The Influence of Fluidized Bed Combustion Fly Ash on the Phase Composition and Microstructure of Cement Paste

Abstract

1. Introduction

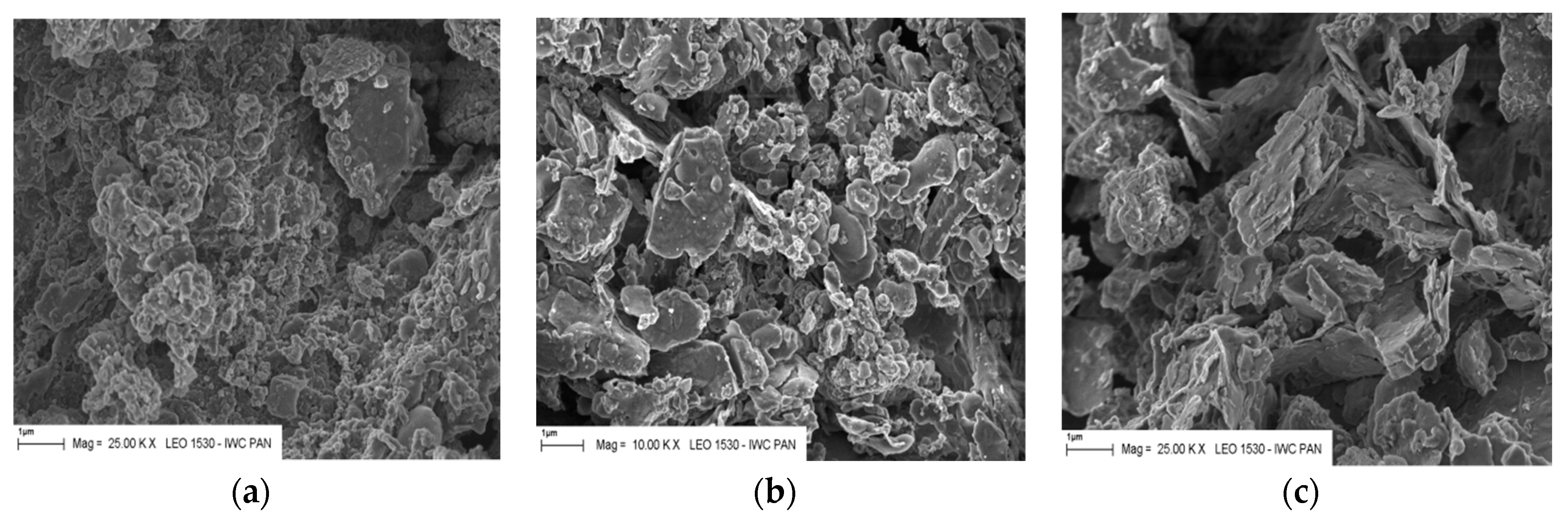

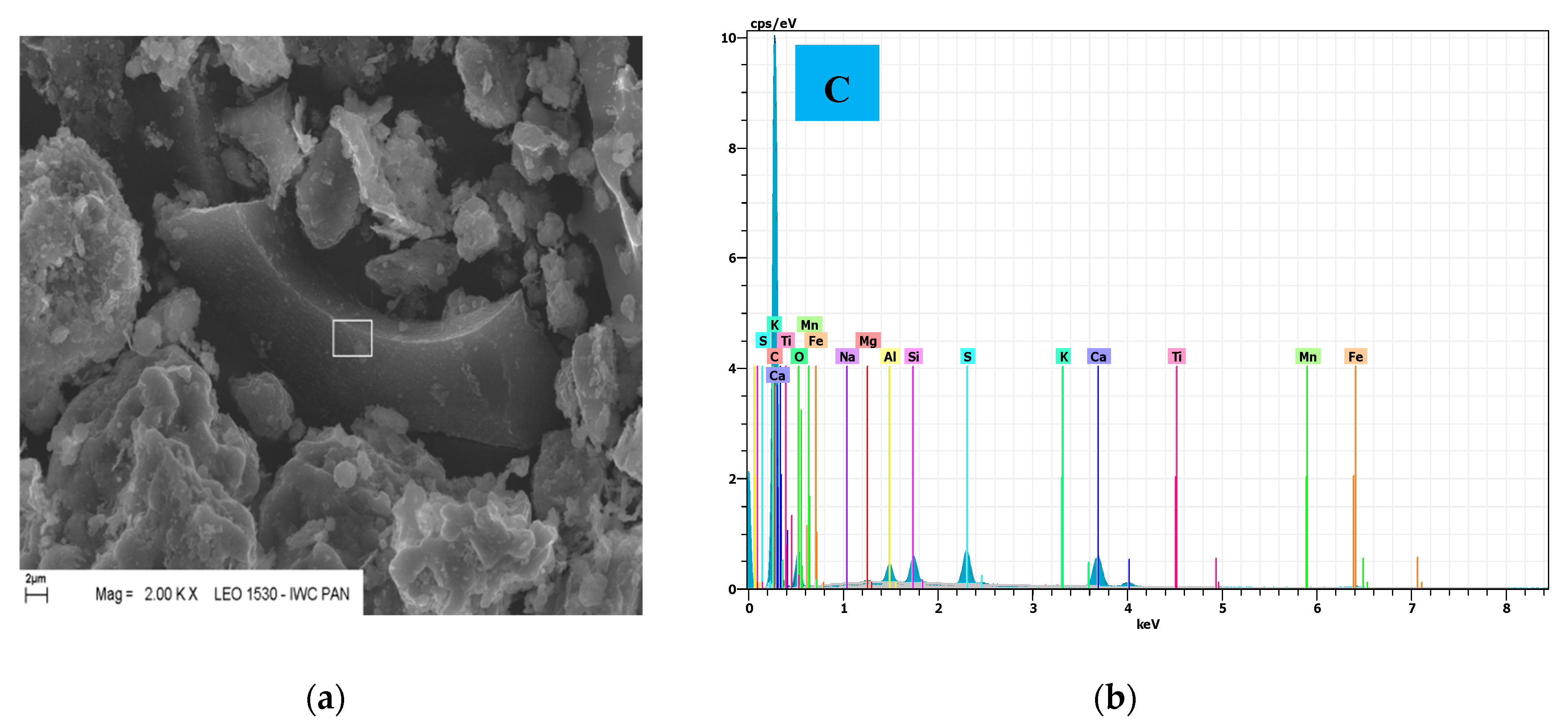

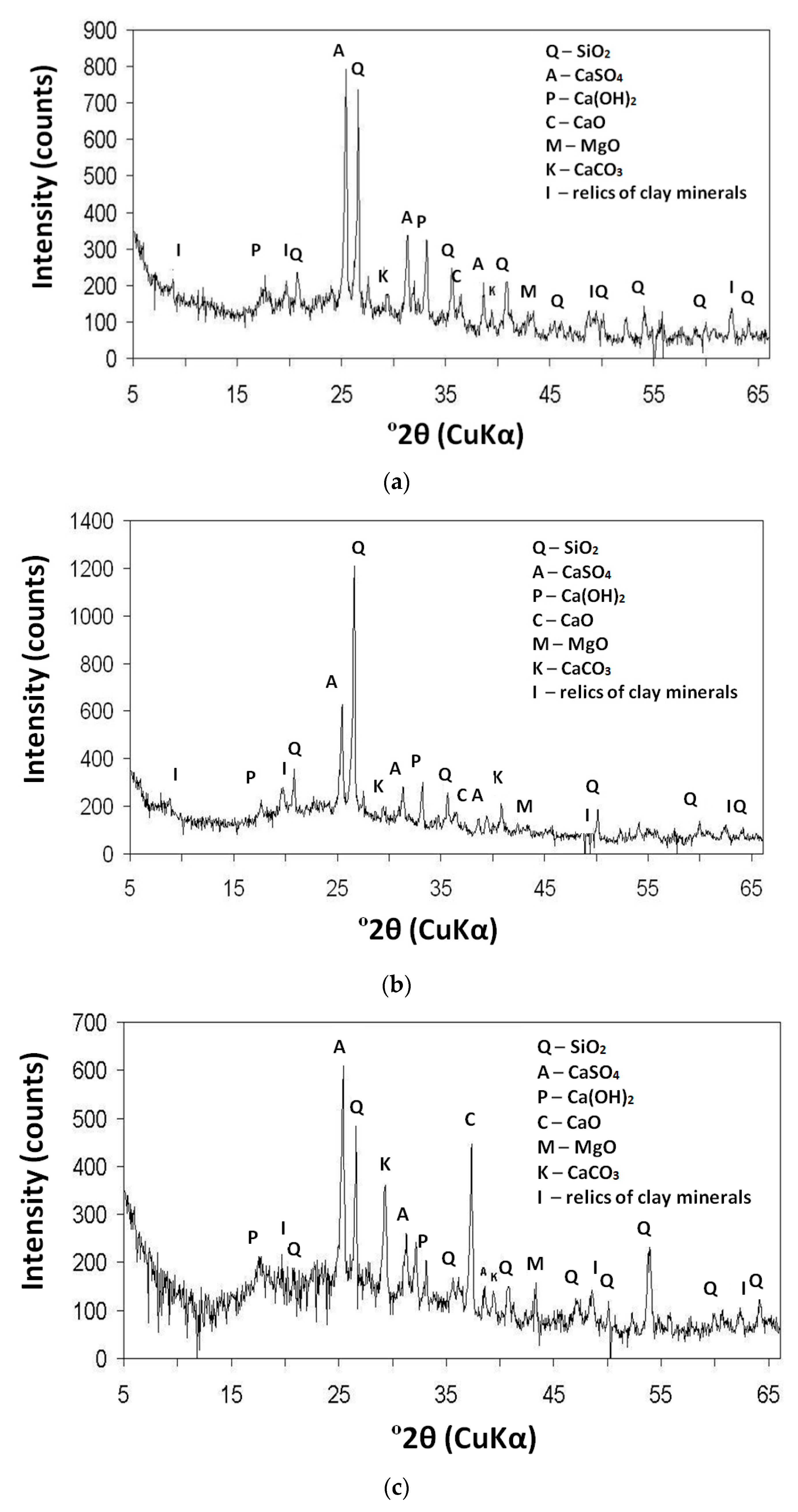

2. Experimental Program

2.1. Materials and Methods

2.2. Test Methods

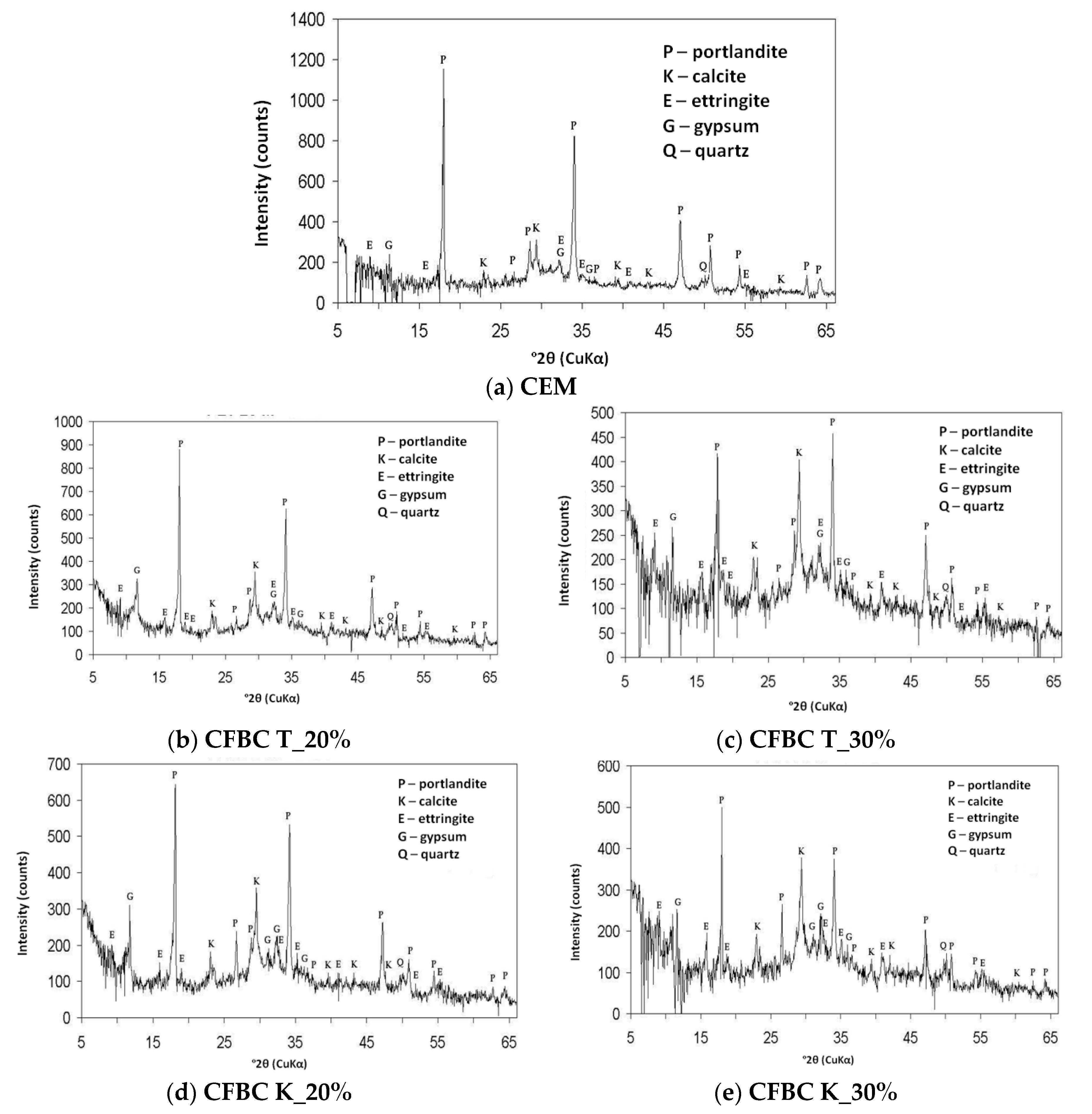

3. Test Results and Discussion

4. Conclusions

- Macroscopic analysis revealed differences in colour of fluidized bed combustion fly ashes, which was assumed to be correlated to carbon content. This method can be applied for preliminary evaluation of CFBC fly ash suitability as concrete additive;

- The major components in the investigated CFBC fly ash consisted of the following (in descending order of content): SiO2, Al2O3, CaO, Fe2O3 and SO3.

- The largest difference between analyzed fly ash was visible in CaO content, which was the result of the type of fuel. The content of the CaO in CFBC fly ash from lignite burning was two to three times higher than in fly ash from hard coal burning.

- A proper determination of the unburned carbon content in fluidized bed fly ash required separation of CaCO3, portlandite and non-hydrated clay minerals content from the loss on ignition data.

- The addition of CFBC fly ash for replacement of cement by 20% or 30% by weight did not induce significant changes in qualitative phase composition of hardened cement paste cured in water up to 400 days in regard to curing for 28 days.

- The addition of the CFBC fly ash resulted in increasing content of C–S–H gel and crystalline ettringite, which was indicated by the increase of water bound in hydration products and the decrease of portlandite content.

- The crystalline ettringite content in hardened cement paste containing 30% CFBC fly ash from lignite burning was higher by about 20% in comparison to cement paste without ash at 28 days of curing.

Author Contributions

Funding

Conflicts of Interest

References

- Gazdiča, D.; Fridrichováa, M.; Kulíseka, K.; Vehovská, L. The potential use of the FBC ash for the preparation of blended cements. Procedia Eng. 2017, 180, 1298–1305. [Google Scholar] [CrossRef]

- Anthony, E.J.; Granatstein, D.L. Sulfation phenomena in fluidized bed combustion systems. Prog. Energy Combust. Sci. 2001, 27, 215–236. [Google Scholar] [CrossRef]

- Nowak, W. Clean coal fluidized–bed technology in Poland. Appl. Energy 2003, 74, 405–413. [Google Scholar] [CrossRef]

- Zhu, Q. Developments in Circulating Fluidized Bed Combustion; IEA Clean Coal Centre: London, UK, 2013; ISBN 978-92-9029-539-6. 60p. [Google Scholar]

- Cai, R.; Ke, X.; Lyu, J.; Yang, H.; Zhang, M.; Yue, G.; Ling, W. Progress of circulating fluidized bed combustion technology in China: A review. Clean Energy 2017, 1, 36–49. [Google Scholar] [CrossRef]

- Strigáč, J.; Števulová, N.; Mikušinec, J.; Sobolev, K. The fungistatic properties and potential application of by-product fly ash from fluidized bed combustion. Constr. Build. Mater. 2018, 159, 351–360. [Google Scholar] [CrossRef]

- Anthony, E.J. Fluidized bed combustion of alternative solid fuels, status, successes and problems of the technology. Prog. Energy Combust. Sci. 1995, 21, 239–268. [Google Scholar] [CrossRef]

- Brandstetr, J.; Havlica, J.; Odler, I. Properties and use of solid residue from fluidized bed coal combustion. In Waste Materials Used in Concrete Manufacturing; Chandra, S., Ed.; Noyes Publications Press: Westwood, NJ, USA, 1997; pp. 1–47. [Google Scholar]

- Conn, R.E.; Sellakumar, K.; Bland, A.E. Utilization of CFB fly ash for construction applications. In Proceedings of the 15th International Conference on Fluidized Bed Combustion, Savannah, Georgia, 16–19 May 1999; 19p. [Google Scholar]

- Roszczynialski, W.; Nocuń-Wczelik, W.; Gawlicki, M. Fly ash from fluidized bed coal combustion as complex cement addition. In Proceedings of the Three-Day CANMET/ACI International Symposium on Sustainable Development and Concrete Technology, San Francisco, CA, USA, 16–19 September 2001; pp. 415–430. [Google Scholar]

- Marks, M.; Jóźwiak-Niedźwiedzka, D.; Glinicki, M.A.; Olek, J.; Marks, M. Assessment of scaling durability of concrete with CFBC ash by automatic classification rules. J. Mater. Civ. Eng. 2012, 24, 860–867. [Google Scholar]

- Glinicki, M.A.; Zieliński, M. The influence of CFBC fly ash addition on phase composition of air-entrained concrete. Bull. Pol. Acad. Sci. Tech. Sci. 2008, 56, 45–52. [Google Scholar]

- Giergiczny, Z. Fly ash and slag. Cem. Concr. Res. 2019, 124, 15. [Google Scholar] [CrossRef]

- Fu, X.; Li, Q.; Zhai, J.; Sheng, G.; Li, F. The physical–chemical characterization of mechanically—Treated CFBC fly ash. Cem. Concr. Compos. 2008, 30, 220–226. [Google Scholar] [CrossRef]

- Sheng, G.; Zhai, J.; Li, Q.; Li, F. Utilization of fly ash doming from a CFBC boiler co-firing coal and petroleum coke in Portland cement. Fuel 2007, 86, 2615–2631. [Google Scholar] [CrossRef]

- Rajczyk, K.; Giergiczny, E. Research on the possibility of application of the waste products from energy. In Proceedings of the 3rd International Scientific Conference Energia i Środowisko w Technologiach Materiałów Budowlanych, Opole, Poland, 27–29 September 2004. (In Polish). [Google Scholar]

- Lothenbach, B.; Scrivener, K.; Hooton, R.D. Supplementary cementitious materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- Rajczyk, K.; Giergiczny, E.; Glinicki, M.A. Use of DTA in the investigations of fly ashes from fluidized bed boilers. J. Therm. Anal. Calorim. 2004, 77, 165–170. [Google Scholar] [CrossRef]

- Nguyen, H.A.; Chang, T.P.; Shih, J.Y.; Chen, C.T.; Nguyen, T.D. Influence of circulating fluidized bed combustion (CFBC) fly ash on properties of modified high volume low calcium fly ash (HVFA) cement paste. Constr. Build. Mater. 2015, 91, 208–215. [Google Scholar] [CrossRef]

- Hlaváček, P.; Šulc, R.; Šmilauer, V.; Rößler, C.; Snop, R. Ternary binder made of CFBC fly ash, conventional fly ash, and calcium hydroxide: Phase and strength evolution. Cem. Concr. Compos. 2018, 90, 100–107. [Google Scholar] [CrossRef]

- Škvára, F.; Šulc, R.; Snop, R.; Peterová, A.; Šídlová, M. Hydraulic clinkerless binder on the fluid sulfocalcic fly ash basis. Cem. Concr. Compos. 2018, 93, 118–126. [Google Scholar] [CrossRef]

- Lin, W.T.; Weng, T.L.; Cheng, A.; Chao, S.J.; Hsu, H.M. Properties of controlled low strength material with circulating fluidized bed combustion ash and recycled aggregates. Materials 2018, 11, 715. [Google Scholar] [CrossRef]

- Chi, M. Synthesis and characterization of mortars with circulating fluidized bed combustion fly ash and ground granulated blast-furnace slag. Constr. Build. Mater. 2016, 123, 565–573. [Google Scholar] [CrossRef]

- Tien Dung, N.; Chang, T.P.; Chen, C.H.T. Circulating fluidized bed combustion fly-ash-activated slag concrete as novel construction material. ACI Mater. J. 2014, 111, 105. [Google Scholar]

- Chen, X.; Gao, J.; Yan, Y.; Liu, Y. Investigation of expansion properties of cement paste with circulating fluidized bed fly ash. Constr. Build. Mater. 2017, 157, 1154–1162. [Google Scholar] [CrossRef]

- Jóźwiak-Niedźwiedzka, D. Effect of fluidized bed combustion fly ash on the chloride resistance and scaling resistance of concrete. In Concrete in Aggressive Aqueous Environments—Performance, Testing, and Modeling; Alexander, M.G., Bertron, A., Eds.; RILEM Publications SARL: Toulouse, France, 2009; pp. 556–563. [Google Scholar]

- Kubissa, W.; Pacewska, B.; Wilińska, I. Comparative investigations of some properties related to durability of cement concretes containing different fly ashes. Adv. Mater. Res. 2014, 1054, 154–161. [Google Scholar] [CrossRef]

- Czarnecki, L.; Woyciechowski, P.; Adamczewski, G. Risk of concrete carbonation with mineral industrial by-products. KSCE J. Civ. Eng. 2018, 22, 755–764. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Ruben Snellings, R.; Bernal, S.A. Supplementary cementitious materials: New sources, characterization, and performance insights. Cem. Concr. Res. 2019, 122, 257–273. [Google Scholar] [CrossRef]

- Methods of Testing Cement. Determination of Strength; PN-EN 196-1:2016-07; The Polish Committee for Standardization: Warsaw, Poland, 2016; 34p.

- Šiler, P.; Bayer, P.; Sehnal, T.; Kolářová, I.; Opravil, T.; Šoukal, F. Effects of high-temperature fly ash and fluidized bed combustion ash on the hydration of Portland cement. Constr. Build. Mater. 2015, 78, 181–188. [Google Scholar] [CrossRef]

- Hanisková, D.; Bartoníčková, E.; Koplík, J.; Opravil, T. The ash from fluidized bed combustion as a donor of sulfates to the Portland clinker. Procedia Eng. 2016, 151, 394–401. [Google Scholar] [CrossRef][Green Version]

- Krzywobłocka-Laurów, R.; Siemaszko-Lotkowska, D. Determination of the phase composition of common cements. Instr. Build. Res. Inst. 2006, 419. [Google Scholar]

- Matschei, T.; Lothenbach, B.; Glasser, F.P. The AFm phase in Portland cement. Cem. Concr. Res. 2007, 37, 118–130. [Google Scholar] [CrossRef]

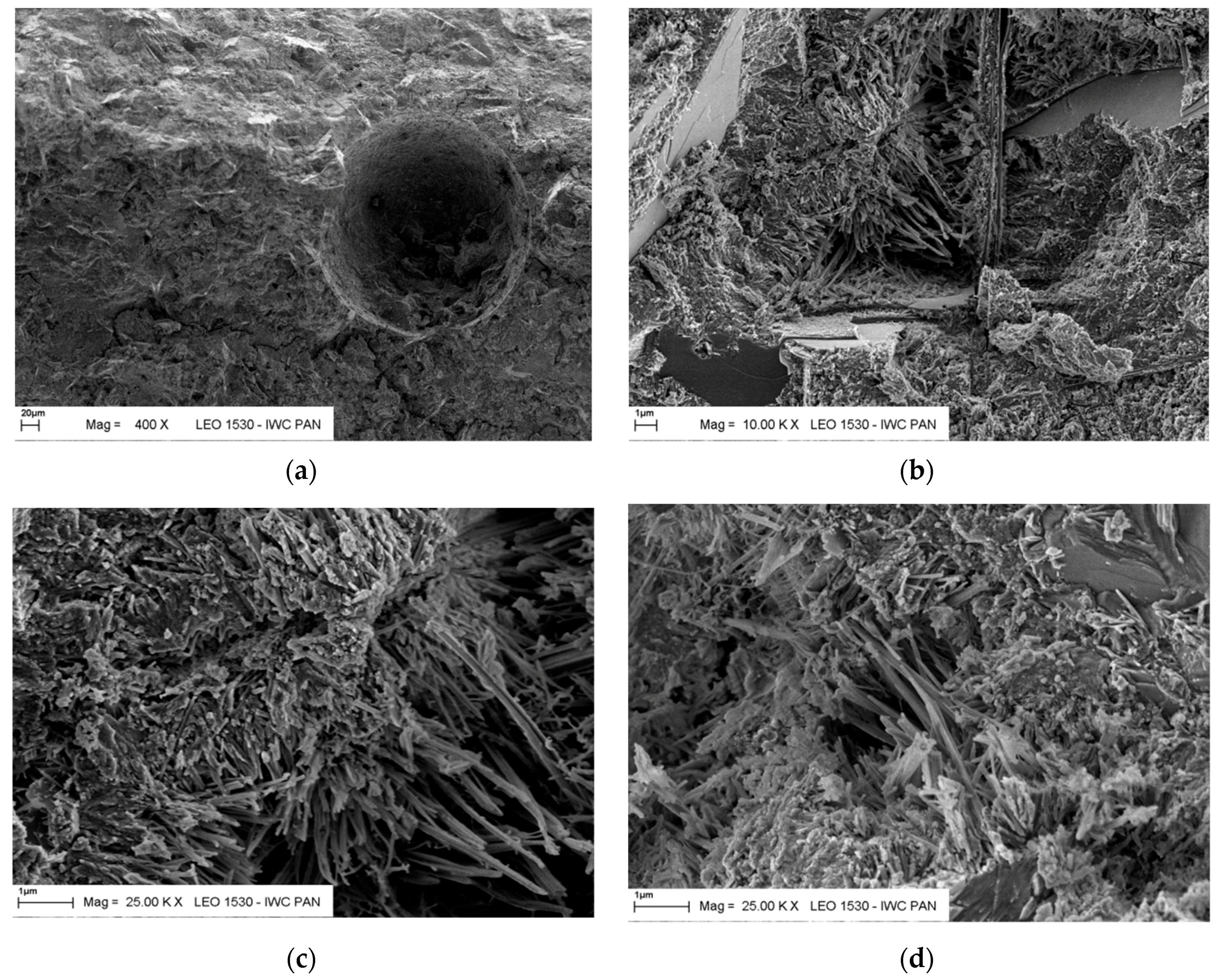

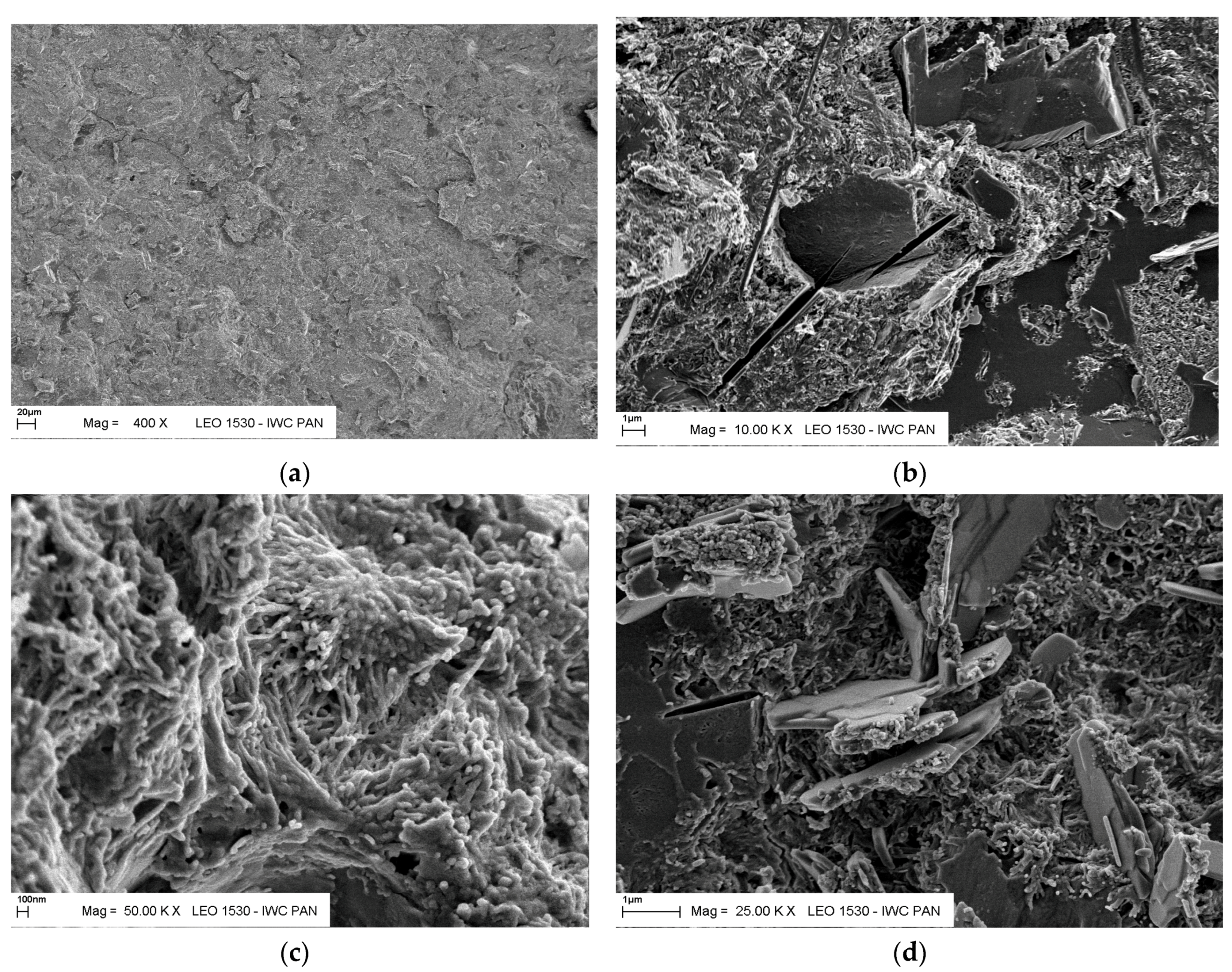

- Glinicki, M.A.; Krzywobłocka-Laurów, R.; Ranachowski, Z.; Dąbrowski, M.; Wołowicz, J. Microstructure analysis of concrete modified with addition of calcareous fly ash. Roads Bridges Drog. i Mosty 2013, 12, 173–189. [Google Scholar]

- Tishmack, J.K.; Olek, J.; Diamond, S. Characterization of high-calcium fly ashes and their potential influence on ettringite formation in cementitious systems. Cem. Concr. Aggreg. 1999, 21, 82–92. [Google Scholar]

- Lee, S.H.; Kim, G.S. Self-cementitious hydration of circulating fluidized bed combustion fly ash. J. Korean Ceram. Soc. 2017, 54, 128–136. [Google Scholar] [CrossRef]

- Gibas, K.; Glinicki, M.A.; Nowowiejski, G. Evaluation of impermeability of concrete containing calcareous fly ash in respect to environmental media. Roads Bridges Drog. i Mosty 2013, 12, 159–171. [Google Scholar]

| Component | CFBC Fly Ash | ||

|---|---|---|---|

| Hard Coal Burning | Lignite Burning | ||

| S | K | T | |

| LOI * | 5.71 | 3.40 | 2.73 |

| SiO2 | 38.80 | 47.18 | 36.47 |

| CaO | 9.80 | 5.84 | 15.95 |

| CaOfree ** | not tested | 3.40 | 4.75 |

| Fe2O3 | 9.59 | 6.80 | 4.40 |

| Al2O3 | 23.26 | 25.62 | 28.4 |

| MgO | 2.28 | 0.15 | 1.65 |

| Na2O | 2.01 | 1.18 | 1.64 |

| K2O | 2.22 | 2.36 | 0.62 |

| SO3 | 5.82 | 3.62 | 3.8 |

| TiO2 | not tested | 1.08 | 3.84 |

| Cl- | 0.40 | 0.10 | 0.03 |

| Component | Cement CEM I 32.5 R |

|---|---|

| LOI | 3.40 |

| SiO2 | 21.40 |

| CaO | 65.06 |

| CaOfree ** | 1.00 |

| Fe2O3 | 2.53 |

| Al2O3 | 4.80 |

| MgO | 1.37 |

| Na2Oeq | 0.76 |

| SO3 | 2.60 |

| Cl- | 0.07 |

| Specific surface, cm2/g | 3210 |

| Density, g/cm3 | 3.09 |

| Designation of Specimens | Cement | CFBC | Water |

|---|---|---|---|

| CEM I | 420 | 0 | 210 |

| S20 | 336 | 84 | 210 |

| T20 | 336 | 84 | 210 |

| K20 | 336 | 84 | 210 |

| S30 | 294 | 126 | 210 |

| T30 | 294 | 126 | 210 |

| K30 | 294 | 126 | 210 |

| Attribute | CFBC Fly Ash | |||

|---|---|---|---|---|

| S | T | K | ||

| >0.045 mm, Yield (%) | 22.0 | 36.1 | 19.5 | |

| Color | Whole lot | brownish-grey 5YR 4/1 | light olive-grey 5Y 6 | olive-grey 5Y4/1 |

| Fraction > 0.045 mm | light brownish-grey 5YR 6/1 | light brownish-grey 5YR 6/1 | brownish-grey 5 | |

| Fraction < 0.045 mm | brownish-grey 5YR 4/1 | not tested | not tested | |

| Designation of Specimens | Flexural Strength | Comressive Strength |

|---|---|---|

| CEM I | 4.6 ± 0.3 | 33.8 ± 0.6 |

| S20 | 5.8 ± 0.2 | 47.8 ± 1.8 |

| T20 | 5.2 ± 0.3 | 39.8 ± 2.2 |

| K20 | 6.4 ± 0.4 | 53.3 ± 2.3 |

| S30 | 5.9 ± 0.3 | 46.0 ± 1.4 |

| T30 | 5.9 ± 0.7 | 35.9 ± 1.0 |

| K30 | 5.9 ± 0.6 | 53.1 ± 2.0 |

| Specimen | LOI *, wt % | Mass Loss at <350 °C, wt % | Relics of Coal, wt % | Portlandite, wt % | Calcium Carbonate, wt % |

|---|---|---|---|---|---|

| S | |||||

| Fraction > 0.045 mm | 1.7 | 0.45 | 0.8 | not detected | not detected |

| Fraction < 0.045 mm | 5.8 | 0.74 | 4.4 | not detected | not detected |

| T | |||||

| Fraction > 0.045 mm | 3.7 | 0.79 | 0.8 | not detected | 4.80 |

| Fraction < 0.045 mm | 5.9 | 1.05 | not detected | 1.2 | 10.35 |

| K | |||||

| Fraction > 0.045 mm | 3.4 | 0.89 | 1.8 | not detected | 1.60 |

| Fraction < 0.045 mm | 5.7 | 0.87 | 4.4 | not detected | 1.05 |

| Age, Days | Composition Parameter | Reference Paste CEM * | WZ Index for Hardened Pastes Containing CFBC Fly Ash in Relation to the Reference Paste (%) | |||

|---|---|---|---|---|---|---|

| T20 | T30 | K20 | K30 | |||

| 28 | Hydration products HI, % | 17.8 = 100% | 116.3 | 133.1 | 119.7 | 130.9 |

| Portlandite CH, % | 16.0 = 100% | 66.9 | 41.3 | 41.3 | 33.1 | |

| Calcium carbonate CC, % | 10.7 = 100% | 100.0 | 91.6 | 112.1 | 103.7 | |

| Ettringite ∑ I, a.u. ** | 326 = 100% | 127.9 | 131.3 | 121.2 | 124.2 | |

| 200 | Hydration products HI, % | 23.0 = 100% | 111.7 | 104.3 | 110.0 | 104.3 |

| Portlandite CH, % | 15.2 = 100% | 53.9 | 34.9 | 53.9 | 27.0 | |

| Calcium carbonate CC, % | 13.6 = 100% | 72.0 | 111.8 | 78.7 | 122.0 | |

| Ettringite ∑ I, a.u. ** | 459 = 100% | 97.8 | 104.1 | 102.8 | 112.9 | |

| 400 | Hydration products HI, % | 18.0 = 100% | 118.0 | 123.9 | 112.7 | 131.1 |

| Portlandite CH, % | 16.4 = 100% | 65.2 | 39.6 | 37.8 | 17.1 | |

| Calcium carbonate CC, % | 10.2 = 100% | 89.2 | 119.6 | 147.1 | 133.3 | |

| Ettringite ∑ I, a.u. ** | 380 = 100% | 105.0 | 115.5 | 97.1 | 112.1 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Glinicki, M.A.; Jóźwiak-Niedźwiedzka, D.; Dąbrowski, M. The Influence of Fluidized Bed Combustion Fly Ash on the Phase Composition and Microstructure of Cement Paste. Materials 2019, 12, 2838. https://doi.org/10.3390/ma12172838

Glinicki MA, Jóźwiak-Niedźwiedzka D, Dąbrowski M. The Influence of Fluidized Bed Combustion Fly Ash on the Phase Composition and Microstructure of Cement Paste. Materials. 2019; 12(17):2838. https://doi.org/10.3390/ma12172838

Chicago/Turabian StyleGlinicki, Michał A., Daria Jóźwiak-Niedźwiedzka, and Mariusz Dąbrowski. 2019. "The Influence of Fluidized Bed Combustion Fly Ash on the Phase Composition and Microstructure of Cement Paste" Materials 12, no. 17: 2838. https://doi.org/10.3390/ma12172838

APA StyleGlinicki, M. A., Jóźwiak-Niedźwiedzka, D., & Dąbrowski, M. (2019). The Influence of Fluidized Bed Combustion Fly Ash on the Phase Composition and Microstructure of Cement Paste. Materials, 12(17), 2838. https://doi.org/10.3390/ma12172838