Memristive Characteristic of an Amorphous Ga-Sn-O Thin-Film Device with Double Layers of Different Oxygen Density

Abstract

1. Introduction

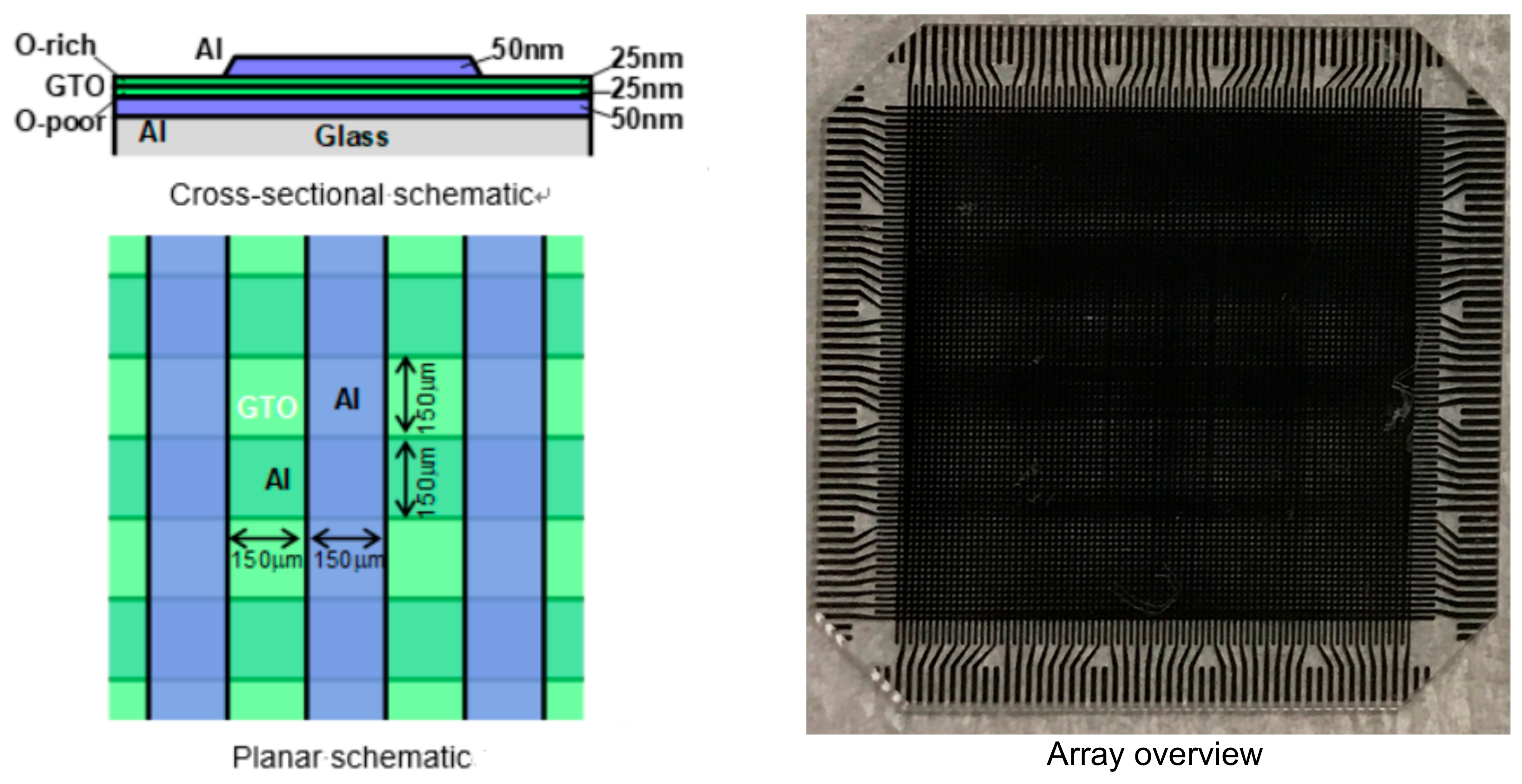

2. Materials and Methods

3. Results

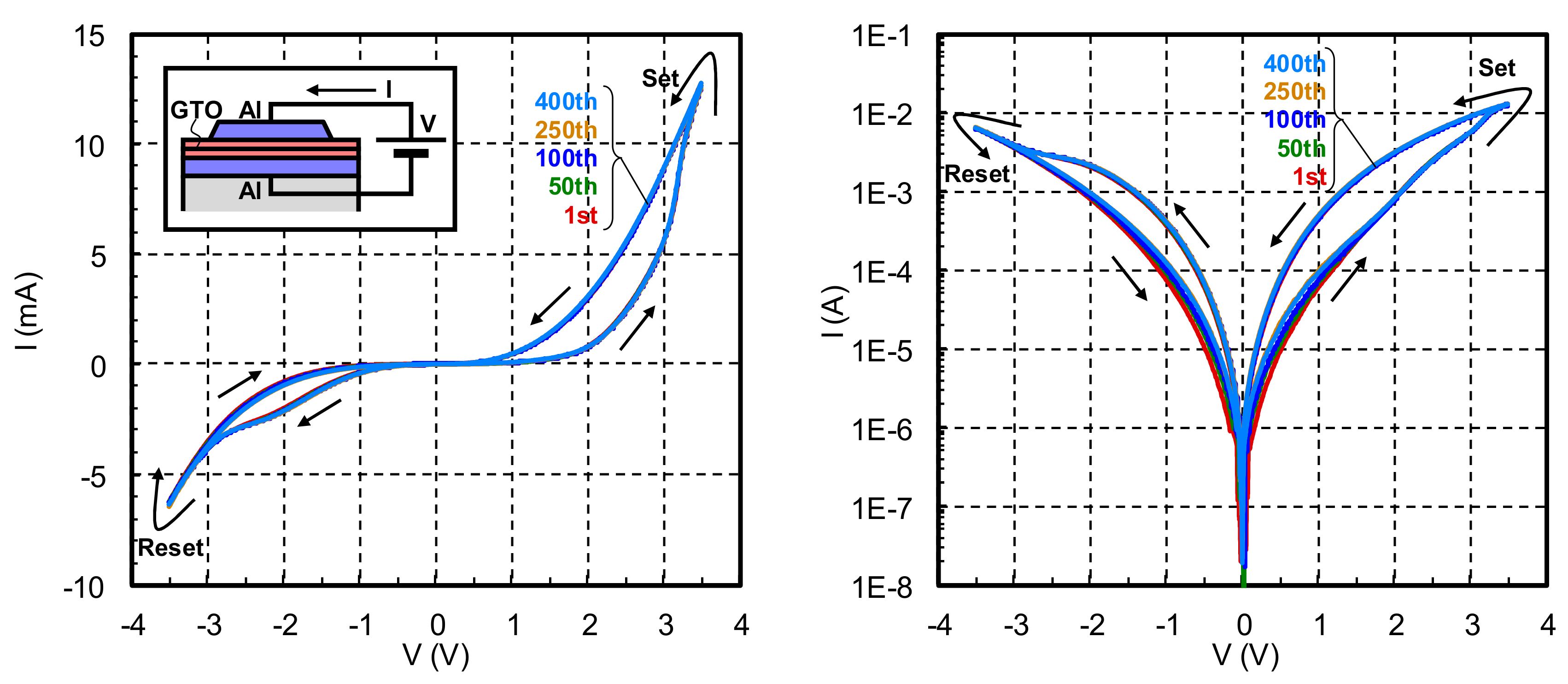

3.1. Electrical Characteristics

3.2. X-Ray Photoelectron Spectroscopy Spectrums

3.3. Memristive Characteristic

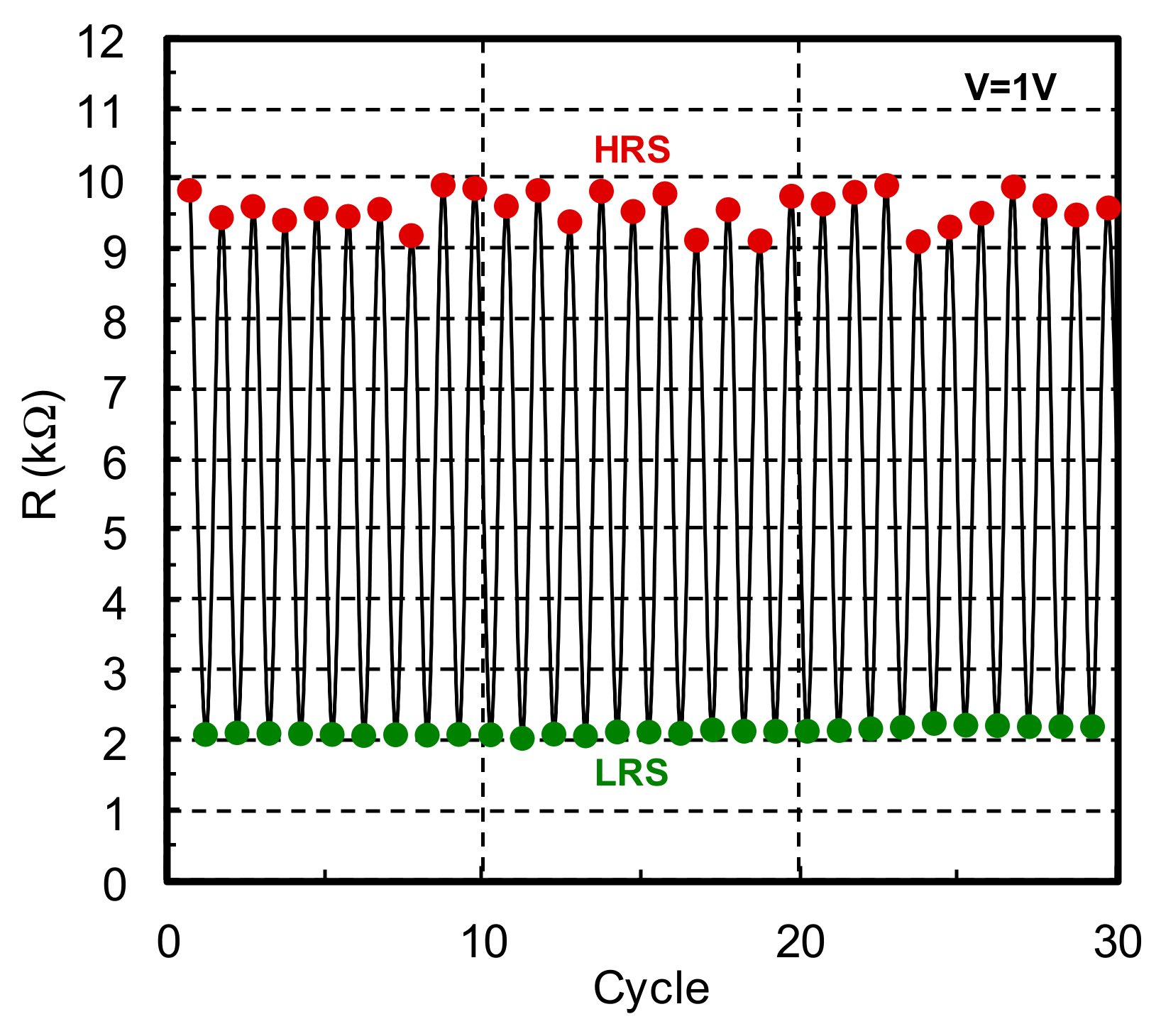

3.4. Repetition Characteristic

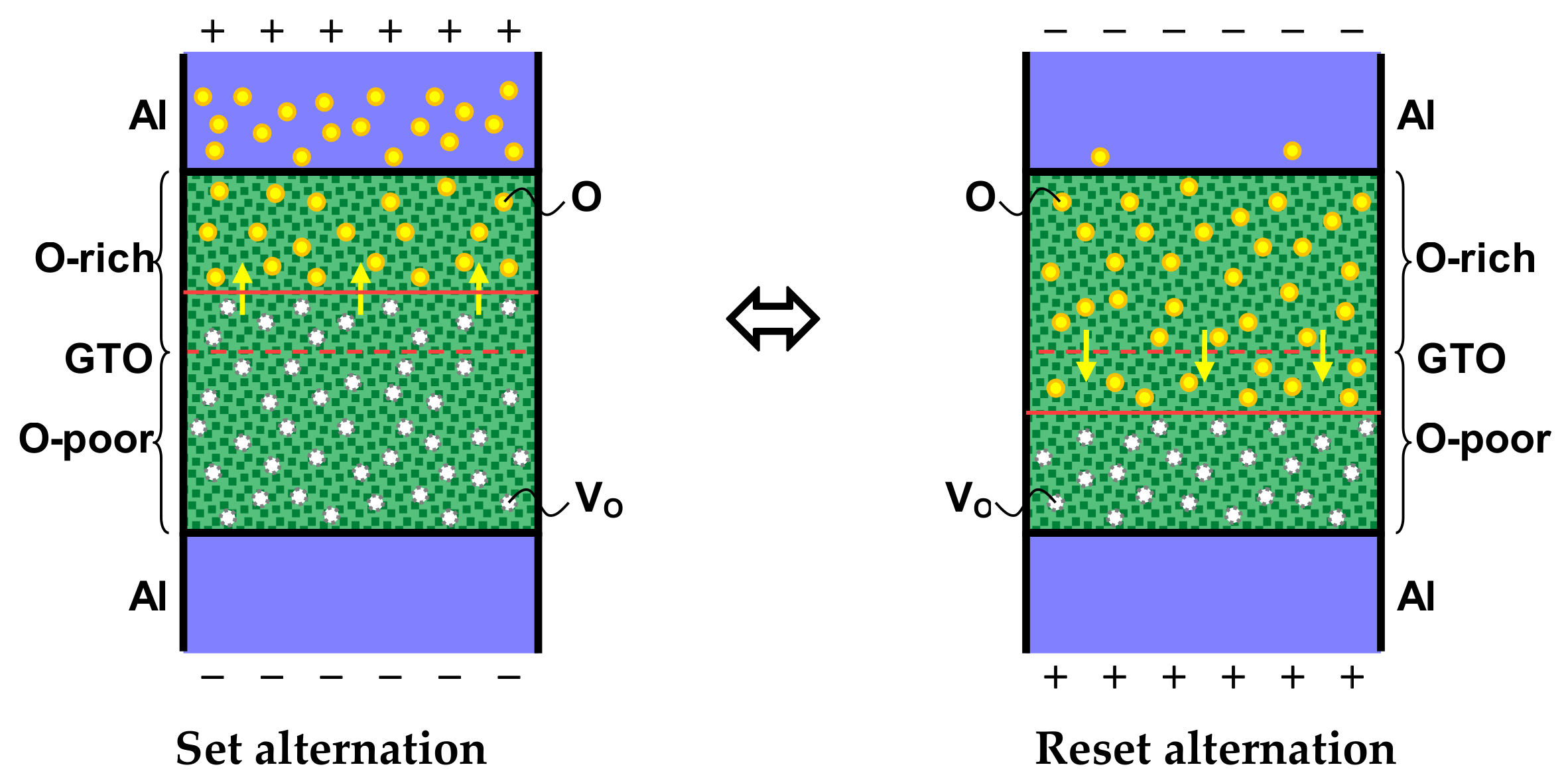

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Nomura, K.; Ohta, H.; Takagi, A.; Kamiya, T.; Hirano, M.; Hosono, H. Room-temperature fabrication of transparent flexible thin-film transistors using amorphous oxide semiconductors. Nature 2004, 432, 488–492. [Google Scholar] [CrossRef] [PubMed]

- Nomura, K.; Takagi, A.; Kamiya, T.; Ohta, H.; Hirano, M.; Hosono, H. Amorphous oxide semiconductors for high-performance flexible thin-film transistors. Jpn. J. Appl. Phys. 2006, 45, 4303–4308. [Google Scholar] [CrossRef]

- Fortunato, E.; Barquinha, P.; Pimentel, A.; Pereira, L.; Gonçalves, G.; Martins, R. Amorphous IZO TTFTs with saturation mobilities exceeding 100 cm2/Vs. Phys. Status Solidi (RRL) 2006, 1, R34–R36. [Google Scholar] [CrossRef]

- Chiang, H.Q.; McFarlane, B.R.; Hong, D.; Presley, R.E.; Wager, J.F. Processing effects on the stability of amorphous indium gallium zinc oxide thin-film transistors. J. Non-Cryst. Solids 2008, 354, 2826–2830. [Google Scholar] [CrossRef]

- Kim, G.H.; Ahn, B.D.; Shin, H.S.; Jeong, W.H.; Kim, H.J.; Kim, H.J. Effect of indium composition ratio on solution-processed nanocrystalline InGaZnO thin film transistors. Appl. Phys. Lett. 2009, 94, 233501. [Google Scholar] [CrossRef]

- Kamiya, T.; Nomura, K.; Hosono, H. Present status of amorphous In–Ga–Zn–O thin-film transistors. Sci. Technol. Adv. Mater. 2010, 11, 044305. [Google Scholar] [CrossRef] [PubMed]

- Furuta, M.; Kawaharamura, T.; Wang, D.; Toda, T.; Hirao, T. Electrical properties of the thin-film transistor with an indium-gallium-zinc oxide channel and an aluminium oxide gate dielectric stack formed by solution-based atmospheric pressure deposition. IEEE Electron Device Lett. 2012, 33, 851–853. [Google Scholar] [CrossRef]

- Urakawa, S.; Tomai, S.; Ueoka, Y.; Yamazaki, H.; Kasami, M.; Yano, K.; Wang, D.; Furuta, M.; Horita, M.; Ishikawa, Y.; et al. Thermal analysis of amorphous oxide thin-film transistor degraded by combination of joule heating and hot carrier effect. Appl. Phys. Lett. 2013, 102, 053506. [Google Scholar] [CrossRef]

- Wager, J.F. Transparent electronics. Science 2003, 300, 1245–1246. [Google Scholar] [CrossRef]

- Fortunato, E.; Barquinha, P.; Martins, R. Oxide Semiconductor thin-film transistors: A review of recent advances. Adv. Mater. 2012, 24, 2945–2986. [Google Scholar] [CrossRef]

- Kimura, M. Emerging applications using metal-oxide semiconductor thin-film devices. Jpn. J. Appl. Phys. 2019, 58, 090503. [Google Scholar] [CrossRef]

- Hsieh, H.-H.; Lu, H.-H.; Ting, H.-C.; Chuang, C.-S.; Chen, C.-Y.; Lin, Y. Development of IGZO TFTs and their applications to next-generation flat-panel displays. J. Information Display 2010, 11, 160–164. [Google Scholar] [CrossRef]

- Jeong, J.K.; Jeong, J.H.; Choi, J.H.; Im, J.S.; Kim, S.H.; Yang, H.W.; Kang, K.N.; Kim, K.S.; Ahn, T.K.; Chung, H.J.; et al. 12.1-inch WXGA AMOLED display driven by indium-gallium-zinc oxide TFTs array. SID Symp. Dig. Tech. Pap. 2008, 39, 1–4. [Google Scholar] [CrossRef]

- Lee, J.-H.; Kim, D.-H.; Yang, D.-J.; Hong, S.-Y.; Yoon, K.-S.; Hong, P.-S.; Jeong, C.-O.; Park, H.-S.; Kim, S.Y.; Lim, S.K.; et al. World’s largest (15-inch) XGA AMLCD panel using IGZO oxide TFT. SID Symp. Dig. Tech. Pap. 2008, 39, 625–628. [Google Scholar] [CrossRef]

- Kimura, M.; Imai, S. Degradation evaluation of α-IGZO TFTs for application to AM-OLEDs. IEEE Electron Device Lett. 2010, 31, 963–965. [Google Scholar] [CrossRef]

- Bermundo, J.P.; Ishikawa, Y.; Yamazaki, H.; Nonaka, T.; Uraoka, Y. Highly reliable polysilsesquioxane passivation layer for a-InGaZnO thin-film transistors. ECS J. Solid State Sci. Technol. 2014, 3, Q16–Q19. [Google Scholar] [CrossRef]

- Yabuta, H.; Sano, M.; Abe, K.; Aiba, T.; Den, T.; Kumomi, H. High-mobility thin-film transistor with amorphous InGaZnO4 channel fabricated by room temperature rf-magnetron sputtering. Appl. Phys. Lett. 2006, 89, 112123. [Google Scholar] [CrossRef]

- Kawaharamura, T. Physics on development of open-air atmospheric pressure thin film fabrication technique using mist droplets: Control of precursor flow. Jpn. J. Appl. Phys. 2014, 53, 05FF08. [Google Scholar] [CrossRef]

- Yamazaki, S.; Koyama, J.; Yamamoto, Y.; Okamoto, K. Research, development, and application of crystalline oxide semi-conductor. SID Symp. Dig. Tech. Pap. 2012, 43, 183–186. [Google Scholar] [CrossRef]

- Yamauchi, Y.; Kamakura, Y.; Isagi, Y.; Matsuoka, T.; Malotaux, S. Study of novel floating-gate oxide semiconductor memory using indium-gallium-zinc oxide for low-power system-on-panel applications. Jpn. J. Appl. Phys. 2013, 52, 094101. [Google Scholar] [CrossRef]

- Kaneko, K.; Inoue, N.; Saito, S.; Furutake, N.; Sunamura, H.; Kawahara, J.; Hane, M.; Hayashi, Y. Highly reliable BEOL-transistor with oxygen-controlled InGaZnO and gate/drain offset design for high/low voltage bridging I/O operations. In Proceedings of the 2011 International Electron Devices Meeting, Washington, DC, USA, 5–7 December 2011. [Google Scholar]

- Lyu, R.-J.; Chiu, Y.-H.; Lin, H.-C.; Li, P.-W.; Huang, T.-Y. High-gain, low-voltage BEOL logic gate inverter built with film profile engineered IGZO transistors. In Proceedings of the 2016 International Symposium on VLSI Technology, Systems and Application (VLSI-TSA), Hsinchu, Taiwan, 25–27 April 2016. [Google Scholar]

- Ohta, H.; Huang, R.; Ikuhara, Y. Large enhancement of the thermoelectric Seebeck coefficient for amorphous oxide semiconductor superlattices with extremely thin conductive layers. Phys. Status Solidi RRL 2008, 2, 105–107. [Google Scholar] [CrossRef]

- Fujimoto, Y.; Uenuma, M.; Ishikawa, Y.; Uraoka, Y. Analysis of thermoelectric properties of amorphous InGaZnO thin film by controlling carrier concentration. AIP Adv. 2015, 5, 097209. [Google Scholar] [CrossRef]

- Matsuda, T.; Umeda, K.; Kato, Y.; Nishimoto, D.; Furuta, M.; Kimura, M. Rare-metal-free high-performance Ga-Sn-O thin film transistor. Sci. Rep. 2017, 7, srep44326. [Google Scholar] [CrossRef] [PubMed]

- Matsuda, T.; Takagi, R.; Umeda, K.; Kimura, M. Room-temperature fabrication of Ga-Sn-O thin-film transistors. Solid State Electron. 2017, 134, 19–21. [Google Scholar] [CrossRef]

- Matsuda, T.; Uenuma, M.; Kimura, M. Thermoelectric effect of amorphous Ga-Sn-O thin film. Jpn. J. Appl. Phys. 2017, 56, 070309. [Google Scholar] [CrossRef]

- Kimura, M.; Koga, Y.; Nakanishi, H.; Matsuda, T.; Kameda, T.; Nakashima, Y. In-Ga-Zn-O thin-film devices as synapse elements in a neural network. IEEE J. Electron Devices Soc. 2017, 6, 100–105. [Google Scholar] [CrossRef]

- Kimura, M.; Umeda, K.; Ikushima, K.; Hori, T.; Tanaka, R.; Shimura, J.; Kondo, A.; Tsuno, T.; Sugisaki, S.; Kurasaki, A.; et al. Neuromorphic system with crosspoint-type amorphous Ga-Sn-O thin-film devices as self-plastic synapse elements. ECS Trans. 2019, 90, 157–166. [Google Scholar] [CrossRef]

- Haxel, G.B.; Hedrick, J.B.; Orris, G.J. Rare earth elements - critical resources for high technology. U.S. Geol. Surv. Fact Sheet 2002. [Google Scholar] [CrossRef]

- Chua, L. Memristor—The missing circuit element. IEEE Trans. Circuit Theory 1971, 18, 507–519. [Google Scholar] [CrossRef]

- Strukov, D.B.; Snider, G.S.; Stewart, D.R.; Williams, R.S. The missing memristor found. Nature 2008, 453, 80–83. [Google Scholar] [CrossRef]

- Prezioso, M.; Merrikh-Bayat, F.; Hoskins, B.D.; Adam, G.C.; Likharev, K.K.; Strukov, D.B. Training and operation of an integrated neuromorphic network based on metal-oxide memristors. Nature 2015, 521, 61–64. [Google Scholar] [CrossRef] [PubMed]

- Covi, E.; Brivio, S.; Serb, A.; Prodromakis, T.; Fanciulli, M.; Spiga, S. HfO2-based memristors for neuromorphic applications. In Proceedings of the 2016 IEEE International Symposium on Circuits and Systems (ISCAS), Montreal, QC, Canada, 22–25 May 2016. [Google Scholar]

- Kawahara, A.; Azuma, R.; Ikeda, Y.; Kawai, K.; Katoh, Y.; Hayakawa, Y.; Tsuji, K.; Yoneda, S.; Himeno, A.; Shimakawa, K.; et al. An 8 Mb multi-layered cross-point ReRAM macro with 443 MB/s write throughput. IEEE J. Solid-State Circuits 2013, 48, 178–185. [Google Scholar] [CrossRef]

- Wei, Z.; Kanzawa, Y.; Arita, K.; Katoh, Y.; Kawai, K.; Muraoka, S.; Mitani, S.; Fujii, S.; Katayama, K.; Iijima, M.; et al. Highly reliable TaOx ReRAM and direct evidence of redox reaction mechanism. In Proceedings of the 2008 IEEE International Electron Devices Meeting, San Francisco, CA, USA, 15–17 December 2008. [Google Scholar]

- Sugisaki, S.; Matsuda, T.; Uenuma, M.; Nabatame, T.; Nakashima, Y.; Imai, T.; Magari, Y.; Koretomo, D.; Furuta, M.; Kimura, M. Memristive characteristic of an amorphous Ga-Sn-O thin-film device. Sci. Rep. 2019, 9, 2757. [Google Scholar] [CrossRef] [PubMed]

| Ar:O2 | (sccm) | 20:0 | 20:10 |

| Electrical conductivity | (S cm−1) | 1.35 | <10−4 |

| Free carrier | (e− or h+) | e− | e− |

| Carrier density | (cm−3) | 7.74 × 1017 | Determination impossible |

| Hall mobility | (cm2 V−1 s−1) | 10.9 |

| Ar:O2 | 20:0 | 20:10 |

| O/Sn (O 1s)/(Sn 3d3/2 + Sn 3d5/2) | 0.220 | 0.259 |

| Distorted-bond/O (Distorted-bond)/(O 1s) | 0.575 | 0.814 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurasaki, A.; Tanaka, R.; Sugisaki, S.; Matsuda, T.; Koretomo, D.; Magari, Y.; Furuta, M.; Kimura, M. Memristive Characteristic of an Amorphous Ga-Sn-O Thin-Film Device with Double Layers of Different Oxygen Density. Materials 2019, 12, 3236. https://doi.org/10.3390/ma12193236

Kurasaki A, Tanaka R, Sugisaki S, Matsuda T, Koretomo D, Magari Y, Furuta M, Kimura M. Memristive Characteristic of an Amorphous Ga-Sn-O Thin-Film Device with Double Layers of Different Oxygen Density. Materials. 2019; 12(19):3236. https://doi.org/10.3390/ma12193236

Chicago/Turabian StyleKurasaki, Ayata, Ryo Tanaka, Sumio Sugisaki, Tokiyoshi Matsuda, Daichi Koretomo, Yusaku Magari, Mamoru Furuta, and Mutsumi Kimura. 2019. "Memristive Characteristic of an Amorphous Ga-Sn-O Thin-Film Device with Double Layers of Different Oxygen Density" Materials 12, no. 19: 3236. https://doi.org/10.3390/ma12193236

APA StyleKurasaki, A., Tanaka, R., Sugisaki, S., Matsuda, T., Koretomo, D., Magari, Y., Furuta, M., & Kimura, M. (2019). Memristive Characteristic of an Amorphous Ga-Sn-O Thin-Film Device with Double Layers of Different Oxygen Density. Materials, 12(19), 3236. https://doi.org/10.3390/ma12193236