Maturity and Strength Development of Mortar with Antifreezing Admixture at Temperatures Lower than 0 °C

Abstract

1. Introduction

2. Experimental Design and Methods

2.1. Experimental Plan and Materials

2.2. Experimental Method

3. Experimental Results and Discussion

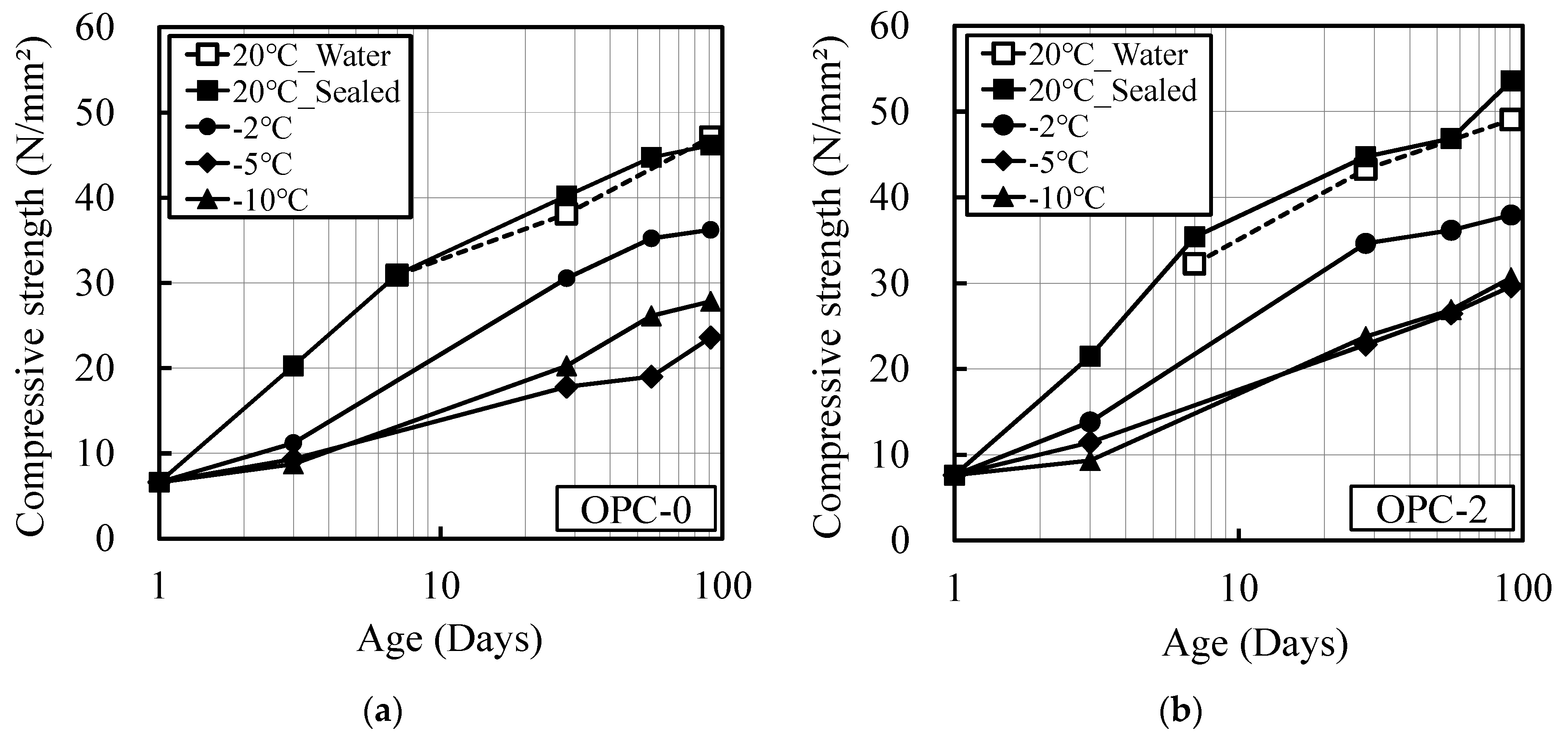

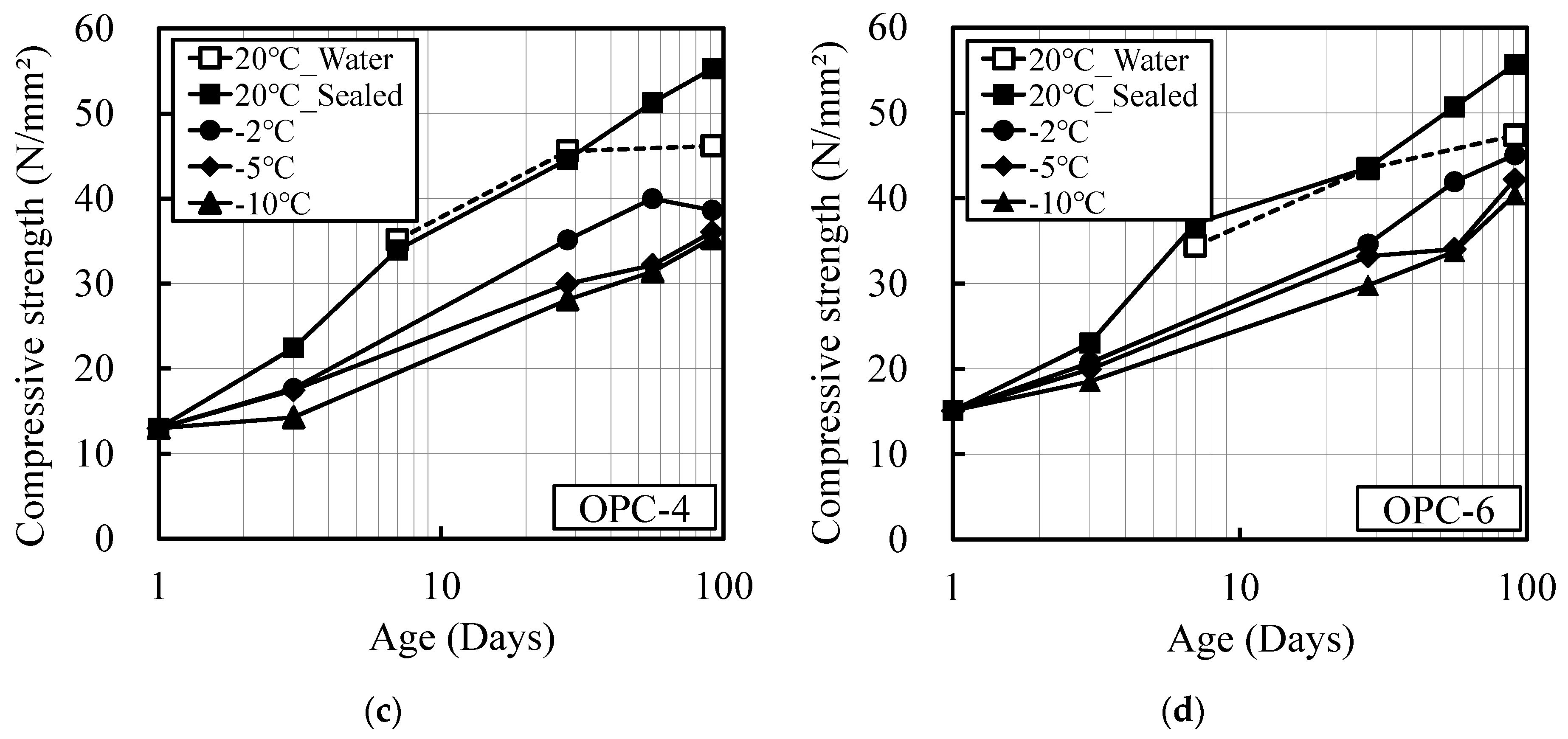

3.1. Relationship Between Age and Compressive Strength

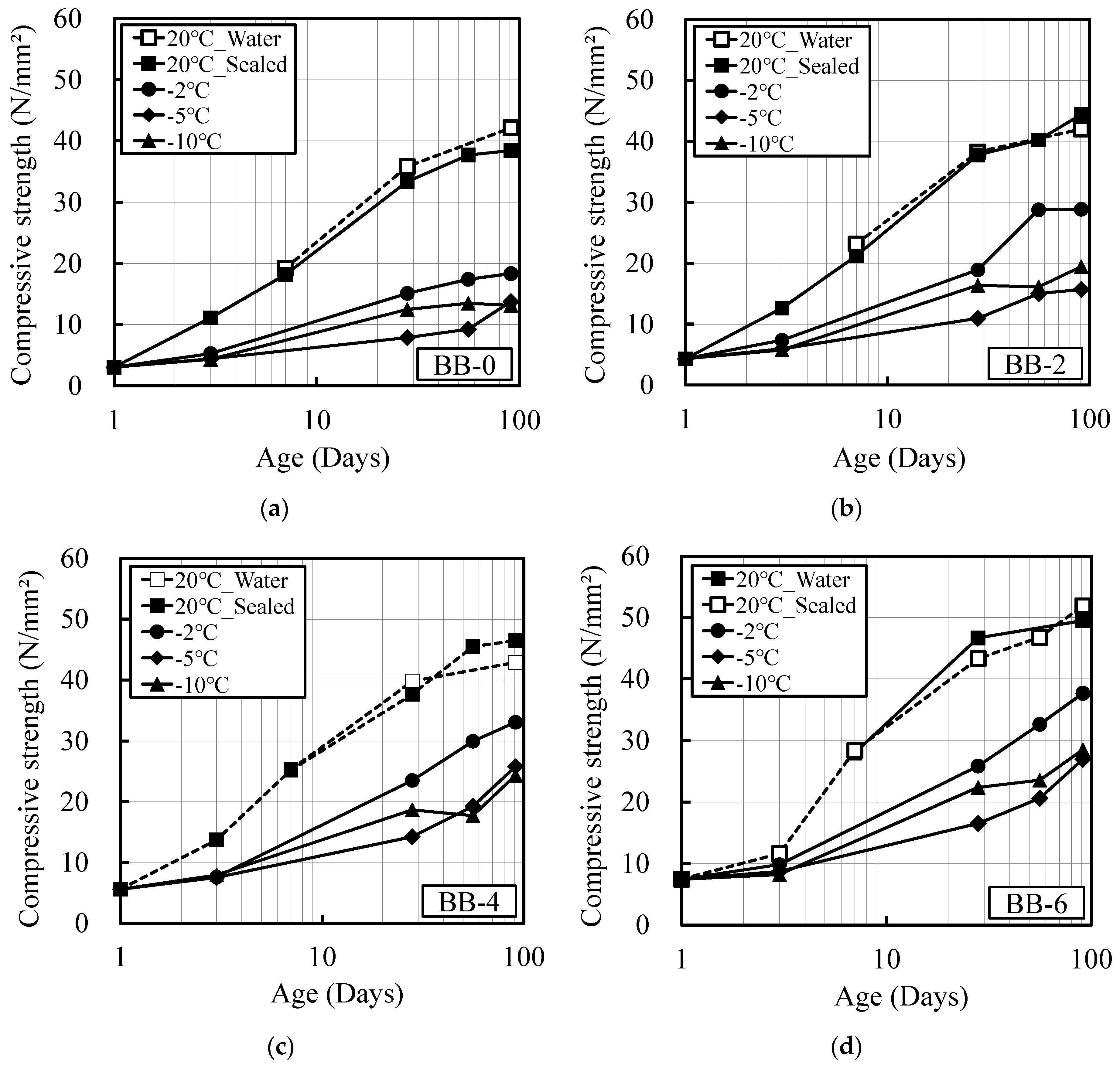

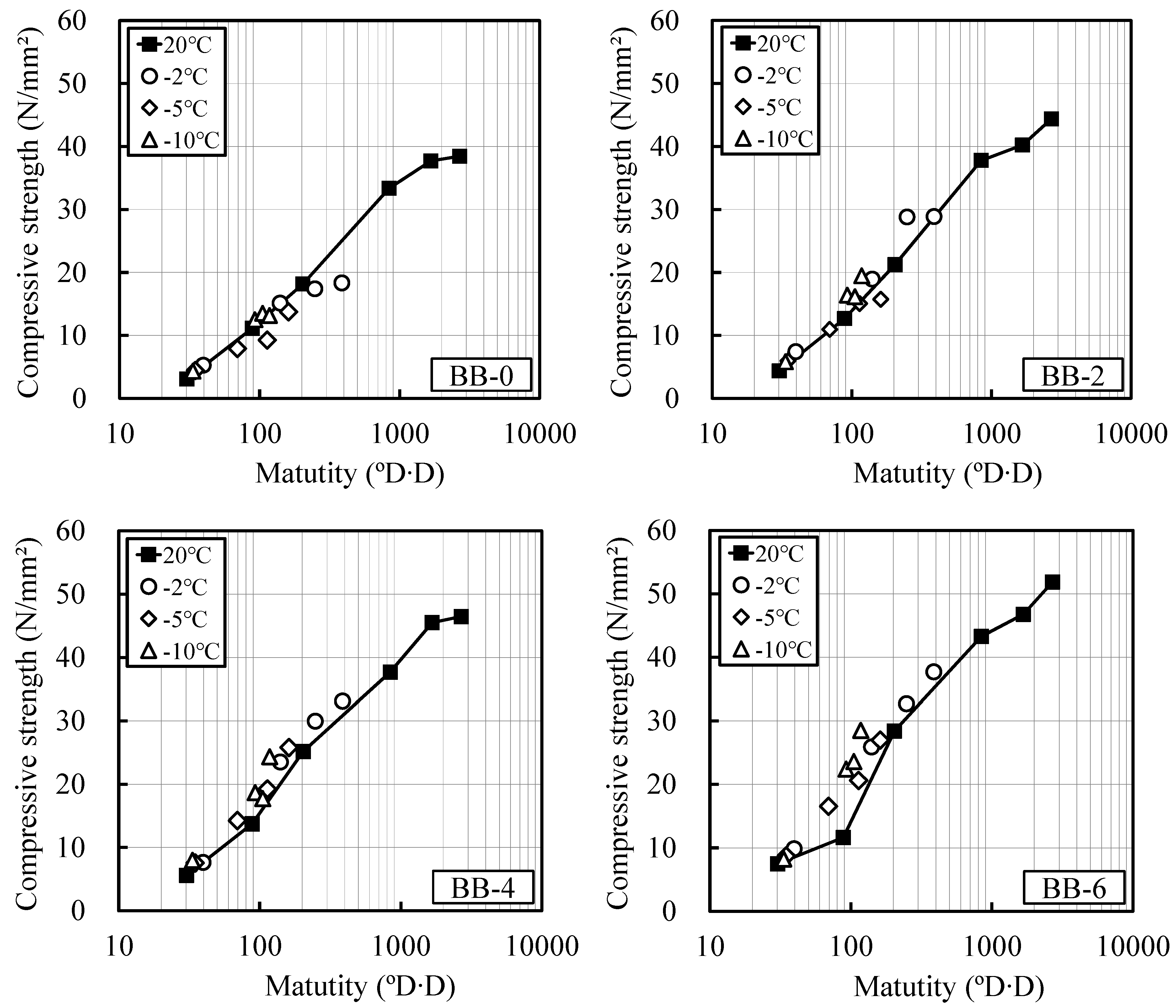

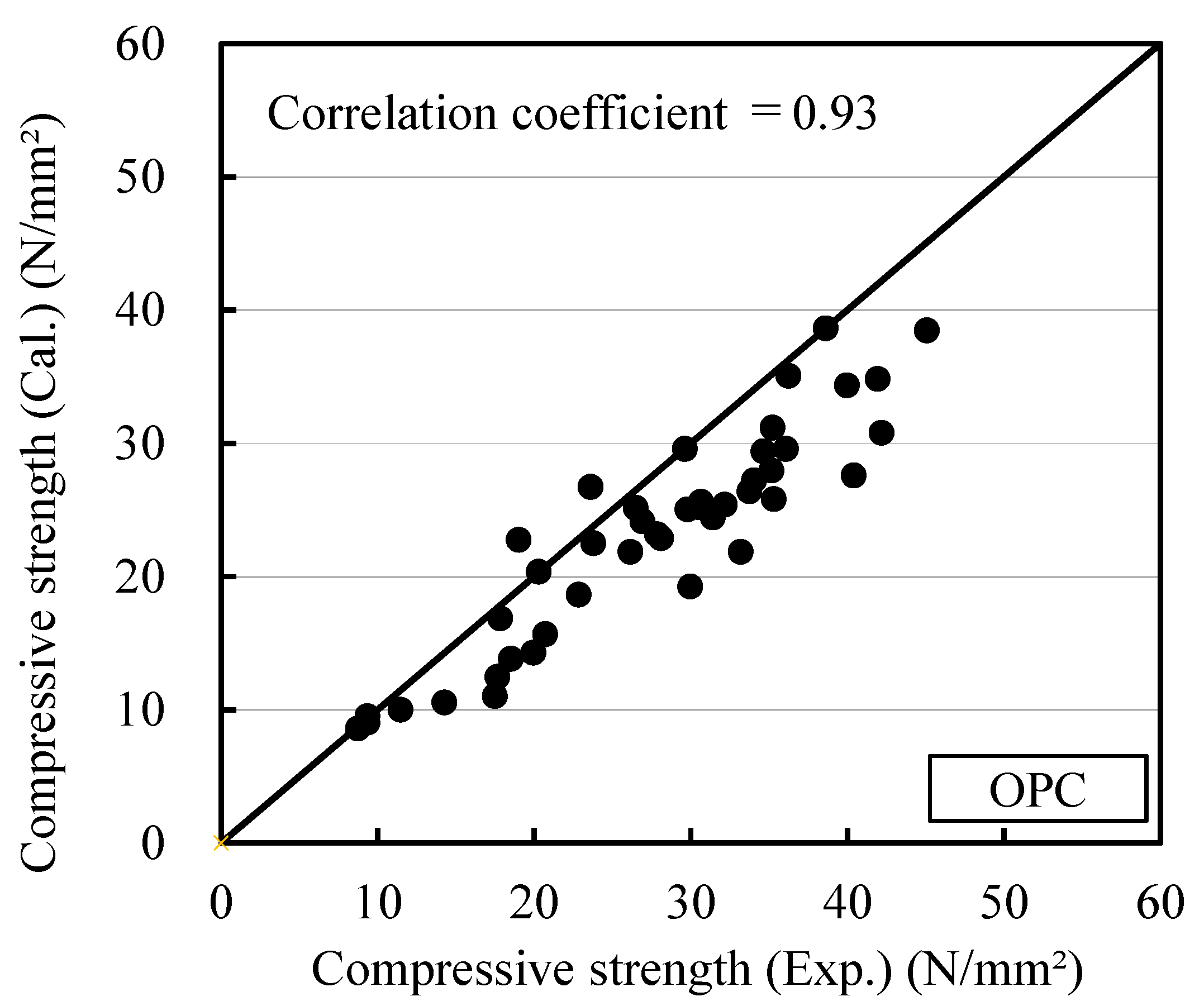

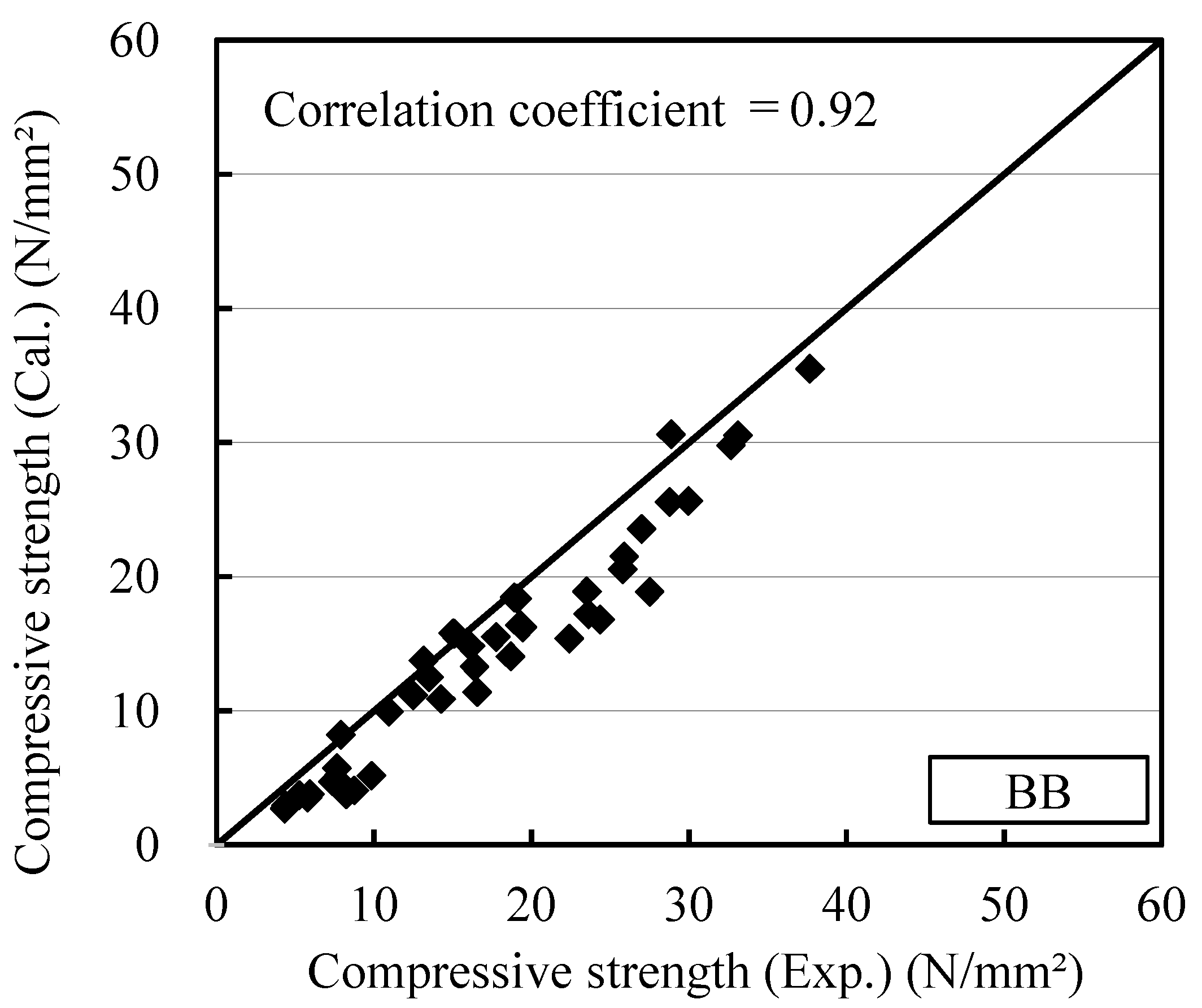

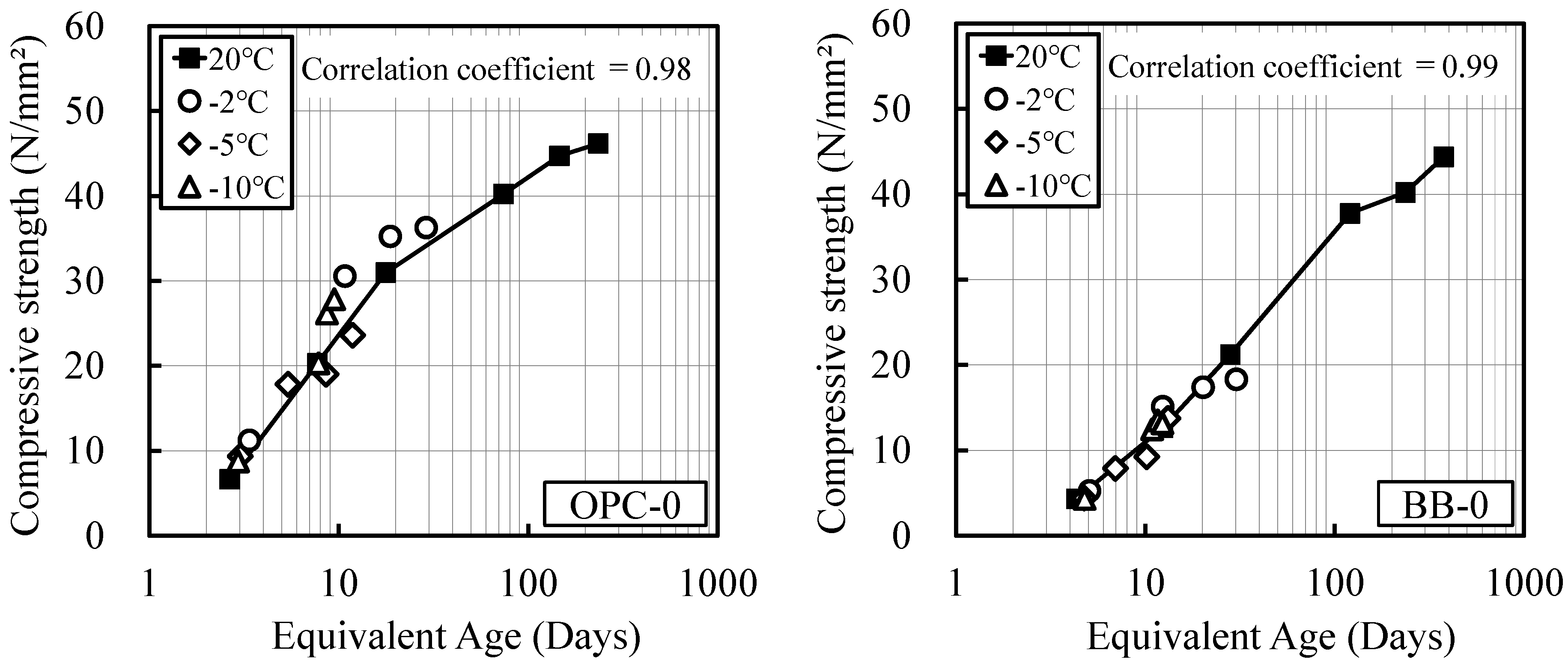

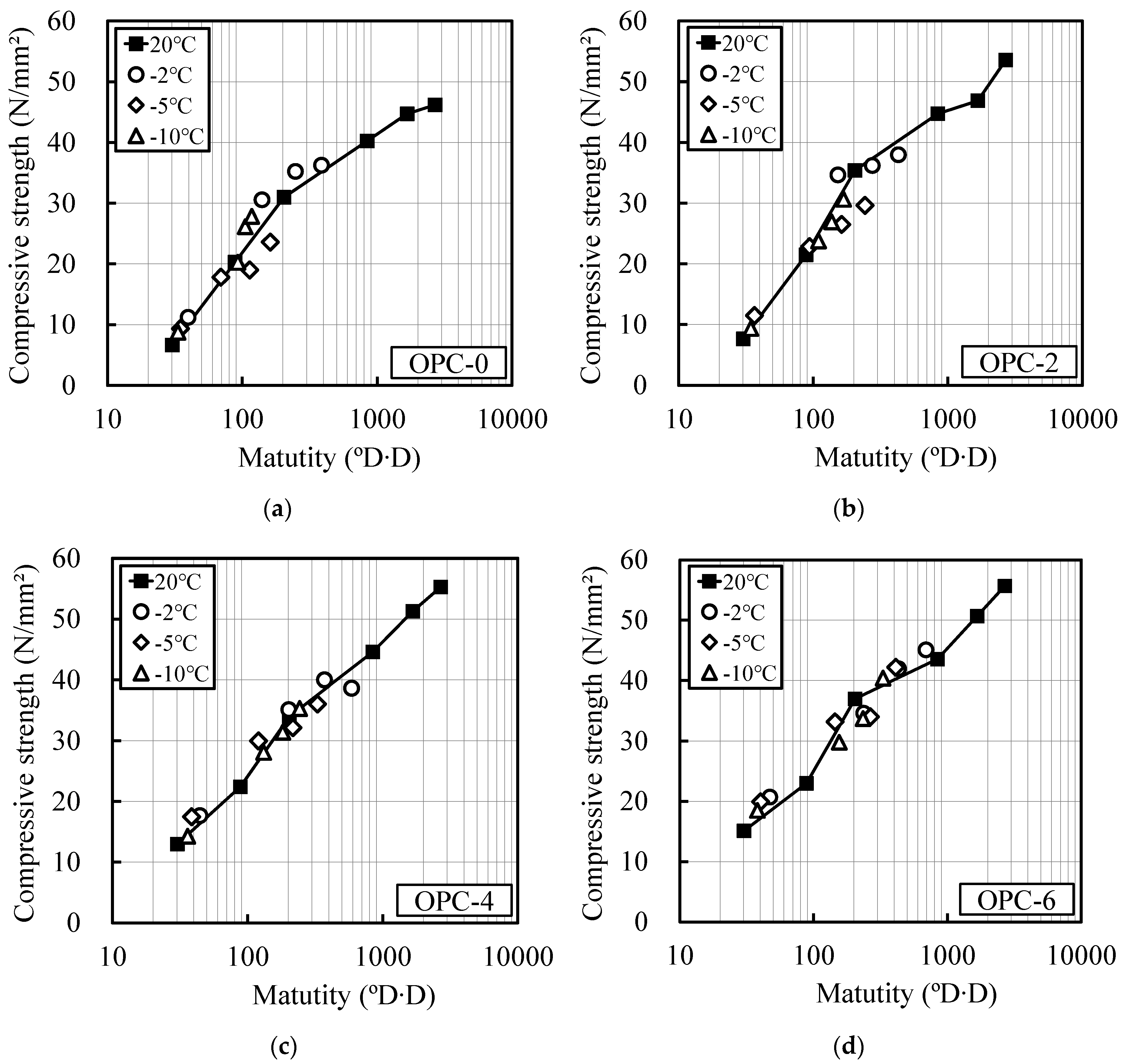

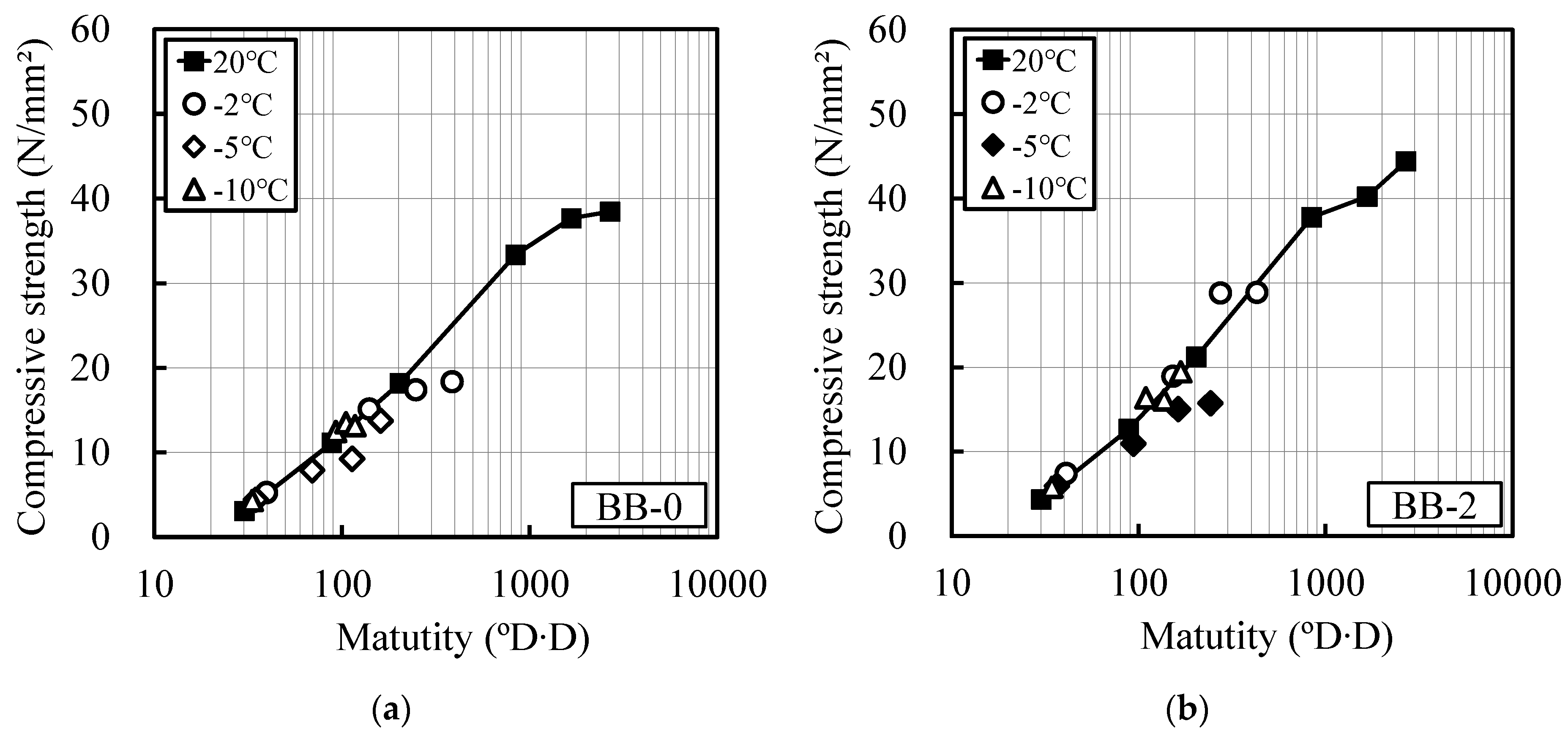

3.2. Maturity and Compressive Strength

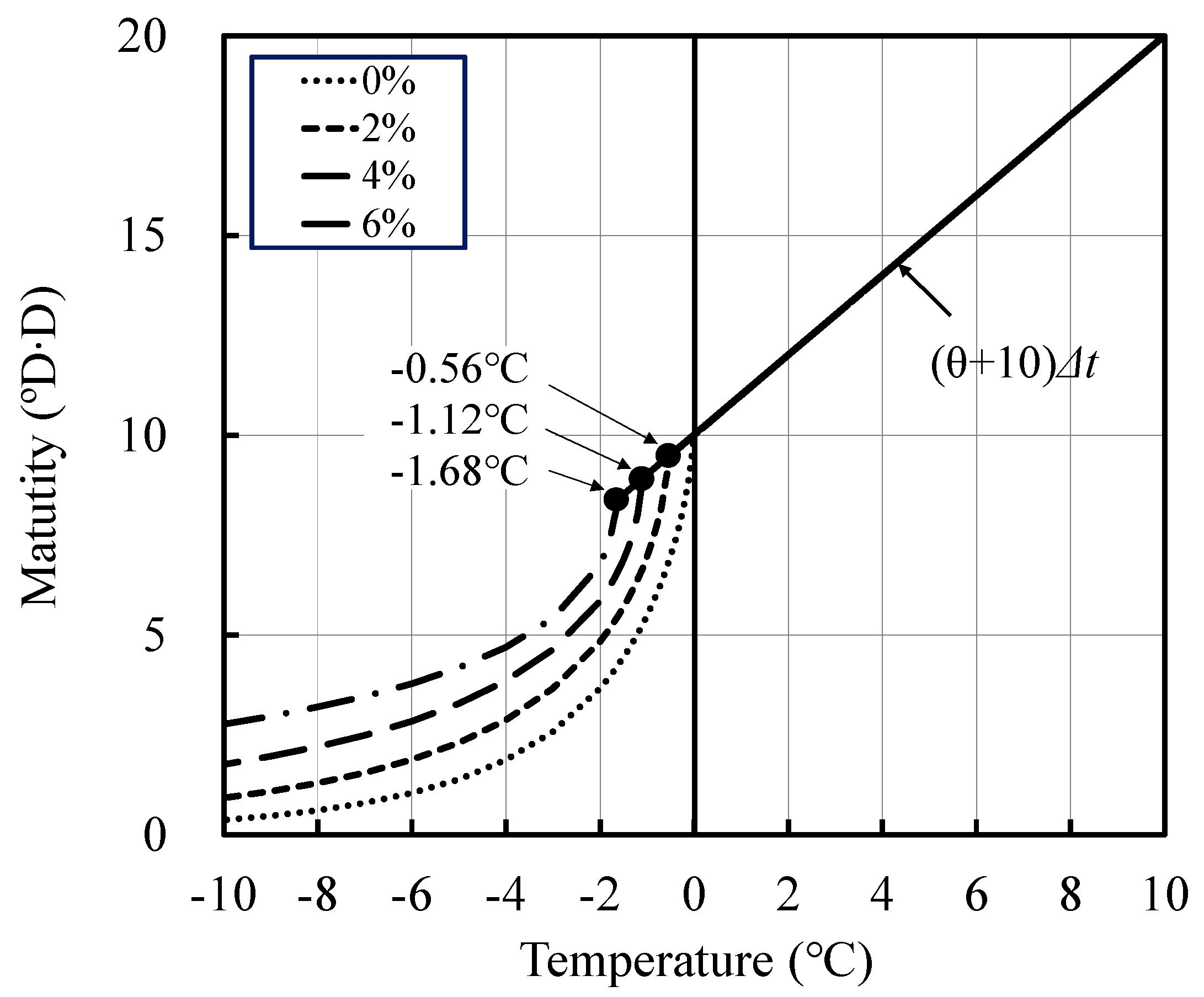

M = ∑(T + 10)Δt

M = ∑10 × exp(−0.60 × (−T)0.74)Δt

3.3. Temperature Dependence of Strength Development

3.4. Effects of Freezing and Antifreezing Admixture

3.4.1. Effect of Reduction in Chemical Potential of Water

3.4.2. Coefficient of the Effect of Antifreezing Admixture

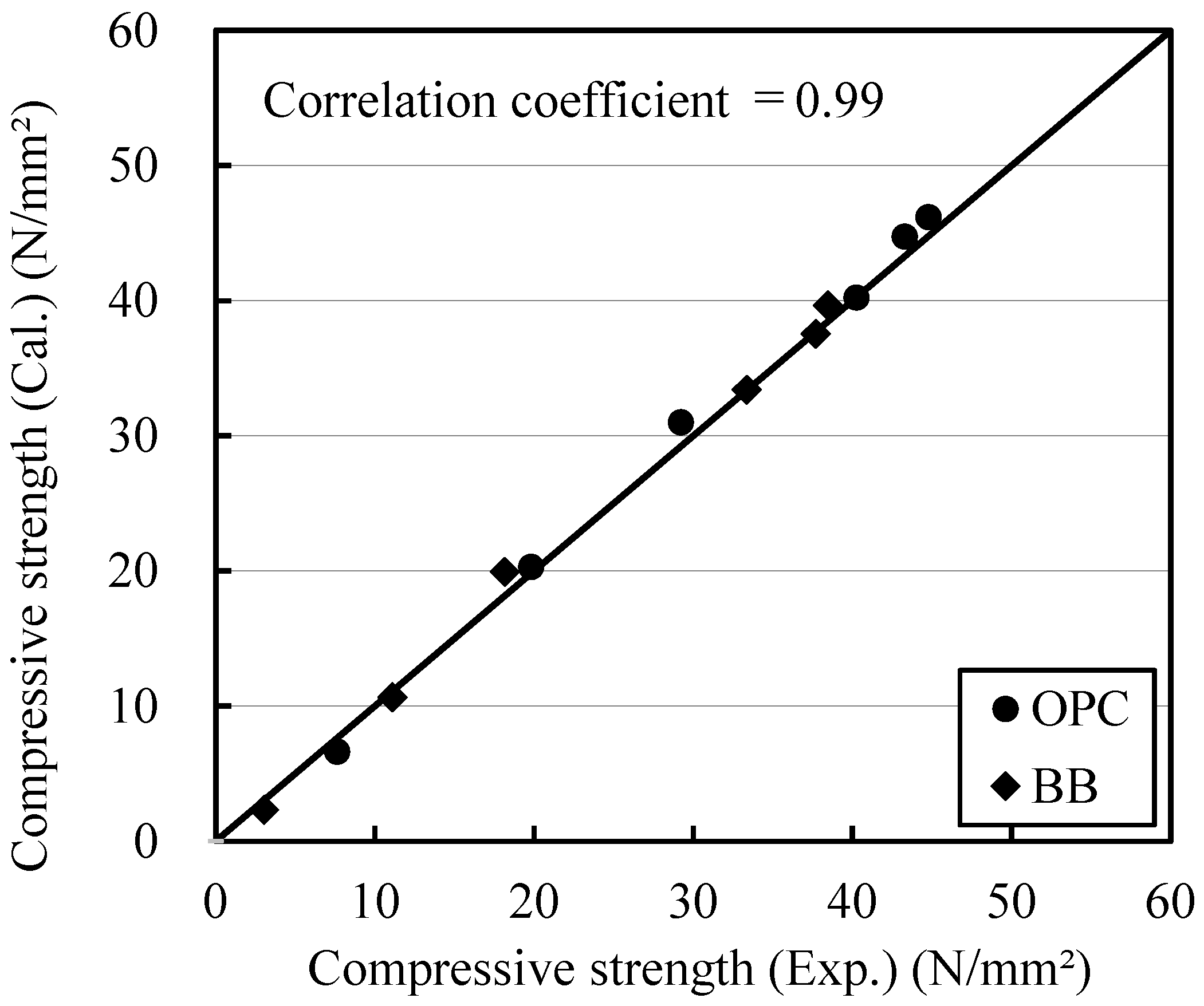

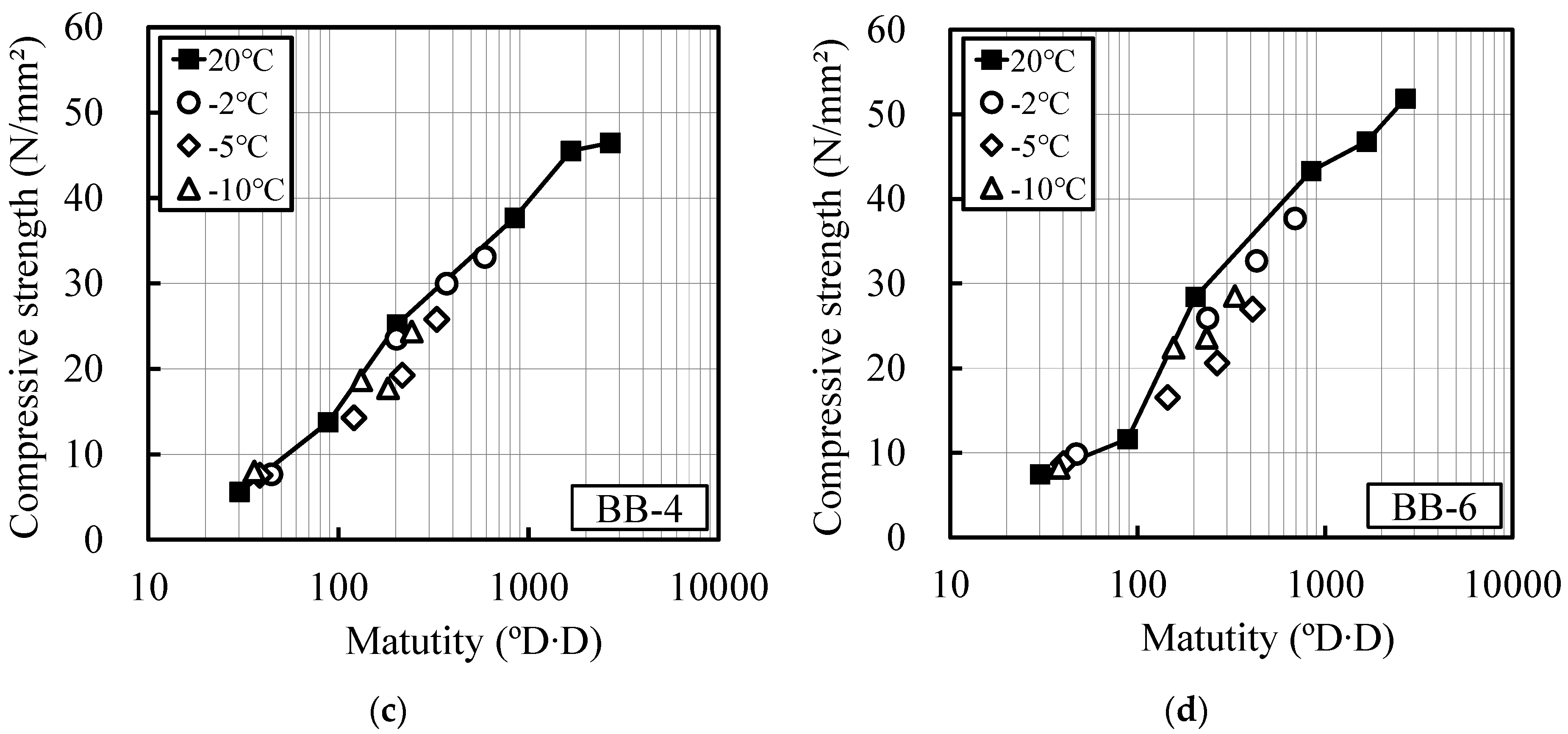

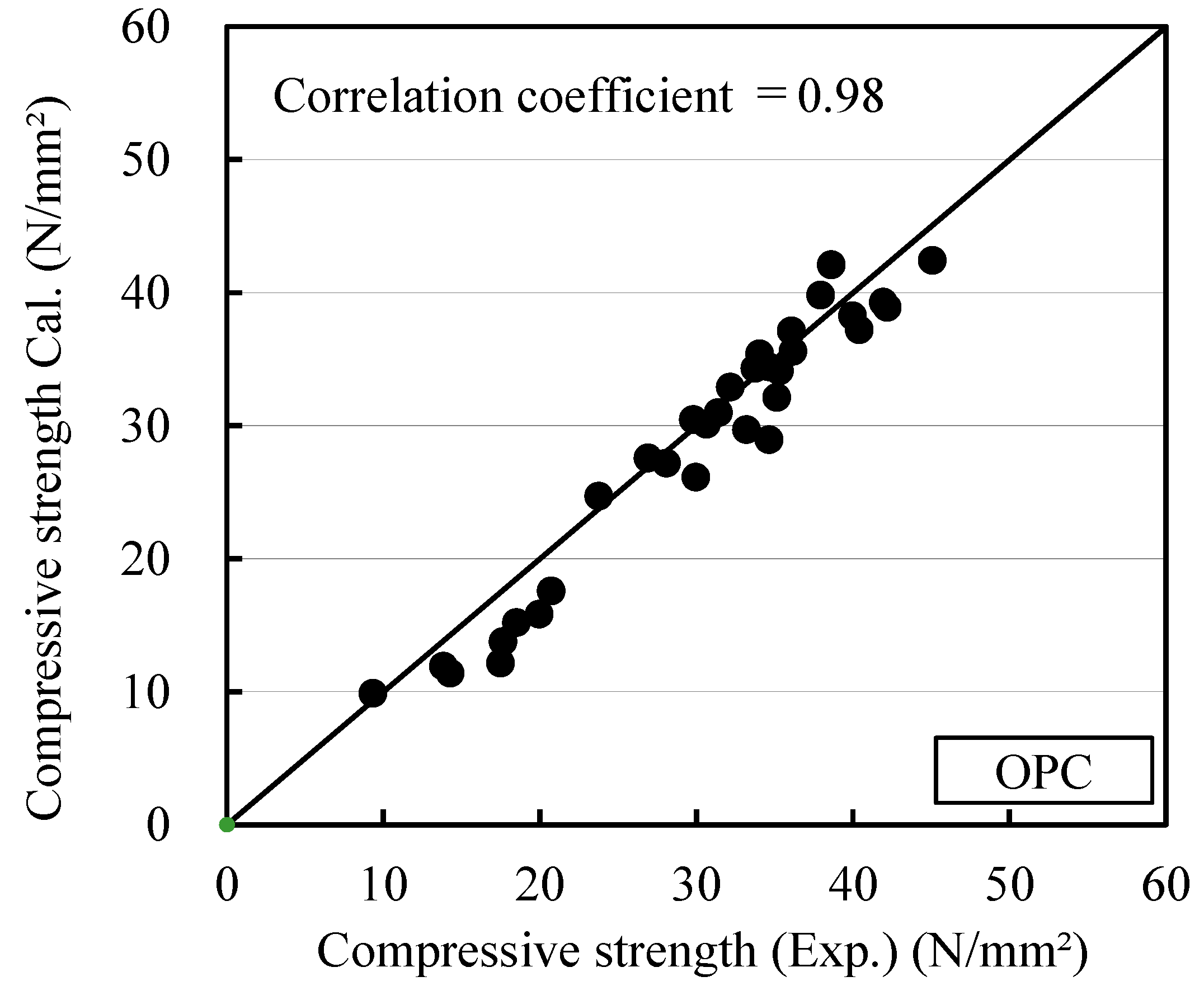

3.5. Maturity Equation for Temperatures Lower than 0 °C Considering the Effect of Antifreezing Admixture

M = ∑(T + 10)Δt

Mf = ∑(10 − 0.28x) × exp{(−0.60 + 0.038x) × (−Tc − 0.28x)(0.74 − 0.038x)}·Δt

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Architectural Institute of Japan. Recommendation for Practice of Concrete with Portland Cement and Ground Granulated Blast-Furnace Slag; Architectural Institute of Japan: Tokyo, Japan, 2001. [Google Scholar]

- American Society for Testing Materials. Standard Specification for Ground Granulated Blast-Furnace Slag for Use in Concrete and Mortars; ASTM C989-05; ASTM International: West Conshohocken, PA, USA, 2005. [Google Scholar]

- Suresh, D.; Nagaraju, K. Ground granulated blast slag (ggbs) in concrete—A review. IOSR J. Mec. Civil. Eng. IOSR. JMCE 2015, 12, 76–82. [Google Scholar]

- Choi, H.G.; Lee, J.C. Shrinkage properties of blast furnace slag cement mortar by using frost-resistant accelerator. J. Korea Ins. Build. Constr. 2019, 19, 59–66. [Google Scholar]

- Architectural Institute of Japan. Recommendation for Practice of Cold Weather Concreting; Architectural Institute of Japan: Tokyo, Japan, 2010. [Google Scholar]

- Taniguchi, M.; Nakamura, T.; Koike, S.; Nishi, H. Study on effect and mechanism of accelerator for freeze protection. Res. Rep. Hokkaido Res. Organ. North. Reg. Build. Res. Ins. 2015, 358, 1–11. [Google Scholar]

- Hama, Y.; Kamada, E. The properties of concrete containing a frost-resistant accelerator. Concr. J. 1999, 37, 3–8. [Google Scholar] [CrossRef]

- Nonomura, Y.; Shimata, A.; Shimada, H.; Yoshida, S. A fundamental study on expansion of use of frost-resistant accelerator for blast furnace slag cement. Mon. Rep. Civil. Eng. Res. Ins. Cold Reg. 2015, 749, 45–50. [Google Scholar]

- American Society for Testing Materials. Standard Practice for Estimating Concrete Strength by the Maturity Method; ASTM C1074-98; ASTM International: West Conshohocken, PA, USA, 2002. [Google Scholar]

- Taniguchi, M.; Katsura, O.; Hama, Y.; Yoshino, T. A proposal of compressive strength prediction method enhanced the applicable range of water-cement ratio. J. Struct. Constr. Eng. 2009, 74, 1205–1210. [Google Scholar] [CrossRef]

- Taniguchi, M.; Katsura, O.; Hama, Y. A proposal of temperature-time function on the strength development of concrete under sub-zero temperature. J. Struct. Constr. Eng. 2009, 74, 995–1003. [Google Scholar] [CrossRef][Green Version]

- Japan Standards Association. Method of Test. for Compressive Strength of Concrete; JIS A 1108; Japanese Industrial Standards: Tokyo, Japan, 2006. [Google Scholar]

- Yoshida, T.; Okanaga, T.; Mikuriya, T.; Ohtsubo, M. Study on Growth Curve of Compressive Strength of Concrete. Proc. Japan Concr. Ins. 1992, 14, 555–560. [Google Scholar]

- Katsura, O.; Kamada, E.; Koh, Y. Strength Development of High Strength Concrete under Low Temperature. Proc. JCI Symp. Perform. Concr. Nat. Weather. Cond. 1993, 32, 41–48. [Google Scholar]

- Sudo, Y.; Katsura, O.; Yoshino, T.; Mimori, T.; Hama, Y. Hydration rate and strength development of cementitious material under freezing or dry condition. J. Struct. Constr. Eng. 2001, 66, 17–22. [Google Scholar] [CrossRef]

- Barnett, S.J.; Soutsos, M.N.; Millard, S.G.; Bungey, J.H. Strength development of mortars containing ground granulated blast-furnace slag. Cem. Concr. Res. 2006, 36, 434–440. [Google Scholar] [CrossRef]

- Taniguchi, M.; Katsura, O.; Sagawa, T.; Hama, Y. Effects of the mineral composition of cement on the temperature dependency of strength development. J. Struct. Constr. Eng. 2011, 76, 443–448. [Google Scholar] [CrossRef]

| Cement | Antifreezing Admixture | W/C (%) | C:S | Placement Temperature (°C) | Curing Temperature (°C) | Curing Condition | Test Item |

|---|---|---|---|---|---|---|---|

| Rate of Addition (ℓ/C = 100 kg) | |||||||

| OPC | 0, 2, 4, 6 | 50 | 1:3 | 20 | 20 * 20→−2 20→−5 20→−10 | Sealed curing Water curing * | Compressive strength Temperature |

| BB |

| Type | |

|---|---|

| Cement | Ordinary Portland cement, Density: 3.15 g/cm3, Specific surface area: 3490 cm3/g |

| Blast furnace slag cement, Density: 2.91 g/cm3, Specific surface area: 3250 cm3/g | |

| Sand | Pit sand (siliceous sand), Density: 2.69 g/cm3, Absorption ratio: 1.52%, Unit volumetric mass: 1.86 kg/l, Actual ratio: 70.2%, Fineness modulus: 2.70 |

| Admixture | Antifreezing admixture (Main component: inorganic nitrogenous compound; Nitrite, Nitrate), Density: 1.41–1.45 g/cm3, Amount of chloride ion: 0.01%, Total alkali amount: 0% |

| Binder | Specific Surface Area (g/cm3) | Density (g/cm3) | Chemical Composition (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | f-CaO | Ig.loss | |||

| OPC | 3490 | 3.15 | 21.4 | 5.5 | 2.9 | 64.3 | 1.9 | 1.8 | 0.25 | 0.68 |

| BB | 3250 | 3.05 | 26.1 | 8.9 | 2.0 | 55.6 | 3.8 | - | - | 0.68 |

| Type | Cumulative Passing (%) | Fineness Modulus (F.M.) | ||||||

| Sieve Size (mm) | 0.15 | 0.3 | 10 | 1.2 | 2.5 | 5 | 10 | |

| Sand | 2.7 | 23.1 | 100 | 67.3 | 87.0 | 99.4 | 100 | 2.70 |

| Antifreezing Admixture (ℓ/C = 100 kg) | Equivalent Age | Maturity | ||||||

|---|---|---|---|---|---|---|---|---|

| OPC | BB | OPC | BB | |||||

| a | b | a | b | a | b | a | b | |

| 0 | −1.81 | −0.55 | −2.87 | −0.62 | −18.0 | −0.66 | −30.4 | −0.68 |

| 2 | −1.88 | −0.66 | −2.74 | −0.64 | −17.6 | −0.66 | −28.1 | −0.67 |

| 4 | −1.69 | −0.54 | −2.48 | −0.53 | −14.0 | −0.60 | −20.8 | −0.61 |

| 6 | −1.46 | −0.54 | −2.84 | −0.58 | −9.5 | −0.55 | −33.8 | −0.72 |

| Type | OPC | BB |

|---|---|---|

| α | 31.2 | 30.4 |

| Antifreezing Admixture (ℓ/C = 100 kg) | c | d | |

|---|---|---|---|

| OPC and BB | OPC | BB | |

| 2 | 13.2 | 1.01 | 1.32 |

| 4 | 6.2 | 1.09 | 1.39 |

| 6 | 3.6 | 1.01 | 1.30 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, H.; Hama, Y.; Taniguchi, M. Maturity and Strength Development of Mortar with Antifreezing Admixture at Temperatures Lower than 0 °C. Materials 2019, 12, 3172. https://doi.org/10.3390/ma12193172

Choi H, Hama Y, Taniguchi M. Maturity and Strength Development of Mortar with Antifreezing Admixture at Temperatures Lower than 0 °C. Materials. 2019; 12(19):3172. https://doi.org/10.3390/ma12193172

Chicago/Turabian StyleChoi, Hyeonggil, Yukio Hama, and Madoka Taniguchi. 2019. "Maturity and Strength Development of Mortar with Antifreezing Admixture at Temperatures Lower than 0 °C" Materials 12, no. 19: 3172. https://doi.org/10.3390/ma12193172

APA StyleChoi, H., Hama, Y., & Taniguchi, M. (2019). Maturity and Strength Development of Mortar with Antifreezing Admixture at Temperatures Lower than 0 °C. Materials, 12(19), 3172. https://doi.org/10.3390/ma12193172