Effect of Extrusion Temperature on the Microstructure and Mechanical Properties of SiCnw/2024Al Composite

Abstract

1. Introduction

2. Experimental Design, Materials and Methods

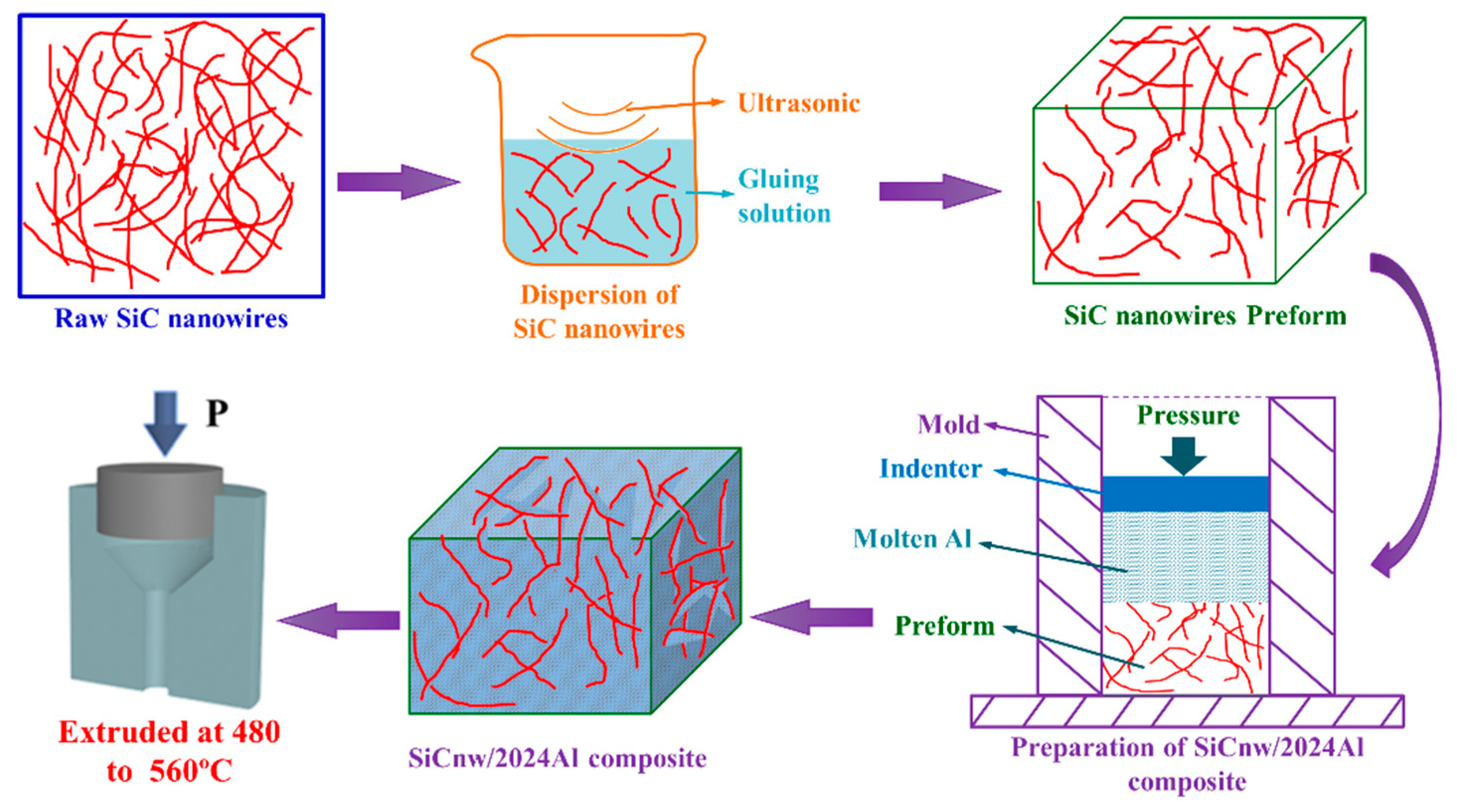

2.1. Materials and Composite Fabrication Process

2.2. Microstructure Characterization

2.3. Mechanical Properties Testing

3. Results and Discussion

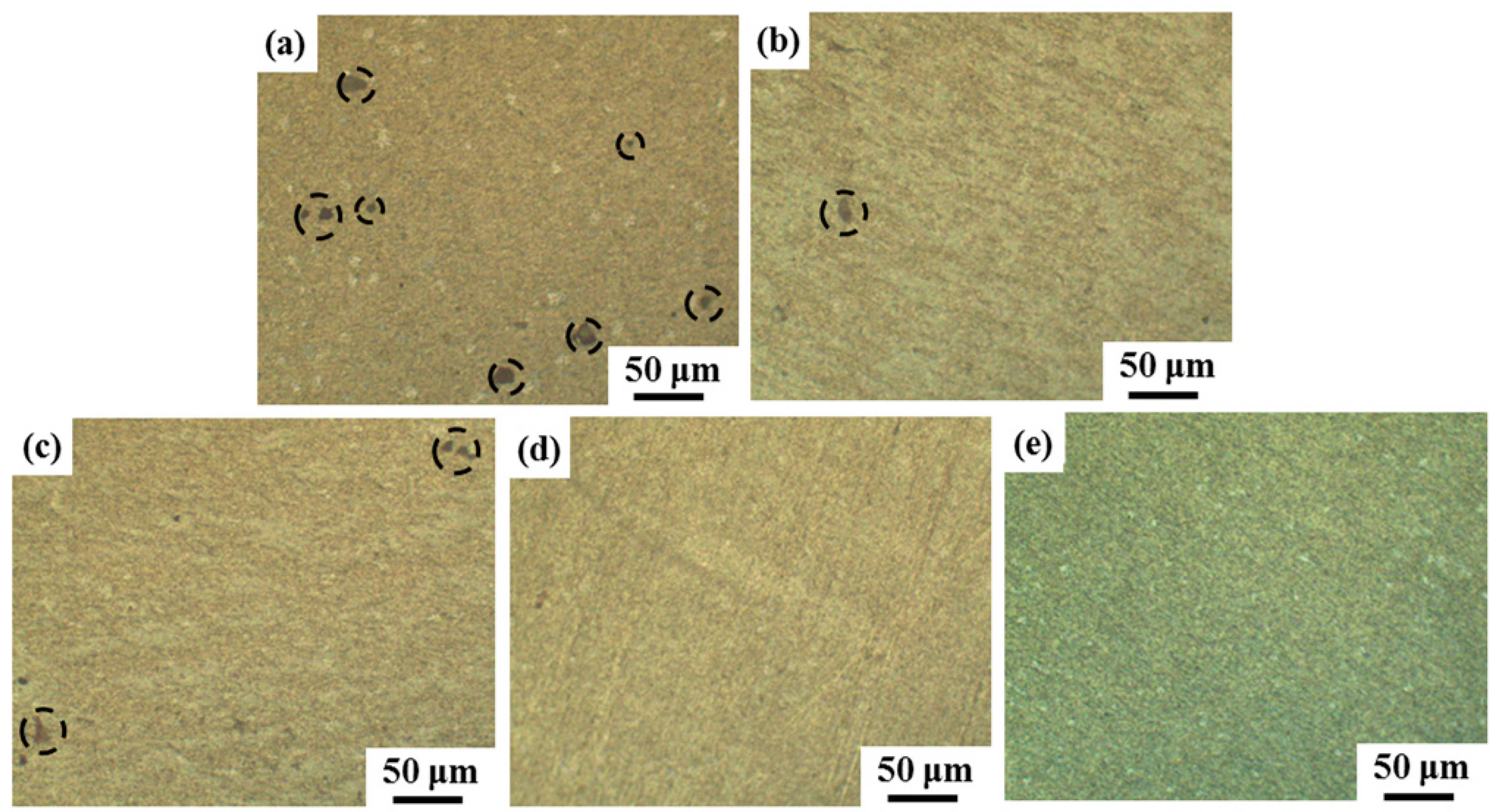

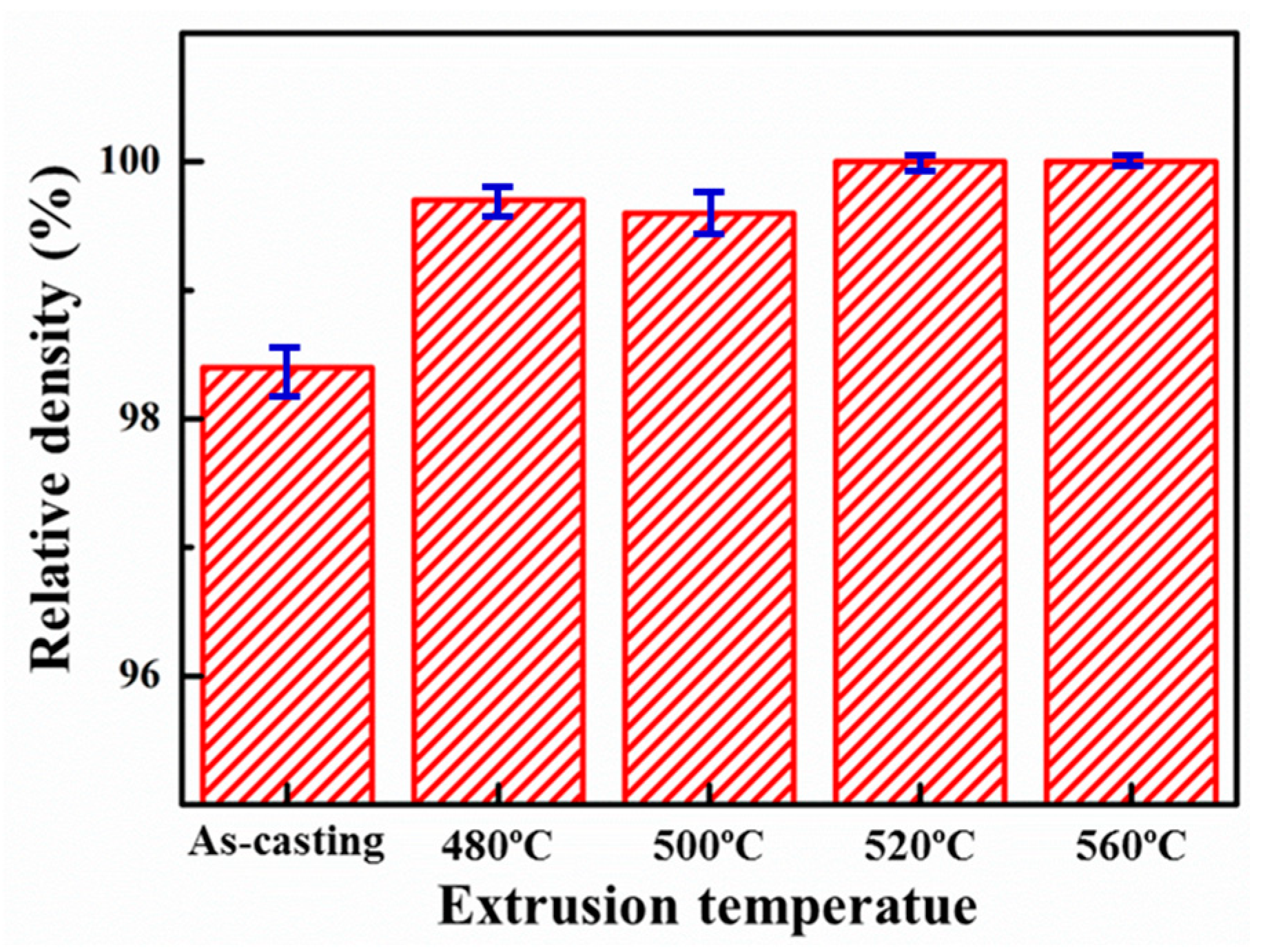

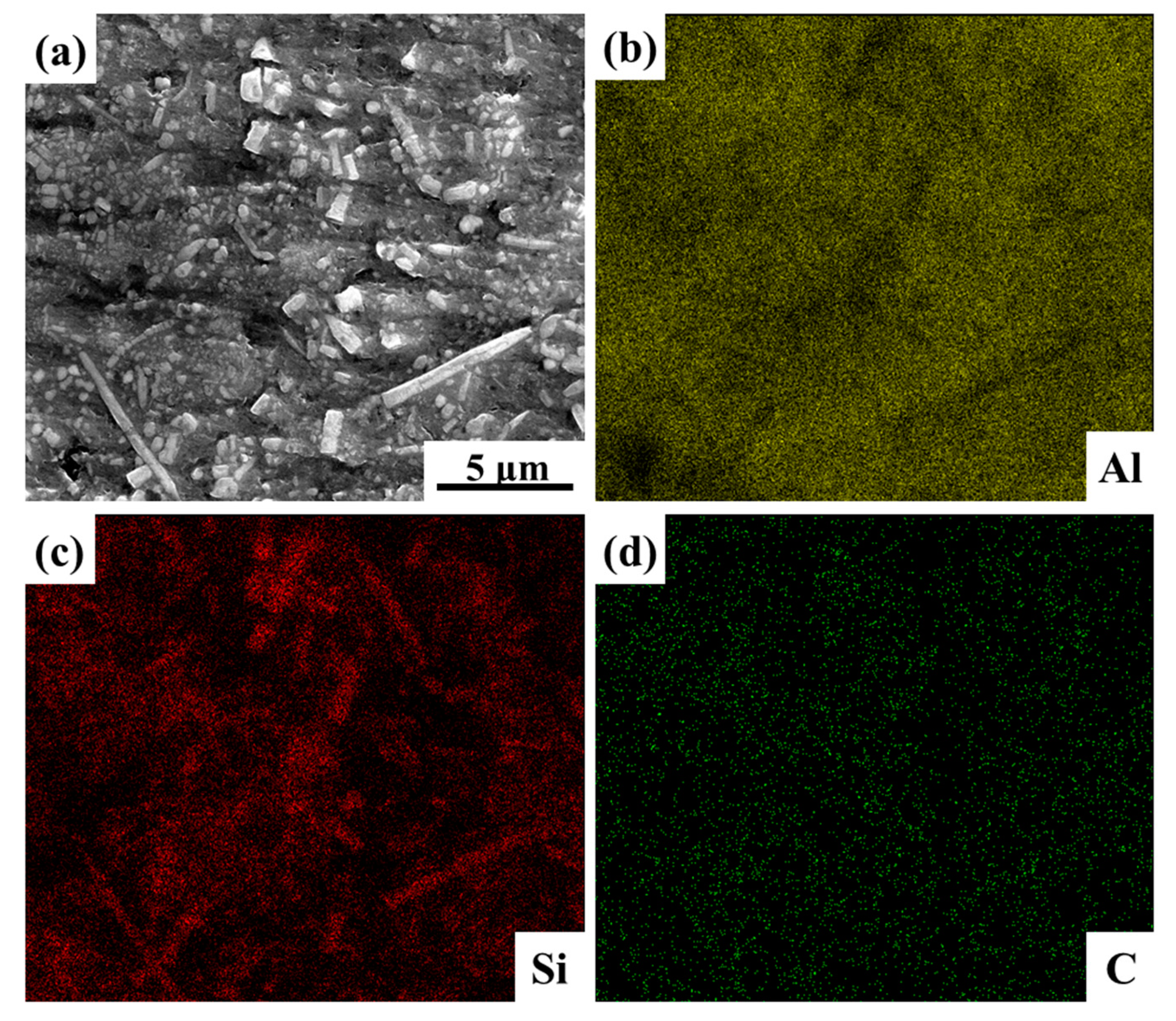

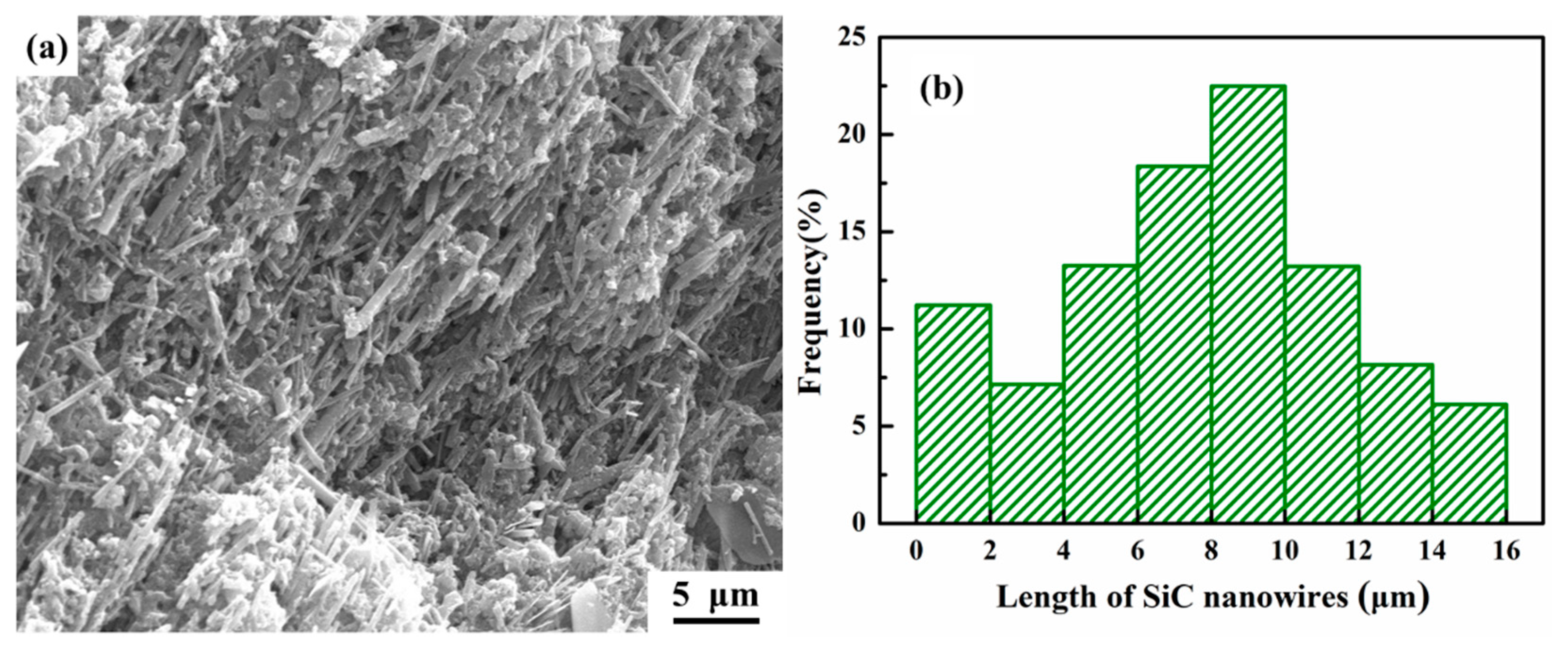

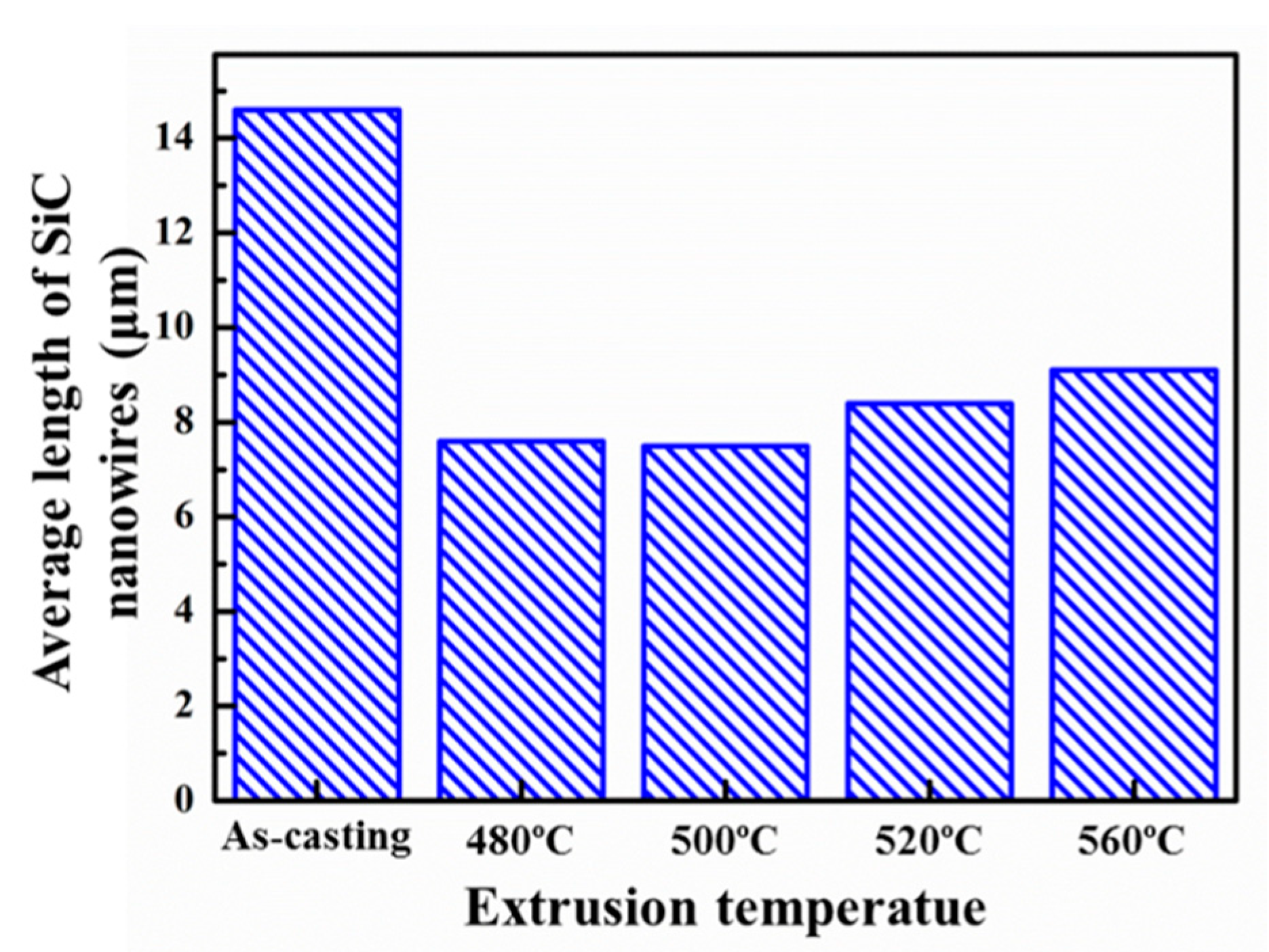

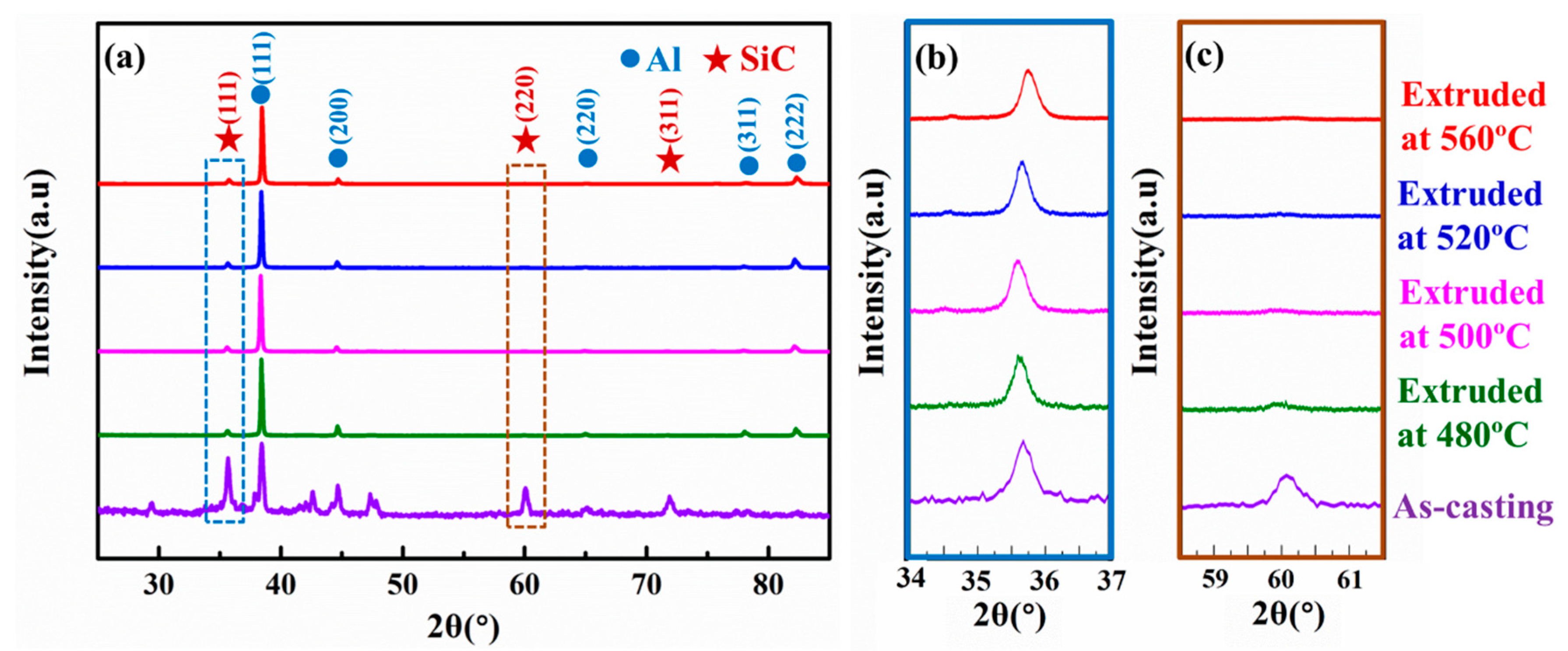

3.1. Effect of Extrusion Temperature on the Microstructure of SiCnw/2024Al Composite

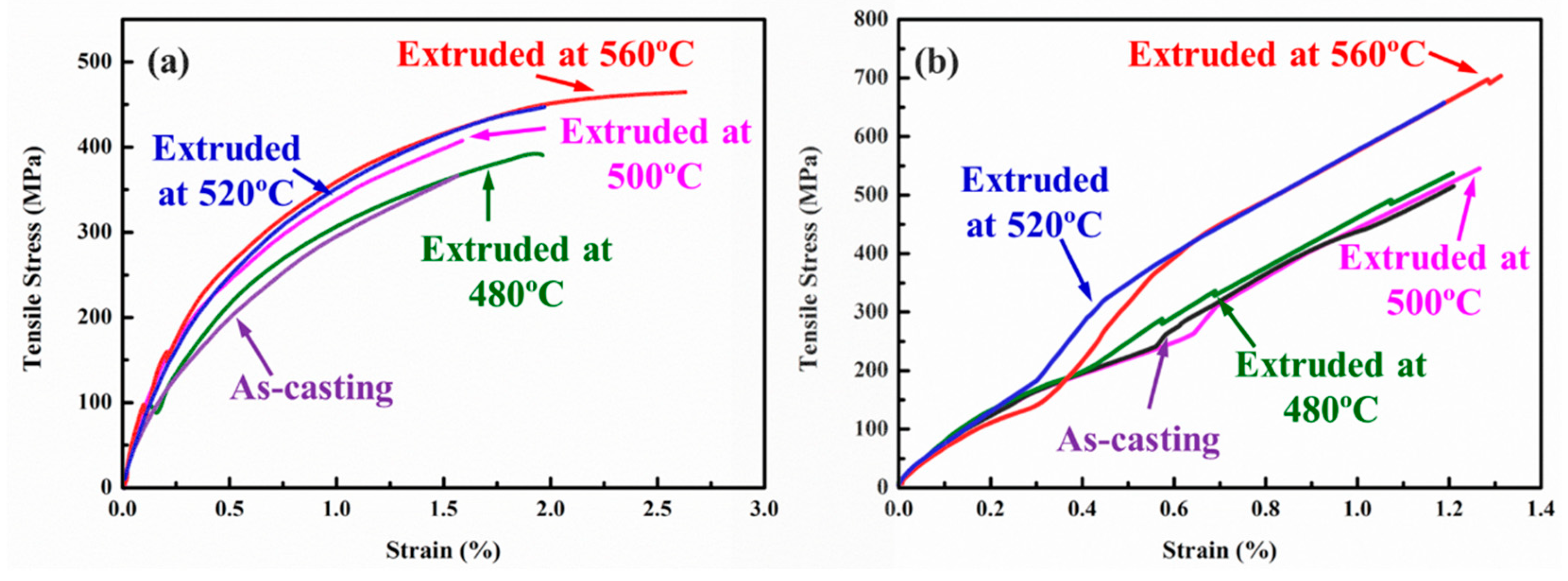

3.2. Effect of Extrusion Temperature on the Mechanical Behavior of SiCnw/2024Al Composite

4. Conclusions

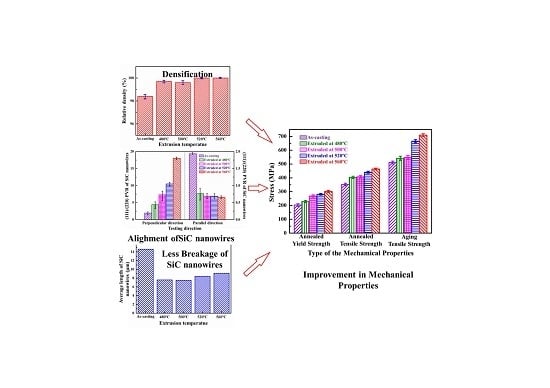

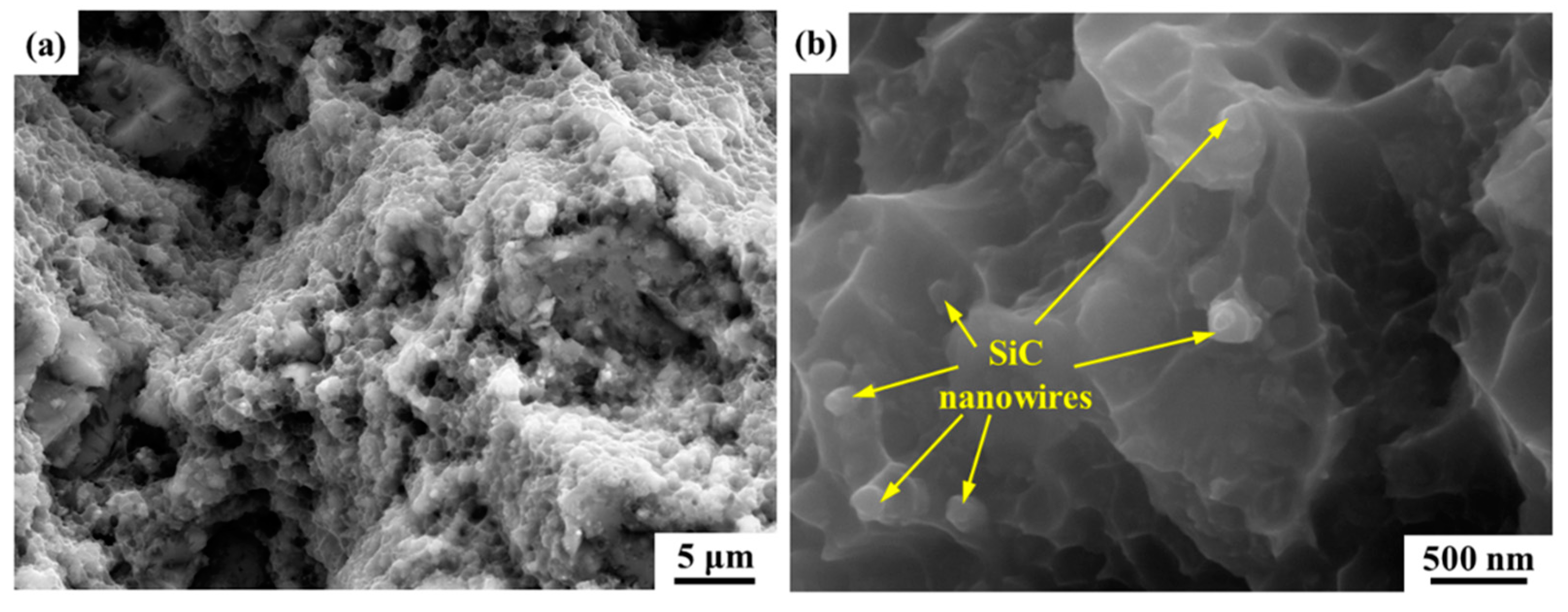

- After extrusion treatment, the porosity of the SiCnw/2024Al composite has been significantly decreased, and the composites have reached full densification after extrusion at 560 °C. Moreover, the average length of the residual SiC nanowires was also increased with the extrusion temperature.

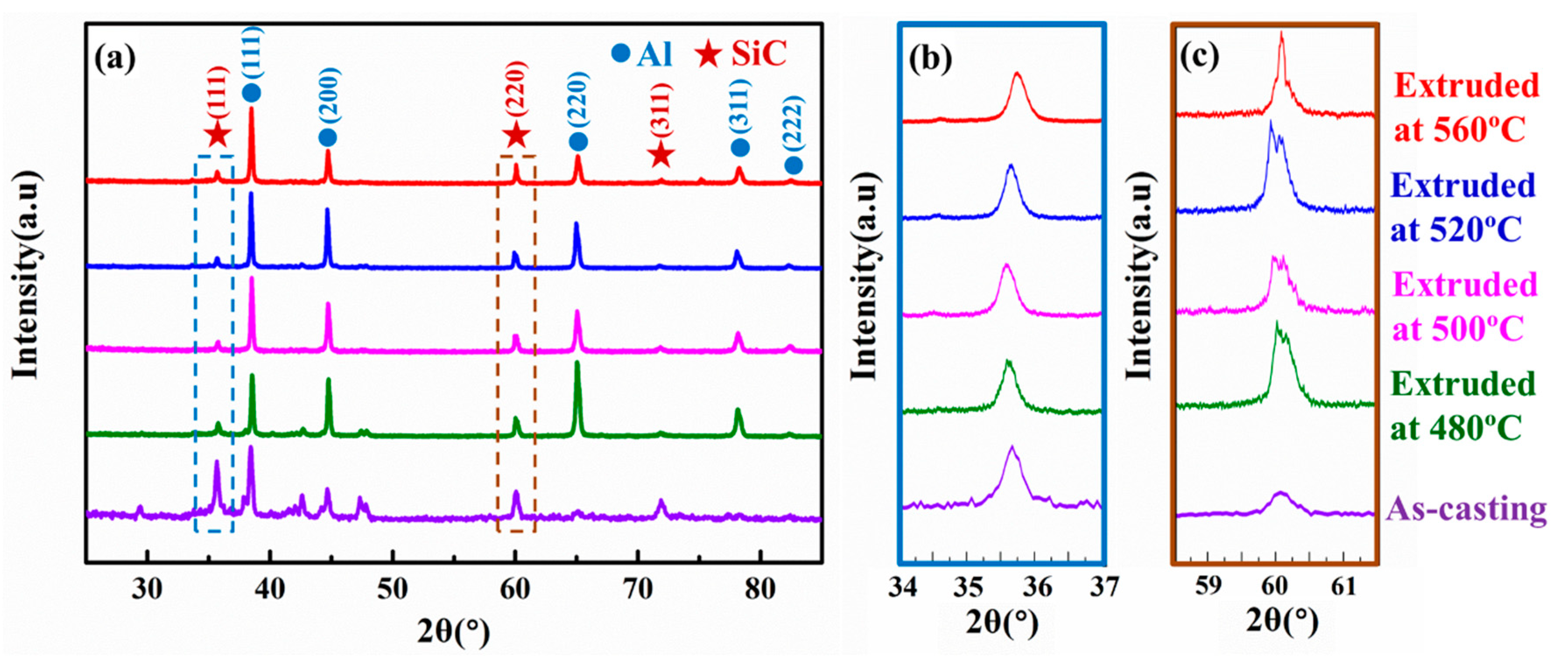

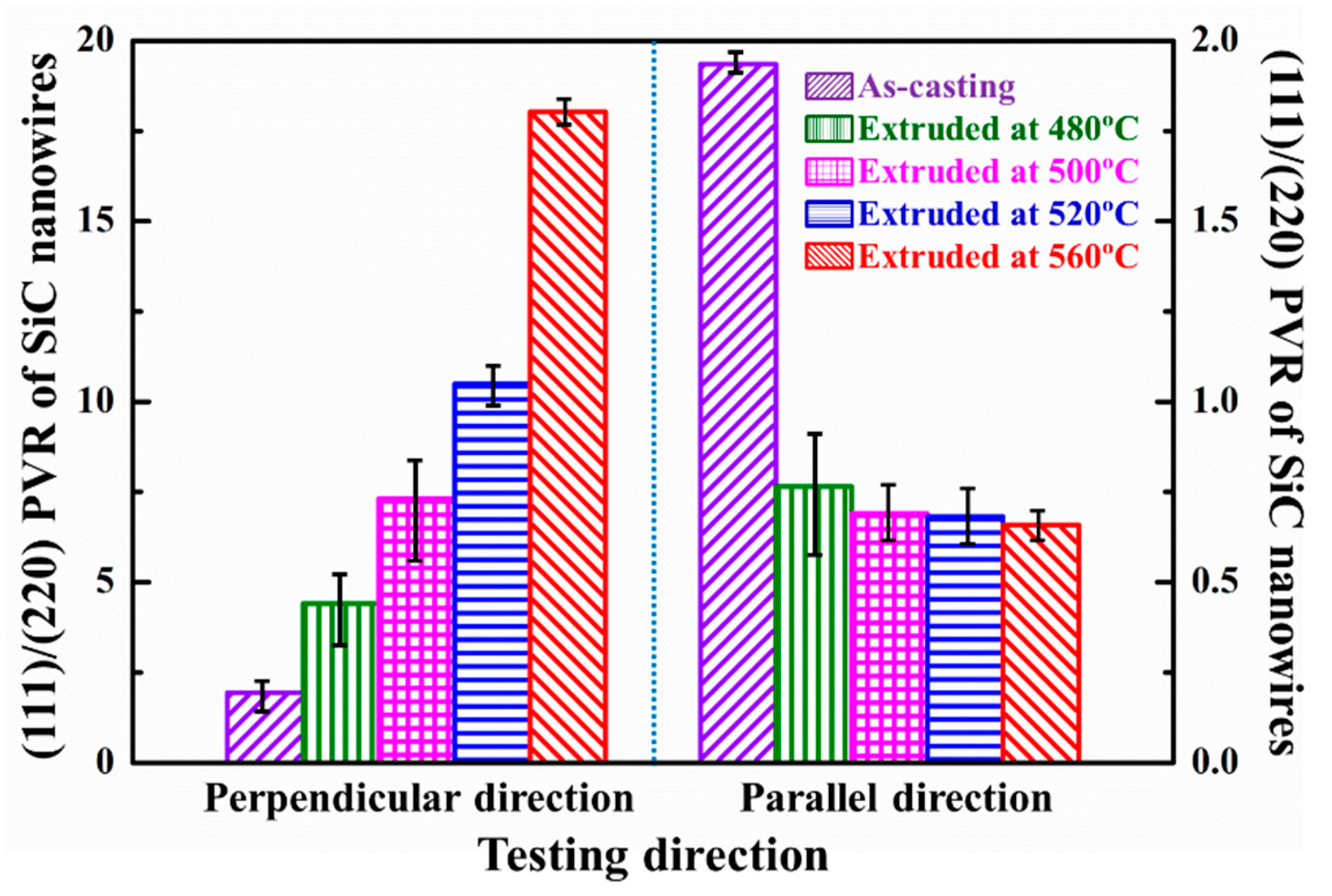

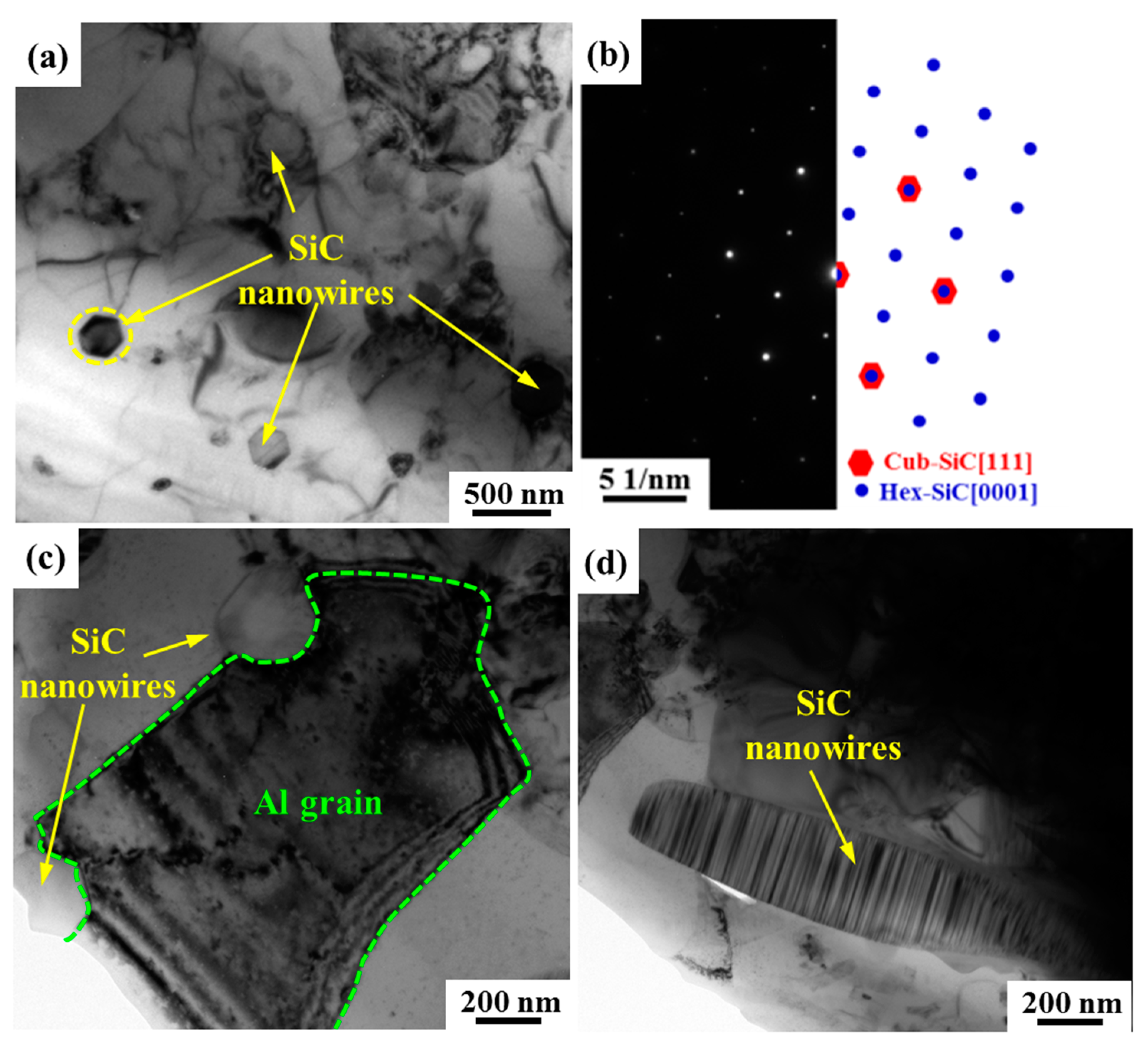

- The distribution of the SiC nanowires has been changed from random to alignment along the extrusion direction, while the alignment degree of the SiC nanowires was increased with the extrusion temperature according to XRD analysis. TEM observation indicated that the presence of the SiC nanowires was mainly located at the boundary of Al grains due to their “non-deformable” character.

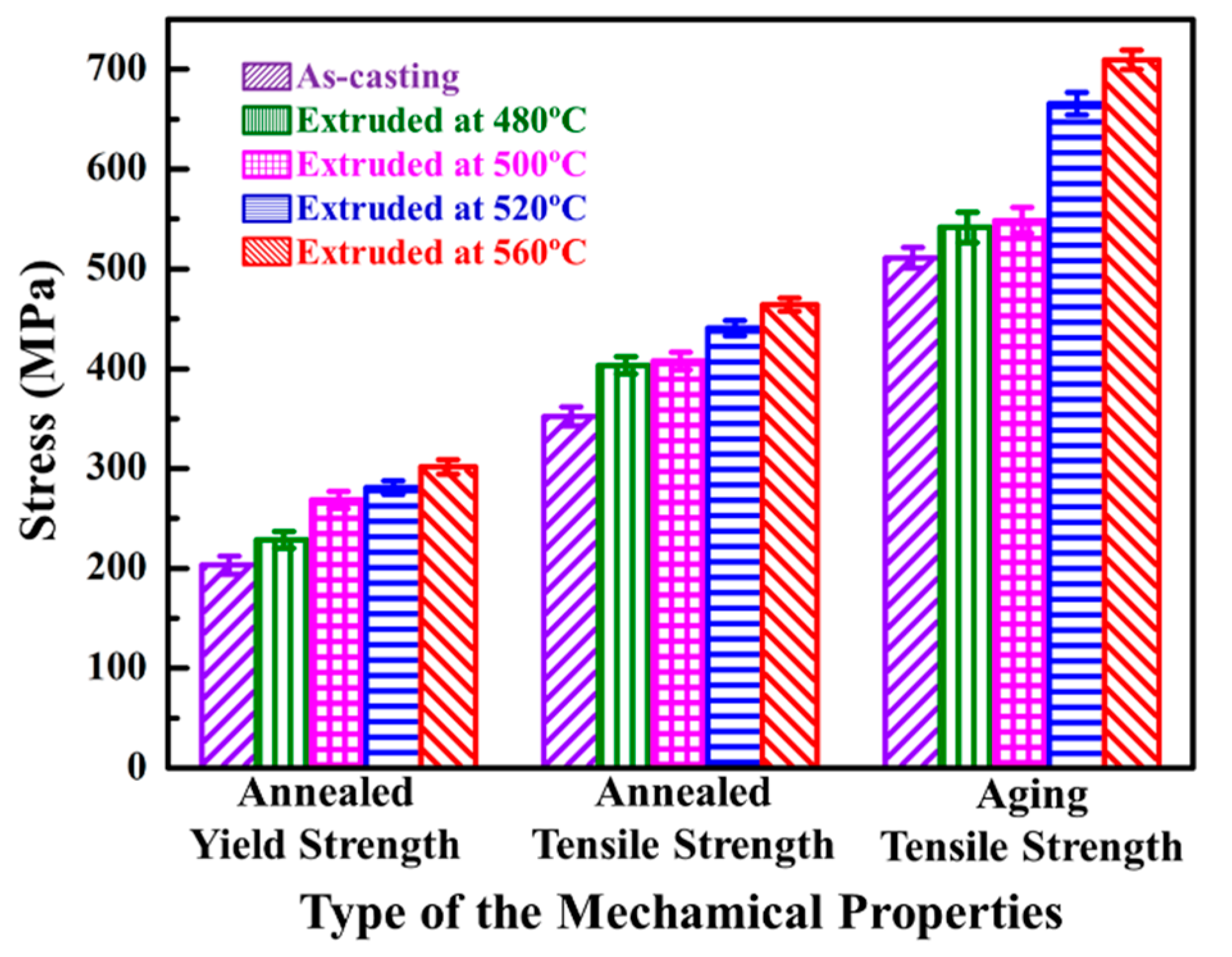

- Regardless of the heat treatment, the yield and tensile strengths of the SiCnw/2024Al composite were increased with the extrusion temperature, and many dimples and tearing ridges were observed in the fracture surface. The peak-aged SiCnw/2024Al composite extruded at 560 °C revealed highest strength (709.4 MPa) and elastic modulus (109.8 GPa).

- Based on the modified shear-lag mode, the effect of the extrusion temperature on the mechanical properties of the SiCnw/2024Al composite has been discussed, and the improved strength was mainly due to the better alignment and longer average length of the SiC nanowires at higher extrusion temperature.

Author Contributions

Funding

Conflicts of Interest

References

- Tian, W.-S.; Zhao, Q.-L.; Zhao, C.-J.; Qiu, F.; Jiang, Q.-C. The Dry Sliding Wear Properties of Nano-Sized TiCp/Al-Cu Composites at Elevated Temperatures. Materials 2017, 10, 939. [Google Scholar] [CrossRef] [PubMed]

- Lin, K.; Wang, W.; Jiang, R.; Xiong, Y.; Zhao, D. Evaluation of residual stress distribution and relaxation on in situ TiB2/7050 Al composites. Materials 2018, 11, 706. [Google Scholar] [CrossRef] [PubMed]

- Jia, D.; Ma, J.; Gan, X.; Tao, J.; Xie, M.; Yi, J.; Liu, Y. A Comparison Study of Ag Composites Prepared by Spark Plasma Sintering and Hot Pressing with Silver-Coated CNTs as the Reinforcements. Materials 2019, 12, 1949. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Yao, P.; Zhou, H.; Gong, T.; Deng, M.; Zhang, Z.; Xiao, Y.; Deng, H.; Li, Y.; Luo, F. Effect of CNTs in Copper Matrix on Mechanical Characteristics and Tribological Behavior under Dry Sliding and Boundary Lubrication Conditions. Materials 2019, 12, 2203. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.; Yang, W.; Zhou, C.; Zhang, N.; Chao, Z.; Liu, H.; Cao, Y.; Sun, Y.; Shao, P.; Wu, G. Effect of ball milling time on graphene nanosheets reinforced Al6063 composite fabricated by pressure infiltration method. Carbon 2019, 141, 25–39. [Google Scholar] [CrossRef]

- Lee, H.K.; Talib, Z.A.; Mamat Mat Nazira, M.S.; Wang, E.; Lim, H.N.; Mahdi, M.A.; Ng, E.K.; Yusoff, N.M.; AL-Jumaili, B.E.; Liew, J.Y.C. Effect of Sodium Hydroxide Concentration in Synthesizing Zinc Selenide/Graphene Oxide Composite via Microwave-Assisted Hydrothermal Method. Materials 2019, 12, 2295. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Li, S.; Li, H.; Pei, L. Bioactive surface modification of carbon/carbon composites with multilayer SiC-SiC nanowire-Si doped hydroxyapatite coating. J. Alloys Compd. 2018, 740, 109–117. [Google Scholar] [CrossRef]

- Li, H.; Wang, Y.; Fu, Q.; Chu, Y. SiC Nanowires Toughed HfC Ablative Coating for C/C Composites. J. Mater. Sci. Technol. 2015, 31, 70–76. [Google Scholar] [CrossRef]

- Fan, J.; Xu, S. Thermal conductivity and mechanical properties of high density polyethylene composites filled with silicon carbide whiskers modified by cross-linked poly (vinyl alcohol). J. Mater. Sci. Technol. 2018, 34, 2407–2414. [Google Scholar] [CrossRef]

- Chu, Y.; Chen, J.; Tang, J. SiC nanowire-induced fabrication of fine-grained and highly-density SiC coating by pressure-less reactive sintering. J. Alloys Compd. 2018, 755, 206–210. [Google Scholar] [CrossRef]

- Pozuelo, M.; Kao, W.H.; Yang, J.M. High-resolution TEM characterization of SiC nanowires as reinforcements in a nanocrystalline Mg-matrix. Mater. Charact. 2013, 77, 81–88. [Google Scholar] [CrossRef]

- Lee, D.; Park, H.; Ryu, H.; Jeon, S.; Hong, S. Microstructure and mechanical properties of SiC-nanowire-augmented tungsten composites. J. Alloys Compd. 2011, 509, 9060–9064. [Google Scholar] [CrossRef]

- Kang, K.; Zhang, L.; Luo, G.; Zhang, J.; Tu, R.; Wu, C.; Shen, Q. Microstructural evolution and mechanical behavior of W-Si-C multi-phase composite prepared by arc-melting. Mater. Sci. Eng. A 2018, 712, 28–36. [Google Scholar] [CrossRef]

- Jintakosol, T.; Kumfu, S.; Singjai, P.; Busabok, C. Effect of wear tests on silicon carbide nanowires/aluminium metal powder composites. Chiang Mai J. Sci. 2012, 39, 41–48. [Google Scholar]

- Dong, R.; Yang, W.; Wu, P.; Hussain, M.; Wu, G.; Jiang, L. High content SiC nanowires reinforced Al composite with high strength and plasticity. Mater. Sci. Eng. A 2015, 630, 8–12. [Google Scholar] [CrossRef]

- Dong, R.; Yang, W.; Yu, Z.; Wu, P.; Hussain, M.; Jiang, L.; Wu, G. Aging behavior of 6061Al matrix composite reinforced with high content SiC nanowires. J. Alloys Compd. 2015, 649, 1037–1042. [Google Scholar] [CrossRef]

- Yang, W.; Dong, R.; Yu, Z.; Wu, P.; Hussain, M.; Wu, G. Strengthening behavior in high content SiC nanowires reinforced Al composite. Mater. Sci. Eng. A 2015, 648, 41–46. [Google Scholar] [CrossRef]

- Dong, R.; Yang, W.; Wu, P.; Hussain, M.; Yu, Z.; Jiang, L.; Wu, G. Effect of reinforcement shape on the stress–strain behavior of aluminum reinforced with SiC nanowire. Mater. Des. 2015, 88, 1015–1020. [Google Scholar] [CrossRef]

- Yang, W.; Chen, G.; Qiao, J.; Zhang, Q.; Dong, R.; Wu, G. Effect of Mg addition on the microstructure and mechanical properties of SiC nanowires reinforced 6061Al matrix composite. Mater. Sci. Eng. A 2017, 689, 189–194. [Google Scholar] [CrossRef]

- Xin, L.; Yang, W.; Zhao, Q.; Dong, R.; Wu, P.; Xiu, Z.; Hussain, M.; Wu, G. Strengthening behavior in SiC nanowires reinforced pure Al composite. J. Alloys Compd. 2017, 695, 2406–2412. [Google Scholar] [CrossRef]

- Shao, P.; Yang, W.; Zhang, Q.; Meng, Q.; Tan, X.; Xiu, Z.; Qiao, J.; Yu, Z.; Wu, G. Microstructure and tensile properties of 5083 Al matrix composites reinforced with graphene oxide and graphene nanoplates prepared by pressure infiltration method. Compos. Part A Appl. Sci. Manuf. 2018, 109, 151–162. [Google Scholar] [CrossRef]

- Xin, L.; Tian, X.; Yang, W.; Chen, G.; Qiao, J.; Hu, F.; Zhang, Q.; Wu, G. Enhanced stability of the Diamond/Al composites by W coatings prepared by the magnetron sputtering method. J. Alloys Compd. 2018, 763, 305–313. [Google Scholar] [CrossRef]

- Ghandvar, H.; Idris, M.H.; Ahmad, N. Effect of hot extrusion on microstructural evolution and tensile properties of Al-15%Mg2Si-xGd in-situ composites. J. Alloys Compd. 2018, 751, 370–390. [Google Scholar] [CrossRef]

- Yang, W.; Zhao, Q.; Xin, L.; Qiao, J.; Zou, J.; Shao, P.; Yu, Z.; Zhang, Q.; Wu, G. Microstructure and mechanical properties of graphene nanoplates reinforced pure Al matrix composites prepared by pressure infiltration method. J. Alloys Compd. 2018, 732, 748–758. [Google Scholar] [CrossRef]

- Chen, X.; Fu, D.; Teng, J.; Zhang, H. Hot deformation behavior and mechanism of hybrid aluminum-matrix composites reinforced with micro-SiC and nano-TiB2. J. Alloys Compd. 2018, 753, 566–575. [Google Scholar] [CrossRef]

- Xin, L.; Yang, W.; Zhao, Q.; Dong, R.; Liang, X.; Xiu, Z.; Hussain, M.; Wu, G. Effect of extrusion treatment on the microstructure and mechanical behavior of SiC nanowires reinforced Al matrix composites. Mater. Sci. Eng. A 2017, 682, 38–44. [Google Scholar] [CrossRef]

- Luan, B.F.; Hansen, N.; Godfrey, A.; Wu, G.H.; Liu, Q. High strength Al–Al2O3p composites: Optimization of extrusion parameters. Mater. Des. 2011, 32, 3810–3817. [Google Scholar] [CrossRef]

- Tavighi, K.; Emamy, M.; Emami, A.R. Effects of extrusion temperature on the microstructure and tensile properties of Al–16 wt% Al4Sr metal matrix composite. Mater. Des. 2013, 46, 598–604. [Google Scholar] [CrossRef]

- Feng, Y.C.; Cao, G.J.; Fan, G.H.; Wang, L.P.; Geng, L.; Jiang, W.Y. Jiang, Influence of hot extrusion temperature on the microstructure and the mechanical properties of (ABOw+WO3p)/Al hybrid composites. JOM 2013, 65, 593–598. [Google Scholar] [CrossRef]

- Hong, S.H.; Chung, K.H.; Lee, C.H. Effects of hot extrusion parameters on the tensile properties and microstructures of SiCw-2124Al composite. Mater. Sci. Eng. A 1996, 206, 225–232. [Google Scholar] [CrossRef]

- Wu, C.; Gao, T.; Sun, Q.; Liu, G.; Du, X.; Liu, X. A novel method of coating ex-situ SiC particles with in-situ SiC interlayer in Al-Si-C alloy. J. Alloys Compd. 2018, 754, 39–47. [Google Scholar] [CrossRef]

- Zhang, C.; Yin, J.; Yao, D.; Zuo, K.; Xia, Y.; Liang, H.; Zeng, Y. Enhanced tensile properties of Al matrix composites reinforced with β-Si3N4 whiskers. Compos. Part A Appl. Sci. Manuf. 2017, 102, 145–153. [Google Scholar] [CrossRef]

- Zhang, C.; Yao, D.; Yin, J.; Zuo, K.; Xia, Y.; Liang, H.; Zeng, Y.P. Effects of whisker surface modification on microstructures, mechanical and thermal properties of β-Si3N4 whiskers reinforced Al matrix composites. Mater. Des. 2018, 159, 117–126. [Google Scholar] [CrossRef]

- Shi, W.; Yuan, L.; Xu, F.; Zheng, Z.; Shan, D. Refining whisker size of 2024Al/Al18B4O33w composite through extrusion and its effects on the material’s micro-structures and mechanical properties. Mater. Charact. 2018, 138, 98–106. [Google Scholar] [CrossRef]

- Du, B.; Hong, C.; Zhang, X.; Wang, J.; Qu, Q. Preparation and mechanical behaviors of SiOC-modified carbon-bonded carbon fiber composite with in-situ growth of three-dimensional SiC nanowires. J. Eur. Ceram. Soc. 2018, 38, 2272–2278. [Google Scholar] [CrossRef]

- Chen, J.; Ding, L.; Xin, L.; Zeng, F.; Chen, J. Thermochemistry and growth mechanism of SiC nanowires. J. Solid State Chem. 2017, 253, 282–286. [Google Scholar] [CrossRef]

- Dong, R.; Yang, W.; Wu, P.; Hussain, M.; Xiu, Z.; Wu, G.; Wang, P. Microstructure characterization of SiC nanowires as reinforcements in composites. Mater. Charact. 2015, 103, 37–41. [Google Scholar] [CrossRef]

- Ji, S. Generalized means as an approach for predicting Young’s moduli of multiphase materials. Mater. Sci. Eng. A 2004, 366, 195–201. [Google Scholar] [CrossRef]

- Chen, G.; Yang, W.; Xin, L.; Wang, P.; Liu, S.; Qiao, J.; Hu, F.; Zhang, Q.; Wu, G. Mechanical properties of Al matrix composite reinforced with diamond particles with W coatings prepared by the magnetron sputtering method. J. Alloys Compd. 2018, 735, 777–786. [Google Scholar] [CrossRef]

- Shin, S.E.; Choi, H.J.; Hwang, J.Y.; Bae, D. Strengthening behavior of carbon/metal nanocomposites. Sci. Rep. 2015, 5, 16114. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, S.; Zhang, B.; Zhan, Y.; Liu, X.; Xin, L.; Yang, W.; Wu, G. Effect of Extrusion Temperature on the Microstructure and Mechanical Properties of SiCnw/2024Al Composite. Materials 2019, 12, 2769. https://doi.org/10.3390/ma12172769

Dong S, Zhang B, Zhan Y, Liu X, Xin L, Yang W, Wu G. Effect of Extrusion Temperature on the Microstructure and Mechanical Properties of SiCnw/2024Al Composite. Materials. 2019; 12(17):2769. https://doi.org/10.3390/ma12172769

Chicago/Turabian StyleDong, Shanliang, Bin Zhang, Yuli Zhan, Xin Liu, Ling Xin, Wenshu Yang, and Gaohui Wu. 2019. "Effect of Extrusion Temperature on the Microstructure and Mechanical Properties of SiCnw/2024Al Composite" Materials 12, no. 17: 2769. https://doi.org/10.3390/ma12172769

APA StyleDong, S., Zhang, B., Zhan, Y., Liu, X., Xin, L., Yang, W., & Wu, G. (2019). Effect of Extrusion Temperature on the Microstructure and Mechanical Properties of SiCnw/2024Al Composite. Materials, 12(17), 2769. https://doi.org/10.3390/ma12172769