Effect of Initial Powders on Properties of FeAlSi Intermetallics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Preparation

- Fe + Al + Si (denoted Fe_Al_Si)

- FeAl25 + Si (denoted FeAl_Si)

- Fe + AlSi30 + Si (denoted Fe_AlSi)

- FeSi25 + Al (denoted FeSi_Al)

2.2. Characterization Techniques

3. Results

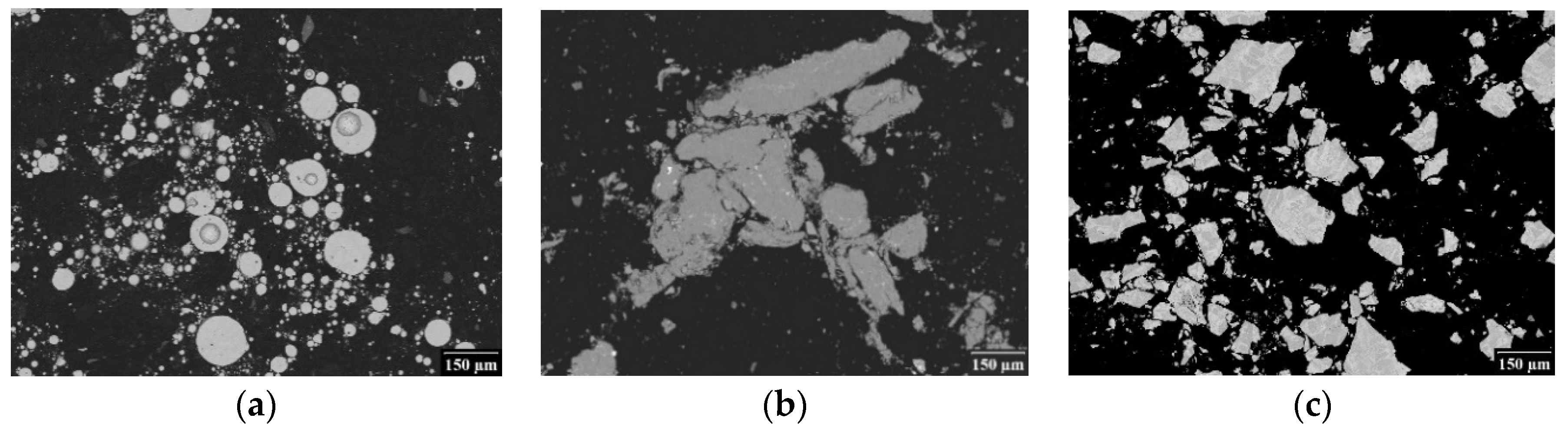

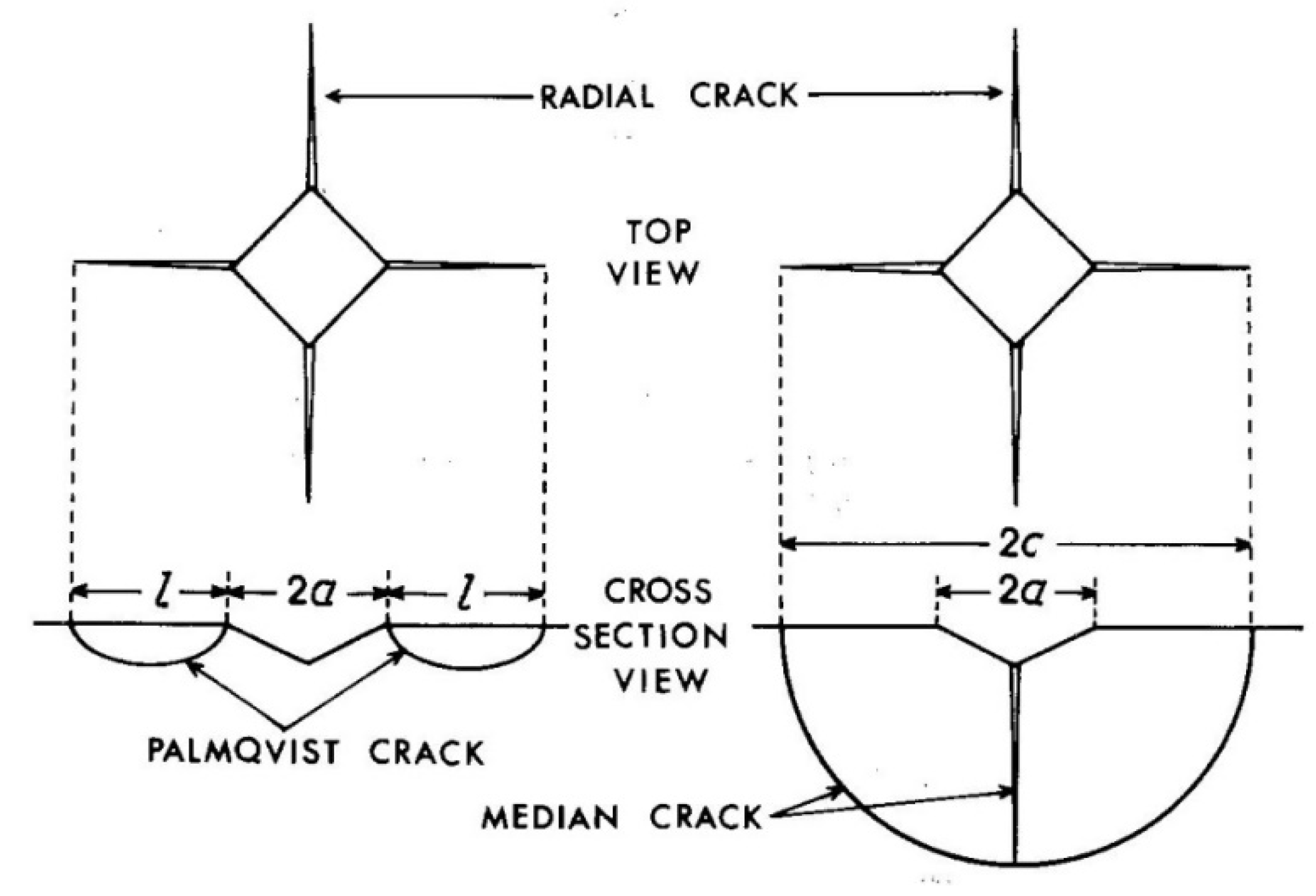

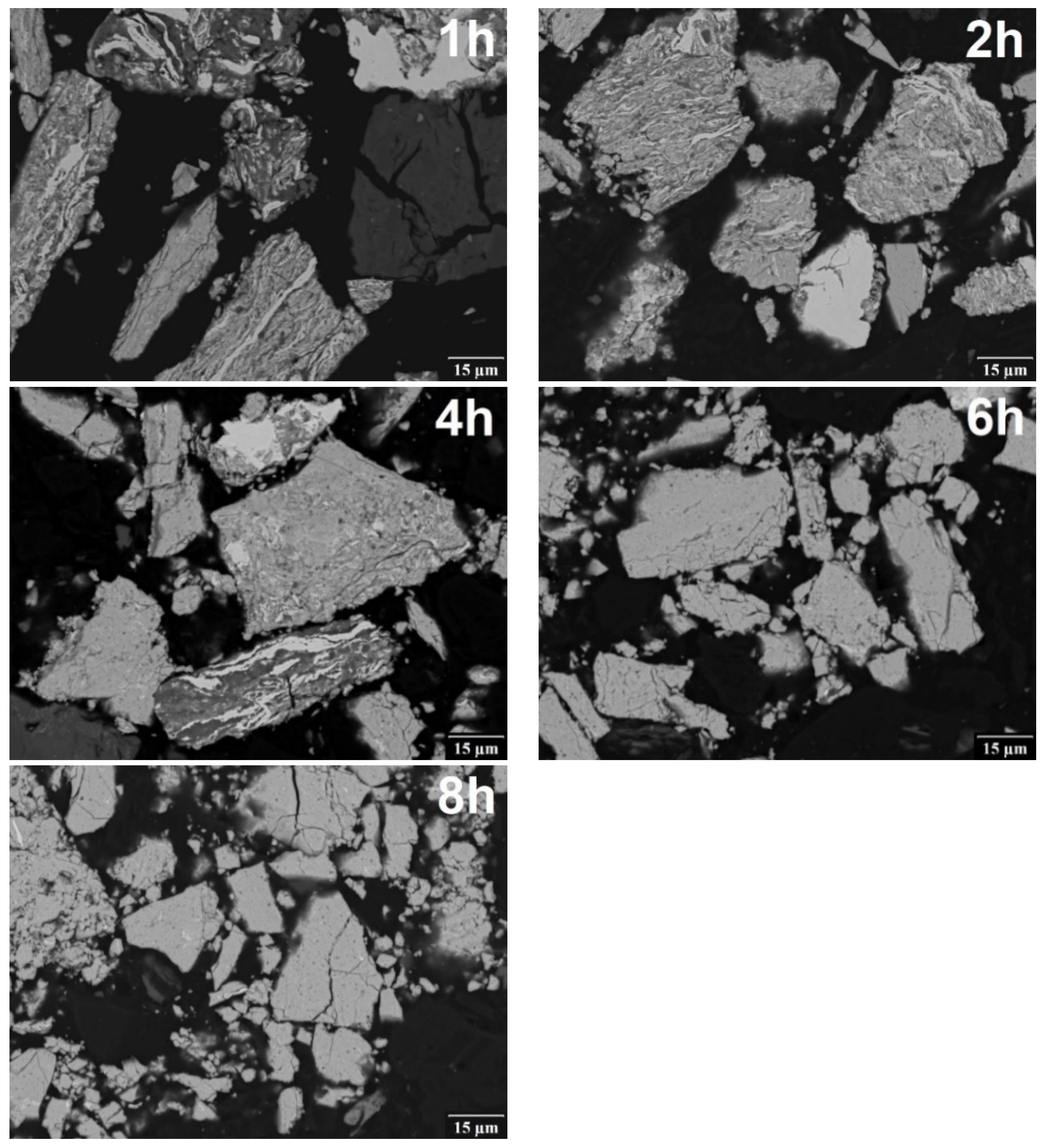

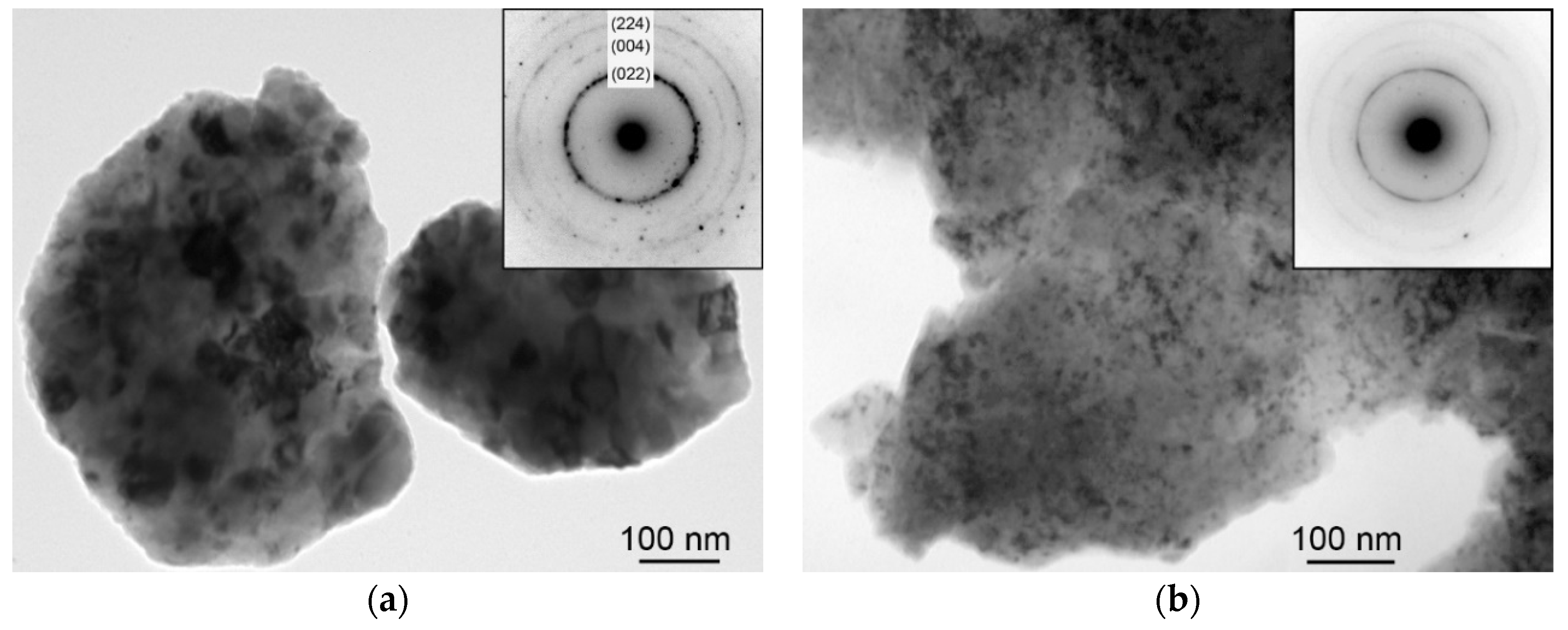

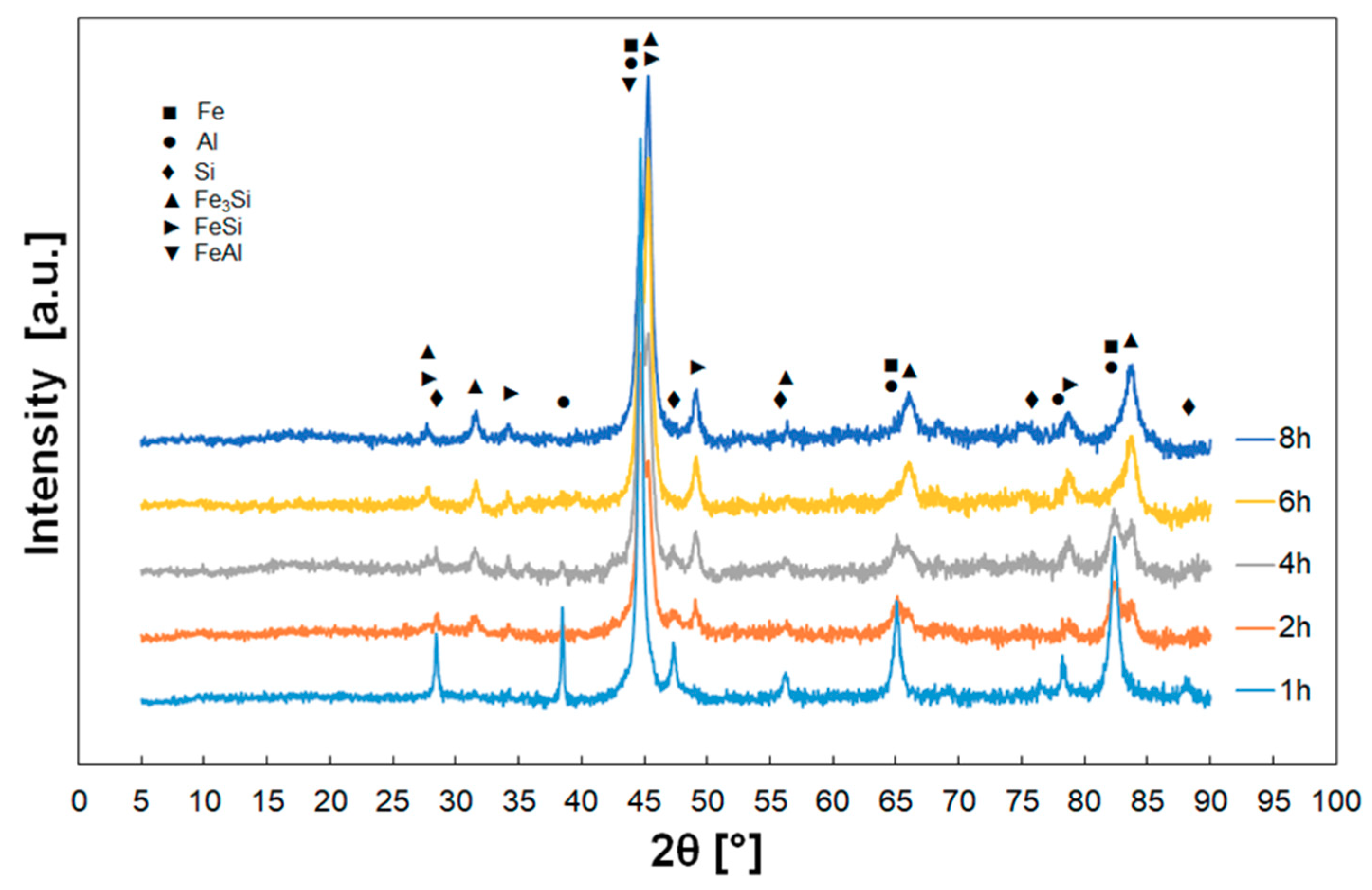

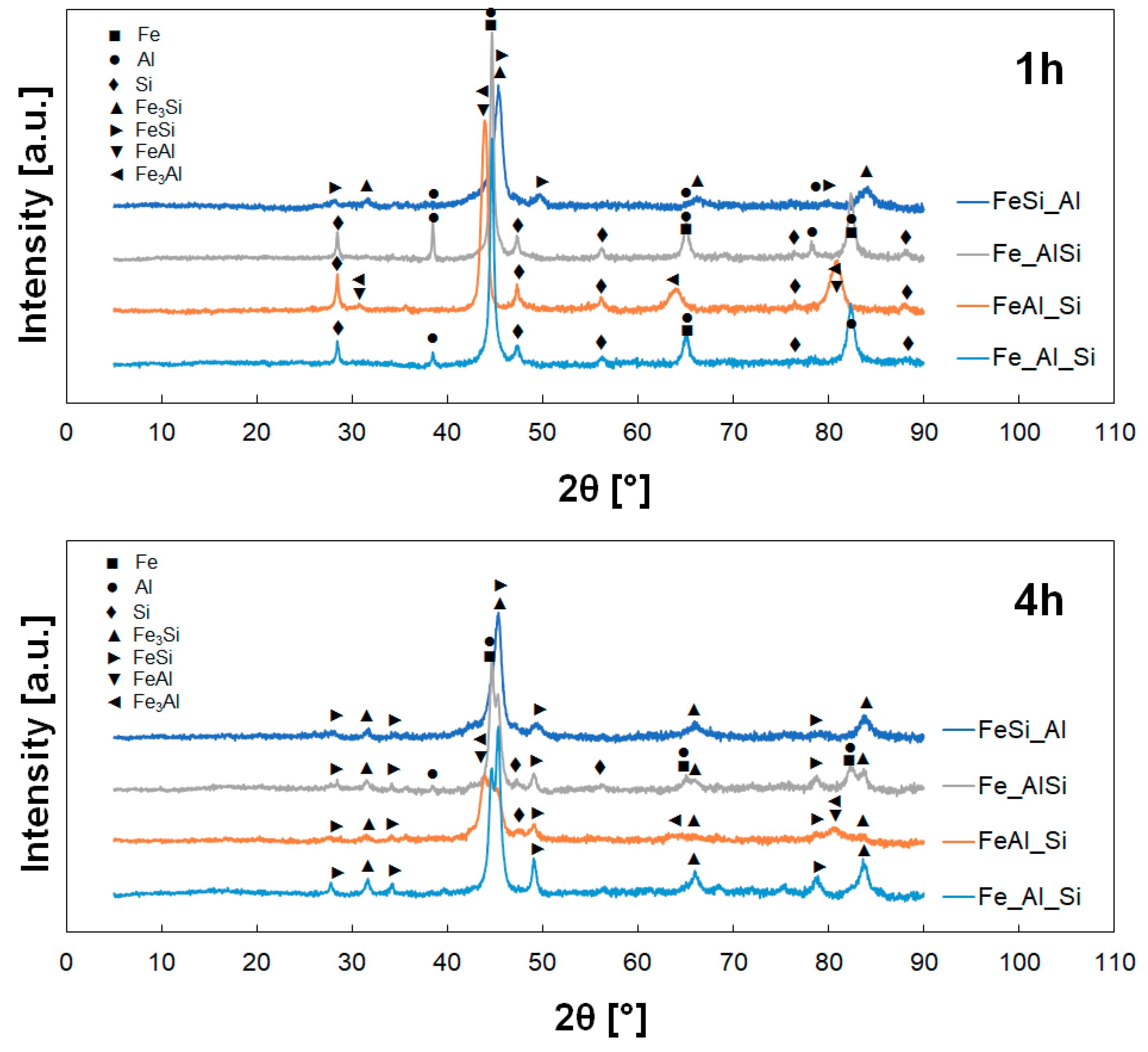

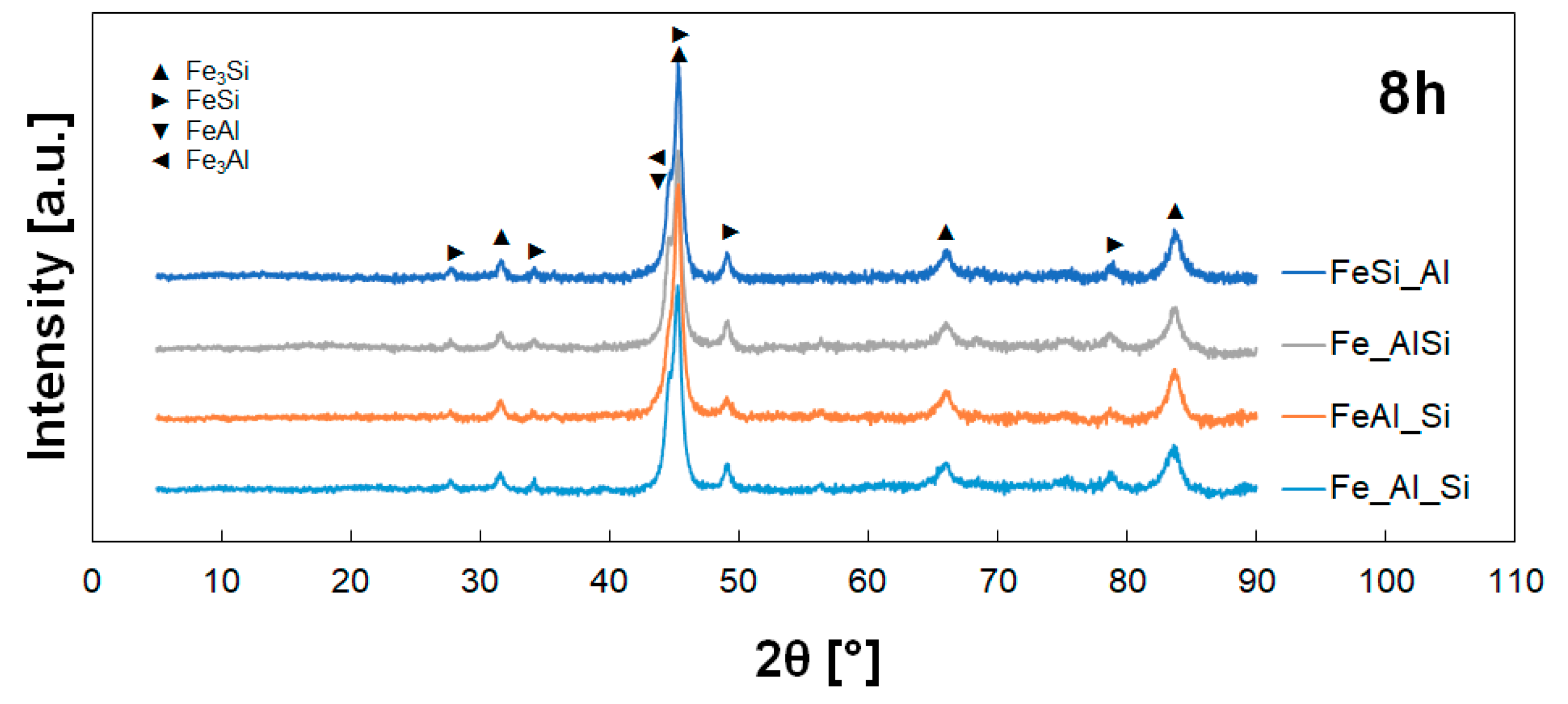

3.1. Powders

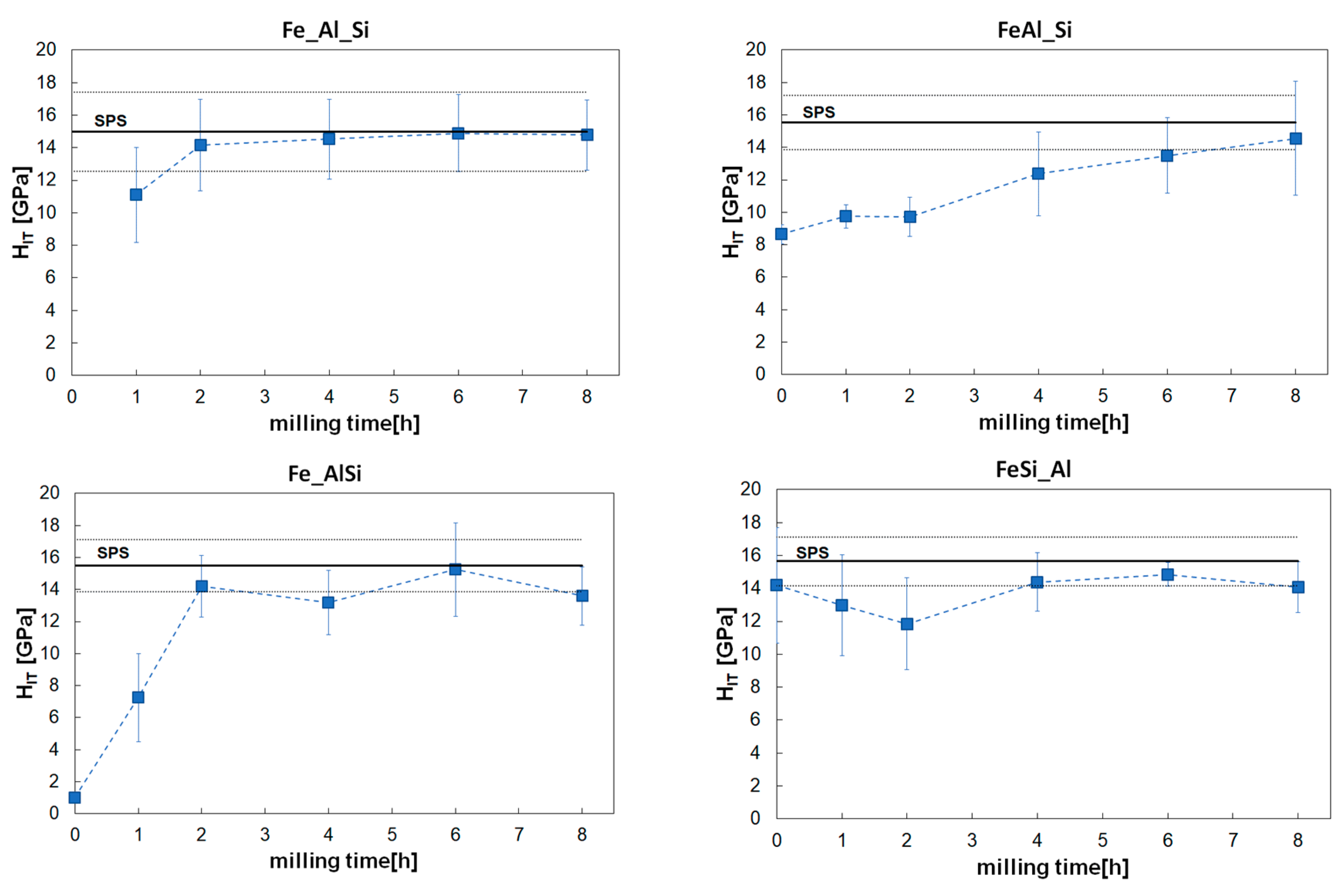

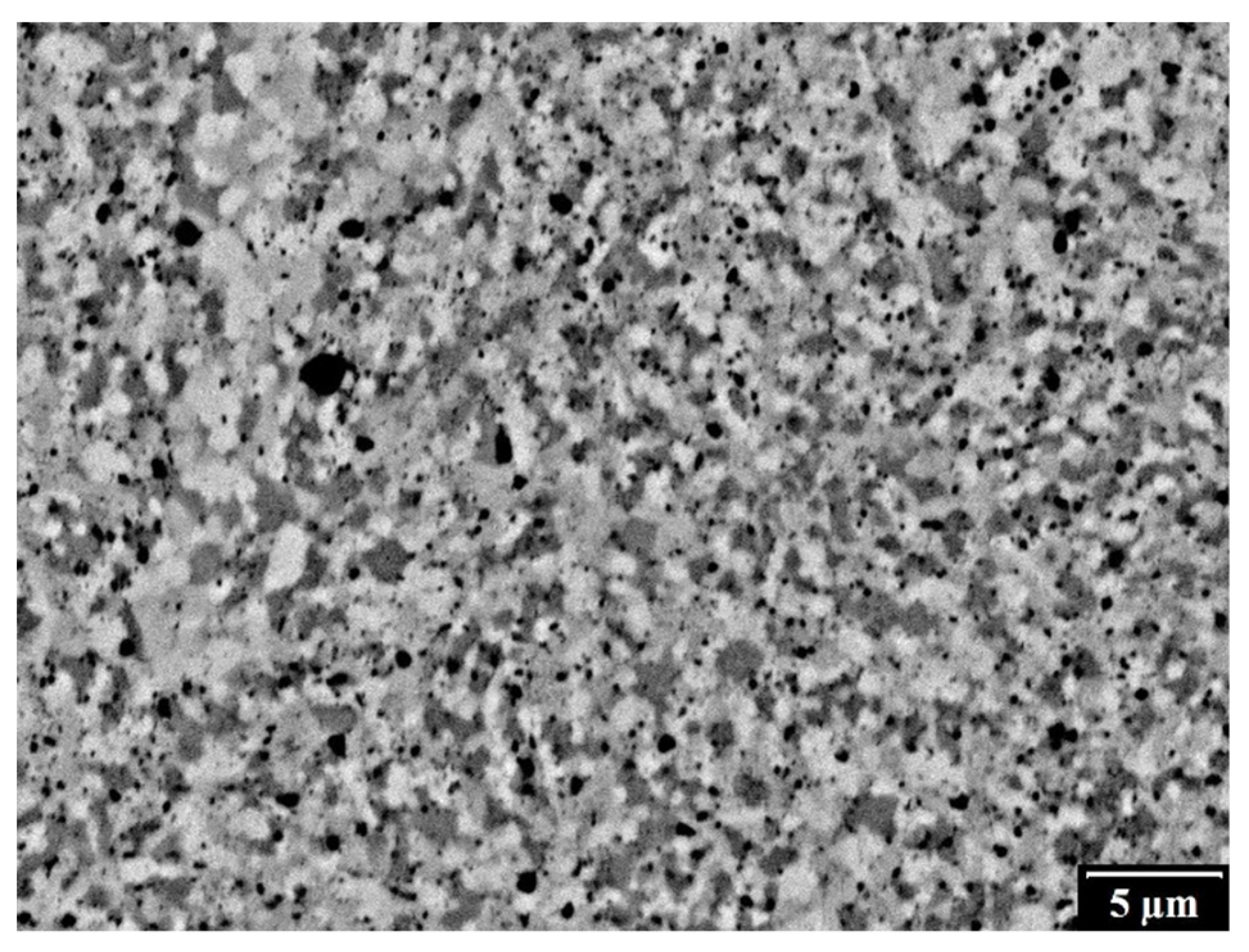

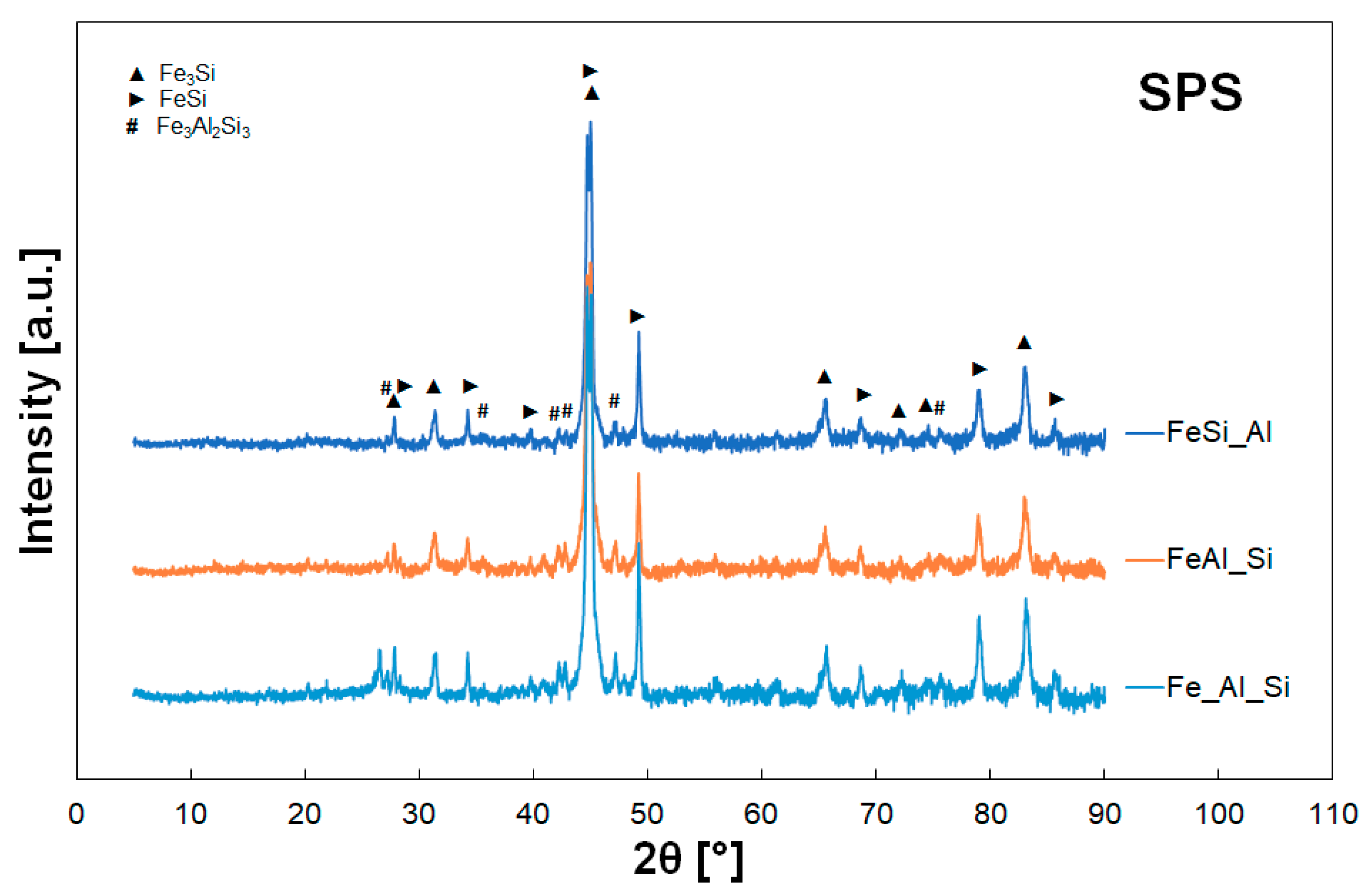

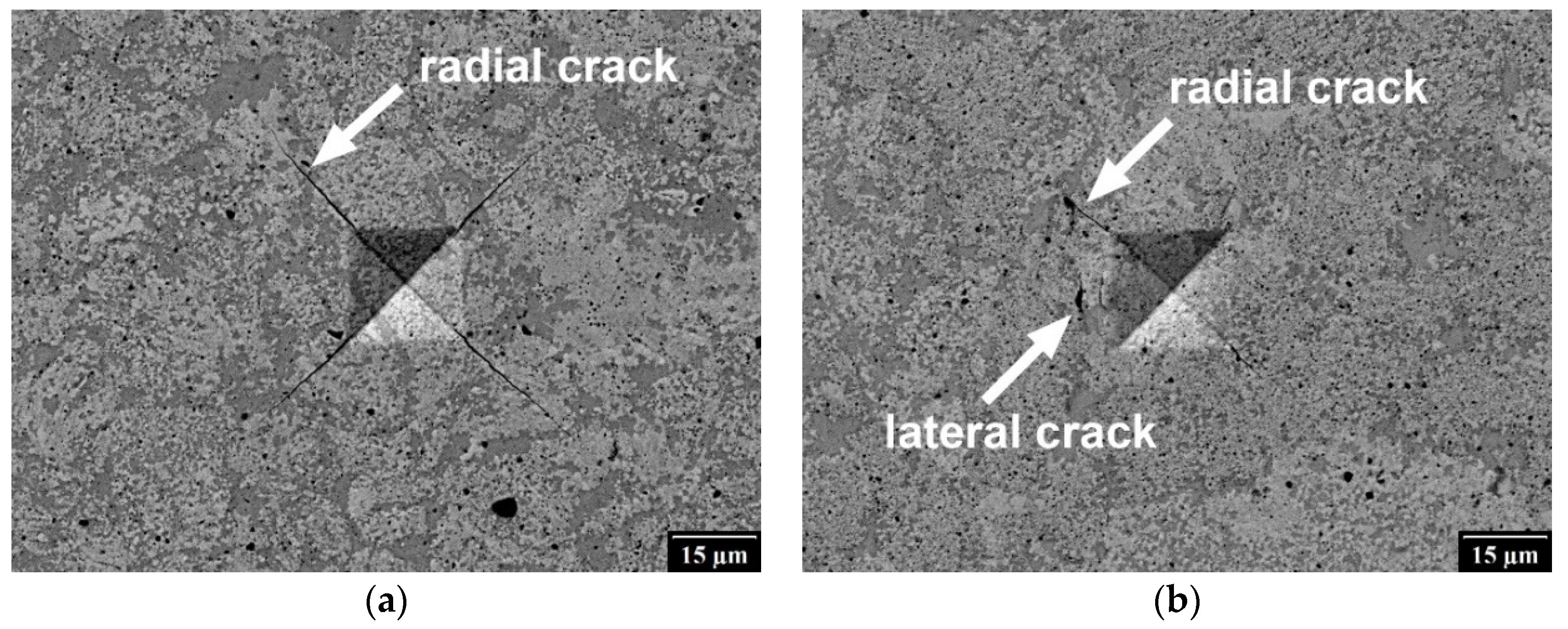

3.2. Compacted Materials

4. Discussion

5. Conclusions

- The final fine microstructure and measured mechanical properties of the powder mixtures are not significantly different. They are composed mainly by Fe3Si and FeSi phases supersaturated by Al.

- The mixture of hard (brittle) and soft (ductile) powders leads to shorter milling times, the mixture of hard initial powders requires longer milling times for complete homogenization.

- For the optimization of the production process (time for complete homogenization), the most efficient is the mixture Fe_Al_Si, followed by Fe_AlSi and FeSi_Al. Longest time to prepare homogenous powder is needed for FeAl_Si mixture.

- Fracture toughness is improved when the milling process is stopped immediately after the complete homogenization (highest fracture toughness was observed for the mixture FeAl_Si with the longest homogenization time).

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Deevi, S.C.; Sikka, V.K. Nickel and iron aluminides: An overview on properties, processing, and applications. Intermetallics 1996, 4, 357–375. [Google Scholar] [CrossRef]

- Zhu, X.; Yao, Z.; Gu, X.; Cong, W.; Zhang, P. Microstructure and corrosion resistance of Fe-Al intermetallic coating on 45 steel synthesized by double glow plasma surface alloying technology. Trans. Nonferrous Met. Soc. China 2009, 19, 143–148. [Google Scholar] [CrossRef]

- Janda, D.; Fietzek, H.; Galetz, M.; Heilmaier, M. The effect of micro-alloying with Zr and Nb on the oxidation behavior of Fe3Al and FeAl alloys. Intermetallics 2013, 41, 51–57. [Google Scholar] [CrossRef]

- Zamanzade, M.; Vehoff, H.; Barnoush, A. Effect of chromium on elastic and plastic deformation of Fe3Al intermetallics. Intermetallics 2013, 41, 28–34. [Google Scholar] [CrossRef]

- Kratochvíl, P.; Karlík, M.; Haušild, P.; Cieslar, M. Influence of Annealing on Mechanical Properties of an Fe-28Al-4Cr-0.1Ce Alloy. Intermetallics 1999, 7, 847–853. [Google Scholar] [CrossRef]

- Karlík, M.; Haušild, P.; Šíma, V.; Málek, P.; Vlasák, T. High Temperature Mechanical Properties of Fe-40-at% Al Based Intermetallic Alloys with C or Ti Addition. Int. J. Mater. Res. 2009, 100, 386–390. [Google Scholar] [CrossRef]

- Prahl, J.; Haušild, P.; Karlík, M.; Crenn, J.-F. Fracture Behaviour of Fe3Al Alloy with Additions of Zr and C at Different Temperatures. Kovové Materiály 2005, 43, 134–144. [Google Scholar]

- Novák, P.; Nová, K. Oxidation Behavior of Fe-Al, Fe-Si and Fe-Al-Si Intermetallics. Materials 2019, 12, 1748. [Google Scholar] [CrossRef]

- Novák, P.; Zelinková, M.; Šerák, J.; Michalcová, A.; Novák, M.; Vojtěch, D. Oxidation resistance of SHS Fe–Al–Si alloys at 800 °C in air. Intermetallics 2011, 19, 1306–1312. [Google Scholar] [CrossRef]

- Critical Raw Materials. Available online: https://ec.europa.eu/growth/sectors/raw-materials/specific-interest/critical_cs (accessed on 28 July 2019).

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. Mechanically alloyed metals. Mater. Sci. Technol. 2000, 16, 1404–1411. [Google Scholar] [CrossRef]

- Novák, P.; Průša, F.; Nová, K.; Bernatiková, A.; Salvetr, P.; Kopeček, J.; Haušild, P. Application of Mechanical Alloying in Synthesis of Intermetallics. Acta Phys. Pol. A 2018, 134, 720–723. [Google Scholar] [CrossRef]

- Zakeri, M.; Ramezanib, M.; Nazari, A. Effect of Ball to Powder Weight Ratio on the Mechanochemical Synthesis of MoSi2-TiC Nanocomposite Powder. Mater. Res. 2012, 15, 891–897. [Google Scholar] [CrossRef]

- Baig, Z.; Mamat, O.; Mustapha, M.; Mumtaz, A.; Sarfraz, M.; Haider, S. An Efficient Approach to Address Issues of Graphene Nanoplatelets (GNPs) Incorporation in Aluminium Powders and Their Compaction Behaviour. Metals 2018, 8, 90. [Google Scholar] [CrossRef]

- Hao, X.-N.; Zhang, H.-P.; Zheng, R.-X.; Zhang, Y.-T.; Ameyama, K.; Ma, C.-L. Effect of mechanical alloying time and rotation speed on evolution of CNTs/Al-2024 composite powders. Trans. Nonferrous Met. Soc. China 2014, 24, 2380–2386. [Google Scholar] [CrossRef]

- Nová, K.; Novák, P.; Průša, F.; Kopeček, J.; Čech, J. Synthesis of Intermetallics in Fe-Al-Si System by Mechanical Alloying. Metals 2019, 12, 20. [Google Scholar] [CrossRef]

- Orru, R.; Licheri, R.; Locci, A.M.; Cincotti, A.; Cao, G. Consolidation/synthesis of materials by electric current activated/assisted sintering. Mater. Sci. Eng. R Rep. 2009, 63, 127–287. [Google Scholar] [CrossRef]

- Novák, P.; Vanka, T.; Nová, K.; Stoulil, J.; Průša, F.; Kopeček, J.; Haušild, P. Structure and properties of Fe-Al-Si alloy prepared by mechanical alloying. Materials 2019, 12, 2463. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- ISO 14577. Metallic Materials—Instrumented Indentation Test for Hardness and Material Parameters; ISO: Geneva, Switzerland, 2002. [Google Scholar]

- Čech, J.; Haušild, P.; Karlík, M.; Kadlecová, V.; Čapek, J.; Průša, F.; Novák, P. Mechanical properties of FeAlSi powders prepared by mechanical alloying from different initial feedstock materials. Matériaux Tech. 2019, 107, 207. [Google Scholar] [CrossRef]

- Niihara, K. A Fracture Mechanics Analysis of Indentation-Induced Palmqvist Crack in Ceramics. J. Mater. Sci. Lett. 1983, 2, 221–223. [Google Scholar] [CrossRef]

- Jems Website. Available online: http://www.jems-saas.ch/Home/jemsWebSite/jems.html (accessed on 28 July 2019).

- Nová, K.; Novák, P.; Vanka, T.; Průša, F. The effect of production process on properties of FeAl20Si20. Manuf. Technol. 2018, 18, 295–298. [Google Scholar] [CrossRef]

- Kruger, M.; Schmelzer, J.; Helmecke, M. Similarities and Differences in Mechanical Alloying Processes of V-Si-B and Mo-Si-B Powders. Metals 2016, 6, 241. [Google Scholar] [CrossRef]

- Hegde, M.R.; Surendranathan, A.O. Phase Transformation, Structural Evolution and Mechanical Property of Nanostructured FeAl as a Result of Mechanical Alloying. Russ. J. Non-Ferr. Met. 2009, 50, 474–484. [Google Scholar] [CrossRef]

- Schmelzer, J.; Baumann, T.; Dieck, S.; Kruger, M. Hardening of V–Si alloys during high energy ball milling. Powder Technol. 2016, 294, 493–497. [Google Scholar] [CrossRef]

- Lei, R.; Wang, M.; Xu, S.; Wang, H.; Chen, G. Microstructure, Hardness Evolution, and Thermal Stability Mechanism of Mechanical Alloyed Cu-Nb Alloy during Heat Treatment. Metals 2016, 6, 194. [Google Scholar] [CrossRef]

- Marker, M.C.; Skolyszewska-Kühberger, B.; Effenberger, H.S.; Schmetterer, C.; Richter, K.W. Phase equilibria and structural investigations in the system Al–Fe–Si. Intermetallics 2011, 19, 1919–1929. [Google Scholar] [CrossRef]

- Huang, B.L.; Perez, R.J.; Lavernia, E.J.; Luton, M.J. Formation of supersaturated solid solutions by mechanical alloying. Nanostruct. Mater. 1996, 7, 67–79. [Google Scholar] [CrossRef]

- Nix, W.D.; Gao, H. Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 1998, 46, 411–425. [Google Scholar] [CrossRef]

- Ponton, C.B.; Rawlings, R.D. Vickers indentation fracture toughness test Part 1 Review of literature and formulation of standardised indentation toughness equations. Mater. Sci. Technol. 1989, 5, 865–872. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, X. Toughness evaluation of hard coatings and thin films. Thin Solid Films 2012, 520, 2375–2389. [Google Scholar] [CrossRef]

- Laugier, M.T. New formula for indentation toughness in ceramics. J. Mater. Sci. Lett. 1987, 6, 355–356. [Google Scholar] [CrossRef]

- Lawn, B.R.; Evans, A.G.; Marshall, D.B. Elastic/plastic indentation damage in ceramics: The median/radial crack system. J. Am. Ceram. Soc. 1980, 63, 574–581. [Google Scholar] [CrossRef]

- Chen, J. Indentation-based methods to assess fracture toughness for thin coatings. J. Phys. D Appl. Phys. 2012, 45, 203001. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, T. Determination of Fracture toughness of Brittle Materials by Indentation. Acta Mech. Solidica Sin. 2015, 28, 221–234. [Google Scholar] [CrossRef]

- Gogotsi, G.A. Fracture toughness of ceramics and ceramic composites. Ceram. Int. 2003, 29, 777–784. [Google Scholar] [CrossRef]

| Powder Mixture | Grain Size [µm] | H [GPa] | E [GPa] | a [µm] | l [µm] | l/a [-] | KIC [MPa·m1/2] | ||

|---|---|---|---|---|---|---|---|---|---|

| Fe_Al_Si | 1.04 | 13.48 | 233.55 | 14.29 | 18.22 | 1.28 | 2.57 | ± | 0.18 |

| FeAl_Si | 1.07 | 13.46 | 220.45 | 14.33 | 7.77 | 0.54 | 3.61 | ± | 0.32 |

| Fe_AlSi | 0.94 | 13.37 | 231.03 | 14.50 | 16.53 | 1.14 | 2.73 | ± | 0.28 |

| FeSi_Al | 0.88 | 12.61 | 220.66 | 14.26 | 9.95 | 0.70 | 3.21 | ± | 0.40 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Čech, J.; Haušild, P.; Karlík, M.; Bouček, V.; Nová, K.; Průša, F.; Novák, P.; Kopeček, J. Effect of Initial Powders on Properties of FeAlSi Intermetallics. Materials 2019, 12, 2846. https://doi.org/10.3390/ma12182846

Čech J, Haušild P, Karlík M, Bouček V, Nová K, Průša F, Novák P, Kopeček J. Effect of Initial Powders on Properties of FeAlSi Intermetallics. Materials. 2019; 12(18):2846. https://doi.org/10.3390/ma12182846

Chicago/Turabian StyleČech, Jaroslav, Petr Haušild, Miroslav Karlík, Václav Bouček, Kateřina Nová, Filip Průša, Pavel Novák, and Jaromír Kopeček. 2019. "Effect of Initial Powders on Properties of FeAlSi Intermetallics" Materials 12, no. 18: 2846. https://doi.org/10.3390/ma12182846

APA StyleČech, J., Haušild, P., Karlík, M., Bouček, V., Nová, K., Průša, F., Novák, P., & Kopeček, J. (2019). Effect of Initial Powders on Properties of FeAlSi Intermetallics. Materials, 12(18), 2846. https://doi.org/10.3390/ma12182846