno, A.; Ameyama, K. Evaluation of near-threshold fatigue crack propagation in Ti-6Al-4V alloy with harmonic structure created by mechanical milling and spark plasma sintering. Frat. Integrita Strutt. 2015, 34, 261–270. [Google Scholar] [CrossRef]

- Kikuchi, S.; Imai, T.; Kubozono, H.; Nakai, Y.; Ota, M.; Ueno, A.; Ameyama, K. Effect of harmonic structure design with bimodal grain size distribution on near-threshold fatigue crack propagation in Ti-6Al-4V alloy. Int. J. Fatigue 2016, 92, 616–622. [Google Scholar] [CrossRef]

- Kikuchi, S.; Mori, T.; Kubozono, H.; Nakai, Y.; Kawabata, M.O.; Ameyama, K. Evaluation of near-threshold fatigue crack propagation in harmonic-structured CP Titanium with a bimodal grain size distribution. Eng. Fract. Mech. 2017, 181, 77–86. [Google Scholar] [CrossRef]

- Kikuchi, S.; Kubozono, H.; Nukui, Y.; Nakai, Y.; Ueno, A.; Kawabata, M.O.; Ameyama, K. Statistical fatigue properties and small fatigue crack propagation in bimodal harmonic structured Ti-6Al-4V alloy under four-point bending. Mater. Sci. Eng. A 2018, 711, 29–36. [Google Scholar] [CrossRef]

- Kikuchi, S.; Nakatsuka, Y.; Nakai, Y.; Nakatani, M.; Kawabata, M.O.; Ameyama, K. Evaluation of fatigue properties under four-point bending and fatigue crack propagation in austenitic stainless steel with a bimodal harmonic structure. Frat. Integrita Strutt. 2019, 48, 545–553. [Google Scholar] [CrossRef]

- Kikuchi, S.; Nukui, Y.; Nakatsuka, Y.; Nakai, Y.; Nakatani, M.; Kawabata, M.O.; Ameyama, K. Effect of bimodal harmonic structure on fatigue properties of austenitic stainless steel under axial loading. Int. J. Fatigue 2019, 127, 222–228. [Google Scholar] [CrossRef]

- Zhou, G.; Ma, H.; Zhang, Z.; Sun, J.; Wang, X.; Zeng, P.; Zheng, R.; Chen, X.; Ameyama, K. Fatigue crack growth behavior in a harmonic structure designed austenitic stainless steel. Mater. Sci. Eng. A 2019, 758, 121–129. [Google Scholar] [CrossRef]

- Kikukawa, M.; Jono, M.; Tanaka, K.; Takatani, M. Measurement of fatigue crack propagation and crack closure at low stress intensity level by unloading elastic compliance method. J. Soc. Mater. Sci. Jpn. 1976, 25, 899–903. [Google Scholar] [CrossRef]

- Nakai, Y.; Tanaka, K. The effects of stress ratio and grain size on near-threshold fatigue crack propagation in low-carbon steel. Eng. Fract. Mech. 1981, 15, 291–302. [Google Scholar] [CrossRef]

- Boyce, B.L.; Ritchie, R.O. Effect of load ratio and maximum stress intensity on the fatigue threshold in Ti-6Al-4V. Eng. Fract. Mech. 2001, 68, 129–147. [Google Scholar] [CrossRef]

- Ogawa, T.; Tokaji, K.; Ohya, K. The effect of microstructure and fracture surface roughness on fatigue crack propagation in a Ti-6Al-4V alloy. Fatigue Fract. Eng. Mater. Struct. 1993, 16, 973–982. [Google Scholar] [CrossRef]

- Sadananda, K.; Vasudevan, A.K. Fatigue crack growth behavior of titanium alloys. Int. J. Fatigue 2005, 27, 1255–1266. [Google Scholar] [CrossRef]

- Nalla, R.K.; Boyce, B.L.; Campbell, J.P.; Peters, J.O.; Ritchie, R.O. Influence of microstructure on high-cycle fatigue of Ti-6Al-4V: Bimodal vs. lamellar structures. Metall. Mater. Trans. A 2002, 33, 899–918. [Google Scholar] [CrossRef]

| Al | V | Fe | C | O | N | Ti |

|---|---|---|---|---|---|---|

| 3.28 | 2.48 | 0.04 | 0.069 | 0.122 | 0.008 | Bal. |

| B | Fe | C | O | N | Ti |

|---|---|---|---|---|---|

| 30.0 | 0.1 | 0.5 | 1.1 | 0.6 | Bal. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kikuchi, S.; Tamai, S.; Kawai, T.; Nakai, Y.; Kurita, H.; Gourdet, S. Effect of TiB Orientation on Near-Threshold Fatigue Crack Propagation in TiB-Reinforced Ti-3Al-2.5V Matrix Composites Treated with Heat Extrusion. Materials 2019, 12, 3685. https://doi.org/10.3390/ma12223685

Kikuchi S, Tamai S, Kawai T, Nakai Y, Kurita H, Gourdet S. Effect of TiB Orientation on Near-Threshold Fatigue Crack Propagation in TiB-Reinforced Ti-3Al-2.5V Matrix Composites Treated with Heat Extrusion. Materials. 2019; 12(22):3685. https://doi.org/10.3390/ma12223685

Chicago/Turabian StyleKikuchi, Shoichi, Shunsuke Tamai, Takao Kawai, Yoshikazu Nakai, Hiroki Kurita, and Sophie Gourdet. 2019. "Effect of TiB Orientation on Near-Threshold Fatigue Crack Propagation in TiB-Reinforced Ti-3Al-2.5V Matrix Composites Treated with Heat Extrusion" Materials 12, no. 22: 3685. https://doi.org/10.3390/ma12223685

APA StyleKikuchi, S., Tamai, S., Kawai, T., Nakai, Y., Kurita, H., & Gourdet, S. (2019). Effect of TiB Orientation on Near-Threshold Fatigue Crack Propagation in TiB-Reinforced Ti-3Al-2.5V Matrix Composites Treated with Heat Extrusion. Materials, 12(22), 3685. https://doi.org/10.3390/ma12223685