The Microstructural Evolution, Tensile Properties, and Phase Hardness of a TiAl Alloy with a High Content of the β Phase

Abstract

1. Introduction

2. Experimental Methods

3. Results and Discussion

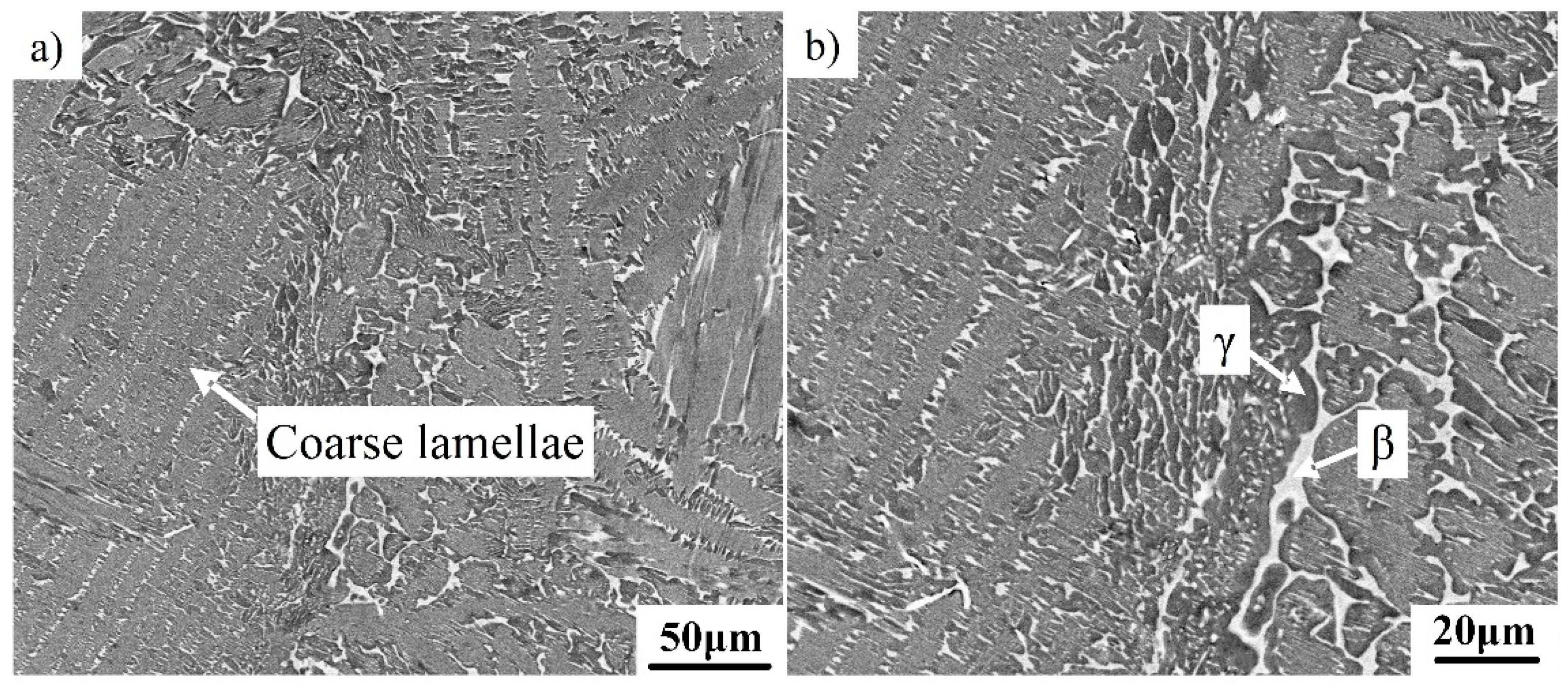

3.1. The As-Cast Microstructure

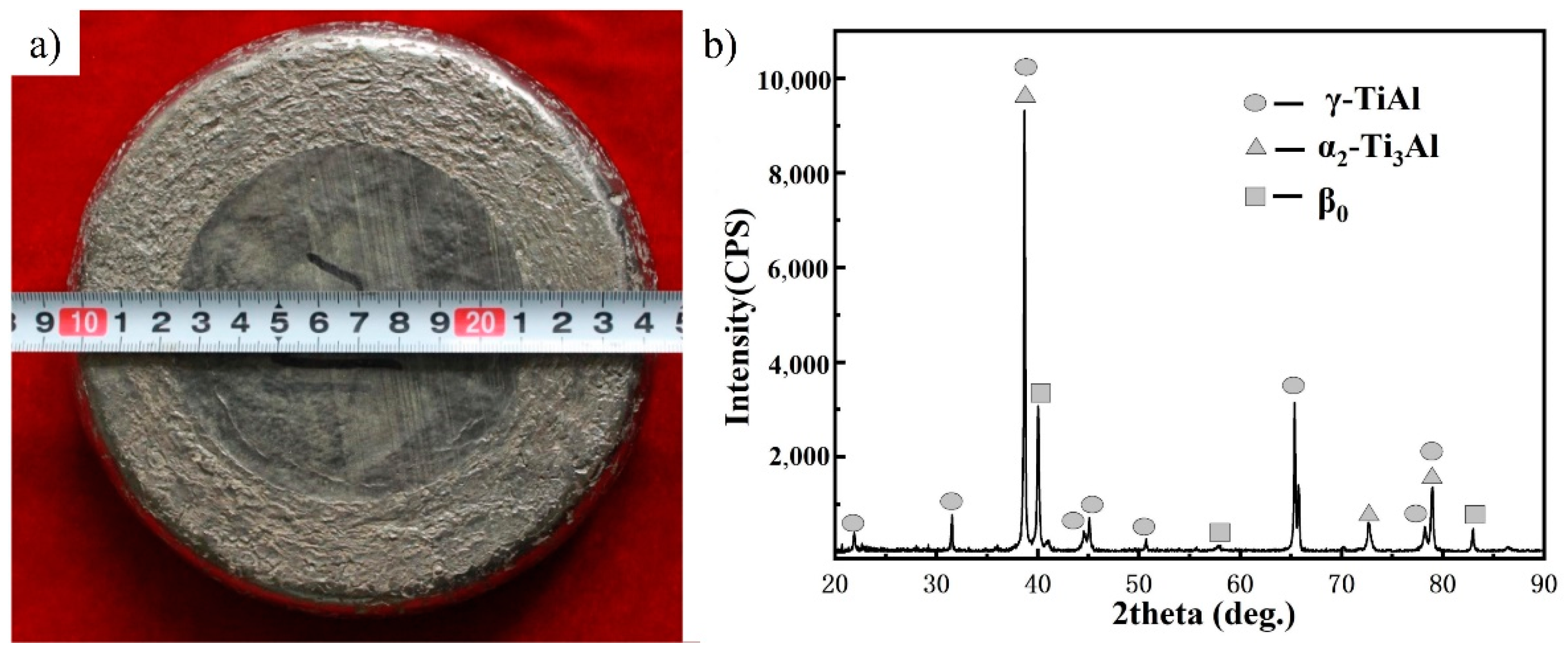

3.2. Noncanned Forging and Microstructural Evolution

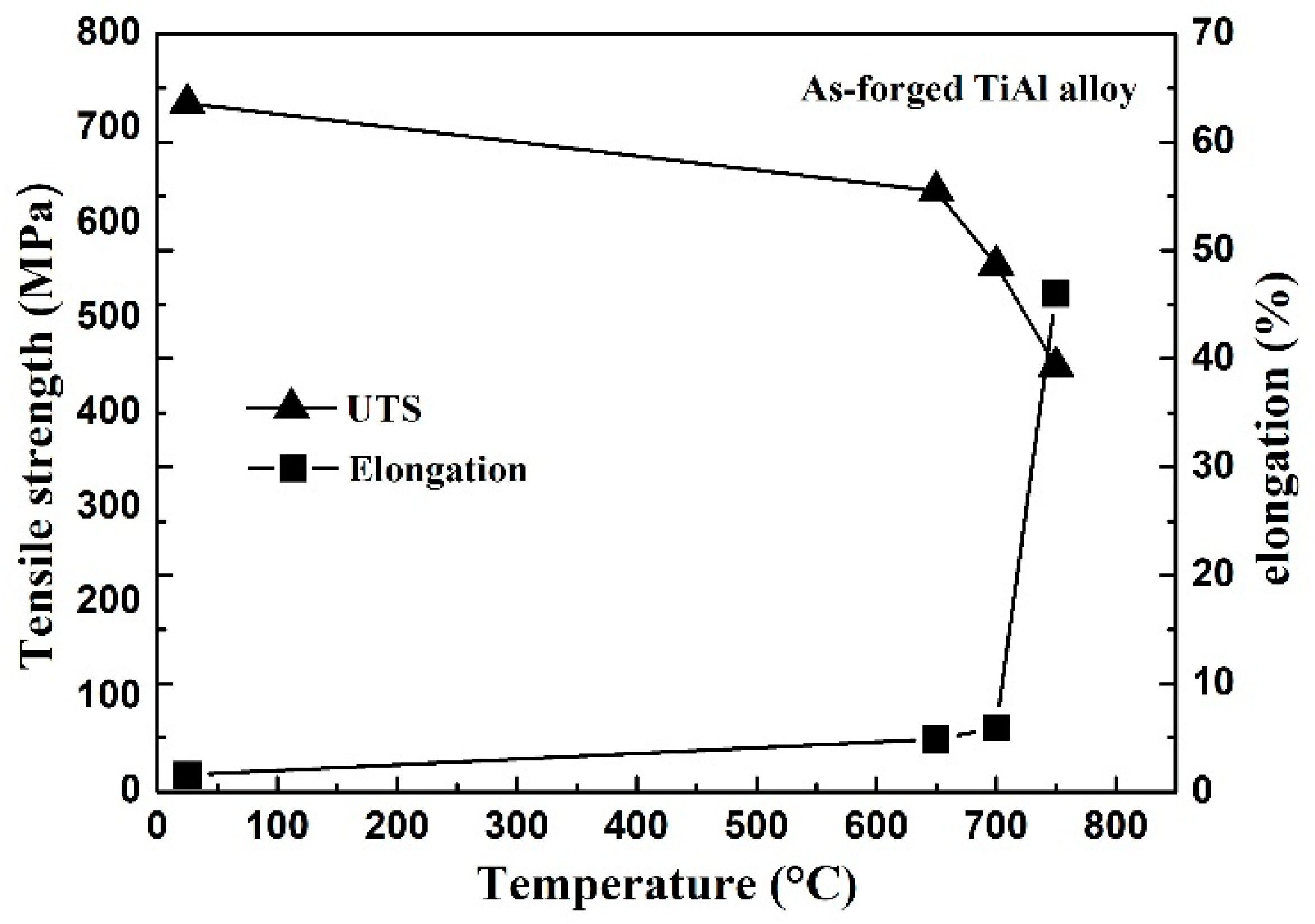

3.3. Tensile Properties

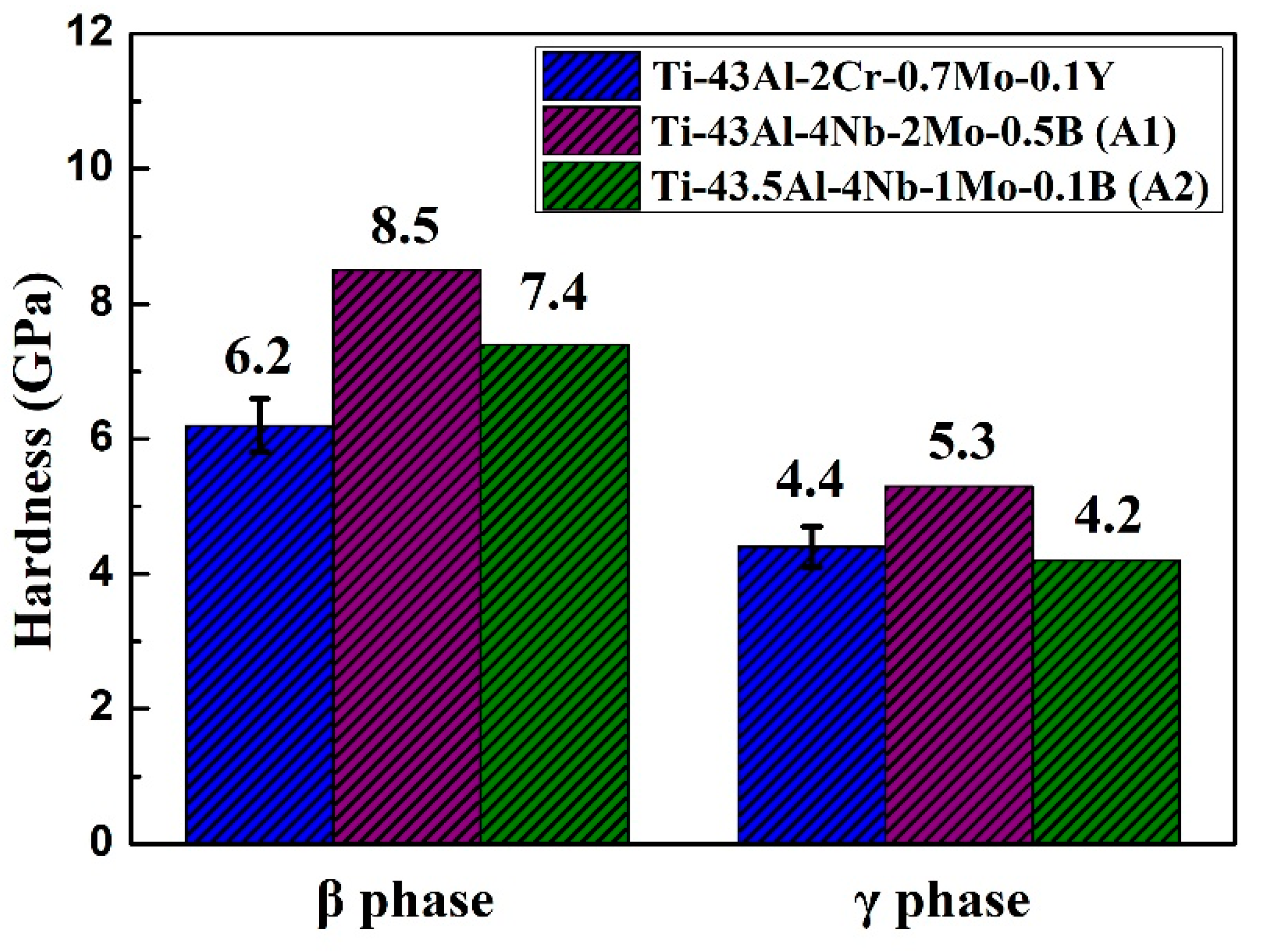

3.4. Nanohardness of the Constituent Phases

4. Conclusions

- (1)

- The Ti–43Al–2Cr–0.7Mo–0.1Y alloy with a high β phase content has a coarse and inhomogeneous as-cast microstructure. The β phase precipitates not only at the lamellar boundaries, but also inside the lamellae. The Ti–43Al–2Cr–0.7Mo–0.1Y alloy has good hot workability due to the high content of its β phase. A high-quality forging stock was prepared after one-step forging with 80% deformation. A high β phase content contributes to the decomposition of the coarse as-cast microstructure during hot forging.

- (2)

- The forging stock has a uniform and fine microstructure, which is composed of γ and β phases and a small amount of the α2 phase. The alloy has good room-temperature ductility, even though it contains a high β phase content. The room-temperature elongation can reach about 1.5%, which can be ascribed to the low β phase hardness. The nanohardness of the β phase in the current alloy is about 6.3 GPa, which is much lower than that in the high-Nb-containing TiAl alloys.

- (3)

- The hardness of the β phase depends closely on β-stabilizers. The β phase containing Cr, Mn, or V has low hardness, while the β phase containing Nb, Mo, or W has high hardness. Reducing the hardness of the β phase by alloying may be an effective way to improve the ductility of β-solidifying TiAl alloys.

Author Contributions

Funding

Conflicts of Interest

References

- Kim, Y.W.; Kim, S.L. Advances in gammalloy materials–processes–application technology: Successes, dilemmas, and future. JOM 2018, 5, 1–8. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Advanced Intermetallic TiAl Alloys. Mater. Sci. Forum 2017, 879, 113–118. [Google Scholar] [CrossRef]

- Kong, F.T.; Cui, N.; Chen, Y.Y.; Wang, X.P. A novel composition design method for beta–gamma TiAl alloys with excellent hot workability. Metall. Mater. Trans. A 2018, 49, 5574–5584. [Google Scholar] [CrossRef]

- Cui, N.; Wu, Q.Q.; Bi, K.X.; Xu, T.W.; Kong, F.T. Effect of heat treatment on microstructures and mechanical properties of a novel β-solidifying TiAl alloy. Materials 2019, 12, 1672. [Google Scholar] [CrossRef]

- Paul, J.D.H.; Lorenz, U.; Oehring, M.; Appel, F. Up-scaling the size of TiAl components made via ingot metallurgy. Intermetallics 2013, 32, 318–328. [Google Scholar] [CrossRef]

- Janschek, P. Wrought TiAl Blades. Mater. Today 2015, 2, 92–97. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Intermetallic titanium aluminides in aerospace applications–processing, microstructure and properties. Mater. High Temp. 2016, 33, 1–11. [Google Scholar] [CrossRef]

- Wu, Q.Q.; Cui, N.; Xiao, X.H.; Wang, X.P.; Zhao, E.T. Hot deformation behavior and microstructural evolution of a novel β-solidifying Ti–43Al–3Mn–2Nb–0.1Y alloy. Materials 2019, 12, 2172. [Google Scholar] [CrossRef]

- Tetsui, T.; Shindo, K.; Kaji, S.; Kobayashi, S.; Takeyama, M. Fabrication of TiAl components by means of hot forging and machining. Intermetallics 2005, 13, 971–978. [Google Scholar] [CrossRef]

- Cui, N.; Wu, Q.Q.; Bi, K.X.; Wang, J.; Xu, T.W.; Kong, F.T. Effect of multi–directional forging on the microstructure and mechanical properties of β-solidifying TiAl alloy. Materials 2019, 12, 1381. [Google Scholar] [CrossRef]

- Erdely, P.; Werner, R.; Schwaighofer, E.; Clemens, H.; Mayer, S. In–situ study of the time–temperature–transformation behaviour of a multi–phase intermetallic β-stabilised TiAl alloy. Intermetallics 2015, 57, 17–24. [Google Scholar] [CrossRef]

- Takeyama, M.; Kobayashi, S. Physical metallurgy for wrought gamma titanium aluminides microstructure control through phase transformations. Intermetallics 2005, 13, 993–999. [Google Scholar] [CrossRef]

- Schloffer, M.; Iqbal, F.; Gabrisch, H.; Schwaighofer, E.; Schimansky, F.P.; Mayer, S.; Stark, A.; Lippmann, T.; Göken, M.; Pyczak, F.; et al. Microstructure development and hardness of a powder metallurgical multi phase γ–TiAl based alloy. Intermetallics 2012, 22, 231–240. [Google Scholar] [CrossRef]

- Schloffer, M.; Rashkova, B.; Schöberl, T.; Schwaighofer, E.; Zhang, Z.; Clemens, H.; Mayer, S. Evolution of the ω0 phase in a β-stabilized multi–phase TiAl alloy and its effect on hardness. Acta Mater. 2014, 64, 241–252. [Google Scholar] [CrossRef]

- Niu, H.Z.; Chen, Y.Y.; Xiao, S.L.; Xu, L.J. Microstructure evolution and mechanical properties of a novel beta γ–TiAl alloy. Intermetallics 2012, 31, 225–231. [Google Scholar] [CrossRef]

- Schmoelzer, T.; Liss, K.D.; Zickler, G.A.; Watson, I.J.; Droessler, L.M.; Wallgram, W.; Buslaps, T.; Studer, A.; Clemens, H. Phase fractions, transition and ordering temperatures in TiAl–Nb–Mo alloys: An in– and ex–situ study. Intermetallics 2010, 18, 1544–1552. [Google Scholar] [CrossRef]

- Tetsui, T.; Shindo, K.; Kobayashi, S.; Takeyama, M. A newly developed hot worked TiAl alloy for blades and structural components. Scr. Mater. 2002, 47, 399–403. [Google Scholar] [CrossRef]

- Wu, Z.; Hu, R.; Zhang, T.; Zhang, F.; Kou, H.; Li, J. Understanding the role of carbon atoms on microstructure and phase transformation of high Nb containing TiAl alloys. Mater. Charact. 2017, 124, 1–7. [Google Scholar] [CrossRef]

- Ren, G.D.; Sun, J. High–resolution electron microscopy characterization of modulated structure in high Nb–containing lamellar γ–TiAl alloy. Acta Mater. 2018, 144, 516–523. [Google Scholar] [CrossRef]

- Niu, H.Z.; Chen, Y.Y.; Kong, F.T.; Lin, J.P. Microstructure evolution, hot deformation behavior and mechanical properties of Ti–43Al–6Nb–1B alloy. Intermetallics 2012, 31, 249–256. [Google Scholar] [CrossRef]

- Niu, H.Z.; Chen, Y.Y.; Xiao, S.L.; Kong, F.T.; Zhang, C.J. High temperature deformation behaviors of Ti–45Al–2Nb–1.5V–1Mo–Y alloy. Intermetallics 2011, 19, 1767–1774. [Google Scholar] [CrossRef]

- Niu, H.Z.; Kong, F.T.; Chen, Y.Y.; Yang, F. Microstructure characterization and tensile properties of β phase containing TiAl pancake. J. Alloys Compd. 2011, 509, 10179–10184. [Google Scholar] [CrossRef]

- Hao, Y.; Yang, R.; Cui, Y.; Li, D. The influence of alloying on the α2/(α2+ γ)/γ phase boundaries in TiAl based systems. Acta Mater. 2000, 48, 1313–1324. [Google Scholar] [CrossRef]

- Huang, Z.W.; Voice, W.; Bowen, P. Thermal exposure induced α2+γ→B2(ω) and α2→B2(ω) phase transformations in a high Nb fully lamellar TiAl alloy. Scr. Mater. 2003, 48, 79–84. [Google Scholar] [CrossRef]

- Zhu, H.; Seo, D.Y.; Maruyama, K.; Au, P. Strengthening of a fully lamellar TiAl + W alloy by dynamic precipitation of β phase during long-term creep. Scr. Mater. 2006, 54, 425–430. [Google Scholar] [CrossRef]

- Cui, N.; Wu, Q.Q.; Wang, J.; Lv, B.J.; Kong, F.T. The directional solidification, microstructural characterization and deformation behavior of β-solidifying TiAl alloy. Materials 2019, 12, 1203. [Google Scholar] [CrossRef] [PubMed]

- Marketz, W.T.; Fischer, F.D.; Clemens, H. Deformation mechanisms in TiAl intermetallics—Experiments and modeling. Int. J. Plasticity 2003, 19, 281–321. [Google Scholar] [CrossRef]

- Schmoelzer, T.; Liss, K.D.; Kirchlechner, C.; Mayer, S.; Stark, A.; Peel, M.; Clemens, H. An in–situ high–energy X–ray diffraction study on the hot–deformation behavior of a β-phase containing TiAl alloy. Intermetallics 2013, 39, 25–33. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Design, processing, microstructure, properties, and applications of advanced intermetallic TiAl alloys. Adv. Eng. Mater. 2013, 15, 191–215. [Google Scholar] [CrossRef]

- Zhang, W.J.; Lorenz, U.; Appel, F. Recovery, recrystallization and phase transformations during thermomechanical processing and treatment of TiAl–based alloys. Acta Mater. 2000, 48, 2803–2813. [Google Scholar] [CrossRef]

- Cui, N.; Kong, F.T.; Wang, X.P.; Chen, Y.Y.; Zhou, H.T. Microstructural evolution, hot workability, and mechanical properties of Ti–43Al–2Cr–2Mn–0.2Y alloy. Mater. Des. 2016, 89, 1020–1027. [Google Scholar] [CrossRef]

- Zhang, S.Z.; Zhang, C.J.; Du, Z.X.; Hou, Z.P.; Lin, P.; Chen, Y.Y. Microstructure and tensile properties of hot fogred high Nb containing TiAl based alloy with initial near lamellar microstructure. Mater. Sci. Eng. A 2015, 642, 16–21. [Google Scholar] [CrossRef]

- Su, Y.J.; Kong, F.T.; Chen, Y.Y.; Gao, N.; Zhang, D.L. Microstructure and mechanical properties of large size Ti–43Al–9V–0.2Y alloy pancake produced by pack-forging. Intermetallics 2013, 34, 29–34. [Google Scholar] [CrossRef]

- Cui, N. Composition design and hot deformation behavior of beta–gamma TiAl alloys. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2016. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, N.; Wu, Q.; Yan, Z.; Zhou, H.; Wang, X. The Microstructural Evolution, Tensile Properties, and Phase Hardness of a TiAl Alloy with a High Content of the β Phase. Materials 2019, 12, 2757. https://doi.org/10.3390/ma12172757

Cui N, Wu Q, Yan Z, Zhou H, Wang X. The Microstructural Evolution, Tensile Properties, and Phase Hardness of a TiAl Alloy with a High Content of the β Phase. Materials. 2019; 12(17):2757. https://doi.org/10.3390/ma12172757

Chicago/Turabian StyleCui, Ning, Qianqian Wu, Zhiyuan Yan, Haitao Zhou, and Xiaopeng Wang. 2019. "The Microstructural Evolution, Tensile Properties, and Phase Hardness of a TiAl Alloy with a High Content of the β Phase" Materials 12, no. 17: 2757. https://doi.org/10.3390/ma12172757

APA StyleCui, N., Wu, Q., Yan, Z., Zhou, H., & Wang, X. (2019). The Microstructural Evolution, Tensile Properties, and Phase Hardness of a TiAl Alloy with a High Content of the β Phase. Materials, 12(17), 2757. https://doi.org/10.3390/ma12172757