Comparative Life Cycle Assessment of a Novel Al-Ion and a Li-Ion Battery for Stationary Applications

Abstract

1. Introduction

2. State of Knowledge

3. Methods and Data

3.1. Functional Unit

3.2. Battery Modelling and Inventory Compilation

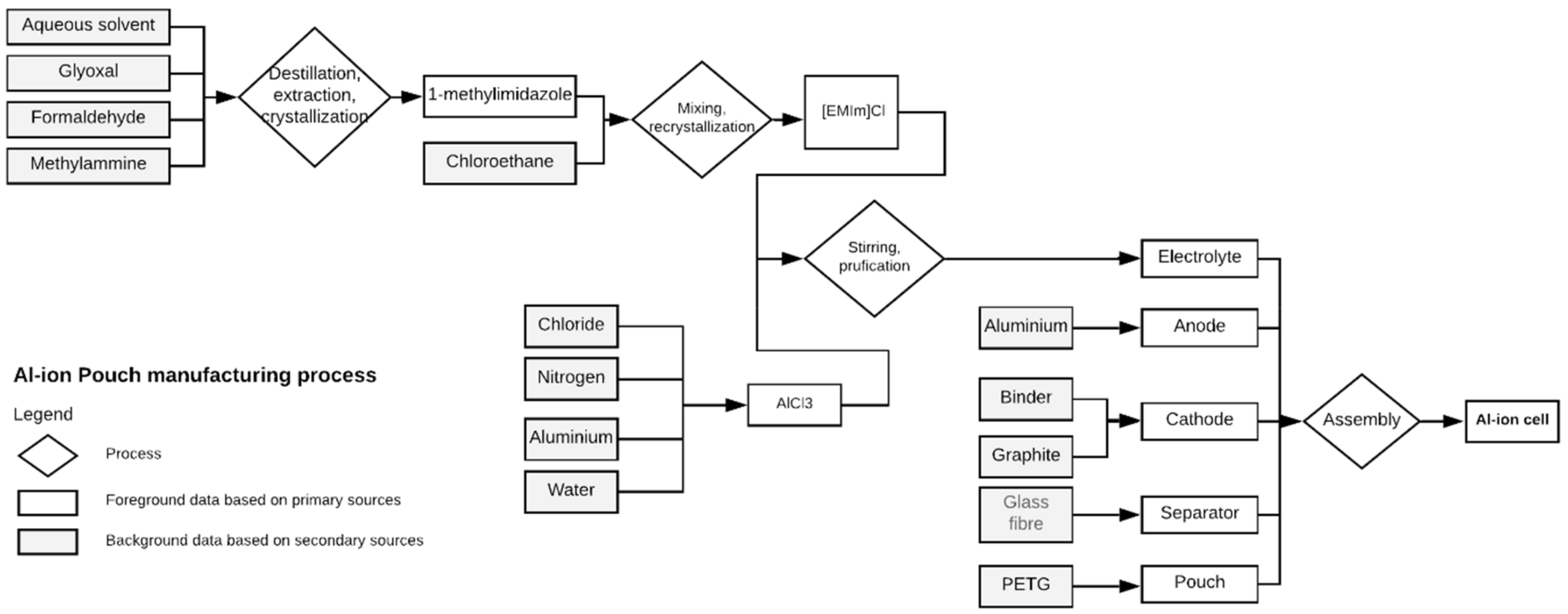

3.2.1. Cell Manufacturing

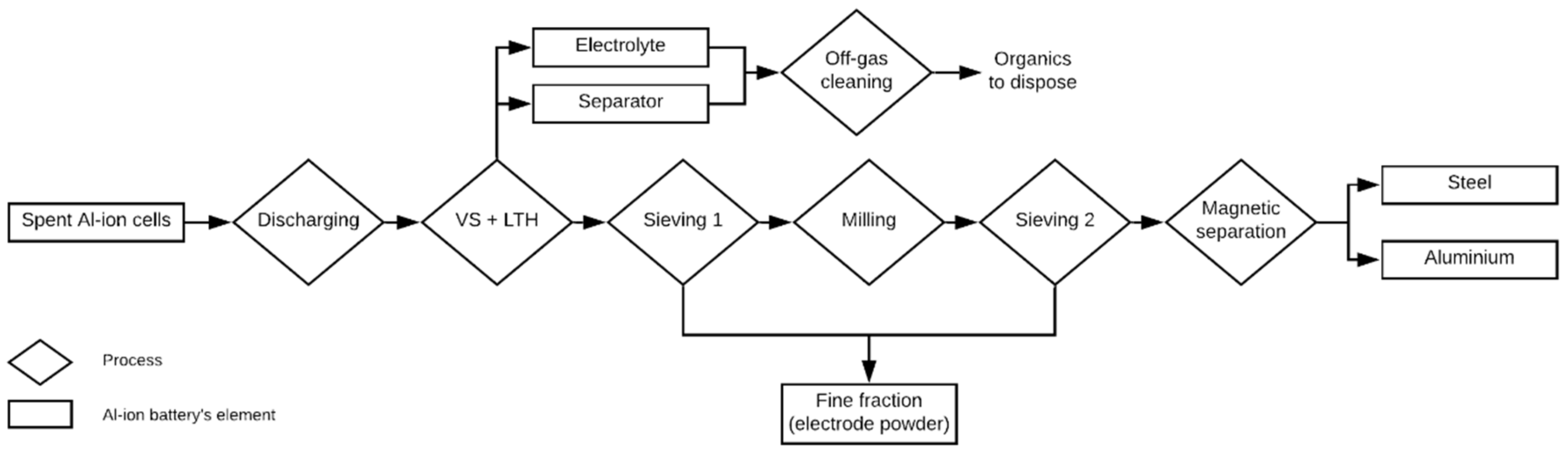

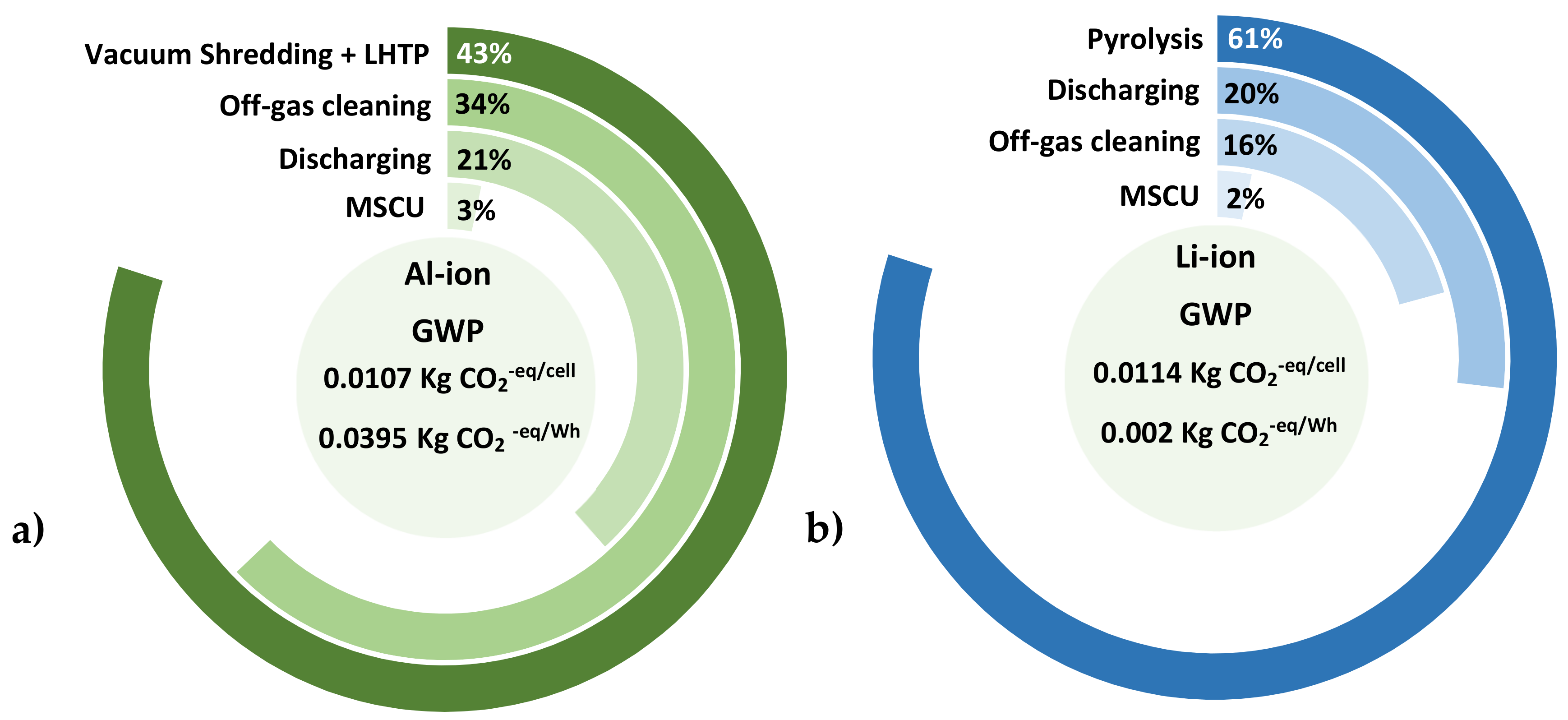

3.2.2. End-of-Life Phase

3.3. Reference Technology

4. Results and Discussion

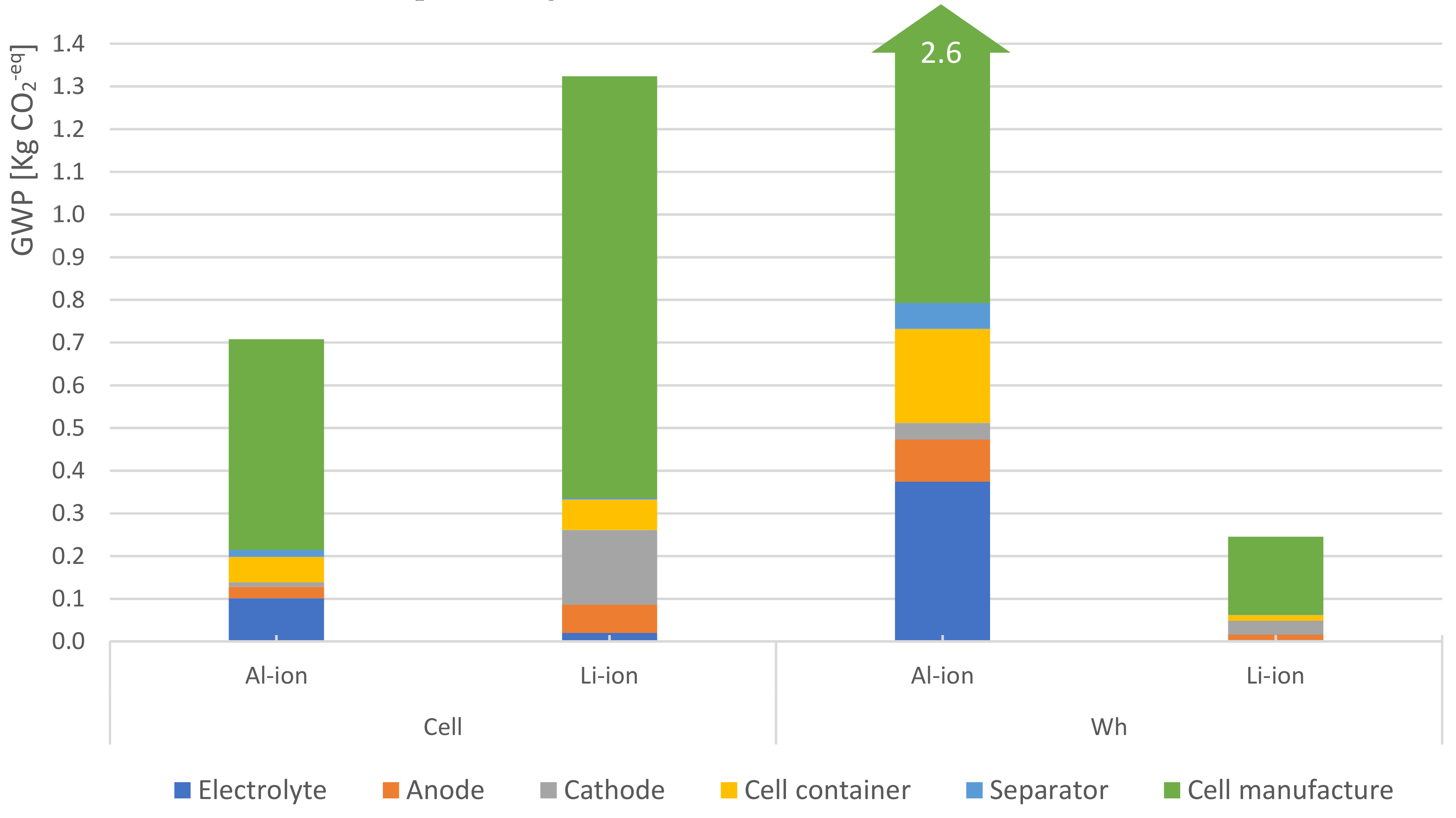

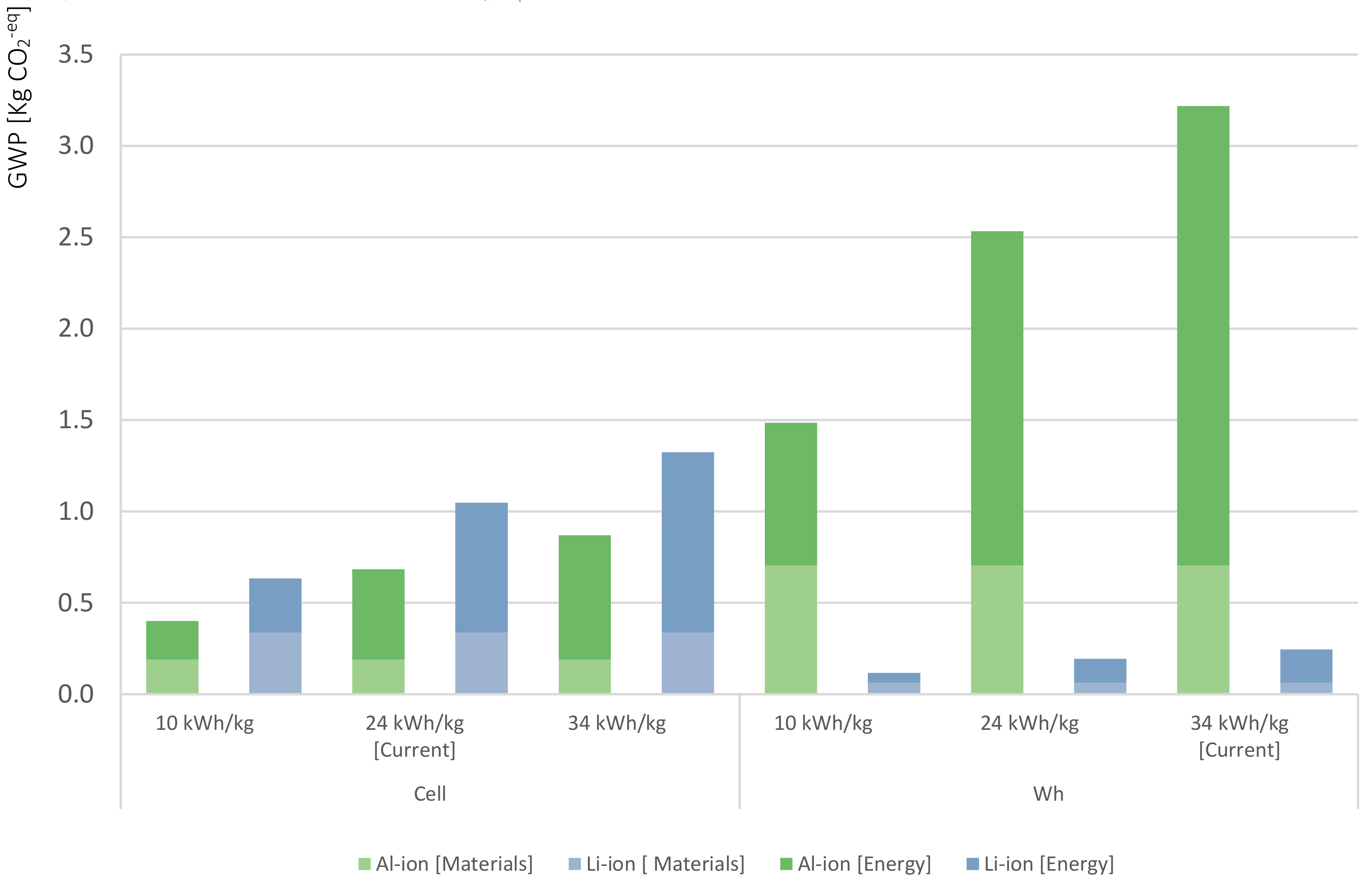

4.1. Cradle-to-Gate

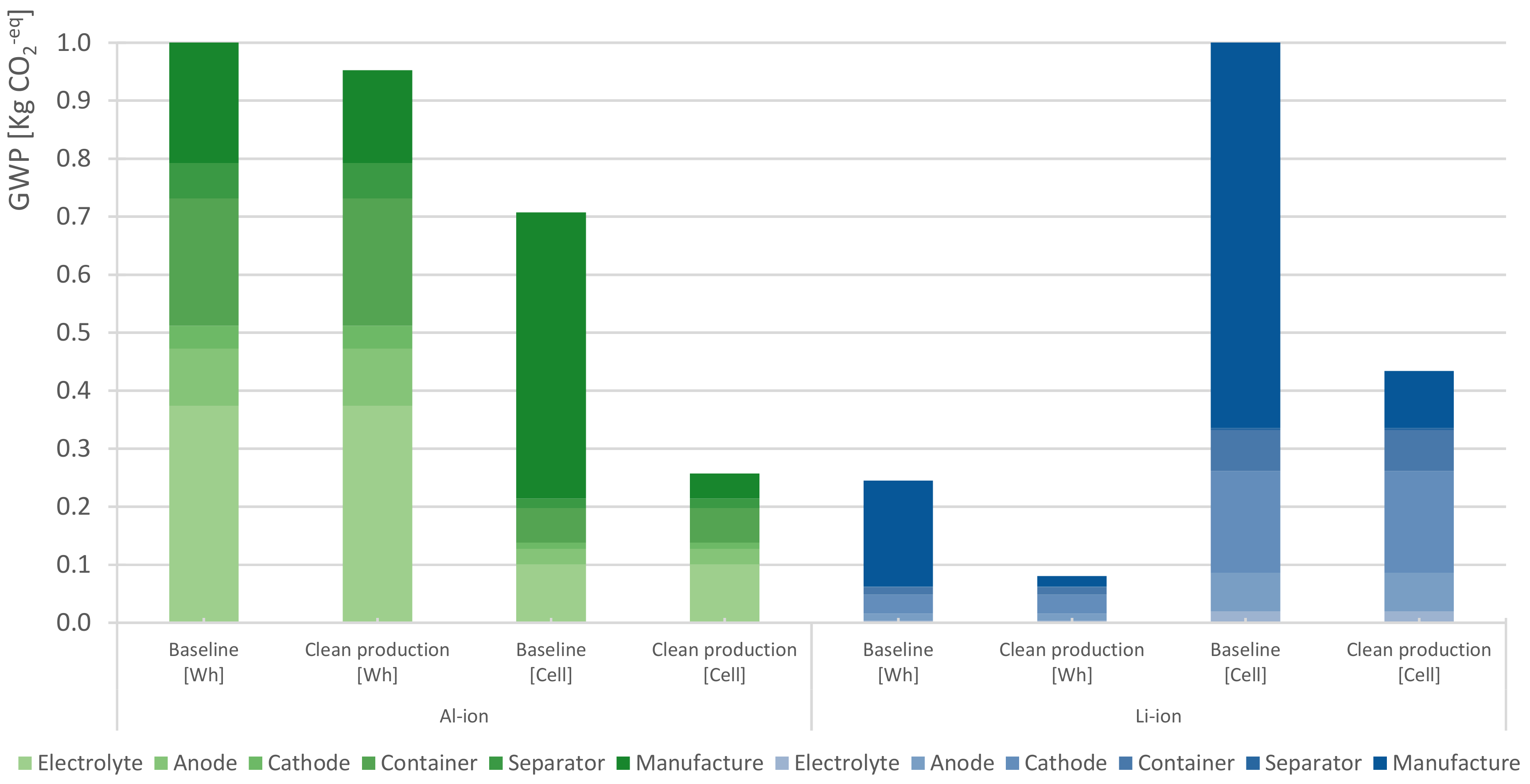

4.1.1. Influence of the Energy Source

4.1.2. Influence of the Data Resolution

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- OECD/IEA. World Energy Outlook 2018, Scenarios 2018. Available online: https://www.iea.org/weo2018/scenarios/ (accessed on 01 June 2019).

- Baumann, M.; Peters, J.F.; Weil, M.; Grunwald, A. CO2 Footprint and Life-Cycle Costs of Electrochemical Energy Storage for Stationary Grid Applications. Energy Technol. 2017, 5, 1071–1083. [Google Scholar] [CrossRef]

- Hiremath, M.; Derendorf, K.; Vogt, T. Comparative life cycle assessment of battery storage systems for stationary applications. Environ. Sci. Technol. 2015, 49, 4825–4833. [Google Scholar] [CrossRef] [PubMed]

- Delmas, C. Sodium and Sodium-Ion Batteries: 50 Years of Research. Adv. Energy Mater. 2018, 8, 1703137. [Google Scholar] [CrossRef]

- Ponrouch, A.; Palacín, M.R. Post-Li batteries: Promises and challenges. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2019, 377, 20180297. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.; Mochiku, T.; Fujii, H.; Tang, K.; Hu, Y.; Huang, Z.; Luo, B.; Ozawa, K.; Wang, L. A new sodium iron phosphate as a stable high-rate cathode material for sodium ion batteries. Nano Res. 2018, 11, 6197–6205. [Google Scholar] [CrossRef]

- Dunn, B.; Kamath, H.; Tarascon, J.M. Electrical Energy Storage for the Grid: A Battery of Choices. Science 2011, 334, 928–935. [Google Scholar] [CrossRef] [PubMed]

- Palizban, O.; Kauhaniemi, K. Energy storage systems in modern grids—Matrix of technologies and applications. J. Energy Storage 2016, 6, 248–259. [Google Scholar] [CrossRef]

- Olivetti, E.A.; Ceder, G.; Gaustad, G.G.; Fu, X. Lithium-Ion Battery Supply Chain Considerations: Analysis of Potential Bottlenecks in Critical Metals. Joule 2017, 1, 229–243. [Google Scholar] [CrossRef]

- Ellingsen, L.A.W.; Majeau-Bettez, G.; Singh, B.; Srivastava, A.K.; Valøen, L.O.; Strømman, A.H. Life Cycle Assessment of a Lithium-Ion Battery Vehicle Pack. J. Ind. Ecol. 2014, 18, 113–124. [Google Scholar] [CrossRef]

- Ellingsen, L.A.W.; Hung, C.R.; Strømman, A.H. Identifying key assumptions and differences in life cycle assessment studies of lithium-ion traction batteries with focus on greenhouse gas emissions. Transp. Res. Part D Transp. Environ. 2017, 55, 82–90. [Google Scholar] [CrossRef]

- Kim, H.C.; Wallington, T.J.; Arsenault, R.; Bae, C.; Ahn, S.; Lee, J. Cradle-to-Gate Emissions from a Commercial Electric Vehicle Li-Ion Battery: A Comparative Analysis. Environ. Sci. Technol. 2016, 50, 7715–7722. [Google Scholar] [CrossRef] [PubMed]

- Majeau-Bettez, G.; Hawkins, T.R.; StrØmman, A.H. Life cycle environmental assessment of lithium-ion and nickel metal hydride batteries for plug-in hybrid and battery electric vehicles. Environ. Sci. Technol. 2011, 45, 4548–4554. [Google Scholar] [CrossRef] [PubMed]

- United States Environmental Protection Agency. Application of Life-Cycle Assessment to Nanoscale Technology: Lithium-Ion Batteries for Electric Vehicles; United States Environmental Protection Agency: Washington, DC, USA, 2013.

- Li, B.; Gao, X.; Li, J.; Yuan, C. Life cycle environmental impact of high-capacity lithium ion battery with silicon nanowires anode for electric vehicles. Environ. Sci. Technol. 2014, 48, 3047–3055. [Google Scholar] [CrossRef] [PubMed]

- Zackrisson, M.; Avellán, L.; Orlenius, J. Life cycle assessment of lithium-ion batteries for plug-in hybrid electric vehicles-Critical issues. J. Clean. Prod. 2010, 18, 1519–1529. [Google Scholar] [CrossRef]

- Bauer, C. Ökobilanz von Lithium-Ionen Batterien [Life Cycle Assessment of Lithium-Ion Batteries] Paul Scherrer Institut; PSI, Technology Assessment/GaBE: Villigen, Switzerland, 2010. [Google Scholar]

- Notter, D.A.; Gauch, M.; Widmer, R.; Wager, P.; Stamp, A.; Zah, R.; Althaus, H.J. Contribution of Li-ion batteries to the environmental impact of electric vehicles. Environ. Sci. Technol. 2010, 6550–6556. [Google Scholar] [CrossRef] [PubMed]

- Dunn, J.B.; Gaines, L.; Sullivan, J.; Wang, M.Q. Impact of recycling on cradle-to-gate energy consumption and greenhouse gas emissions of automotive lithium-ion batteries. Environ. Sci. Technol. 2012, 46, 12704–12710. [Google Scholar] [CrossRef] [PubMed]

- Spanos, C.; Tuonrney, D.E.; Fthenakis, V. Life-cycle analysis of flow-assisted nickel zinc-, manganese dioxide-, and valve-regulated lead-acid batteries designed for demand-charge reduction. Renew. Sustain. Energy Rev. 2015, 43, 478–494. [Google Scholar] [CrossRef]

- Longo, S.; Antonucci, V.; Cellura, M.; Ferraro, M. Life cycle assessment of storage systems: The case study of a sodium/nickel chloride battery. J. Clean. Prod. 2014, 85, 337–346. [Google Scholar] [CrossRef]

- Vandepaer, L.; Cloutier, J.; Amor, B. Environmental impacts of Lithium Metal Polymer and Lithium-ion stationary batteries. Renew. Sustain. Energy Rev. 2017, 78, 46–60. [Google Scholar] [CrossRef]

- Peters, J.F.; Weil, M. Aqueous hybrid ion batteries—An environmentally friendly alternative for stationary energy storage? J. Power Sources 2017, 364, 258–265. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO 14040: Environmental Management—Life Cycle Assessment—Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Chaffey, N. Encyclopedia of Ecology. Ann. Bot. 2010, 4, 359–366. [Google Scholar] [CrossRef]

- ISO. ISO 14044: Environmental Management, Life Cycle Assessment, Requirements and Guidelines; ISO: Geneve, Switzerland, 2006; Volume 2006. [Google Scholar]

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.; Schryver, A.; Struijs, J.; Zelm, R. ReCiPE 2008: A life cycle impact assessment method which comprises harmonised category indicators at the midpoint and the endpoint level. 2008. [Google Scholar]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. Ecoinvent version 3. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Piccinno, F.; Hischier, R.; Seeger, S.; Som, C. From laboratory to industrial scale: A scale-up framework for chemical processes in life cycle assessment studies. J. Clean. Prod. 2016, 135, 1085–1097. [Google Scholar] [CrossRef]

- Kaufman, J.G. Applications for Aluminium Alloys and Tempers. In Introduction to Aluminum Alloys and Tempers; ASM International: Materials Park, OH, USA, 2000; pp. 93–94. ISBN 978-0-87-170689-8. [Google Scholar]

- Johnson, J.L.; Sullivan, C.M. Lightweight Materials for Auotomotive Application. Argonne Natl. Lab. 2017, 91, 399–404. [Google Scholar]

- Elia, G.A.; Hasa, I.; Greco, G.; Diemant, T.; Marquardt, K.; Hoeppner, K.; Behm, R.J.; Hoell, A.; Passerini, S.; Hahn, R. Insights into the reversibility of aluminum graphite batteries. J. Mater. Chem. A 2017, 5, 9682–9690. [Google Scholar] [CrossRef]

- Reuss, G.; Disteldorf, W.; Gamer, A.O.; Hilt, A. Fluorine Compounds, Organic. In Ulmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2012. [Google Scholar]

- Ebel, K.; Koehler, H.; Gamer, A.O.; Jäckh, R. Imidazole and Derivatives. In Ulman’s Encyclopedia of Industrial Chemistry; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2000. [Google Scholar]

- Howells, R.D.; Mc Cown, J.D. Trifluoromethanesulfonic Acid and Derivatives. Chem. Rev. 1977, 77, 69–92. [Google Scholar] [CrossRef]

- Ellingsen, L.A.-W.; Holland, A.; Drillet, J.F.; Peters, W.; Eckert, M.; Concepcion, C.; Ruiz, O.; Colin, J.F.; Knipping, E.; Pan, Q.; et al. Environmental screening of electrode materials for a rechargeable aluminum battery with an AlCl3/EMIMCl electrolyte. Materials (Basel) 2018, 11, 936. [Google Scholar] [CrossRef]

- Cohn, G.; Ma, L.; Archer, L.A. A novel non-aqueous aluminum sulfur battery. J. Power Sources 2015, 283, 416–422. [Google Scholar] [CrossRef]

- Grenland Energy AS (Nesttund, Norway). Personal communication, 2016.

- Miljøbil Grenland AS (Nesttund, Norway). Personal communication, 2012.

- Casals, L.C.; García, B.A.; Canal, C. Second life batteries lifespan: Rest of useful life and environmental analysis. J. Environ. Manag. 2019, 232, 354–363. [Google Scholar] [CrossRef]

- Casals, L.C.; García, B.A.; Aguesse, F.A. Iturrondobeitia, Second life of electric vehicle batteries: Relation between materials degradation and environmental impact. Int. J. Life Cycle Assess. 2017, 22, 82–89. [Google Scholar] [CrossRef]

- Heymans, C.; Walker, S.B.; Young, S.B.; Fowler, M. Economic analysis of second use electric vehicle batteries for residential energy storage and load-levelling. Energy Policy 2014, 71, 22–30. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salgado Delgado, M.A.; Usai, L.; Ellingsen, L.A.-W.; Pan, Q.; Hammer Strømman, A. Comparative Life Cycle Assessment of a Novel Al-Ion and a Li-Ion Battery for Stationary Applications. Materials 2019, 12, 3270. https://doi.org/10.3390/ma12193270

Salgado Delgado MA, Usai L, Ellingsen LA-W, Pan Q, Hammer Strømman A. Comparative Life Cycle Assessment of a Novel Al-Ion and a Li-Ion Battery for Stationary Applications. Materials. 2019; 12(19):3270. https://doi.org/10.3390/ma12193270

Chicago/Turabian StyleSalgado Delgado, Mario Amin, Lorenzo Usai, Linda Ager-Wick Ellingsen, Qiaoyan Pan, and Anders Hammer Strømman. 2019. "Comparative Life Cycle Assessment of a Novel Al-Ion and a Li-Ion Battery for Stationary Applications" Materials 12, no. 19: 3270. https://doi.org/10.3390/ma12193270

APA StyleSalgado Delgado, M. A., Usai, L., Ellingsen, L. A.-W., Pan, Q., & Hammer Strømman, A. (2019). Comparative Life Cycle Assessment of a Novel Al-Ion and a Li-Ion Battery for Stationary Applications. Materials, 12(19), 3270. https://doi.org/10.3390/ma12193270