Solid-State Phase Transformations in Thermally Treated Ti–6Al–4V Alloy Fabricated via Laser Powder Bed Fusion

Abstract

1. Introduction

2. Materials and Methods

2.1. Material and Production Process

2.2. Thermal Treatments

2.3. Mechanical Tests

2.4. Characterization Techniques

3. Results

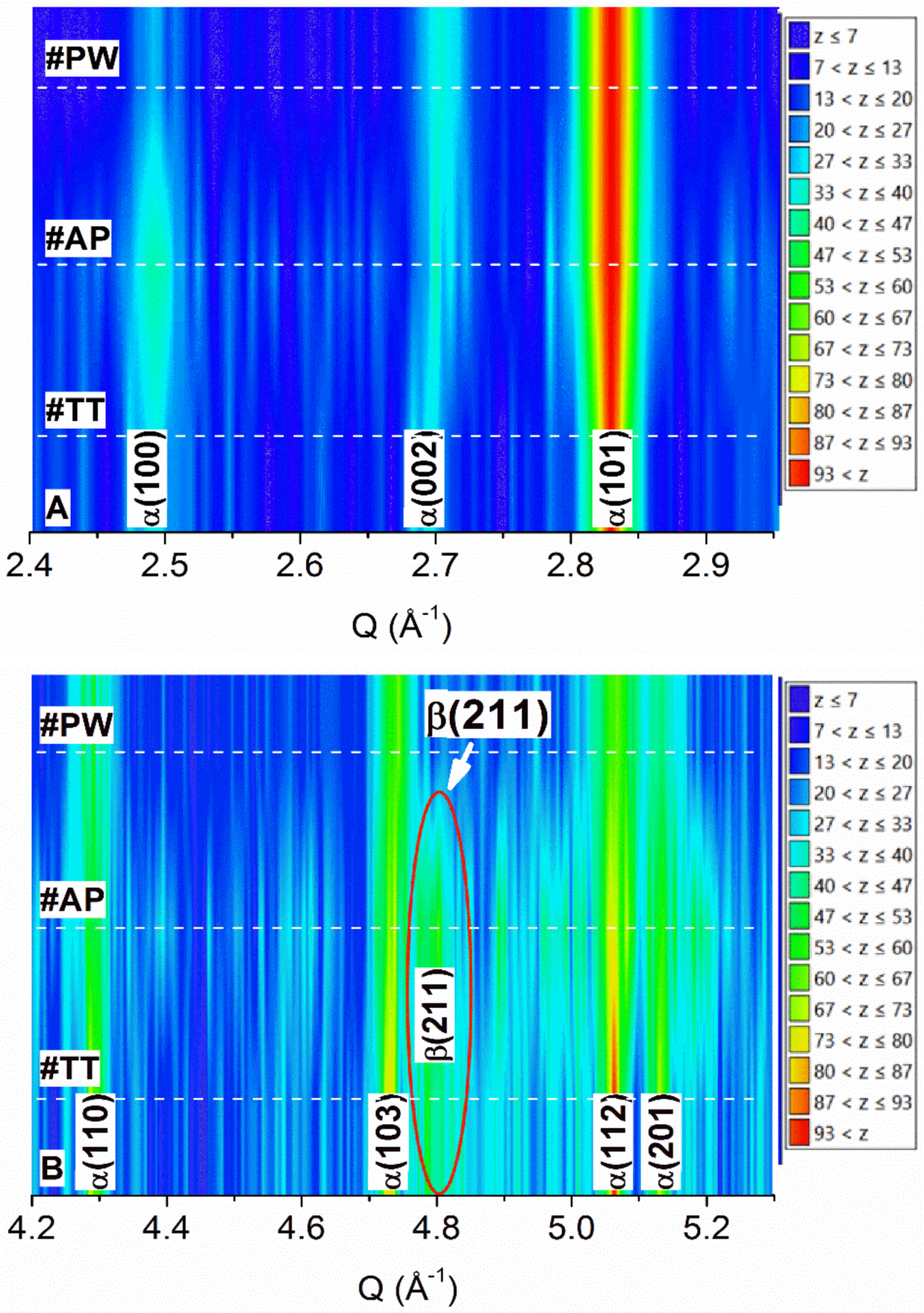

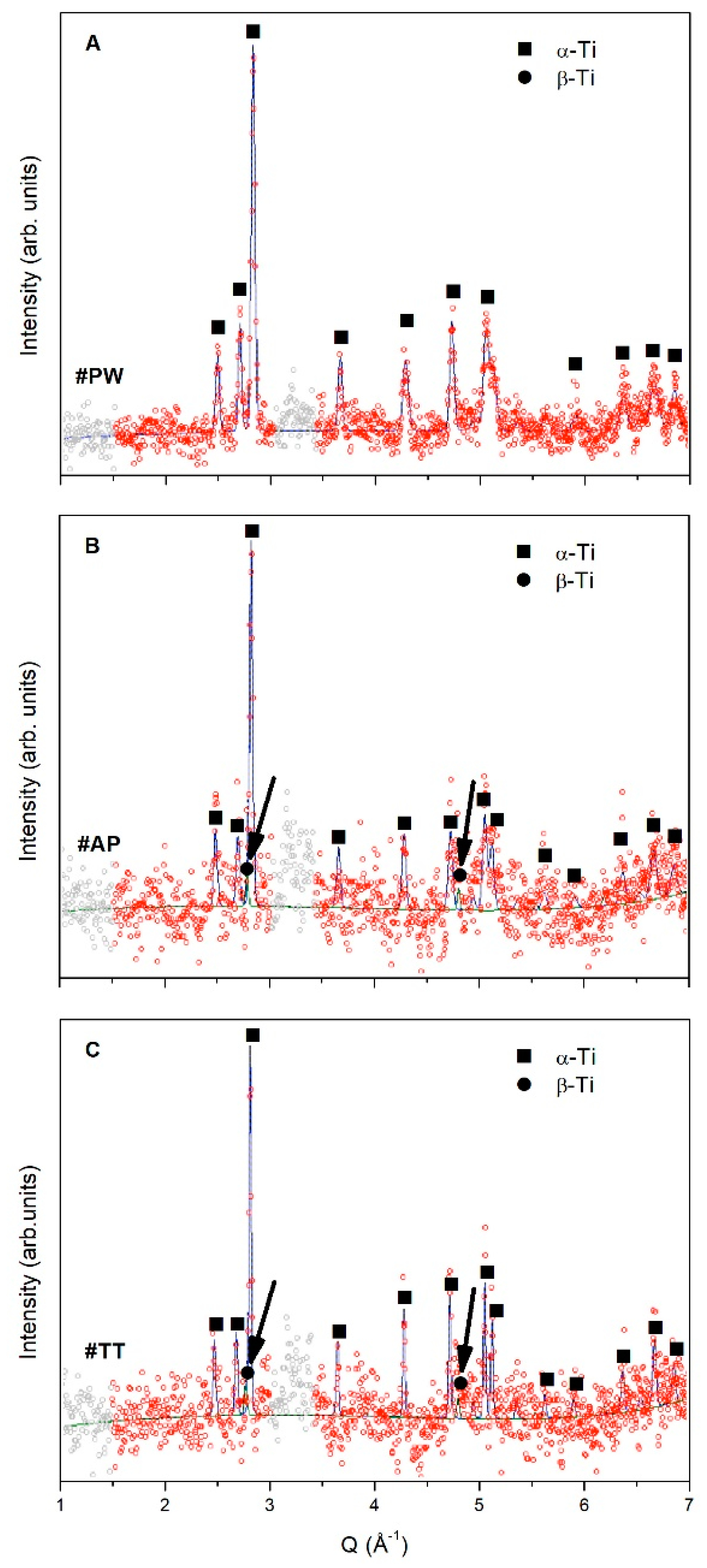

3.1. Neutron Diffraction (ND)

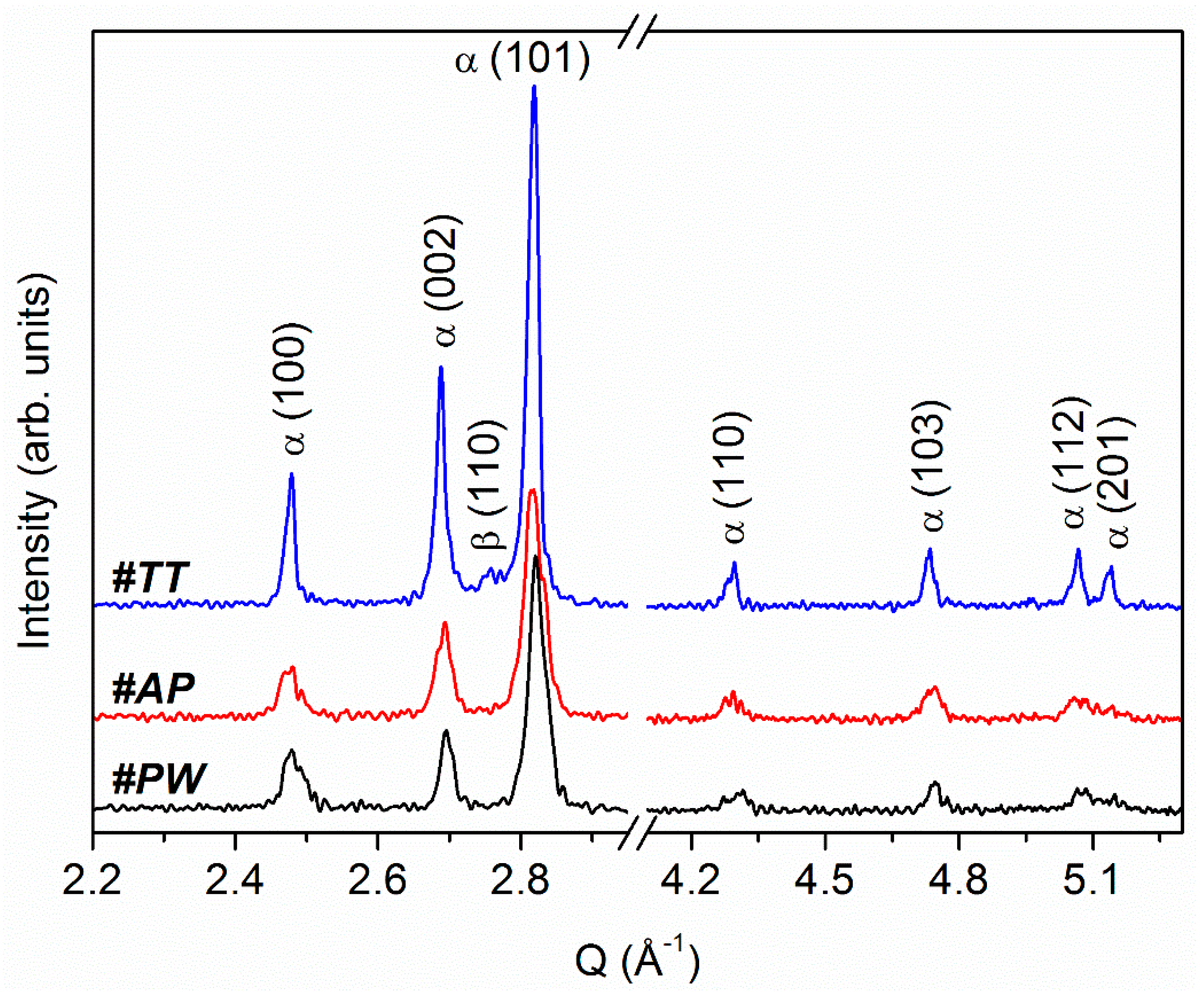

3.2. X-ray Diffraction (XRD)

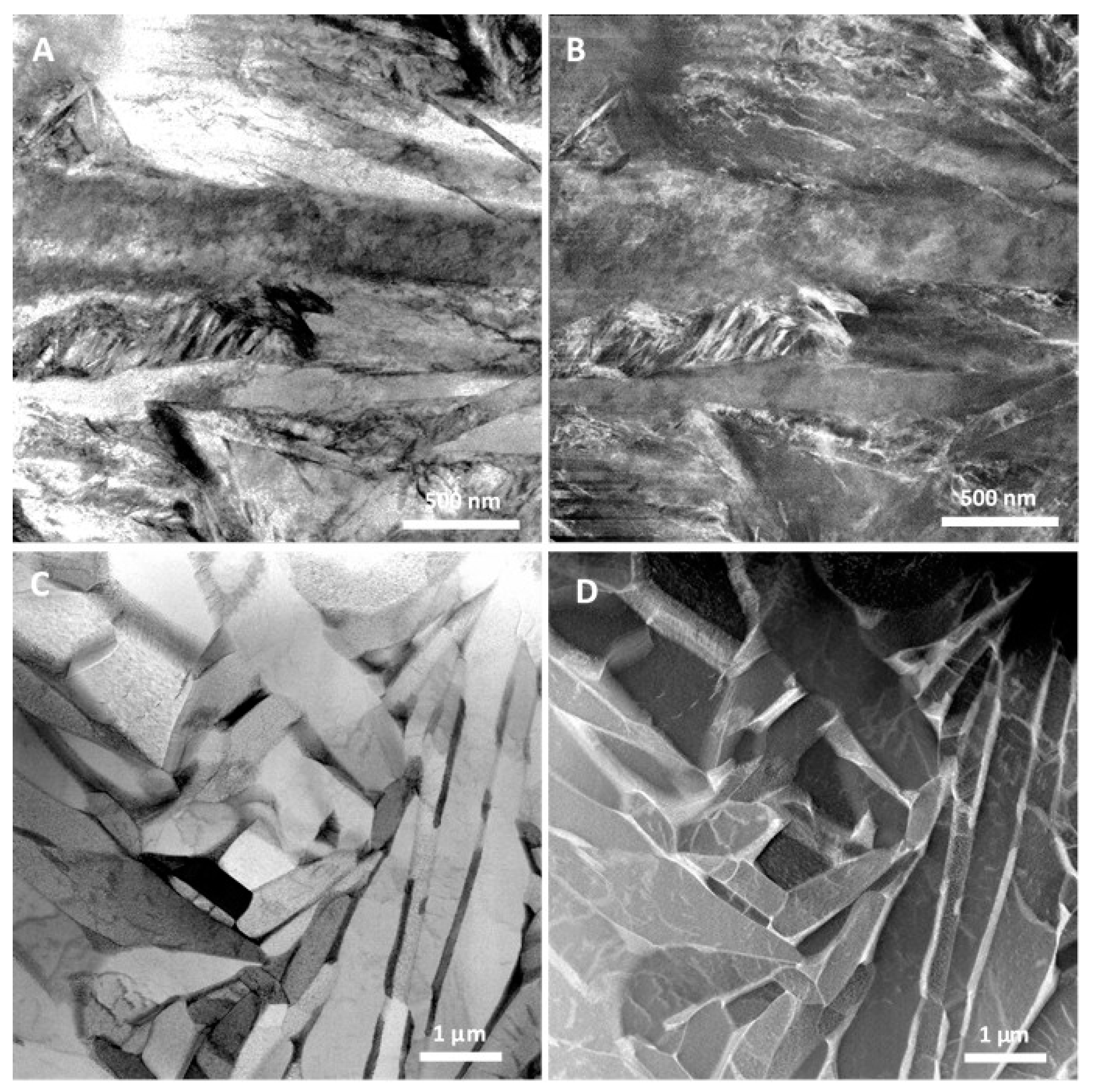

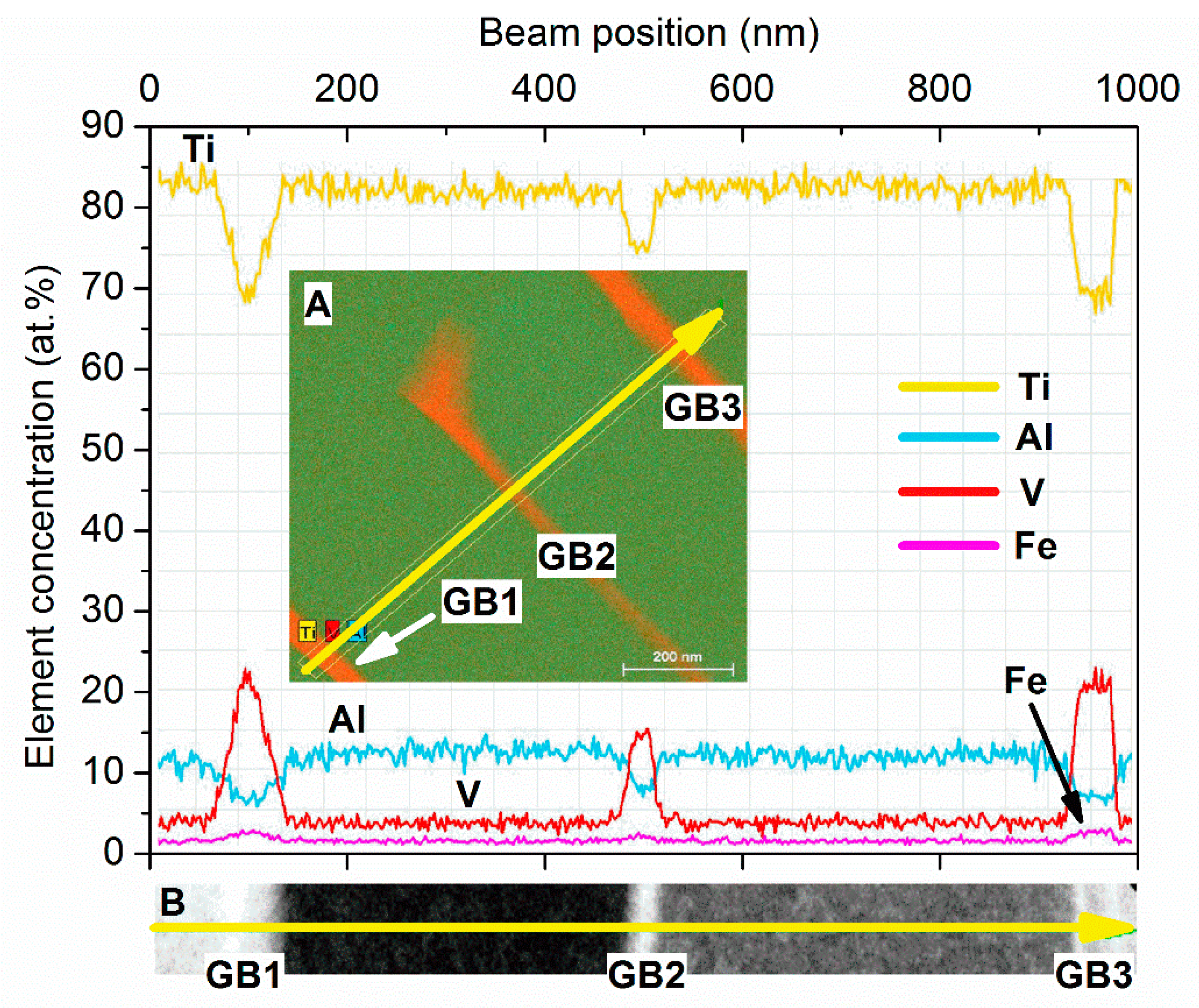

3.3. Scanning Transmission Electron Microscopy (STEM) and Microanalysis (EDS)

4. Discussion

5. Conclusions

- The raw powder is composed of single-phase α-Ti;

- The as-produced sample (#AP) is formed of highly defective α’-Ti martensite with retained β-Ti phase (evidenced only by ND);

- The thermally treated sample (#TT) has more regularly shaped grains, with defects density sensibly reduced and elongated β-Ti phase at the grain boundaries;

- The β-Ti phase accumulates high quantity of V (up to 25 wt.%) during annealing due to element diffusion and partitioning;

- Increase of V content is always accompanied by an increase of Fe.

Author Contributions

Funding

Conflicts of Interest

References

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Das, S.; Bourell, D.L.; Bab, S.S. Metallic materials for 3D printing. Mrs Bull. 2016, 41, 729–741. [Google Scholar] [CrossRef]

- Lutjering, G.; Williams, J.C. Titanium, 2nd ed.; Springer: Berlin, Germany, 2007. [Google Scholar]

- Yan, M.; Xu, W.; Dargusch, M.S.; Tang, H.P.; Brandt, M.; Qian, M. Review of effect of oxygen on room temperature ductility of titanium and titanium alloys. Powder Metall. 2014, 57, 251–257. [Google Scholar] [CrossRef]

- Tirelli, S.; Chiappini, E.; Strano, M.; Monno, M.; Semeraro, Q. Economical comparison of cryogenic vs. traditional turning of Ti–6Al–4V: A case study. Key Eng. Mater. 2015, 651–653, 1204–1210. [Google Scholar] [CrossRef]

- Barnes, J.E.; Peter, W.; Blue, C.A. Evaluation of low cost titanium alloy products. Mater. Sci. Forum. 2009, 618–619, 165–168. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Design. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Kobryn, P.A.; Semiatin, S.L. The laser additive manufacture of Ti–6Al–4V. JOM. 2001, 53, 40–42. [Google Scholar] [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. Effect of the build orientation on the mechanical properties and fracture modes of SLM Ti–6Al–4V. Mat. Sci. Eng. A 2014, 616, 1–11. [Google Scholar] [CrossRef]

- Yang, J.; Yu, H.; Yin, J.; Gao, M.; Wang, Z.; Zeng, X. Formation and control of martensite in Ti–6Al–4V alloy produced by selective laser melting. Mater. Des. 2016, 108, 308–316. [Google Scholar] [CrossRef]

- Barriobero-Vila, P.; Gussone, J.; Haubrich, J.; Sandlöbes, S.; Da Silva, J.C.; Cloetens, P.; Schell, N.; Requena, G. Inducing stable α + β microstructures during selective laser melting of Ti–6Al–4V using intensified intrinsic heat treatments. Materials 2017, 10, 268. [Google Scholar] [CrossRef]

- Qiu, C.; Adkins, N.J.E.; Attallah, M.M. Microstructure and tensile properties of selectively laser-melted and of HIPed laser-melted Ti–6Al–4V. Mat. Sci. Eng. A 2013, 578, 230–239. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.P.; Van Humbeeck, J. Heat treatment of Ti6Al4V produced by Selective Laser Melting: Microstructure and mechanical properties. J. Alloy. Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef]

- Vilaro, T.; Colin, C.; Bartout, JD. As-fabricated and heat-treated microstructures of the Ti–6Al–4V Alloy processed by selective laser melting. Met. Mater. Trans. A 2011, 42, 3190–3199. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101-1–041101-21. [Google Scholar] [CrossRef]

- Cho, J.Y.; Xu, W.; Brandt, M.; Qian, M. Selective laser melting-fabricated Ti–6Al–4V alloy: Microstructural inhomogeneity, consequent variations in elastic modulus and implications. Opt. Laser Technol. 2019, 111, 664–670. [Google Scholar] [CrossRef]

- Xu, W.; Brandt, M.; Sun, S.; Elambasseril, J.; Liu, Q.; Latham, K.; Xia, K.; Qian, M. Additive manufacturing of strong and ductile Ti–6Al–4V by selective laser melting via in situ martensite decomposition. Acta Mater. 2015, 850, 74–84. [Google Scholar] [CrossRef]

- Xu, W.; Sun, S.; Elambasseril, J.; Liu, Q.; Brandt, M.; Qian, M. Ti–6Al–4V additively manufactured by selective laser melting with superior mechanical properties. JOM. 2015, 67, 668–673. [Google Scholar] [CrossRef]

- Barucca, G.; Santecchia, E.; Majni, G.; Girardin, E.; Bassoli, E.; Denti, L.; Gatto, A.; Iuliano, L.; Moskalewicz, T.; Mengucci, P. Structural characterization of biomedical Co–Cr–Mo components produced by direct metal laser sintering. Mat. Sci. Eng. C 2015, 48, 263–269. [Google Scholar] [CrossRef] [PubMed]

- Mengucci, P.; Barucca, G.; Gatto, A.; Bassoli, E.; Denti, L.; Fiori, F.; Bastianoni, P.; Rutkowski, B.; Czyrska-Filemonowicz, A. Effects of thermal treatments on microstructure and mechanical properties of a Co–Cr–Mo–W biomedical alloy produced by laser sintering. J. Mech. Behav. Biomed. Mat. 2016, 60, 106–117. [Google Scholar] [CrossRef]

- Mengucci, P.; Gatto, A.; Bassoli, E.; Denti, L.; Fiori, F.; Girardin, E.; Bastianoni, P.; Rutkowski, B.; Czyrska-Filemonowicz, A.; Barucca, G. Effects of build orientation and element partitioning on microstructure and mechanical properties of biomedical Ti–6Al–4V alloy produced by laser sintering. J. Mech. Behav. Biomed. Mat. 2017, 71, 1–9. [Google Scholar] [CrossRef]

- Lutterotti, L. Total pattern fitting for the combined size-strain-stress-texture determination in thin film diffraction. Nucl. Inst. Meth. Phys. Res. B 2010, 268, 334–340. [Google Scholar] [CrossRef]

- Origin Pro, ver. 8.5; OriginLab Corporation: One Roundhouse Plaza, Northampton, MA, USA, 2010; 01060.

- Polmear, I.J.; StJohn, D.; Nie, J.F.; Qian, M. Light Alloys—Metallurgy of the Light Metals, 5th ed.; Butterworth-Heinemann: Oxford, UK, 2017. [Google Scholar]

- Sha, W.; Malinov, S. Titanium Alloys: Modelling of Microstructure, Properties and Applications; Woodhead Publishing Limited: Cambridge, UK, 2009. [Google Scholar]

- Malinov, S.; Sha, W.; Guo, Z.; Tang, C.C.; Long, A.E. Synchrotron X-ray diffraction study of the phase transformations in titanium alloys. Mater. Charact. 2002, 48, 279–295. [Google Scholar] [CrossRef]

- Dawidowski, J.; Cuello, G.J.; Rodríguez Palomino, L.A. Data processing steps in neutron diffraction: From the raw data to the differential cross section. In Nautron Diffraction; Khiridov, I., Ed.; InTech: Rijeka, Croatia, 2012. [Google Scholar]

- Kisi, E.H.; Howard, C.J. Applications of Neutron Powder Diffraction; Oxford University Press: New York, NY, USA, 2008. [Google Scholar]

- Ahmed, T.; Rack, H.J. Phase transformations during cooling in α + β titanium alloys. Mat. Sci. Eng. A 1998, 243, 206–211. [Google Scholar] [CrossRef]

- Kirka, M.M.; Nandwana, P.; Lee, Y.; Dehoff, R.R. Solidification and solid-state transformation sciences in metals additive manufacturing. Scr. Mater. 2017, 135, 130–134. [Google Scholar] [CrossRef]

- Haubrich, J.; Gussone, J.; Barriobero-Vila, P.; Kurnsteiner, P.; Jagle, E.A.; Raabe, D.; Schell, N.; Requena, G. The role of lattice defects on the microstructure in selective laser melted Ti-6Al-4V. Acta Mater. 2019, 167, 136–148. [Google Scholar] [CrossRef]

- Barriobero-Vila, P.; Requena, G.; Buslaps, T.; Alfeld, M.; Boesenberg, U. Role of element partitioning on the α-β transformation kinetics of a bi-modal Ti–6Al–4V alloy during continuous heating. J. Alloy. Compd. 2015, 626, 330–339. [Google Scholar] [CrossRef]

- Elmer, J.W.; Palmer, T.A.; Babu, S.S.; Specht, E.D. In situ observations of lattice expansion and transformation rates of α and β phases in Ti–6AL–4V. Mat. Sci. Eng. A 2005, 391, 104–113. [Google Scholar] [CrossRef]

| Al (wt.%) | V (wt.%) | O (ppm) | N (ppm) | C (ppm) | H (ppm) | Fe (ppm) | Ti |

|---|---|---|---|---|---|---|---|

| 5.50–6.75 | 3.50–4.50 | <2000 | <500 | <800 | <150 | <3000 | Balance |

| Ti Phase | #PW | #AP | #TT | Reference |

|---|---|---|---|---|

| α | a = 0.29291 nm (XRD) c = 0.46631 nm (XRD) | a = 0.29222 nm (XRD) c = 0.46604 nm (XRD) | a = 0.29274 nm (XRD) c = 0.46742 nm (XRD) | a = 0.29505 nm c = 0.46826 nm |

| β | not detected (XRD) not detected (ND) | not detected (XRD) a = 0.31973 nm (ND) | a = 0.32259 nm (XRD) a = 0.32037 nm (ND) | a = 0.33065 nm |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mengucci, P.; Santecchia, E.; Gatto, A.; Bassoli, E.; Sola, A.; Sciancalepore, C.; Rutkowski, B.; Barucca, G. Solid-State Phase Transformations in Thermally Treated Ti–6Al–4V Alloy Fabricated via Laser Powder Bed Fusion. Materials 2019, 12, 2876. https://doi.org/10.3390/ma12182876

Mengucci P, Santecchia E, Gatto A, Bassoli E, Sola A, Sciancalepore C, Rutkowski B, Barucca G. Solid-State Phase Transformations in Thermally Treated Ti–6Al–4V Alloy Fabricated via Laser Powder Bed Fusion. Materials. 2019; 12(18):2876. https://doi.org/10.3390/ma12182876

Chicago/Turabian StyleMengucci, Paolo, Eleonora Santecchia, Andrea Gatto, Elena Bassoli, Antonella Sola, Corrado Sciancalepore, Bogdan Rutkowski, and Gianni Barucca. 2019. "Solid-State Phase Transformations in Thermally Treated Ti–6Al–4V Alloy Fabricated via Laser Powder Bed Fusion" Materials 12, no. 18: 2876. https://doi.org/10.3390/ma12182876

APA StyleMengucci, P., Santecchia, E., Gatto, A., Bassoli, E., Sola, A., Sciancalepore, C., Rutkowski, B., & Barucca, G. (2019). Solid-State Phase Transformations in Thermally Treated Ti–6Al–4V Alloy Fabricated via Laser Powder Bed Fusion. Materials, 12(18), 2876. https://doi.org/10.3390/ma12182876