Moisture Susceptibility Evaluation of Asphalt Mixtures Containing Steel Slag Powder as Filler

Abstract

1. Introduction

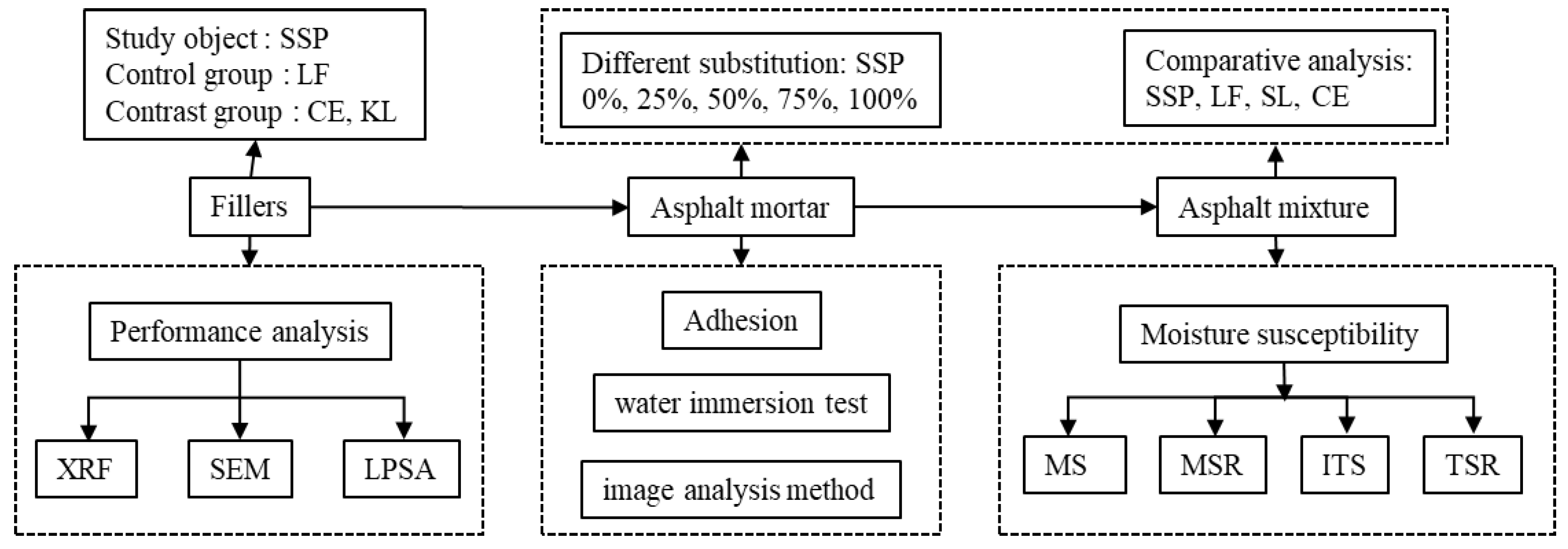

2. Materials and Methods

2.1. Raw Materials

2.1.1. Asphalt Binder

2.1.2. Fillers and Aggregate

2.1.3. Preparation of Asphalt Mortar

2.2. Experimental Methods

2.2.1. Fillers and Aggregate Characteristics

2.2.2. Marshall Mixtures Design Method

2.2.3. Adhesion of Asphalt Mortar and Aggregate

2.2.4. Moisture Damage Resistance of Asphalt Mixtures

3. Results and Discussion

3.1. Filler Characteristics

3.1.1. Surface Characteristics

3.1.2. Chemical Compositions

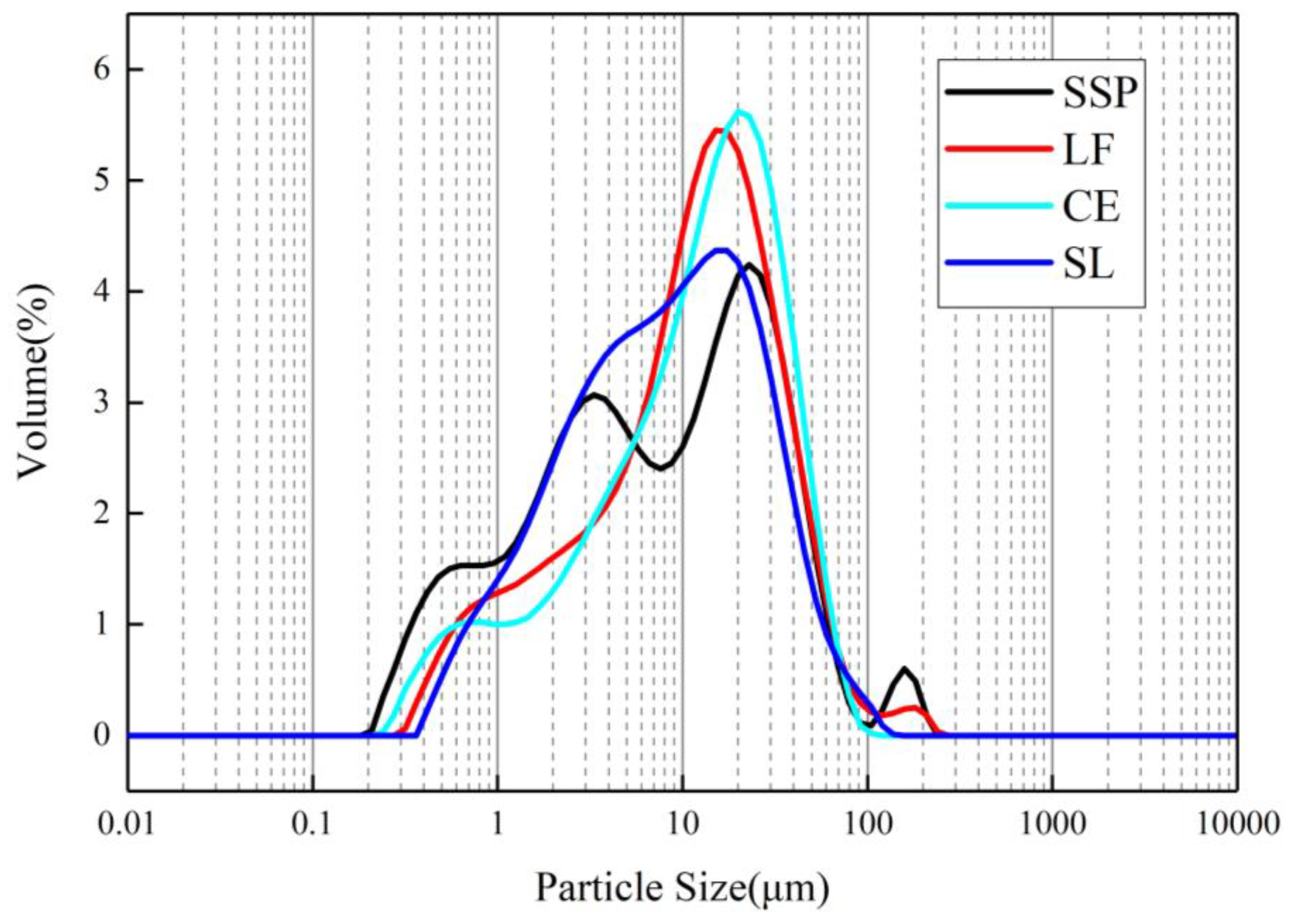

3.1.3. Particle Size Distributions

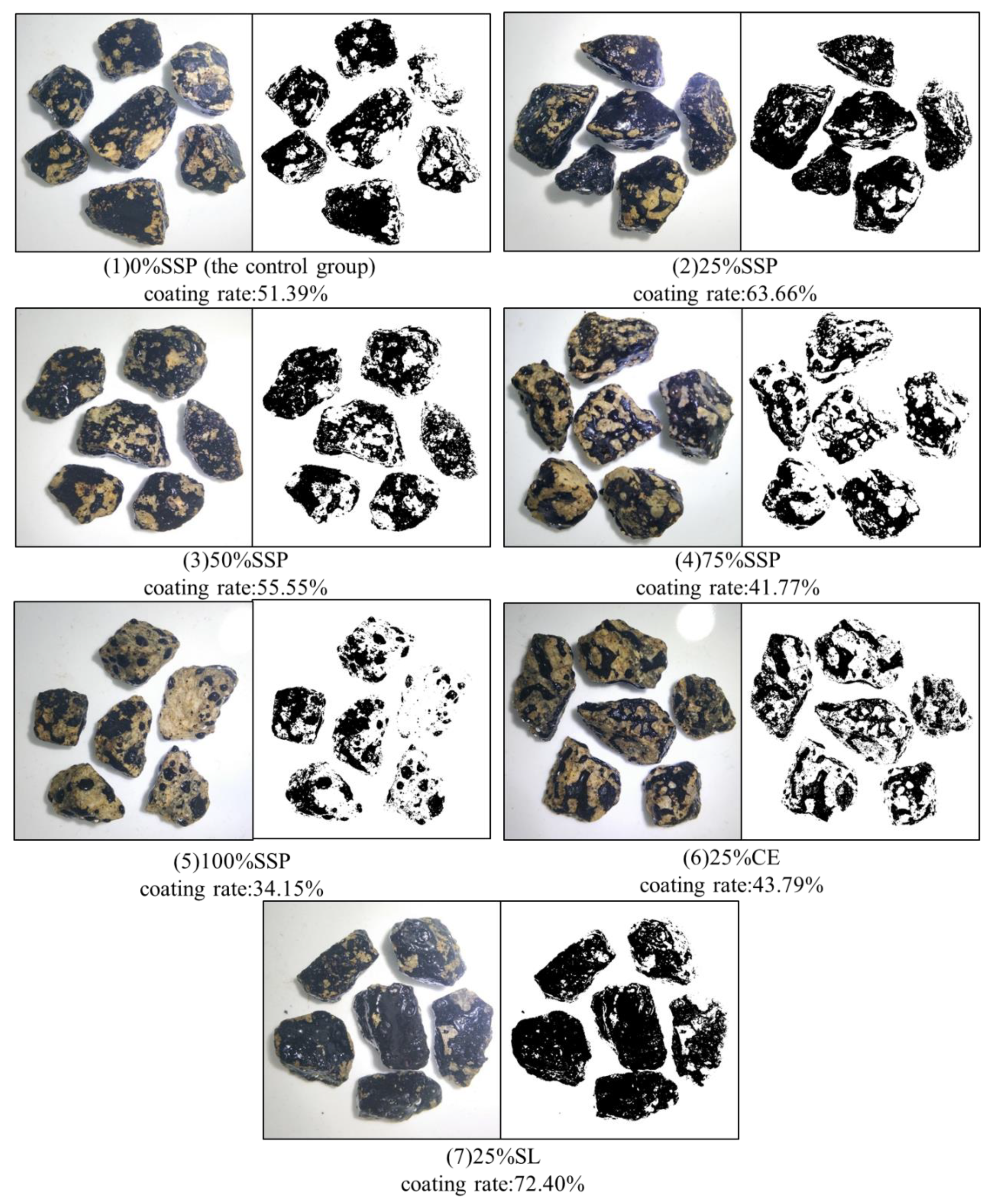

3.2. Adhesion of Asphalt and Aggregate

3.3. Moisture Damage Resistance of Asphalt Mixtures

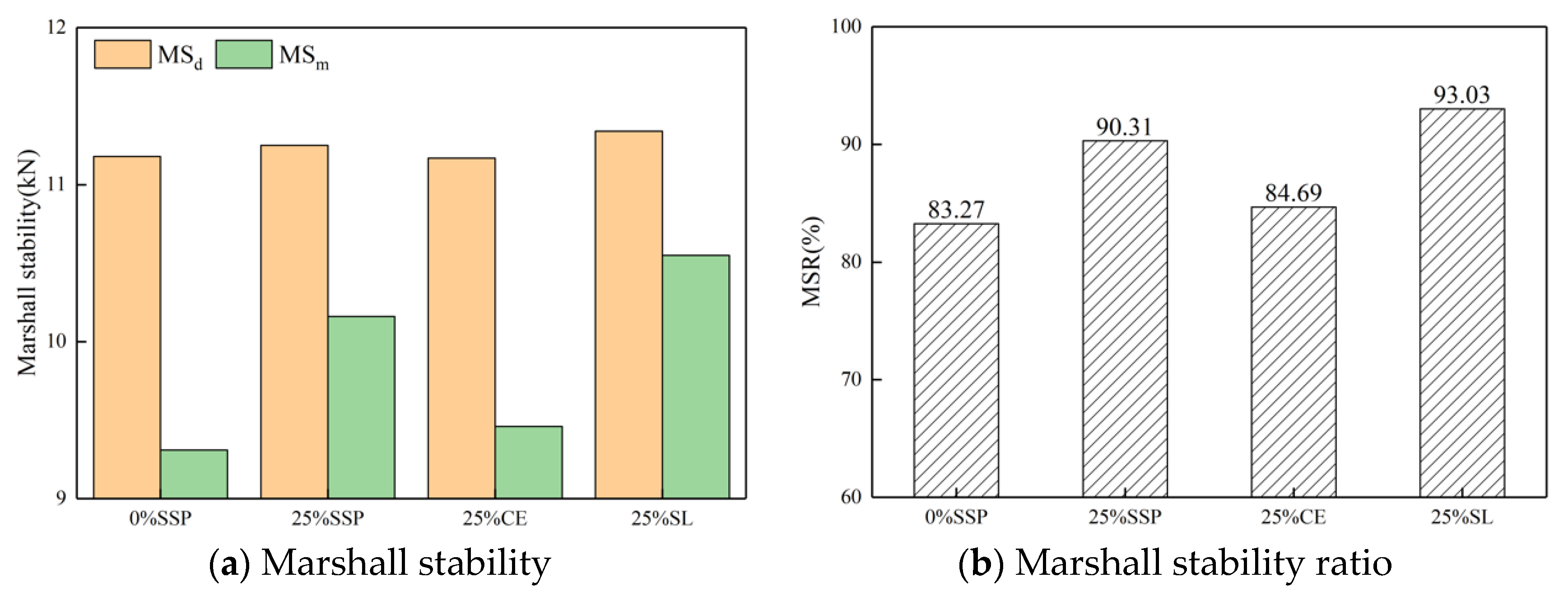

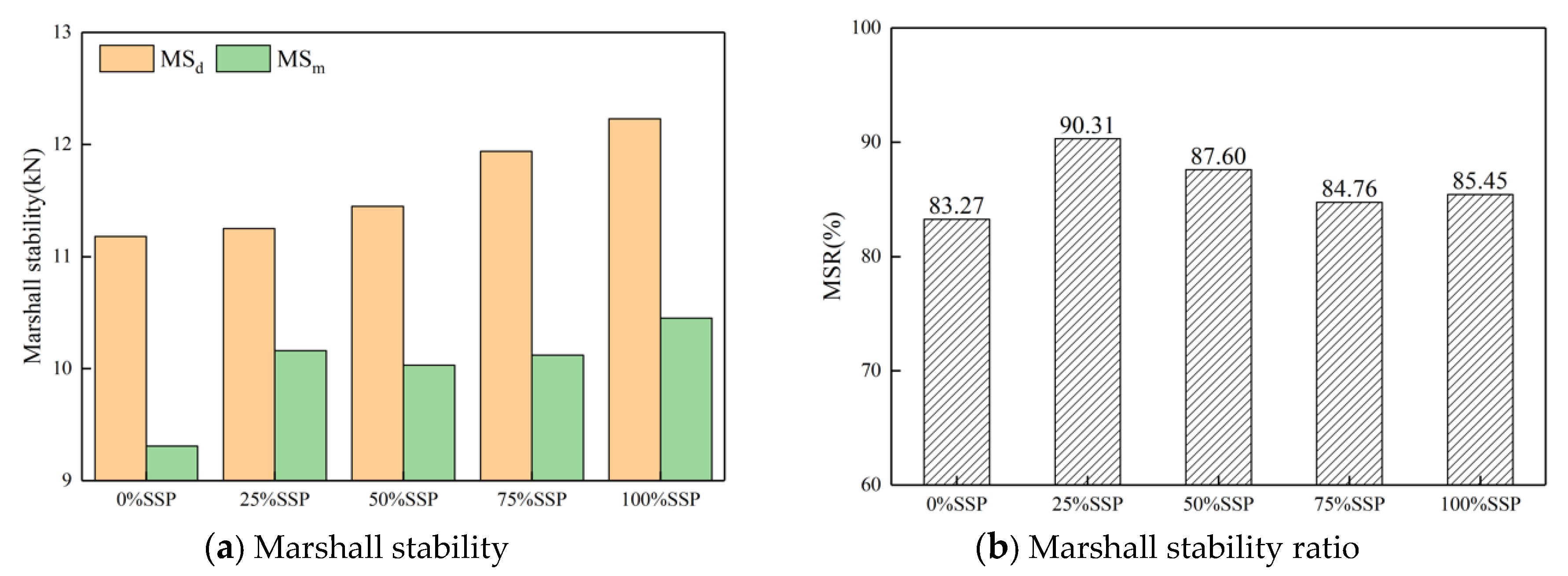

3.3.1. Marshall Stability and Marshall Stability Ratio

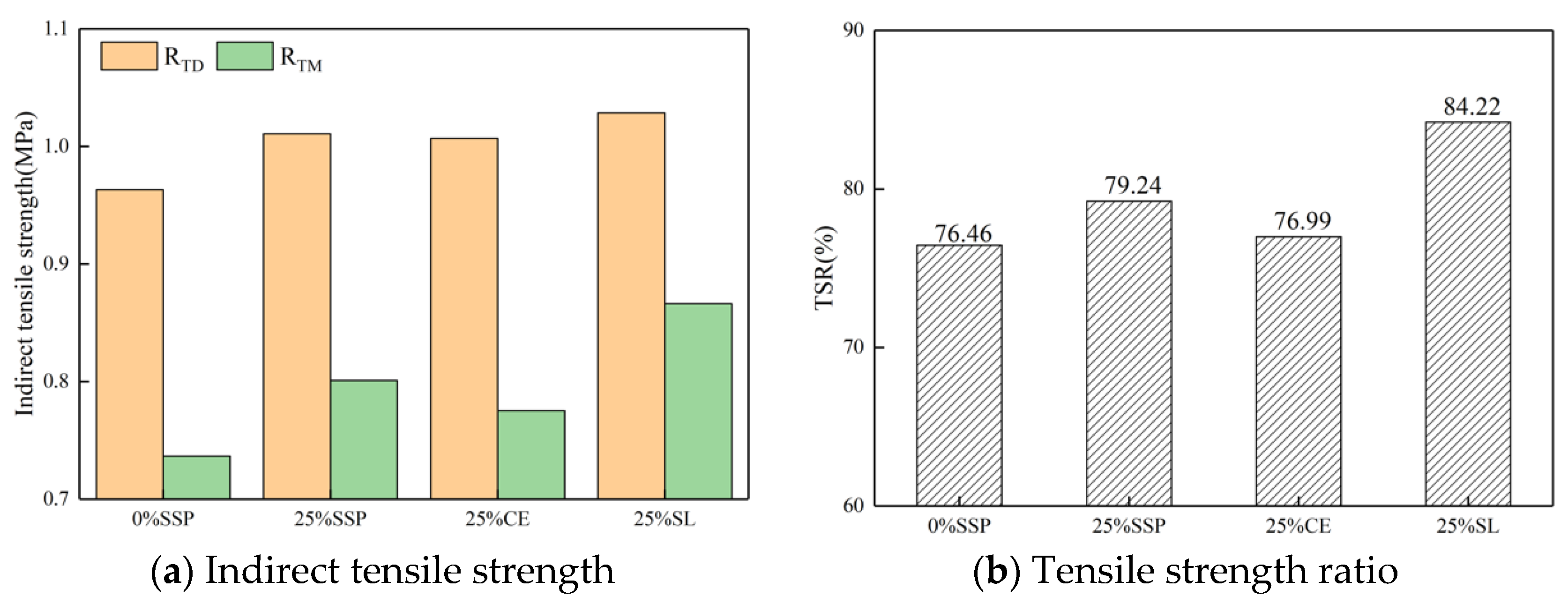

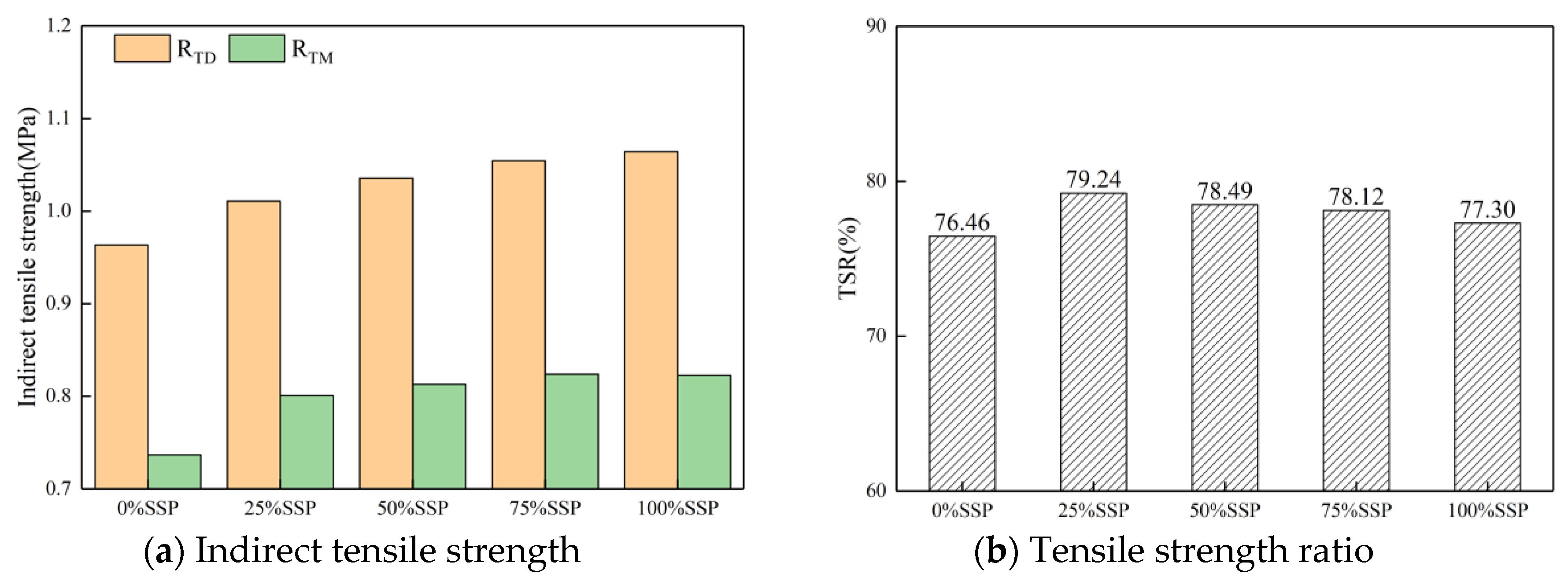

3.3.2. Indirect Tensile Strength and Tensile Strength Ratio

4. Conclusions

- (1)

- The effective CaO content of SSP is higher than that of limestone filler but lower than that of cement and hydrated lime, indicating that it is a high alkalinity slag filler with potential activity. However, the large amount of iron contained in SSP may have adverse effects on the moisture damage resistance of asphalt mixtures. The SSP has a rougher surface texture with obvious lumps or holes, and also has a finer particle size compared with LF and CE. The specific surface area of SSP is significantly higher than that of the other three fillers, which means that its contact area with asphalt is larger, and consequently, that it affects the performance of the asphalt mixtures.

- (2)

- SSP and SL can improve the adhesion between asphalt and aggregate under the same substitution, but CE has the opposite effect. The 25% SL group exhibits the best anti-stripping performance with 72.4% asphalt coverage rate, compared to an asphalt coating rate of 43.79% for the 25% CE group; this value is 51.39% for the control group (0% SSP group). Under the same substitution, the asphalt mixtures with SSP have a 63.66% asphalt coverage rate after water immersion treatment, which will gradually decrease with the increase of the substitution amount. The asphalt coverage rate will be reduced to 34.15% when SSP replaces LF by 100%.

- (3)

- It was found that the replacement of LF by CE, SL, and SSP with the same substitution amount (25%) had little effect on Marshall stability and indirect tensile strength without water treatment, and that the increase of SSP replacement amount promotes the growth of MS and ITS. After the water treatment, the effect of CE, SL, and SSP on improving water damage resistance will become more prominent, and the three fillers can resist the reduction of water on the performance of mixtures, which is attributed to their improvement of asphalt-aggregate adhesion. The effect of slaked lime on improving water damage resistance is the most obvious. Compared with the control group (0% SSP group), the value of MSR and TSR of the mixtures mixed with SL were improved by 11.72% and 10.15%, respectively. The effect of cement on improving water damage resistance was slightly worse. SSP had a positive effect on improving the water stability of asphalt mixture, but with the increase of substitution amount, MSR and TSR decreased; the optimal dosage is 25%. Nevertheless, the addition of SSP improved the water damage resistance of asphalt mixtures compared to the whole LP group, regardless of the amount of substitution.

- (4)

- Both the water immersion test and the water stability test indicated that the SSP could replace part of the limestone filler as a filler, but that the substitution amount should not be too great. In this experiment, the best substitution amount of SSP was found to be 25% of the total volume of fillers.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, J.; Sun, C.; Li, P.; Liang, M.; Jiang, H.; Yao, Z. Experimental study on rheological properties and moisture susceptibility of asphalt mastic containing red mud waste as a filler substitute. Constr. Build. Mater. 2019, 211, 159–166. [Google Scholar] [CrossRef]

- Oliveira, J.R.; Silva, H.M.; Abreu, L.P.; Fernandes, S.R. Use of a warm mix asphalt additive to reduce the production temperatures and to improve the performance of asphalt rubber mixtures. J. Clean. Prod. 2013, 41, 15–22. [Google Scholar] [CrossRef]

- Simone, A.; Mazzotta, F.; Eskandarsefat, S.; Sangiorgi, C.; Vignali, V.; Lantieri, C.; Dondi, G. Experimental Application of Waste Glass Powder Filler in Recycled Dense-Graded Asphalt Mixtures. Road Mater. Pavement 2019, 20, 592–607. [Google Scholar] [CrossRef]

- Pasandín, A.R.; Pérez, I.P.; Oliveira, J.R.; Silva, H.M.; Pereira, P.A.; Pasandín, A.M.R. Influence of ageing on the properties of bitumen from asphalt mixtures with recycled concrete aggregates. J. Clean. Prod. 2015, 101, 165–173. [Google Scholar] [CrossRef]

- Moghadas Nejad, F.; Azarhoosh, A.; Hamedi, G.H.; Roshani, H. Rutting Performance Prediction of Warm Mix Asphalt Containing Reclaimed Asphalt Pavements. Road Mater. Pavement 2014, 15, 207–219. [Google Scholar] [CrossRef]

- Antunes, V.; Freire, A.C.; Quaresma, L.; Micaelo, R. Evaluation of waste materials as alternative sources of filler in asphalt mixtures. Mater. Struct. 2017, 50, 254. [Google Scholar] [CrossRef]

- Bocci, E. Use of ladle furnace slag as filler in hot asphalt mixtures. Constr. Build. Mater. 2018, 161, 156–164. [Google Scholar] [CrossRef]

- Li, J.F.; Luo, X.C.; Sun, M.K.; Shen, W.G.; Cao, B.; Li, X.L. Utilization of Steel Slags in the Cement Industry. Key Eng. Mater. 2014, 599, 98–102. [Google Scholar] [CrossRef]

- Reddy, A.S.; Pradhan, R.; Chandra, S. Utilization of Basic Oxygen Furnace (BOF) slag in the production of a hydraulic cement binder. Int. J. Miner. Process. 2006, 79, 98–105. [Google Scholar] [CrossRef]

- Shen, D.-H.; Wu, C.-M.; Du, J.-C. Laboratory investigation of basic oxygen furnace slag for substitution of aggregate in porous asphalt mixture. Constr. Build. Mater. 2009, 23, 453–461. [Google Scholar] [CrossRef]

- Chen, Z.; Wu, S.; Xiao, Y.; Zeng, W.; Yi, M.; Wan, J. Effect of hydration and silicone resin on Basic Oxygen Furnace slag and its asphalt mixture. J. Clean. Prod. 2016, 112, 392–400. [Google Scholar] [CrossRef]

- Amelian, S.; Manian, M.; Abtahi, S.M.; Goli, A. Moisture sensitivity and mechanical performance assessment of warm mix asphalt containing by-product steel slag. J. Clean. Prod. 2018, 176, 329–337. [Google Scholar] [CrossRef]

- Li, C.; Chen, Z.; Wu, S.; Li, B.; Xie, J.; Xiao, Y. Effects of steel slag fillers on the rheological properties of asphalt mastic. Constr. Build. Mater. 2017, 145, 383–391. [Google Scholar] [CrossRef]

- Tao, G.; Xiao, Y.; Yang, L.; Cui, P.; Kong, D.; Xue, Y. Characteristics of steel slag filler and its influence on rheological properties of asphalt mortar. Constr. Build. Mater. 2019, 201, 439–446. [Google Scholar] [CrossRef]

- Mirhosseini, S.F.; Khabiri, M.; Kavussi, A.; Kamali, M.J.; Kamali, M.H.J. Applying surface free energy method for evaluation of moisture damage in asphalt mixtures containing date seed ash. Constr. Build. Mater. 2016, 125, 408–416. [Google Scholar] [CrossRef]

- Badru, M.; Roberts, F.L. Stripping in Hma Mixtures: State of the Art and Critical Review of Test Methods; National Center for Asphalt Technology, Auburn University: Auburn, AL, USA, 1988. [Google Scholar]

- Cala, A.; Caro, S.; Lleras, M.; Rojas-Agramonte, Y. Impact of the chemical composition of aggregates on the adhesion quality and durability of asphalt-aggregate systems. Constr. Build. Mater. 2019, 216, 661–672. [Google Scholar] [CrossRef]

- Ameri, M.; Vamegh, M.; Naeni, S.F.C.; Molayem, M. Moisture susceptibility evaluation of asphalt mixtures containing Evonik, Zycotherm and hydrated lime. Constr. Build. Mater. 2018, 165, 958–965. [Google Scholar] [CrossRef]

- ASTM. D3625-96: Standard Practice for Effect of Water on Bituminous-Coated Aggregate Using Boiling Water; Book of Standards; ASTM International: West Conshohocken, PA, USA, 2005; p. 4. [Google Scholar]

- Zeng, M.L.; Luo, L.W.; Liu, T. Improving Moisture Susceptibility of Granite Asphalt Mixture Using Different Additives. J. Hum. Univ. 2005, 32, 119–122. [Google Scholar]

- Huang, B.; Shu, X.; Dong, Q.; Shen, J. Laboratory Evaluation of Moisture Susceptibility of Hot-Mix Asphalt Containing Cementitious Fillers. J. Mater. Civ. Eng. 2010, 22, 667–673. [Google Scholar] [CrossRef]

- Khodaii, A.; Tehrani, H.K.; Haghshenas, H. Hydrated lime effect on moisture susceptibility of warm mix asphalt. Constr. Build. Mater. 2012, 36, 165–170. [Google Scholar] [CrossRef]

- Sebaaly, P.E.; Little, D.N.; Epps, J.A. The Benefits of Hydrated Lime in Hot Mix Asphalt; The National Lime Association: Arlington, VA, USA, 2006. [Google Scholar]

- Chen, Z.; Jiao, Y.; Wu, S.; Tu, F. Moisture-induced damage resistance of asphalt mixture entirely composed of gneiss and steel slag. Constr. Build. Mater. 2018, 177, 332–341. [Google Scholar] [CrossRef]

- JTG E20-2011: Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering; Ministry of Transport: Beijing, China, 2011.

- JTG F40-2004: Technical Specifications for Construction of Highway Asphalt Pavements; Ministry of Transport: Beijing, China, 2004.

- Amelian, S.; Abtahi, S.M.; Hejazi, S.M. Moisture susceptibility evaluation of asphalt mixes based on image analysis. Constr. Build. Mater. 2014, 63, 294–302. [Google Scholar] [CrossRef]

- Pasandín, A.R.; Pérez, I.P.; Ramírez, A.; Cano, M.M.; Pasandín, A.M.R. Moisture damage resistance of hot-mix asphalt made with paper industry wastes as filler. J. Clean. Prod. 2016, 112, 853–862. [Google Scholar] [CrossRef]

- Craus, J.; Ishai, I.; Sides, A. Some Physico-Chemical Aspects of the Effect and the Role of the Filler in Bituminous Paving Mixtures; Paper Presented at the Association of Asphalt Paving Technologists Proc 1978; Technion-Israel Institute of Technology: Haifa, Israel, 1978. [Google Scholar]

- Kandhal, P.S. Moisture Susceptibility of Hma Mixes: Identification of Problem and Recommended Solutions; National Asphalt Pavement Association: Greenbelt, MD, USA, 1992. [Google Scholar]

- Ahmedzade, P.; Sengoz, B. Evaluation of steel slag coarse aggregate in hot mix asphalt concrete. J. Hazard. Mater. 2009, 165, 300–305. [Google Scholar] [CrossRef] [PubMed]

| Properties | AH-90 Asphalt | Standard [25] |

|---|---|---|

| Density (g/cm3) | 1.032 | T 0603-2011 |

| Penetration (25 °C, 0.1 mm) | 85 | T 0604-2011 |

| Softening point (°C) | 46 | T 0606-2011 |

| Ductility (10 °C, cm) | 165 | T 0605-2011 |

| Viscosity (135 °C, Pa·s) | 0.35 | T 0625-2011 |

| flash point (°C) | 278 | T 0611-2011 |

| Properties | LF | SSP | CE | SL |

|---|---|---|---|---|

| Density (g/cm3) | 2.691 | 3.735 | 3.125 | 2.24 |

| Hydrophilic coefficient | 0.716 | 0.693 | 0.746 | 0.578 |

| Water content (%) | 0.423 | 0.781 | 0.525 | 0.137 |

| Sample Numbers | 0% SSP | 25% SSP | 50% SSP | 75% SSP | 100% SSP | 25% CE | 25% SL |

|---|---|---|---|---|---|---|---|

| Filler constitution | 100% LF | 25% SSP + 75% LF | 50% SSP + 50% LF | 75% SSP + 25% LF | 100% SSP | 25%CE + 75% LF | 25%SL + 75% LF |

| Components | CaO | Fe2O3 | SiO2 | MgO | MnO | Al2O3 | SO3 | LOI | Others |

|---|---|---|---|---|---|---|---|---|---|

| Steel slag powder | 36.075 | 26.276 | 17.163 | 6.567 | 4.876 | 3.650 | 0.639 | 0.365 | 4.389 |

| Limestone filler | 55.539 | 0.094 | 1.769 | 0.534 | 0.166 | 0.036 | 41.838 | 0.024 | |

| Cement | 58.111 | 3.212 | 20.663 | 2.624 | 0.148 | 6.135 | 3.253 | 4.045 | 1.809 |

| Slaked lime | 73.256 | 0.693 | 0.752 | 0.120 | 24.927 | 0.252 | |||

| Granite | 2.678 | 3.573 | 67.065 | 1.064 | 0.091 | 14.976 | 0.033 | 1.287 | 9.233 |

| Particle Size Parameters | SSP | LF | CE | SL |

|---|---|---|---|---|

| d (0.1) | 0.814 | 1.464 | 1.468 | 1.549 |

| d (0.5) | 8.262 | 12.785 | 14.046 | 8.981 |

| d (0.9) | 41.283 | 41.163 | 41.205 | 35.561 |

| Average particle size of surface area (μm) | 2.485 | 4.195 | 3.956 | 4.034 |

| Average particle size of volume (μm) | 17.899 | 19.000 | 18.287 | 14.998 |

| Specific surface area (m2/g) | 2.41 | 1.43 | 1.52 | 1.49 |

| Mix Type | Number of Compaction | VV (%) | VMA (%) | MSR | TSR |

|---|---|---|---|---|---|

| 0%SSP | 75 | 5.10 | 15.80 | 83.27 | 76.46 |

| 50 | 6.55 | 17.05 | |||

| 25%SSP | 75 | 5.17 | 15.83 | 90.31 | 79.24 |

| 50 | 6.60 | 17.13 | |||

| 50%SSP | 75 | 5.15 | 15.83 | 87.60 | 78.50 |

| 50 | 6.63 | 17.13 | |||

| 75%SSP | 75 | 5.11 | 15.81 | 84.76 | 78.12 |

| 50 | 6.34 | 16.90 | |||

| 100%SSP | 75 | 5.13 | 15.83 | 85.45 | 77.30 |

| 50 | 6.57 | 17.10 | |||

| 25%CE | 75 | 5.12 | 15.82 | 84.69 | 77.00 |

| 50 | 6.45 | 17.00 | |||

| 25%SL | 75 | 5.18 | 15.86 | 93.03 | 84.22 |

| 50 | 6.63 | 17.17 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Z.; Chen, M.; Wu, S.; Xie, J.; Kong, D.; Qiao, Z.; Niu, C. Moisture Susceptibility Evaluation of Asphalt Mixtures Containing Steel Slag Powder as Filler. Materials 2019, 12, 3211. https://doi.org/10.3390/ma12193211

Xiao Z, Chen M, Wu S, Xie J, Kong D, Qiao Z, Niu C. Moisture Susceptibility Evaluation of Asphalt Mixtures Containing Steel Slag Powder as Filler. Materials. 2019; 12(19):3211. https://doi.org/10.3390/ma12193211

Chicago/Turabian StyleXiao, Zhifeng, Meizhu Chen, Shaopeng Wu, Jun Xie, Dezhi Kong, Zhi Qiao, and Changchang Niu. 2019. "Moisture Susceptibility Evaluation of Asphalt Mixtures Containing Steel Slag Powder as Filler" Materials 12, no. 19: 3211. https://doi.org/10.3390/ma12193211

APA StyleXiao, Z., Chen, M., Wu, S., Xie, J., Kong, D., Qiao, Z., & Niu, C. (2019). Moisture Susceptibility Evaluation of Asphalt Mixtures Containing Steel Slag Powder as Filler. Materials, 12(19), 3211. https://doi.org/10.3390/ma12193211