Tensile Behavior Characteristics of High-Performance Slurry-Infiltrated Fiber-Reinforced Cementitious Composite with Respect to Fiber Volume Fraction

Abstract

1. Introduction

2. Existing Works Related to Direct Tensile Test

3. Experiment Overview

3.1. SIFRCCs

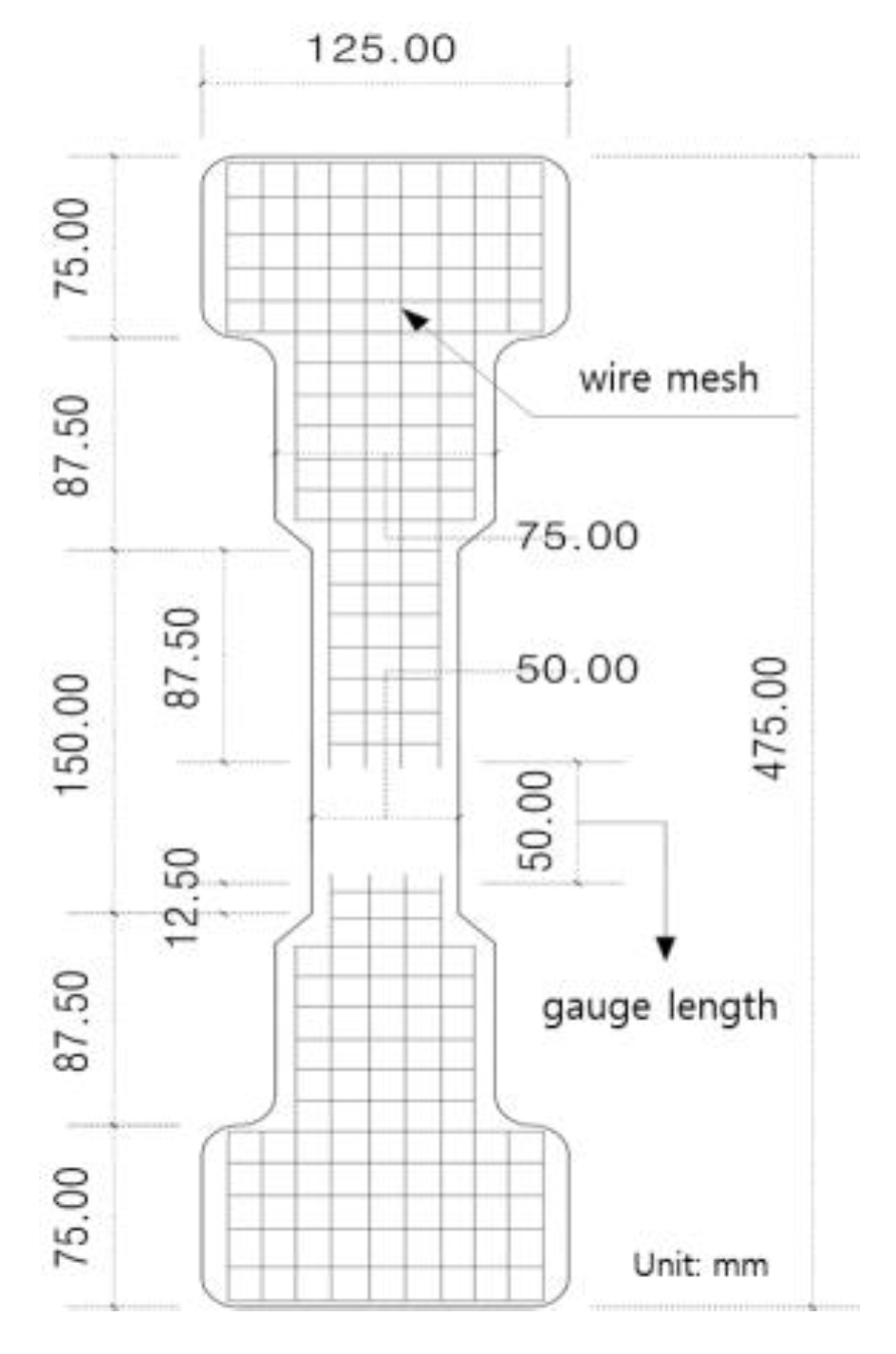

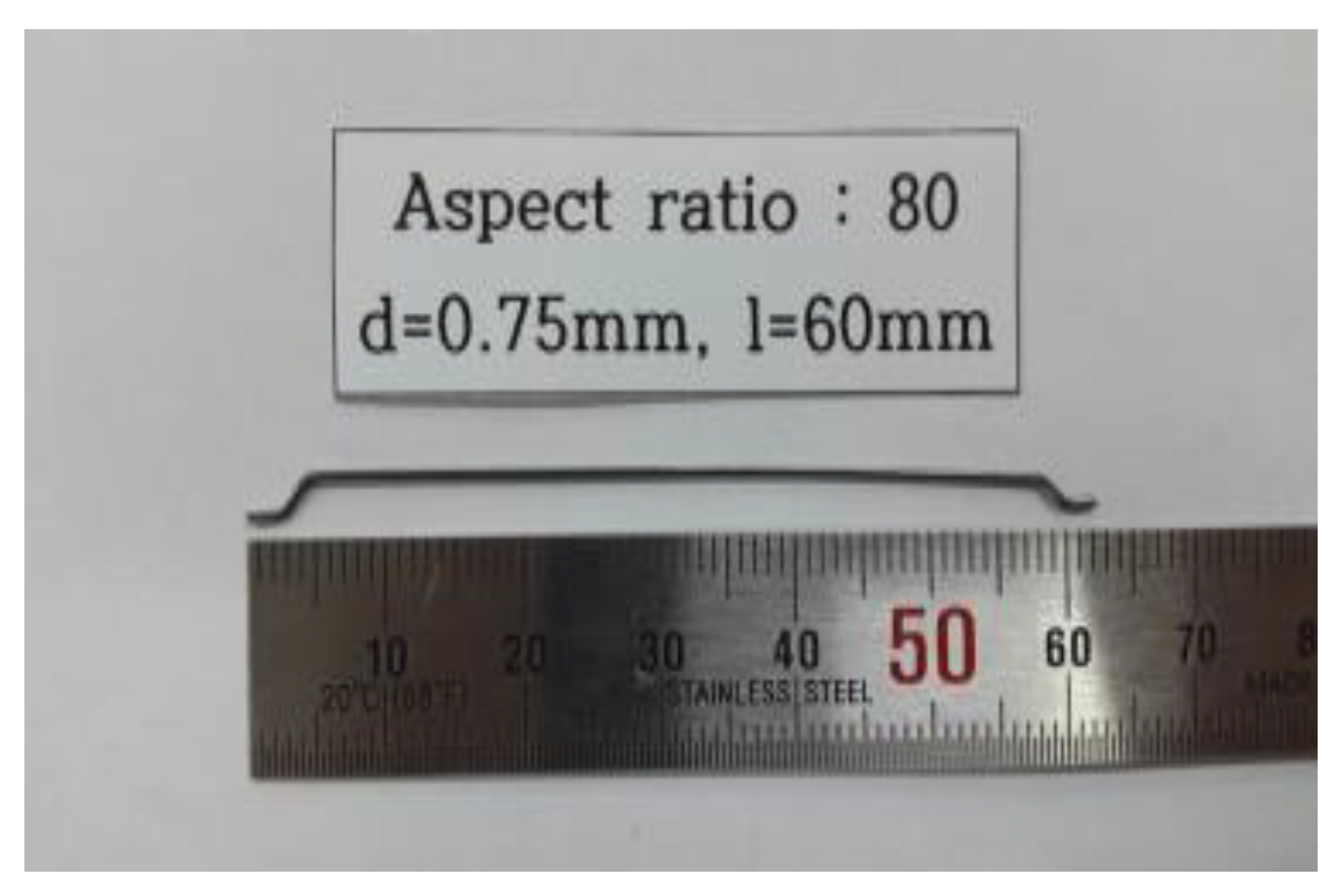

3.2. Experiment Method

3.3. Materials

3.4. Mixing and Fabrication of Specimens

4. Results and Analysis

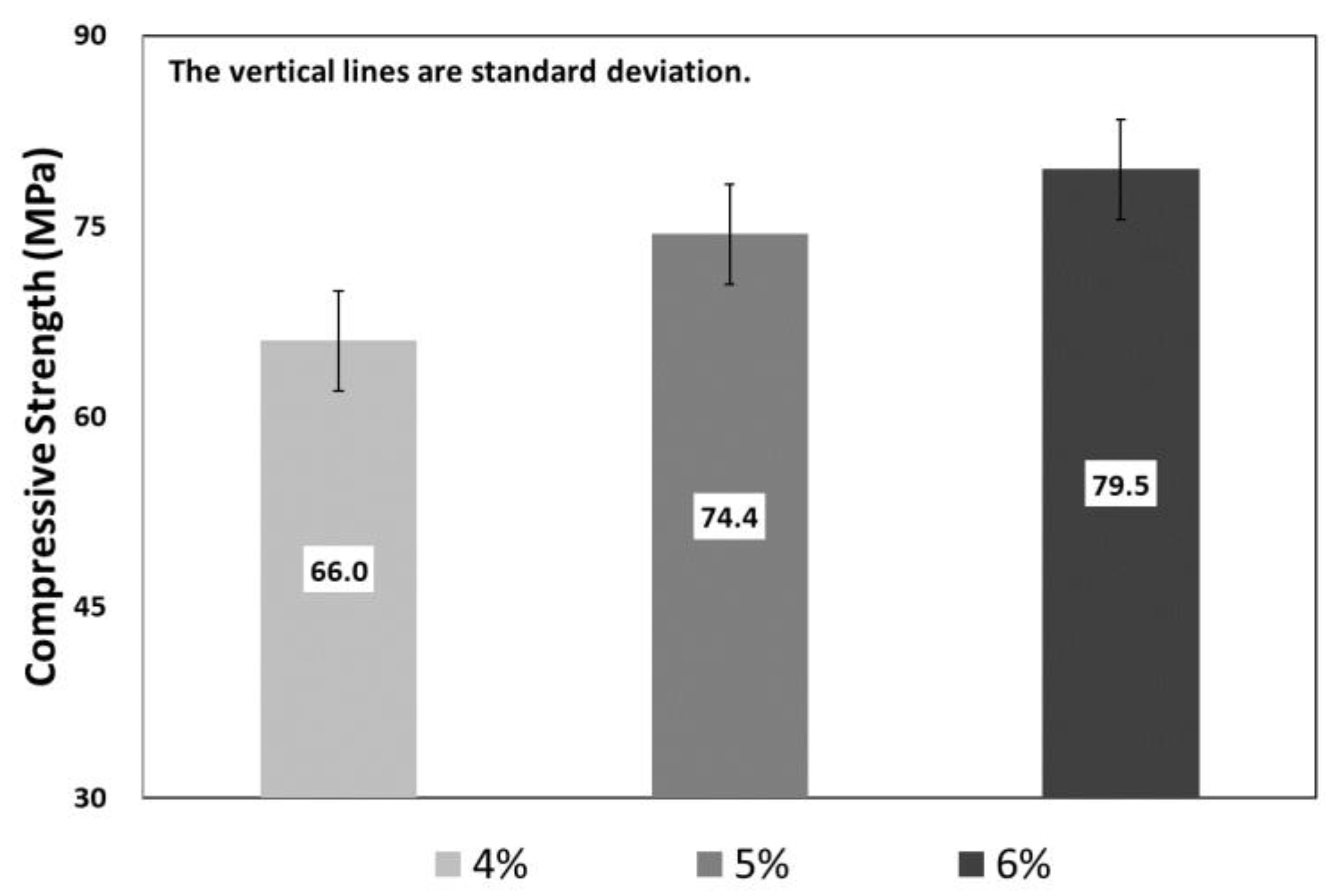

4.1. Compressive Strength

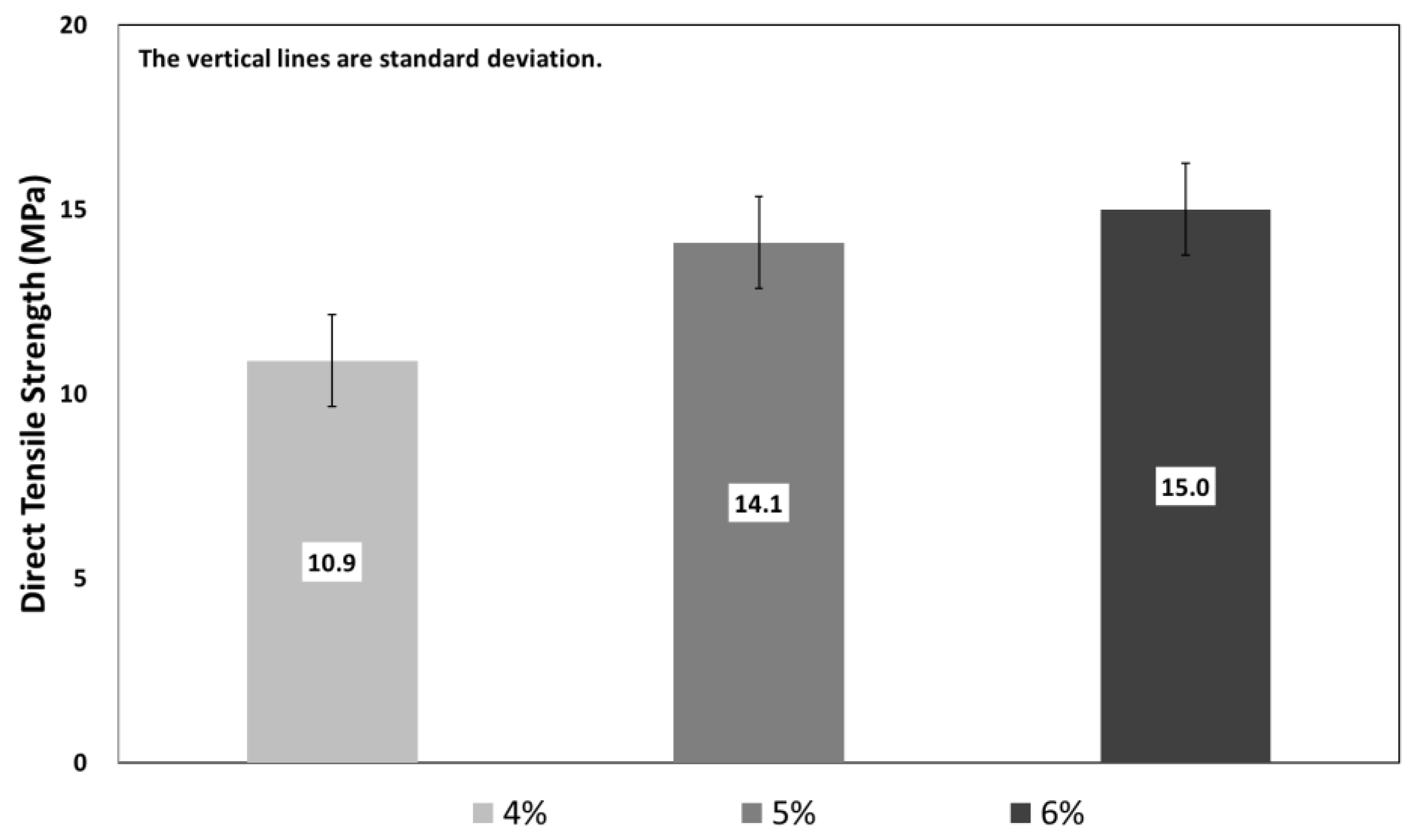

4.2. Direct Tensile Strength

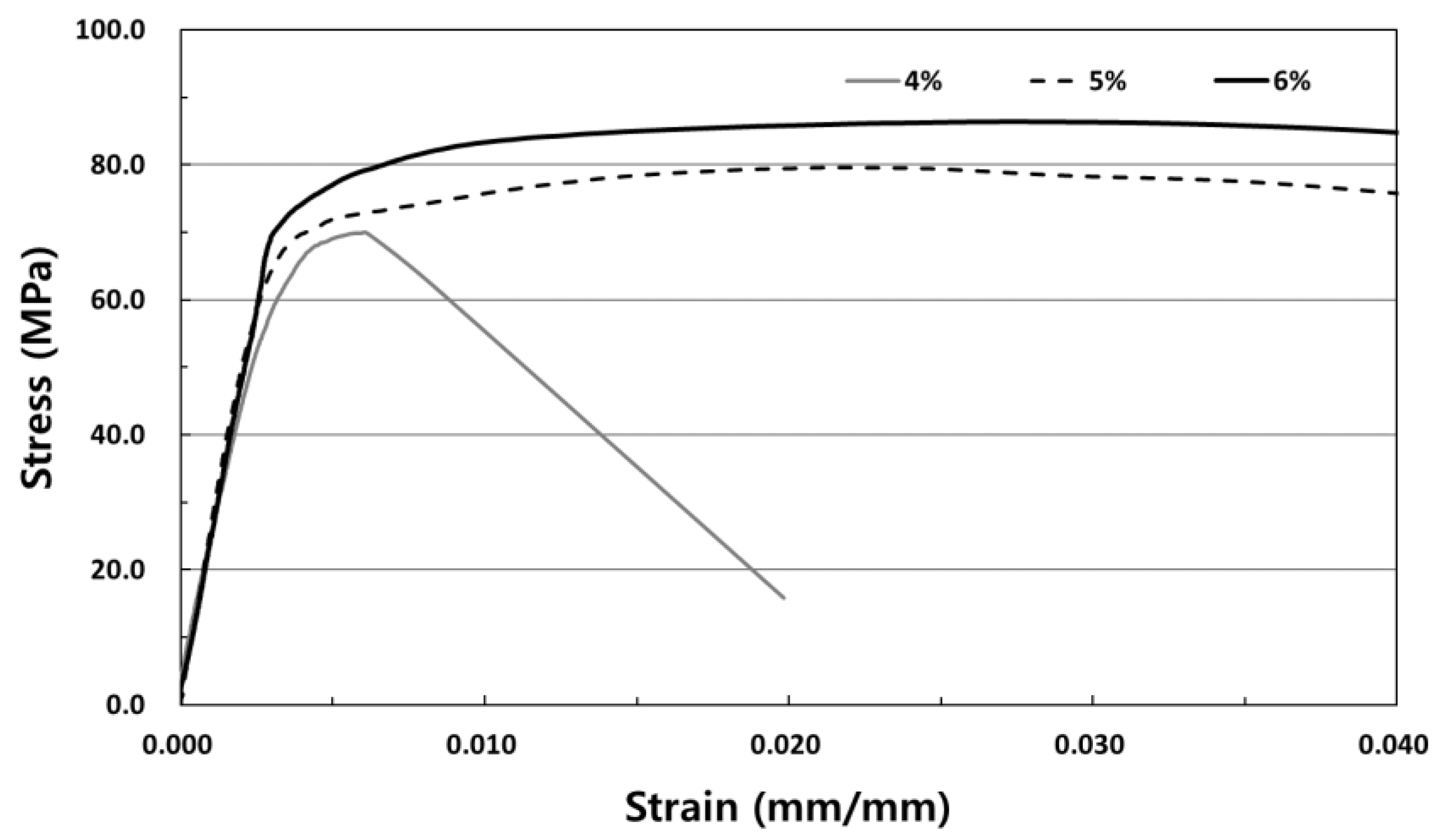

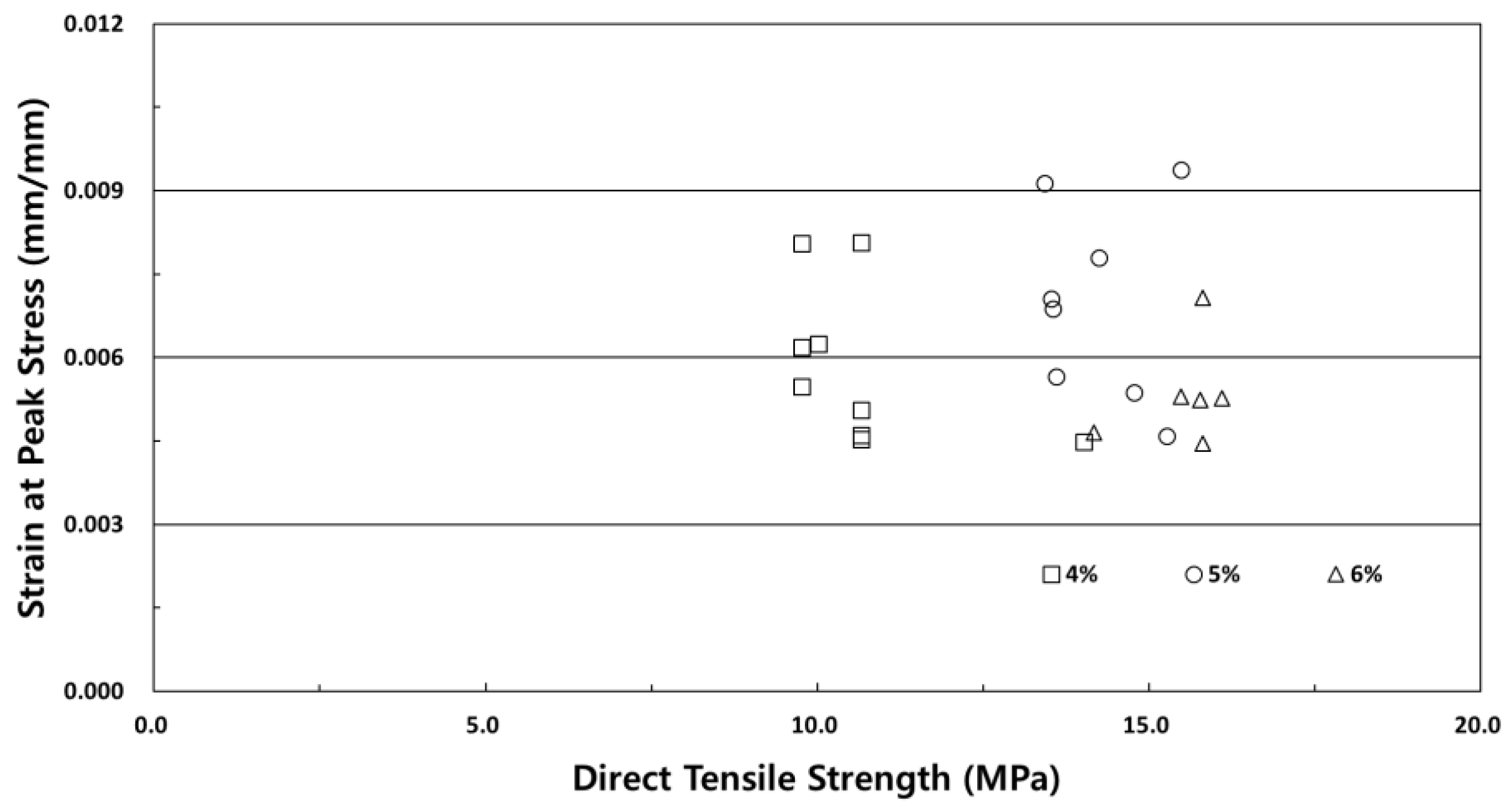

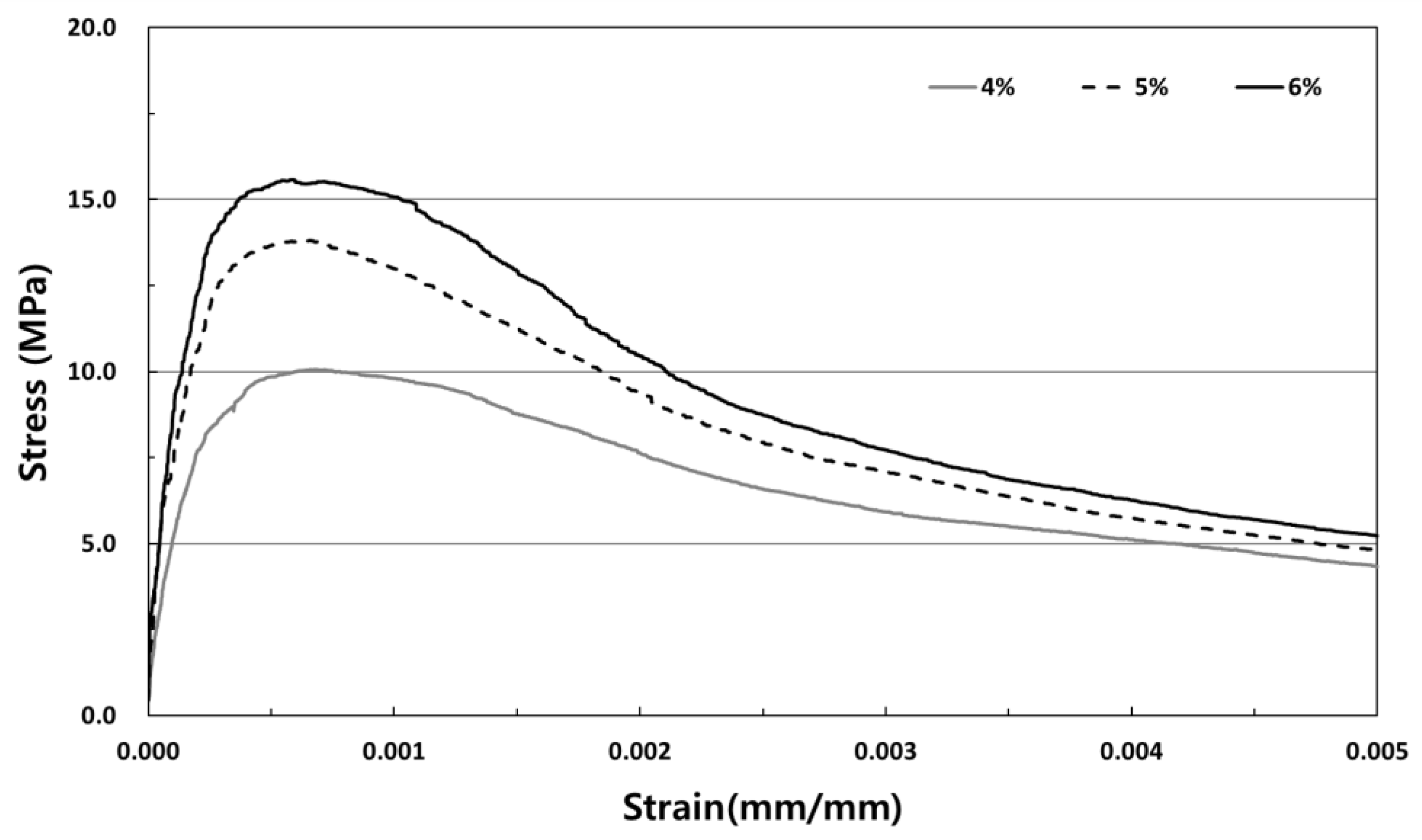

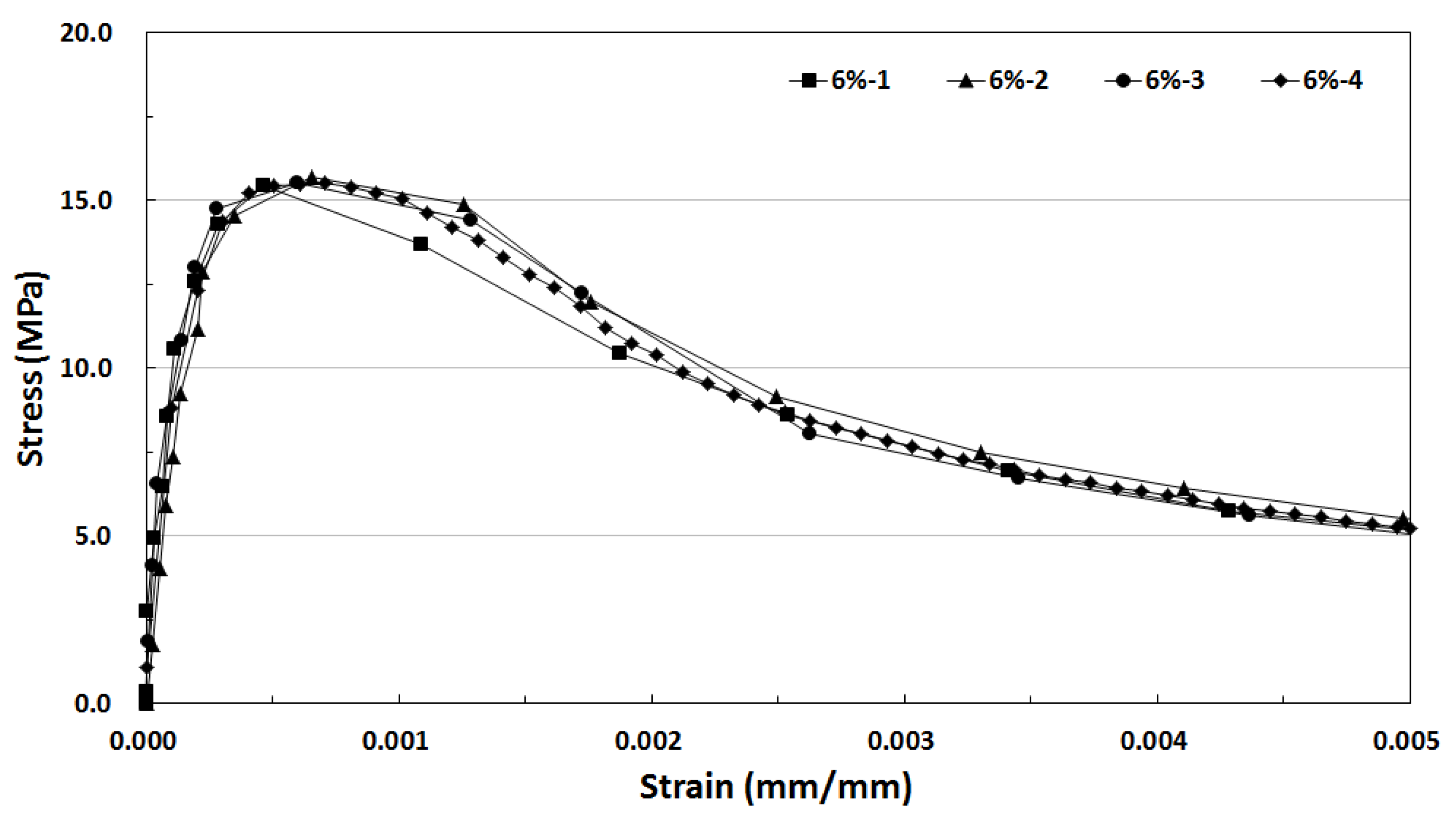

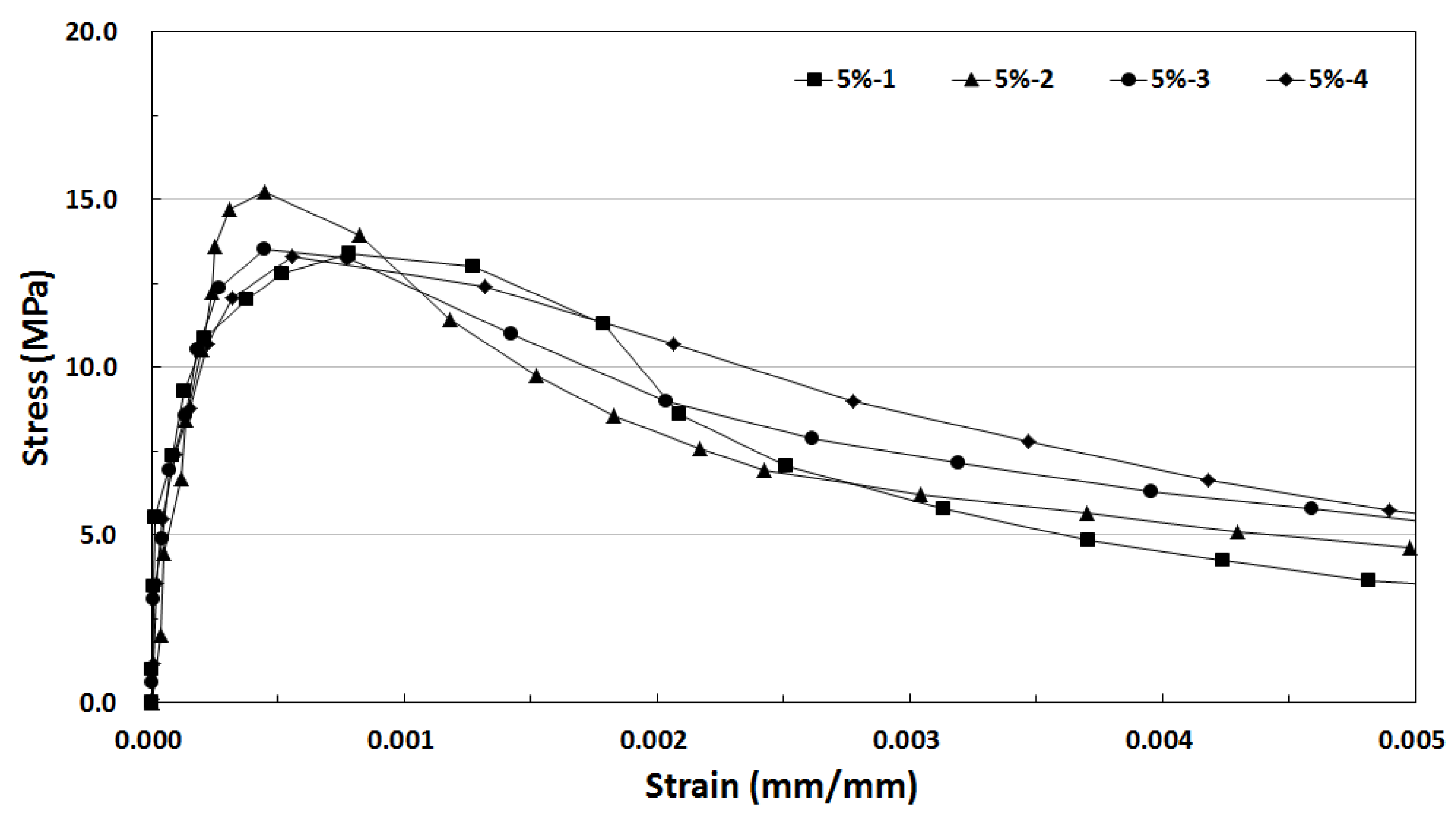

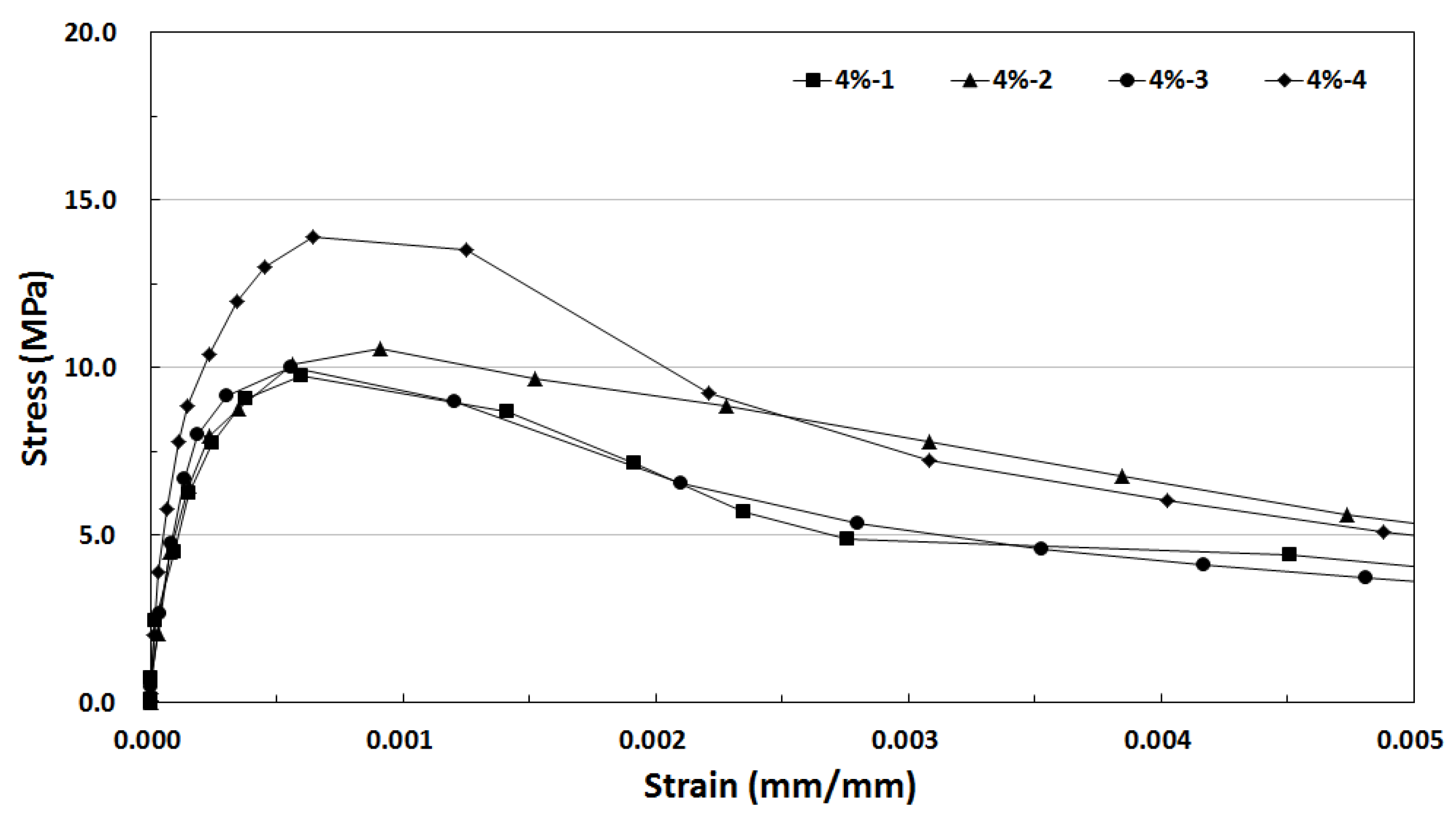

4.3. Strain Capacity and Tensile Stress-Strain Curve

5. Conclusions

- (1)

- The analysis result of the tensile behavior characteristics through direct tensile tests of the SIFRCCs showed a high direct tensile strength, more than 15 MPa (Vf = 6%), which is higher than conventional HPFRCCs and UHPC due to increasing the fiber volume fraction. Also the load of SIFRCCs with respect to the fiber volume fraction continuously increased because of the high fiber volume fraction after the initial crack, and sufficient residual strength was obtained after the maximum strength. This sufficient residual strength is expected to bring about positive effects to the brittle fracture of structures when unexpected loads is applied.

- (2)

- The reinforcement with a high fiber volume fraction improved brittleness, which is a disadvantage of conventional concrete. After the initial cracking, cracks gradually spread and led to fracture. The maximum strain capacity was approximately 0.7%, which showed excellent energy absorption capacity. However, the interface adhesion performance between the high-performance slurry and steel fibers was insufficient due to small cross-section of the direct tensile test specimen. It is expected that the strain capacity and energy absorption capacity can be improved by increasing the cross-section size.

- (3)

- The energy absorption capacity increased but the strain capacity tended to decrease with increasing fiber volume fractions. It is that the size of the direct tensile specimen is too small to exert the maximum interface adhesive characteristics between the high-performance slurry and steel fibers, indicating different direct tensile behavior for each fiber volume fraction.

- (4)

- The bridging effect of steel fibers caused strain hardening behavior and multiple cracks, resulting in the increase of the direct tensile strength and energy absorption capacity. In the case of the strain capacity, it was suppressed by the high-performance slurry restraint due to the increase of the adhesion of the slurry and steel fibers.

Author Contributions

Funding

Conflicts of Interest

References

- Kim, H.-S.; Kim, G.-Y.; Lee, S.-K.; Choe, G.-C.; Nam, J.-S. Direct Tensile Properties of Fiber-Reinforced Cement Based Composites according to the Length and Volume Fraction of Amorphous Metallic Fiber. J. Korea Inst. Build. Constr. 2019, 19, 201–207. [Google Scholar]

- Naaman, A.E.; Shah, S.P. Pull-out mechanism in steel fiber-reinforced concrete. J. Struct. Div. 1976, 102, 1537–1548. [Google Scholar]

- Chan, Y.-W.; Chu, S.-H. Effect of silica fume on steel fiber bond characteristics in reactive powder concrete. Cem. Concr. Res. 2004, 34, 1167–1172. [Google Scholar] [CrossRef]

- Li, V.C.; Wang, Y.; Backer, S. Effect of inclining angle, bundling and surface treatment on synthetic fibre pull-out from a cement matrix. Composites 1990, 21, 132–140. [Google Scholar] [CrossRef]

- Kim, H.-S.; Kim, G.-Y.; Lee, S.-K.; Son, M.-J.; Choe, G.-C.; Nam, J.-S. Strain rate effects on the compressive and tensile behavior of bundle-type polyamide fiber-reinforced cementitious composites. Compos. Part B Eng. 2019, 160, 50–65. [Google Scholar] [CrossRef]

- Nam, J.-S.; Shinohara, Y.; Atou, T.; Kim, H.-S.; Kim, G.-Y. Comparative assessment of failure characteristics on fiber-reinforced cementitious composite panels under high-velocity impact. Compos. Part B Eng. 2016, 99, 84–97. [Google Scholar] [CrossRef]

- Choi, J.-I.; Park, S.-E.; Lee, B.Y.; Kim, Y.Y. Tensile Properties of Polyethylene Fiber-Reinforced Highly Ductile Composite with Compressive Strength of 100 MPa Class. J. Korea Concr. Inst. 2018, 30, 497–503. [Google Scholar] [CrossRef]

- Park, J.W.; Lee, G.C. Effect of Compressive Strength and Curing Condition on the Direct Tensile Strength Properties of Ultra High Performance Concrete. J. Korea Inst. Build. Constr. 2017, 17, 175–181. [Google Scholar] [CrossRef]

- Kim, S.; Jung, H.; Kim, Y.; Park, C. Effect of steel fiber volume fraction and aspect ratio type on the mechanical properties of SIFCON-based HPFRCC. Struct. Eng. Mech. 2018, 65, 163–171. [Google Scholar]

- Kim, S.-W.; Cho, H.-M.; Lee, H.-Y.; Park, C.-W. Flexural Performance Characteristics of High Performance Slurry Infiltrated Fiber Reinforced Cementitious Composite according to Fiber Volume Fraction. J. Korea Inst. Struct. Maint. Insp. 2015, 19, 109–115. [Google Scholar]

- Yang, I.-H.; Kim, K.-C.; Joh, C.-B. Flexural strength of hybrid steel fiber-reinforced ultra-high strength concrete beams. J. Korea Concr. Inst. 2015, 27, 280–287. [Google Scholar]

- AFNOR. NF P 18–470; AFNOR: Pairs, France, 2016; p. 96. [Google Scholar]

- Lee, J.W.; Joh, C.B. The effect of specimen size & shape on tensile strength of K-UHPC. In Proceedings of the Korea Concrete Institute, Gyeongju, Korea, 2–4 May 2012; pp. 97–98. [Google Scholar]

- Park, J.W.; Lee, G.C.; Koh, K.T.; Ryu, G.S. Study on Direct Tensile Properties and Reliability Review of Steel Fiber Reinforced UHPC. J. Korea Inst. Build. Constr. 2018, 18, 125–132. [Google Scholar]

- Korea Institute of Construction Technology (KICT). Design Specific Technology for Ultra High Performance Concrete; Report of 4th Year of Super Bridge; Korea Institute of Construction Technology: Goyang, Korea, 2010. [Google Scholar]

- Kim, S.; Kim, Y.; Kim, S.-W.; Kim, Y.J.; Park, C. Strengthening Effect of Externally Reinforced RC Structure with SIFRCC on Impact Load. In Proceedings of the 5th International Conference on Protective Structures, Poznan, Poland, 19–23 August 2018; pp. 522–528. [Google Scholar]

- Korea Standards. Standard test method for compressive strength of concrete. In KS F 2405:2010; Korean Standards Association: Seoul, Korea, 2017. [Google Scholar]

| Physical Properties | |||||||

|---|---|---|---|---|---|---|---|

| Specific Gravity | Fineness (cm2/g) | Stability (%) | Setting Time (min) | LOI (%) | |||

| Initial | Final | ||||||

| 3.15 | 3400 | 0.10 | 230 | 410 | 2.58 | ||

| Chemical compositions (%, mass) | |||||||

| SiO2 | CaO | MgO | SO3 | Al2O3 | |||

| 21.95 | 60.12 | 3.32 | 2.11 | 6.59 | |||

| Physical Properties | |||||

|---|---|---|---|---|---|

| Specific Gravity | Fineness (cm2/g) | ||||

| 2.10 | 200,000 | ||||

| Chemical compositions (%, mass) | |||||

| SiO2 | CaO | MgO | SO3 | Al2O3 | |

| 96.00 | 0.38 | 0.10 | - | 0.25 | |

| Variables | W/B (%) | Unit Material Quantity (kg/m3) | |||||

|---|---|---|---|---|---|---|---|

| W | C | Fine Aggregate | Silica Fume | HRWR | Steel Fibers | ||

| 4% | 35 | 407.4 | 962.8 | 566.4 | 169.9 | 28.3 | 312 |

| 5% | 390 | ||||||

| 6% | 468 | ||||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; Kim, D.J.; Kim, S.-W.; Park, C. Tensile Behavior Characteristics of High-Performance Slurry-Infiltrated Fiber-Reinforced Cementitious Composite with Respect to Fiber Volume Fraction. Materials 2019, 12, 3335. https://doi.org/10.3390/ma12203335

Kim S, Kim DJ, Kim S-W, Park C. Tensile Behavior Characteristics of High-Performance Slurry-Infiltrated Fiber-Reinforced Cementitious Composite with Respect to Fiber Volume Fraction. Materials. 2019; 12(20):3335. https://doi.org/10.3390/ma12203335

Chicago/Turabian StyleKim, Seungwon, Dong Joo Kim, Sung-Wook Kim, and Cheolwoo Park. 2019. "Tensile Behavior Characteristics of High-Performance Slurry-Infiltrated Fiber-Reinforced Cementitious Composite with Respect to Fiber Volume Fraction" Materials 12, no. 20: 3335. https://doi.org/10.3390/ma12203335

APA StyleKim, S., Kim, D. J., Kim, S.-W., & Park, C. (2019). Tensile Behavior Characteristics of High-Performance Slurry-Infiltrated Fiber-Reinforced Cementitious Composite with Respect to Fiber Volume Fraction. Materials, 12(20), 3335. https://doi.org/10.3390/ma12203335