Strength Development and Strain Localization Behavior of Cemented Paste Backfills Using Portland Cement and Fly Ash

Abstract

1. Introduction

2. Materials and Methods

2.1. Mine Tailings

2.2. Binder, Additive and Mine Water

2.3. Mix Designs and Sample Preparations

2.4. UCS Test

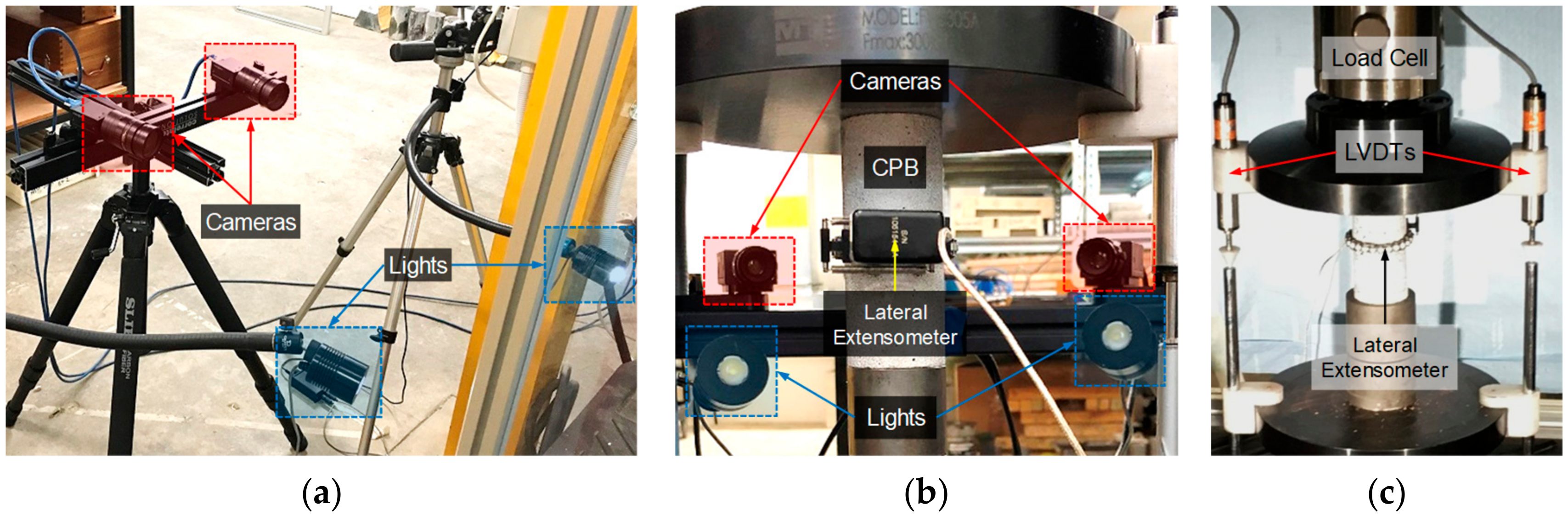

2.5. Three-Dimensional DIC Technique

3. Results and Discussion

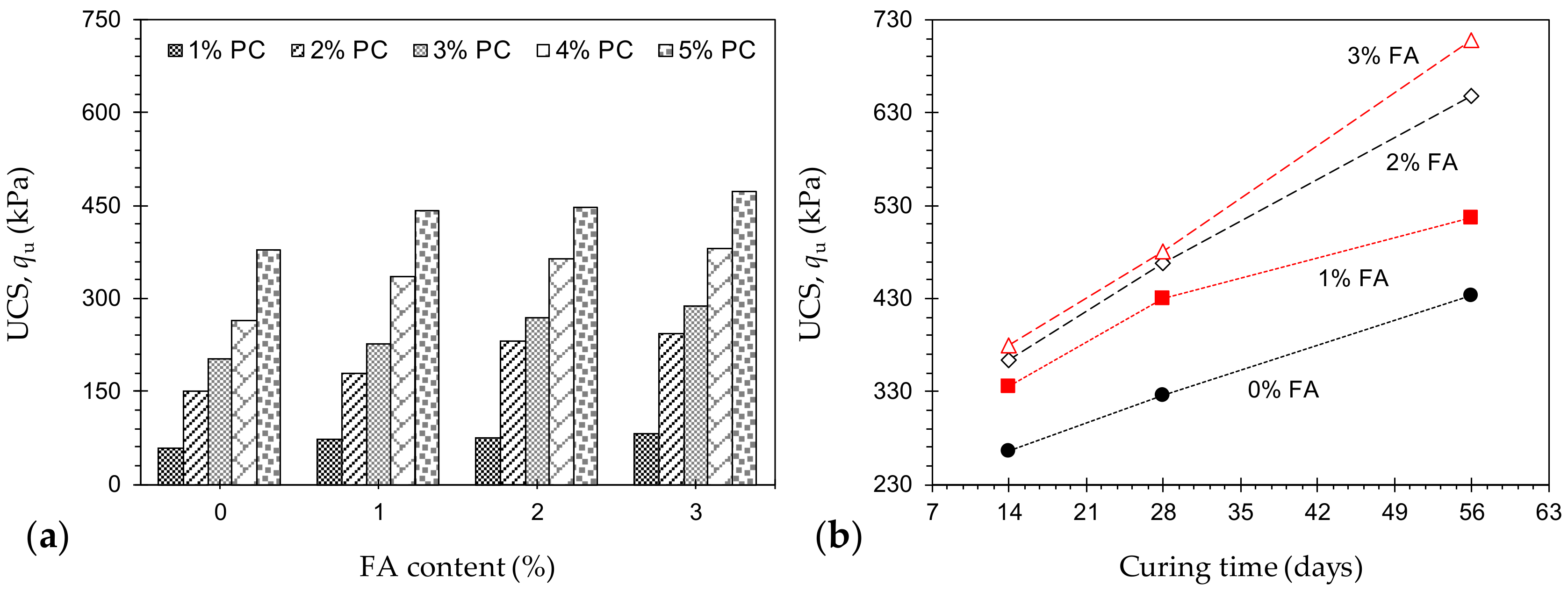

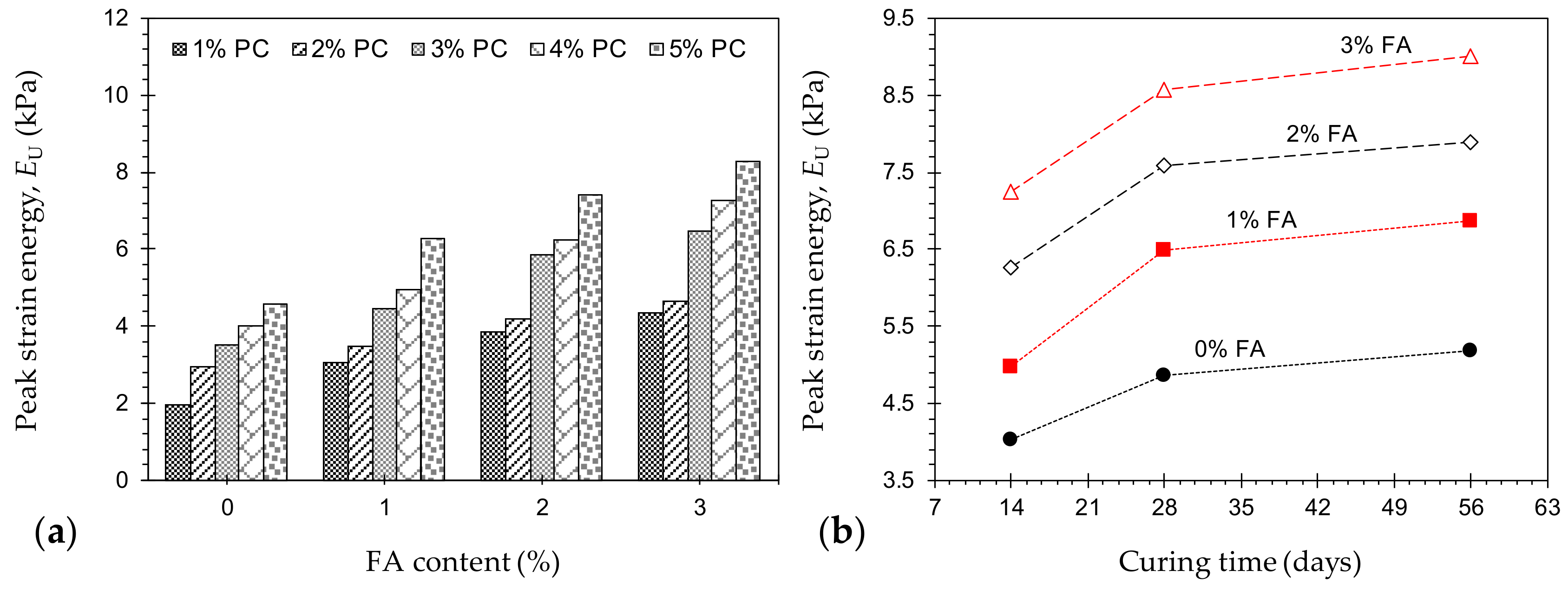

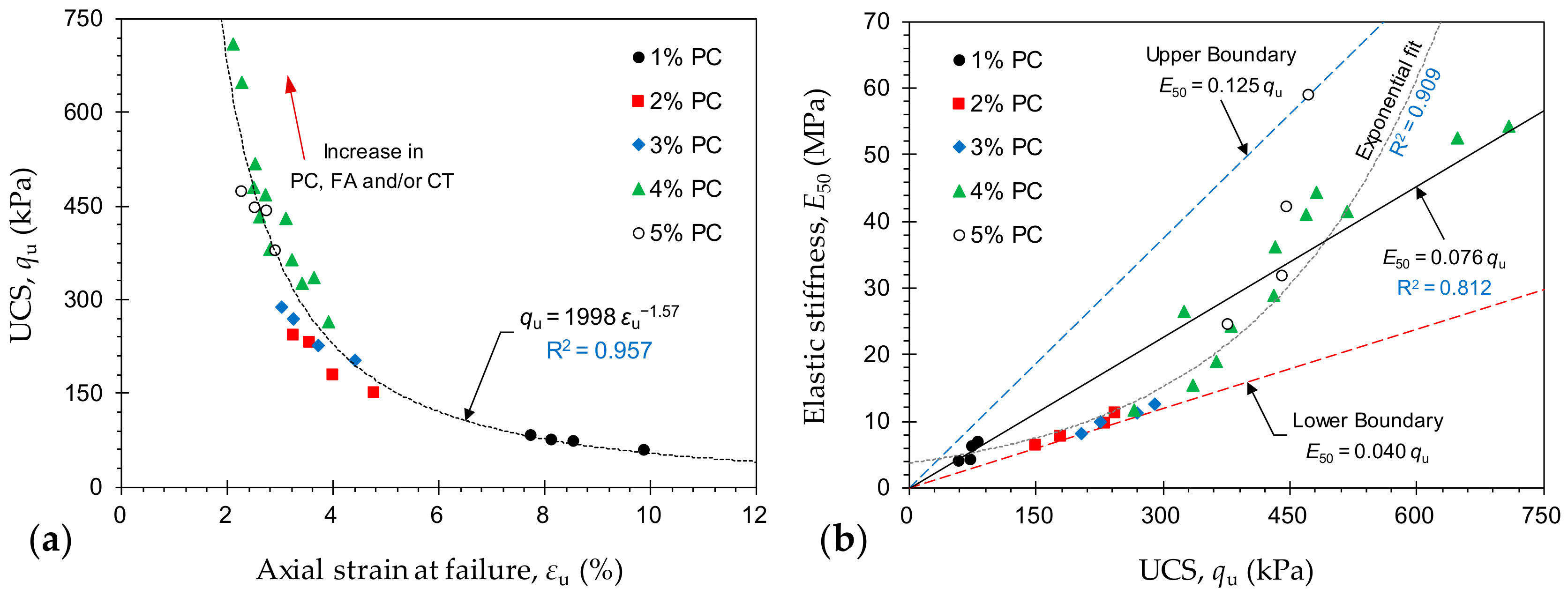

3.1. Effect of PC + FA on UCS

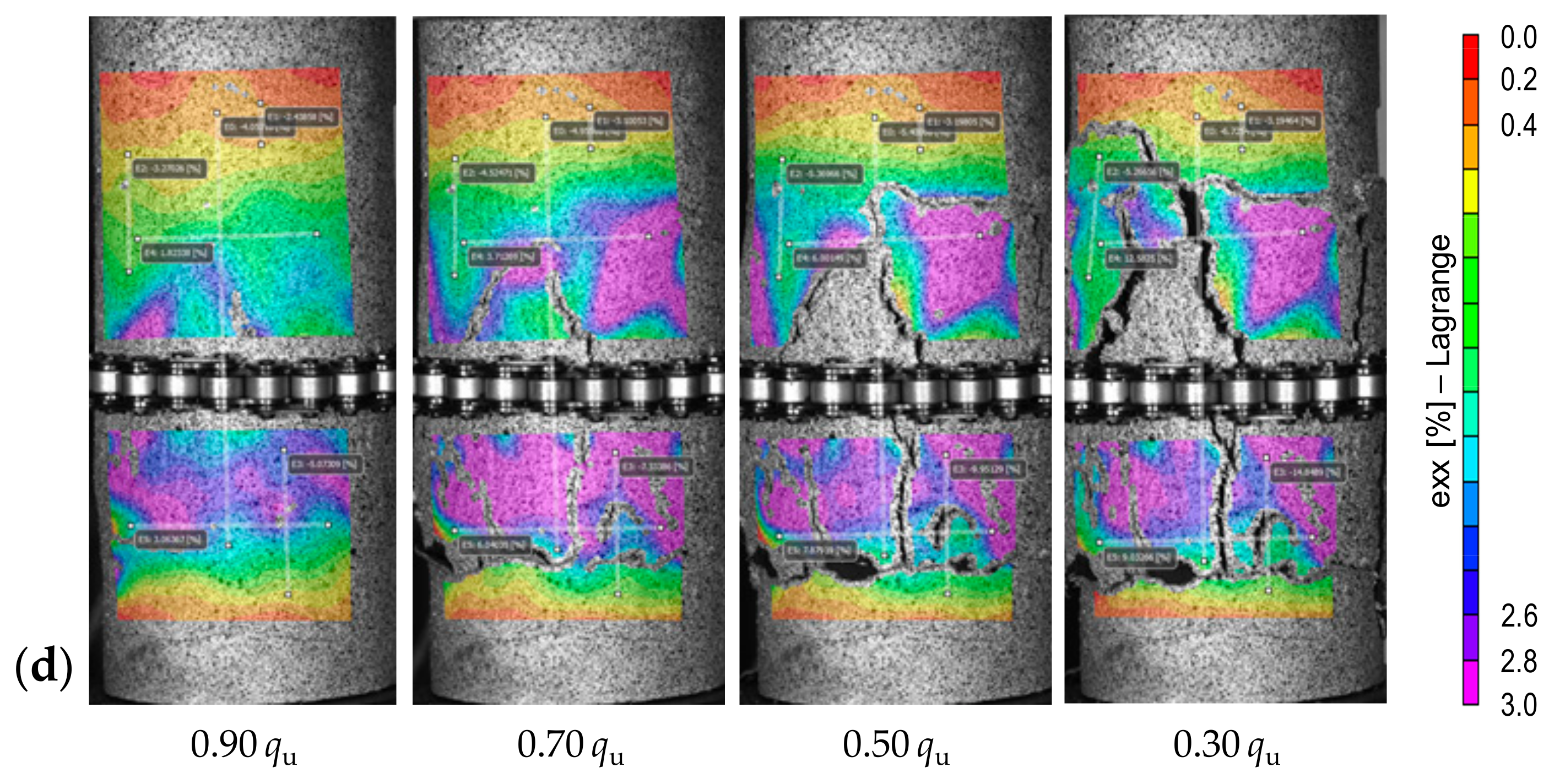

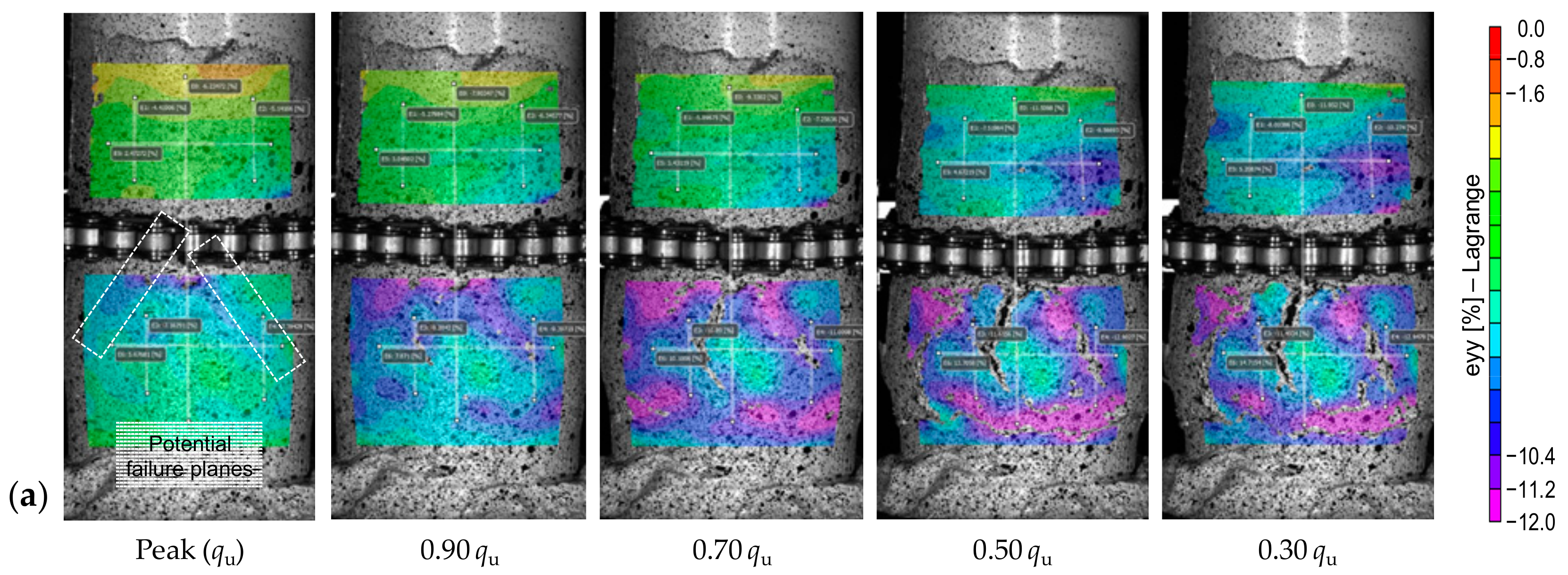

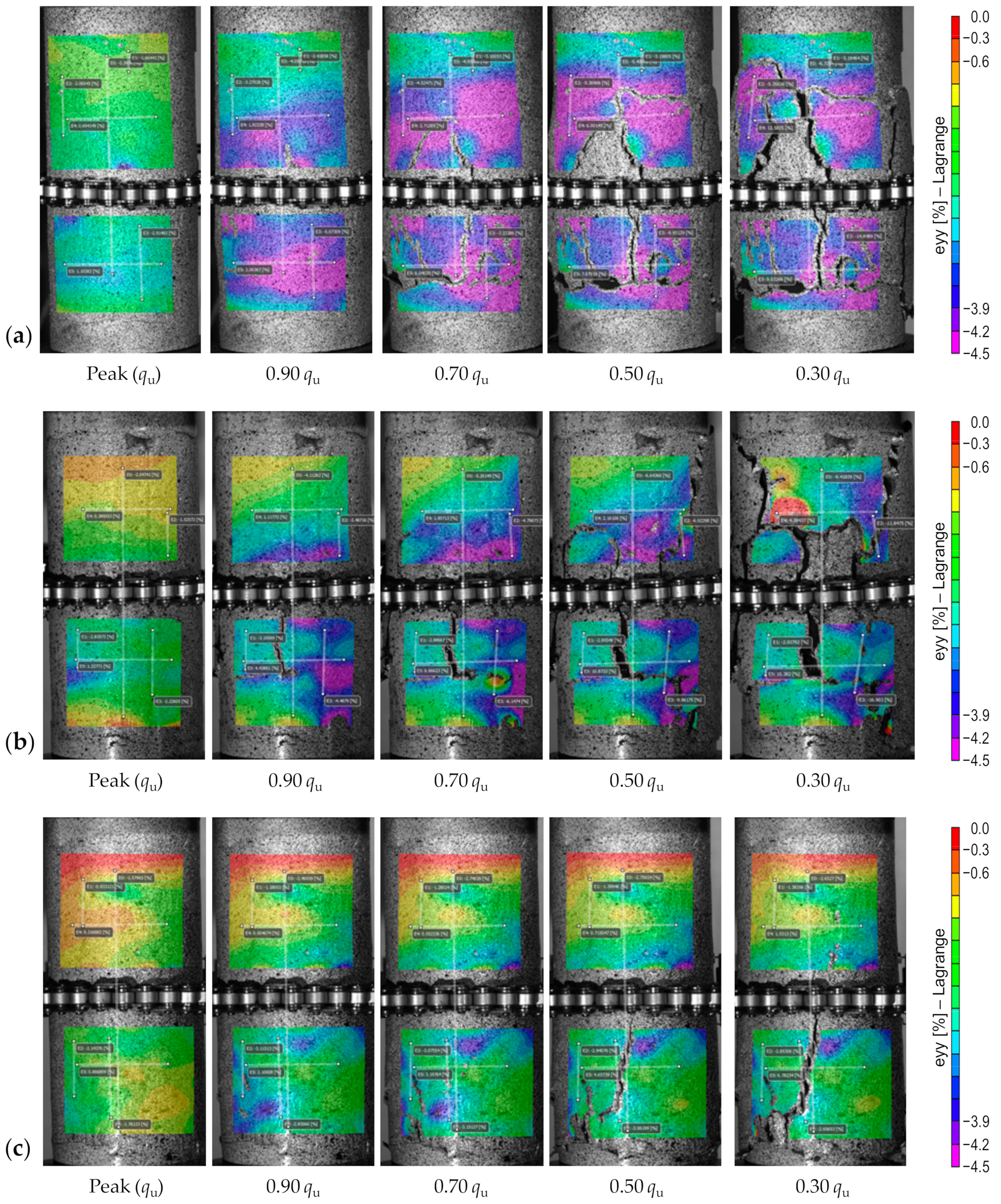

3.2. Field Strain Patterns

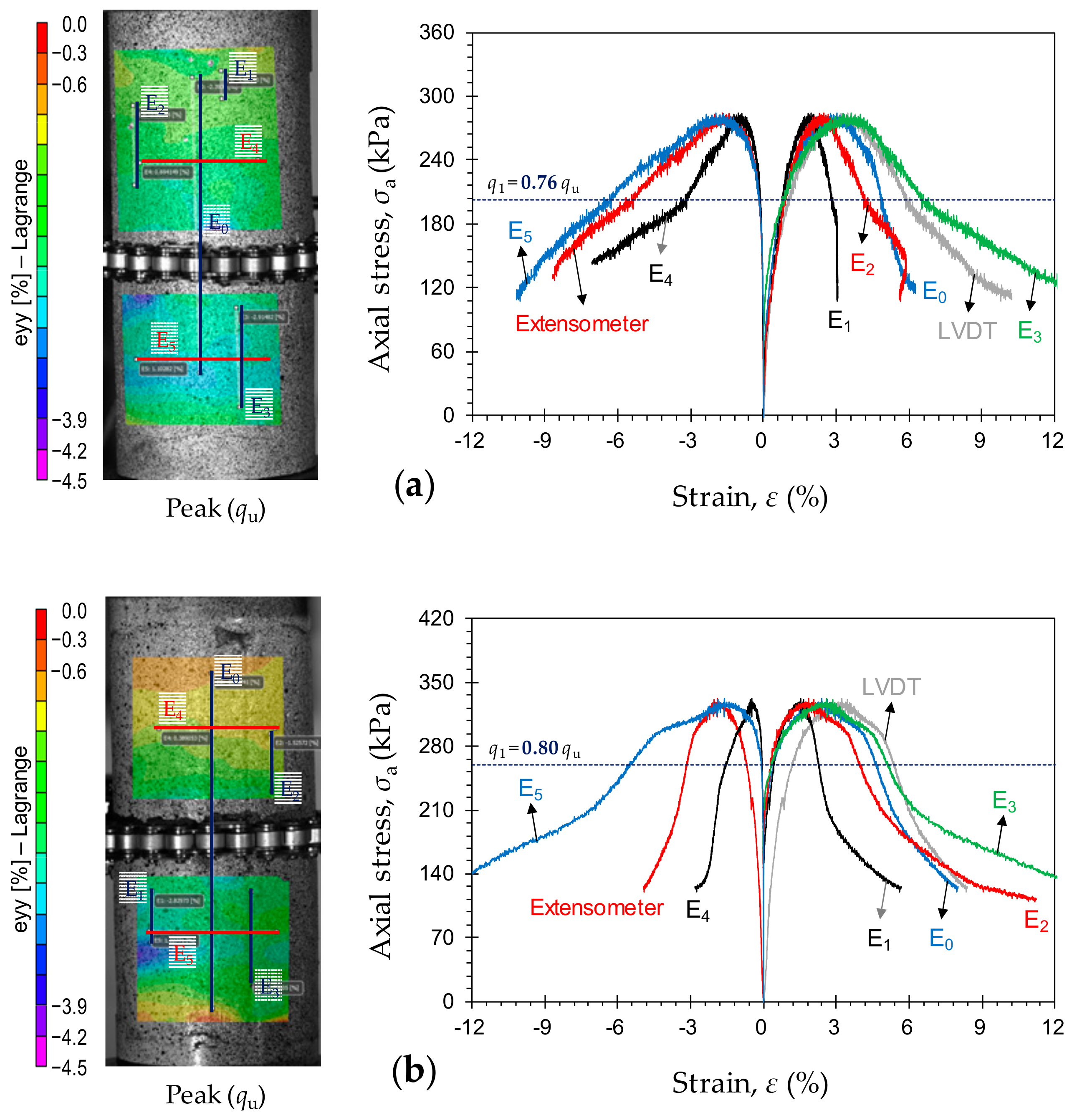

3.3. Localization of the Stress–Strain Curves

4. Concluding Remarks

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AS | Australian Standard |

| ASTM | American Society for Testing and Materials |

| BC | Binder Content |

| C-A-H | Calcium–Aluminate–Hydrate |

| C-A-S-H | Calcium–Aluminate–Silicate–Hydrate |

| CDZ | Crack Damage Zone |

| CL | Clay with Low Plasticity |

| CLSM | Controlled Low-Strength Material |

| CPB | Cemented Paste Backfill |

| C-S-H | Calcium–Silicate–Hydrate |

| CT | Curing Time |

| DIC | Digital Image Correlation |

| FA | Fly Ash |

| LDZ | Local Damage Zone |

| LL | Liquid Limit |

| LVDT | Linear Variable Differential Transducer |

| ML | Silt with Low Plasticity |

| PC | Portland Cement |

| PI | Plasticity Index |

| PL | Plastic Limit |

| SC | Solids Content |

| UCS | Unconfined Compressive Strength |

| USCS | Unified Soil Classification System |

| WC | Water Content |

References

- Jones, H.; Boger, D.V. Sustainability and waste management in the resource industries. Ind. Eng. Chem. Res. 2012, 51, 10057–10065. [Google Scholar] [CrossRef]

- Zhang, J.; Soltani, A.; Deng, A.; Jaksa, M.B. Mechanical performance of jute fiber-reinforced micaceous clay composites treated with ground-granulated blast-furnace slag. Materials 2019, 12, 576. [Google Scholar] [CrossRef] [PubMed]

- Cai, J.W.; Zhang, S.B.; Hou, G.X.; Wang, C.M.; Feng, X.X. Effects of ferrous mill tailings as aggregates on workability and strength of concrete. J. Wuhan Univ. Technol. 2009, 7, 104–107. [Google Scholar]

- Huang, X.; Ranade, R.; Li, V.C. Feasibility study of developing green ECC using iron ore tailings powder as cement replacement. J. Mater. Civ. Eng. 2013, 25, 923–931. [Google Scholar] [CrossRef]

- Chen, S.; Wang, H.; Zhang, J.; Xing, H.; Wang, H. Low-strength similar materials for backfill mining: Insight from experiments on components and influence mechanism. Geotech. Test. J. 2015, 38, 929–935. [Google Scholar] [CrossRef]

- Qian, G.; Huang, T.; Bai, S. Use of cement-stabilized granite mill tailings as pavement subbase. J. Mater. Civ. Eng. 2011, 23, 1575–1578. [Google Scholar] [CrossRef]

- Naganathan, S.; Razak, H.A.; Hamid, S.N.A. Properties of controlled low-strength material made using industrial waste incineration bottom ash and quarry dust. Mater. Des. 2012, 33, 56–63. [Google Scholar] [CrossRef]

- Fall, M.; Célestin, J.C.; Pokharel, M.; Touré, M. A contribution to understanding the effects of curing temperature on the mechanical properties of mine cemented tailings backfill. Eng. Geol. 2010, 114, 397–413. [Google Scholar] [CrossRef]

- Yilmaz, E.; Fall, M. Introduction to paste tailings management. In Paste Tailings Management, 1st ed.; Yilmaz, E., Fall, M., Eds.; Springer International Publishing: Gewerbestrasse, Cham, Switzerland, 2017; pp. 1–5. ISBN 9783319396828. [Google Scholar] [CrossRef]

- Zhang, J.; Deng, H.; Taheri, A.; Deng, J.; Ke, B. Effects of superplasticizer on the hydration, consistency, and strength development of cemented paste backfill. Minerals 2018, 8, 381. [Google Scholar] [CrossRef]

- Zhao, Y.; Soltani, A.; Taheri, A.; Karakus, M.; Deng, A. Application of slag–cement and fly ash for strength development in cemented paste backfills. Minerals 2019, 9, 22. [Google Scholar] [CrossRef]

- Rankine, R.M.; Sivakugan, N. Geotechnical properties of cemented paste backfill from Cannington Mine, Australia. Geotech. Geol. Eng. 2007, 25, 383–393. [Google Scholar] [CrossRef]

- Orejarena, L.; Fall, M. The use of artificial neural networks to predict the effect of sulphate attack on the strength of cemented paste backfill. Bull. Eng. Geol. Environ. 2010, 69, 659–670. [Google Scholar] [CrossRef]

- Sivakugan, N.; Veenstra, R.; Naguleswaran, N. Underground mine backfilling in Australia using paste fills and hydraulic fills. Int. J. Geosynth. Gr. Eng. 2015, 1, 1–7. [Google Scholar] [CrossRef]

- Yilmaz, E.; Kesimal, A.; Deveci, H.; Ercikdi, B. The Factors Affecting the Performance of Paste Backfill: Physical, Chemical and Mineralogical Characterization. In Proceedings of the First Engineering Sciences Congress for Young Researchers (MBGAK’03), Istanbul, Turkey, 17–20 February 2003; pp. 683–690. [Google Scholar]

- Sivakugan, N.; Rankine, R.M.; Rankine, K.J.; Rankine, K.S. Geotechnical considerations in mine backfilling in Australia. J. Clean. Prod. 2006, 14, 1168–1175. [Google Scholar] [CrossRef]

- Belem, T.; Benzaazoua, M. Design and application of underground mine paste backfill technology. Geotech. Geol. Eng. 2008, 26, 147–174. [Google Scholar] [CrossRef]

- Huang, S.; Xia, K.; Qiao, L. Dynamic tests of cemented paste backfill: Effects of strain rate, curing time, and cement content on compressive strength. J. Mater. Sci. 2011, 46, 5165–5170. [Google Scholar] [CrossRef]

- Benzaazoua, M.; Fall, M.; Belem, T. A contribution to understanding the hardening process of cemented pastefill. Miner. Eng. 2004, 17, 141–152. [Google Scholar] [CrossRef]

- Kesimal, A.; Yilmaz, E.; Ercikdi, B. Evaluation of paste backfill mixtures consisting of sulphide-rich mill tailings and varying cement contents. Cem. Concr. Res. 2004, 34, 1817–1822. [Google Scholar] [CrossRef]

- Kesimal, A.; Yilmaz, E.; Ercikdi, B.; Alp, I.; Deveci, H. Effect of properties of tailings and binder on the short- and long-term strength and stability of cemented paste backfill. Mater. Lett. 2005, 59, 3703–3709. [Google Scholar] [CrossRef]

- Fall, M.; Samb, S.S. Effect of high temperature on strength and microstructural properties of cemented paste backfill. Fire Saf. J. 2009, 44, 642–651. [Google Scholar] [CrossRef]

- Taheri, A.; Tatsuoka, F. Stress–strain relations of cement-mixed gravelly soil from multiple-step triaxial compression test results. Soils Found. 2012, 52, 748–766. [Google Scholar] [CrossRef]

- Taheri, A.; Tatsuoka, F. Small- and large-strain behaviour of a cement-treated soil during various loading histories and testing conditions. Acta Geotech. 2015, 10, 131–155. [Google Scholar] [CrossRef]

- Wu, J.; Feng, M.; Chen, Z.; Mao, X.; Han, G.; Wang, Y. Particle size distribution effects on the strength characteristic of cemented paste backfill. Minerals 2018, 8, 322. [Google Scholar] [CrossRef]

- Markeset, G.; Hillerborg, A. Softening of concrete in compression — Localization and size effects. Cem. Concr. Res. 1995, 25, 702–708. [Google Scholar] [CrossRef]

- Van Mier, J.G.M. Framework for a generalized four-stage fracture model of cement-based materials. Eng. Fract. Mech. 2008, 75, 5072–5086. [Google Scholar] [CrossRef]

- Tung, N.D.; Tue, N.V. Post-peak behavior of concrete specimens undergoing deformation localization in uniaxial compression. Constr. Build. Mater. 2015, 99, 109–117. [Google Scholar] [CrossRef]

- Munoz, H.; Taheri, A.; Chanda, E.K. Pre-peak and post-peak rock strain characteristics during uniaxial compression by 3D digital image correlation. Rock Mech. Rock Eng. 2016, 49, 2541–2554. [Google Scholar] [CrossRef]

- Panteleev, I.; Plekhov, O.; Pankov, I.; Evseev, A.; Naimark, O.; Asanov, V. Experimental investigation of the spatio-temporal localization of deformation and damage in sylvinite specimens under uniaxial tension. Eng. Fract. Mech. 2014, 129, 38–44. [Google Scholar] [CrossRef]

- Munoz, H.; Taheri, A. Local damage and progressive localisation in porous sandstone during cyclic loading. Rock Mech. Rock Eng. 2017, 50, 3253–3259. [Google Scholar] [CrossRef]

- Munoz, H.; Taheri, A. Postpeak deformability parameters of localized and nonlocalized damage zones of rocks under cyclic loading. Geotech. Test. J. 2019, 42. [Google Scholar] [CrossRef]

- Blotz, L.R.; Benson, C.H.; Boutwell, G.P. Estimating optimum water content and maximum dry unit weight for compacted clays. J. Geotech. Geoenvironmental Eng. 1998, 124, 907–912. [Google Scholar] [CrossRef]

- Lee, Y.H.; William, K. Mechanical properties of concrete in uniaxial compression. ACI Mater. J. 1997, 94, 457–471. [Google Scholar] [CrossRef]

- Sutton, M.A.; Orteu, J.J.; Schreier, H. Image Correlation for Shape, Motion and Deformation Measurements, 1st ed.; Springer US: New York, NY, USA, 2009; ISBN 9780387787473. [Google Scholar] [CrossRef]

- Chu, T.C.; Ranson, W.F.; Sutton, M.A. Applications of digital-image-correlation techniques to experimental mechanics. Exp. Mech. 1985, 25, 232–244. [Google Scholar] [CrossRef]

- Sharma, A.K.; Sivapullaiah, P.V. Ground granulated blast furnace slag amended fly ash as an expansive soil stabilizer. Soils Found. 2016, 56, 205–212. [Google Scholar] [CrossRef]

- Firoozi, A.A.; Olgun, C.G.; Firoozi, A.A.; Baghini, M.S. Fundamentals of soil stabilization. Int. J. Geo-Eng. 2017, 8, 1–16. [Google Scholar] [CrossRef]

- Soltani, A.; Taheri, A.; Khatibi, M.; Estabragh, A.R. Swelling potential of a stabilized expansive soil: A comparative experimental study. Geotech. Geol. Eng. 2017, 35, 1717–1744. [Google Scholar] [CrossRef]

- Behnood, A. Soil and clay stabilization with calcium- and non-calcium-based additives: A state-of-the-art review of challenges, approaches and techniques. Transp. Geotech. 2018, 17, 14–32. [Google Scholar] [CrossRef]

- Grice, T. Underground Mining with Backfill. In Proceedings of 2nd Annual Summit—Mine Tailings Disposal Systems; Australasian Institute of Mining and Metallurgy: Carlton, VIC, Australia, 1998; pp. 234–239. [Google Scholar]

- Tariq, A. Synergistic and Environmental Benefits of Using Cement Kiln Dust with Slag and Fly Ash in Cemented Paste Tailings. Ph.D. Thesis, The University of Western Ontario, London, ON, Canada, 2012. [Google Scholar]

- Brackebusch, F.W. Basics of paste backfill systems. Min. Eng. 1994, 46, 1175–1178. [Google Scholar]

- United States Environmental Protection Agency (USEPA). Handbook for Stabilization/Solidification of Hazardous Waste; Hazardous Waste Engineering Research Laboratory: Cincinnati, OH, USA, 1986. [Google Scholar]

- Standard Guide for Evaluating Effectiveness of Admixtures for Soil Stabilization; ASTM D4609–08; ASTM International: West Conshohocken, PA, USA, 2008. [CrossRef]

- Jewell, R.J.; Fourie, A.B. Paste and Thickened Tailings — A Guide, 1st ed.; Australian Centre for Geomechanics: Perth, WA, Australia, 2002; pp. 103–126. [Google Scholar]

- Taheri, A.; Tani, K. Use of down-hole triaxial apparatus to estimate the mechanical properties of heterogeneous mudstone. Int. J. Rock Mech. Min. Sci. 2008, 45, 1390–1402. [Google Scholar] [CrossRef]

- Soltani, A.; Deng, A.; Taheri, A.; Sridharan, A. Swell–shrink–consolidation behavior of rubber-reinforced expansive soils. Geotech. Test. J. 2019, 42, 761–788. [Google Scholar] [CrossRef]

- Soltani, A.; Taheri, A.; Deng, A.; Nikraz, H. Tyre rubber and expansive soils: Two hazards, one solution. Proc. Inst. Civ. Eng. Constr. Mater. 2019. [Google Scholar] [CrossRef]

- Munoz, H.; Taheri, A.; Chanda, E.K. Rock cutting characteristics on soft-to-hard rocks under different cutter inclinations. Int. J. Rock Mech. Min. Sci. 2016, 87, 85–89. [Google Scholar] [CrossRef]

- Nguyen, T.L.; Hall, S.A.; Vacher, P.; Viggiani, G. Fracture mechanisms in soft rock: Identification and quantification of evolving displacement discontinuities by extended digital image correlation. Tectonophysics 2011, 503, 117–128. [Google Scholar] [CrossRef]

- Zhang, H.; Huang, G.; Song, H.; Kang, Y. Experimental investigation of deformation and failure mechanisms in rock under indentation by digital image correlation. Eng. Fract. Mech. 2012, 96, 667–675. [Google Scholar] [CrossRef]

- Song, H.; Zhang, H.; Kang, Y.; Huang, G.; Fu, D.; Qu, C. Damage evolution study of sandstone by cyclic uniaxial test and digital image correlation. Tectonophysics 2013, 608, 1343–1348. [Google Scholar] [CrossRef]

| Geotechnical Properties | Standard | Value | Chemical Components | MF (%) 1 |

|---|---|---|---|---|

| Specific gravity, Gs | ASTM D854–14 | 2.61 | SiO2 | 38.27 |

| Fines content (<75 μm) (%) | ASTM D422–07 | 39 | Fe2O3 | 37.70 |

| Sand content (0.075–2 mm) (%) | ASTM D422–07 | 61 | Al2O3 | 7.19 |

| Liquid limit, LL (%) | AS 1289.3.9.1–15 | 19.2 | K2O | 2.33 |

| Plastic limit, PL (%) | AS 1289.3.2.1–09 | 13.1 | CaO | 0.81 |

| Plasticity index, PI (%) 2 | AS 1289.3.3.1–09 | 6.1 | MgO | 0.75 |

| USCS classification 3 | ASTM D2487–11 | CL–ML 4 | TiO2 | 0.56 |

| Optimum water content (%) | ASTM D698–12 | 8.7 | Na2O | 0.07 |

| Maximum dry density (g/cm3) | ASTM D698–12 | 2.06 | Other | 12.32 |

| Properties | Value | Standard |

|---|---|---|

| Fineness index (m2/g) | 370–430 | AS 2350.8–06 |

| Initial setting time (min) | 105 | AS 2350.4–06 |

| Final setting time (min) | 180 | AS 2350.4–06 |

| 3-Day compressive strength (MPa) | 31 | AS 2350.11–06 |

| 7-Day compressive strength (MPa) | 42 | AS 2350.11–06 |

| 28-Day compressive strength (MPa) | 60 | AS 2350.11–06 |

| Portland clinker (% by mass) | 85–93 | – |

| Natural gypsum (% by mass) | 5–7 | – |

| Mineral additives (% by mass) | <8 | – |

| Sulfur trioxide, SO3 (% by mass) | 2.8 | – |

| Equivalent alkalis (% by mass) | 0.5 | – |

| Chloride, Cl− (% by mass) | 0.05 | – |

| Loss on ignition, LOI (at 1000 °C) (%) | 3–4 | – |

| Chemical Components | Concentration (mg/L) |

|---|---|

| Chloride, Cl− | 5800 |

| Sodium, Na+ | 3800 |

| Sulfate, SO42− | 2400 |

| Calcium, Ca2+ | 480 |

| Potassium, K+ | 380 |

| Magnesium, Mg2+ | 280 |

| Nitrate, NO3− | 6 |

| Designation | PC (%) 1 | FA (%) 1 | SC (%) 2 | WC (%) 3 | Tests |

|---|---|---|---|---|---|

| P1F0T14 | 1 | 0 | 77 | 30 | UCS 4 + DIC 5 |

| P1F1T14 | 1 | 1 | 77 | 30 | |

| P1F2T14 | 1 | 2 | 77 | 30 | |

| P1F3T14 | 1 | 3 | 77 | 30 | |

| P2F0T14 | 2 | 0 | 77 | 30 | UCS + DIC |

| P2F1T14 | 2 | 1 | 77 | 30 | |

| P2F2T14 | 2 | 2 | 77 | 30 | |

| P2F3T14 | 2 | 3 | 77 | 30 | |

| P3F0T14 | 3 | 0 | 77 | 30 | UCS + DIC |

| P3F1T14 | 3 | 1 | 77 | 30 | |

| P3F2T14 | 3 | 2 | 77 | 30 | |

| P3F3T14 | 3 | 3 | 77 | 30 | |

| P4F0T14,28,56 | 4 | 0 | 77 | 30 | UCS + DIC |

| P4F1T14,28,56 | 4 | 1 | 77 | 30 | |

| P4F2T14,28,56 | 4 | 2 | 77 | 30 | |

| P4F3T14,28,56 | 4 | 3 | 77 | 30 | |

| P5F0T14 | 5 | 0 | 77 | 30 | UCS + DIC |

| P5F1T14 | 5 | 1 | 77 | 30 | |

| P5F2T14 | 5 | 2 | 77 | 30 | |

| P5F3T14 | 5 | 3 | 77 | 30 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Taheri, A.; Soltani, A.; Karakus, M.; Deng, A. Strength Development and Strain Localization Behavior of Cemented Paste Backfills Using Portland Cement and Fly Ash. Materials 2019, 12, 3282. https://doi.org/10.3390/ma12203282

Zhao Y, Taheri A, Soltani A, Karakus M, Deng A. Strength Development and Strain Localization Behavior of Cemented Paste Backfills Using Portland Cement and Fly Ash. Materials. 2019; 12(20):3282. https://doi.org/10.3390/ma12203282

Chicago/Turabian StyleZhao, Yue, Abbas Taheri, Amin Soltani, Murat Karakus, and An Deng. 2019. "Strength Development and Strain Localization Behavior of Cemented Paste Backfills Using Portland Cement and Fly Ash" Materials 12, no. 20: 3282. https://doi.org/10.3390/ma12203282

APA StyleZhao, Y., Taheri, A., Soltani, A., Karakus, M., & Deng, A. (2019). Strength Development and Strain Localization Behavior of Cemented Paste Backfills Using Portland Cement and Fly Ash. Materials, 12(20), 3282. https://doi.org/10.3390/ma12203282