Effect of Conductive Coatings on Micro-Electro-Discharge Machinability of Aluminum Nitride Ceramic Using On-Machine-Fabricated Microelectrodes

Abstract

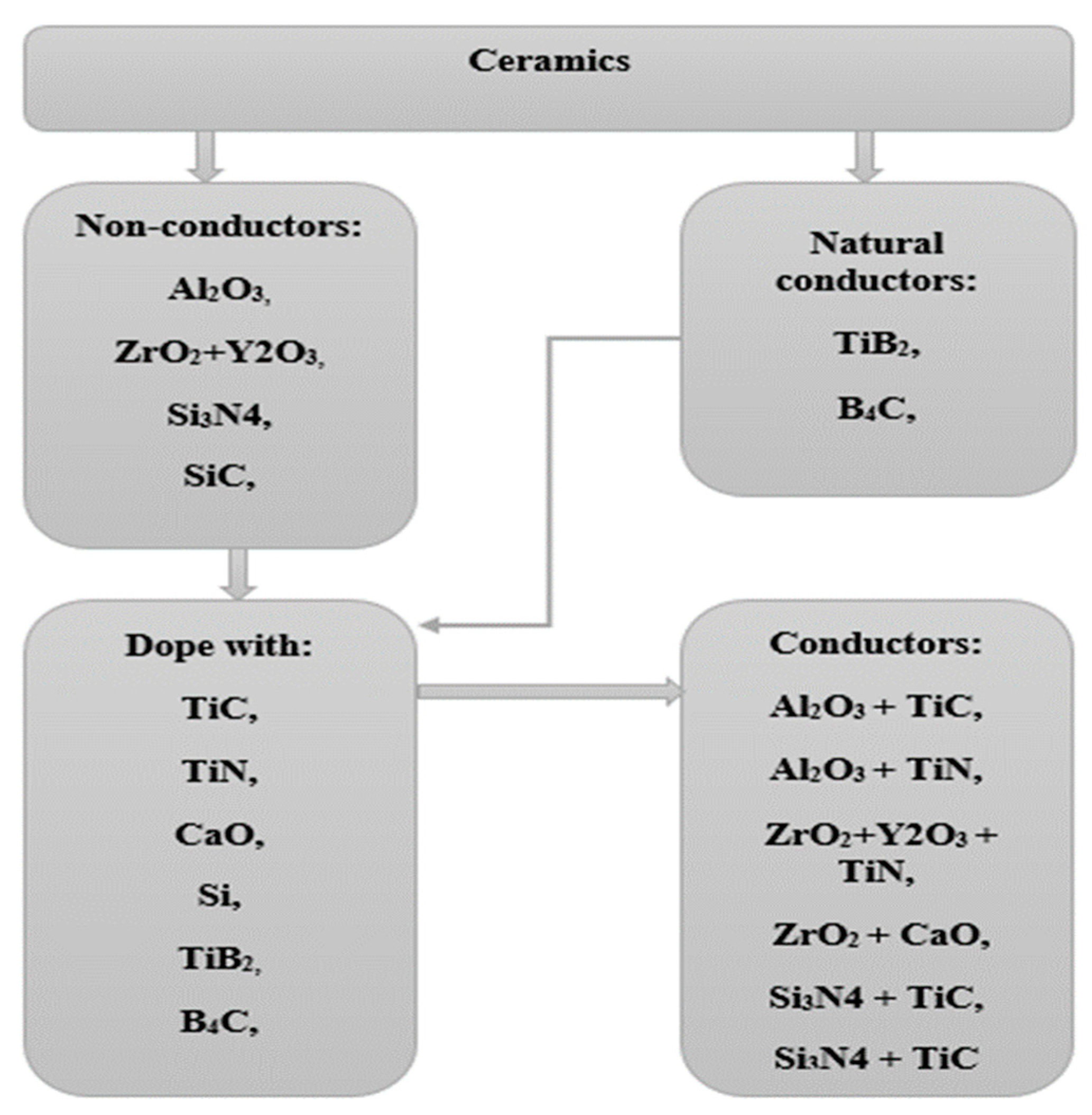

:1. Introduction

2. Experimental Setup, Parameters, and Materials

3. Experimental Procedure

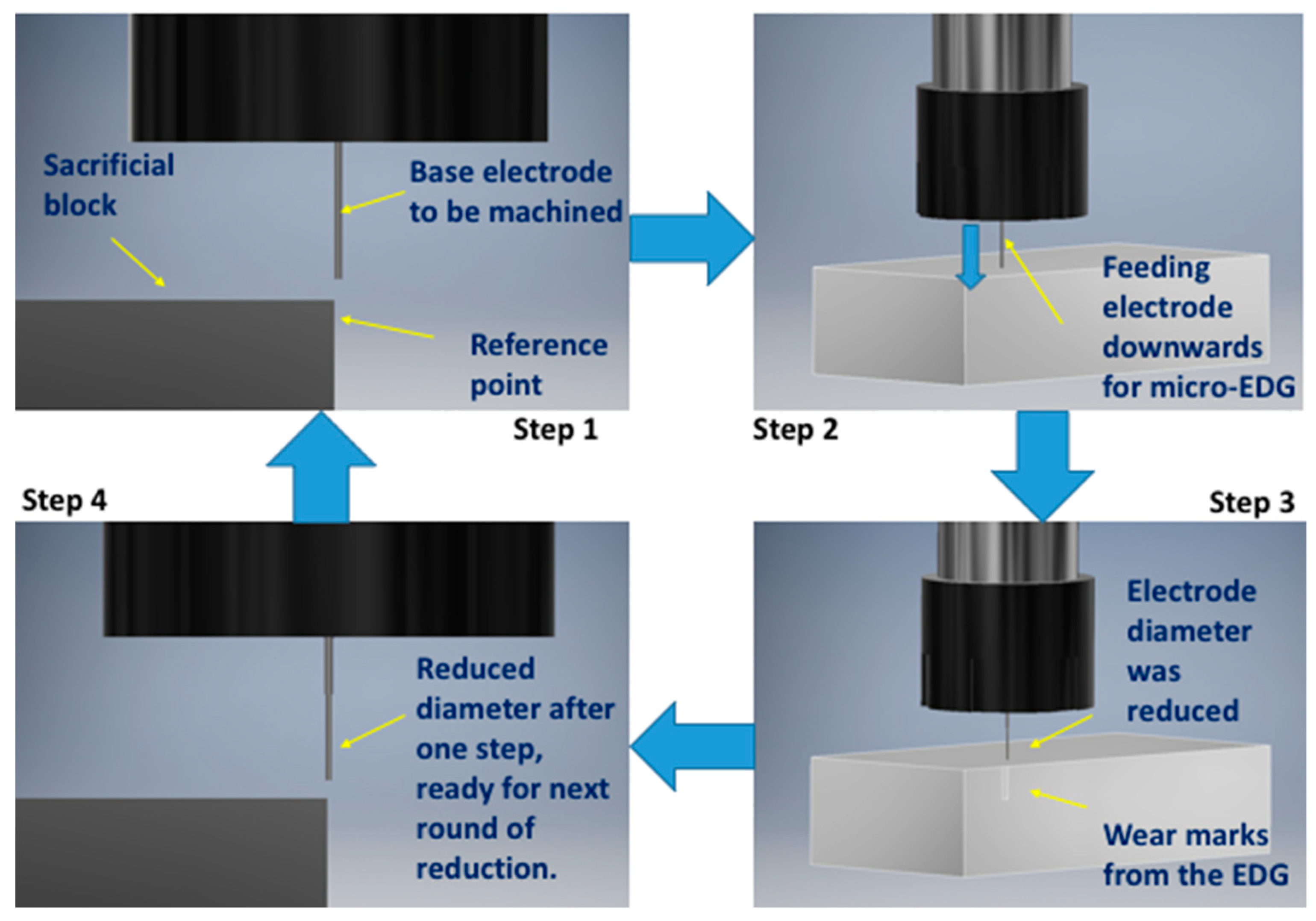

3.1. In Situ Fabrication of Tungsten Microelectrodes

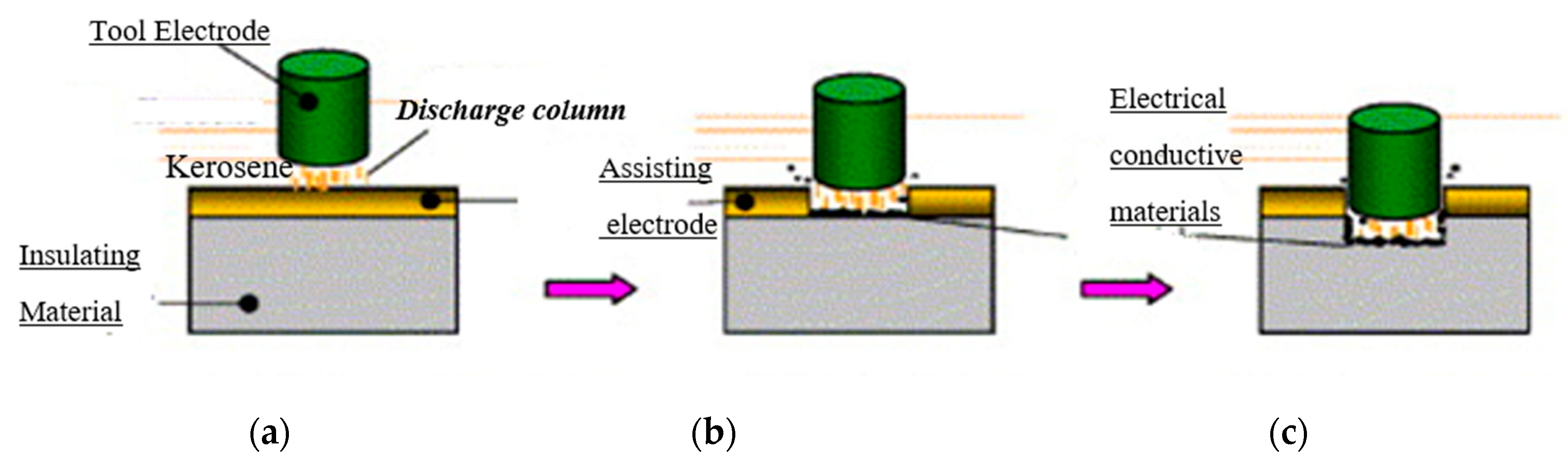

3.2. Mechanism of Coatings in “Assistive Electrode Method”

- Coating with a paintbrush: In this process, the conductive coatings of three different materials, silver, copper, and carbon coatings, were provided on the surface of the ceramic workpieces, and then the workpieces were kept in the atmospheric condition overnight for the drying of the coating layer. The process is fully manual and, hence, the surface finish of coating layers is non-uniform and rough. Moreover, the thickness of the coating layers is very difficult to control in this process. Cases 3–8 did not provide successful machining where single copper conductive paint was used. Cases 16 and 18 with single carbon and silver conductive paint also did not experience any machining.

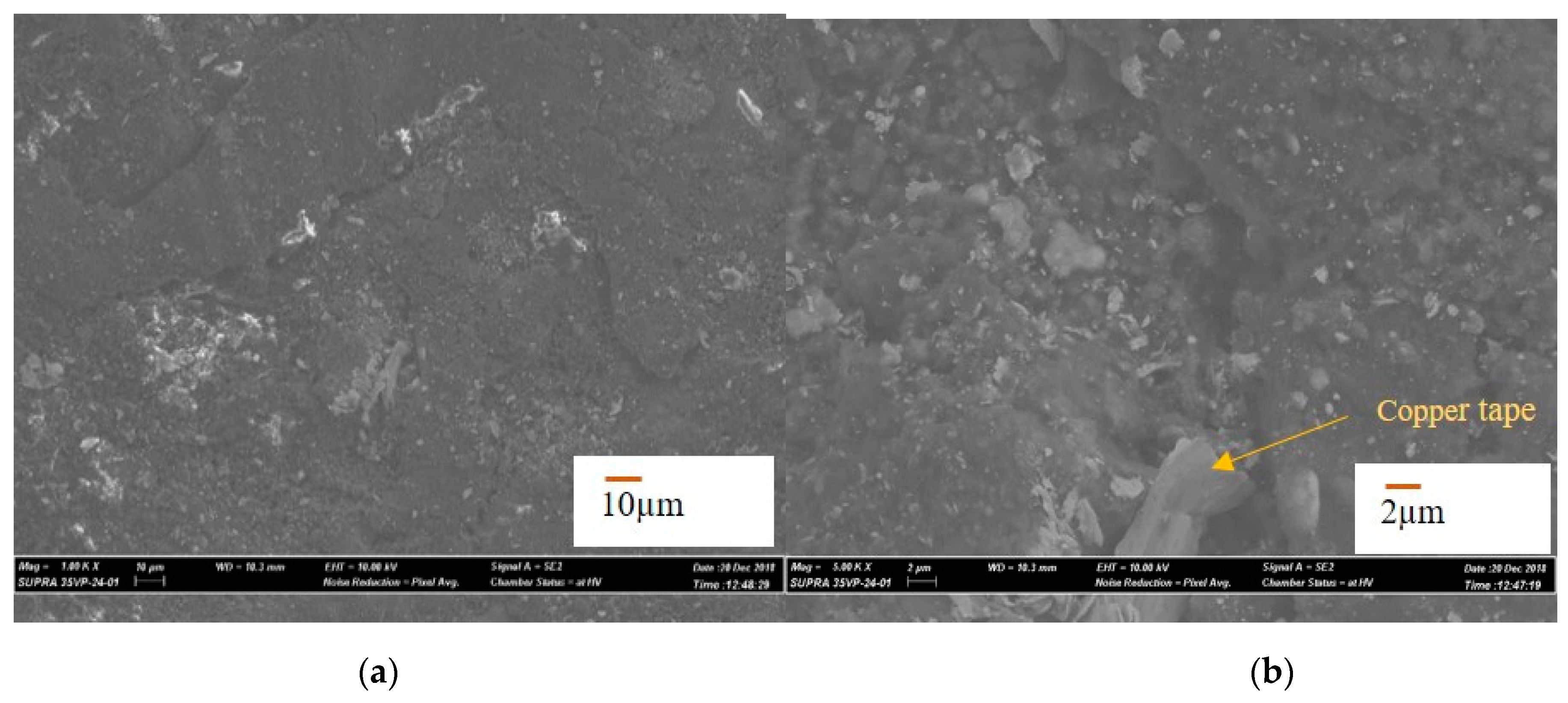

- Coating with conductive tapes: In this process, the conductive tapes of copper and carbon have been applied manually on the surface of the ceramic workpieces. The advantage of this process over paint brush method is that the coating thickness is uniform. However, the major challenge of this technique is that there is some interface gap between the conductive tape and the ceramics surface, which allows air bubbles to trap in between the conductive tape and ceramic surface during EDM. As the assistive electrode method requires the presence of conductive substances on the surface for continuous occurrences of sparks, this method was found to be challenging for obtaining successful machining of micro-holes in ceramics. Cases 9–15 with single layer of copper tape demonstrated no successful machining for different discharge energy level, whereas case 2 with lower energy level (no flushing, no tool rotation) and triple copper layer demonstrated successful machining. Moreover, case 25 demonstrated some machining even with tool rotation of 100 rpm.

- Coating with baking/sintering: One of the major challenges faced during the experiments was to maintain conductive paint/coatings on the ceramics surface, which is integral for the continuation of machining on the ceramics. In order to make strong bonding between the coating layer and ceramic surface, the sintering of the coating was done. In this process, the coating layer was provided using the paint brush manually; after that, another layer of silver nanoparticles was dispersed on top of paint coatings. After that, the sample was baked in a sintering oven for 1 hour at 900 °C. The baking of ceramics resulted in a strong coating of silver and copper coatings on the ceramic surfaces. Case 27 used this type of sample preparation, which resulted in unsuccessful machining when used with tool rotation and flushing.

- Multiple layers of coating with mixed methods: The successful machining of ceramics is dependent on the critical thickness of conductive coating layers. Although the baking of conductive coating paints inside the sintering oven was found to be effective in producing a uniform coating layer, the thickness of the coating layer was not very high. Moreover, if further coating was provided and re-baking was done in the oven, the coating layer could not be increased infinitely. As a result, we provided the first layer of coating by the sintering process with the consecutive layers by manual paintbrush method and re-baking again. In this process, we have tried multiple layers of coating of the same materials only and two time of baking. Case 20 demonstrated no successful machining; however, cases 21 and 23 showed some machining. Case 1 showed successful machining when flushing was not used and low energy level was chosen.

4. Results and Discussions

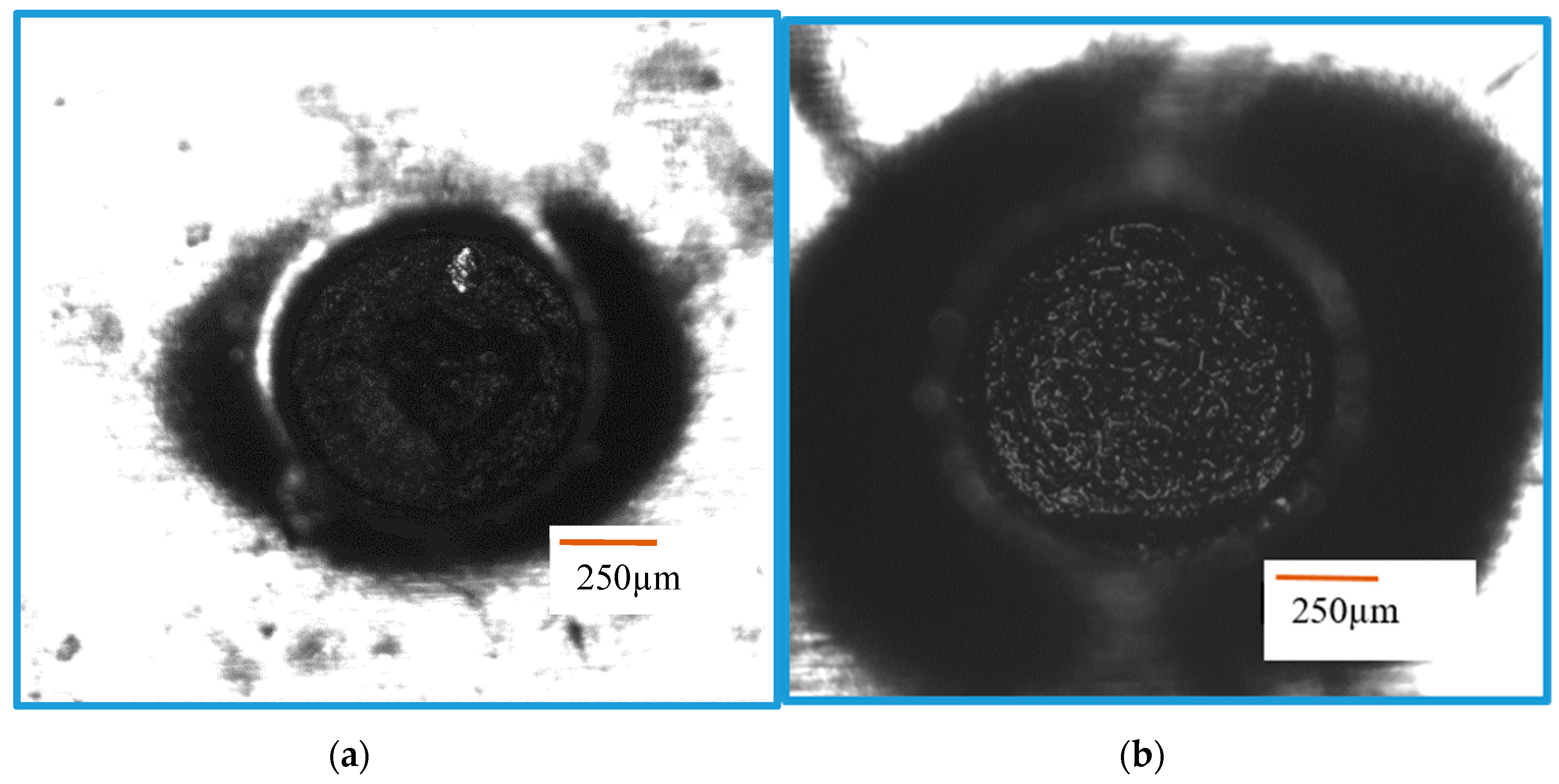

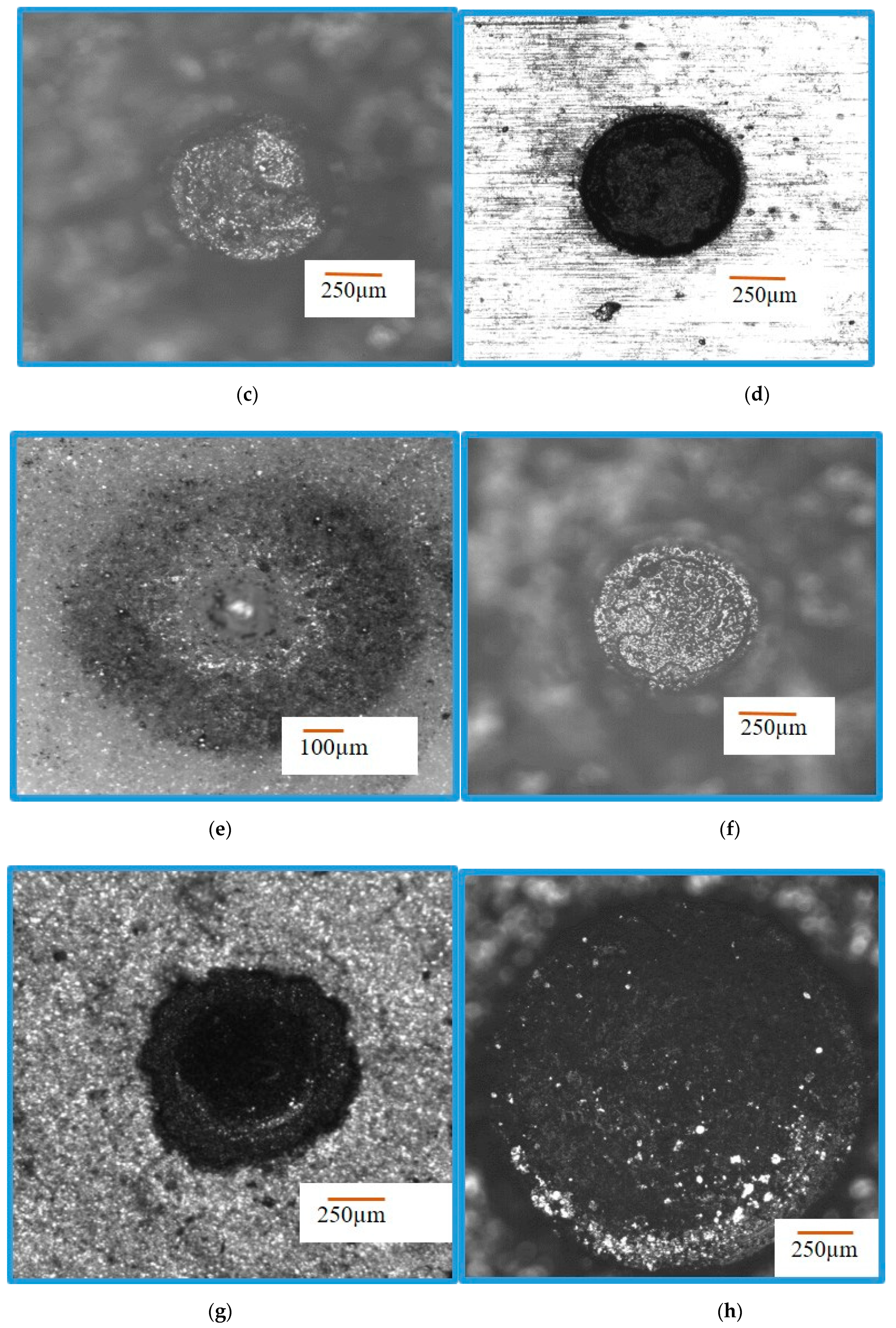

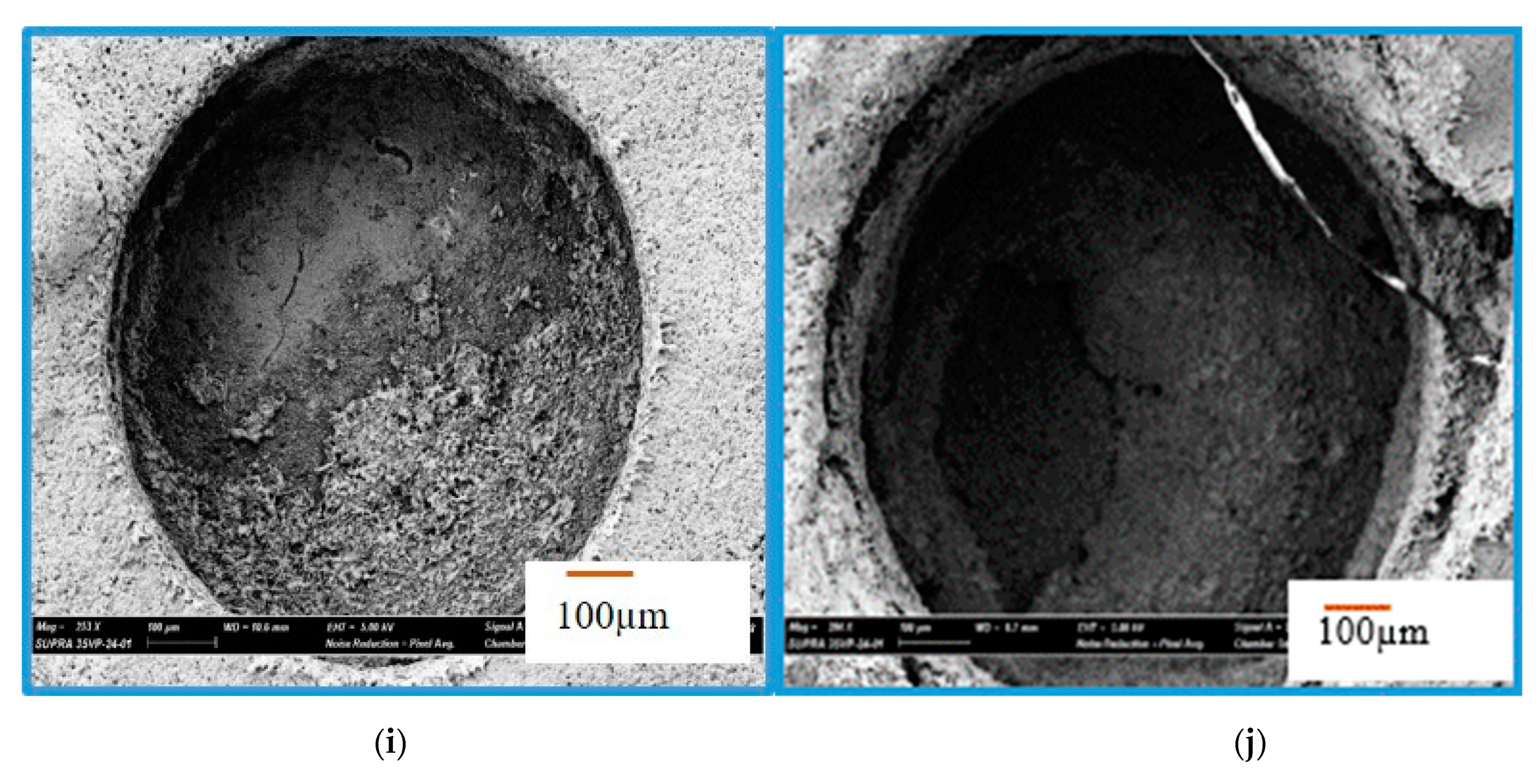

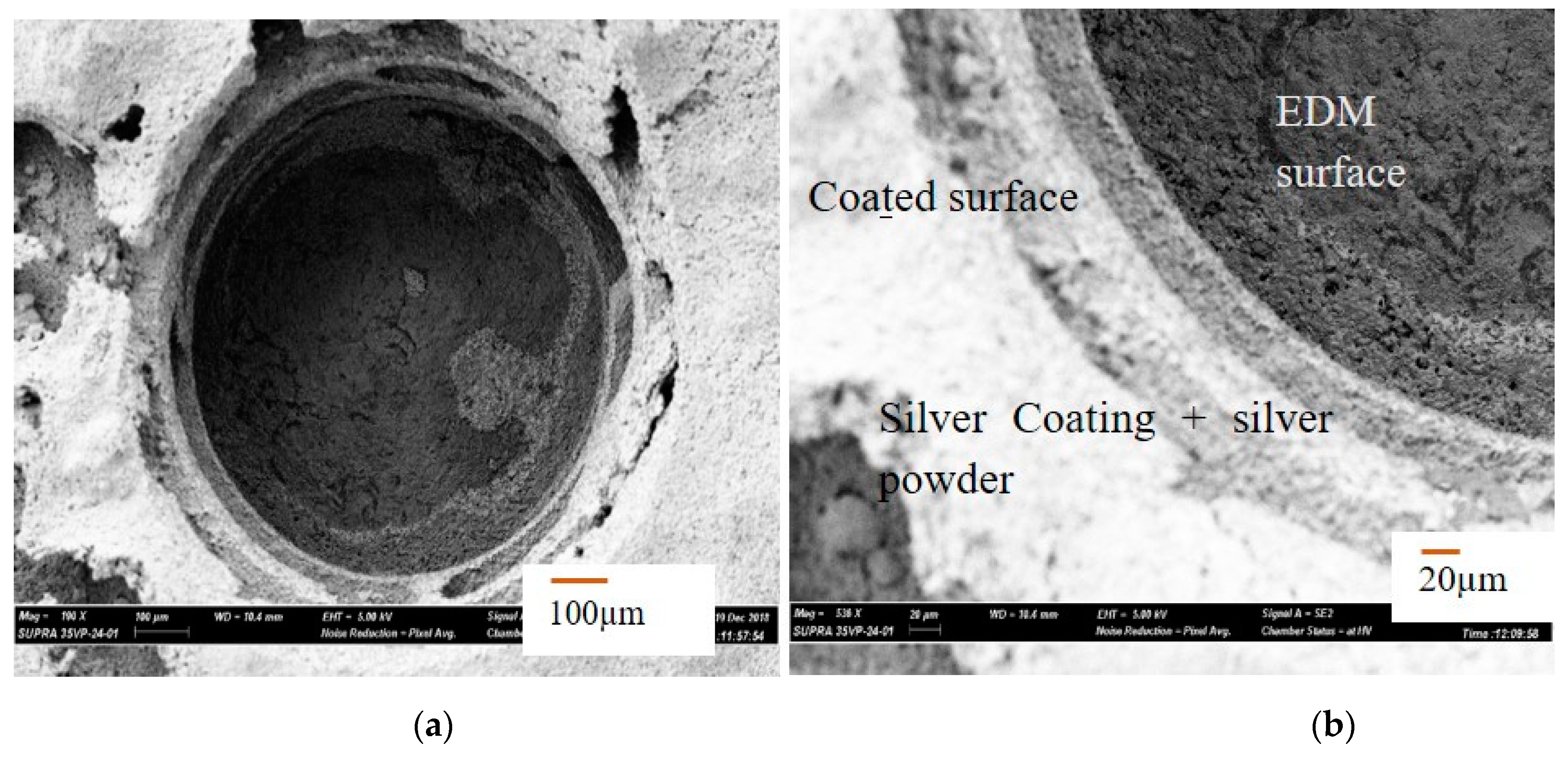

4.1. Silver Coating as “Assistive Electrode”

4.2. Copper Coating as “Assistive Electrode”

4.3. Powder-Mixed EDM with Combined Silver and Copper Coating

5. Conclusions

- Successful machining of blind micro-holes is feasible on the non-conductive ceramics using this modified assistive electrode method in micro-EDM. However, selection and optimization of machining condition including assistive coating is critical for the successful machining in non-conductive ceramics. It was found that 759 µm diameter holes with 700 µm machining depth could be successfully machined using multi-layer coatings of silver containing silver paints and silver nanopowder with controlled machining environment;

- In this study, consistently successful machining was obtained with silver paint baked on the ceramics surface in the sintering oven. As the coating materials stayed on the ceramics surface during machining process, the sintering of coating provided more consistent machining. Both silver coating and conductive copper tapes were found to produce successful machining of micro-holes on the AlN ceramics. Micro-holes with close to 4 aspect ratio are machined using combined silver and copper tape coatings along with silver nanoparticles mixed EDM. Powder-mixed micro-EDM along with assistive electrode method was found to be more effective than assistive electrode method only, especially in terms of obtaining higher aspect ratios of micro-holes;

- The machining was found to successfully continue without electrode rotation and without flushing, as the deposited carbon layer remains undisturbed and favors further secondary discharging process. In addition, the machining was found to be more stable when the machining was carried out in submerged die-sinking condition rather than side flushing. It was also found that comparatively lower levels of discharge energies, i.e., voltages and capacitances, are favorable for successful machining of micro-holes in ceramics;

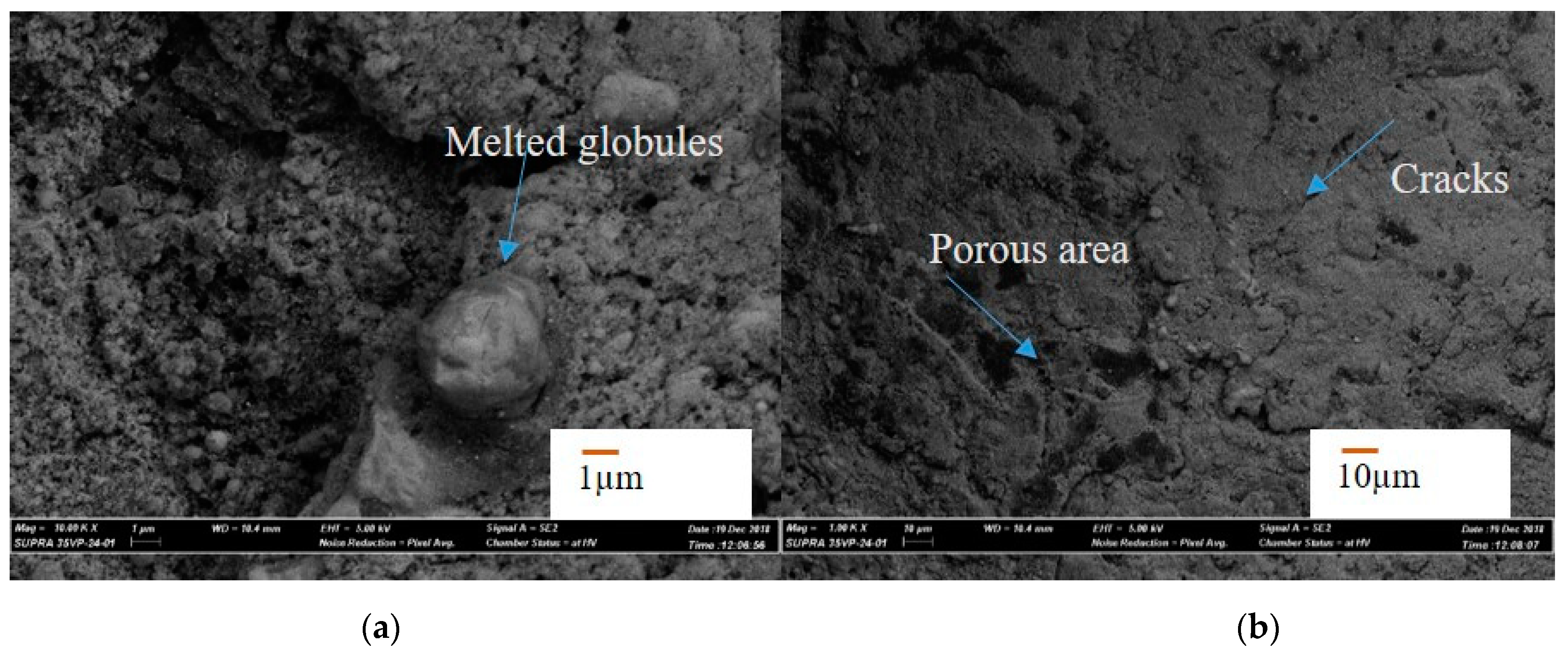

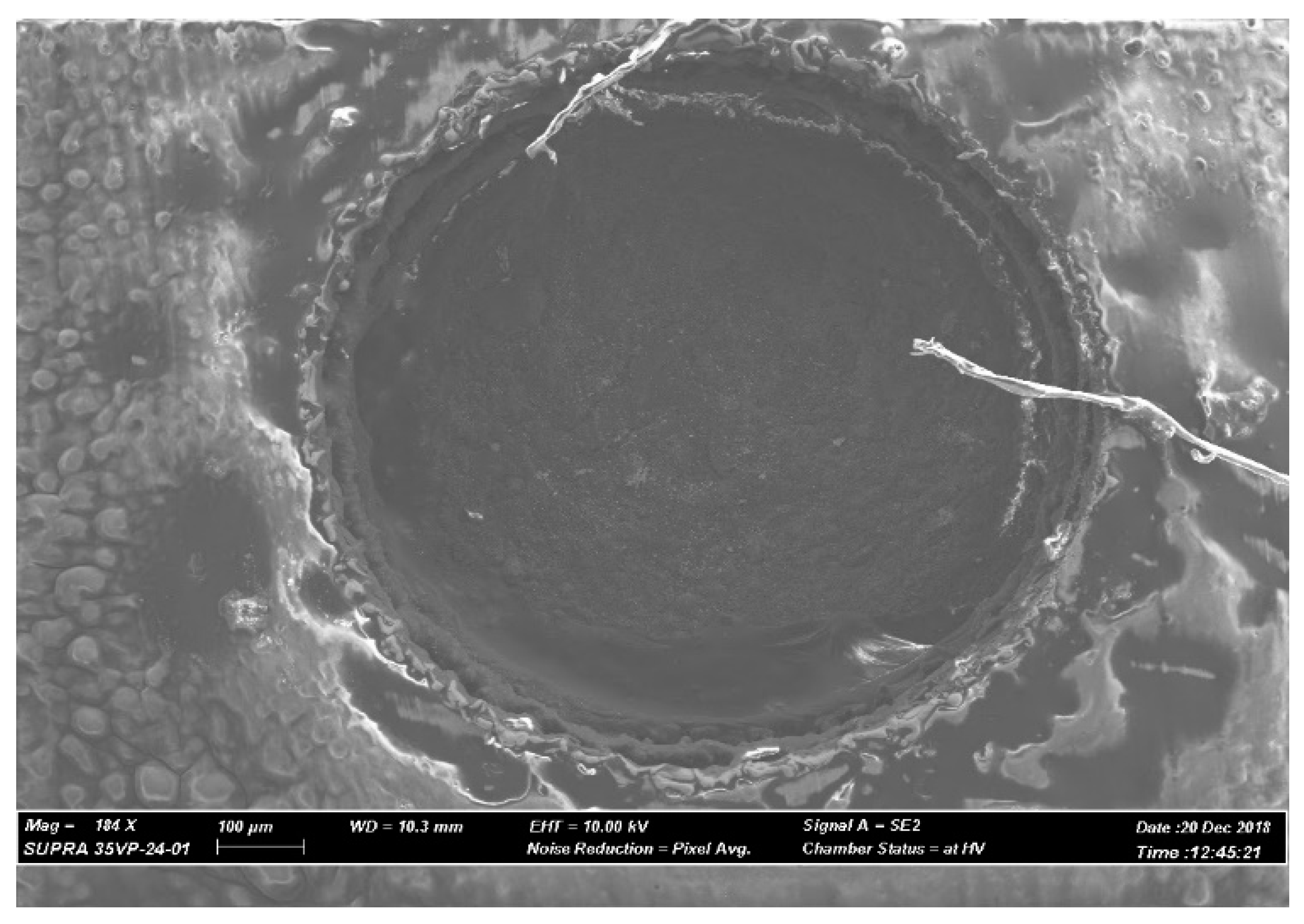

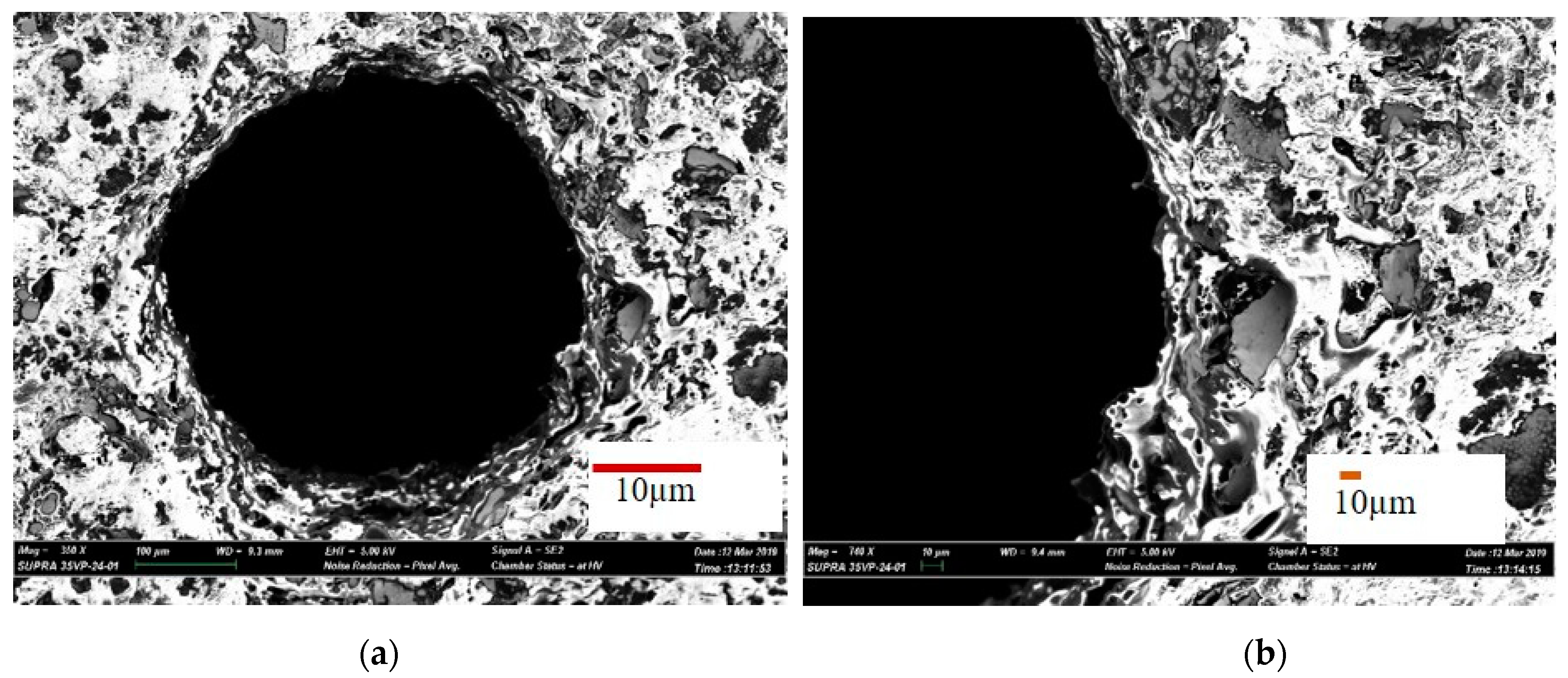

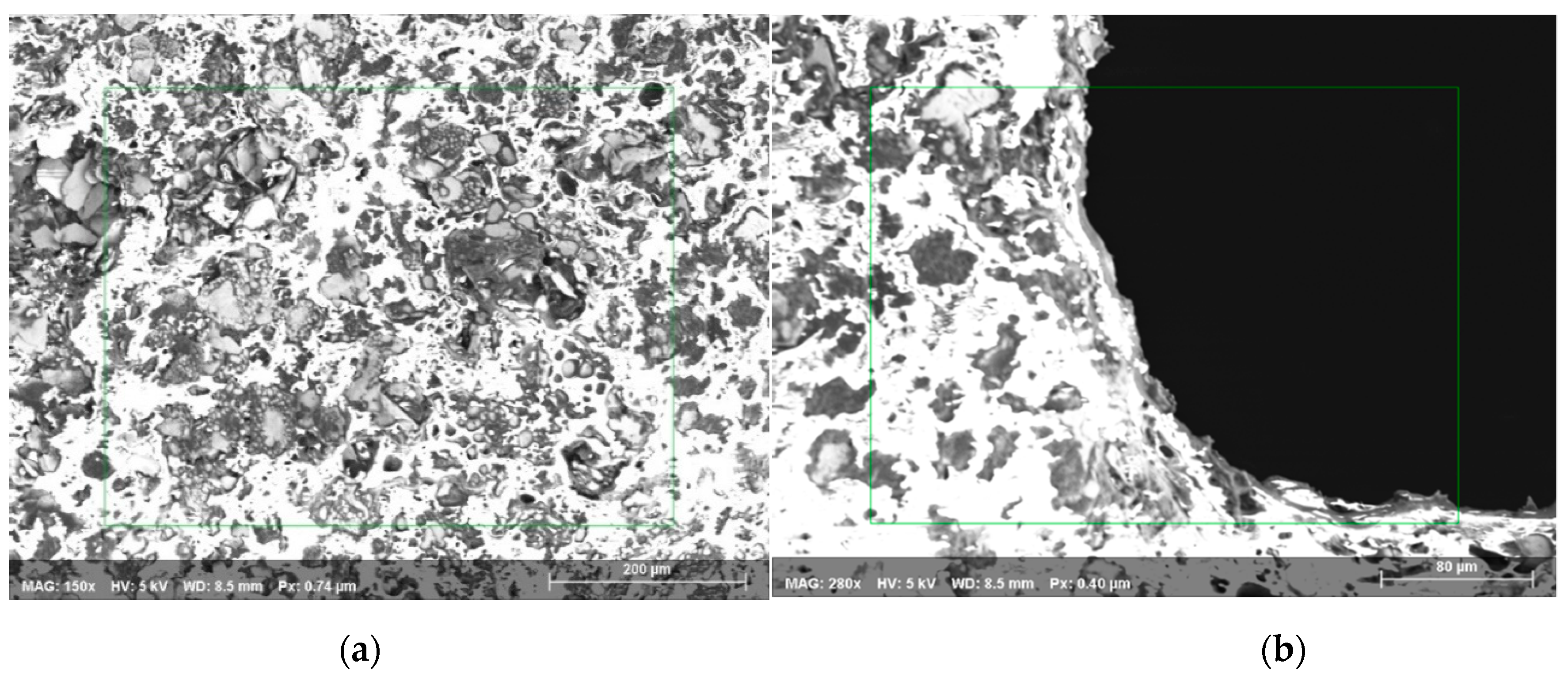

- The SEM images of the machined surfaces on the ceramics show very rough surface, although the discharge energy used for machining was not very high. The machined surfaces indicate that melting and evaporation, as well as thermal spalling, are the dominating material removal mechanisms. In addition, the machined surface contains many thermal cracks and porosity on the surface;

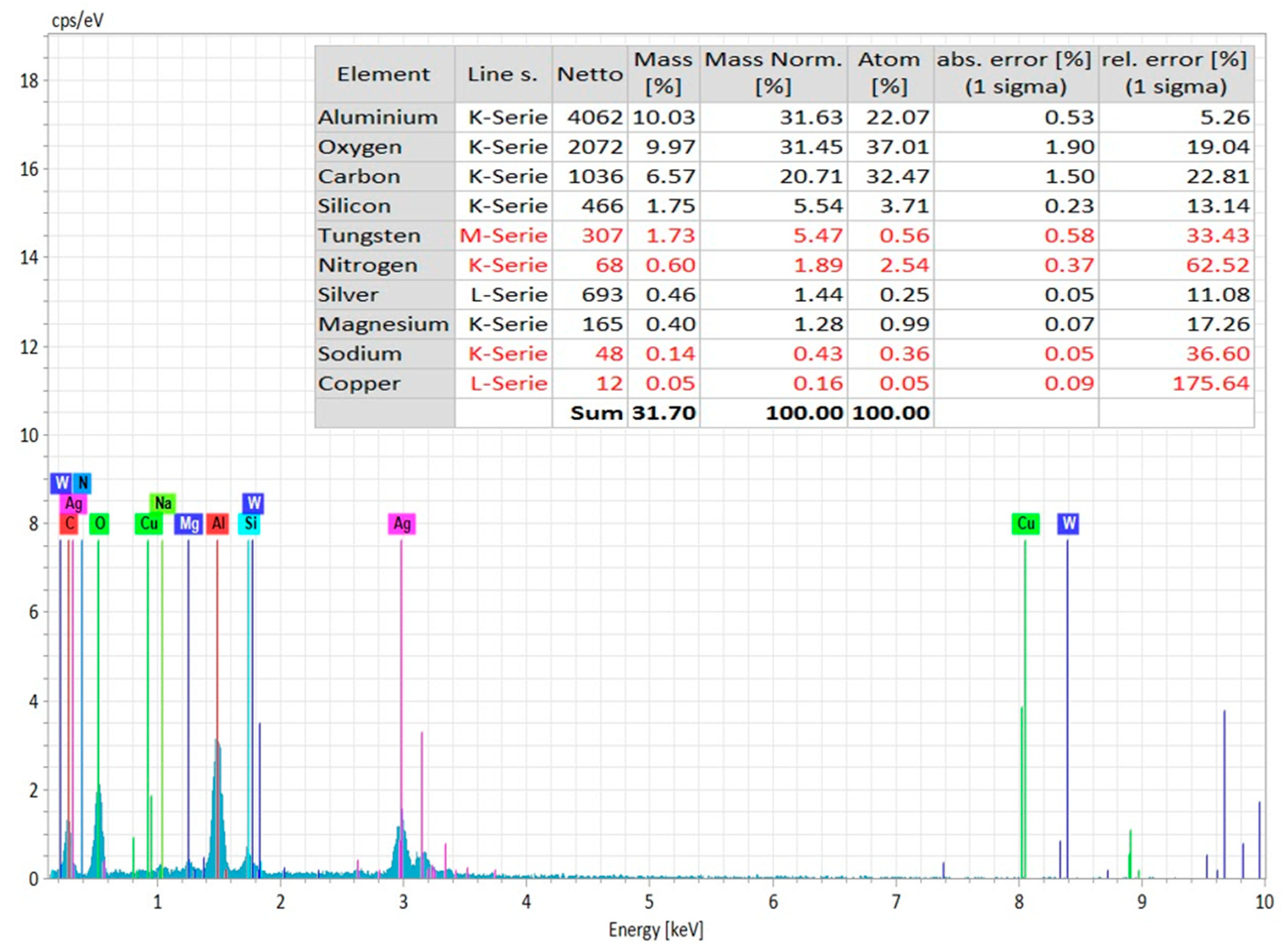

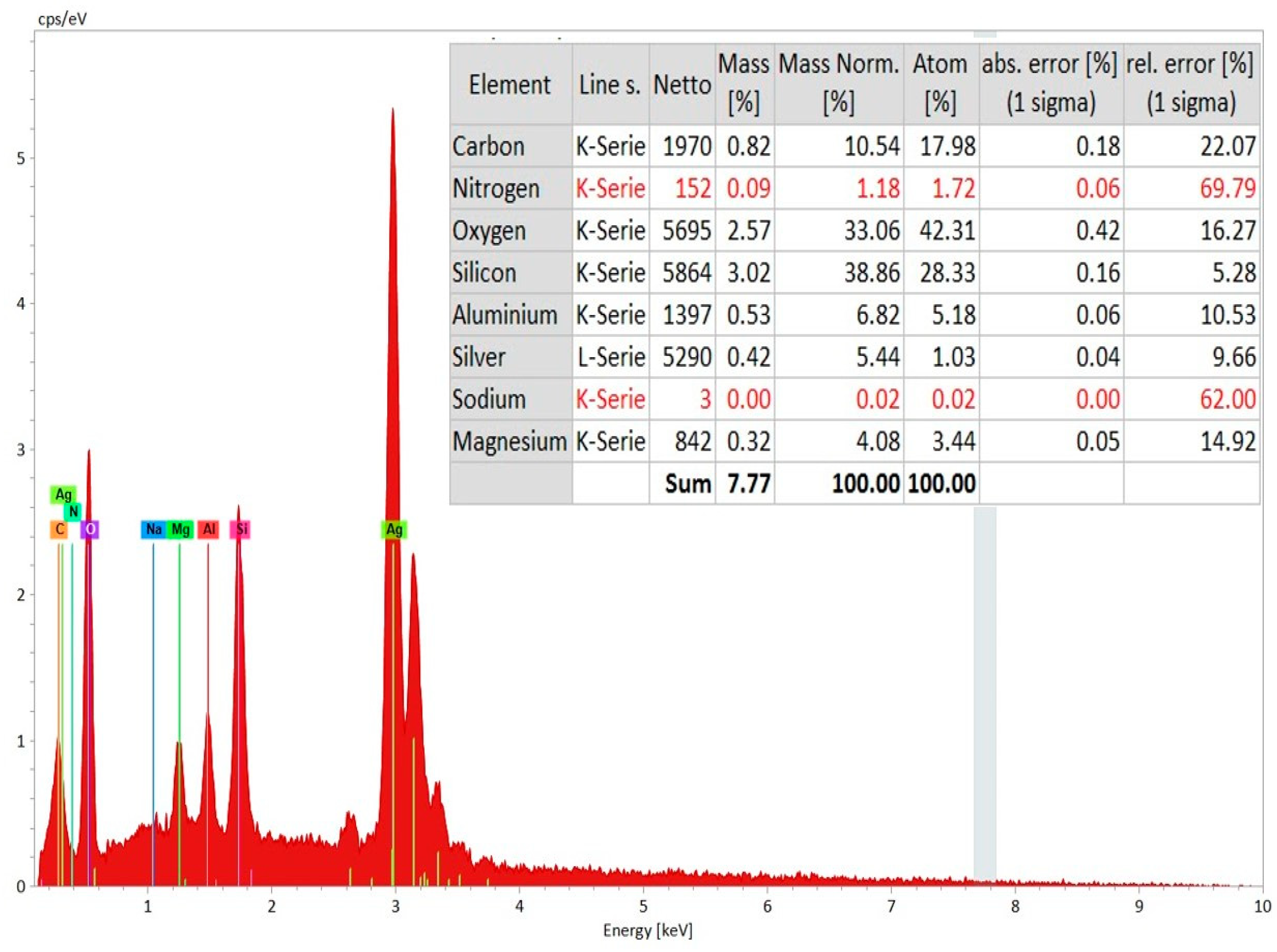

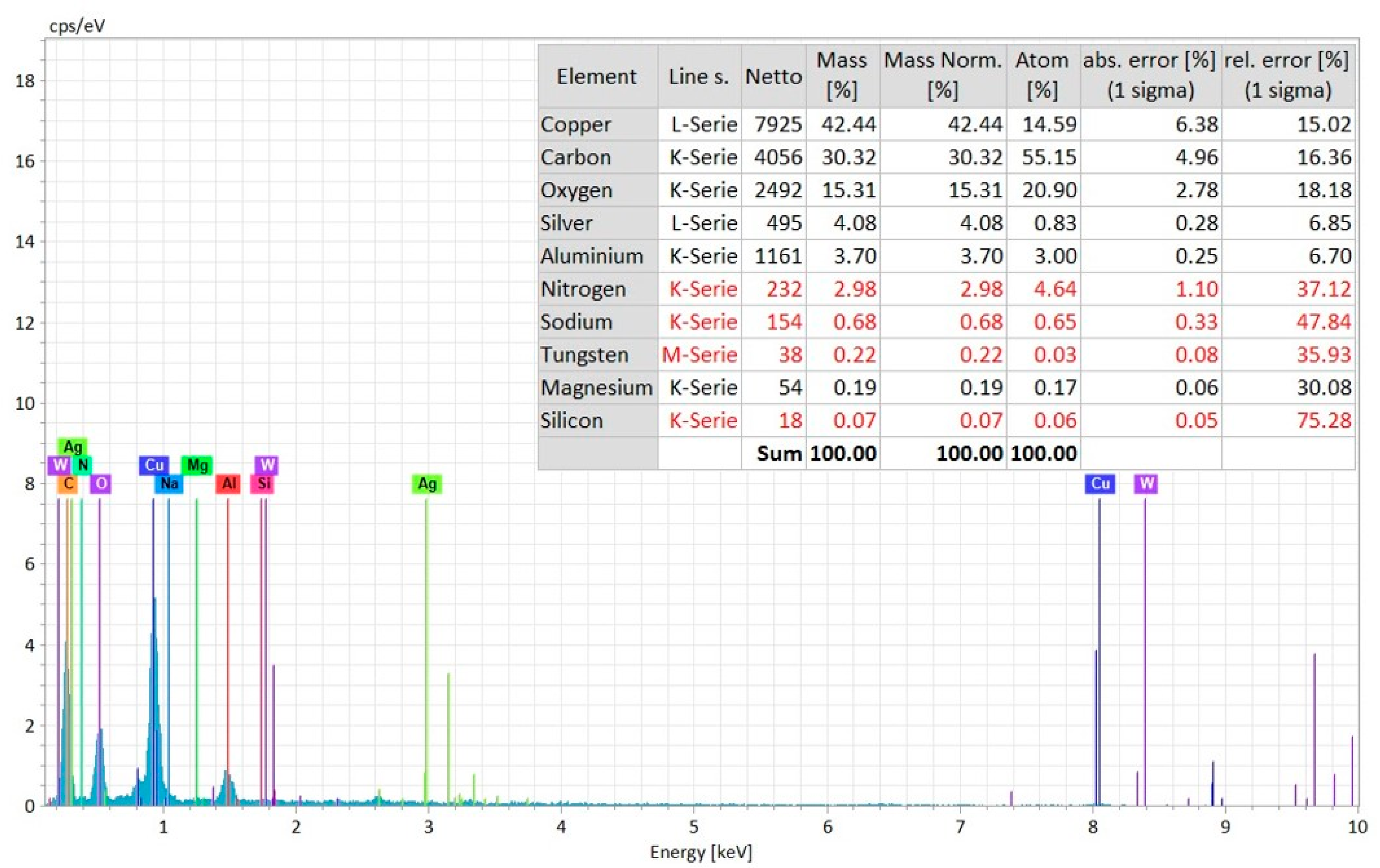

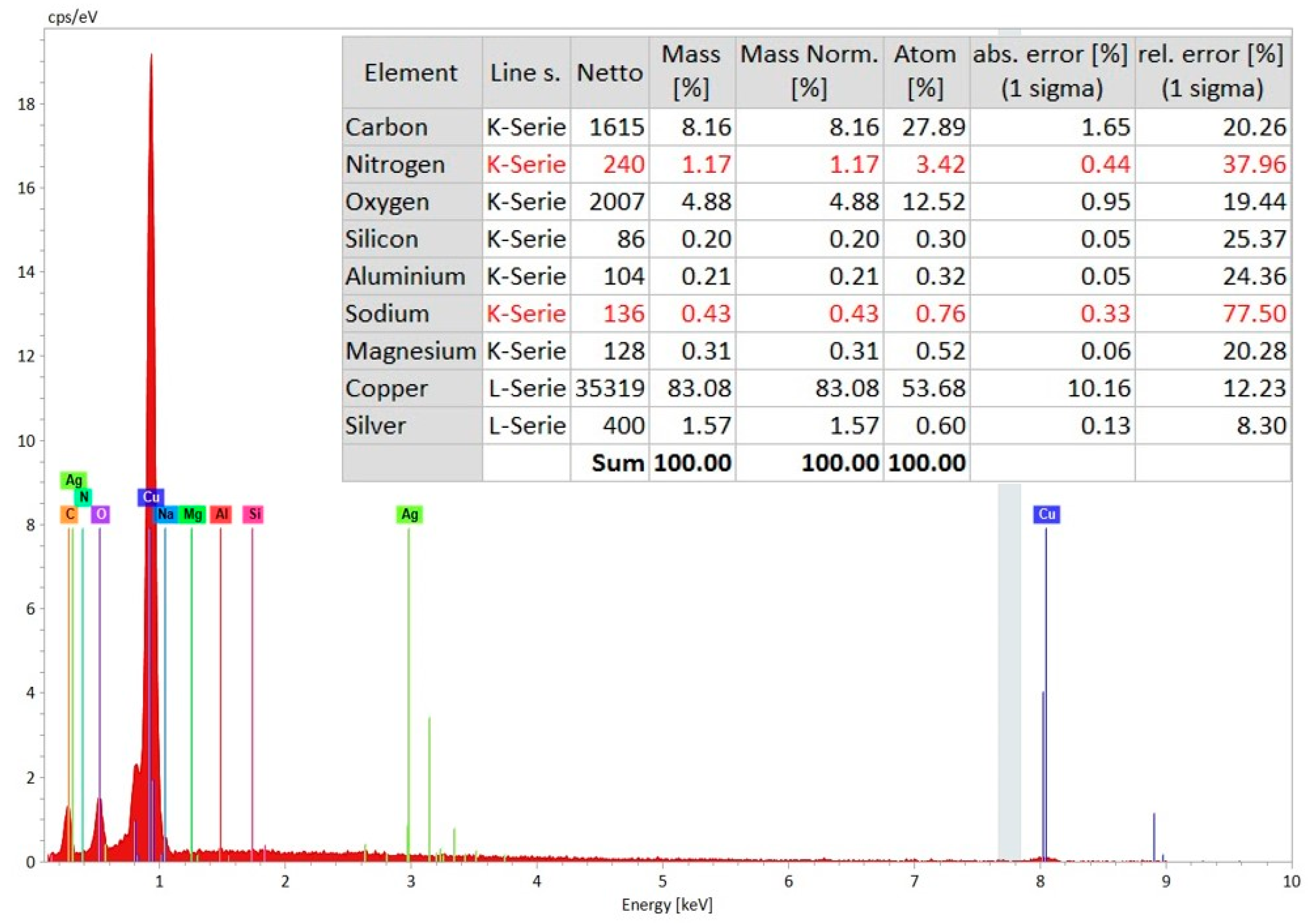

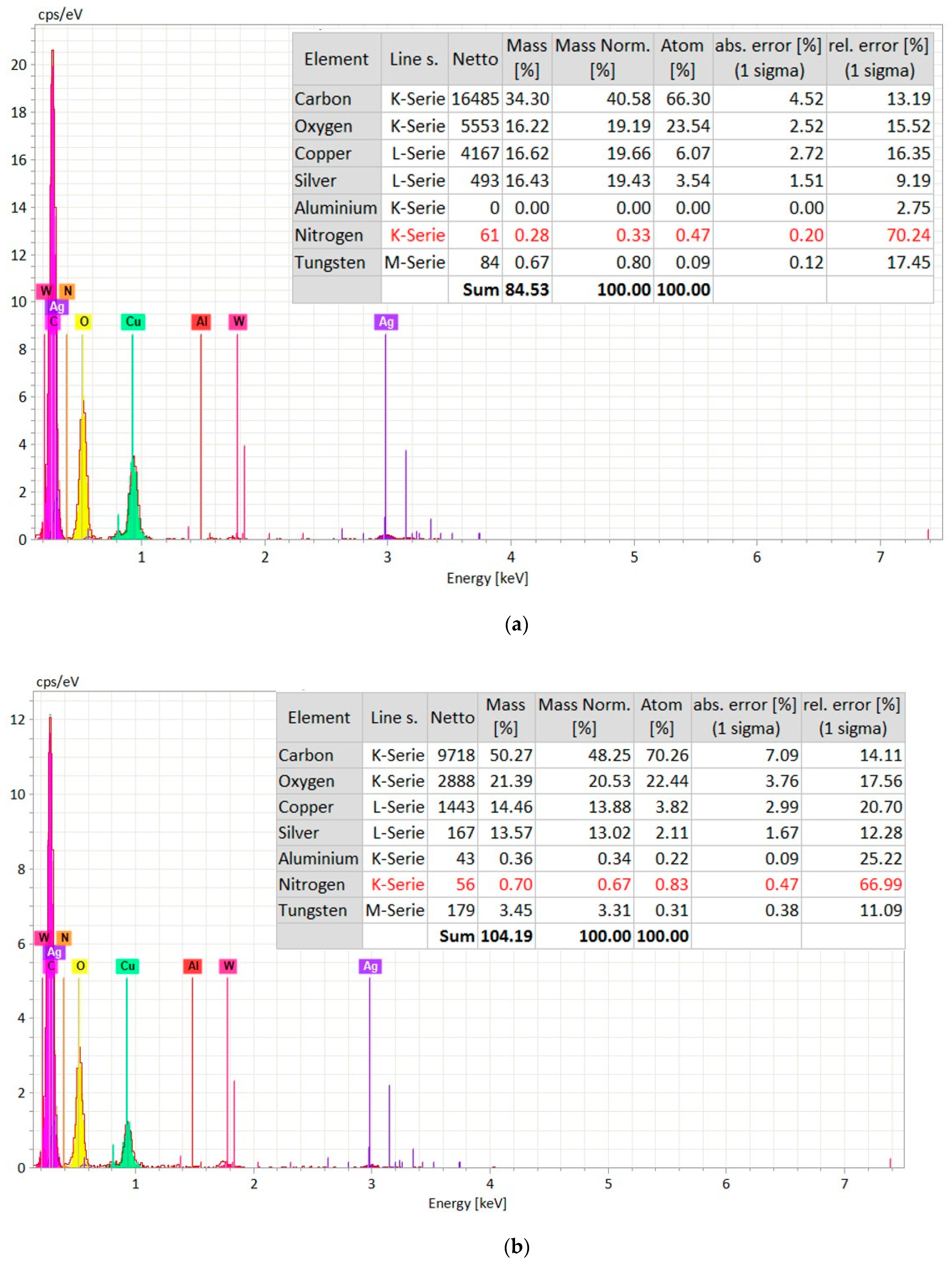

- The elemental compositions obtained from EDS analysis confirmed the presence of aluminum and nitrogen on the machined surface. In addition, there was a significant presence of oxygen on the machined surface. The EDS spectrum on the top surface of the machined hole (on the layers of silver coating) indicates the presence of silver, oxygen, carbon, and silicon on the coating layer with no or minimal existence of aluminum and nitrogen, which are the main constituents of the ceramics.

Author Contributions

Funding

Conflicts of Interest

References

- Farooqui, M.N.; Patil, N.G. A perspective on shaping of advanced ceramics by electro discharge machining. Procedia Manuf. 2018, 20, 65–72. [Google Scholar] [CrossRef]

- Rajeevalochanam, P.; Banda, B.V.G. Mechanical design and analysis of ceramic stator blades for gas turbine stage. Mater. Today Proc. 2017, 4, 8613–8623. [Google Scholar] [CrossRef]

- Fernández-Valdivielso, A.; López de Lacalle, L.; Urbikain, G.; Rodriguez, A. Detecting the key geometrical features and grades of carbide inserts for the turning of nickel-based alloys concerning surface integrity. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2016, 230, 3725–3742. [Google Scholar] [CrossRef]

- Pérez, J.; Llorente, J.; Sanchez, J. Advanced cutting conditions for the milling of aeronautical alloys. J. Mater. Process. Technol. 2000, 100, 1–11. [Google Scholar]

- Zheng, Y.; Zhang, K.; Liu, T.; Liao, W.; Zhang, C.; Shao, H. Cracks of alumina ceramics by selective laser melting. Ceram. Int. 2019, 45, 175–184. [Google Scholar] [CrossRef]

- Xing, Y.; Liu, L.; Wu, Z.; Wang, X.; Huang, P.; Tang, L. Fabrication and characterization of micro-channels on al2o3/tic ceramic produced by nanosecond laser. Ceram. Int. 2018, 44, 23035–23044. [Google Scholar] [CrossRef]

- Bilal, A.; Jahan, M.; Talamona, D.; Perveen, A. Electro-discharge machining of ceramics: A review. Micromachines 2019, 10, 10. [Google Scholar] [CrossRef] [PubMed]

- Uhlmann, E.; Domingos, D. Investigations on vibration-assisted edm-machining of seal slots in high-temperature resistant materials for turbine components. Procedia CIRP 2013, 6, 71–76. [Google Scholar] [CrossRef]

- Uhlmann, E.; Domingos, D.C. Investigations on vibration-assisted edm-machining of seal slots in high-temperature resistant materials for turbine components–part ii. Procedia CIRP 2016, 42, 334–339. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, A.; Kumar, V.; Singh, N. Study of machining of inconel 825 super alloy using powder mixed edm process. Mater. Today Proc. 2018, 5, 18129–18134. [Google Scholar] [CrossRef]

- Sabyrov, N.; Jahan, M.; Bilal, A.; Perveen, A. Ultrasonic vibration assisted electro-discharge machining (edm)—An overview. Materials 2019, 12, 522. [Google Scholar] [CrossRef] [PubMed]

- Gupta, K.; Jain, N.K. Analysis and optimization of micro-geometry of miniature spur gears manufactured by wire electric discharge machining. Precis. Eng. 2014, 38, 728–737. [Google Scholar] [CrossRef]

- Chen, X.; Wang, Z.; Xu, J.; Wang, Y.; Li, J.; Liu, H. Sustainable production of micro gears combining micro reciprocated wire electrical discharge machining and precision forging. J. Clean. Prod. 2018, 188, 1–11. [Google Scholar] [CrossRef]

- Guo, Y.F.; Feng, Y.R.; Li, W.; Kelie, D.; Ma, C.J.; Lin, T. Experimental investigation of edm parameters for zrb 2-sic ceramics machining. Procedia CIRP 2018, 68, 46–51. [Google Scholar]

- Liu, Y.; Ji, R.; Li, Q.; Yu, L.; Li, X. Electric discharge milling of silicon carbide ceramic with high electrical resistivity. Int. J. Mach. Tools Manuf. 2008, 48, 1504–1508. [Google Scholar] [CrossRef]

- Schumacher, B.M. After 60 years of edm the discharge process remains still disputed. J. Mater. Process. Technol. 2004, 149, 376–381. [Google Scholar] [CrossRef]

- Selvarajan, L.; Manohar, M.; Jayachandran, J.A.R.; Mouri, P.; Selvakumar, P. A review on less tool wear rate and improving surface quality of conductive ceramic composites by spark edm. Mater. Today Proc. 2018, 5, 5774–5782. [Google Scholar] [CrossRef]

- König, W.; Dauw, D.; Levy, G.; Panten, U. Edm-future steps towards the machining of ceramics. CIRP Ann. Manuf. Technol. 1988, 37, 623–631. [Google Scholar] [CrossRef]

- Yoo, H.K.; Ko, J.H.; Lim, K.Y.; Kwon, W.T.; Kim, Y.W. Micro-electrical discharge machining characteristics of newly developed conductive sic ceramic. Ceram. Int. 2015, 41, 3490–3496. [Google Scholar] [CrossRef]

- Salehi, S.; Van der Biest, O.; Vleugels, J. Electrically conductive zro2–tin composites. J. Eur. Ceram. Soc. 2006, 26, 3173–3179. [Google Scholar] [CrossRef]

- Mohri, N.; Fukuzawa, Y.; Tani, T.; Saito, N.; Furutani, K. Assisting electrode method for machining insulating ceramics. CIRP Ann. Manuf. Technol. 1996, 45, 201–204. [Google Scholar] [CrossRef]

- Hösel, T.; Müller, C.; Reinecke, H. Spark erosive structuring of electrically nonconductive zirconia with an assisting electrode. CIRP J. Manuf. Sci. Technol. 2011, 4, 357–361. [Google Scholar] [CrossRef]

- Fukuzawa, Y.; Mohri, N.; Tani, T.; Muttamara, A. Electrical discharge machining properties of noble crystals. J. Mater. Process. Technol. 2004, 149, 393–397. [Google Scholar] [CrossRef]

- Schubert, A.; Zeidler, H.; Hahn, M.; Hackert-Oschätzchen, M.; Schneider, J. Micro-edm milling of electrically nonconducting zirconia ceramics. Procedia Cirp 2013, 6, 297–302. [Google Scholar] [CrossRef]

- Schubert, A.; Zeidler, H.; Kühn, R.; Hackert-Oschätzchen, M.; Flemmig, S.; Treffkorn, N. Investigation of ablation behaviour in micro-edm of nonconductive ceramic composites atz and si3n4-tin. Procedia CIRP 2016, 42, 727–732. [Google Scholar] [CrossRef]

- Kunieda, M.; Lauwers, B.; Rajurkar, K.; Schumacher, B. Advancing edm through fundamental insight into the process. CIRP Ann. Manuf. Technol. 2005, 54, 64–87. [Google Scholar] [CrossRef]

- Zeller, F.; Hösel, T.; Müller, C.; Reinecke, H. Microstructuring of non-conductive silicon carbide by electrical discharge machining. Microsyst. Technol. 2014, 20, 1875–1880. [Google Scholar] [CrossRef]

- Srivastava, M. Study of machining non-conducting materials using EDM. Int. J. Eng. Trends Technol. 2016, 34, 88–92. [Google Scholar] [CrossRef]

- Sabur, A.; Ali, M.Y.; Maleque, M.A.; Khan, A.A. Investigation of material removal characteristics in edm of nonconductive zro2 ceramic. Procedia Eng. 2013, 56, 696–701. [Google Scholar] [CrossRef]

- Fukuzawa, Y.; Mohri, N.; Gotoh, H.; Takayuki, T. Three-dimensional machining of insulating ceramics materials with electrical discharge machining. Trans. Nonferrous Met. Soc. China 2009, 19, 50–156. [Google Scholar] [CrossRef]

- Banu, A.; Ali, M.Y.; Rahman, M.A. Micro-electro discharge machining of non-conductive zirconia ceramic: Investigation of mrr and recast layer hardness. Int. J. Adv. Manuf. Technol. 2014, 75, 257–267. [Google Scholar] [CrossRef]

- Ferraris, E.; Reynaerts, D.; Lauwers, B. Micro-edm process investigation and comparison performance of Al3O2 and ZrO2 based ceramic composites. CIRP Ann. Manuf. Technol. 2011, 60, 235–238. [Google Scholar] [CrossRef]

- Singh, J.; Sharma, R.K. Assessing the effects of different dielectrics on environmentally conscious powder-mixed edm of difficult-to-machine material (wc-co). Front. Mech. Eng. 2016, 11, 374–387. [Google Scholar] [CrossRef]

- Gadow, R.; Landfried, R.; Kern, F. Electrical discharge machining (EDM) of high-performance ceramics. In Proceedings of the III Advanced Ceramics and Applications Conference, Belgrade, Serbia, 29 September–1 October 2014; Springer: Paris, France, 2016; pp. 25–32. [Google Scholar]

- Liu, K.; Reynaerts, D.; Lauwers, B. Influence of the pulse shape on the edm performance of Si3N4–tin ceramic composite. CIRP Ann. 2009, 58, 217–220. [Google Scholar] [CrossRef]

- Liew, P.J.; Yan, J.; Kuriyagawa, T. Carbon nanofiber assisted micro electro discharge machining of reaction-bonded silicon carbide. J. Mater. Process. Technol. 2013, 213, 1076–1087. [Google Scholar] [CrossRef]

- Jahan, M.; Rahman, M.; Wong, Y. Modelling and experimental investigation on the effect of nanopowder-mixed dielectric in micro-electrodischarge machining of tungsten carbide. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2010, 224, 1725–1739. [Google Scholar] [CrossRef]

| Parameters | Case 1 | Case 2 | Case 3 |

|---|---|---|---|

| Ceramic | AIN | AIN | AIN |

| Coating | Baked double layer silver coating with silver nanopowder in between (Both layers baked for 1 h at 900 °C) | Triple layered copper tape. Coating Thickness of 150 µm | Silver nanoparticles sandwiched between two layers of silver with copper on top, baked at 900 °C for 60 min |

| Tool | Copper–Tungsten | Copper–Tungsten | Copper–Tungsten |

| Tool diameter | 600 µm | 600 µm | 308 µm |

| Tool rotation | No rotation | No rotation | No rotation |

| Dielectric: | Hydrocarbon oil | Hydrocarbon oil | Hydrocarbon oil with Silver nanoparticle (100 mg/L) |

| Voltage | 80 V | 100 V | 80 V |

| Capacitance: | 10 nF (4) | 10 nF (4) | 100 nF |

| Machining time | 600 min | 120 min | 150 min |

| Depth of hole | 700 µm from coating surface | 700 µm from the tape surface | 1693 µm from coating surface |

| Flushing condition | No flushing | No flushing | No flushing |

| No | Coating | Machining Parameters | Coolant | Spindle Spinning | Tool Material | Machining Condition | |

|---|---|---|---|---|---|---|---|

| Capacitance | Voltage (V) | Flushing | |||||

| 1 | Baked double layer silver coating with silver nanopowder in between (Both layers baked for 1 h at 900 °C) | 10 nF | 80 | No | No spinning | Copper-Tungsten | Successful machining |

| 2 | Copper Tape (triple layer) | 10 nF | 100 | No | No spinning | Copper-Tungsten | Successful machining |

| 3 | Copper conductive paint (single layer) | 400 nF | 130 | Yes | 1200 RPM | Tungsten | No machining |

| 4 | Copper conductive paint (single layer) | 100 nF | 130 | Yes | 1200 RPM | Tungsten | No machining |

| 5 | Copper conductive paint (single layer) | 10 nF | 130 | Yes | 1200 RPM | Tungsten | No machining |

| 6 | Copper conductive paint (single layer) | 1000 pF | 130 | Yes | 1200 RPM | Tungsten | No machining |

| 7 | Copper conductive paint (single layer) | 100 pF | 130 | Yes | 1200 RPM | Tungsten | No machining |

| 8 | Copper conductive paint (single layer) | 10 pF | 130 | Yes | 1200 RPM | Tungsten | No machining |

| 9 | Copper Tape (single layer) | 400 nF | 130 | Yes | 1200 RPM | Tungsten | No machining |

| 10 | Copper Tape (single layer) | 100 nF | 130 | Yes | 1200 RPM | Tungsten | No machining |

| 11 | Copper Tape (single layer) | 10 nF | 130 | Yes | 1200 RPM | Tungsten | No machining |

| 12 | Copper Tape (single layer) | 1000 pF | 130 | Yes | 1200 RPM | Tungsten | No machining |

| 13 | Copper Tape (single layer) | 100 pF | 130 | Yes | 1200 RPM | Tungsten | No machining |

| 14 | Copper Tape (single layer) | 10 pF | 130 | Yes | 1200 RPM | Tungsten | No machining |

| 15 | Copper Tape (single layer) | 400 nF | 130 | Yes | 1200 RPM | Tungsten | No machining |

| 16 | Carbon conductive paint (single layer) | 10 nF | 80 | Yes | 1200 RPM | Carbon | No machining |

| 17 | Copper Tape (single layer) | 100 nF | 130 | Yes | 1200 RPM | Carbon | No machining |

| 18 | Silver conductive paint (single layer) | 10 nF | 130 | Yes | 1200 RPM | Carbon | No machining |

| 19 | Copper conductive paint (single layer) | 10 nF | 130 | Yes | 1200 RPM | Carbon | No machining |

| 20 | Baked double layer silver coating with silver nanopowder in between (Both layers baked for 1 h at 900 °C) | 10 nF | 80 | Yes | 1200 RPM | Copper–Tungsten | No machining |

| 21 | Baked double layer silver coating with silver nanopowder in between (Both layers baked for 1 h at 900°C) | 400 nF | 80 | No | No spinning | Copper–Tungsten | Some machining |

| 22 | Baked double layer silver coating with silver nanopowder in between (Both layers baked for 1 h at 900 °C) – single layer copper tape on top | 10 nF | 80 | No | No spinning | Copper–Tungsten | No machining |

| 23 | Baked double layer silver coating with silver nanopowder in between (Both layers baked for 1 h at 900 °C) | 10 nF | 80 | No | No spinning | Copper–Tungsten | Machining happened at the bottom of the hole |

| 24 | Copper Tape (single layer 50 µm) | 10 nF | 80 | No | 200 RPM | Copper–Tungsten | No machining |

| 25 | Copper Tape (triple layer, 150 µm) | 10 nF | 100 | No | 100 RPM | Copper–Tungsten | Some machining |

| 26 | Copper Tape (triple layer, 150 µm) | 10 nF | 130 | No | No spinning | Copper–Tungsten | Electrode just repeat going up and down |

| 27 | Double layered silver coating with silver nanoparticles in between, baked at 900 °C for 60 min | 10nf | 80 | Yes | 1200RPM | Tungsten | No machining |

| 28 | Double layered silver coating with silver nanoparticles in between, baked at 900 °C for 60 min | 400nf | 80 | No | No | Tungsten | No machining |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rashid, A.; Bilal, A.; Liu, C.; Jahan, M.P.; Talamona, D.; Perveen, A. Effect of Conductive Coatings on Micro-Electro-Discharge Machinability of Aluminum Nitride Ceramic Using On-Machine-Fabricated Microelectrodes. Materials 2019, 12, 3316. https://doi.org/10.3390/ma12203316

Rashid A, Bilal A, Liu C, Jahan MP, Talamona D, Perveen A. Effect of Conductive Coatings on Micro-Electro-Discharge Machinability of Aluminum Nitride Ceramic Using On-Machine-Fabricated Microelectrodes. Materials. 2019; 12(20):3316. https://doi.org/10.3390/ma12203316

Chicago/Turabian StyleRashid, Asif, Azat Bilal, Chong Liu, M. P. Jahan, Didier Talamona, and Asma Perveen. 2019. "Effect of Conductive Coatings on Micro-Electro-Discharge Machinability of Aluminum Nitride Ceramic Using On-Machine-Fabricated Microelectrodes" Materials 12, no. 20: 3316. https://doi.org/10.3390/ma12203316

APA StyleRashid, A., Bilal, A., Liu, C., Jahan, M. P., Talamona, D., & Perveen, A. (2019). Effect of Conductive Coatings on Micro-Electro-Discharge Machinability of Aluminum Nitride Ceramic Using On-Machine-Fabricated Microelectrodes. Materials, 12(20), 3316. https://doi.org/10.3390/ma12203316